Multi-Objective Optimization of Design Parameters to Improve Dynamic Performances of Distributed Actuation Mechanism

Abstract

1. Introduction

Contributions of This Study

- (1)

- Mathematical modeling and optimization formulation.

- (2)

- Co-simulation-based optimization architecture.

- (3)

- Quantitative verification of structural advantages of DAM.

2. Modeling and Multi-Objective Optimization Formulation of the DAM

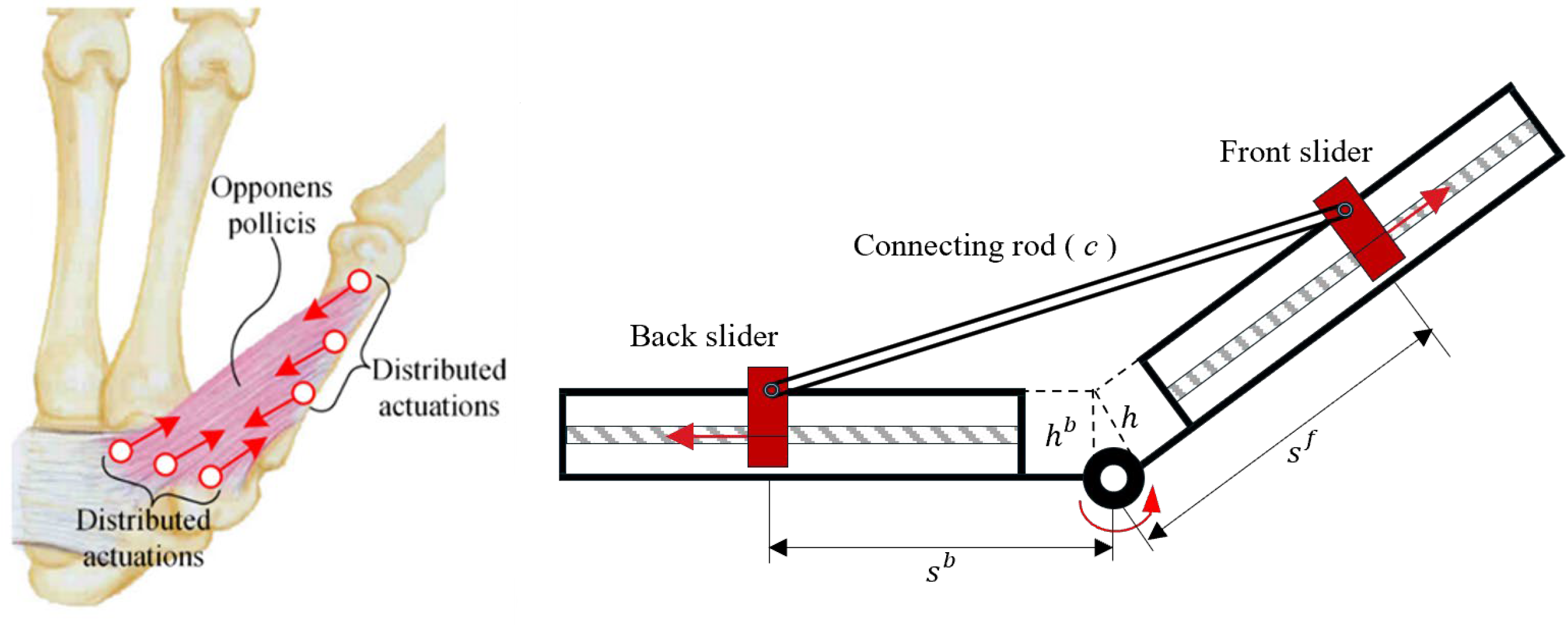

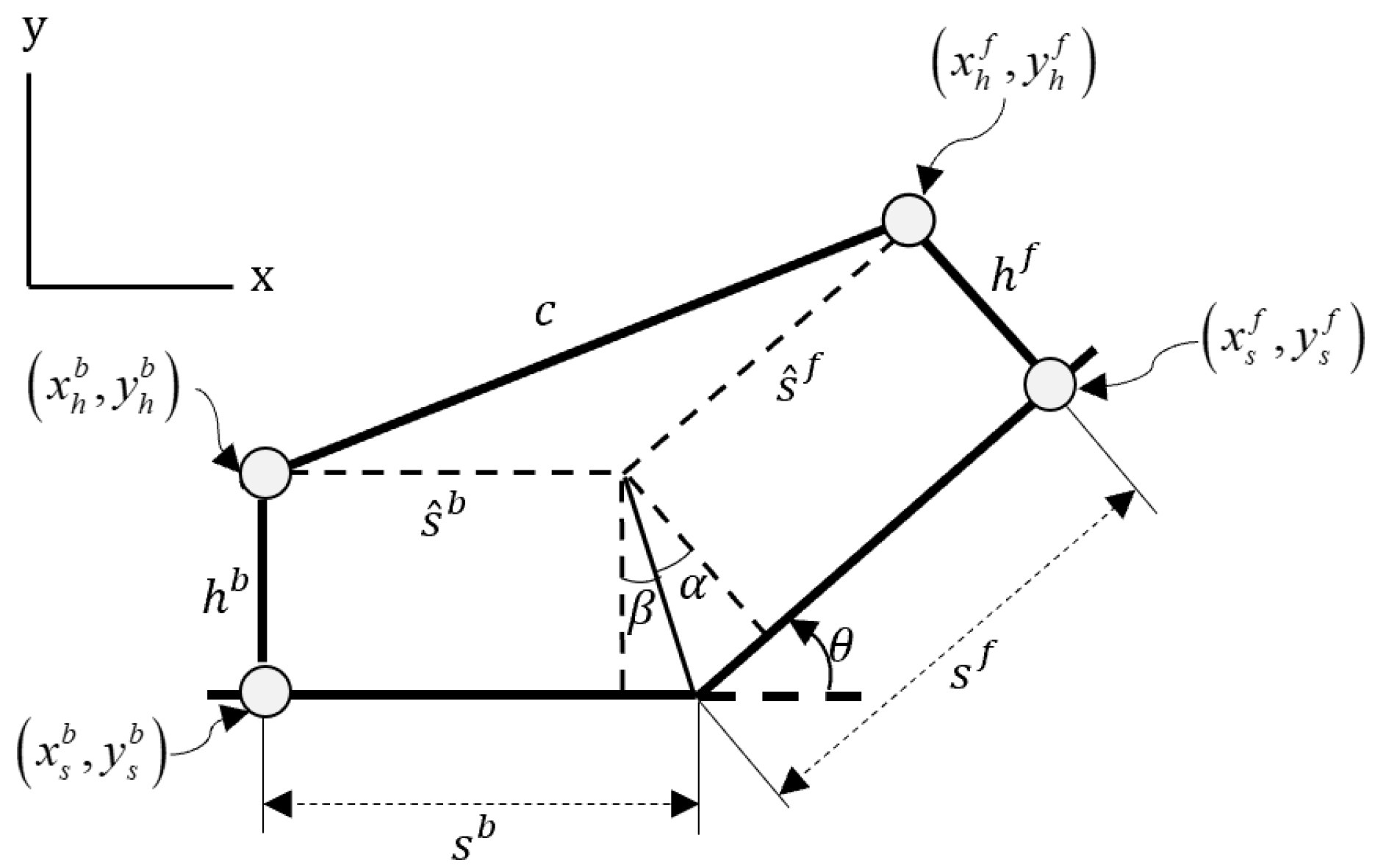

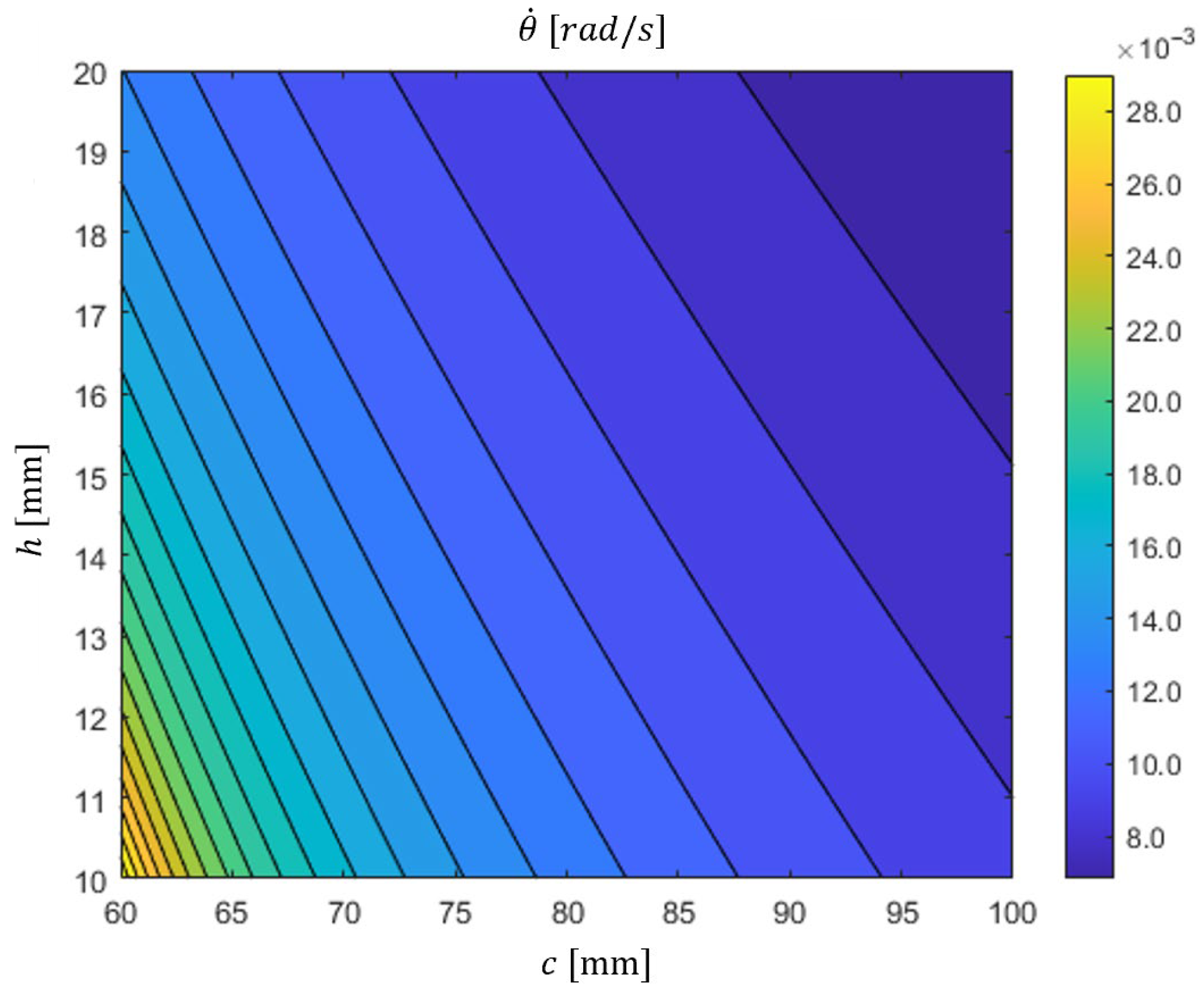

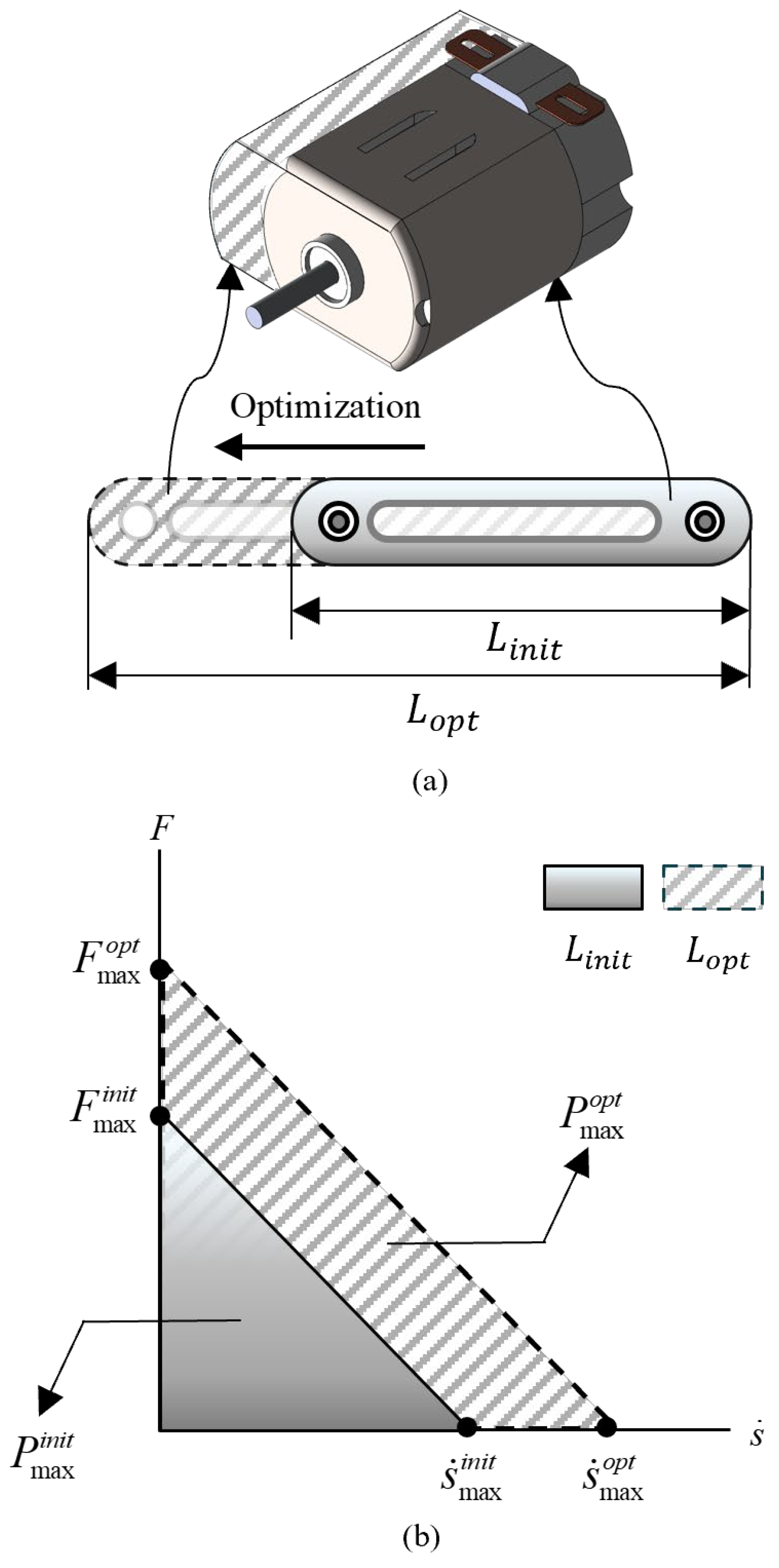

2.1. Kinematic Characteristics and Design Parameters of DAM

- (1)

- The use of multiple actuators on a single link provides redundant DOFs and offers flexibility in dynamic performance optimization.

- (2)

- The actuator torque can be modulated solely by adjusting the slider position, enabling speed–force conversion without changing the joint positions.

- (3)

- This mechanism exhibits fault tolerance because the function can be maintained through alternative actuation paths in the event of actuator failure.

- (4)

- Variable gearing allows real-time adaptation to load variations, thereby improving energy efficiency and operational stability.

- (5)

- The overall system performance is determined by parameters such as the slider position, velocity, and hinge offset, emphasizing the need to optimize these design variables.

2.2. Definition of Constraints

- (1)

- Equality Constraints

- (2)

- Inequality Constraints

2.3. Multi-Objective Optimization Formulation

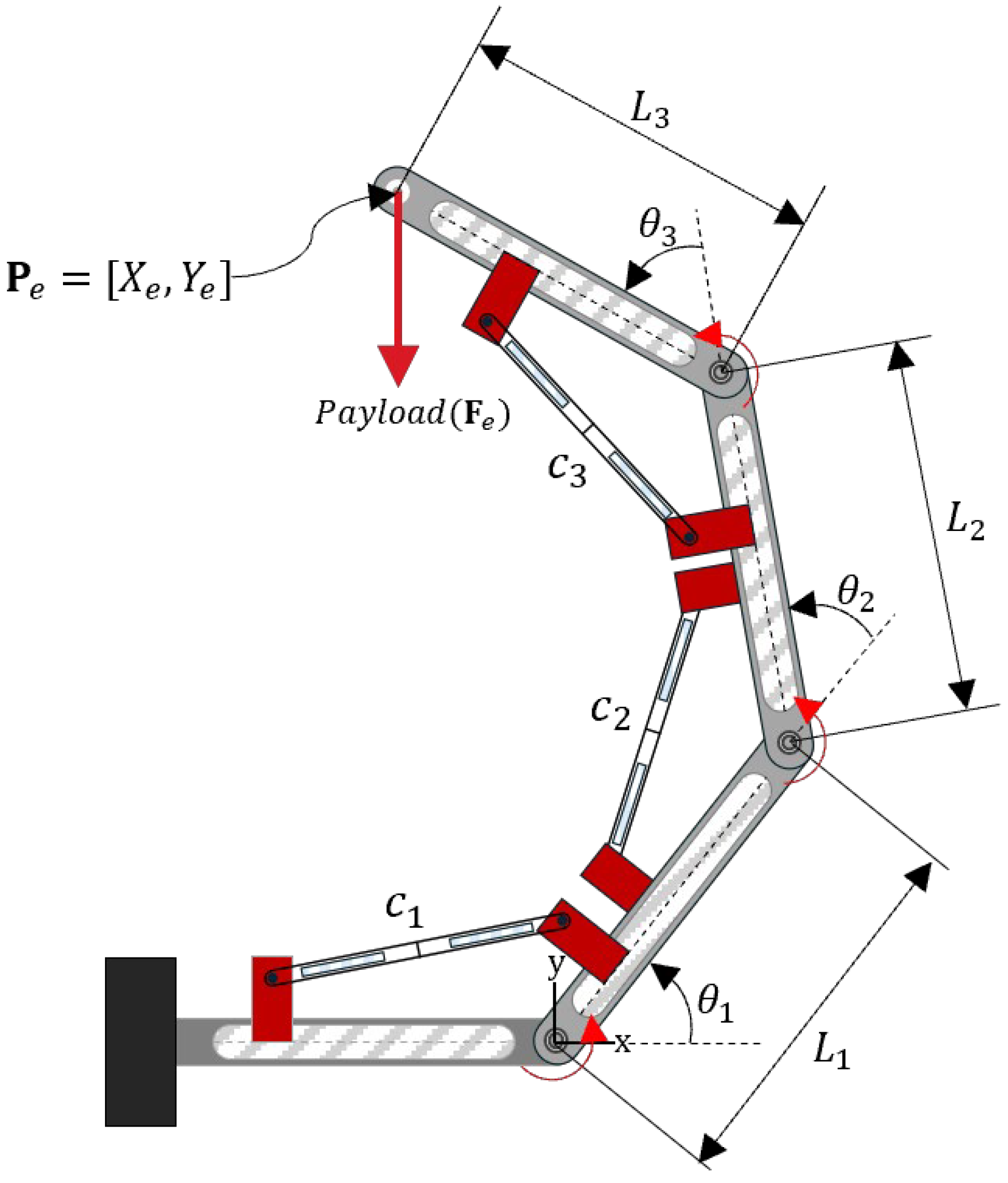

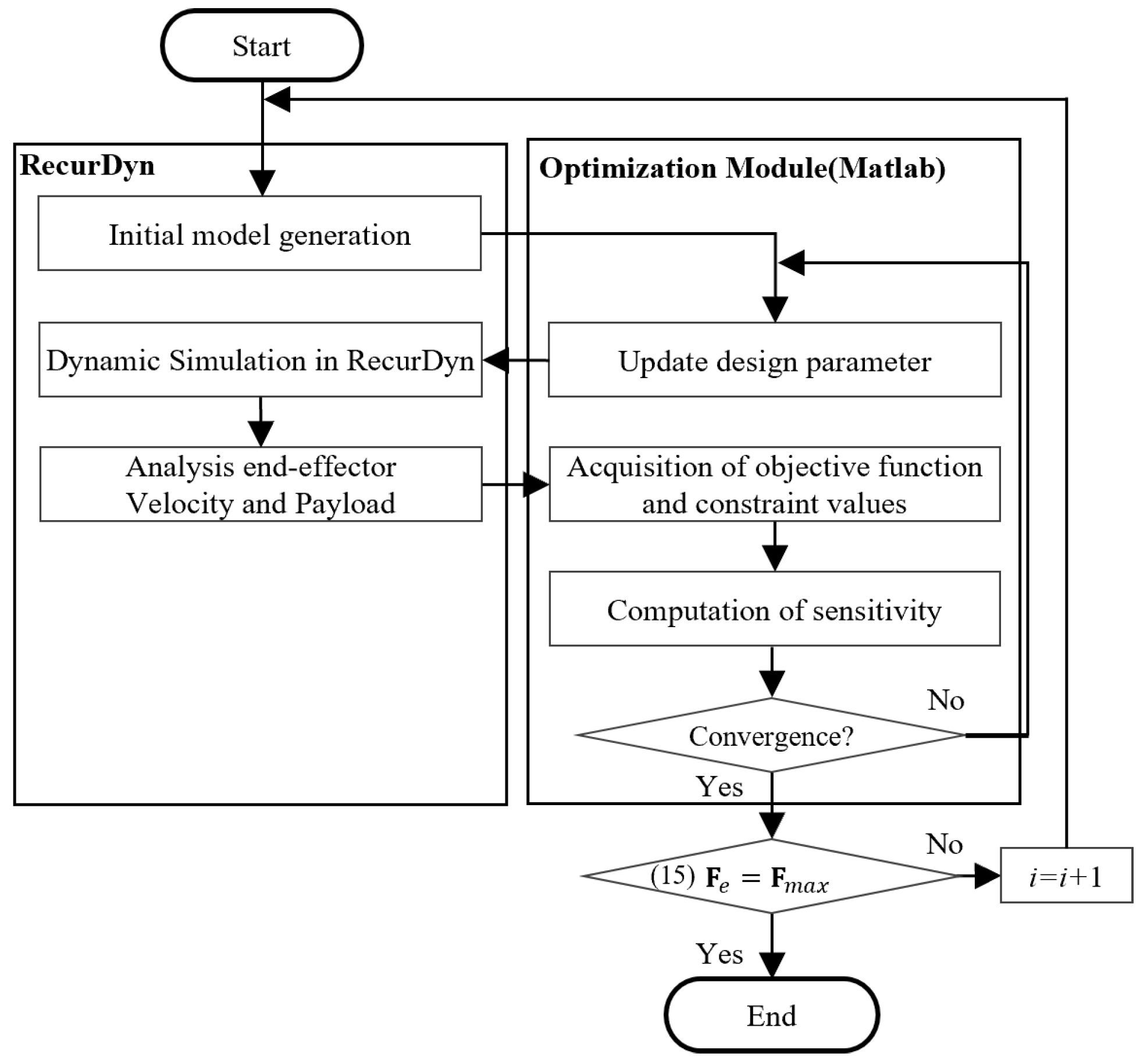

3. Numerical Analysis and Optimization Results

3.1. Optimization Setup

- (1)

- Initialization of design variables, including slider positions, velocities, hinge offsets, and link-length ratios.

- (2)

- A dynamic analysis was performed using RecurDyn to compute the end-effector velocity and payload.

- (3)

- Evaluation of the objective functions and constraints was performed using MATLAB.

- (4)

- Iterative improvement of objective functions and verification of constraint satisfaction using the SQP algorithm.

- (5)

- Extraction of Pareto-optimal solutions representing the trade-off between performance objectives.

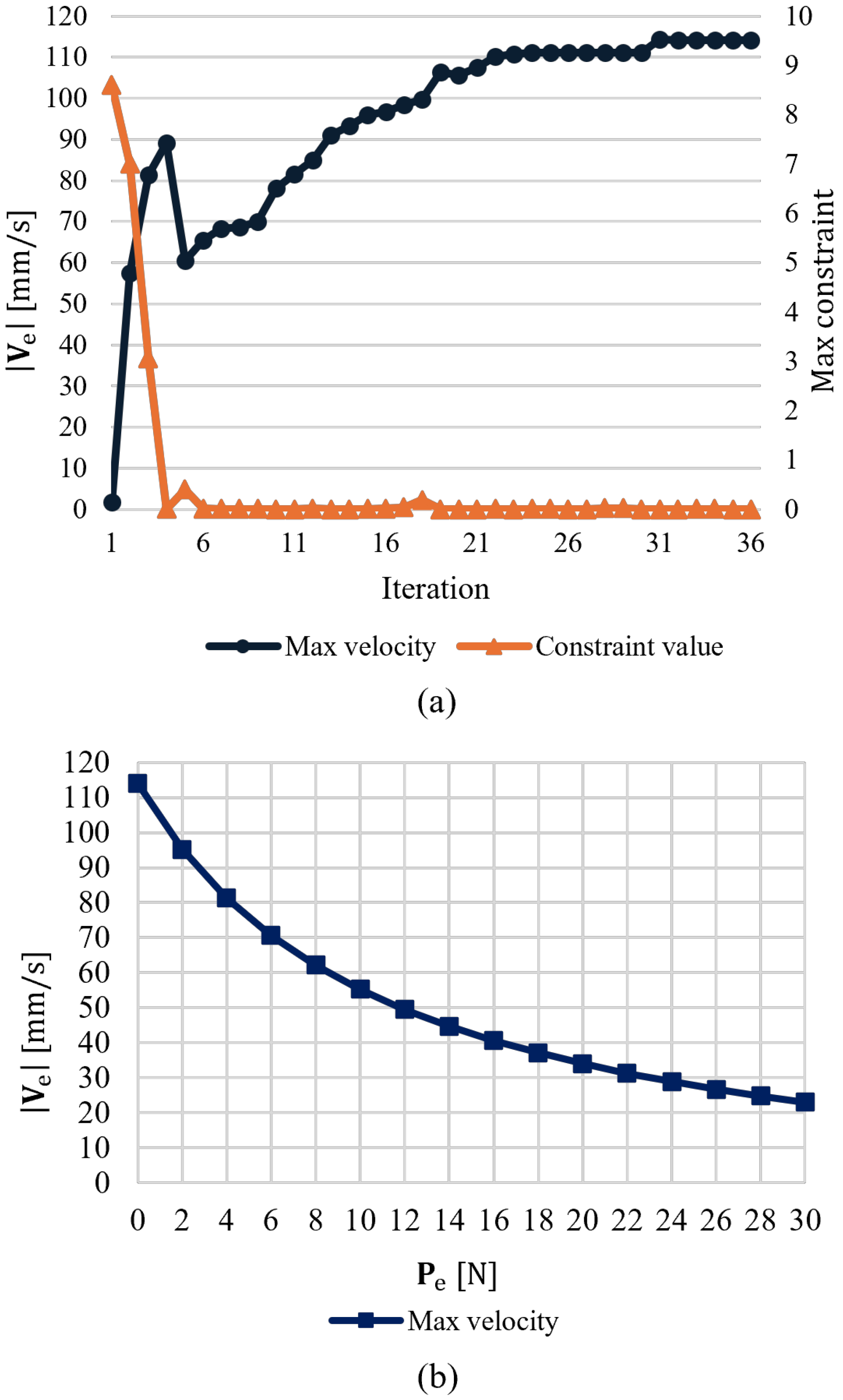

3.2. Optimization Convergence Characteristics

3.3. Optimization Results and Performance Analysis

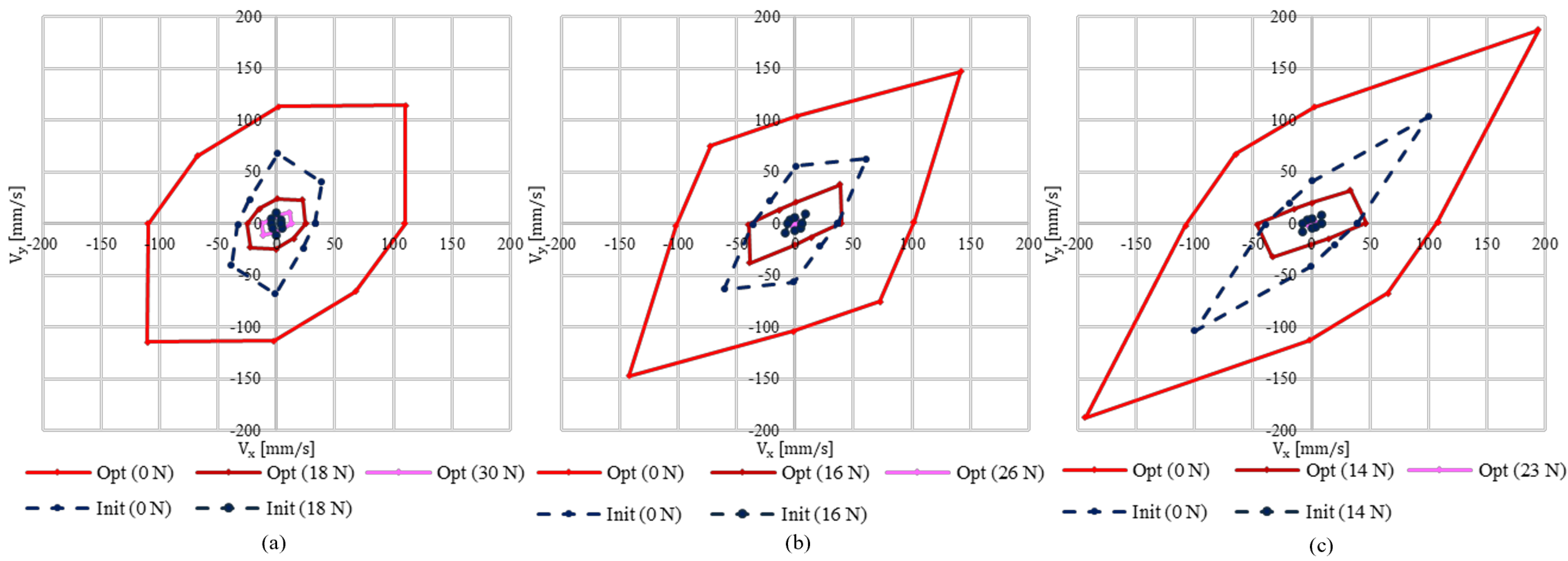

- (1)

- When no payload is applied (), the maximum velocity of the initial DAM.

- (2)

- When the maximum payload is applied (), the maximum velocity of the initial DAM.

- (3)

- When no payload is applied (), the maximum end-effector velocity of the DAM obtained through design parameter optimization.

- (4)

- When the maximum payload is applied (), the maximum end-effector velocity of the DAM obtained through design parameter optimization.

- (5)

- For comparison with the initial DAM, the maximum end-effector velocity of the optimized DAM under the same payload conditions as those in the initial configuration.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DAM | Distributed Actuation Mechanism |

| MOO | Multi-Objective Optimization |

| DOF | Degree of Freedom |

| MPE | Maximum Performance Evaluation |

| SQP | Sequential Quadratic Programming |

References

- Abdelmaksoud, S.I.; Al-Mola, M.H.; Abro, G.E.M.; Asirvadam, V.S. In-Depth Review of Advanced Control Strategies and Cutting-Edge Trends in Robot Manipulators: Analyzing the Latest Developments and Techniques. IEEE Access 2024, 12, 47672–47701. [Google Scholar] [CrossRef]

- Kim, S.-H.; Shin, Y.J.; Kim, K.-S.; Kim, S. Design and Control of Robot Manipulator with a Distributed Actuation Mechanism. Mechatronics 2014, 24, 1223–1230. [Google Scholar] [CrossRef]

- Gao, Z.; He, Y.; Xie, F.; Cui, L. Parametric Design and Multi-Objective Optimization of a General 6-PUS Parallel Manipulator. Mech. Mach. Theory 2020, 152, 103913. [Google Scholar] [CrossRef]

- Yu, J.; Wang, L. Parameter Optimization of Simplified Propulsive Model for Biomimetic Robot Fish. In Proceedings of the 2005 IEEE International Conference on Robotics and Automation (ICRA), Barcelona, Spain, 18–22 April 2005. [Google Scholar] [CrossRef]

- Datta, R.; Pradhan, S.; Bhattacharya, B. Analysis and Design Optimization of a Robotic Gripper Using Multiobjective Genetic Algorithm. IEEE Trans. Syst. Man Cybern. Syst. 2016, 46, 16–26. [Google Scholar] [CrossRef]

- Bowling, A.; Khatib, O. The Dynamic Capability Equations: A New Tool for Analyzing Robotic Manipulator Performance. IEEE Trans. Robot. 2005, 21, 115–123. [Google Scholar] [CrossRef]

- Kobelev, V.; Larichev, D.V.; Banichuk, N.V.; German, G.V. Methods of Optimal Design. In Optimal Design: Theory and Applications to Materials and Structures; Vasiliev, V.V., Gtirdal, Z., Eds.; Technomic Publishing Company: Lancaster, PA, USA, 1999; pp. 31–63. [Google Scholar]

- York, P.A.; Swaney, P.J.; Gilbert, H.B.; Webster, R.J., III. A Wrist for Needle-Sized Surgical Robots. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 1776–1783. [Google Scholar]

- Bedell, C.; Lock, J.; Gosline, A.; Dupont, P.E. Design Optimization of Concentric Tube Robots Based on Task and Anatomical Constraints. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Shanghai, China, 9–13 May 2011; pp. 398–405. [Google Scholar]

- Ebrahimi, A.; Urias, M.G.; Patel, N.; Taylor, R.H.; Gehlbach, P.; Iordachita, I. Adaptive Control Improves Sclera Force Safety in Robot-Assisted Eye Surgery: A Clinical Study. IEEE Trans. Biomed. Eng. 2021, 68, 3356–3365. [Google Scholar] [CrossRef] [PubMed]

- Tesch, J.; Lipkin, H.; Moran, J. Expensive Multiobjective Optimization for Robotics. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Karlsruhe, Germany, 6–10 May 2013; pp. 973–980. [Google Scholar]

- Choi, J.W.; Kim, M.G.; Kim, J.J.; Kim, J. Topology Optimization of Automotive Vibration Test Jig: Natural Frequency Maximization and Weight Reduction. Mathematics 2025, 13, 1716. [Google Scholar] [CrossRef]

- Hua, Y.; Liu, Q.; Hao, K.; Jin, Y. A Survey of Evolutionary Algorithms for Multi-Objective Optimization Problems with Irregular Pareto Fronts. IEEE/CAA J. Autom. Sin. 2021, 8, 303–318. [Google Scholar] [CrossRef]

- Jung, Y.-H.; Kim, D.-M.; Cha, K.-S.; Park, S.-H.; Park, M.-R. Vibration Reduction of Permanent Magnet Synchronous Motors by Four-Layer Winding: Mathematical Modeling and Experimental Validation. Mathematics 2025, 13, 1603. [Google Scholar] [CrossRef]

- Luo, D.; Jo, S.-H.; Kim, T. Progressive Domain Decomposition for Efficient Training of Physics-Informed Neural Network. Mathematics 2025, 13, 1515. [Google Scholar] [CrossRef]

- Li, C.; Li, Y.; Zhou, F.; Fan, C. Multi-Objective Path Planning for the Mobile Robot. In Proceedings of the IEEE International Conference on Automation and Logistics (ICAL), Jinan, China, 18–21 August 2007; pp. 2248–2252. [Google Scholar]

- Li, A.; Mukadam, M.; Egerstedt, M.; Boots, B. Multi-Objective Policy Generation for Multi-Robot Systems Using Riemannian Motion Policies. In The International Symposium of Robotics Research; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Kim, Y.; Pan, Z.; Hauser, K. MO-BBO: Multi-Objective Bilevel Bayesian Optimization for Robot and Behavior Co-Design. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Xi’an, China, 30 May–5 June 2021; pp. 9877–9883. [Google Scholar]

- Wei, C.; Ji, Z.; Cai, B. Particle Swarm Optimization for Cooperative Multi-Robot Task Allocation: A Multi-Objective Approach. IEEE Robot. Autom. Lett. 2020, 5, 2530–2537. [Google Scholar] [CrossRef]

- Ajeil, F.H.; Ibraheem, I.K.; Sahib, M.A.; Humaidi, A.J. Multi-Objective Path Planning of an Autonomous Mobile Robot Using Hybrid PSO-MFB Optimization Algorithm. Appl. Soft Comput. 2020, 89, 106076. [Google Scholar] [CrossRef]

- Majou, F.; Gosselin, C.; Wenger, P.; Chablat, D. Parametric Stiffness Analysis of the Orthoglide. arXiv 2007, arXiv:0708.3607. [Google Scholar] [CrossRef]

- Tewari, J.P.; Kapoor, A.K. An Adaptive Model Following Control for Robotic Manipulators. In Proceedings of the IEEE In-ternational Conference on Industrial Technology 2000, Goa, India, 19–22 January 2000; pp. 55–57. [Google Scholar]

- Ma, R.R.; Dollar, A.M. On Dexterity and Dexterous Manipulation. In Proceedings of the 15th International Conference on Advanced Robotics (ICAR), Tallinn, Estonia, 20–23 June 2011; pp. 1–7. [Google Scholar] [CrossRef]

- Liu, T.; Mu, Z.; Wang, H.; Xu, W.; Li, Y. A Cable-Driven Redundant Spatial Manipulator with Improved Stiffness and Load Capacity. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 6628–6633. [Google Scholar] [CrossRef]

- Jia, J.; Sun, X. Structural Optimization Design of a Six-Degrees-of-Freedom Serial Robot with Integrated Topology and Dimensional Parameters. Sensors 2023, 23, 7183. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Jang, I.G. Optimization-Based Investigation of Bioinspired Variable Gearing of the Distributed Actuation Mechanism to Maximize Velocity and Force. IEEE Robot. Autom. Lett. 2020, 5, 6326–6333. [Google Scholar] [CrossRef]

- Shin, Y.J.; Kim, K.S. Distributed-Actuation Mechanism for a Finger-Type Manipulator: Theory and Experiments. IEEE Trans. Robot. 2010, 26, 569–575. [Google Scholar] [CrossRef]

- Arora, J.S. Introduction to Optimum Design; Academic Press: New York, NY, USA, 2004. [Google Scholar]

- Buryanov, A.; Kotiuk, V. Proportions of Hand Segments. Int. J. Morphol. 2010, 28, 755–758. [Google Scholar] [CrossRef]

| Design Variables | Joint 1 | Joint 2 | Joint 3 | |||

|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | Lower Bound | Upper Bound | Lower Bound | Upper Bound | |

| 20.0 | 90.0 | 20.0 | 90.0 | |||

| 37.0 | 77.0 | 37.0 | 77.0 | 37.0 | 77.0 | |

| 37.0 | 77.0 | 37.0 | 77.0 | 37.0 | 77.0 | |

| −14.0 | 14.0 | −14.0 | 14.0 | −14.0 | 14.0 | |

| −14.0 | 14.0 | −14.0 | 14.0 | −14.0 | 14.0 | |

| 10.0 | 20.0 | 10.0 | 20.0 | 10.0 | 20.0 | |

| 10.0 | 20.0 | 10.0 | 20.0 | 10.0 | 20.0 | |

| 77.0 | 154.0 | 77.0 | 154.0 | 77.0 | 154.0 | |

| 114.0 | 200.0 | 87.0 | 129.0 | 80.0 | 129.0 | |

| Design constants | Joint 1 | Joint 2 | Joint 3 | |||

| M | 8 | |||||

| [mm/s] | ||||||

| DAM (Init) | DAM (Adv) | Difference | ||

|---|---|---|---|---|

| p1 | Max |ve| [mm/s] | 67.63 | 159.06 | 57.48% |

| Max |F| [N] | 18 | 30 | 40.00% | |

| p2 | Max |ve| [mm/s] | 87.42 | 191.55 | 54.36% |

| Max |F| [N] | 16 | 26 | 38.46% | |

| p3 | Max |ve| [mm/s] | 144.02 | 269.41 | 46.54% |

| Max |F| [N] | 14 | 24 | 41.66% |

| Initial | Optimal Solution | Difference | |

|---|---|---|---|

| [mm] | 15.5 | 20 | 22.5% |

| [mm] | 15.5 | 20 | 22.5% |

| [mm] | 15.5 | 20 | 22.5% |

| [mm] | 80 | 100 | 20% |

| [mm] | 80 | 100 | 20% |

| [mm] | 80 | 100 | 20% |

| [mm] | 114 | 148 | 22.97% |

| [mm] | 114 | 129 | 11.62% |

| [mm] | 127 | 80 | −37% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jo, I.H.; Kim, J.H. Multi-Objective Optimization of Design Parameters to Improve Dynamic Performances of Distributed Actuation Mechanism. Mathematics 2025, 13, 3773. https://doi.org/10.3390/math13233773

Jo IH, Kim JH. Multi-Objective Optimization of Design Parameters to Improve Dynamic Performances of Distributed Actuation Mechanism. Mathematics. 2025; 13(23):3773. https://doi.org/10.3390/math13233773

Chicago/Turabian StyleJo, Ik Hyun, and Jong Ho Kim. 2025. "Multi-Objective Optimization of Design Parameters to Improve Dynamic Performances of Distributed Actuation Mechanism" Mathematics 13, no. 23: 3773. https://doi.org/10.3390/math13233773

APA StyleJo, I. H., & Kim, J. H. (2025). Multi-Objective Optimization of Design Parameters to Improve Dynamic Performances of Distributed Actuation Mechanism. Mathematics, 13(23), 3773. https://doi.org/10.3390/math13233773