Entropy-Based Optimization of 3D-Printed Microchannels for Efficient Heat Dissipation

Abstract

1. Introduction

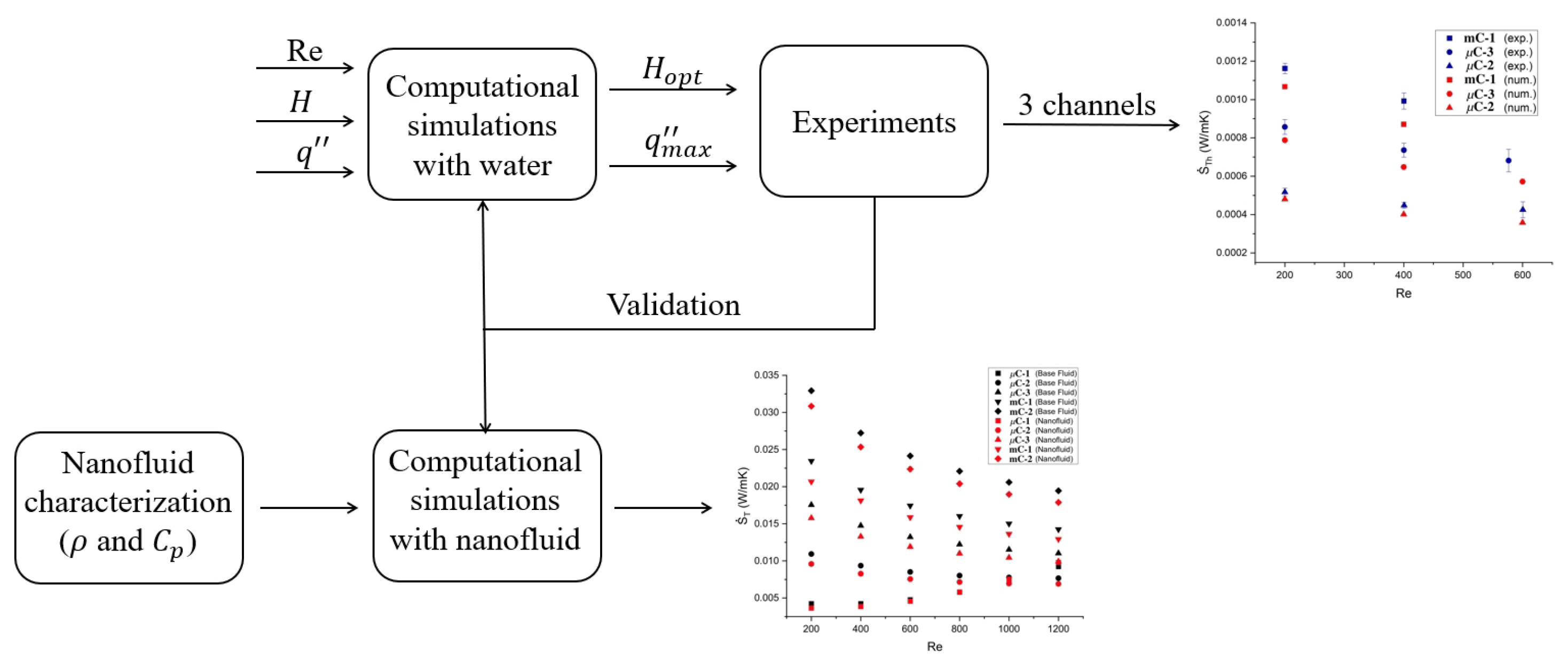

2. Computational Simulations

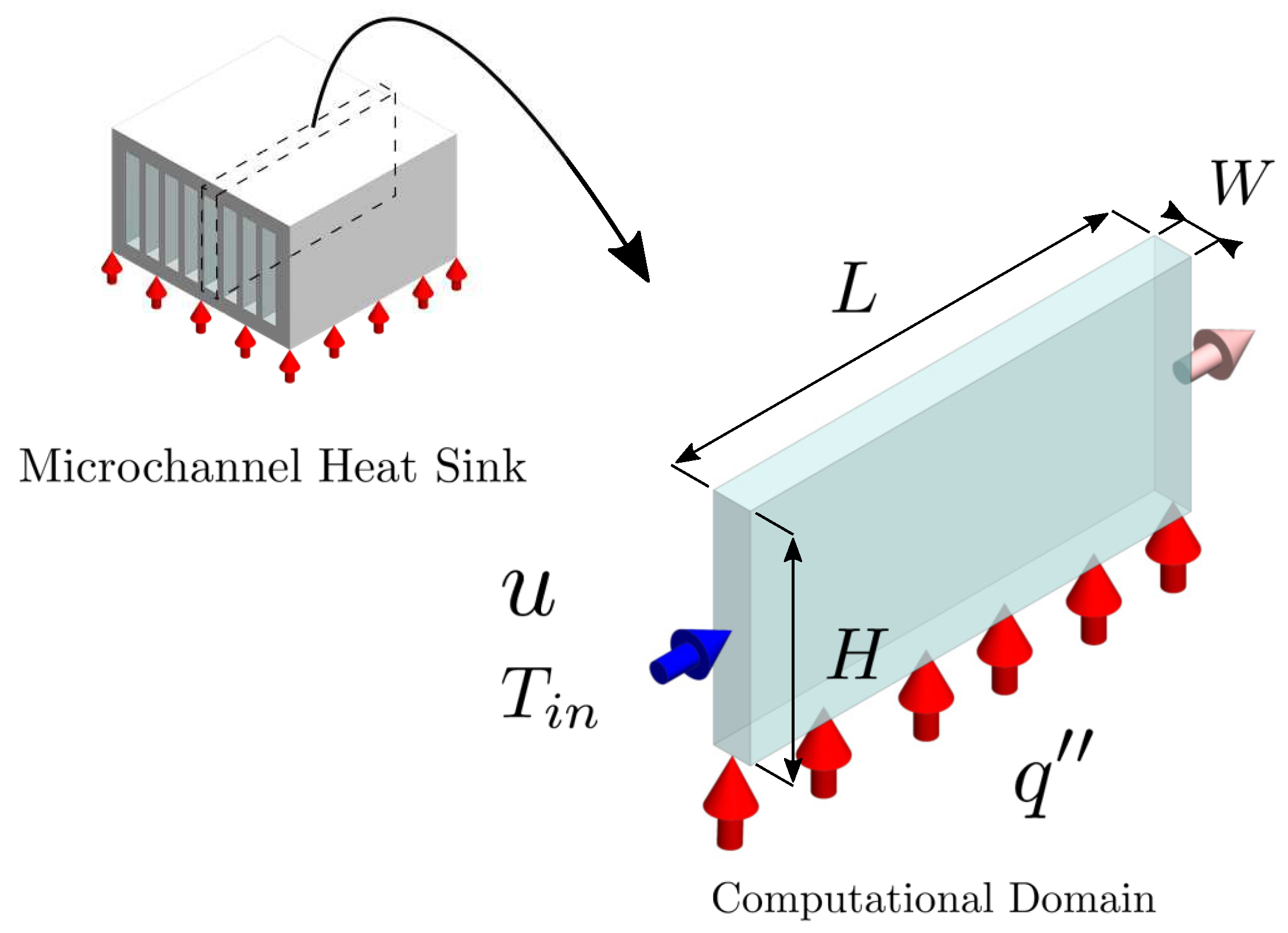

2.1. Computational Domain

2.2. Mathematical Model

2.2.1. Governing Equations

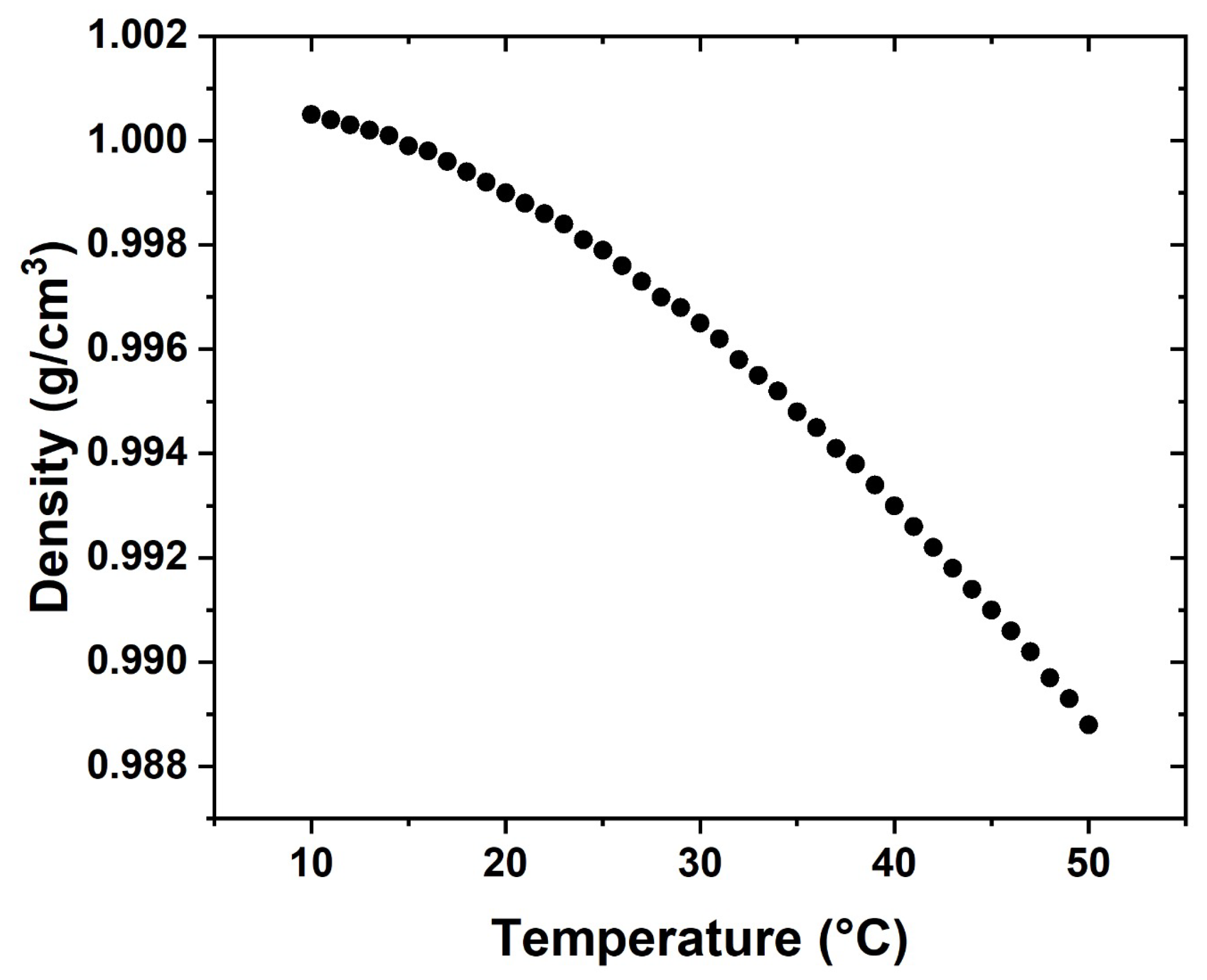

2.2.2. Thermal Properties

2.2.3. Boundary Conditions

2.3. Numerical Parameters

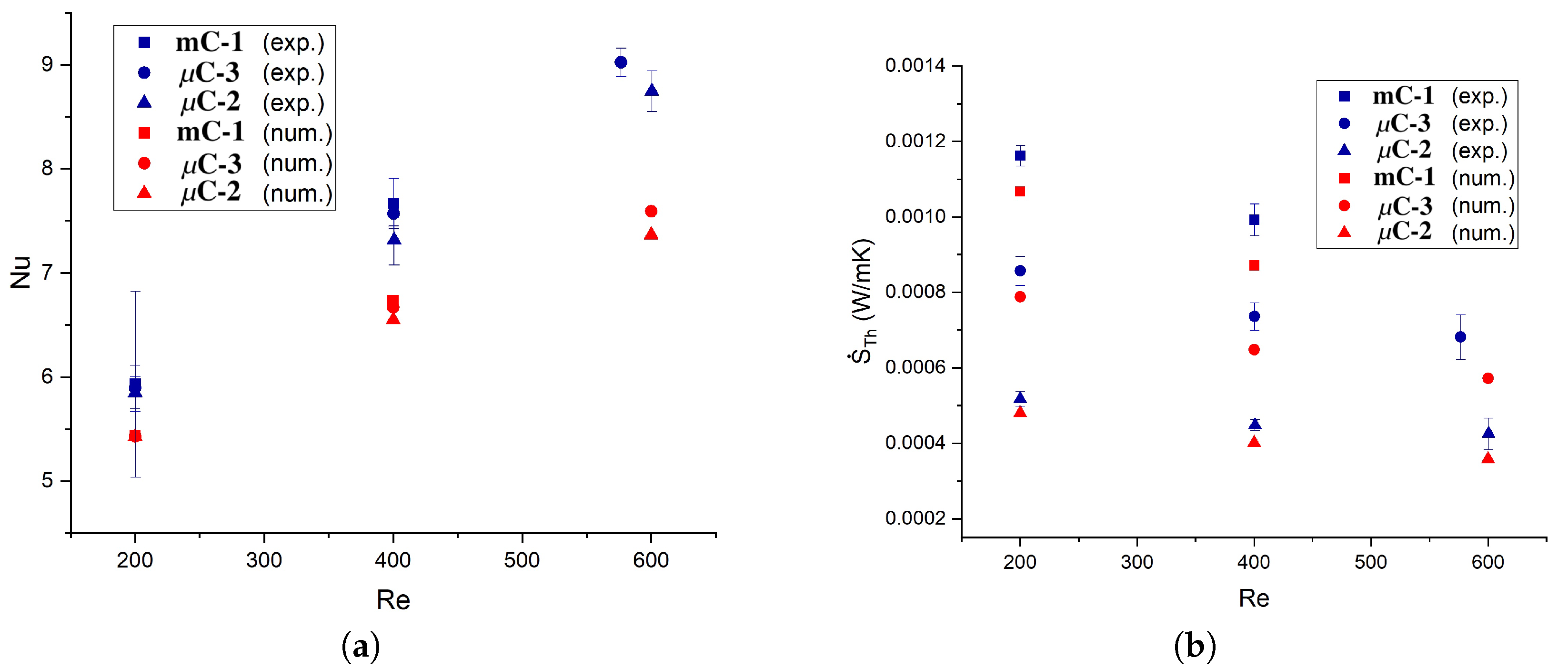

Grid Size Analysis and Validation

3. Materials and Methods

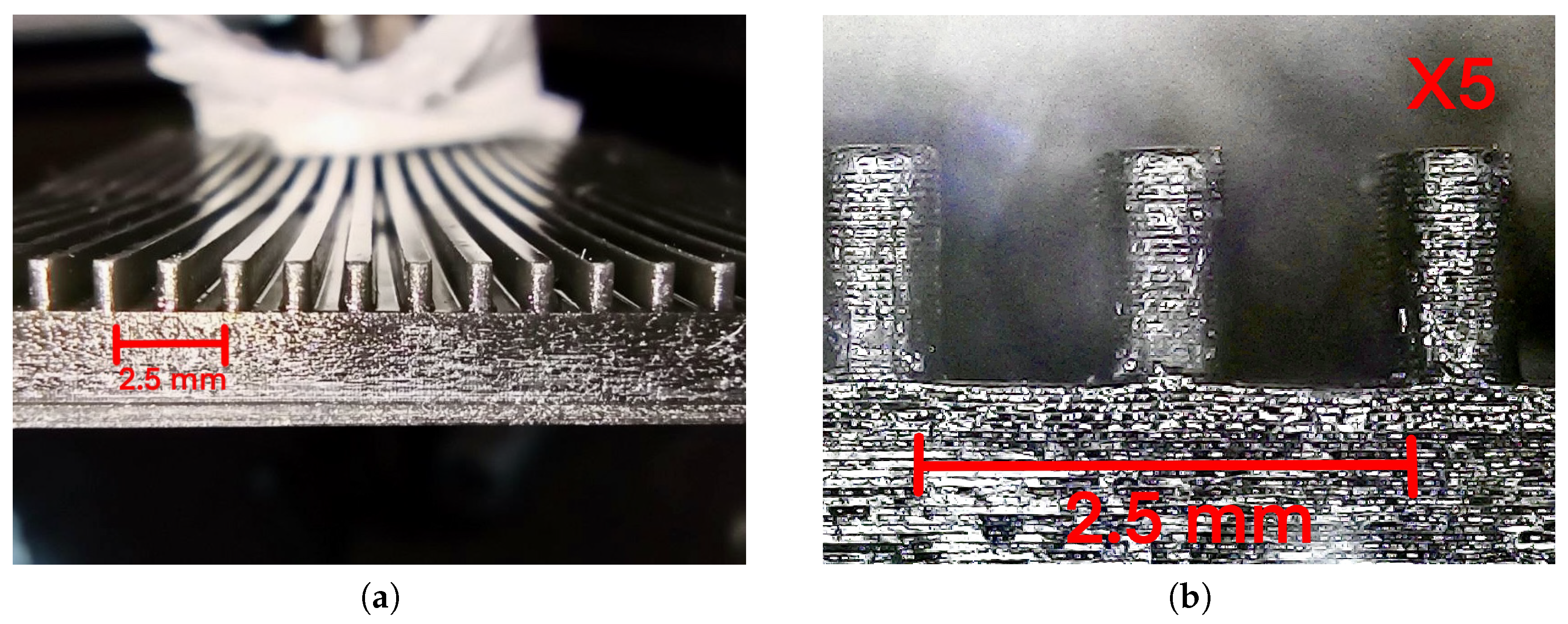

3.1. Heat Sink Manufacturing

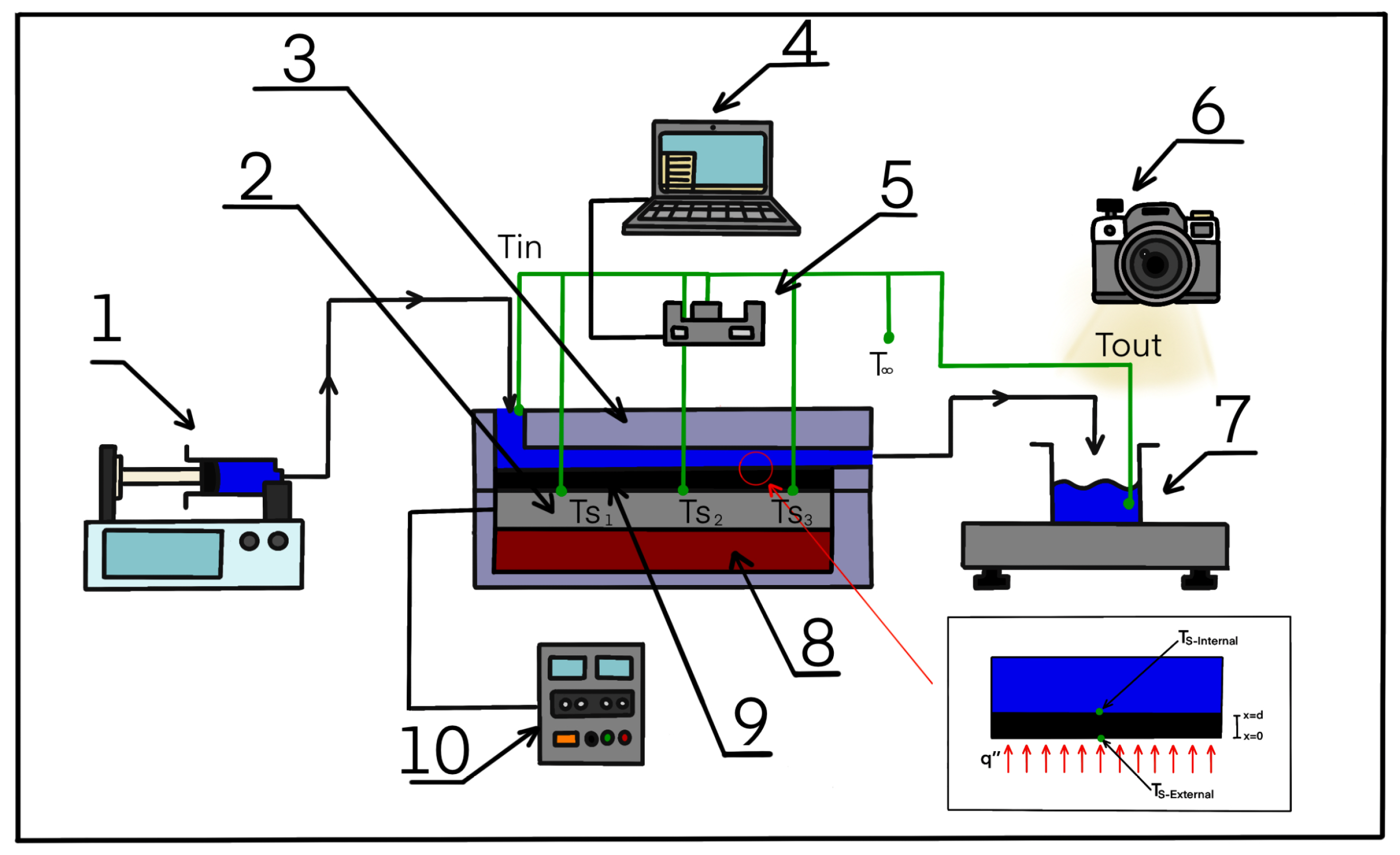

3.2. Experimental Setup

4. Results and Discussion

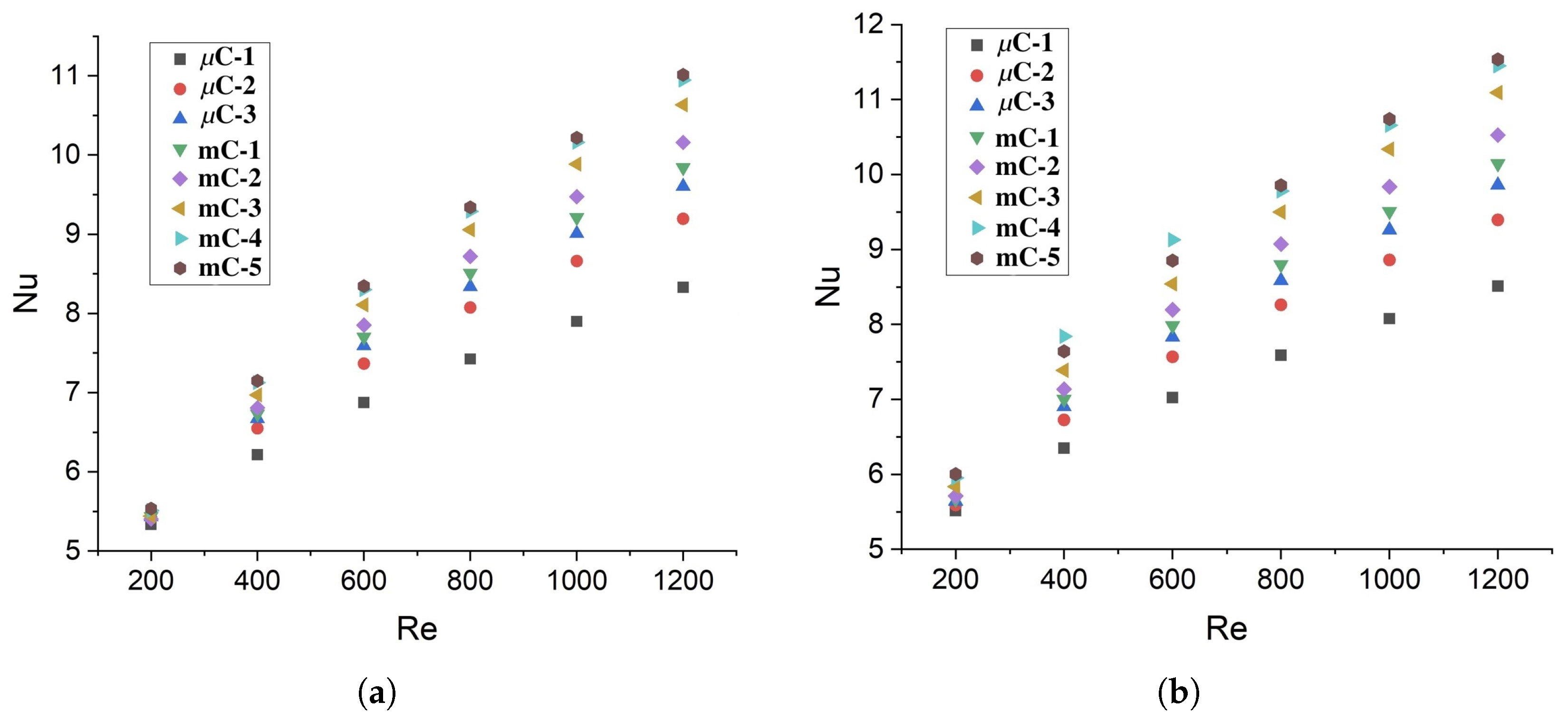

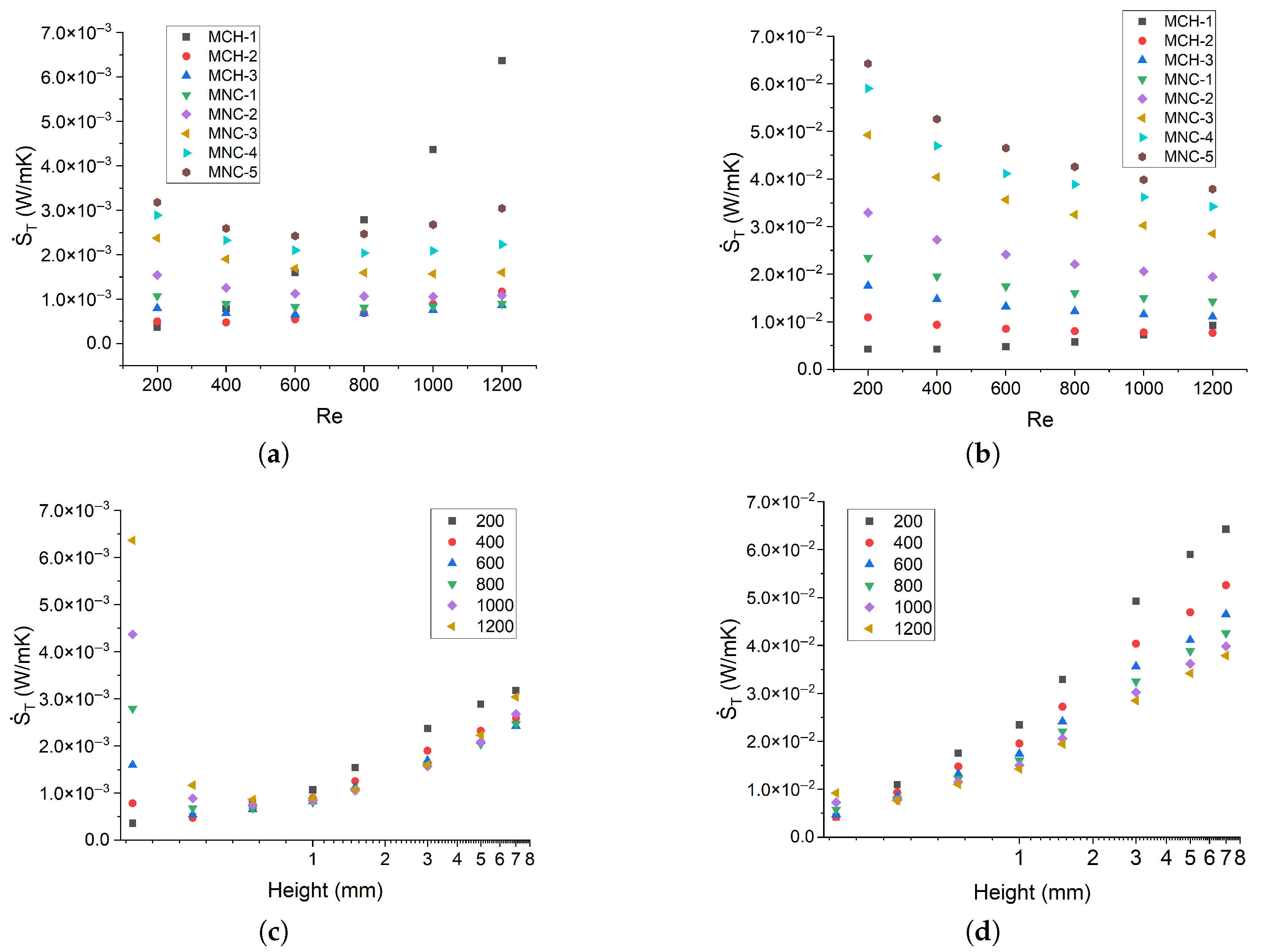

4.1. Computational Results with Water

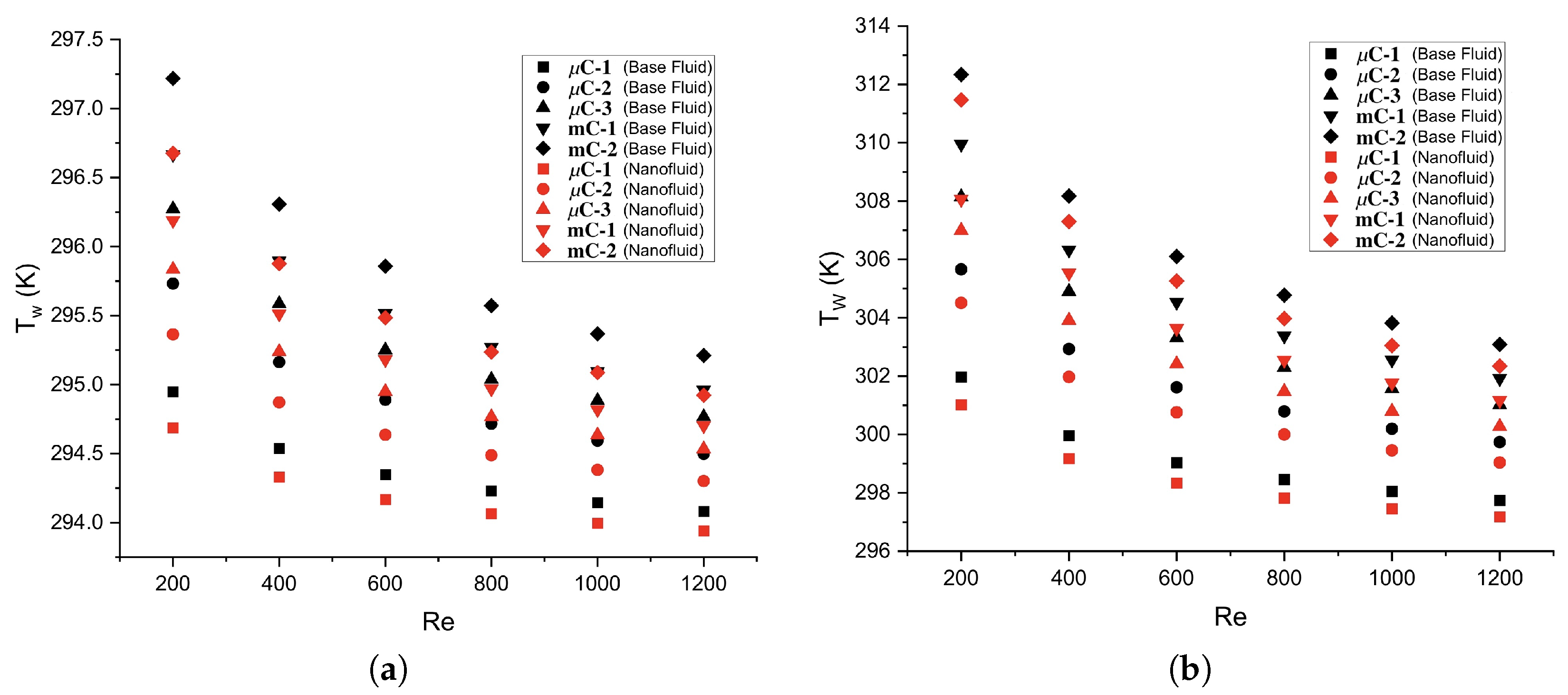

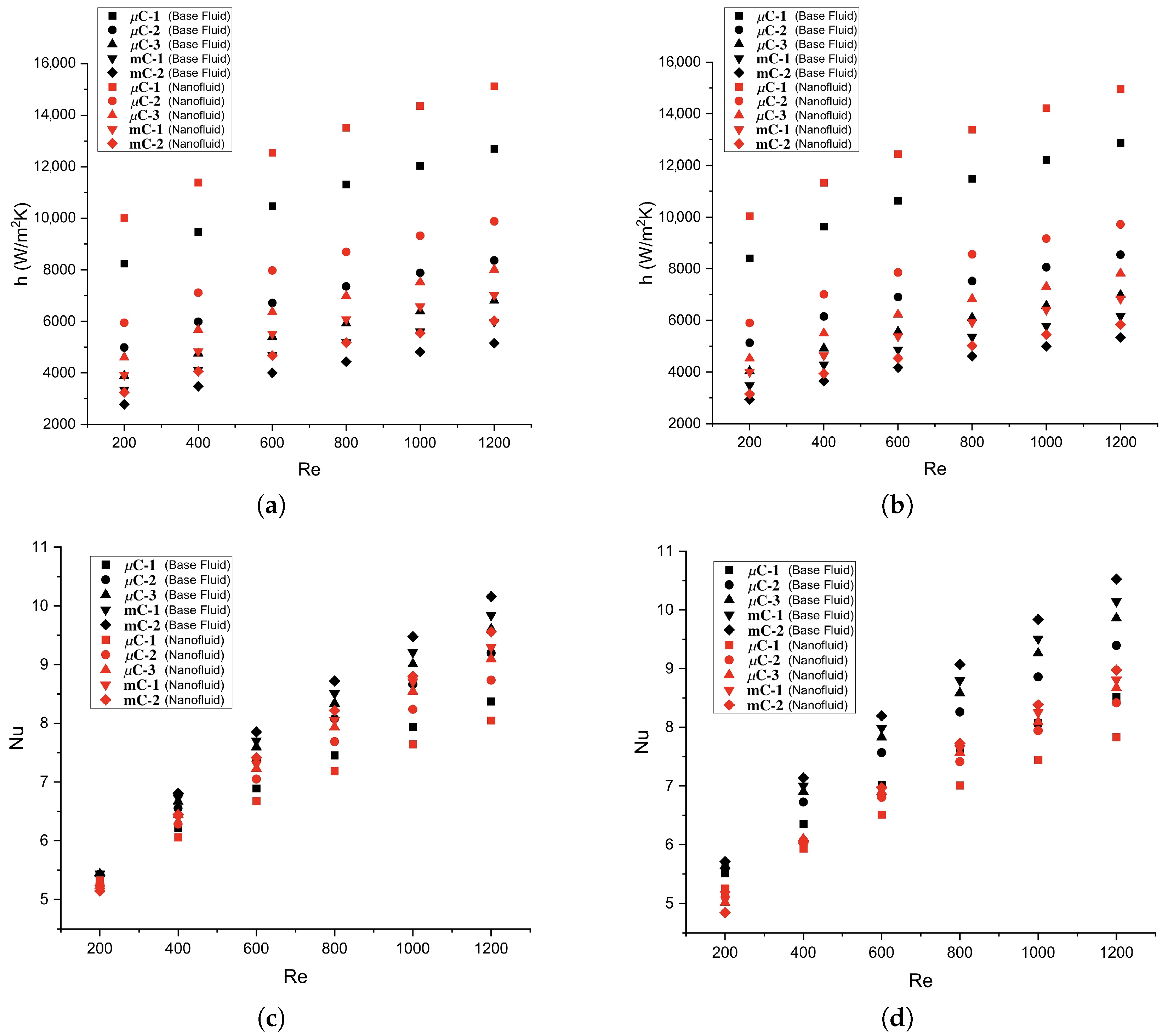

4.2. Experimental Results

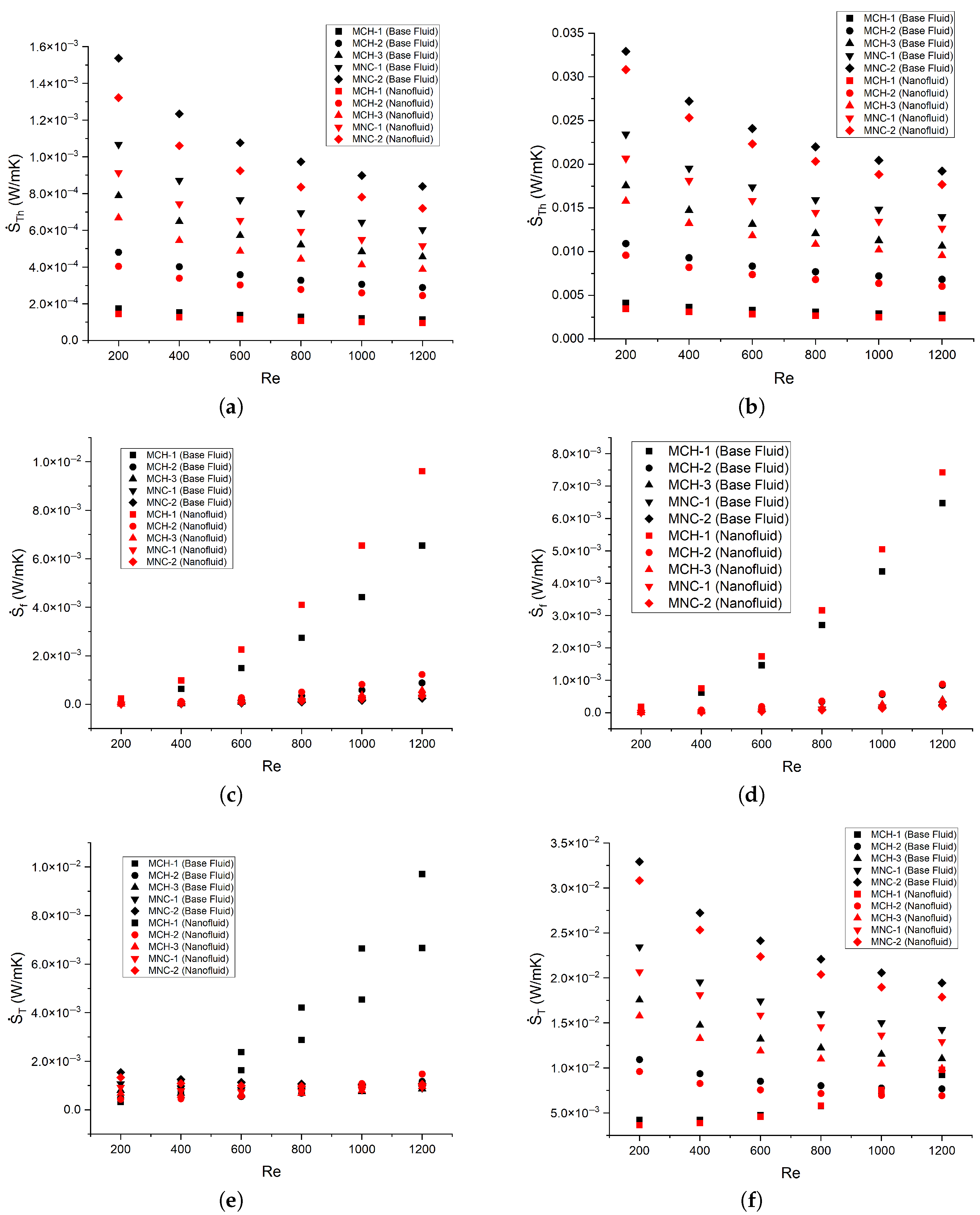

4.3. Computational Results with Nanofluid

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Masanet, E.; Shehabi, A.; Lei, N.; Smith, S.; Koomey, J. Recalibrating global data center energy-use estimates. Science 2020, 367, 984–986. [Google Scholar] [CrossRef] [PubMed]

- Heydari, A.; Gharaibeh, A.R.; Tradat, M.; Soud, Q.; Manaserh, Y.; Radmard, V.; Eslami, B.; Rodriguez, J.; Sammakia, B. Experimental evaluation of direct-to-chip cold plate liquid cooling for high-heat-density data centers. Appl. Therm. Eng. 2024, 239, 122122. [Google Scholar] [CrossRef]

- Lee, J.; Mudawar, I. Fluid flow and heat transfer characteristics of low temperature two-phase micro-channel heat sinks–Part 1: Experimental methods and flow visualization results. Int. J. Heat Mass Transf. 2008, 51, 4315–4326. [Google Scholar] [CrossRef]

- Reece, D.; Huss, R. The Standard Electronic Modules Program. IEEE Trans. Compon. Hybrids Manuf. Technol. 1979, 2, 491–499. [Google Scholar] [CrossRef]

- Kodama, H. Automatic method for fabricating a three-dimensional plastic model with photo-hardening polymer. Rev. Sci. Instrum. 1981, 52, 1770–1773. [Google Scholar] [CrossRef]

- Kivanani, A.N.; Khalilpourazary, S.; Mobadersani, F. Additive manufacturing for producing microchannel heat sinks. Prog. Addit. Manuf. 2025, 10, 231–245. [Google Scholar] [CrossRef]

- Tiwari, R.; Andhare, R.S.; Shooshtari, A.; Ohadi, M. Development of an additive manufacturing-enabled compact manifold microchannel heat exchanger. Appl. Therm. Eng. 2019, 147, 781–788. [Google Scholar] [CrossRef]

- Shah, A.K.; Li, H.; Xin, Z.; Wu, Z. A Review on Additive Manufacturing of Topology Optimized Microchannel Heat Sink. Heat Transf. Eng. 2025, 1–27. [Google Scholar] [CrossRef]

- Ozguc, S.; Teague, T.F.; Pan, L.; Weibel, J.A. Experimental study of topology optimized, additively manufactured microchannel heat sinks designed using a homogenization approach. Int. J. Heat Mass Transf. 2023, 209, 124108. [Google Scholar] [CrossRef]

- Jung, S.Y.; Park, H. Experimental investigation of heat transfer of Al2O3 nanofluid in a microchannel heat sink. Int. J. Heat Mass Transf. 2021, 179, 121729. [Google Scholar] [CrossRef]

- Darvanjooghi, M.H.K.; Esfahany, M.N. Experimental investigation of the effect of nanoparticle size on thermal conductivity of in-situ prepared silica–ethanol nanofluid. Int. Commun. Heat Mass Transf. 2016, 77, 148–154. [Google Scholar] [CrossRef]

- Tuckerman, D.B.; Pease, R.F.W. High-performance heat sinking for VLSI. IEEE Electron Device Lett. 1981, 2, 126–129. [Google Scholar] [CrossRef]

- Mehendale, S.S.; Jacobi, A.M.; Shah, R.K. Fluid Flow and Heat Transfer at Micro- and Meso-Scales with Application to Heat Exchanger Design. Appl. Mech. Rev. 2000, 53, 175–193. [Google Scholar] [CrossRef]

- Kandlikar, S.G.; Grande, W.J. Evolution of microchannel flow passages–thermohydraulic performance and fabrication technology. Heat Transf. Eng. 2003, 24, 3–17. [Google Scholar] [CrossRef]

- Toghraie, D.; Chaharsoghi, V.A.; Afrand, M. Measurement of thermal conductivity of ZnO–TiO2/EG hybrid nanofluid: Effects of temperature and nanoparticles concentration. J. Therm. Anal. Calorim. 2016, 125, 527–535. [Google Scholar] [CrossRef]

- Zadkhast, M.; Toghraie, D.; Karimipour, A. Developing a new correlation to estimate the thermal conductivity of MWCNT-CuO/water hybrid nanofluid via an experimental investigation. J. Therm. Anal. Calorim. 2017, 129, 859–867. [Google Scholar] [CrossRef]

- Mintsa, H.A.; Roy, G.; Nguyen, C.T.; Doucet, D. New temperature dependent thermal conductivity data for water-based nanofluids. Int. J. Therm. Sci. 2009, 48, 363–371. [Google Scholar] [CrossRef]

- Beck, M.P.; Yuan, Y.; Warrier, P.; Teja, A.S. The thermal conductivity of aqueous nanofluids containing ceria nanoparticles. J. Appl. Phys. 2010, 107, 066101. [Google Scholar] [CrossRef]

- Lee, J.H.; Hwang, K.S.; Jang, S.P.; Lee, B.H.; Kim, J.H.; Choi, S.U.; Choi, C.J. Effective viscosities and thermal conductivities of aqueous nanofluids containing low volume concentrations of Al2O3 nanoparticles. Int. J. Heat Mass Transf. 2008, 51, 2651–2656. [Google Scholar] [CrossRef]

- Jang, S.P.; Choi, S.U. Cooling performance of a microchannel heat sink with nanofluids. Appl. Therm. Eng. 2006, 26, 2457–2463. [Google Scholar] [CrossRef]

- Wu, J.; Zhao, J.; Lei, J.; Liu, B. Effectiveness of nanofluid on improving the performance of microchannel heat sink. Appl. Therm. Eng. 2016, 101, 402–412. [Google Scholar] [CrossRef]

- Manay, E.; Akyürek, E.F.; Sahin, B. Entropy generation of nanofluid flow in a microchannel heat sink. Res. Phys. 2018, 9, 615–624. [Google Scholar] [CrossRef]

- Bejan, A. Advanced Engineering Thermodynamics; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Rastogi, P.; Mahulikar, S.P. Optimization of micro-heat sink based on theory of entropy generation in laminar forced convection. Int. J. Therm. Sci. 2018, 126, 96–104. [Google Scholar] [CrossRef]

- Datta, A.; Sharma, V.; Sanyal, D.; Das, P. A conjugate heat transfer analysis of performance for rectangular microchannel with trapezoidal cavities and ribs. Int. J. Therm. Sci. 2019, 138, 425–446. [Google Scholar] [CrossRef]

- Yang, Y.T.; Wang, Y.H.; Huang, B.Y. Numerical optimization for nanofluid flow in microchannels using entropy generation minimization. Numer. Heat Transf. Part Appl. 2015, 67, 571–588. [Google Scholar] [CrossRef]

- Adio, S.A.; Olalere, A.E.; Olagoke, R.O.; Alo, T.A.; Veeredhi, V.R.; Ewim, D.R.; Olakoyejo, O.T. Thermal and entropy analysis of a manifold microchannel heat sink operating on CuO–water nanofluid. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 1–15. [Google Scholar] [CrossRef]

- Li, J.; Kleinstreuer, C. Entropy Generation Analysis for Nanofluid Flow in Microchannels. J. Heat Transf. 2010, 132, 122401. [Google Scholar] [CrossRef]

- Joy, A.; Shiblemon, K.V.; Baby, B. Review on fabrication and experimental study of microchannel heat sinks for cooling of electronic components. Mater. Today Proc. 2023, 72, 2985–2991. [Google Scholar] [CrossRef]

- Collins, I.L.; Weibel, J.A.; Pan, L.; Garimella, S.V. Experimental Characterization of a Microchannel Heat Sink Made by Additive Manufacturing. In Proceedings of the 2018 17th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), San Diego, CA, USA, 29 May–1 June 2018; pp. 171–177. [Google Scholar] [CrossRef]

- Xu, J.; Rios, J. An Experimental Study of Single-Phase Heat Transfer inside an Additively Fabricated Microchannel Heat Exchanger. In Proceedings of the 2019 18th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Las Vegas, NV, USA, 28–31 May 2019; pp. 465–471. [Google Scholar] [CrossRef]

- Collins, I.L.; Weibel, J.A.; Pan, L.; Garimella, S.V. Evaluation of Additively Manufactured Microchannel Heat Sinks. IEEE Trans. Comp. Packag. Manuf. Technol. 2019, 9, 446–457. [Google Scholar] [CrossRef]

- Chej, L.G.; Monastra, A.G.; Carusela, M.F. Modeling considerations about a microchannel heat sink. Phys. Fluids 2024, 36, 082005. [Google Scholar] [CrossRef]

- Koo, J.; Kleinstreuer, C. Viscous dissipation effects in microtubes and microchannels. Int. J. Heat Mass Transf. 2004, 47, 3159–3169. [Google Scholar] [CrossRef]

- Lozano-Steinmetz, F.; Martinez, V.A.; Vasco, D.A.; Sepulveda-Mualin, A.; Singh, D.P. The effect of Ag-decoration on rGO/water nanofluid thermal conductivity and viscosity. Nanomaterials 2022, 12, 1095. [Google Scholar] [CrossRef] [PubMed]

- Zografos, A.I.; Martin, W.A.; Sunderland, J.E. Equations of properties as a function of temperature for seven fluids. Comput. Methods Appl. Mech. Eng. 1987, 61, 177–187. [Google Scholar] [CrossRef]

- Bhanvase, B.; Barai, D. Nanofluids for Heat and Mass Transfer: Fundamentals, Sustainable Manufacturing and Applications; Academic Press: Cambridge, MA, USA, 2021. [Google Scholar]

- Martínez, V.A.; Vasco, D.A.; García-Herrera, C.M.; Ortega-Aguilera, R. Numerical study of TiO2-based nanofluids flow in microchannel heat sinks: Effect of the Reynolds number and the microchannel height. Appl. Therm. Eng. 2019, 161, 114130. [Google Scholar] [CrossRef]

- Ho, C.J.; Chen, W. An experimental study on thermal performance of Al2O3/water nanofluid in a minichannel heat sink. Appl. Therm. Eng. 2013, 50, 516–522. [Google Scholar] [CrossRef]

- Moraveji, M.K.; Ardehali, R.M. CFD modeling (comparing single and two-phase approaches) on thermal performance of Al2O3/water nanofluid in mini-channel heat sink. Int. Commun. Heat Mass Transf. 2013, 44, 157–164. [Google Scholar] [CrossRef]

- Uysal, C.; Gedik, E.; Chamkha, A. A numerical analysis of laminar forced convection and entropy generation of a diamond-Fe3O4/water hybrid nanofluid in a rectangular minichannel. J. Appl. Fluid Mech. 2019, 12, 391–402. [Google Scholar] [CrossRef]

- Liu, C.; Yu, H. Experimental investigations on heat transfer characteristics of direct contact liquid cooling for CPU. Buildings 2022, 12, 913. [Google Scholar] [CrossRef]

- Bejan, A. A Study of Entropy Generation in Fundamental Convective Heat Transfer. J. Heat Transf. 1979, 101, 718–725. [Google Scholar] [CrossRef]

- Bejan, A. Fundamentals of exergy analysis, entropy generation minimization, and the generation of flow architecture. Int. J. Energy Res. 2002, 26. [Google Scholar] [CrossRef]

- Jung, J.; Kim, S.J. Entropy Generation Analysis of Microchannel Heat. In Proceedings of the ASME 2009 International Mechanical Engineering Congress and Exposition. Volume 9: Heat Transfer, Fluid Flows, and Thermal Systems, Parts A, B and C, Lake Buena Vista, FL, USA, 13–19 November 2009; ASME: New York, NY, USA, 2009. [Google Scholar] [CrossRef]

- Martinez, V.A.; Lozano-Steinmetz, F.; Vasco, D.A.; Zapata, P.A.; Chi-Durán, I.; Singh, D.P. Thermal characterization and stability analysis of aqueous ZnO-based nanofluids numerically implemented in microchannel heat sinks. Therm. Sci. Eng. Prog. 2021, 22, 100792. [Google Scholar] [CrossRef]

- Cruz-Duarte, J.M.; Garcia-Perez, A.; Amaya-Contreras, I.M.; Correa-Cely, C.R. Designing a microchannel heat sink with colloidal coolants through the entropy generation minimisation criterion and global optimisation algorithms. Appl. Therm. Eng. 2016, 100, 1052–1062. [Google Scholar] [CrossRef]

- Narendran, G.; Gnanasekaran, N.; Perumal, D.A. Thermodynamic irreversibility and conjugate effects of integrated microchannel cooling device using TiO2 nanofluid. Heat Mass Transf. 2020, 56, 489–505. [Google Scholar] [CrossRef]

- Shahsavar, A.; Jafari, M.; Talebizadehsardari, P.; Toghraie, D. Hydrothermal and entropy generation specifications of a hybrid ferronanofluid in microchannel heat sink embedded in CPUs. Chin. J. Chem. Eng. 2021, 32, 27–38. [Google Scholar] [CrossRef]

- Shahsavar, A.; Entezari, S.; Askari, I.B.; Ali, H.M. The effect of using connecting holes on heat transfer and entropy generation behaviors in a micro channels heat sink cooled with biological silver/water nanofluid. Int. Commun. Heat Mass Transf. 2021, 123, 104929. [Google Scholar] [CrossRef]

- Adio, S.A.; Alo, T.A.; Olagoke, R.O.; Olalere, A.E.; Veeredhi, V.R.; Ewim, D.R.E. Thermohydraulic and entropy characteristics of Al2O3-water nanofluid in a ribbed interrupted microchannel heat exchanger. Heat Transf. 2021, 50, 1951–1984. [Google Scholar] [CrossRef]

- Rehman, M.M.U.; Cheema, T.A.; Ahmad, F.; Abbas, A.; Malik, M.S. Numerical investigation of heat transfer enhancement and fluid flow characteristics in a microchannel heat sink with different wall/design configurations of protrusions/dimples. Heat Mass Transf. 2020, 56, 239–255. [Google Scholar] [CrossRef]

- Feng, Z.; Lan, Y.; Hu, Z.; Zheng, S.; Zhang, Y.; Huang, Z.; Zhang, J. Effects of longitudinal vortex generator pairs in transverse microchambers on thermal–hydraulic performances and entropy generation in an interrupted microchannel heat sink. J. Therm. Anal. Calorim. 2022, 147, 8551–8567. [Google Scholar] [CrossRef]

- Akhtar, K.; Ali, H.; Ud Din, I.; Abbas, A.; Zahir, M.Z.; Ahmad, F.; Alam, F.; Shah, N.; Aamir, M. Heat Transfer Augmentation and Entropy Generation Analysis of Microchannel Heat Sink (MCHS) with Symmetrical Ogive-Shaped Ribs. Energies 2023, 16, 2783. [Google Scholar] [CrossRef]

- Mukherjee, S.; Wciślik, S.; Khadanga, V.; Mishra, P.C. Influence of nanofluids on the thermal performance and entropy generation of varied geometry microchannel heat sink. Case Stud. Therm. Eng. 2023, 49, 103241. [Google Scholar] [CrossRef]

| Channel | C-1 | C-2 | C-3 | mC-1 | mC-2 | mC-3 | mC-4 | mC-5 |

|---|---|---|---|---|---|---|---|---|

| H [mm] | 0.25 | 0.50 | 0.75 | 1.00 | 1.50 | 3.00 | 5.00 | 7.00 |

| Thermal Property | [W/m K] | [MJ/m3 K] | [mm2/s] |

|---|---|---|---|

| Measured value | 0.1217 ± 0.0013 | 1.1436 ± 0.0246 | 0.1113 ± 0.0019 |

| C-1 | ||

|---|---|---|

| Grid | Nu | Difference % |

| 10 × 28 × 180 | 6.48 | - |

| 12 × 36 × 210 | 6.81 | 5.05% |

| 15 × 44 × 240 | 7.02 | 3.10% |

| 18 × 52 × 270 | 7.18 | 2.15% |

| Channel | C-1 | C-2 | C-3 | mC-1 | mC-2 | mC-3 | mC-4 | mC-5 |

|---|---|---|---|---|---|---|---|---|

| Mesh | 15 × 44 × 240 | 15 × 77 × 240 | 15 × 100 × 240 | |||||

| Channel | 10 kW/m2 | 50 kW/m2 |

|---|---|---|

| C-1 | 200.0 | 290.2 |

| C-2 | 331.3 | 1055.8 |

| C-3 | 639.2 | 1167.2 |

| mC-1 | 807.8 | 1186.7 |

| mC-2 | 930.1 | 1191.0 |

| mC-3 | 943.6 | 1183.2 |

| mC-4 | 840.6 | 1219.0 |

| mC-5 | 709.6 | 1149.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lozano-Steinmetz, F.; Martínez, V.A.; Zambra, C.A.; Vasco, D.A. Entropy-Based Optimization of 3D-Printed Microchannels for Efficient Heat Dissipation. Mathematics 2025, 13, 2394. https://doi.org/10.3390/math13152394

Lozano-Steinmetz F, Martínez VA, Zambra CA, Vasco DA. Entropy-Based Optimization of 3D-Printed Microchannels for Efficient Heat Dissipation. Mathematics. 2025; 13(15):2394. https://doi.org/10.3390/math13152394

Chicago/Turabian StyleLozano-Steinmetz, Felipe, Victor A. Martínez, Carlos A. Zambra, and Diego A. Vasco. 2025. "Entropy-Based Optimization of 3D-Printed Microchannels for Efficient Heat Dissipation" Mathematics 13, no. 15: 2394. https://doi.org/10.3390/math13152394

APA StyleLozano-Steinmetz, F., Martínez, V. A., Zambra, C. A., & Vasco, D. A. (2025). Entropy-Based Optimization of 3D-Printed Microchannels for Efficient Heat Dissipation. Mathematics, 13(15), 2394. https://doi.org/10.3390/math13152394