Hierarchical Fuzzy-Adaptive Position Control of an Active Mass Damper for Enhanced Structural Vibration Suppression

Abstract

1. Introduction

1.1. Literature Review

1.2. Novel Contribution

- Formulation of an LQ-PID control law for precise position regulation of the AMD, combining optimal control and classical PID principles to achieve efficient damping with minimal control effort.

- Development of a fuzzy adaptive mechanism that modulates the LQR state-weighting matrices based on the system’s displacement error and normalized acceleration to acquire self-tuning of PID gains.

- Integration of the fuzzy and LQ-PID layers, enabling online gain adaptation while preserving asymptotic stability and robustness under vibrational disturbances.

- Validation of the proposed controller’s effectiveness and adaptability using customized simulations in MATLAB/SIMULINK from MathWorks, Natick, Massachusetts, United States, assessing both standard step response and real-world vibrational disturbance scenarios.

1.3. Benefits of the Proposed Methodology

- ▪

- Since the proposed controller is an LQR-optimized PID controller, its Lyapunov-based stability can be formally guaranteed, providing a rigorous stability proof that conventional PID-type controllers typically lack.

- ▪

- The hierarchical fuzzy adaptation enables real-time self-tuning of LQR weighting matrices based on displacement error and normalized acceleration. While conventional LQR controllers rely on fixed weightings and thus struggle with uncertainties, the proposed scheme continuously updates the internal weights, ensuring responsiveness to dynamic conditions.

- ▪

- The proposed scheme effectively suppresses seismic disturbances across diverse scenarios, where conventional controllers typically show degraded performance.

- ▪

- The adaptive gain tuning gently commutes between sliding modes to prevent chattering.

- ▪

- Unlike MPC or data-driven control methods that are computationally expensive, the proposed scheme achieves adaptability with modest computational overhead, making it practical for real-time applications.

- ▪

- The proposed scheme provides a balanced trade-off between fast response, low overshoot, and limited control effort compared to classical PID and LQR.

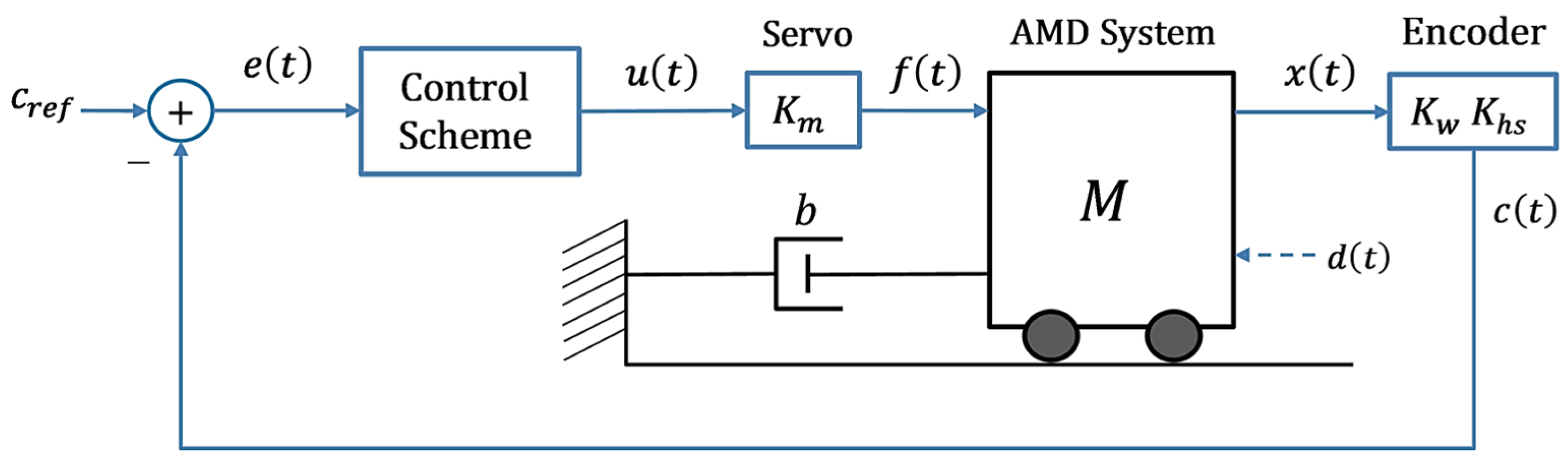

2. System Description

2.1. Mathematical Model

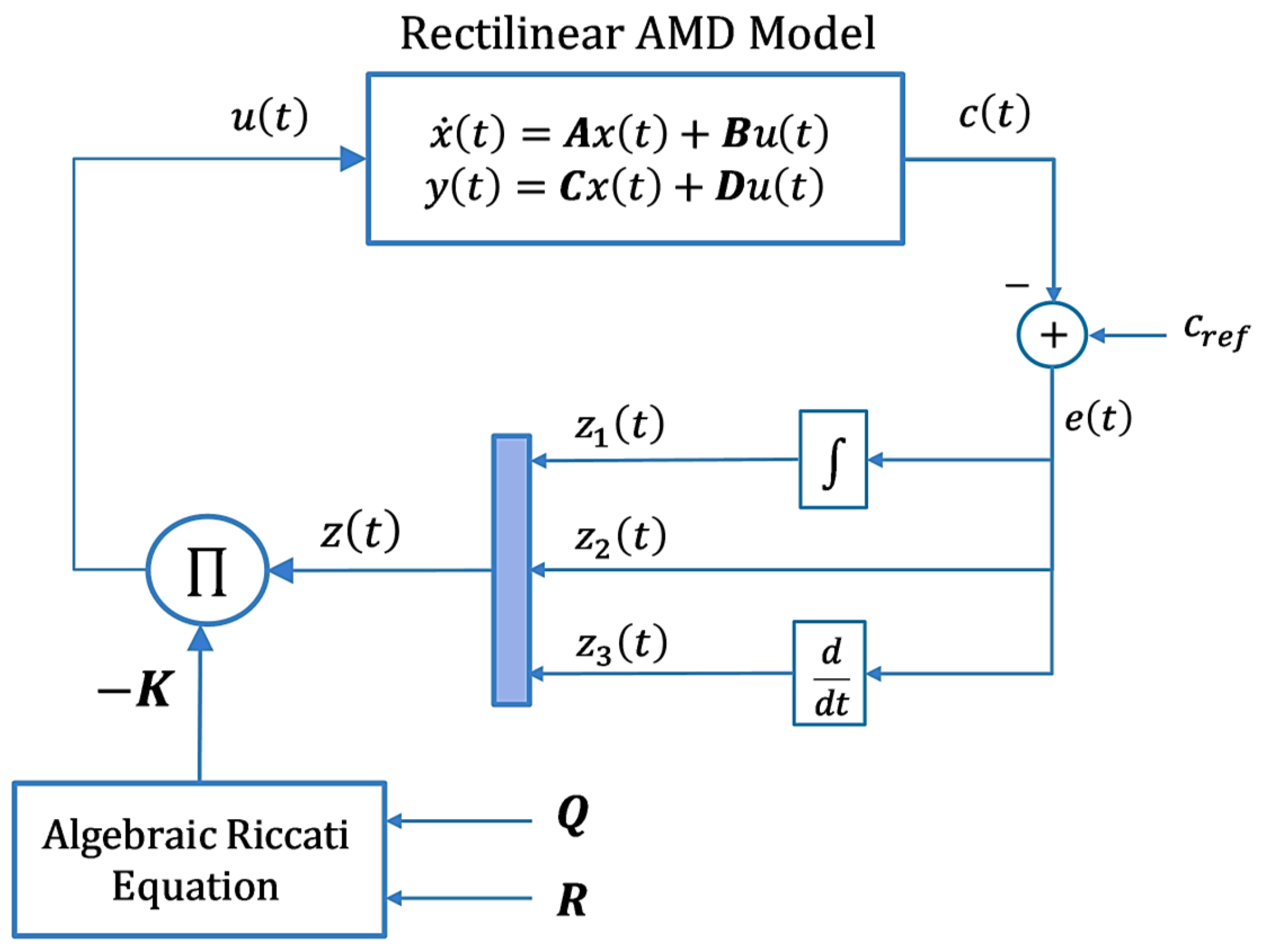

2.2. Baseline LQ-PID Regulator Design

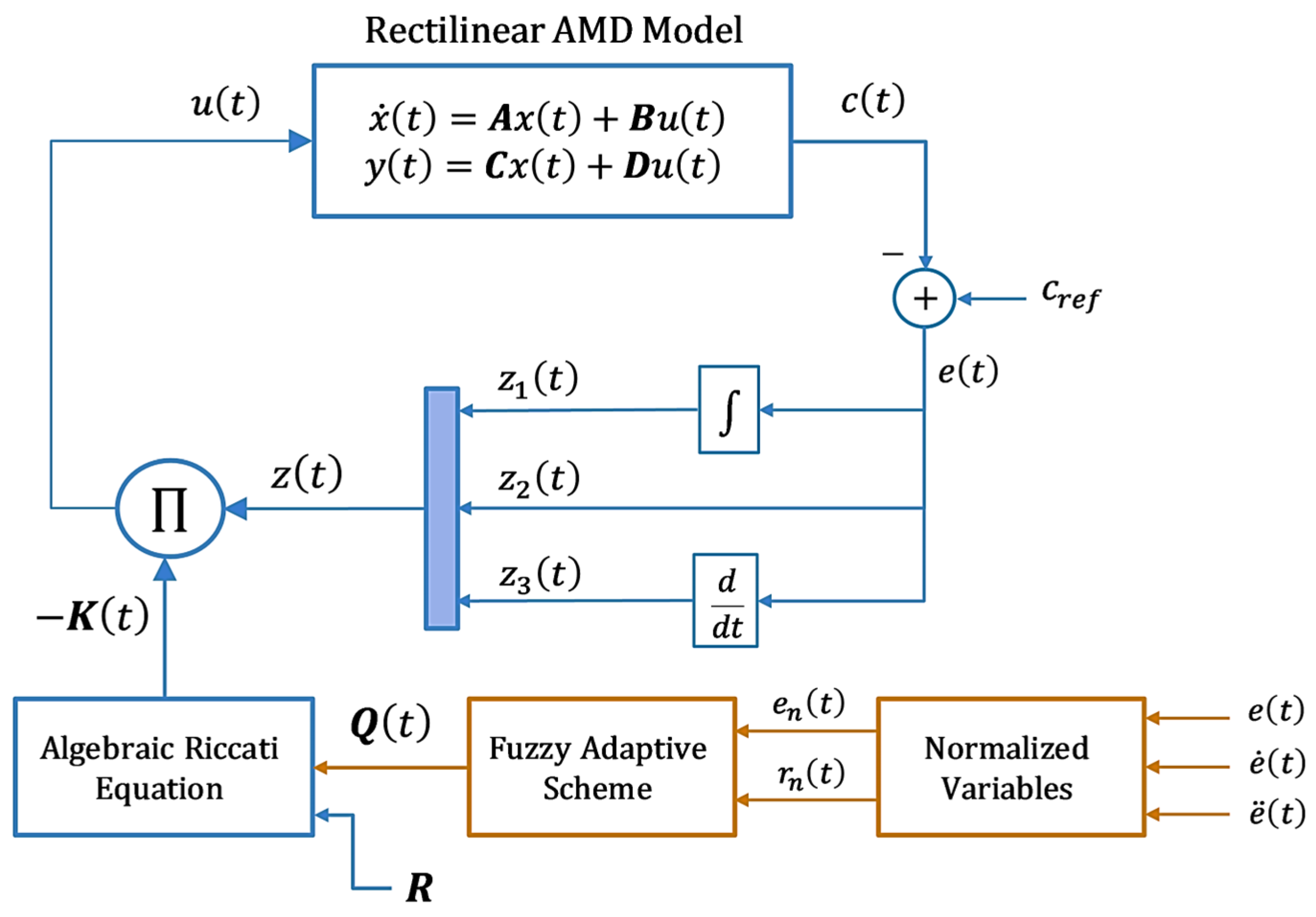

3. Proposed Fuzzy-Adaptive PID Control Law

3.1. Adaptive Control Law Formulation

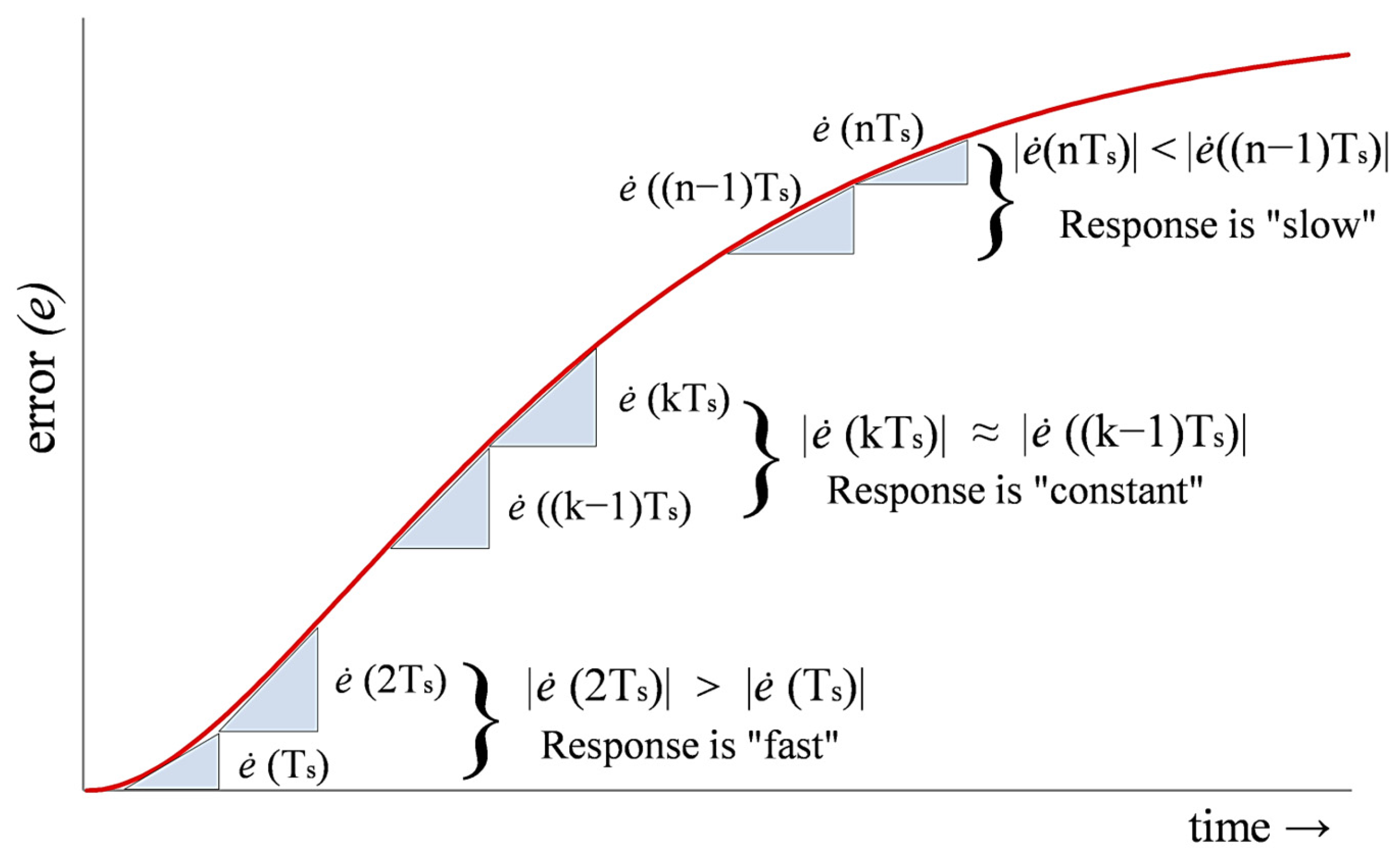

3.2. Online Weight Adaptation Rationale

- Slow when the error velocity and acceleration have opposite signs.

- Fast when the error velocity and acceleration share the same sign.

- Moderate when the error velocity remains constant.

3.3. Fuzzy Adaptive Scheme

- Fast response with small error: Low values for and high values for and are used. This minimizes overshoot and swiftly adjusts the control gains to dampen disturbances.

- Fast response with large error: In order to avoid taking excessively forceful control measures that can exacerbate overshoot, moderate values of state weighting coefficients are selected.

- Slow response (regardless of error magnitude): To apply smoother control for removing residual errors and preserving accurate tracking, is increased while and are decreased.

4. Parameter Optimization Procedure

5. Simulation Results and Discussions

5.1. Simulation Setup

5.2. Simulations and Results

- A.

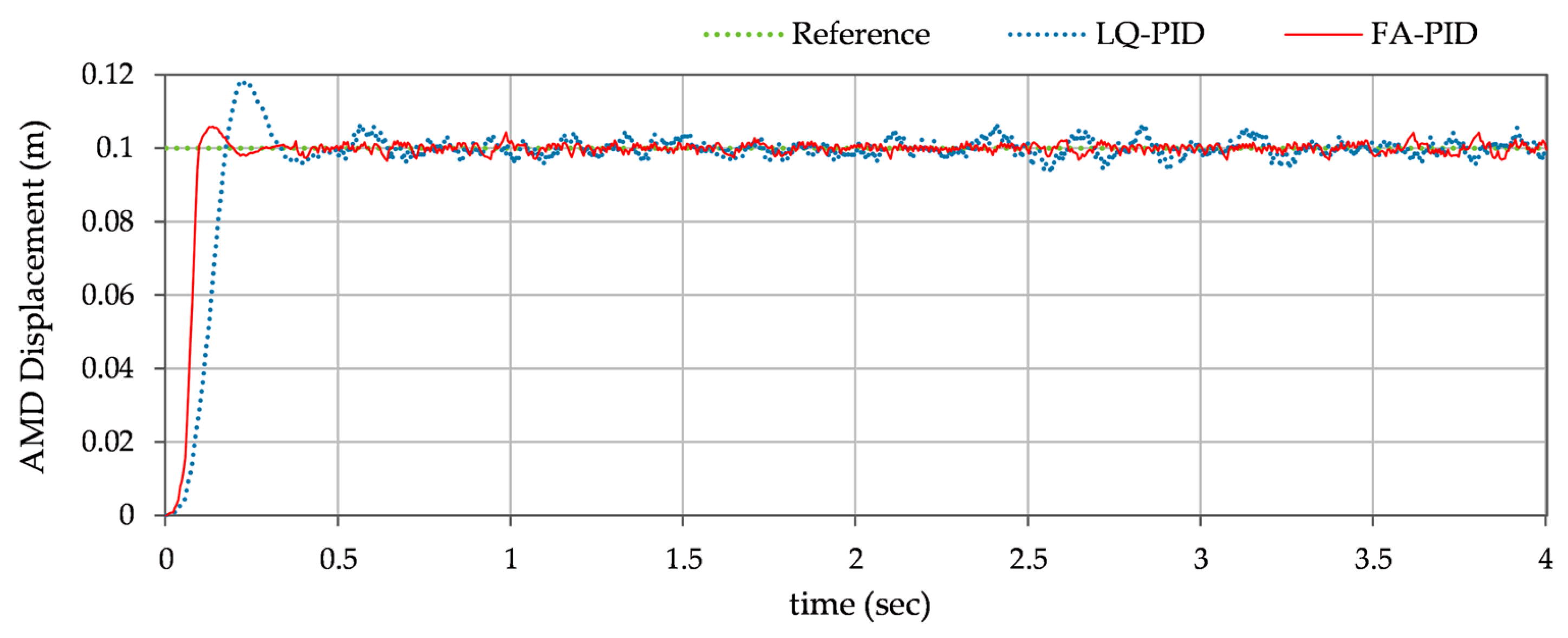

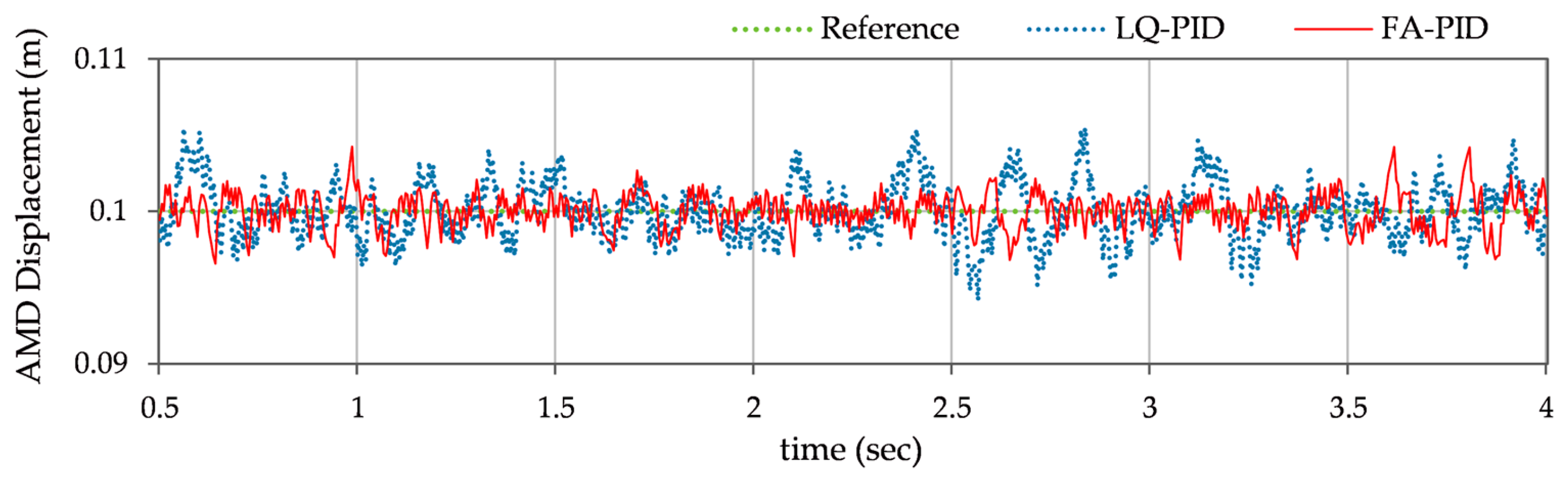

- Step-reference tracking: This test case evaluates the control scheme’s step-reference tracking performance. The AMD system is subjected to an abrupt step force in order to simulate real-world situations such as machinery startup or small seismic shocks. As discussed in Section 5.1, a synthetic disturbance signal is added to the displacement signal to emulate sensor imperfections and ambient structural vibrations. This disturbance signal is configured to produce zero-mean Gaussian noise with a noise power of 10−4. The objective is to assess the system’s overshoot and response time in the event of an abrupt, prolonged displacement demand. The resulting mass displacement response is shown in Figure 8. The steady state response of the system is magnified and depicted in Figure 9 to assess the steady state fluctuations contributed by the additive white noise.

- B.

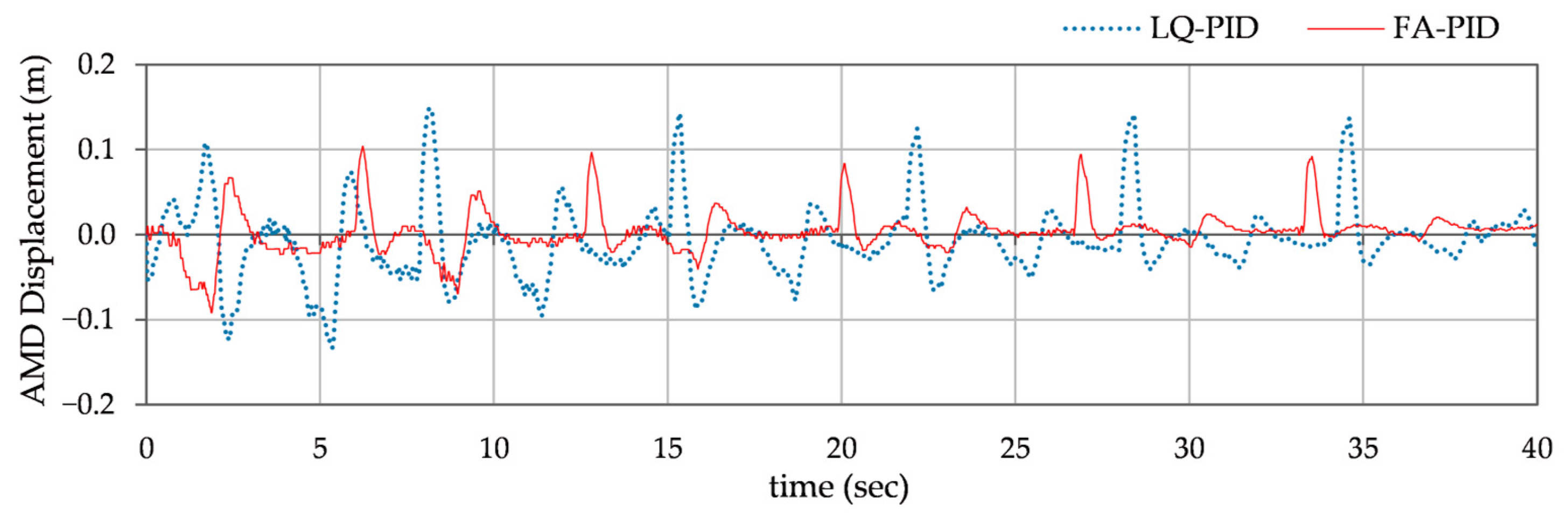

- Response under decaying sinusoidal excitation: This test evaluates the controller’s ability to suppress harmonic vibrations and maintain stability. This test case investigates the AMD system’s behavior under decaying periodic excitation, such as that brought on by HVAC systems, rotating machinery, marine wave forces, or minor seismic activities. To realistically represent the decaying sinusoidal excitation, the test introduces a synthetic decaying sinusoidal signal of 1.0 Hz frequency in the control input. The reference displacement of AMD is set to zero. The disturbance signal used for this test case is represented in (43).

- C.

- Response under sinusoidal and Impulsive disturbance: This test case replicates real-world events like collision shocks, explosions, or transient seismic pulses by simulating a brief, high-intensity force applied to the structure. To observe the AMD’s damping capacity and its ability to quickly restore the structure to equilibrium, synthetic pulse signals of +4.0 V magnitude and 0.5 sec duration are injected in the control input at discrete intervals. These impulsive disturbances are superimposed on the decaying sinusoidal disturbance signal , as defined in (43). The reference displacement of AMD is set to zero. The output displacement under the dual excitation scenario is illustrated in Figure 12.

- D.

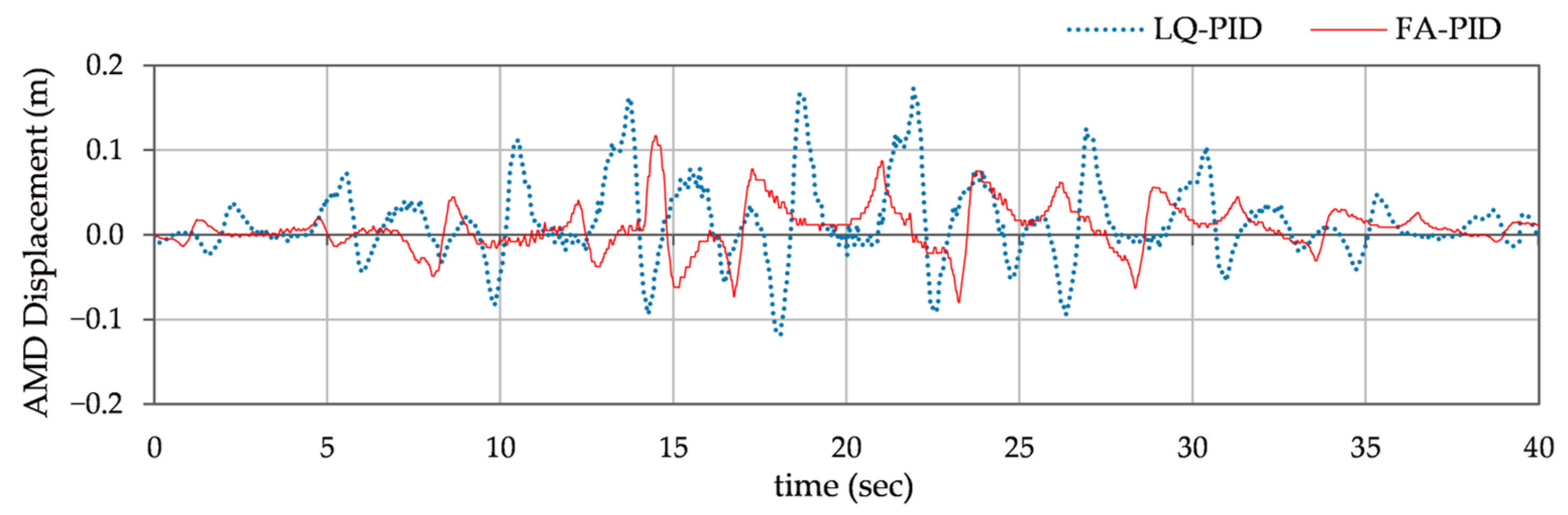

- Response under parametric variations: To assess the controller’s robustness and adaptability against parametric variations, this test simulates structural and actuator uncertainties by varying key system parameters during operation. To carry out the test, the mass of the AMD is perturbed by +20% from its nominal value to emulate the effect of payload changes at t = 10.0 s. During the test, the decaying sinusoidal disturbance is also injected into the control input to simulate fading external excitations, while the reference displacement is kept at zero. The resulting displacement response is illustrated in Figure 13.

- E.

- Response under modulated Gaussian signal: This test case simulates the high-energy and transient characteristics of short-duration earthquakes. The system’s displacement response under this realistic seismic profile is analyzed to assess the AMD’s responsiveness during rapid energy buildup and decay. A sine wave modulated by a Gaussian envelope is applied to the control input to replicate a burst-like ground acceleration. The reference displacement of AMD is set to zero. The disturbance signal used for this test is represented in (44).

5.3. Analytical Discussion

- : Root-mean-square value of the AMD system’s position error, computed as shown in (45).

- : Time taken for the system’s displacement to rise from 10% to 90% of the step amplitude.

- : Time taken by the AMD to settle within ±0.05 m of its resting position.

- : Peak overshoot due to initial displacement or excitation.

- : Peak overshoot or undershoot in response to disturbances.

- : Time required by the AMD to re-settle within ±0.05 m of its resting position, after a disturbance.

5.4. Final Remarks

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, D.H.; Shin, J.H.; Lee, H.; Kim, S.K.; Kwak, M.K. Active vibration control of structure by active mass damper and multi-modal negative acceleration feedback control algorithm. J. Sound Vib. 2017, 392, 18–30. [Google Scholar] [CrossRef]

- Zhang, B.L.; Liu, Y.J.; Han, Q.L.; Tang, G.Y. Optimal tracking control with feedforward compensation for offshore steel jacket platforms with active mass damper mechanisms. J. Vib. Control 2014, 22, 695–709. [Google Scholar] [CrossRef]

- Yang, F.; Sedaghati, R.; Esmailzadeh, E. Vibration suppression of structures using tuned mass damper technology: A state-of-the-art review. J. Vib. Control 2021, 28, 812–836. [Google Scholar] [CrossRef]

- Feng, J.; Liu, Z.; He, X.; Fu, Q.; Li, G. Adaptive Vibration Control for an Active Mass Damper of a High-Rise Building. IEEE Trans. Syst. Man Cybern. Syst. 2022, 52, 1970–1983. [Google Scholar] [CrossRef]

- Chang, S. Active Mass Damper for Reducing Wind and Earthquake Vibrations of a Long-Period Bridge. Actuators 2020, 9, 66. [Google Scholar] [CrossRef]

- Kraus, K.; Šika, Z.; Beneš, P.; Krivošej, J.; Vyhlídal, T. Mechatronic robot arm with active vibration absorbers. J. Vib. Control 2020, 26, 1145–1156. [Google Scholar] [CrossRef]

- Brodersen, M.L.; Bjørke, A.S.; Høgsberg, J. Active tuned mass damper for damping of offshore wind turbine vibrations. Wind Energy 2017, 20, 783–796. [Google Scholar] [CrossRef]

- Noori, M.; Narjabadifam, P. Innovative civil engineering applications of smart materials for smart sustainable urbanization. J. Civil. Eng. Urban. 2019, 9, 24–35. [Google Scholar] [CrossRef]

- Fei, J.; Lin, B.; Yan, S.; Ding, M.; Xiao, J.; Zhang, J.; Zhang, X.; Ji, C.; Sui, T. Chatter mitigation using moving damper. J. Sound Vib. 2017, 410, 49–63. [Google Scholar] [CrossRef]

- Xie, W.; Hua, Y. Structural Vibration Comfort: A Review of Recent Developments. Buildings 2024, 14, 1592. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Q.; Zhao, X.; Liu, Z.; Li, G. Vibration Control for an Active Mass Damper of a High-Rise Building With Input and Output Constraints. IEEE/ASME Trans. Mechatron. 2023, 28, 186–196. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, G.; Wu, G.; Li, L. Modeling and nonlinear optimal control of active mass damper with rotating actuator for structural vibration control. Struct. Control Health Monit. 2022, 29, e2871. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, C.; Chen, L.; Zhang, X. Phase deviation of semi-active suspension control and its compensation with inertial suspension. Acta Mech. Sin. 2024, 40, 523367. [Google Scholar] [CrossRef]

- Dharmajan, N.B.; AlHamaydeh, M. State-of-the-Art Review of Structural Vibration Control: Overview and Research Gaps. Appl. Sci. 2025, 15, 7966. [Google Scholar] [CrossRef]

- Saaed, T.E.; Nikolakopoulos, G.; Jonasson, J.E.; Hedlund, H. A state-of-the-art review of structural control systems. J. Sound Vib. 2015, 21, 919–937. [Google Scholar] [CrossRef]

- Rahimi, F.; Aghayari, R.; Samali, B. Application of tuned mass dampers for structural vibration control: A state-of-the-art review. Civ. Eng. J. 2020, 6, 1622–1651. [Google Scholar] [CrossRef]

- Ab Talib, M.H.; Mat Darus, I.Z.; Mohd Samin, P.; Mohd Yatim, H.; Ardani, M.I.; Shaharuddin, N.M.R.; Hadi, M.S. Vibration control of semi-active suspension system using PID controller with advanced firefly algorithm and particle swarm optimization. J. Ambient. Intell. Humaniz. Comput. 2021, 12, 1119–1137. [Google Scholar] [CrossRef]

- Jafarzadeh, O.; Sabetahd, R.; Ghasemi, S.A.M.; Zahrai, S.M. Design of a novel intelligent adaptive fractional-order proportional-integral-derivative controller for mitigation of seismic vibrations of a building equipped with an active tuned mass damper. Smart Mater. Struct. 2024, 33, 095020. [Google Scholar] [CrossRef]

- Al-Baidhani, H.; Kazimierczuk, M.K. Design and Implementation of Digital PID Control for Mass-Damper Rectilinear Systems. Mathematics 2024, 12, 2921. [Google Scholar] [CrossRef]

- Amini, M.; Waezi, Z.; Manthouri, M. Seismic control of the structures with active tuned mass damper and variable fractional order fuzzy proportional–integral–derivative controller. J. Vib. Control 2023, 29, 4302–4316. [Google Scholar] [CrossRef]

- Soleymani, M.; Abolmasoumi, A.H.; Bahrami, H.; Khalatbari-S, A.; Khoshbin, E.; Sayahi, S. Modified sliding mode control of a seismic active mass damper system considering model uncertainties and input time delay. J. Vib. Control 2018, 24, 1051–1064. [Google Scholar] [CrossRef]

- Kumar, G.; Kumar, A.; Jakka, R.S. An adaptive LQR controller based on PSO and maximum predominant frequency approach for semi-active control scheme using MR damper. Mech. Ind. 2018, 19, 109. [Google Scholar] [CrossRef]

- Xiang, P.; Nishitani, A. Optimum design of tuned mass damper floor system integrated into bending-shear type building based on H∞, H2, and stability maximization criteria. Struct. Control Health Monit. 2015, 22, 919–938. [Google Scholar] [CrossRef]

- Nguyen, S.D.; Kim, W.; Park, J.; Choi, S.B. A new fuzzy sliding mode controller for vibration control systems using integrated-structure smart dampers. Smart Mater. Struct. 2017, 26, 045038. [Google Scholar] [CrossRef]

- Talebitooti, R.; Darvish Gohari, H.; Zarastvand, M.; Loghmani, A. A robust optimum controller for suppressing radiated sound from an intelligent cylinder based on sliding mode method considering piezoelectric uncertainties. J. Intell. Mater. Sys. Struct. 2019, 30, 3066–3079. [Google Scholar] [CrossRef]

- Moutsopoulou, A.; Stavroulakis, G.E.; Petousis, M.; Pouliezos, A.; Vidakis, N. Developments in the Use of Hinfinity Control and μ-Analysis for Reducing Vibration in Intelligent Structures. Inventions 2023, 8, 119. [Google Scholar] [CrossRef]

- Chen, P.C.; Sugiarto, B.J.; Chien, K.Y. Performance-based optimization of LQR for active mass damper using symbiotic organisms search. Smart Struct. Syst. 2021, 27, 705–717. [Google Scholar]

- Khan, O.; Pervaiz, M.; Ahmad, E.; Iqbal, J. On the derivation of novel model and sophisticated control of flexible joint manipulator. Rev. Roum. Des Sci. Tech. Série Électrotechnique Et Énergétique 2017, 62, 103–108. [Google Scholar]

- Chen, P.C.; Chien, K.Y. Machine-learning based optimal seismic control of structure with active mass damper. Appl. Sci. 2020, 10, 5342. [Google Scholar] [CrossRef]

- Tianjun, Z.; Wan, H.; Wang, Z.; Wei, M.; Xu, X.; Zhiliang, Z.; Sanmiao, D. Model reference adaptive control of semi-active suspension model based on AdaBoost algorithm for rollover prediction. SAE Int. J. Veh. Dyn. Stab. NVH 2021, 6, 71–86. [Google Scholar] [CrossRef]

- Wang, E.; Wu, S.; Xun, G.; Liu, Y.; Wu, Z. Active vibration suppression for large space structure assembly: A distributed adaptive model predictive control approach. J. Vib. Control 2021, 27, 365–377. [Google Scholar] [CrossRef]

- Zeng, X.; Xiao, Y.; Zhou, M.; Zhu, Z.; Li, Y. Self-tuning vibration absorber based on model reference adaptive control. Mech. Syst. Sig. Proc. 2025, 237, 113063. [Google Scholar] [CrossRef]

- Ümütlü, R.C.; Ozturk, H.; Bidikli, B. A robust adaptive control design for active tuned mass damper systems of multistory buildings. J. Vib. Control 2021, 27, 2765–2777. [Google Scholar] [CrossRef]

- Moutsopoulou, A.; Petousis, M.; Vidakis, N.; Pouliezos, A.; Stavroulakis, G.E. Advancement in Intelligent Control for Dampening Structural Vibrations. Vibration 2024, 7, 844–862. [Google Scholar] [CrossRef]

- Takin, K.; Doroudi, R.; Doroudi, S. Vibration control of structure by optimising the placement of semi-active dampers and fuzzy logic controllers. Aust. J. Struct. Eng. 2021, 22, 222–235. [Google Scholar] [CrossRef]

- Yan, X.; Xu, Z.D.; Shi, Q.X. Fuzzy neural network control algorithm for asymmetric building structure with active tuned mass damper. J. Vib. Control 2020, 26, 2037–2049. [Google Scholar] [CrossRef]

- Demircioğlu, U.; Bakır, H. Artificial intelligence-based position control: Reinforcement learning approach in spring mass damper systems. Phys. Scr. 2024, 99, 046003. [Google Scholar] [CrossRef]

- Jia, S.; Ouyang, Y.; Wu, H.; Kou, X.; Li, Y.M. Data-driven design of vibration control with active mass damper. J. Phy. Conf. Ser. 2025, 2977, 012015. [Google Scholar] [CrossRef]

- Chen, P.C.; Chou, C.W.; Wang, W.J. Rapid controller generation for vibration suppression of structures using direct excitation with machine learning. J. Struct. Eng. 2024, 150, 04023237. [Google Scholar] [CrossRef]

- Sharma, S.K.; Sharma, R.C.; Upadhyay, R.K.; Lee, J. Enhanced ship engine vibration reduction using magnetorheological dampers and adaptive neuro-fuzzy control system. Ships Offshore Struct. 2025, 20, 143–159. [Google Scholar] [CrossRef]

- Yao, H.; Tan, P.; Yang, T.Y.; Zhou, F. Deep reinforcement learning-based active mass driver decoupled control framework considering control–structure interaction effects. Comput. Aided Civ. Infrastruct. Eng. 2024, 39, 1573–1596. [Google Scholar] [CrossRef]

- Badr, M.F.; Karam, E.H.; Mjeed, N.M. Control design of damper mass spring system based on backstepping controller scheme. Int. Rev. Appl. Sci. Eng. 2020, 11, 181–187. [Google Scholar] [CrossRef]

- Safakhaneh, M.M.; Farzam, M.F.; Ahmadi, H.; Farnam, A. Vibration control of structure using active tuned mass damper: A new control algorithm. J. Vib. Control 2024, 31, 2908–2919. [Google Scholar] [CrossRef]

- Saleem, O.; Ahmad, K.R.; Iqbal, J. Fuzzy-Augmented Model Reference Adaptive PID Control Law Design for Robust Voltage Regulation in DC–DC Buck Converters. Mathematics 2024, 12, 1893. [Google Scholar] [CrossRef]

- Lewis, F.L.; Vrabie, D.; Syrmos, V.L. Optimal Control; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Saleem, O.; Awan, F.G.; Mahmood-ul-Hasan, K.; Ahmad, M. Self-adaptive fractional-order LQ-PID voltage controller for robust disturbance compensation in DC-DC buck converters. Int. J. Numer. Model. 2020, 33, e2718. [Google Scholar] [CrossRef]

- Saleem, O.; Mahmood-ul-Hasan, K.; Rizwan, M. An experimental comparison of different hierarchical self-tuning regulatory control procedures for under-actuated mechatronic systems. PLoS ONE 2021, 16, e0256750. [Google Scholar] [CrossRef]

- Saleem, O.; Mahmood-ul-Hasan, K. Hierarchical adaptive control of self-stabilizing electromechanical systems using artificial-immune self-tuning mechanism for state weighting-factors. J. Mech. Sci. Technol. 2021, 35, 1235–1250. [Google Scholar] [CrossRef]

- Karasakal, O.; Guzelkaya, M.; Eksin, I.; Yesil, E.; Kumbasar, T. Online tuning of fuzzy PID controllers via rule weighing based on normalized acceleration. Eng. Appl. Artif. Intell. 2013, 26, 184–197. [Google Scholar] [CrossRef]

- Saleem, O. An enhanced adaptive-LQR procedure for under-actuated systems using relative-rate feedback to dynamically reconfigure the state-weighting-factors. J. Vib. Control 2023, 29, 2316–2331. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J.; Lu, G. Self-organizing fuzzy optimal control for under-actuated systems. J. Syst. Control Eng. 2014, 228, 578–590. [Google Scholar] [CrossRef]

- Das, S.; Pan, I.; Das, S.; Gupta, A. A novel fractional order fuzzy PID controller and its optimal time domain tuning based on integral performance indices. Eng. Appl. Artif. Intell. 2012, 25, 430–442. [Google Scholar] [CrossRef]

- Baizid, K.; Ćuković, S.; Iqbal, J.; Yousnadj, A.; Chellali, R.; Devedzic, G.; Ghionea, I. IRoSim: Industrial Robotics Simulation Design Planning and Optimization Platform Based on CAD and Knowledge ware Technologies. Robot. Comput. Integr. Manuf. 2016, 42, 121–134. [Google Scholar] [CrossRef]

| Parameters | Description | Value | Units |

|---|---|---|---|

| Carriage and brass weight mass | 2.77 | kg | |

| Viscous damping coefficient | 15.235 | N/m/s | |

| Overall steady-state gain | 140 | - |

| System’s Response | ||

|---|---|---|

| Positive | Positive | Fast |

| Positive | Zero | Moderate |

| Positive | Negative | Slow |

| Negative | Positive | Slow |

| Negative | Zero | Moderate |

| Negative | Negative | Fast |

| SL | M | MF | F | |

| S | M | M | L | L |

| SM | SM | M | M | L |

| M | S | SM | M | M |

| L | S | S | SM | M |

| Simulation Case | KPM | Control Scheme | Percentage Improvement | ||

|---|---|---|---|---|---|

| Symbol | Unit | LQ-PID | FA-PID | ||

| A | m | 0.013 | 0.010 | 23.1% | |

| sec. | 0.165 | 0.135 | 18.2% | ||

| m | 0.017 | 0.007 | 58.8% | ||

| sec. | 0.48 | 0.35 | 27.1% | ||

| B | m | 0.039 | 0.023 | 41.0% | |

| m | 0.153 | 0.127 | 17.0% | ||

| sec. | 32.6 | 25.5 | 21.8% | ||

| C | m | 0.043 | 0.026 | 39.5% | |

| m | 0.14 | 0.10 | 28.6% | ||

| sec. | 1.42 | 1.15 | 19.0% | ||

| D | m | 0.041 | 0.027 | 34.1% | |

| m | −0.16 | −0.11 | 31.2% | ||

| sec. | 18.3 | 15.2 | 16.9% | ||

| E | m | 0.046 | 0.029 | 40.4% | |

| m | 0.17 | 0.12 | 37.0% | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saleem, O.; Filograno, M.L.; Alharbi, S.; Iqbal, J. Hierarchical Fuzzy-Adaptive Position Control of an Active Mass Damper for Enhanced Structural Vibration Suppression. Mathematics 2025, 13, 2816. https://doi.org/10.3390/math13172816

Saleem O, Filograno ML, Alharbi S, Iqbal J. Hierarchical Fuzzy-Adaptive Position Control of an Active Mass Damper for Enhanced Structural Vibration Suppression. Mathematics. 2025; 13(17):2816. https://doi.org/10.3390/math13172816

Chicago/Turabian StyleSaleem, Omer, Massimo Leonardo Filograno, Soltan Alharbi, and Jamshed Iqbal. 2025. "Hierarchical Fuzzy-Adaptive Position Control of an Active Mass Damper for Enhanced Structural Vibration Suppression" Mathematics 13, no. 17: 2816. https://doi.org/10.3390/math13172816

APA StyleSaleem, O., Filograno, M. L., Alharbi, S., & Iqbal, J. (2025). Hierarchical Fuzzy-Adaptive Position Control of an Active Mass Damper for Enhanced Structural Vibration Suppression. Mathematics, 13(17), 2816. https://doi.org/10.3390/math13172816