Research on the Deformation Prediction Method for the Laser Deposition Manufacturing of Metal Components Based on Feature Partitioning and the Inherent Strain Method

Abstract

1. Introduction

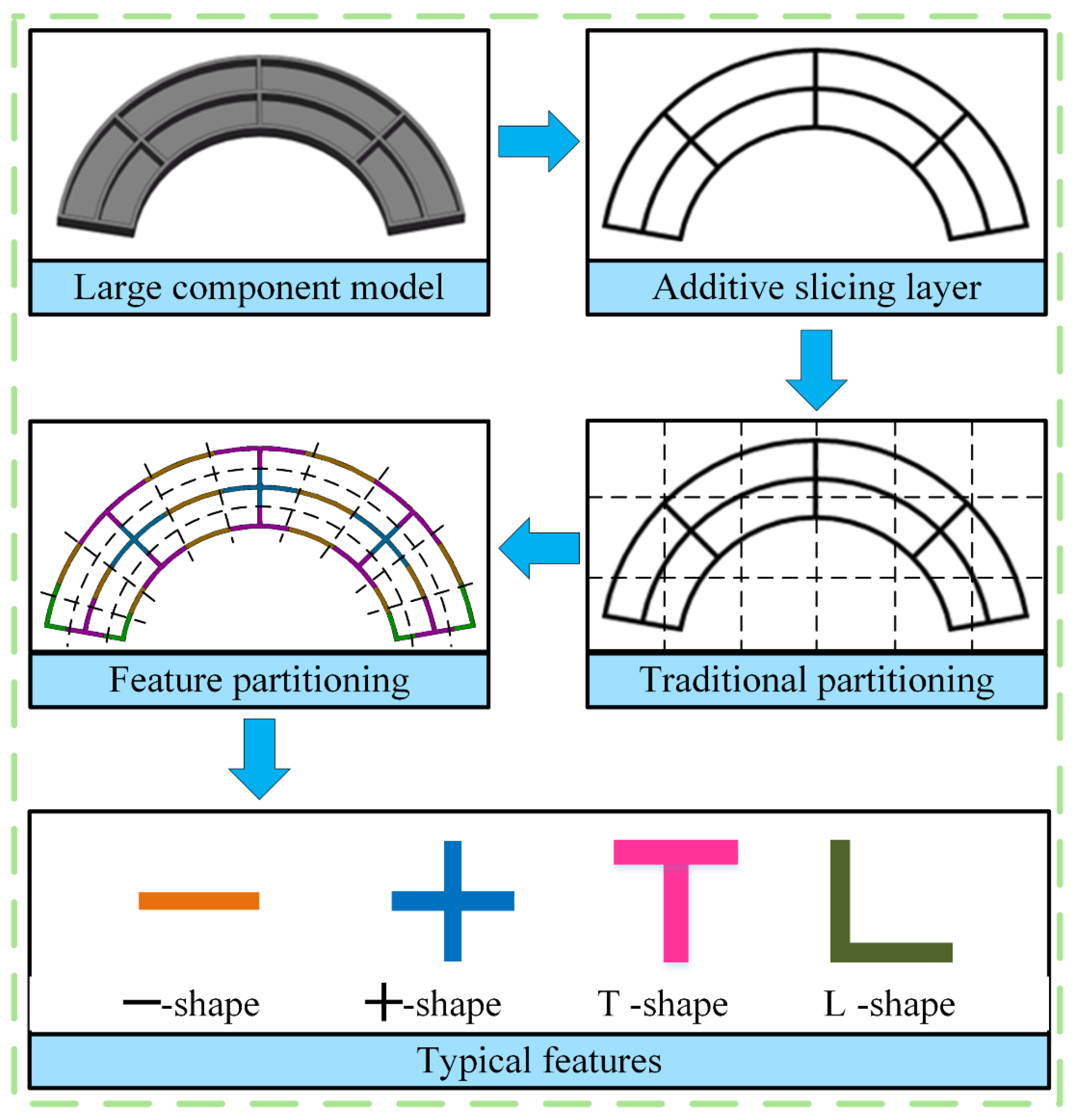

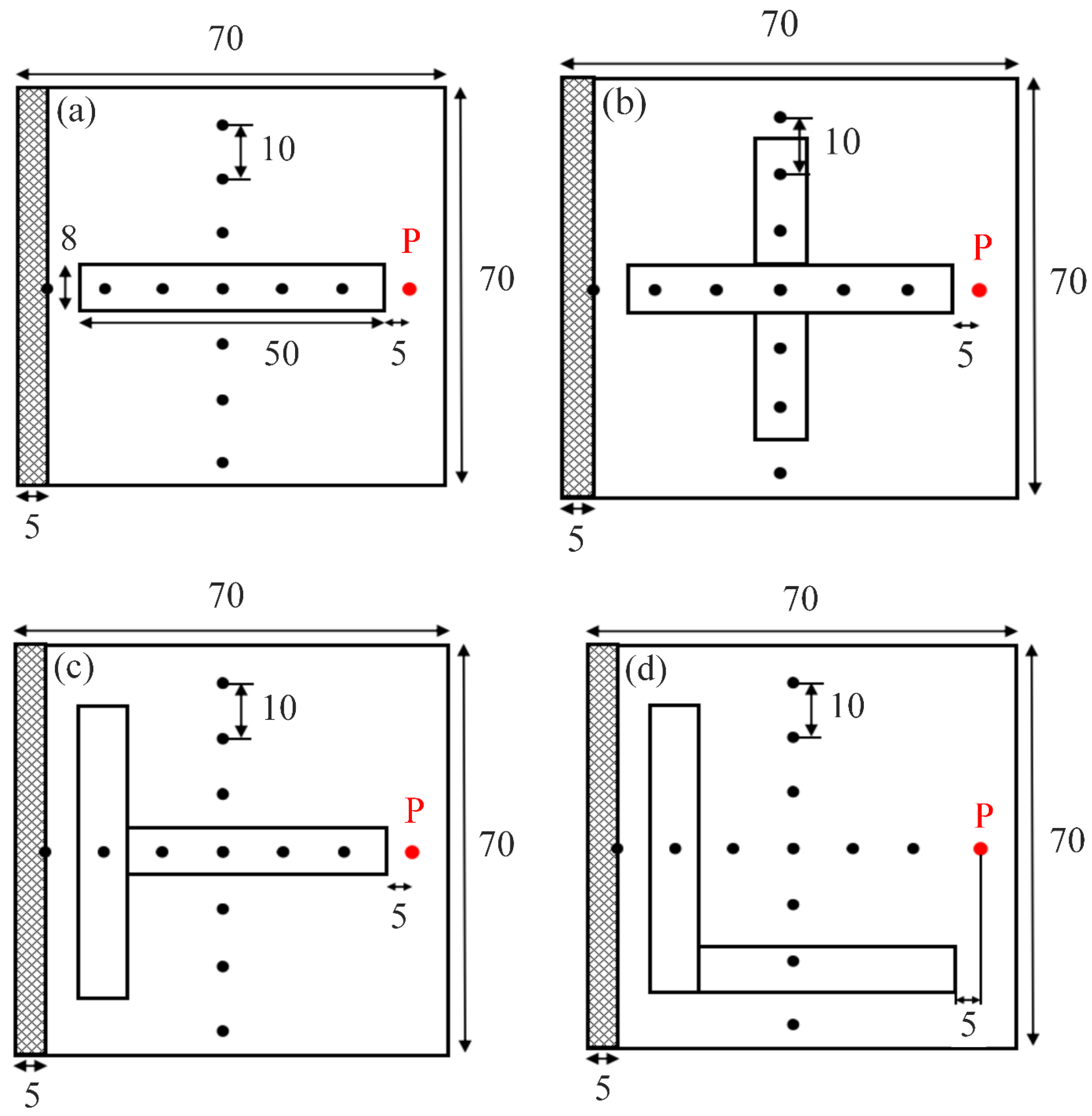

2. Typical Feature Partitioning and Modeling

2.1. Feature Partitioning

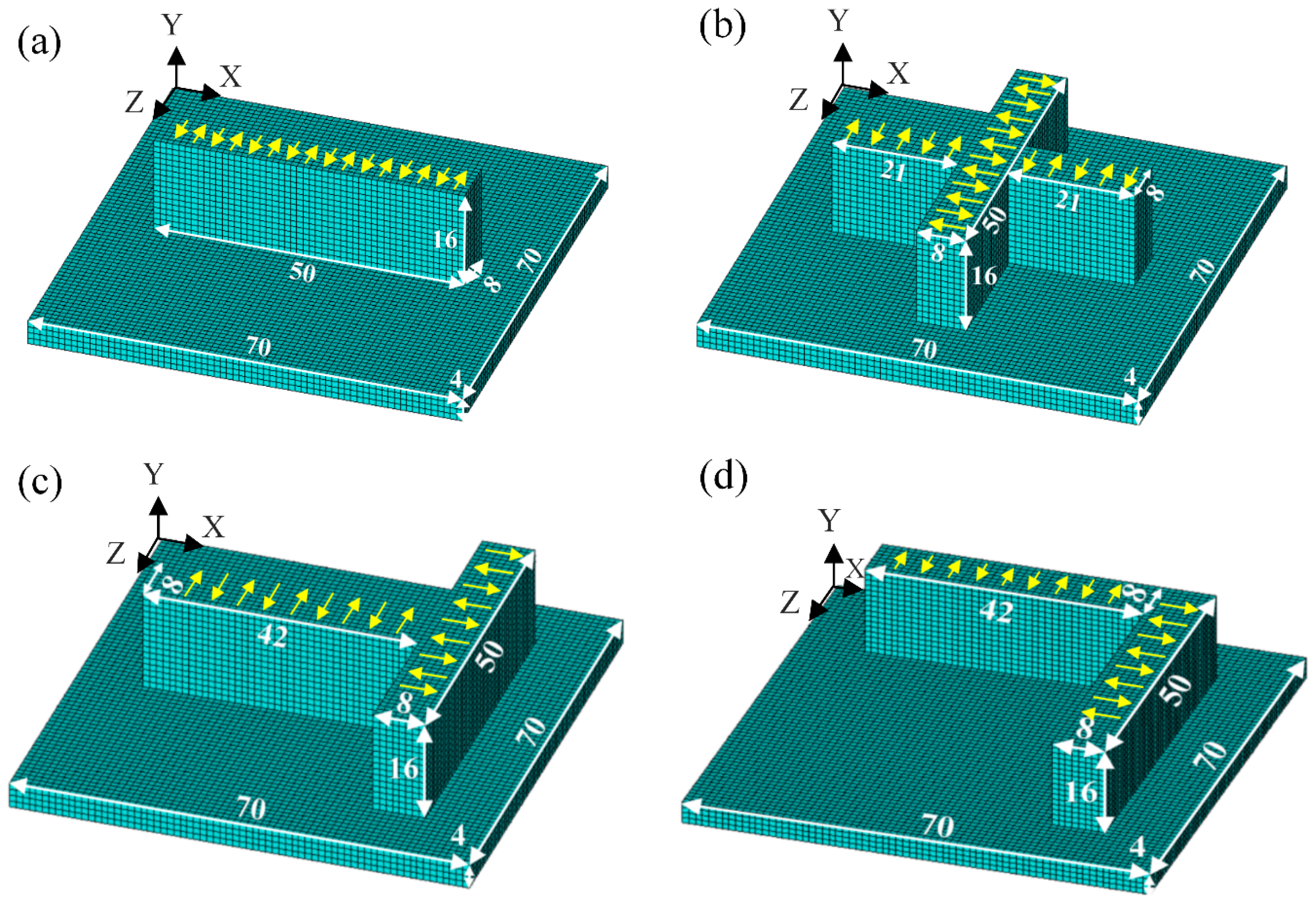

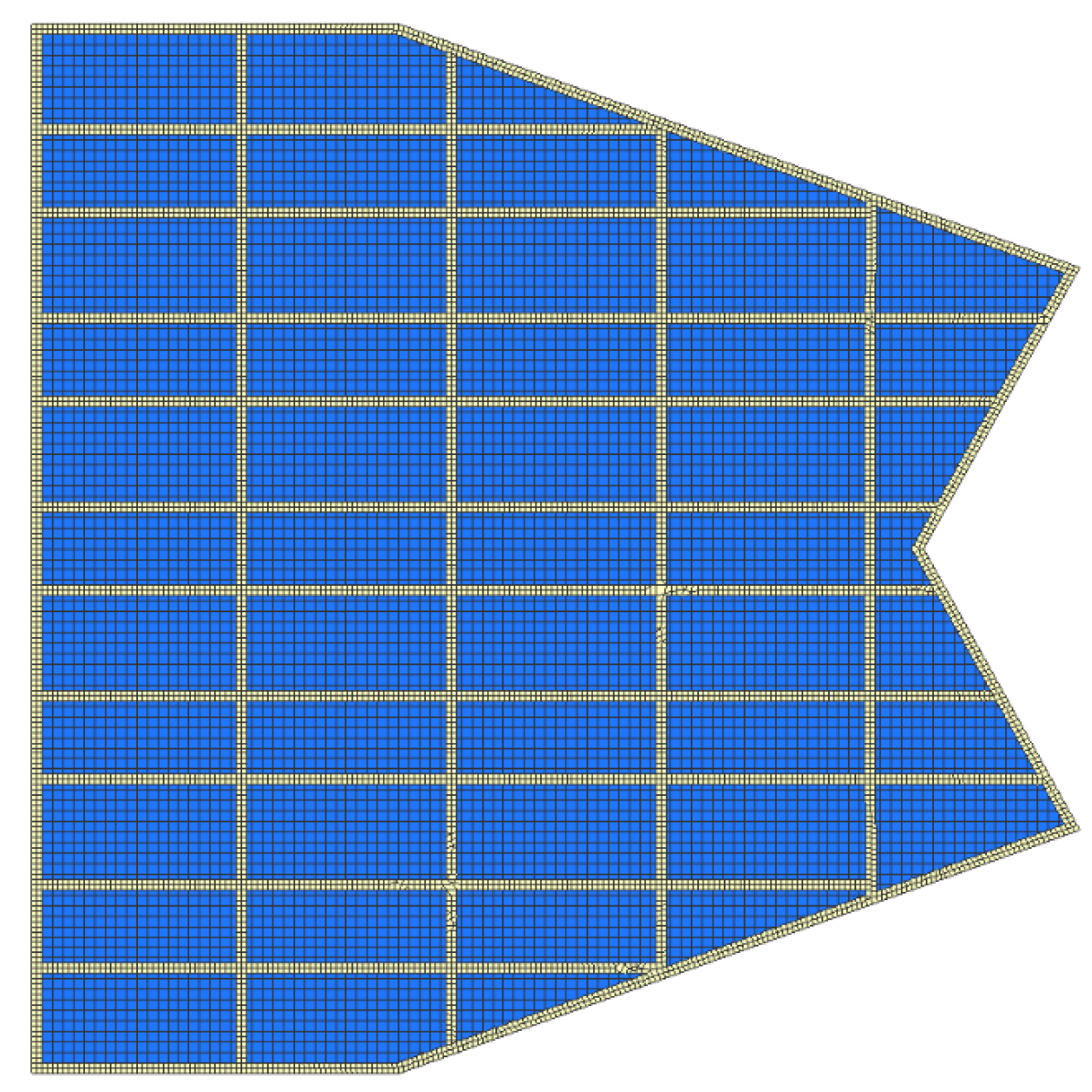

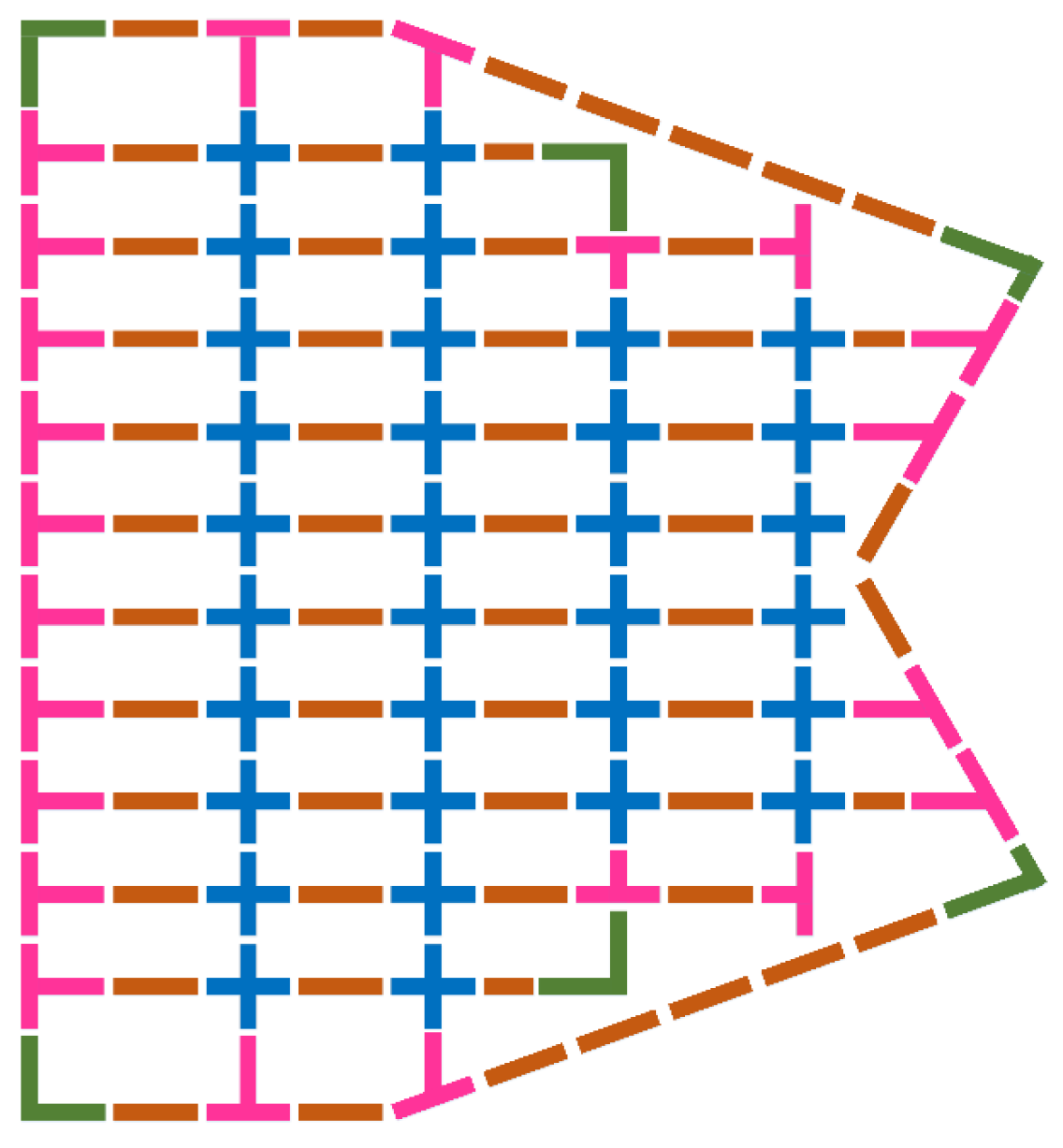

2.2. Finite Element Modeling

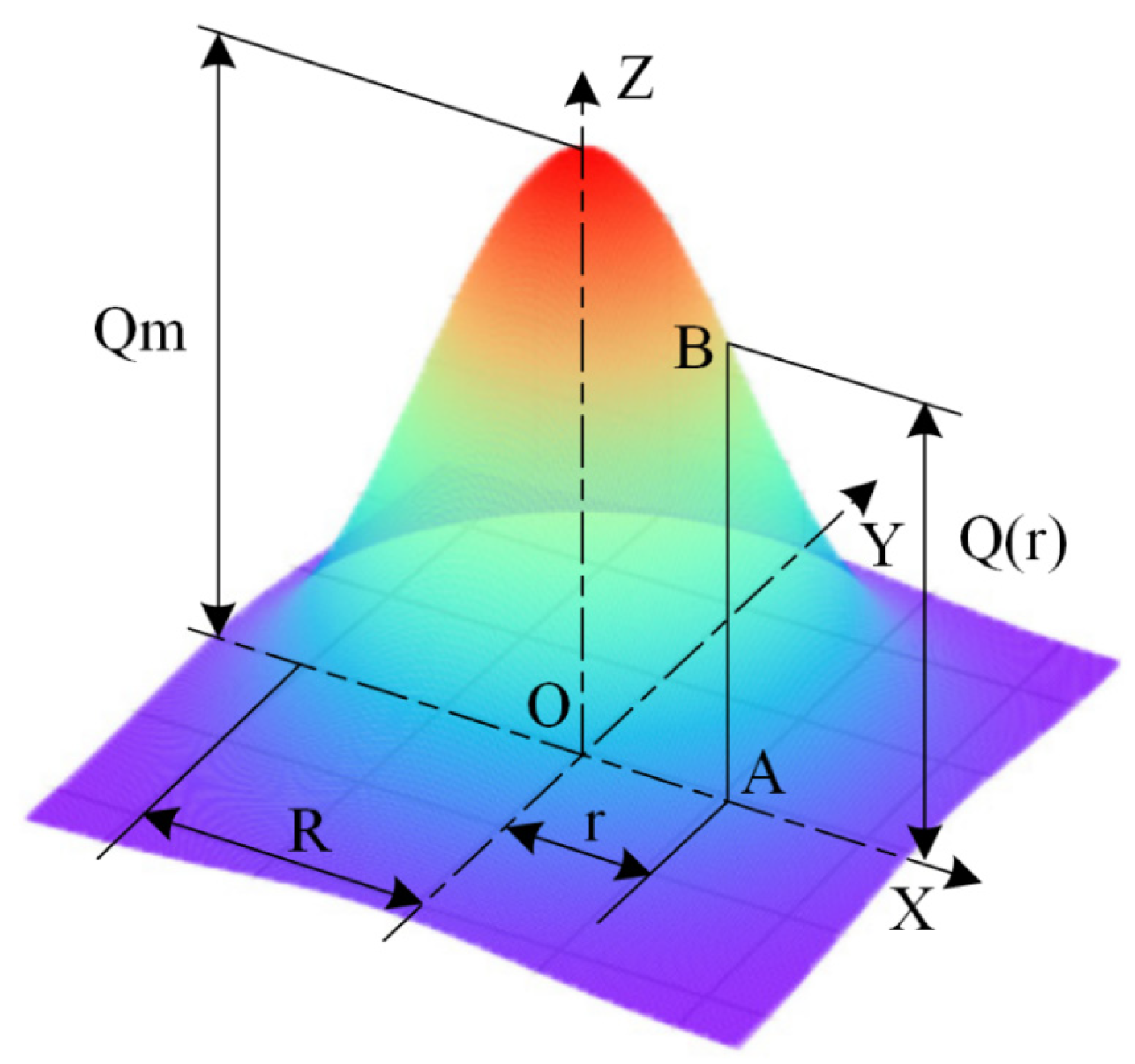

2.3. Heat Source Model and Material Parameters

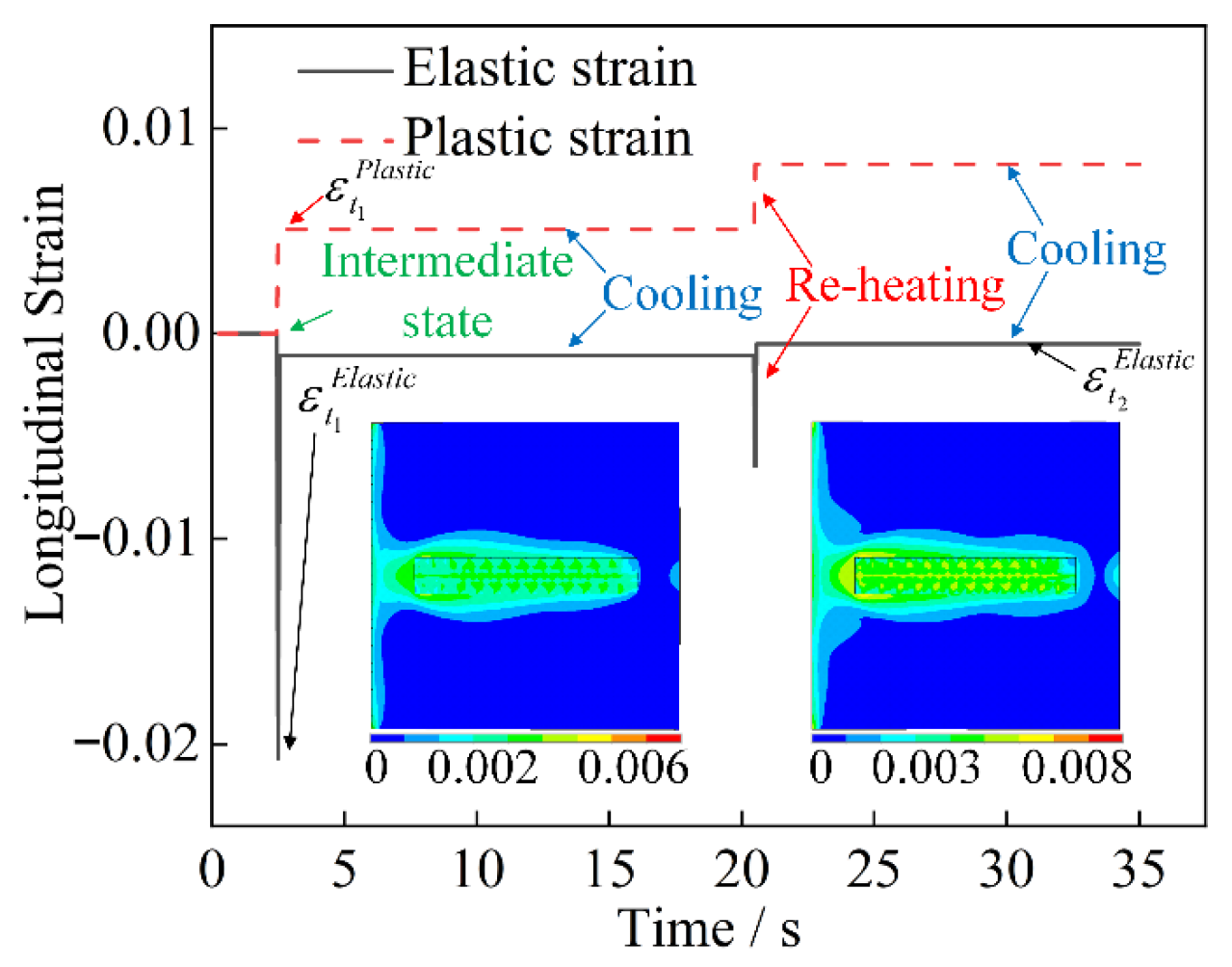

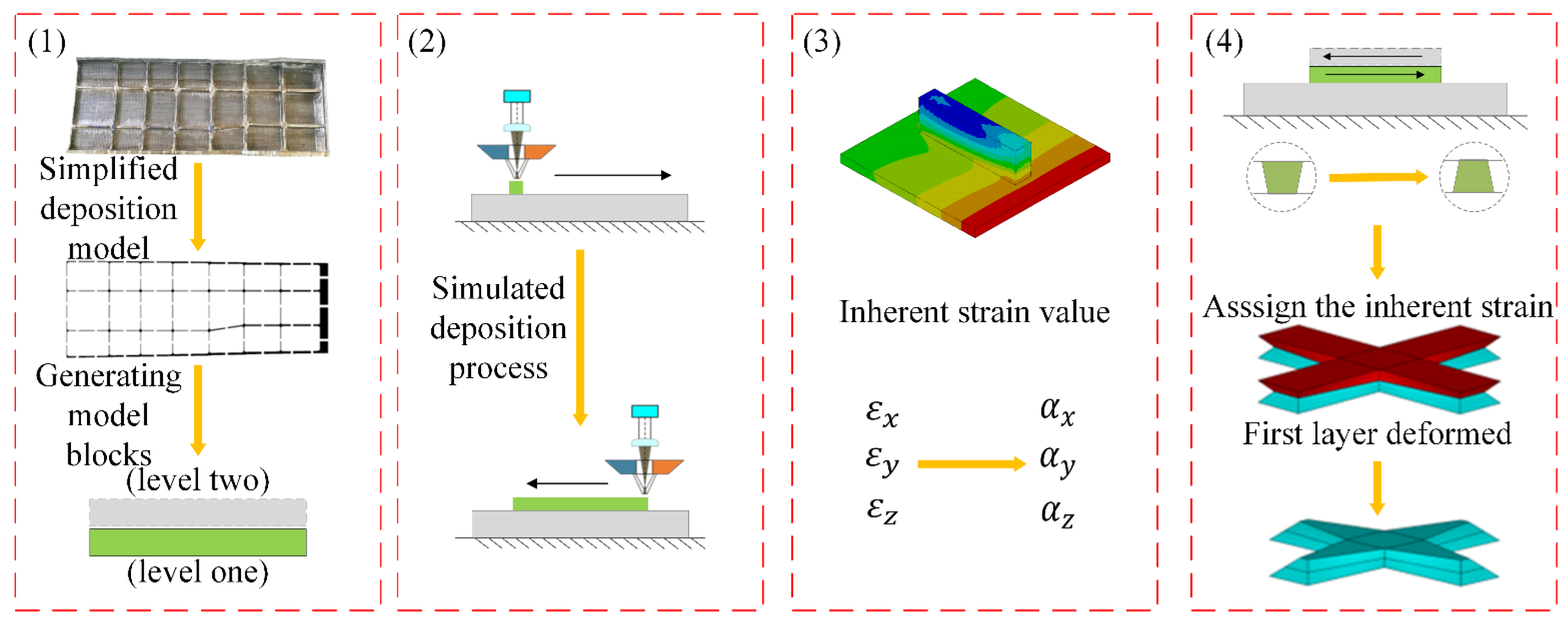

3. Inherent Strain Method

3.1. Inherent Strain Correction

3.2. The Deformation Prediction Method Based on the Inherent Strain

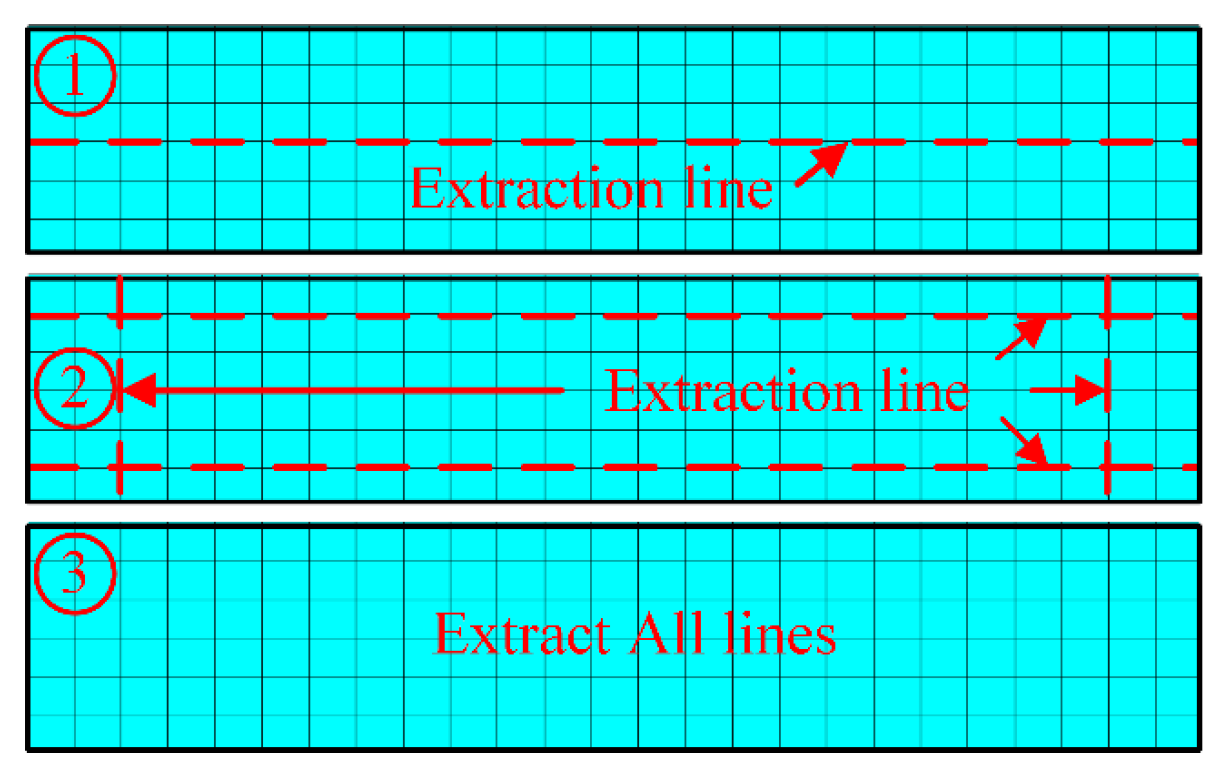

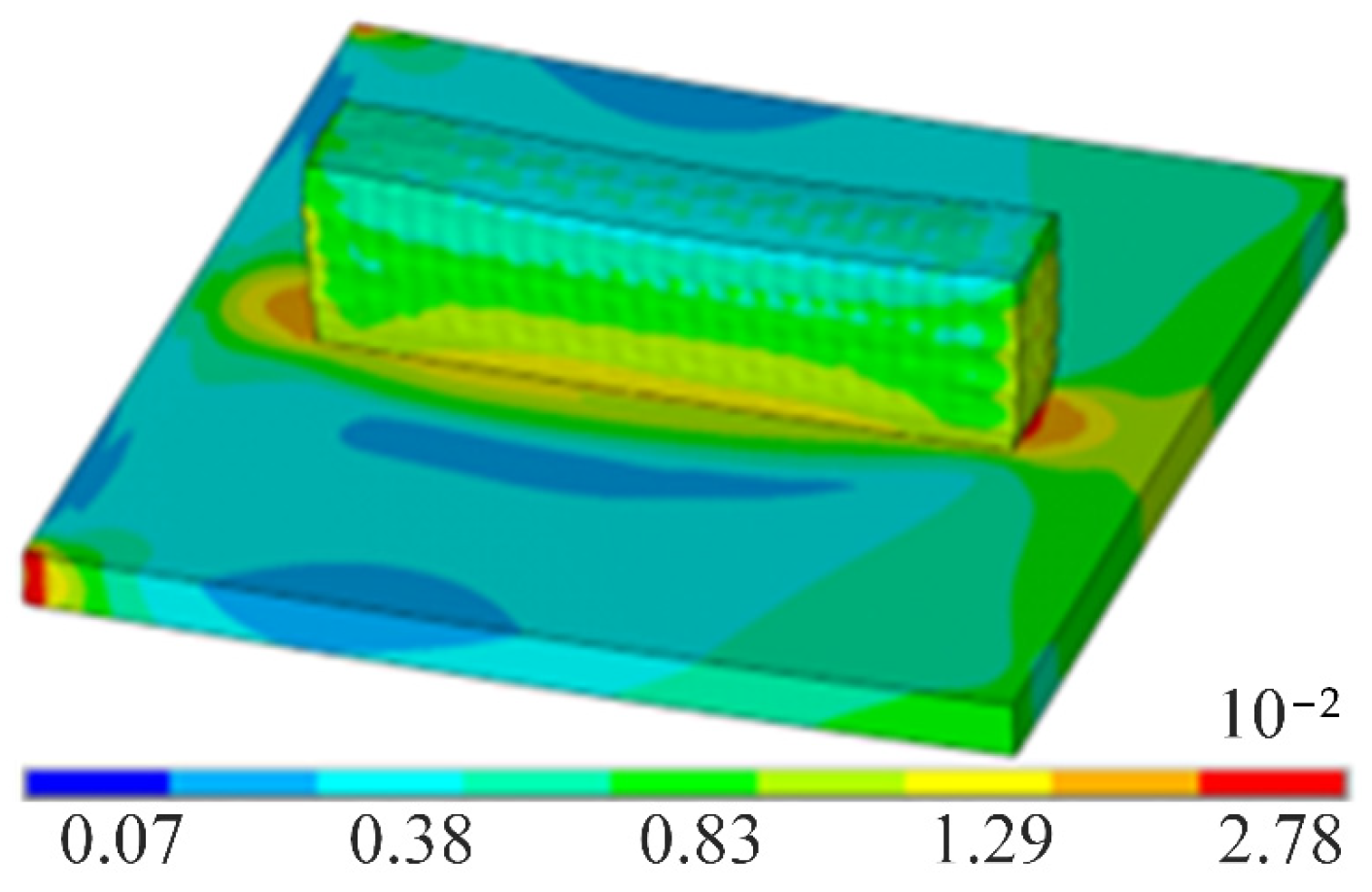

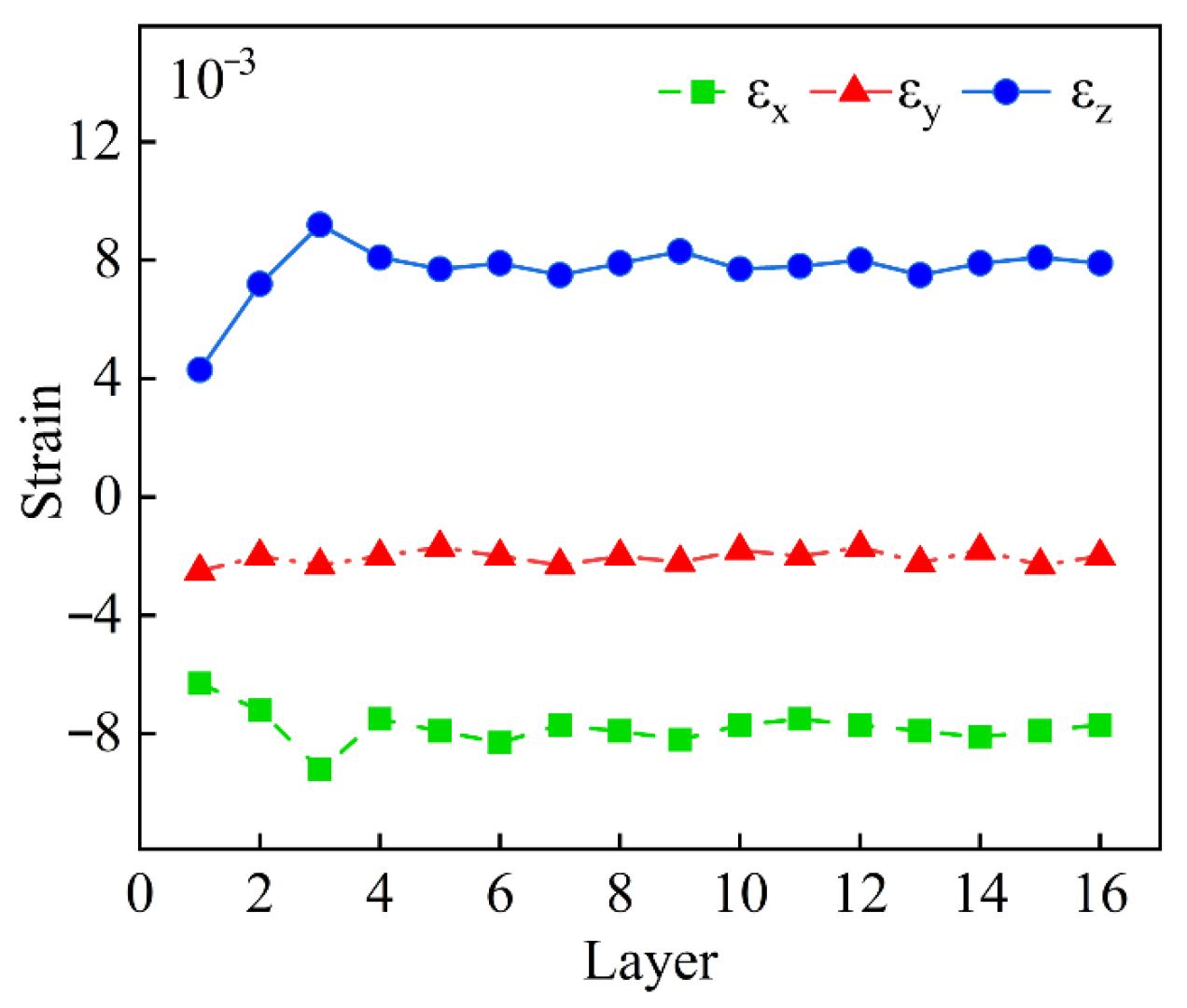

3.3. Inherent Strain Extraction

4. Method Validation

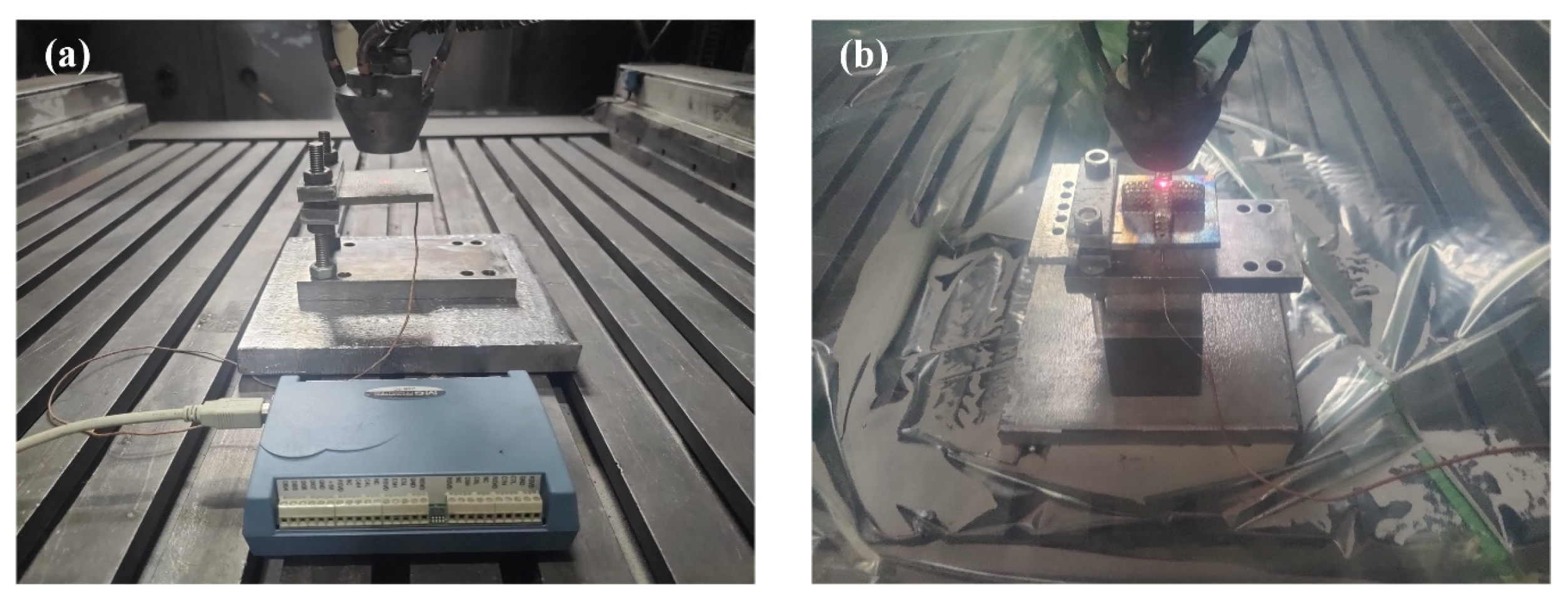

4.1. Experimental Program

4.2. Validation of Results

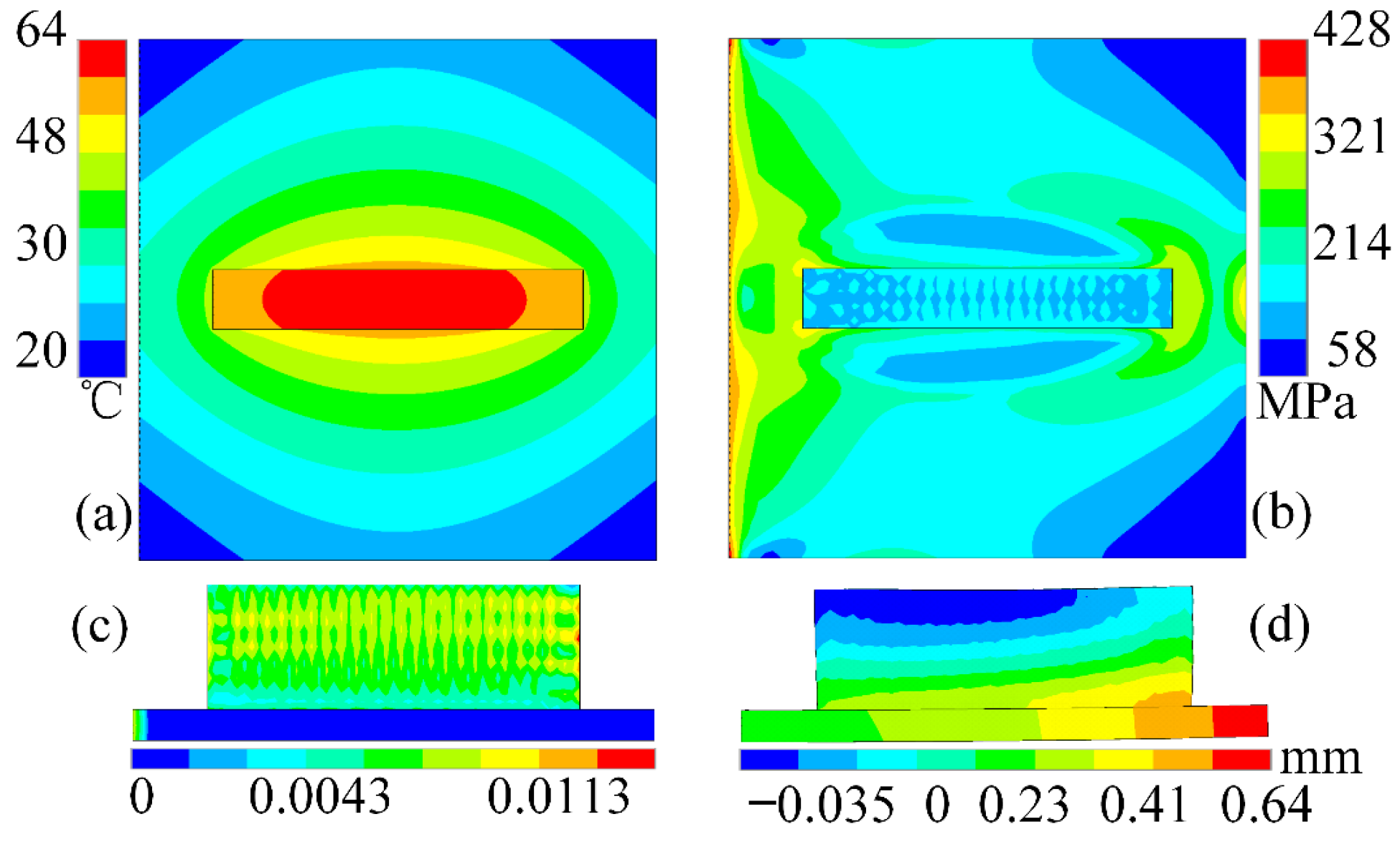

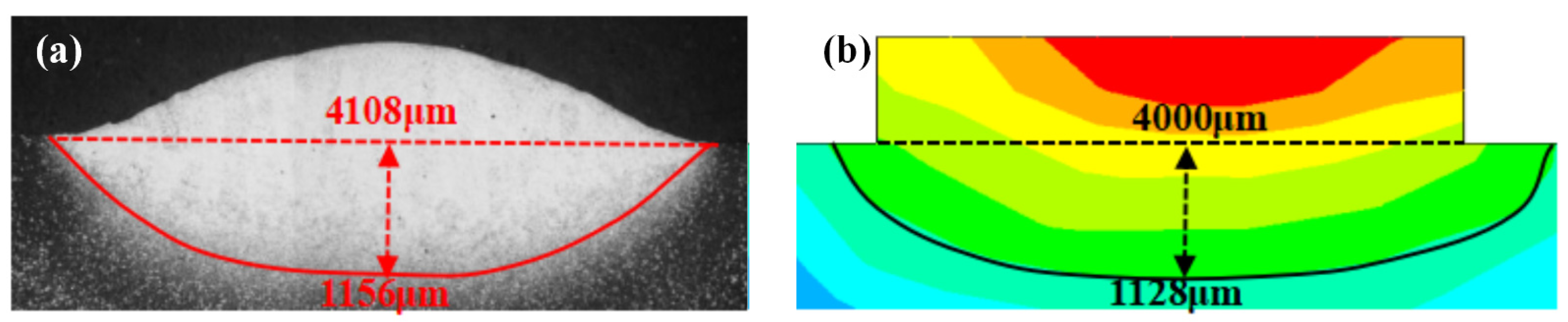

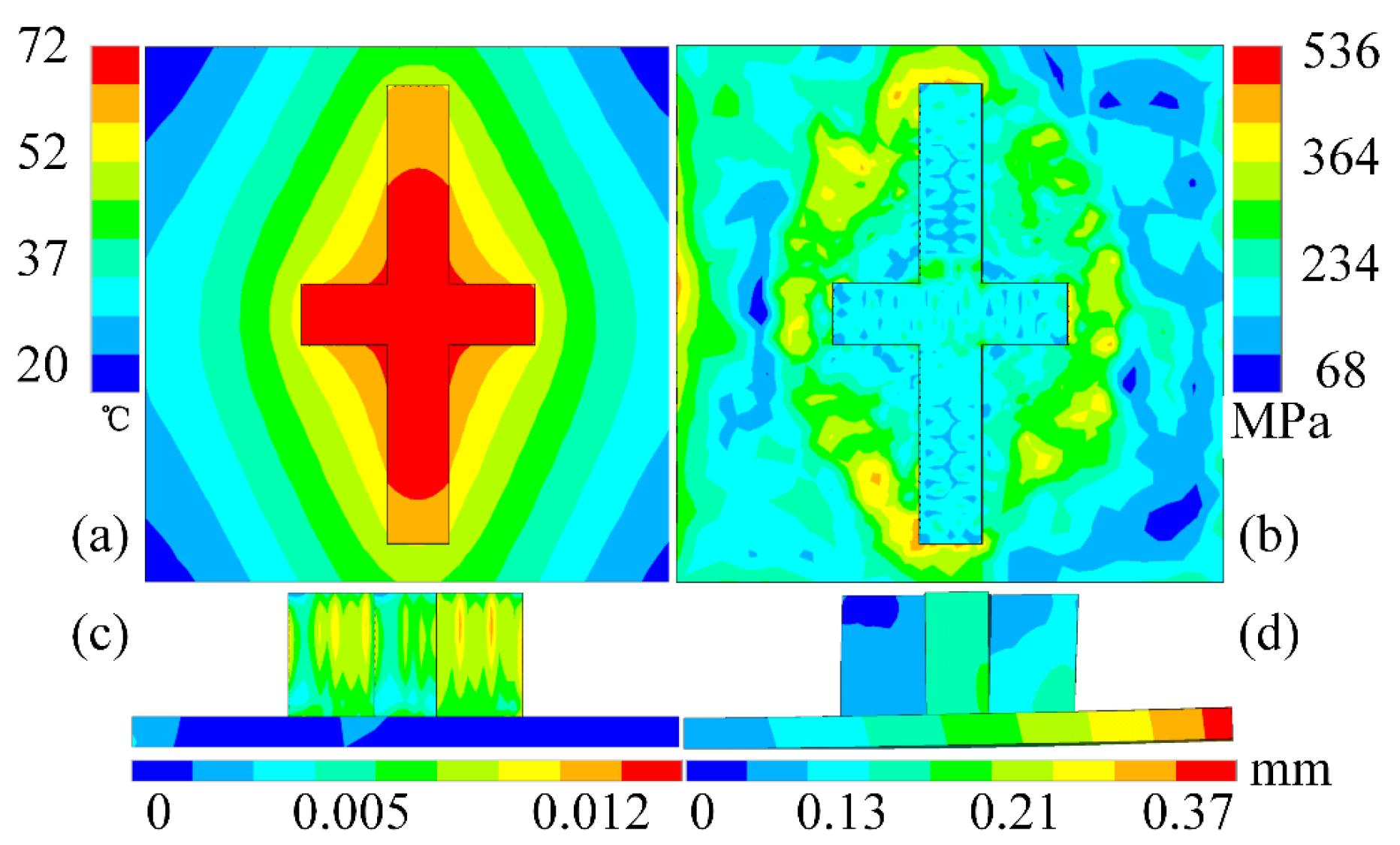

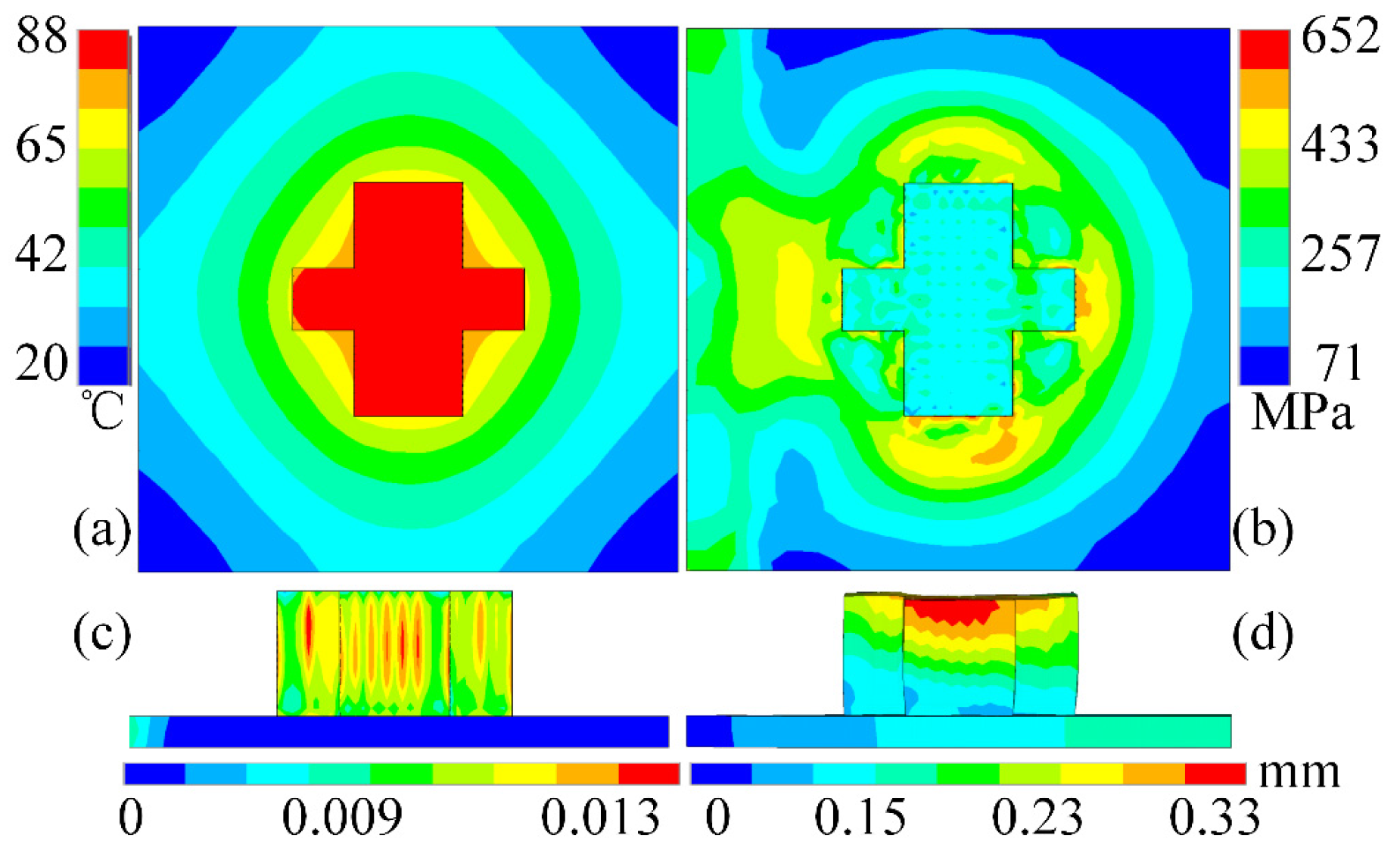

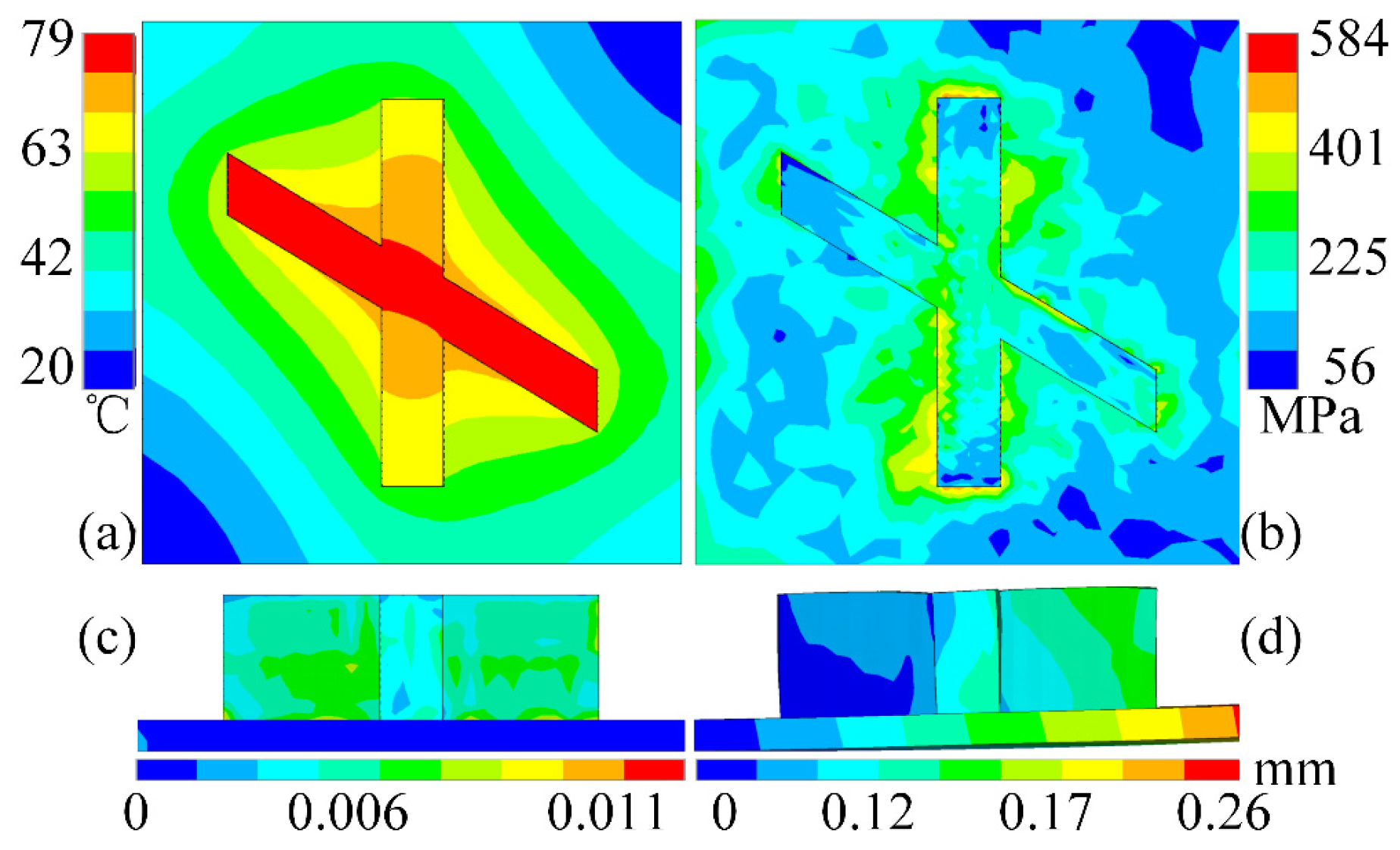

4.2.1. Heat Source Model Validation

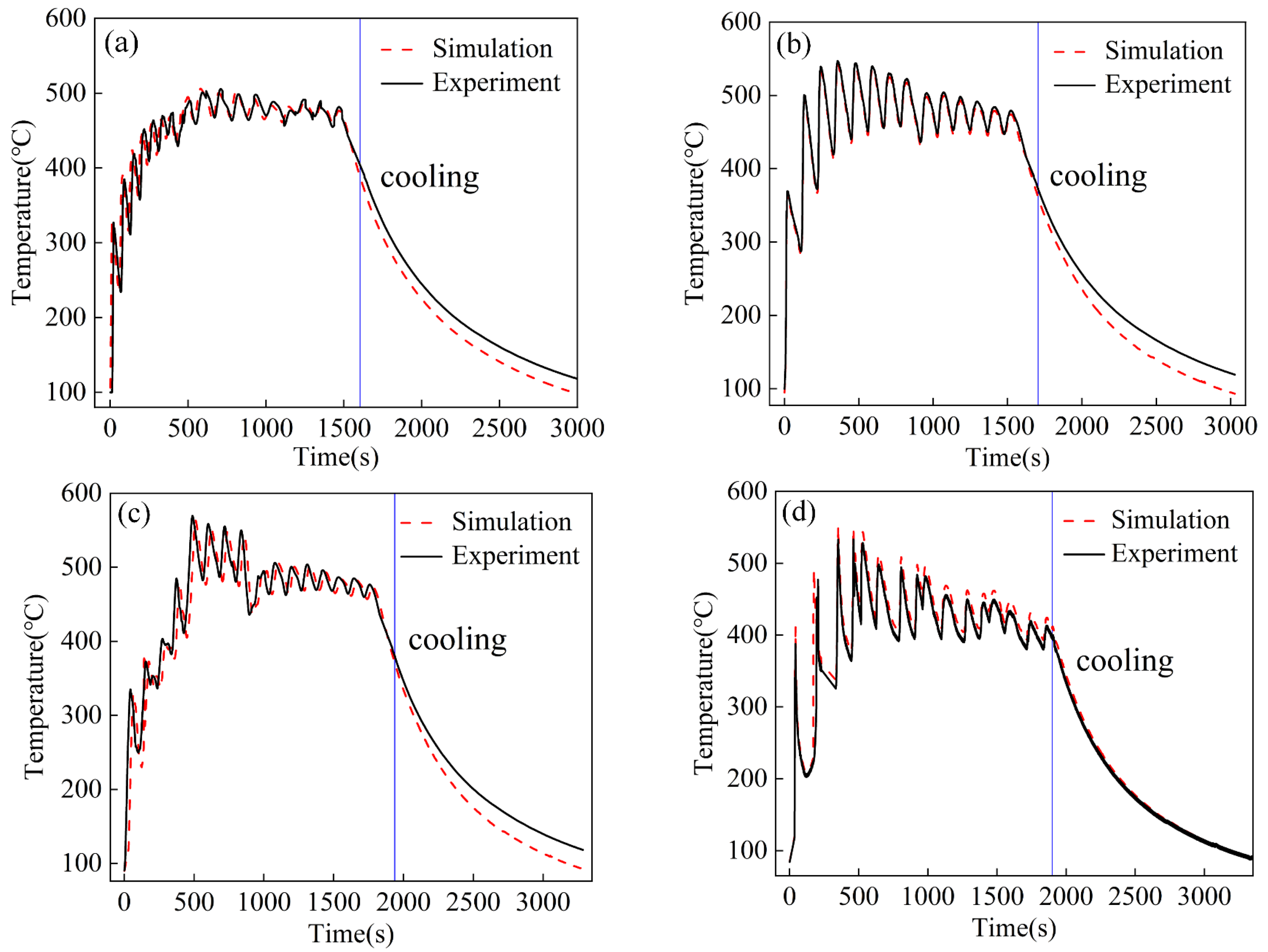

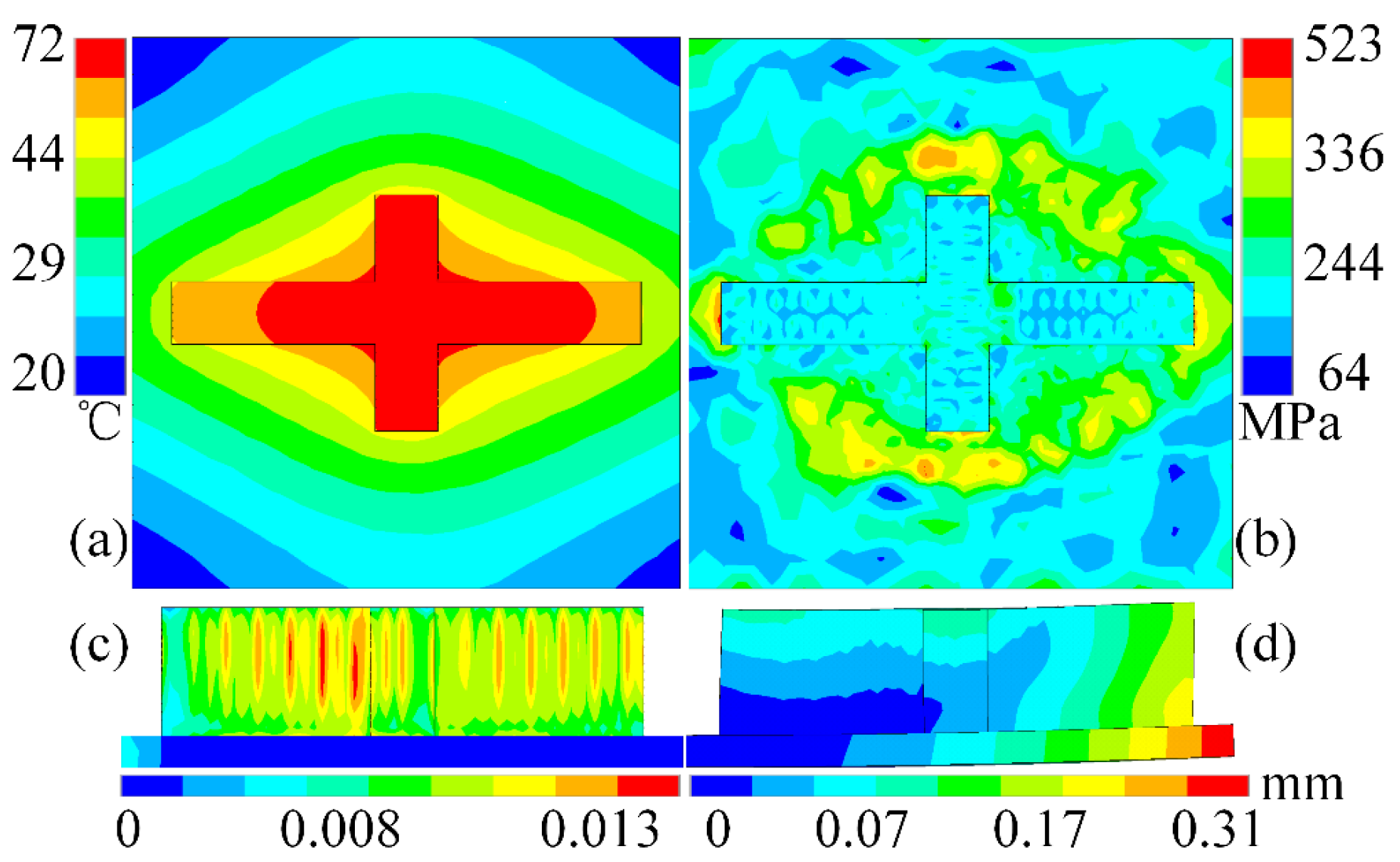

4.2.2. Temperature Field Validation

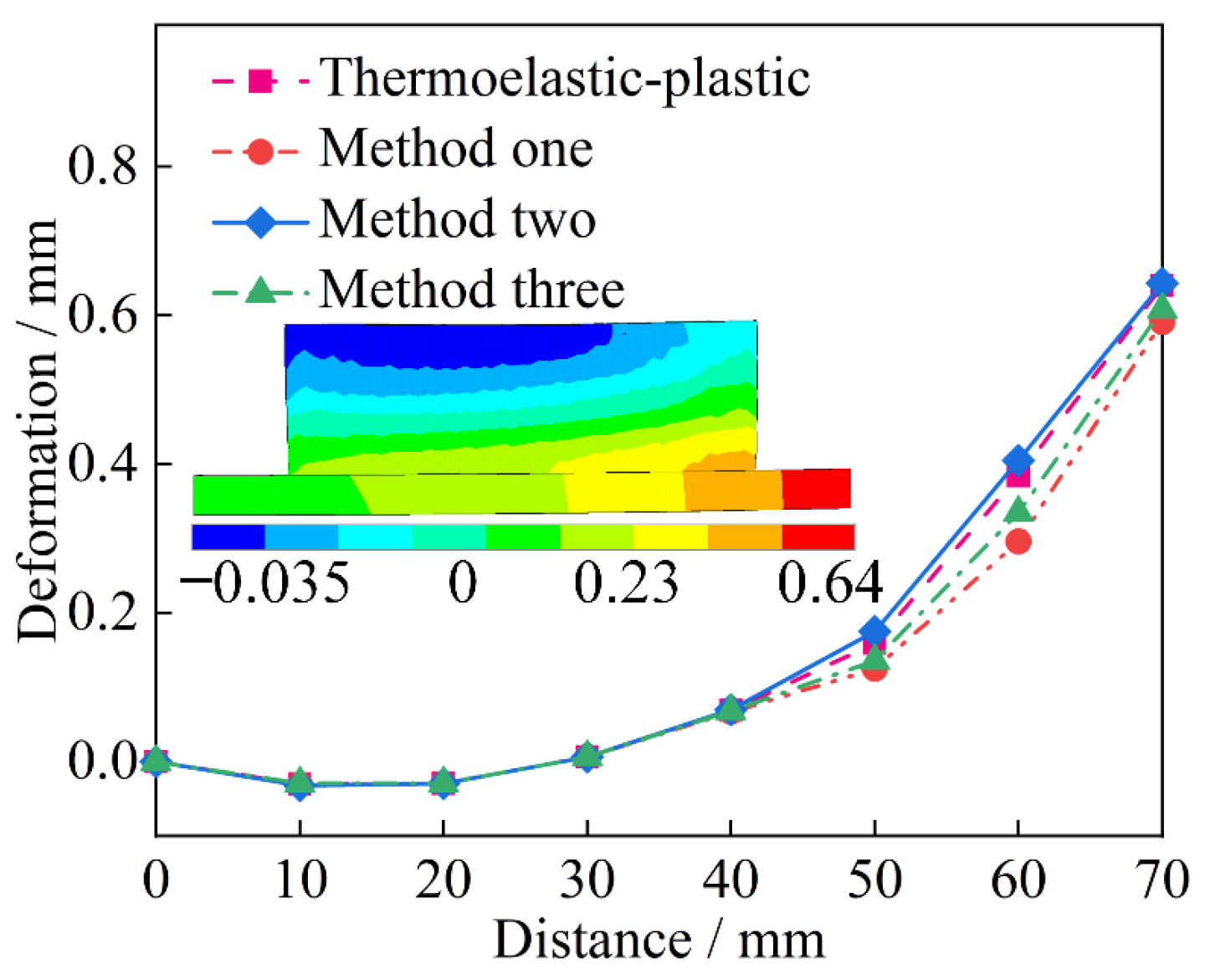

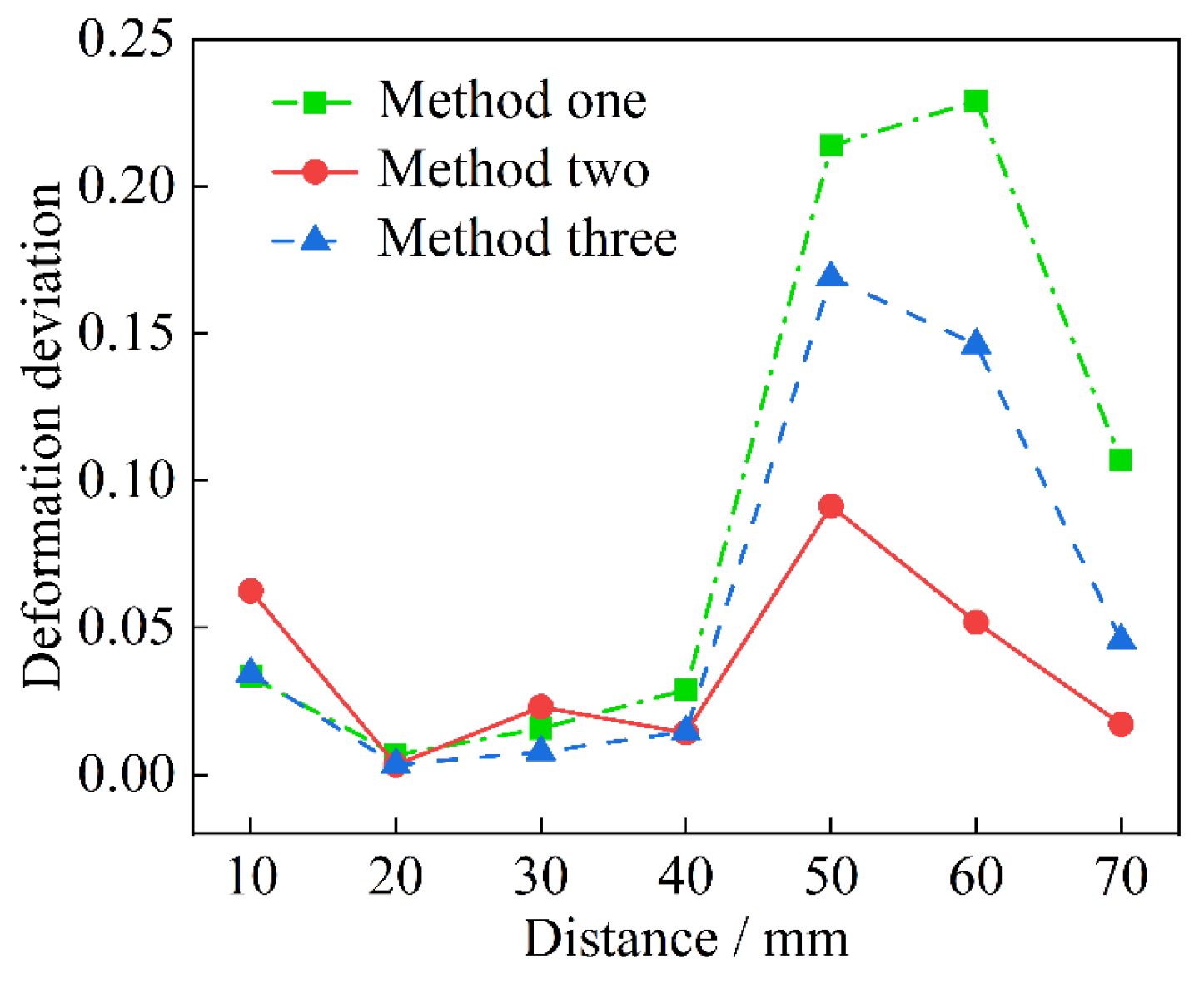

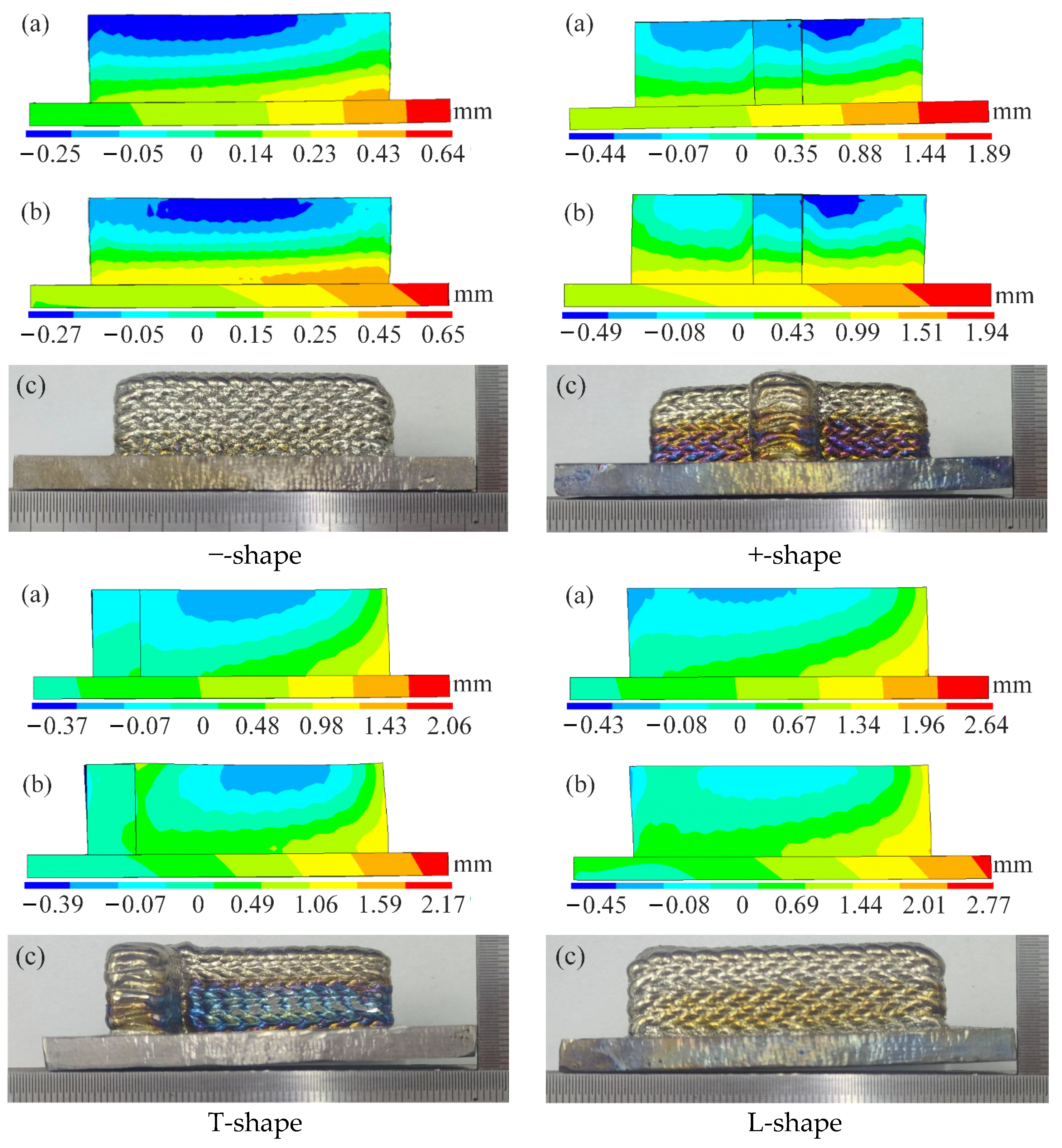

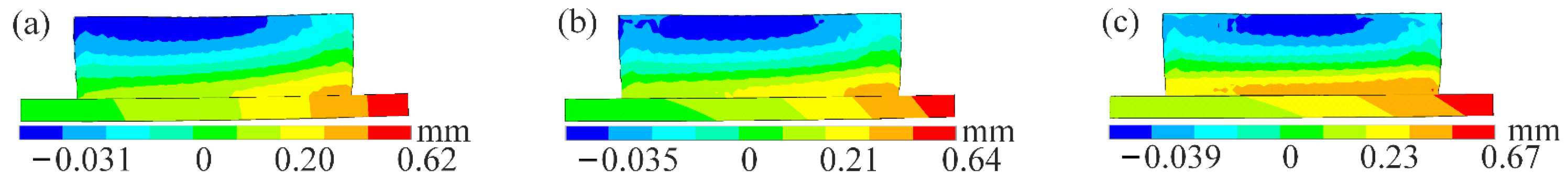

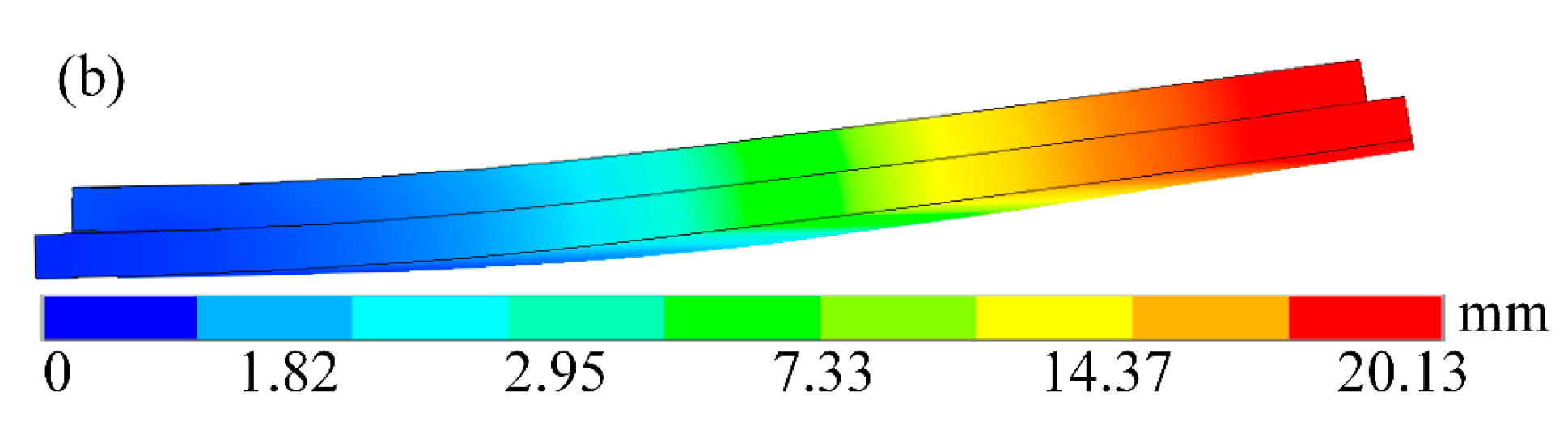

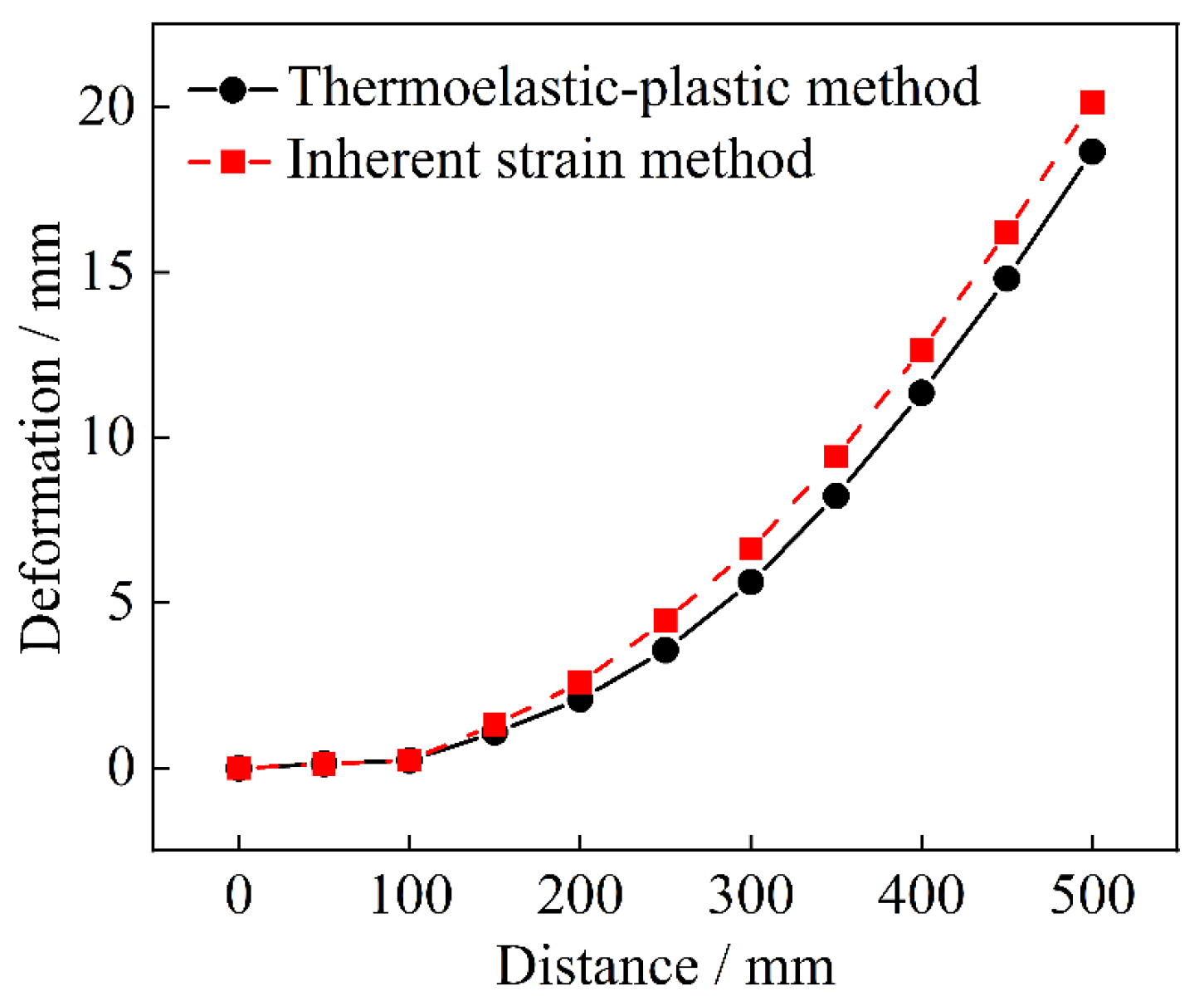

4.2.3. Deformation Results Comparison

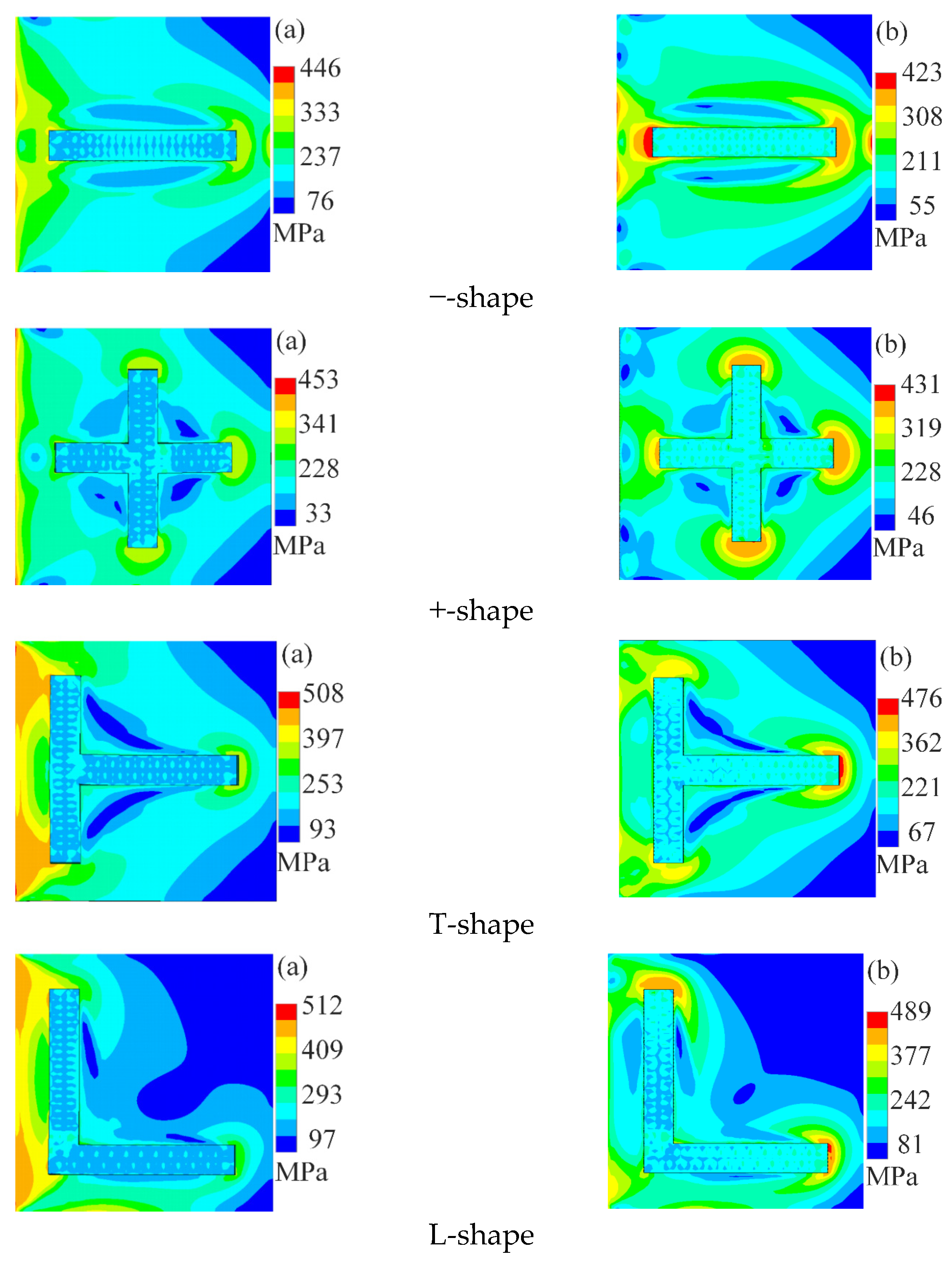

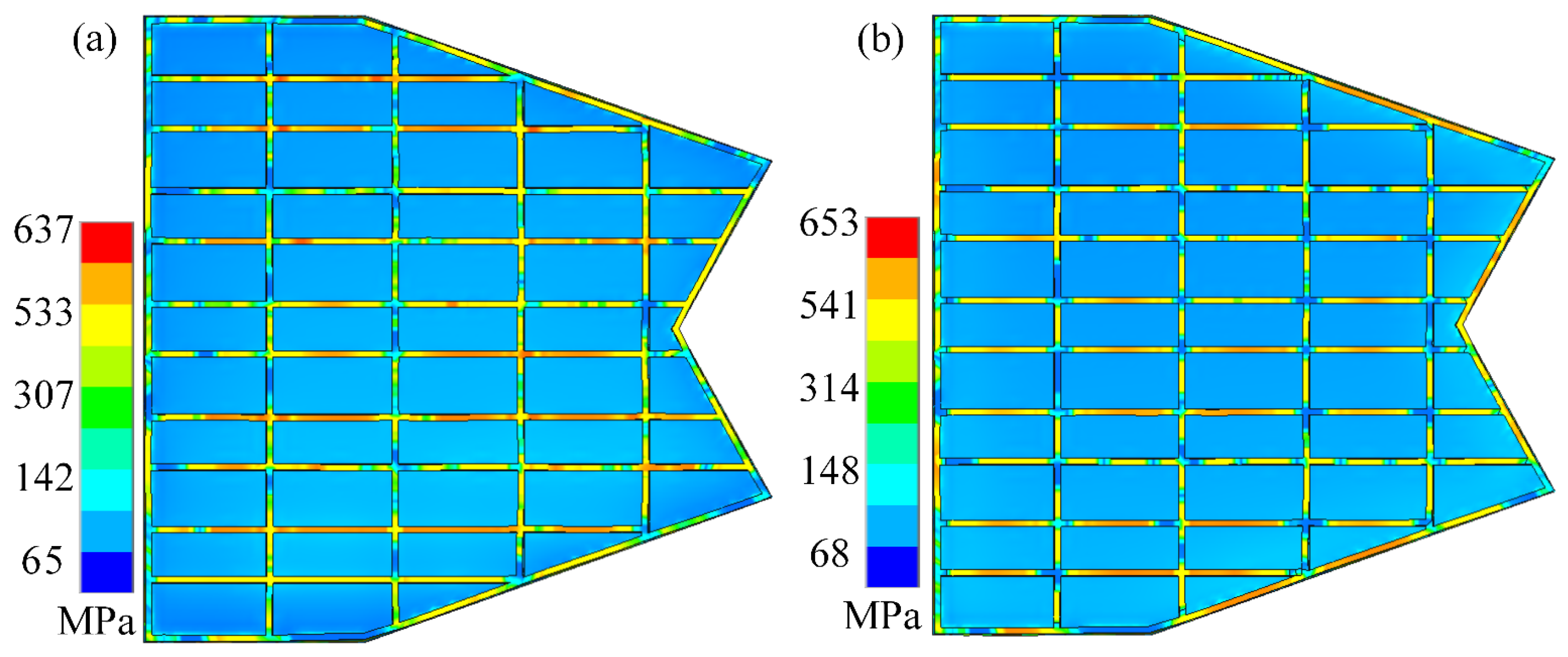

4.2.4. Stress Results Comparison

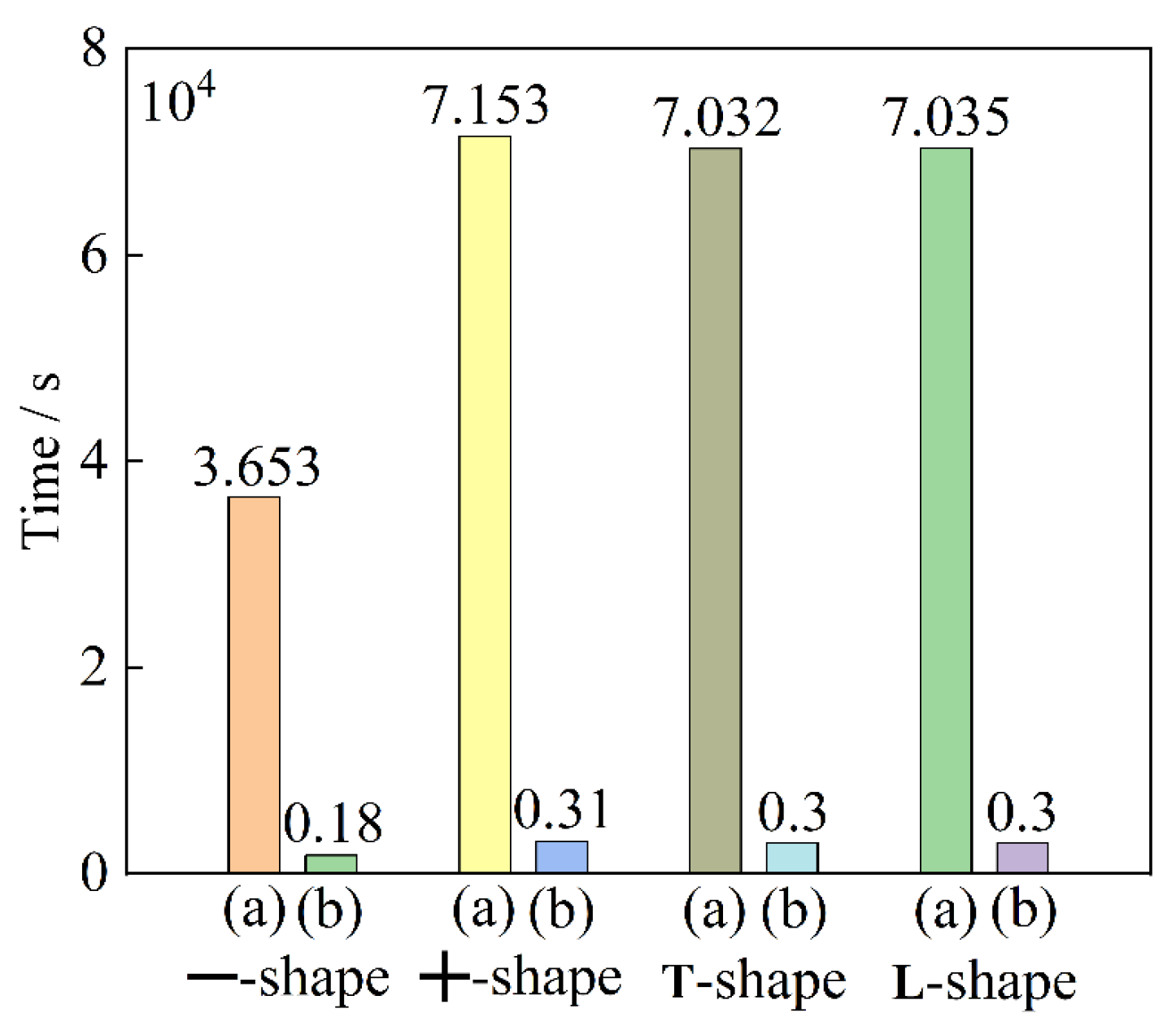

4.2.5. Efficiency Comparison

5. Analysis of Impact Factors

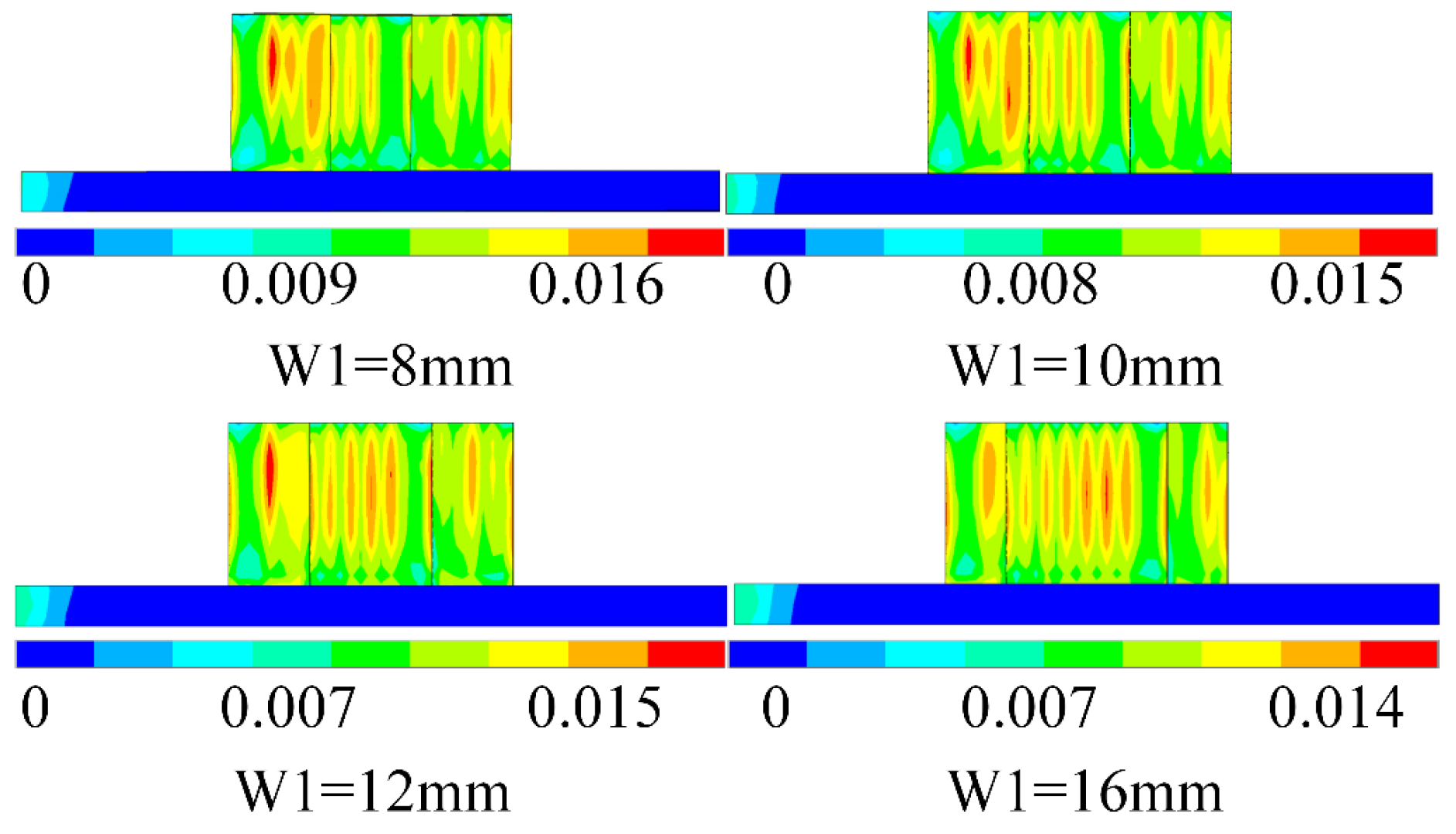

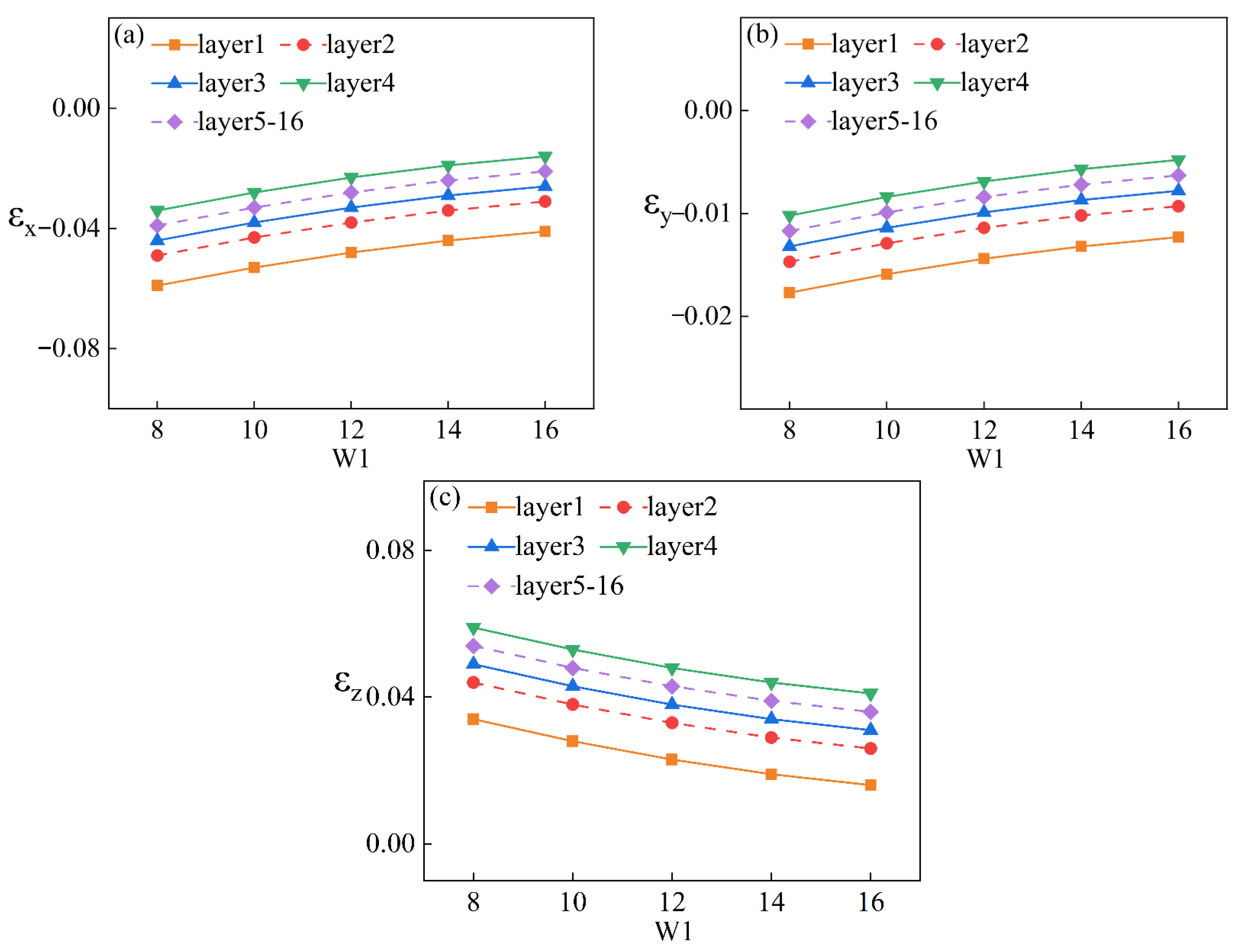

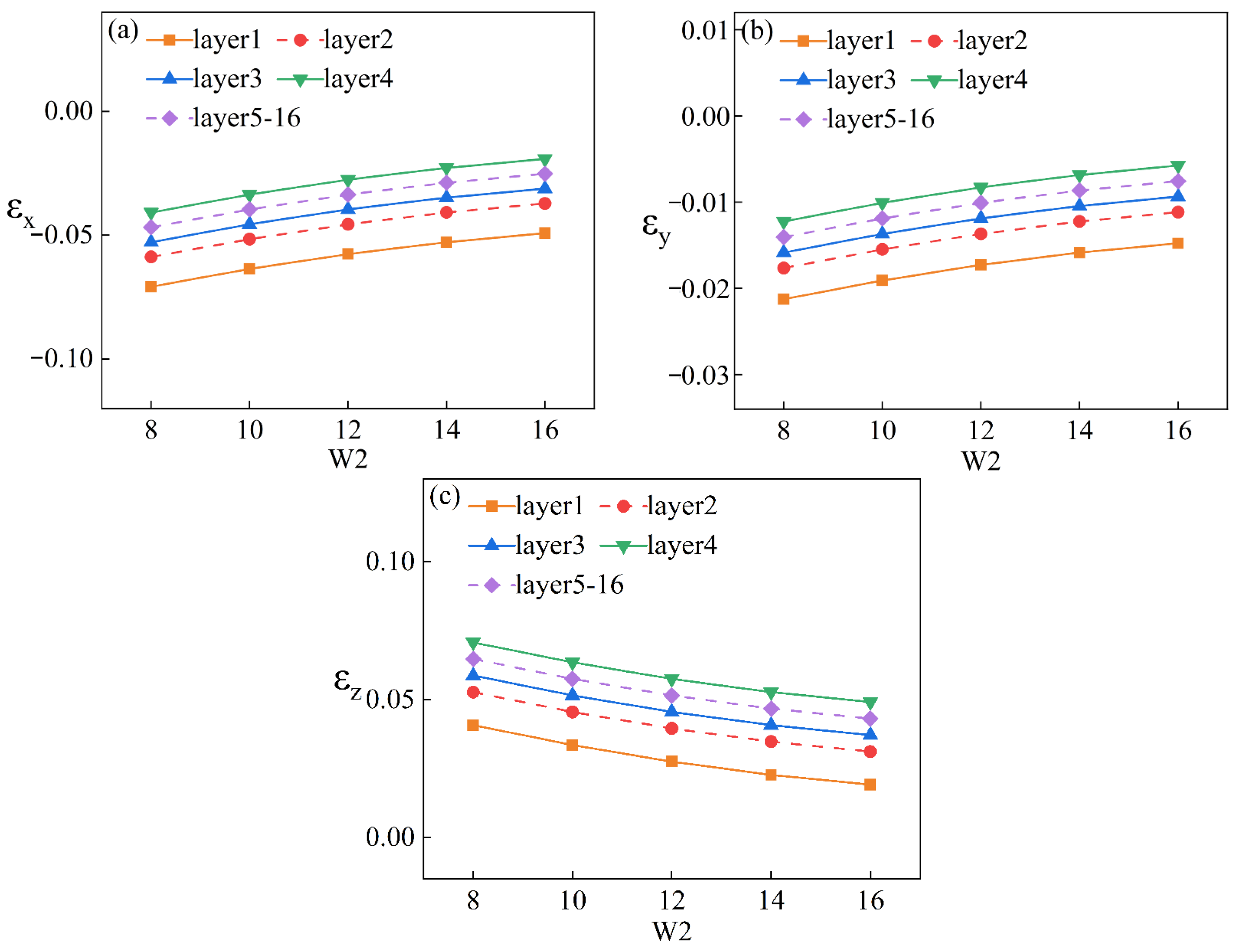

5.1. Mesh Size

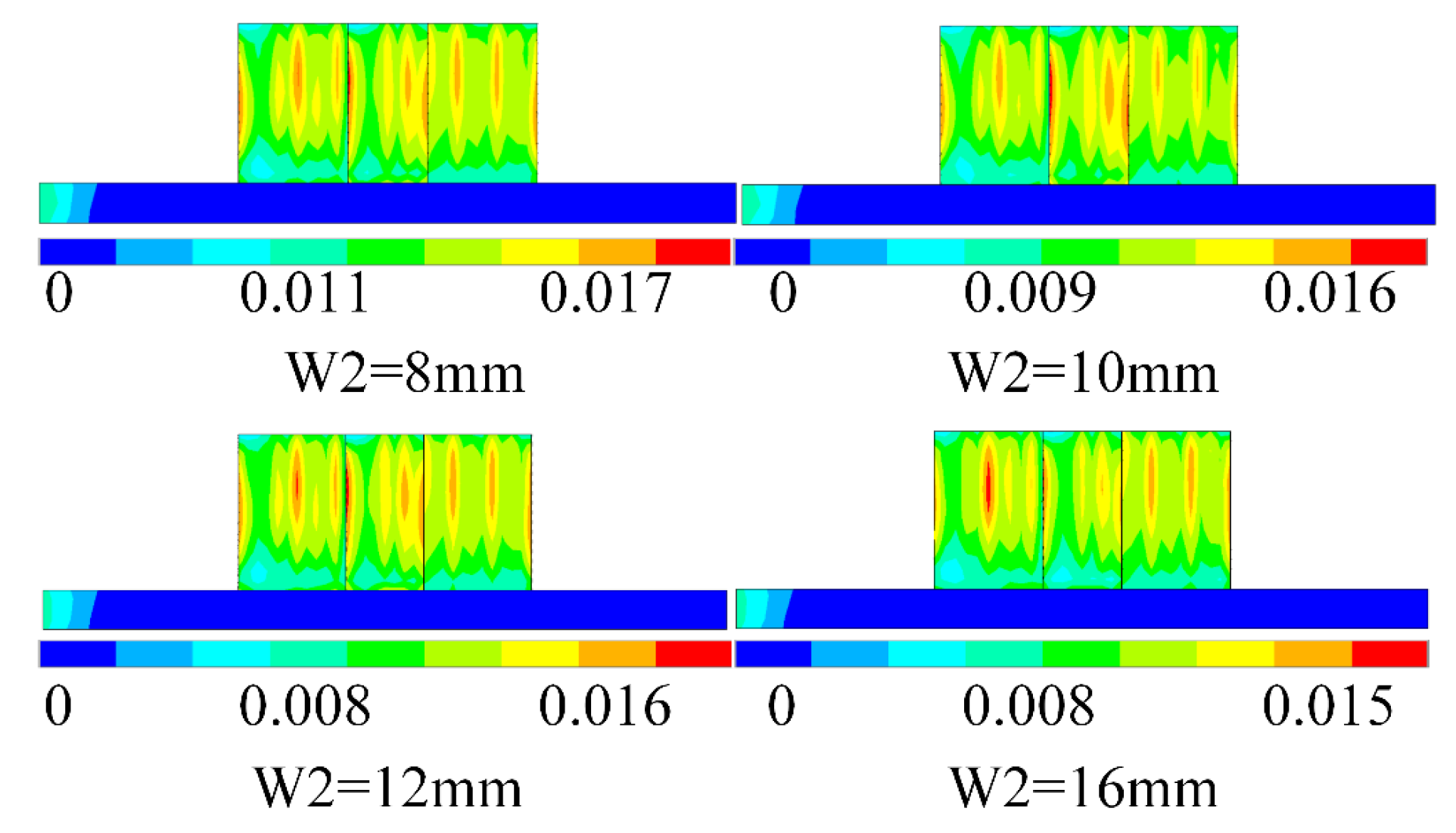

5.2. Equivalence Layer

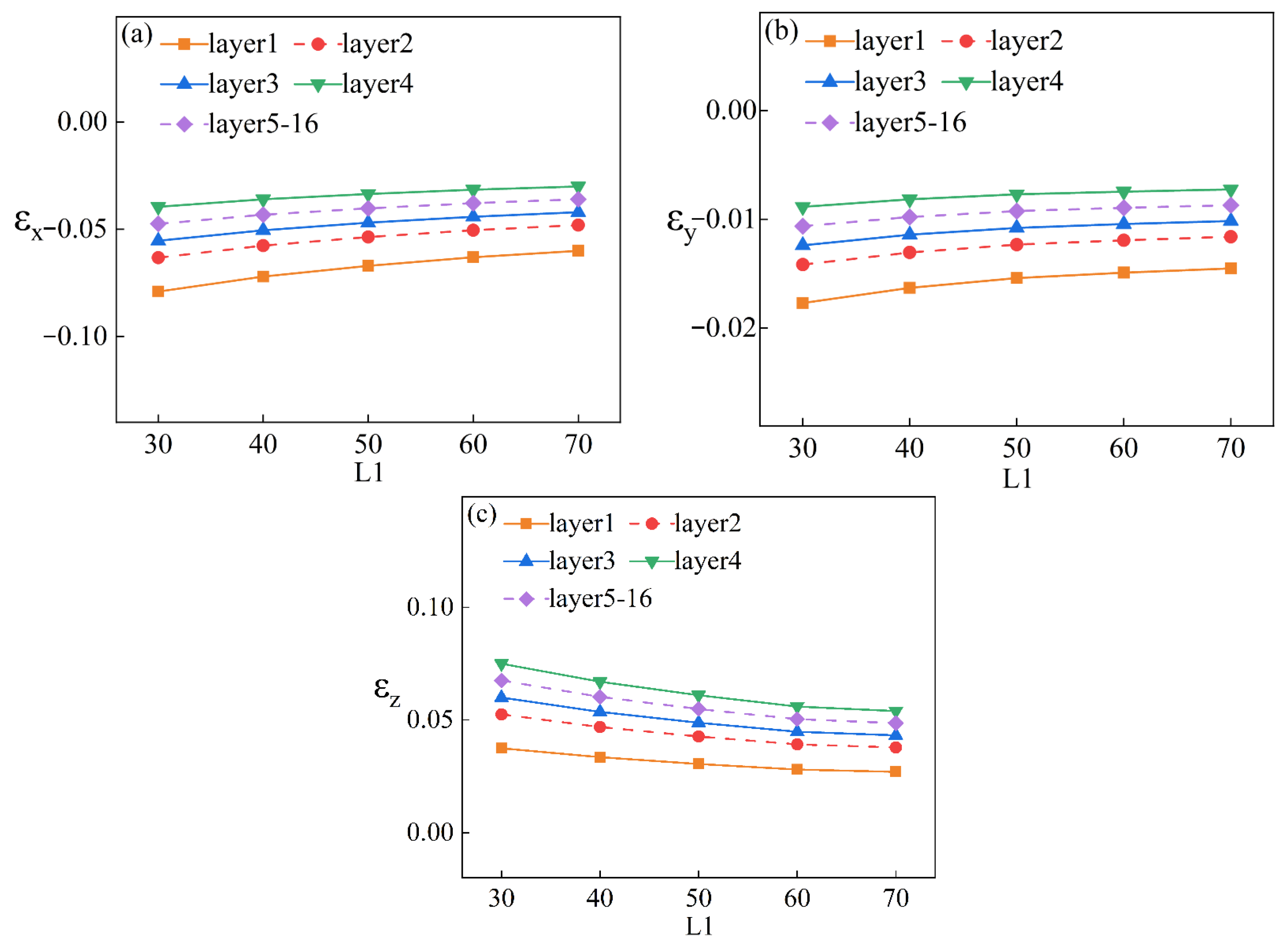

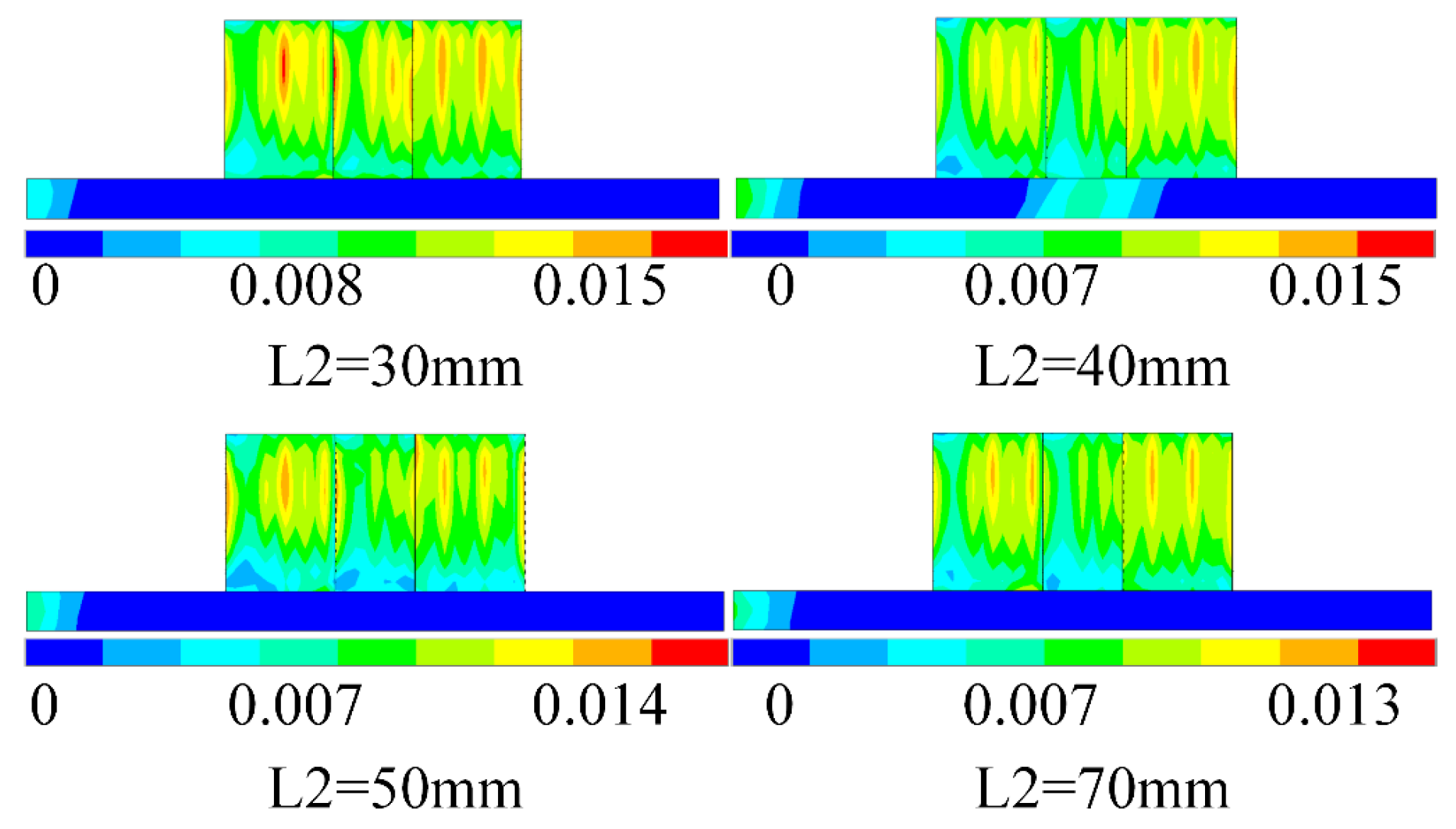

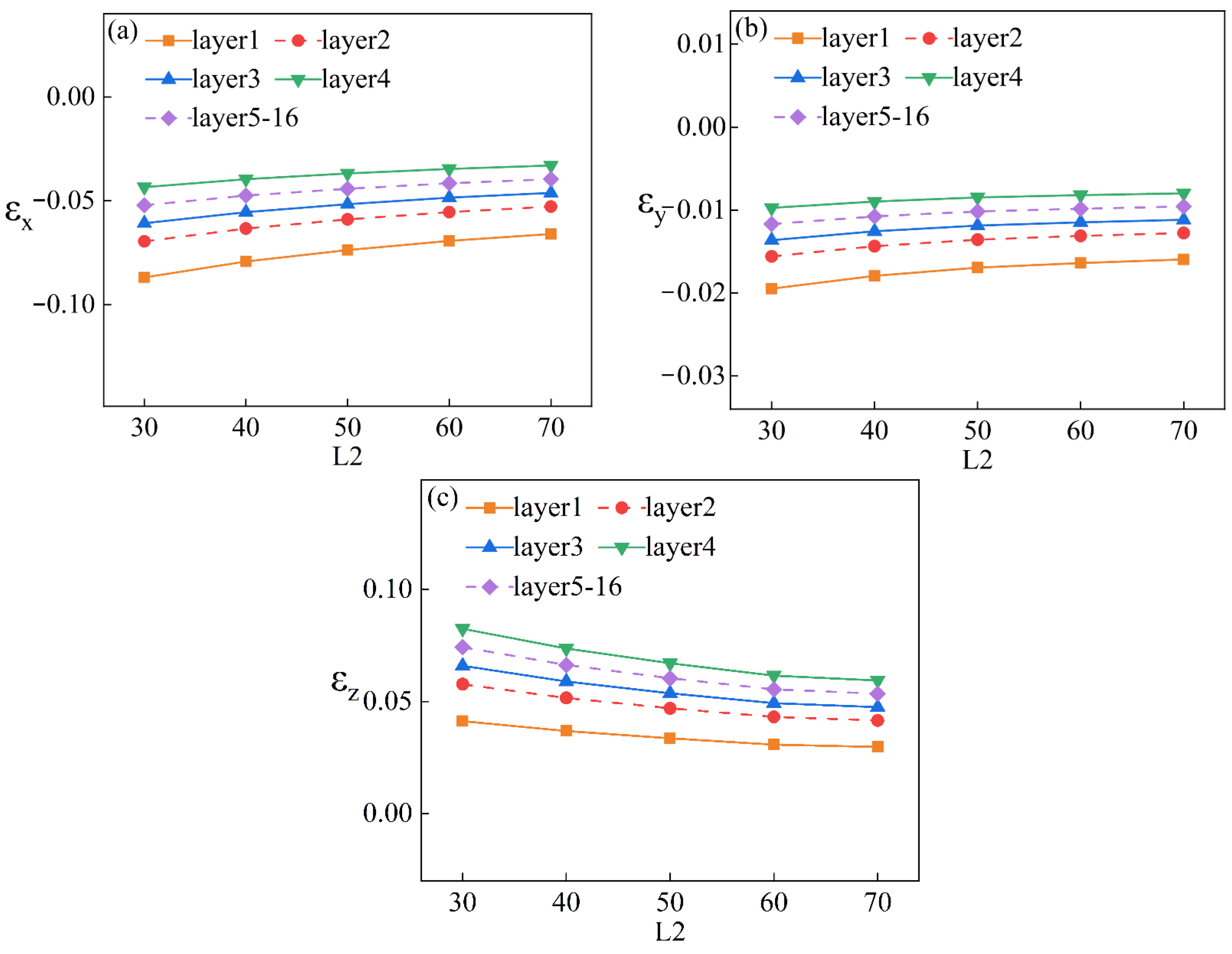

5.3. Dimensional Effects

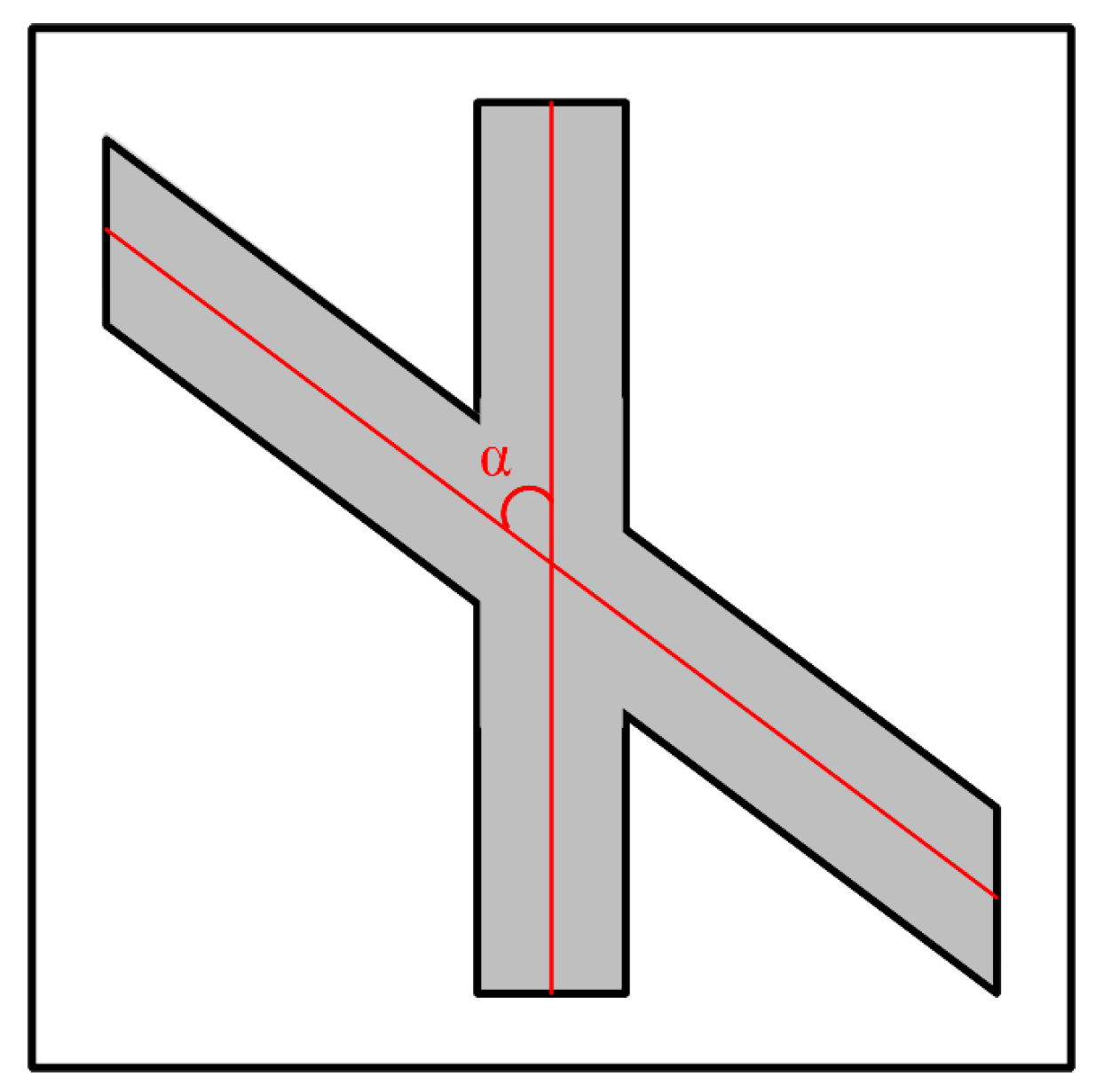

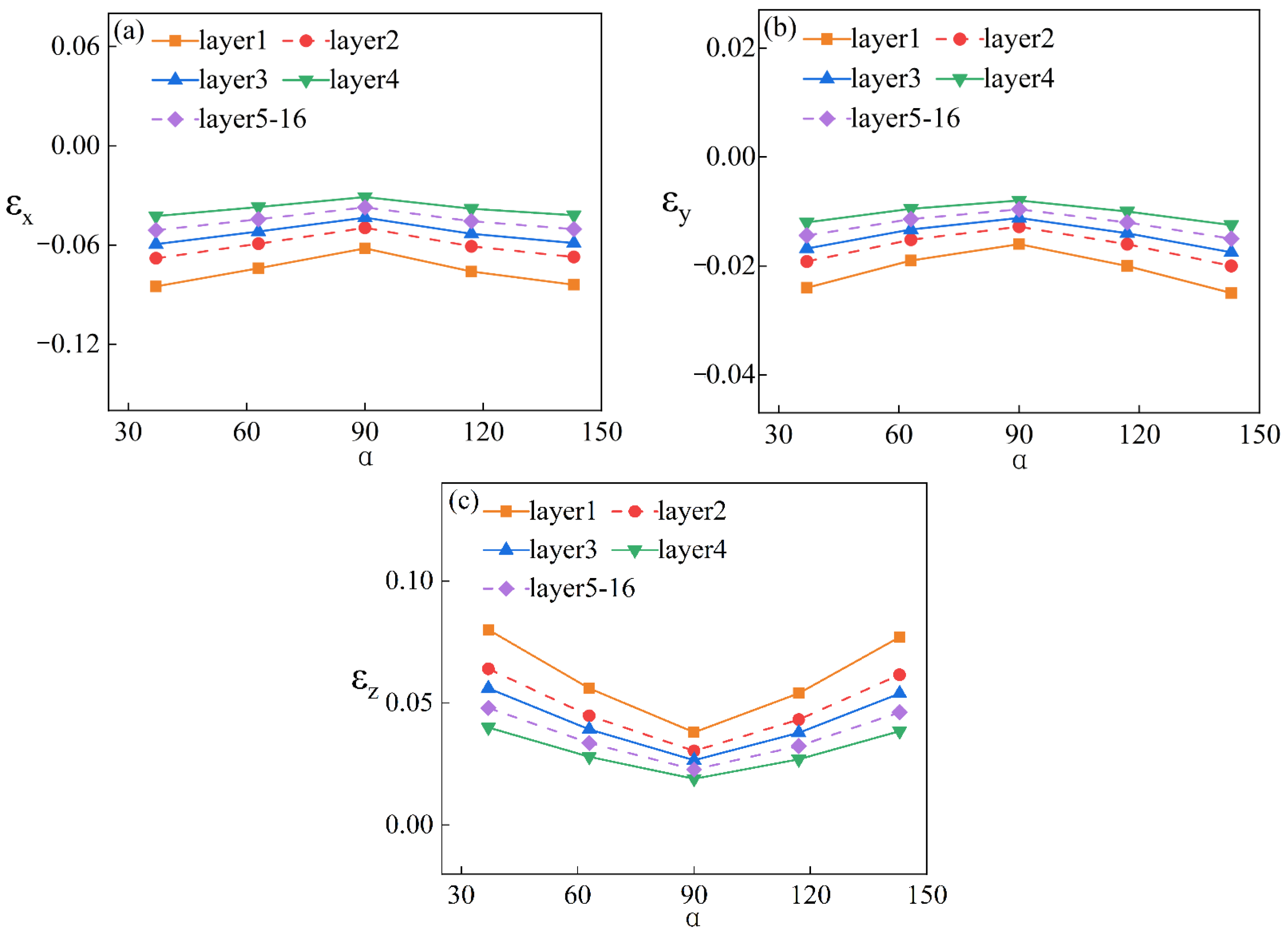

5.4. Characterization angle Impact Study

6. Deformation Prediction for Large and Complex Frame Beam Components

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hartmann, S.; Murua, O.; Arrizubieta, J.I.; Lamikiz, A.; Mayr, P. Digital Twin of the Laser-DED Process Based on a Multiscale Approach. Simul. Model. Pract. Theory 2024, 132, 102881. [Google Scholar] [CrossRef]

- Armstrong, M.; Mehrabi, H.; Naveed, N. An Overview of Modern Metal Additive Manufacturing Technology. J. Manuf. Processes 2022, 84, 1001–1029. [Google Scholar] [CrossRef]

- Mirazimzadeh, S.E.; Mohajernia, B.; Pazireh, S.; Urbanic, J.; Jianu, O. Investigation of Residual Stresses of Multi-Layer Multi-Track Components Built by Directed Energy Deposition: Experimental, Numerical, and Time-Series Machine-Learning Studies. Int. J. Adv. Manuf. Technol. 2024, 130, 329–351. [Google Scholar] [CrossRef]

- Farias, F.W.C.; dos Santos, T.J.G.; Oliveira, J.P. Directed Energy Deposition + Mechanical Interlayer Deformation Additive Manufacturing: A State-of-the-Art Literature Review. Int. J. Adv. Manuf. Technol. 2024, 131, 999–1038. [Google Scholar] [CrossRef]

- Wei, H.L.; Liu, F.Q.; Wei, L.; Liu, T.T.; Liao, W.H. Multiscale and Multiphysics Explorations of the Transient Deposition Processes and Additive Characteristics during Laser 3D Printing. J. Mater. Sci. Technol. 2021, 77, 196–208. [Google Scholar] [CrossRef]

- Strantza, M.; Ganeriwala, R.K.; Clausen, B.; Phan, T.Q.; Levine, L.E.; Pagan, D.; King, W.E.; Hodge, N.E.; Brown, D.W. Coupled Experimental and Computational Study of Residual Stresses in Additively Manufactured Ti-6Al-4V Components. Mater. Lett. 2018, 231, 221–224. [Google Scholar] [CrossRef]

- Mukherjee, T.; Zhang, W.; DebRoy, T. An Improved Prediction of Residual Stresses and Distortion in Additive Manufacturing. Comput. Mater. Sci. 2017, 126, 360–372. [Google Scholar] [CrossRef]

- Barile, C.; Carone, S.; Casavola, C.; Pappalettera, G. Implementation of Gaussian Process Regression to Strain Data in Residual Stress Measurements by Hole Drilling. Measurement 2023, 211, 112590. [Google Scholar] [CrossRef]

- Shen, C.; Ma, Y.; Reid, M.; Pan, Z.; Hua, X.; Cuiuri, D.; Paradowska, A.; Wang, L.; Li, H. Neutron Diffraction Residual Stress Determinations in Titanium Aluminide Component Fabricated Using the Twin Wire-Arc Additive Manufacturing. J. Manuf. Processes 2022, 74, 141–150. [Google Scholar] [CrossRef]

- Zhou, S.; Wu, H.; Li, X.; Li, B.; Wang, Y.; Guo, X.; Yang, G. Control of Residual Stress in Inter-Layer Hammering Hybrid Arc-Based Directed Energy Deposition Manufacturing of Cross-Structure Based on Finite Element Method. Mater. Des. 2024, 238, 112721. [Google Scholar] [CrossRef]

- Zhou, S.; Wu, H.; Li, B.; Guo, X.; Yang, G. Modelling and Researching the Evolution of Stress during Arc-Directed Energy Deposition (ADED) Hybrid Inter-Layer Hammering. Virtual Phys. Prototyp. 2024, 19, e2319435. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, J.; Yang, G.; Wang, Y.; Li, B.; An, D.; Zheng, J.; Wei, W. Microstructure Evolution and Fracture Behavior of Ti–6Al–4V Fabricated by WAAM-LDM Additive Manufacturing. J. Mater. Res. Technol. 2024, 28, 347–362. [Google Scholar] [CrossRef]

- Denlinger, E.R.; Irwin, J.; Michaleris, P. Thermomechanical Modeling of Additive Manufacturing Large Parts. J. Manuf. Sci. Eng. 2014, 136, 061007. [Google Scholar] [CrossRef]

- Lundbäck, A.; Lindgren, L.-E. Modelling of Metal Deposition. Finite Elem. Anal. Des. 2011, 47, 1169–1177. [Google Scholar] [CrossRef]

- Polyzos, E.; Pulju, H.; Mäckel, P.; Hinderdael, M.; Ertveldt, J.; Van Hemelrijck, D.; Pyl, L. Measuring and Predicting the Effects of Residual Stresses from Full-Field Data in Laser-Directed Energy Deposition. Materials 2023, 16, 1444. [Google Scholar] [CrossRef]

- Dong, W.; Jimenez, X.A.; To, A.C. Temperature-Dependent Modified Inherent Strain Method for Predicting Residual Stress and Distortion of Ti6Al4V Walls Manufactured by Wire-Arc Directed Energy Deposition. Addit. Manuf. 2023, 62, 103386. [Google Scholar] [CrossRef]

- Yuan, M.G.; Ueda, Y. Prediction of Residual Stresses in Welded T- and I-Joints Using Inherent Strains. J. Eng. Mater. Technol. 1996, 118, 229–234. [Google Scholar] [CrossRef]

- Deng, D.; Murakawa, H.; Liang, W. Numerical Simulation of Welding Distortion in Large Structures. Comput. Methods Appl. Mech. Eng. 2007, 196, 4613–4627. [Google Scholar] [CrossRef]

- Liang, X.; Chen, Q.; Cheng, L.; Hayduke, D.; To, A.C. Modified Inherent Strain Method for Efficient Prediction of Residual Deformation in Direct Metal Laser Sintered Components. Comput. Mech. 2019, 64, 1719–1733. [Google Scholar] [CrossRef]

- Liang, X.; Cheng, L.; Chen, Q.; Yang, Q.; To, A.C. A Modified Method for Estimating Inherent Strains from Detailed Process Simulation for Fast Residual Distortion Prediction of Single-Walled Structures Fabricated by Directed Energy Deposition. Addit. Manuf. 2018, 23, 471–486. [Google Scholar] [CrossRef]

- Liang, X.; Dong, W.; Hinnebusch, S.; Chen, Q.; Tran, H.T.; Lemon, J.; Cheng, L.; Zhou, Z.; Hayduke, D.; To, A.C. Inherent Strain Homogenization for Fast Residual Deformation Simulation of Thin-Walled Lattice Support Structures Built by Laser Powder Bed Fusion Additive Manufacturing. Addit. Manuf. 2020, 32, 101091. [Google Scholar] [CrossRef]

- Chen, Q.; Liang, X.; Hayduke, D.; Liu, J.; Cheng, L.; Oskin, J.; Whitmore, R.; To, A.C. An Inherent Strain Based Multiscale Modeling Framework for Simulating Part-Scale Residual Deformation for Direct Metal Laser Sintering. Addit. Manuf. 2019, 28, 406–418. [Google Scholar] [CrossRef]

- Tran, H.T.; Liang, X.; To, A.C. Efficient Prediction of Cracking at Solid-Lattice Support Interface during Laser Powder Bed Fusion via Global-Local J-Integral Analysis Based on Modified Inherent Strain Method and Lattice Support Homogenization. Addit. Manuf. 2020, 36, 101590. [Google Scholar] [CrossRef]

- Costello, S.C.A.; Cunningham, C.R.; Xu, F.; Shokrani, A.; Dhokia, V.; Newman, S.T. The State-of-the-Art of Wire Arc Directed Energy Deposition (WA-DED) as an Additive Manufacturing Process for Large Metallic Component Manufacture. Int. J. Comput. Integr. Manuf. 2023, 36, 469–510. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, P.; Cheng, L.; Min, Z.; Chyu, M.; To, A.C. Finite Element Modeling and Validation of Thermomechanical Behavior of Ti-6Al-4V in Directed Energy Deposition Additive Manufacturing. Addit. Manuf. 2016, 12, 169–177. [Google Scholar] [CrossRef]

- Foroozmehr, A.; Badrossamay, M.; Foroozmehr, E.; Golabi, S. Finite Element Simulation of Selective Laser Melting Process Considering Optical Penetration Depth of Laser in Powder Bed. Mater. Des. 2016, 89, 255–263. [Google Scholar] [CrossRef]

- Cao, Y.; Lin, X.; Kang, N.; Ma, L.; Wei, L.; Zheng, M.; Yu, J.; Peng, D.; Huang, W. A Novel High-Efficient Finite Element Analysis Method of Powder Bed Fusion Additive Manufacturing. Addit. Manuf. 2021, 46, 102187. [Google Scholar] [CrossRef]

- Yue, K.; Liu, J.; Zhang, H.; Yu, H.; Song, Y.; Hu, Q.; Wang, Q.; Yang, R. Precipitates and Alloying Elements Distribution in near α Titanium Alloy Ti65. J. Mater. Sci. Technol. 2020, 36, 91–96. [Google Scholar] [CrossRef]

| Process Parameter | Laser Power | Scan Speed | Laser Spot Diameter | Overlap Rate | Convection Coefficient |

|---|---|---|---|---|---|

| Value | 1700 W | 10 mm/s | 4 mm | 0.3 | 40 W/(m2·K) |

| Temperature | Density | Thermal Conductivity | Specific Heat | Thermal Expansion Coefficient |

|---|---|---|---|---|

| T/°C | Ρ/kg·m−3 | λ/W·m−1·K−1 | C/J·kg−1·K | α/10−6·K−1 |

| 100 | 4593 | 6.11 | 468.5 | 9.13 |

| 200 | 4593 | 6.89 | 475.8 | 9.25 |

| 300 | 4593 | 7.67 | 483.1 | 9.99 |

| 400 | 4593 | 8.46 | 490.4 | 10.5 |

| 500 | 4593 | 8.46 | 510.7 | 10.6 |

| 600 | 4593 | 11.11 | 531.3 | 10.8 |

| 700 | 4593 | 12 | 555.5 | 11.0 |

| 800 | 4593 | 12.92 | 580.1 | 11.3 |

| 900 | 4593 | 14.48 | 605.8 | 11.6 |

| 1300 | 4593 | 19.35 | 629.3 | 12.3 |

| 1650 | 4593 | 24.71 | 673.1 | 12.4 |

| Temperature | Young’s Modulus | Yield Strength | Poisson’s Ratio |

|---|---|---|---|

| T/°C | E/MPa | G/MPa | μ |

| 25 | 1230 | 451 | 0.37 |

| 100 | 1190 | 432 | 0.37 |

| 200 | 1140 | 411 | 0.39 |

| 300 | 1090 | 391 | 0.40 |

| 400 | 1040 | 371 | 0.41 |

| 500 | 994 | 351 | 0.41 |

| 600 | 947 | 333 | 0.42 |

| 700 | 899 | 314 | 0.43 |

| 800 | 852 | 297 | 0.44 |

| 900 | 805 | 279 | 0.44 |

| 1300 | 743 | 243 | 0.45 |

| 1650 | 550 | 186 | 0.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Gao, E.; Yin, J.; Li, X.; Yang, G.; Liu, Q. Research on the Deformation Prediction Method for the Laser Deposition Manufacturing of Metal Components Based on Feature Partitioning and the Inherent Strain Method. Mathematics 2024, 12, 898. https://doi.org/10.3390/math12060898

Li B, Gao E, Yin J, Li X, Yang G, Liu Q. Research on the Deformation Prediction Method for the Laser Deposition Manufacturing of Metal Components Based on Feature Partitioning and the Inherent Strain Method. Mathematics. 2024; 12(6):898. https://doi.org/10.3390/math12060898

Chicago/Turabian StyleLi, Bobo, Enze Gao, Jun Yin, Xiaodan Li, Guang Yang, and Qi Liu. 2024. "Research on the Deformation Prediction Method for the Laser Deposition Manufacturing of Metal Components Based on Feature Partitioning and the Inherent Strain Method" Mathematics 12, no. 6: 898. https://doi.org/10.3390/math12060898

APA StyleLi, B., Gao, E., Yin, J., Li, X., Yang, G., & Liu, Q. (2024). Research on the Deformation Prediction Method for the Laser Deposition Manufacturing of Metal Components Based on Feature Partitioning and the Inherent Strain Method. Mathematics, 12(6), 898. https://doi.org/10.3390/math12060898