Abstract

With the emergence of the fourth industrial revolution, the use of intelligent technologies in supply chains is becoming increasingly common. The aim of this research is to propose an optimal design for an intelligent supply chain of multiple perishable products under a vendor-managed inventory management policy aided by IoT-related technologies to address the challenges associated with traditional supply chains. Various levels of the intelligent supply chain employ technologies such as Wireless Sensor Networks (WSNs), Radio Frequency Identification (RFID), and Blockchain. In this paper, we develop a bi-objective nonlinear integer mathematical programming model for designing a four-level supply chain consisting of suppliers, manufacturers, retailers, and customers. The model determines the optimal network nodes, production level, product distribution and sales, and optimal choice of technology for each level. The objective functions are total cost and delivery times. The GAMS 24.2.1 optimization software is employed to solve the mathematical model in small dimensions. Considering the NP-Hard nature of the problem, the Grey Wolf Optimizer (GWO) algorithm is employed, and its performance is compared with the Multi-Objective Whale Optimization Algorithm (MOWOA) and NSGA-III. The results indicate that the adoption of these technologies in the supply chain can reduce delivery times and total supply chain costs.

Keywords:

intelligent supply chain; Internet of Things; Radio Frequency Identification; Wireless Sensor Network; mathematical modeling MSC:

90B06

1. Introduction

Traditional supply chains face multiple challenges such as uncertainty, high costs, complexity, and the perishability of products. To overcome these problems, supply chains need to become more intelligent []. Due to the complexity of supply chain management and the need for better management, companies consider innovative technologies as potential factors for improving their supply chain performance []. The use of these innovative technologies can serve as a competitive advantage for companies and improve their supply chain performance. The Internet of Things (IoT) can play a significant role in this process. Implementing this technology enables accurate real-time data coverage, facilitates operations, and enhances the transparency in the progression of processes [].

Another notable hurdle in supply chain management lies in the coordination of material flow, both among multiple organizations and within each individual organization. Each supply chain requires the use of logistics technologies and tools to meticulously track materials from origin to destination while recording crucial information at every stage []. Having comprehensive and dependable databases is an essential requirement for effective supply chain management. Consequently, the proper implementation of integrated information systems, such as IoT, is critically important in this context []. IoT is able to optimize supply chain management, make the best of the available resources, provide sufficient visibility across the entire chain, enhance the transparency of supply chain information, enable real-time management, and ultimately achieve maximum agility and integration []. IoT is a network of physical devices interconnected through electrical circuits, software, sensors, and mechanical actuators, all of which are connected to the internet by definition, enabling remote control and monitoring of system behavior [].

Designing supply chains with perishable and short-lifecycle goods, such as food products, has long been considered one of the most crucial and challenging subjects in the field of supply chain management. Given the diversity of the food industry products, it is essential to keep track of the flow of goods through the supply chain and control the temperature around food products []. Today, with the globalization of food trade, food products inevitably travel great distances from manufacturers to consumers. Thus, it is critically important to preserve the safety and quality of perishable goods []. It is possible to manage perishable goods, such as food and pharmaceutical products, in such a way as to avoid losses resulting from expired or spoiled items. For instance, special sensors can be installed to ensure that products have not been exposed to hazardous environmental conditions [].

IoT revolutionizes the speed at which data are collected and decisions are made, enabling supply chains to respond to changes in real-time. Within the context of IoT, each object’s connection spans from production to sale, service operations, and even recycling. Although information about an object can be distributed across multiple organizations, a unique identifier for each object serves as a common reference point, facilitating the identification and utilization of the data on said object at any level within the organization [].

In this research, our focus lies in optimizing the supply chain through the application of IoT technologies and mathematical modeling approaches. By tapping into information from various levels of the supply chain through IoT, our aim is to achieve more precise planning in inventory control, shorten delivery times, and reduce the total supply chain cost. The key advantages of utilizing IoT in this supply chain are threefold: minimizing delays by reducing delivery times, enabling real-time demand analysis within the supply chain, and ensuring cost reduction, all considered critical issues in effective supply chain management.

In brief, the innovations of this study can be outlined as follows:

- Introducing a novel nonlinear integer mathematical model for supply chain design, taking into account IoT-related technologies (RFID and WSN);

- Selecting the suitable technology between RFID and WSN for each level of the supply chain;

- Modeling the inventory management process in the supply chain using these technologies and implementing a vendor-managed inventory management policy;

- Considering simultaneous time and cost optimization in a real case of intelligent supply chain.

Motivation and Contribution

Traditional supply chains of perishable products have disadvantages such as long delivery times, multiple decision points, non-transparent information, and minimal coordination, and they also face many challenges such as uncertainty, cost, complexity, and vulnerability issues. On the other hand, customer demand is constantly changing and it is very appropriate for all organizations to adapt to changes and maintain supply chain inventory and at the same time be flexible with customer demand. Creating a smart and agile supply chain is necessary to solve these disadvantages and challenges.

In this research, we used technologies related to the Internet of Things to solve the challenges and disadvantages of the traditional supply chain and its effective management, using mathematical modeling and taking into account technology and automation considerations; in order to be more coordinated with customer demand, online sales for retailers were also considered and we used blockchain for data security and chain information.

Finally, we achieved an optimized supply chain distribution system and simultaneously optimized the cost and delivery time of the intelligent supply chain.

2. Literature Review

Christopher is one of the early proponents of the concept of agility in supply chains. For a supply chain to be truly agile, it must possess four characteristics: market sensitivity, IT utilization, process integration, and networked structure []. It was reportedly Kevin Ashton who originally coined the term “Internet of Things” in 1999 []. Subsequently, Lee and Lee (2015) defined five key IoT technologies: Radio Frequency Identification (RFID), Wireless Sensor Networks (WSN), Cloud Computing, Middleware, and IoT applications [].

A supply chain may be defined as a set of entities and processes involved in fulfilling customer orders. The entities often include suppliers, manufacturers, distributors, retailers, and end-customers. Using IoT technology, supply chain managers can automatically identify the status of an object, warehouse, equipment, machinery, and even workers by gathering and employing real-time data. For example, RFID–IoT can detect the start/completion of a process through the entry/exit signal transmitted from the RFID–IoT coverage area [].

Intelligent supply chain management involves the use of a vast amount of data to ensure better decision-making, utilizing advanced technology and obtaining comprehensive information throughout operations. In other words, for intelligent supply chain management, all the components in warehouses, distribution centers, retailers, and e-commerce portals should be interconnected and in full communication with each other. The above-mentioned centers should be aware of customers’ demand at any given time and location, and have the capability to exchange information and place new orders if necessary [].

In today’s competitive world, due to factors such as random demand, managers must pay more attention to the importance of production and inventory control. In a study of production system failure, a multi-product network with perishable items is considered. The production control policy is based on the cover point policy, which includes the production and maintenance of products in order to meet demand and prevent shortages. Its main objective is to determine the optimal production rates that minimize the average total costs, including shortage, production, storage, and perishable costs. Due to the uncertainty and complexity of this system, the optimization simulation of this system was conducted using ARENA software 14 [].

Vendor-managed inventory (VMI) is a popular inventory management strategy that gives the vendor access to information on retailers’ sales and inventory levels. Implementing VMI can be beneficial for both the vendor and the retailer. IoT data, when combined with VMI, not only support inventory management but also can be a crucial factor in improving supply agility. These data, therefore, help organizations remain competitive in the market by serving customers with a level of inventory without the need for warehousing and ensuring their satisfaction [].

RFID refers to the wireless use of radio frequency waves to transfer data at high speeds. RFID monitors the dynamic status, location, and other characteristics of tagged objects. There are two types of tags: active and passive. Active tags continuously work to track objects by providing real-time data, while passive tags work with a large number of labeled objects to facilitate cost-effective deployment [].

WSN is a network of sensors for monitoring and tracking the status of multiple devices. Sensors can be used for various purposes, including the monitoring of location, movements, temperature, pressure, flow, level, imaging, sound, air pollution, proximity, infrared, humidity, and speed []. They can also collaborate and communicate with RFID tags. Since RFID and WSN are regarded as complementary technologies, their integration is often considered as an option [].

Blockchain is a fully distributed database shared by different nodes within a massive computer network. A blockchain serves as a database that stores information in digital format. By creating a convenient and highly secure space, blockchain helps buyers and vendors connect with each other without intermediaries. Four key characteristics have been associated with blockchain technology: transparency, reliability, intelligent execution, and encryption []. The use of the IoT in warehousing allows for space optimization. Using inventory tags, information about the goods can be transferred to a database, enabling better control over inventory and the location of goods. Intelligent sorting of goods, along with rapid and accurate assessment of inventory levels, are other applications of IoT in this field [,]. In a study, the production rate control of multiple machines in failure-prone production systems in the presence of perishable goods has been carried out in order to minimize the expected costs including maintenance, shortages, lost goods, and repair costs [].

In an article, a network of production machines prone to failure is considered and the final product is a perishable product. The purpose of this study is to find the optimal production rate of machines based on the breakeven policy in such a way that the average costs of the system are minimal. Due to the uncertainty in such systems, discrete event simulation with the help of ARENA software is used in this paper to estimate system costs. The Taguchi method has been used to determine the optimal values of decision variables [].

Utilizing IoT with the goal of returning recycled goods to factories has drawn the attention of researchers as well. Scholars have especially focused on providing configurations in this area and aim to minimize the negative impact of the waste generated by decommissioned electronic and electrical equipment on the environment through the use of IoT []. In the production sector, IoT can facilitate the identification and tracking of raw materials and finished products in the automation of production lines. The technology may thus help to significantly lower human labor costs, simplify industrial operations, and enhance the overall quality of products [].

As for sales, customers can obtain the information they need through the tags embedded on the products. In supermarkets, the invoice is automatically generated by reading product labels and the payment is transferred from the customer’s linked credit card to the store’s account []. Establishing appropriate pricing strategies that satisfy consumers, suppliers, and intermediaries is a challenging task. Using IoT to calculate the actual product price based on the costs of production processes, packaging, and transportation is considered a highly effective strategy to prevent overpricing, fraud, and other unethical business practices []. Lee et al. in 2018 presented an IoT-based inventory management system with an analytical approach to advanced data analysis []. The authors demonstrated that the use of IoT can enhance warehouse productivity, selection accuracy, and order diversity []. A multi-temperature system of delivery planning has been proposed based on IoT which identified and rerouted in the event of unforeseen crises, thus increasing the system’s ability to handle electronic orders and maintaining customer satisfaction at an adequate level []. A blockchain-based tracking system has been investigated in the market of perishable goods over two sales channels under different pricing policies. The system was able to reduce product losses and provide reliable information.

Many previous studies have utilized IoT in two-level multi-product supply chains, concluding that the effective use of IoT can optimize multi-product supply chains. The authors demonstrated that the proper deployment of information processing leads to better information dissemination throughout the supply chain []. Tian in 2016 discussed the priority of developing and using RFID and blockchain technologies. Specifically, the researcher analyzed the pros and cons of using RFID and blockchain in constructing a tracking system for agrifood supply chains []. A combination of RFID and other IoT technologies allows for the tracking of products from the manufacturer to the retailer and reduces the production time in a cost-effective manner. Additionally, intelligent supply chain management enhances brand protection, quality assurance, and customization for customers. For instance, consumers tend to have a more positive perception of products when each ingredient, process, and status can be traced and verified. Given the complexity and dynamism of each process, it is somewhat challenging to make accurate cost and time estimates. In short, RFID and other IoT technologies are often essential to ensure cost and time tracking in the supply chain []. Blockchain has the potential to take distribution transparency to a new level; however, the scientific understanding and managerial acceptance of blockchain technologies are still comparably limited. To address this issue, Francisco and Swanson in 2018 proposed an advanced conceptual model that utilized the unified theory of acceptance and use of technology (UTAUT) and the concept of innovation acceptance as the basic framework for product distribution tracking. Table 1 presents a summary of the most prominent studies conducted on the subject thus far []. In a recent study, a mathematical model for vendor-managed intelligent supply chains (VMI) was conducted through Internet of Things (IoT) technology. This research shows that to overcome traditional supply chain challenges and solve problems such as uncertainty, high costs, and changes in customer demand, it is necessary to create a smart and agile supply chain [].

Table 1.

Summary of the literature on the subject.

Based on the investigations of previous studies, it seems that a significant volume of research has been conducted on intelligent supply chains, IoT, their combinations, discussions regarding their pros and cons, implementation challenges, and real-world applications. Our review indicates that the utilization of mathematical modeling in these studies has been limited, and the present research creates an opportunity to optimize decision-making in the field of intelligent supply chains by solving problems through mathematical models. Among the previous research, there appears to have been a positive view toward supply chains and, in particular, toward IoT. However, despite the extensive research conducted in this area thus far, there remains a distinct lack of comprehensive and diverse mathematical programming models that fully address the requirements, assumptions, technological requirements, and automation considerations of an academic study.

3. Model Assumptions and Notations

The proposed model considers a four-level supply chain consisting of three relationships: supplier–manufacturer, manufacturer–retailer, and retailer–customer. The three technologies of RFID, WSN, and blockchain can be utilized across the levels of this supply chain. The model aims to determine the optimal combination of these technologies with respect to the time and cost objective functions. To further clarify this goal, the assumptions of the model are presented as follows:

- IoT involves two technologies, RFID and WSN, but only one of these technologies is used at each node.

- There are multiple types of products and materials.

- The supply time of raw materials is influenced by the use of RFID or WSN technologies.

- The total cost includes the cost of establishing each node in the supply chain, blockchain implementation, RFID implementation, WSN implementation, and transportation among nodes.

- Delivery time is considered as the model’s secondary objective.

- The products are perishable.

- The conversion factor of raw materials to final products is assumed to equal 1.

- The model parameters are deterministic.

| Indices | |||||

| n | m | l | k | j | i |

| Raw materials | Product | Customer | Retailer | Manufacturer | Supplier |

4. Mathematical Model and Analysis

Objective Functions

Relation (1) aims to minimize the total cost of the supply chain, which consists of the implementation costs of the nodes, RFID, WSN, blockchain, and online sales platform.

Relation (2) aims to minimize the time, consisting of the time it takes to make the deliveries and procure the required raw materials from the supplier both using RFID and WSN and without using the two technologies.

Relation (3) indicates that the delivery of any type of raw material from the supplier to the factory is only possible if a supply center is established.

Relation (4) indicates that the delivery of any type of product from the factory to the retailer is only feasible if a factory is established.

Relation (5) indicates that the delivery of any type of product from the retailer to end-customers is only feasible if a retailer is established.

Relation (6) states that each supplier only delivers one type of raw material to the manufacturer in each order.

Relation (7) states that each factory only delivers one type of product to the retailer in each order.

Relation (8) states that each retailer only delivers one type of product to the customer in each order.

Relation (9) indicates that only one of the WSN and RFID technologies can be installed for each customer.

Relation (10) indicates that only one of the WSN and RFID technologies can be installed for each retailer.

Relation (11) indicates that only one of the WSN and RFID technologies can be installed for each supplier.

Relation (12) states that the quantity of products delivered by suppliers that adopt blockchain is considered in light of the presence of this technology.

Relation (13) assumes that the supplier does not utilize the blockchain technology.

Relations (14) to (17) represent the raw materials delivered from the supplier to the factory based on customer demand and factory capacity.

Relation (18) states that the quantity of products delivered by manufacturers that adopt blockchain is considered in light of the presence of this technology.

Relation (19) assumes that the factory does not utilize the blockchain technology.

Relations (20) to (23) represent the products delivered from the factory to the retailer based on customer demand and factory capacity. Due to their perishability, the quantity of the products should not exceed the demand.

Relation (24) states that the quantity of products delivered for retailers that adopt blockchain is considered in light of the presence of this technology.

Relation (25) assumes the non-implementation of blockchain technology for the retailer.

Relations (26) to (29) represent the products delivered from the retailer to the end-customer based on customer demand and factory capacity. Due to their perishability, the quantity of the products should not exceed the demand.

Relation (30) states the retailer’s maximum capacity for each type of product for online sales.

Relation (31) indicates the total quantity of products sent from each retailer to end-customers based on the inventory of that retailer.

Relation (32) is the formula for calculating the inventory of retailer k based on the VMI technique.

Relation (33) represents the maximum inventory level of retailer k for product m based on its capacity.

Relation (34) represents the minimum inventory level of retailer k based on the VMI technique.

Relation (35) states that the inventory level of retailer k should be higher than its initial inventory level at the beginning of the period.

Relation (36) represents the maximum replenishment level of retailer k based on the VMI technique.

Relation (37) represents the minimum replenishment level of retailer k based on the VMI technique.

Relation (38) indicates that the initial inventory plus replenishment form the inventory of retailer k.

Relation (39) expresses the constraint on launching online sales for retailer k.

Relation (40) states that it is possible to implement online sales for retailer k only if retailer k has been established.

Relations (41) to (43) indicate that each of the supply chain’s components and nodes can be established at most once.

Relations (44) and (45) indicate that RFID and WSN can be installed at most once for each customer, respectively.

Relations (46) and (47) indicate that RFID and WSN can be installed at most once for each retailer, respectively.

Relations (48) and (49) indicate that RFID and WSN can be installed at most once for each supplier, respectively.

Relations (50) to (52) indicate that the blockchain system can be implemented at most once for each supplier, factory, or retailer node, respectively.

5. Approach to Model Solution

5.1. Model Validation

The model is initially validated at a small scale. For instance, we first considered a problem with the following dimensions:

| Types of raw materials | Types of products | No. of customers | No. of retailers | No. of manufacturers | No. of suppliers |

| 2 | 3 | 12 | 7 | 3 | 4 |

After solving the model by obtaining the values of the objective functions using the optimization software GAMS, the technology to be used by each of the suppliers, retailers, and customers was determined. The values of the primary and secondary objective functions were 13,995 and 21,406, respectively.

RFID: Suppliers 3 and 4; Retailers 3 and 4; Customers 5, 6, 7, 9, and 12.

WSN: Suppliers 1 and 2; Retailers 1, 2, 5, 6, and 7; Customers 1, 2, 3, 4, 8, 10, and 11.

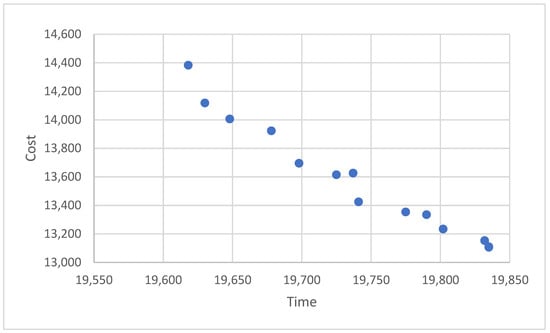

The basic problem above was solved using the ε-constraint method. The values of the objective functions and the Pareto figure indicated that the results were optimal (Table 2 and Figure 1).

Table 2.

Pareto points obtained by ε-constraint method.

Figure 1.

Pareto front obtained by ε-constraint method.

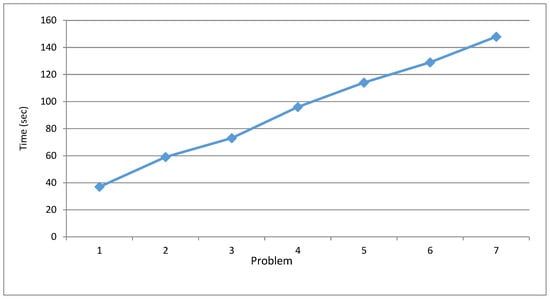

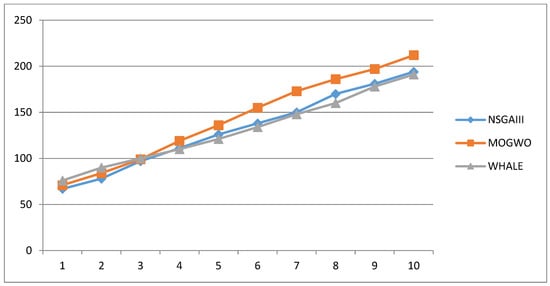

As Table 3 and Table 4 and Figure 2 indicate, 10 small-scale problems were considered and the values of the objective functions and solution time were obtained by solving the model in small dimensions using GAMS. Since the model could not be solved by exact methods in large dimensions, and given the software and hardware limitations of using GAMS for this purpose, it was decided to solve the model in large dimensions by metaheuristic algorithms provided by the MATLAB R2020a programming platform.

Table 3.

Problem dimensions.

Table 4.

Results of solving the model in small dimensions.

Figure 2.

Time to solve the problem.

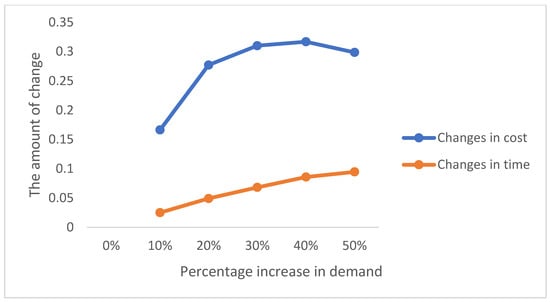

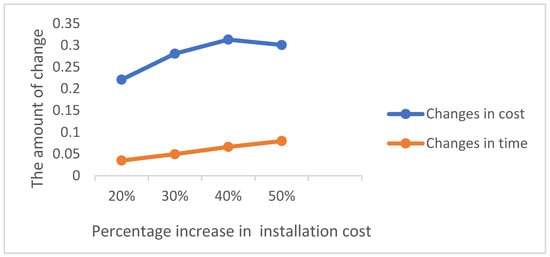

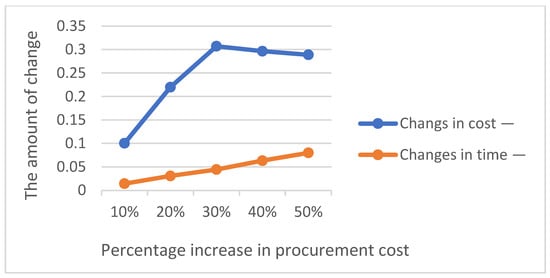

5.2. Sensitivity Analysis in Small Size

This analysis examined the impact of changes in the values of three parameters: demand, procurement cost, and installation cost. The results of the analysis are presented in the following Table 5, Table 6 and Table 7 and Figure 3, Figure 4 and Figure 5.

Table 5.

Sensitivity analysis of demand.

Table 6.

Sensitivity analysis of system installation costs.

Table 7.

Sensitivity analysis of procurement costs.

Figure 3.

Sensitivity analysis of demand.

Figure 4.

Sensitivity analysis of system installation costs.

Figure 5.

Sensitivity analysis of procurement costs.

To solve the problem in large dimensions, we utilized three metaheuristic algorithms: Multi-Objective Grey Wolf Optimization (MOGWO) [], Non-Dominated Sorting Genetic Algorithm III (NSGA-III)) [], and Multi-Objective Whale Optimization Algorithm (MOWOA) [].

The grey wolf algorithm is a new SI optimization algorithm inspired by grey wolves. This algorithm mimics the proposed method of social hierarchy and hunting behavior of grey wolves. The results showed that GWO can provide very competitive results compared to well-known heuristics such as PSO, GSA, DE, EP, and ES [].

The Multi-Objective Grey Wolf Optimization (MOGWO) algorithm is used to optimize problems with multiple objectives. Two new components were integrated into the GWO algorithm to enable it to perform multi-objective optimization [].

NSGA-III algorithm is an evolutionary multi-objective optimization method based on reference points to achieve objective functions. The NSGA-III algorithm eliminates the drawbacks of the NSGA-II algorithm, such as the inability to maintain diversity among population members, which is avoided by providing and adaptively updating several well-extended reference points in NSGA-III [].

The MOWOA multi-objective algorithm is designed based on the Whale Optimization Algorithm (WOA). The original WOA algorithm is popular among researchers due to rotating the moments of agents (humpback whales) in the search space, which provides a good balance between exploration and exploitation, faster convergence, and fewer parameters. The multi-objective version has all the above advantages of the original algorithm, and additionally shows accurate convergence to real Pareto fronts and preserves the effective diversity between solutions [].

Based on the prior research on multi-level and network-structured problems, these three metaheuristic algorithms offer superior performance and can be executed with relative ease.

5.3. Parameter Tuning

The algorithm proposed in this study consists of three problem categories: small, medium, and large problems. The results are presented separately for each category in the following Table 8, Table 9, Table 10 and Table 11.

Table 8.

Parameter settings for NSGA-III, MOGWO, and MOWOA for small size problems.

Table 9.

Parameter settings for NSGA-III, MOGWO, and MOWOA for medium size problems.

Table 10.

Parameter settings for NSGA-III, MOGWO, and MOWOA for large size problems.

Table 11.

Problem in large dimensions.

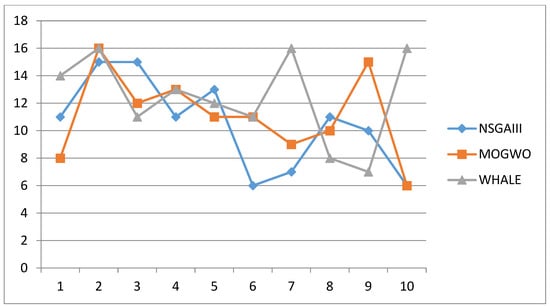

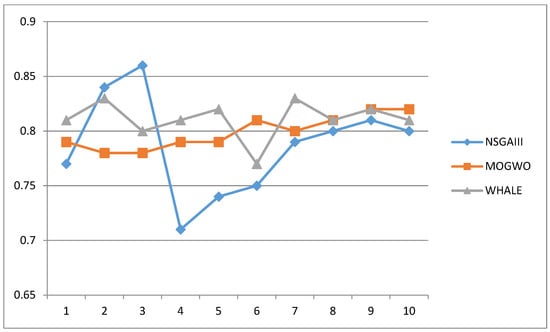

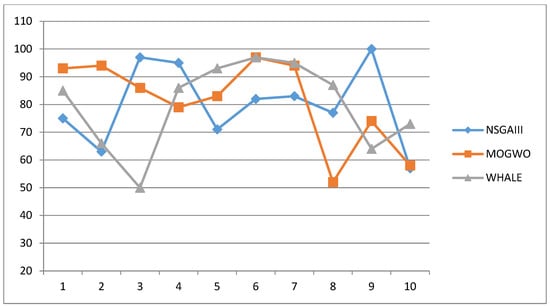

By solving the problem in large dimensions using the aforementioned algorithms and considering the obtained Pareto points, it can be concluded that all three algorithms could successfully solve the developed model. In the next section, the algorithms will be compared in terms of efficiency. The performance criteria of the algorithms include the number of generated Pareto points, distance to the ideal point, crowding distance, and computation time. In the first criterion, a higher value indicates better algorithm performance. However, for the remaining three criteria, a lower value indicates the efficiency and superiority of the algorithm (Table 12 and Figure 6, Figure 7, Figure 8 and Figure 9).

Table 12.

Algorithm performance comparison.

Figure 6.

Number of Pareto points.

Figure 7.

Distance to ideal point.

Figure 8.

Crowding distance.

Figure 9.

Computation time.

- Evidently, MOGWO generated the highest number of Pareto points, with NSGA-III closely following. The higher the number of Pareto points, the more efficient the algorithm is considered.

- In terms of distance to the ideal point, NSGA-III yielded the smallest distance to the ideal point, while the other two algorithms show relatively similar performance in this criterion.

- As for crowding distance, where smaller values indicate better efficiency, MOGWO achieved the smallest crowding distance. However, MOWOA yielded the shortest smalling distance in the third example.

- Computation time is another important criterion where lower values suggest that the algorithm is more suitable. MOGWO achieved the shortest computation time, followed closely by NSGA-III. MOWOA produced the highest computation time.

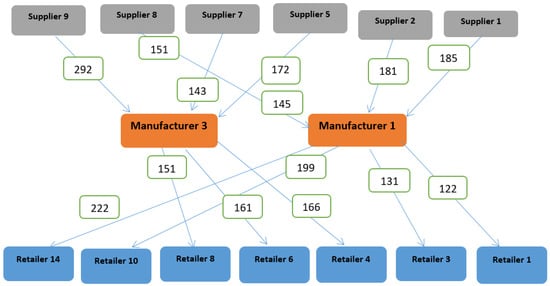

5.4. Results of Solving One of the Problems

In this subsection, a complete example is provided where the results of solving one of the problems and the computation of decision variables are presented. By solving this specific example, it is determined which supplier, factory, or retailer is optimal, and thus the links between the nodes under optimal conditions are established. Additionally, the transportation load to be delivered from one node to another is determined. The results are provided in the form of the two schematic figures.

As can be observed in the Figure 10, the optimal selection of nodes has been completed and it is specified which nodes are preferred, how the nodes should be connected, and what quantity of products should be transferred.

Figure 10.

Optimal quantity of products to deliver, node selection, and node links.

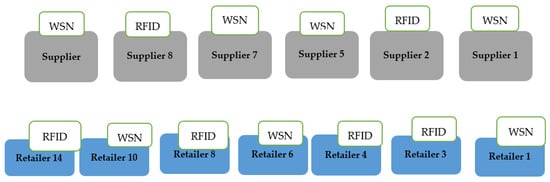

Figure 11 shows which technology has been assigned to which nodes. Notably, the model has been unable to simultaneously assign two technologies to any node and this can be regarded as a limitation of this research.

Figure 11.

Optimal assignment of WSN or RFID to retailer or supplier nodes.

5.5. Analysis of the Impact of WSN and RFID

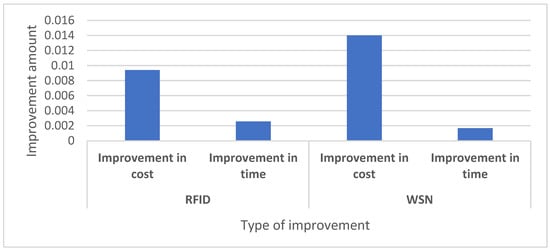

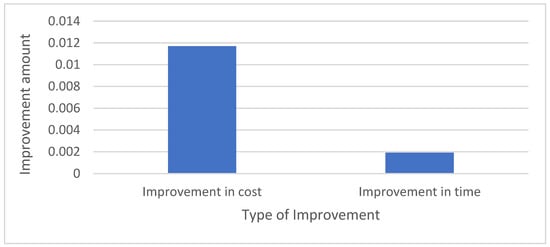

In this subsection, we analyze the way the WSN and RFID technologies affect the cost and time objective functions of customers, suppliers, and retailers.

As can be observed, the use of RFID and WSN improved costs much more significantly than times. Moreover, RFID appears to be generally more effective in improving customers’ cost and time (Table 13 and Figure 12).

Table 13.

Impact of WSN and RFID on customers’ cost and time objective functions.

Figure 12.

Impact of WSN and RFID on customers’ cost and time objective functions.

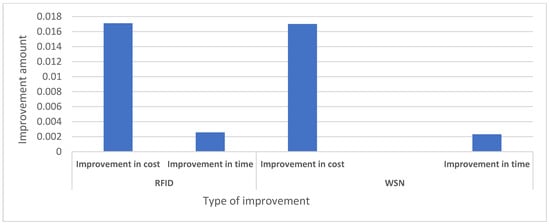

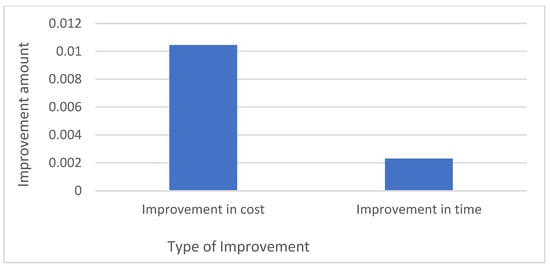

According to Table 14 and Figure 13, WSN generated better results for retailers and caused a greater reduction in costs. On the other hand, RFID was better in terms of reducing delivery times.

Table 14.

Impact of WSN and RFID on retailers’ cost and time objective functions.

Figure 13.

Impact of WSN and RFID on retailers’ cost and time objective functions.

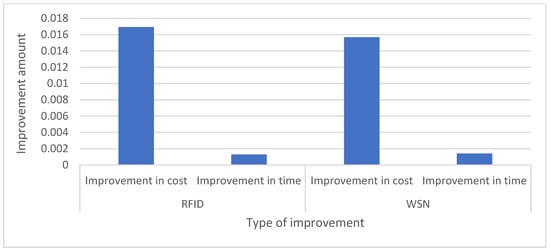

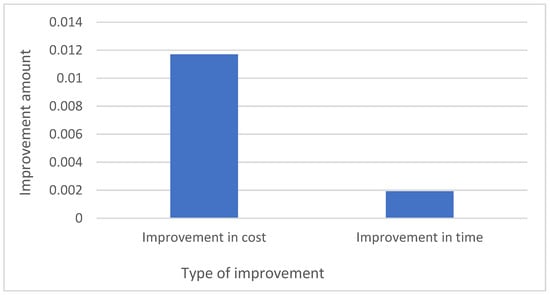

Table 15 and Figure 14 shows that RFID slightly outperforms WSN in terms of improving suppliers’ cost and time objective functions.

Table 15.

Impact of WSN and RFID on suppliers’ cost and time objective functions.

Figure 14.

Impact of WSN and RFID on suppliers’ cost and time objective functions.

5.6. Analysis of the Impact of Blockchain

In this subsection, we investigate the impact of implementing the blockchain technology on the cost and time of the supply chain’s components.

Table 16 and Figure 15 show that using blockchain leads to a greater reduction in cost than in time.

Table 16.

Impact of blockchain on suppliers’ cost and time objective functions.

Figure 15.

Impact of blockchain on suppliers’ cost and time objective functions.

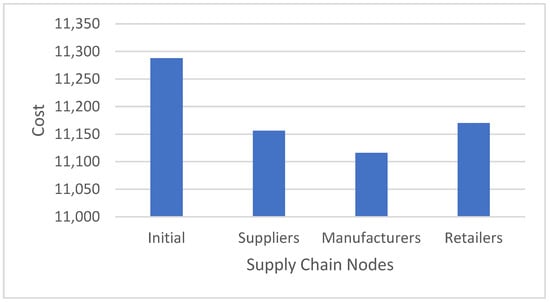

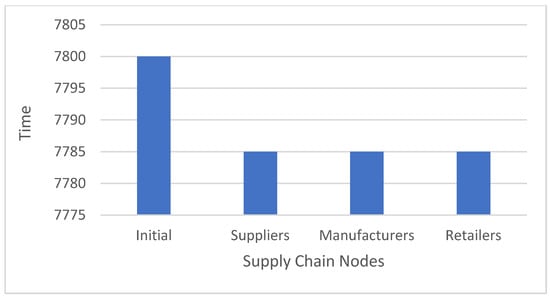

Table 17 and Figure 16 show that adopting the blockchain technology can reduce the production cost. Furthermore, the positive impact of blockchain on costs exceeds its impact on time.

Table 17.

Impact of blockchain on manufacturers’ cost and time objective functions.

Figure 16.

Impact of blockchain on manufacturers’ cost and time objective functions.

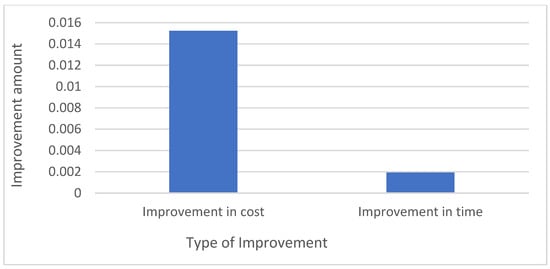

As Table 18 and Figure 17 show, using blockchain simultaneously reduces retailers’ delivery times and costs. The impact of this technology is more significant on costs than on time.

Table 18.

Impact of blockchain on retailers’ cost and time objective functions.

Figure 17.

Impact of blockchain on retailers’ cost and time objective functions.

5.7. Analysis of the Impact of Online Sales

We now look at the improvements caused by the use of online sales which can only be applied for the retailer. Similar to the previous sections, the results are presented in the form of a table and a figure.

As Table 19 and Figure 18 show, the impact of online sales on cost reduction or improvement is more significant than on time.

Table 19.

Impact of online sales on retailers’ cost and time objective functions.

Figure 18.

Impact of online sales on retailers’ cost and time objective functions.

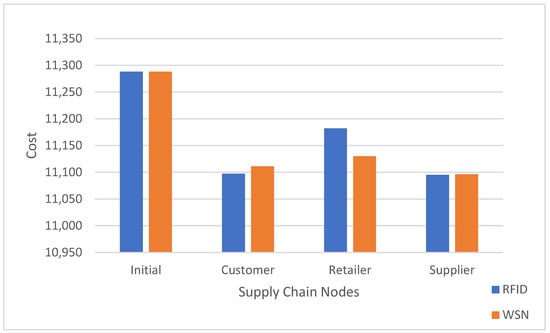

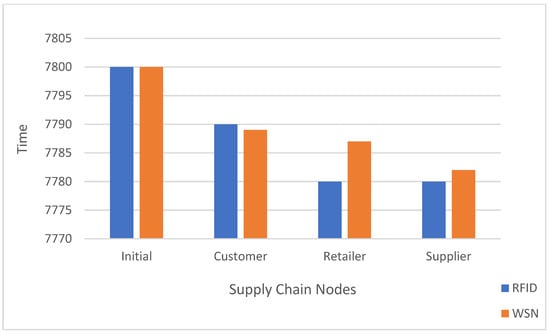

5.8. Comparison of the Results

This section focuses on specifying which technology has proven to have a greater impact on improvement of the cost and time objective functions at each level of the supply chain. The comparison is presented in the form of the following Table 20 and Table 21 and Figure 19, Figure 20, Figure 21 and Figure 22.

Table 20.

Comparison of the improvements caused by the use of RFID and WSN.

Table 21.

Comparison of the improvements caused by the use of blockchain.

Figure 19.

Comparison of the improvements in cost caused by the use of RFID and WSN in supply chain nodes.

Figure 20.

Comparison of the improvements in time caused by the use of RFID and WSN in supply chain nodes.

Figure 21.

Comparison of the improvements in cost caused by the use of blockchain in supply chain nodes.

Figure 22.

Comparison of the improvements in time caused by the use of blockchain in supply chain nodes.

- The use of RFID at the customer and supplier levels resulted in a greater reduction in costs compared to WSN.

- For retailers, WSN was more effective in reducing the cost.

- The use of RFID at the retail and supplier levels led to a significant reduction in time.

- Overall, WSN had a more significant impact overall compared to RFID for customers; however, RFID had a more positive impact on time.

- Blockchain contributed to a significant reduction in costs for suppliers, manufacturers, and retailers.

- Blockchain significantly reduced the delivery times of retailers, manufacturers, and suppliers.

- Overall, blockchain had the greatest impact on manufacturers.

6. Conclusions

The model presented in this research was subjected to extensive analysis and validation. Due to its NP-Hard nature, we utilized metaheuristic algorithms to solve the problem. After defining the problem in large dimensions, the efficiency of the algorithms was evaluated based on four criteria: distance to the ideal point, Pareto point generation, crowding distance, and computation time. Overall, the MOWOA method appeared to have performed better in terms of Pareto point generation, while MOGWO demonstrated higher computational efficiency. Subsequently, a general example was considered and the impact of solving the model was examined on the example. Next, the optimal node selection, product selection, and node interconnections were determined. After completing the aforementioned steps, a full analysis was conducted on the use of each of the IoT technologies explored in this research.

The outcome indicated a significant overall impact on total cost and delivery times, accomplishing the goal of the model by minimizing both the primary and secondary objective functions. However, the general conclusion is that the impact of adopting the two technologies on the reduction in cost is more significant than their impact on time. Therefore, the authors recommend that they should be utilized in supply chains since, in spite of the costs associated with adopting such technologies, they cause a notable reduction in the overall cost, with a significant portion of the cost reduction attributed to the decreased inventory costs. Thus, due to the long-term cost and time reduction benefits, the optimal use of these technologies is strongly advised, and industry managers should establish a culture of utilizing the technologies within their respective organizations.

The use of these technologies can lead to the improvement of cost and time performance for all nodes of the supply chain, but the general result is that these two technologies lead to a significant improvement in cost compared to time. This amount is ten times the time, which shows the importance of using these two technologies.

Based on the limitations of this study, the authors would like to propose the following directions for future research: (a) Considering reliability, perishable product deterioration rate, and risk in intelligent supply chain; (b) incorporating uncertain parameters and utilizing robust optimization; (c) classifying different technologies according to their levels; (d) assessing the adaptability of different technologies; and finally (e) developing multi-stage mathematical models as the solution.

Author Contributions

Conceptualization, T.M. and S.M.S.; Methodology, T.M. and S.M.S.; Software, T.M.; Validation, T.M.; Formal analysis, T.M.; Investigation, T.M.; Resources, T.M.; Data curation, T.M. and S.M.S.; Writing—original draft, T.M.; Writing—review & editing, T.M., S.M.S., S.E.N. and M.T.-Y.; Visualization, T.M. and S.M.S.; Supervision, T.M. and S.M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The authors confirm that the data supporting the findings of this study are available within the article.

Acknowledgments

The authors thank the anonymous reviewers whose comments helped us improve the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| Customer demand for product m from retailer k | |

| Fixed cost of establishing supplier i | |

| Fixed cost of establishing factory j | |

| Fixed cost of establishing retailer k | |

| Cost of installing RFID technology at customer node l | |

| Cost of installing WSN technology at customer node l | |

| Cost of installing RFID technology at retailer node k | |

| Cost of installing WSN technology at retailer node k | |

| Capacity of supplier i for procuring material n | |

| Capacity of factory j for manufacturing product m | |

| Capacity of retailer k for product m | |

| Cost of purchasing factory j’s raw material n from supplier i | |

| Cost of purchasing factory j’s product m from retailer k | |

| Cost of purchasing product m from retailer k for customer l | |

| Delivery time of raw material n from supplier i to factory j | |

| Delivery time of product m from factory j to retailer k | |

| Delivery time of product m from retailer k to customer l | |

| Cost of transporting raw material n from supplier i to factory j | |

| Cost of transporting product m from factory j to retailer k | |

| Cost of transporting product m from retailer k to customer l | |

| Average procurement time of raw material n by supplier i for factory j without RFID | |

| Average procurement time of raw material n by supplier i for factory j with RFID | |

| Average procurement time of raw material n by supplier i for manufacturer j without WSN | |

| Average procurement time of raw material n by supplier i for manufacturer j with WSN | |

| Cost of implementing blockchain for supplier i | |

| Cost of implementing blockchain for factory j | |

| Cost of implementing blockchain for retailer k | |

| Cost of implementing online sales for retailer k | |

| Maximum inventory level of product m for retailer k | |

| Minimum inventory level of product m for retailer k |

Decision Variables

| A binary variable that equals 1 if supplier i is active; otherwise, 0 | |

| A binary variable that equals 1 if factory j is active; otherwise, 0 | |

| A binary variable that equals 1 if retailer k is active; otherwise, 0 | |

| A binary variable that equals 1 if supplier i delivers raw material n to factory j; otherwise, 0 | |

| A binary variable that equals 1 if factory j delivers product m to retailer k; otherwise, 0 | |

| A binary variable that equals 1 if retailer k delivers product m to customer l; otherwise, 0 | |

| A binary variable that equals 1 if RFID technology is installed at customer node l; otherwise, 0 | |

| A binary variable that equals 1 if WSN technology is used at customer node l; otherwise, 0 | |

| A binary variable that equals 1 if RFID technology is installed at retailer node k; otherwise, 0 | |

| A binary variable that equals 1 if WSN technology is used at retailer node k; otherwise, 0 | |

| A binary variable that equals 1 if RFID technology is installed at supplier node i; otherwise, 0 | |

| A binary variable that equals 1 if WSN technology is used at supplier node i; otherwise, 0 | |

| Quantity of raw material n transported from supplier i to factory j with blockchain | |

| Quantity of raw material n transported from supplier i to factory j without blockchain | |

| Quantity of product m transported from factory j to retailer k with blockchain | |

| Quantity of product m transported from factory j to retailer k without blockchain | |

| Quantity of product m transported from retailer k to customer l with blockchain | |

| Quantity of product m transported from retailer k to customer l without blockchain | |

| A binary variable that equals 1 if blockchain is used for supplier i; otherwise, 0 | |

| A binary variable that equals 1 if blockchain is used for factory j; otherwise, 0 | |

| A binary variable that equals 1 if blockchain is used for retailer k; otherwise, 0 | |

| A binary variable that equals 1 if online sales are used for retailer k; otherwise, 0 | |

| The sales quantity of product m through online sales for retailer k | |

| Inventory level of product m for retailer k | |

| Initial inventory level of product m for retailer k | |

| Optimal replenishment level of product m under VMI policy for retailer k |

References

- Abdel-Basset, M.; Manogaran, G.; Mohamed, M. Internet of Things (IoT) and its impact on supply chain: A framework for building smart, secure and efficient systems. Future Gener. Comput. Syst. 2018, 86, 614–628. [Google Scholar] [CrossRef]

- Yu, J.; Subramanian, N.; Ning, K.; Edwards, D. Product delivery service provider selection and customer satisfaction in the era of internet of things: A Chinese e-retailers’ perspective. Int. J. Prod. Econ. 2015, 159, 104–116. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Y.F.; Zang, D.X. Real-Time Visibility and Traceability Framework for Discrete Manufacturing Shopfloor. In Proceedings of the 22nd International Conference on Industrial Engineering and Engineering Management 2015; Qi, E., Shen, J., Dou, R., Eds.; Atlantis Press: Paris, France, 2016; pp. 763–772. [Google Scholar]

- Fang, C.; Liu, X.; Pardalos, P.M.; Pei, J. Optimization for a three-stage production system in the Internet of Things: Procurement, production and product recovery, and acquisition. Int. J. Adv. Manuf. Technol. 2016, 83, 689–710. [Google Scholar] [CrossRef]

- Leung, J.; Cheung, W.; Chu, S.-C. Aligning RFID applications with supply chain strategies. Inf. Manag. 2014, 51, 260–269. [Google Scholar] [CrossRef]

- Rejeb, A.; Simske, S.; Rejeb, K.; Treiblmaier, H.; Zailani, S. Internet of Things Re-search in Supply Chain Management and Logistics: A Bibliometric Analysis. Internet Things 2020, 12, 100318. [Google Scholar] [CrossRef]

- Ng, I.C.L.; Wakenshaw, S.Y.L. The Internet-of-Things: Review and research directions. Int. J. Res. Mark. 2017, 34, 3–21. [Google Scholar] [CrossRef]

- Feng, H.; Wang, X.; Duan, Y.; Zhang, J.; Zhang, X. Applying blockchain technology to improve agri-food traceability: A review of development methods, benefits and challenges. J. Clean. Prod. 2020, 260, 121031. [Google Scholar] [CrossRef]

- Aung, M.M.; Chang, Y.S. Traceability in a food supply chain: Safety and quality perspectives. Food Control. 2014, 39, 172–184. [Google Scholar] [CrossRef]

- Bandyopadhyay, D.; Sen, J. Internet of Things: Applications and Challenges in Technology and Standardization. Wirel. Pers. Commun. 2011, 58, 49–69. [Google Scholar] [CrossRef]

- Macaulay, T. Understanding and Managing Risks and the Internet of Things, RIoT Control; Morgan Kaufmann: San Francisco, CA, USA, 2016. [Google Scholar]

- Christopher, M. The Agile Supply Chain. Ind. Mark. Manag. 2000, 29, 37–44. [Google Scholar] [CrossRef]

- Greengard, S. Putting the Internet of Things to Work. In The Internet of Things; MIT Press: Cambridge, MA, USA, 2015; pp. 111–134. Available online: https://ieeexplore.ieee.org/document/7087520 (accessed on 1 January 2015).

- Lee, I.; Lee, K. The Internet of Things (IoT): Applications, Investments, and Challenges for Enterprises. Bus. Horiz. 2015, 58, 431–440. Available online: https://linkinghub.elsevier.com/retrieve/pii/S0007681315000373 (accessed on 1 July 2015). [CrossRef]

- Fleisch, E. What Is the Internet of Things An Economic Perspective. Econ. Manag. Financ. Mark. 2010, 5, 125–157. [Google Scholar]

- Tavan, F.; Sajadi, S.M. Determination of optimum of production rate of Network failure-prone manufacturing systems with perishable items using discrete event simulation and Taguchi design of experiment. Asian J. Res. Bus. Econ. Manag. 2015, 5, 126–139. [Google Scholar] [CrossRef]

- Yerpude, S.; Singhal, T.K. Augmentation of effectiveness of vendor managed inventory (VMI) operations with IoT Data—A research perspective. Int. J. Appl. Bus. Econ. Res. 2017, 15, 469–482. [Google Scholar]

- Chen, Q.; Adey, B.T.; Haas, C.; Hall, D.M. Using look-ahead plans to improve material flow processes on construction projects when using BIM and RFID technologies. Constr. Innov. 2020, 20, 471–508. [Google Scholar] [CrossRef]

- Rayes, A.; Salam, S. The Things in IoT: Sensors and Actuators. In Internet of Things from Hype to Reality: The Road to Digitization; Springer International Publishing: Cham, Switzerland, 2022; pp. 63–82. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, G. Optimization of the Intelligent Asset Management System Based on WSN and RFID Technology. J. Sens. 2022, 2022, 3436530. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J. Blockchains and the Supply Chain: Findings from a Broad Study of Practitioners. IEEE Eng. Manag. Rev. 2019, 47, 95–103. [Google Scholar] [CrossRef]

- Harrison, M. The ‘Internet of Things’ and Commerce. XRDS 2011, 17, 19–22. [Google Scholar] [CrossRef]

- Shen, G.; Liu, B. Research on Application of Internet of Things in Electronic Commerce. In Proceedings of the Third International Symposium on Electronic Commerce and Security, Guangzhou, China, 29–31 July 2010; pp. 13–16. [Google Scholar]

- Hatami-Marbini, A.; Sajadi, S.M.; Malekpour, H. Optimal control and simulation for production planning of network failure-prone manufacturing systems with perishable goods. Comput. Ind. Eng. 2020, 146, 106614. [Google Scholar] [CrossRef]

- Malekpour, H.; Sajadi, S.M.; Vahdani, H. Using discrete-event simulation and the Taguchi method for optimising the production rate of network failure-prone manufacturing systems with perishable goods. Int. J. Serv. Oper. Manag. 2016, 23, 387–406. [Google Scholar] [CrossRef]

- Garrido-Hidalgo, C.; Olivares, T.; Ramirez, F.J.; Roda-Sanchez, L. An End-to-End Internet of Things Solution for Reverse Supply Chain Management in Industry 4.0. Comput. Ind. 2019, 112, 103127. [Google Scholar] [CrossRef]

- Xu, L.D.; He, W.; Li, S. Internet of Things in Industries: A Survey. IEEE Trans. Ind. Inform. 2014, 10, 2233–2243. [Google Scholar] [CrossRef]

- Lee, C.; Lv, Y.; Ng, K.; Ho, W.; Choy, K. Design and application of Internet of things-based warehouse management system for smart logistics. Int. J. Prod. Res. 2018, 56, 2753–2768. [Google Scholar] [CrossRef]

- Tsang, Y.P.; Wu, C.H.; Lam, H.Y.; Choy, K.L.; Ho, G.T.S. Integrating Internet of Things and multi-temperature delivery planning for perishable food E-commerce logistics: A model and application. Int. J. Prod. Res. 2021, 59, 1534–1556. [Google Scholar] [CrossRef]

- Zhu, Q.; Kouhizadeh, M. Blockchain Technology, Supply Chain Information, and Strategic Product Deletion Management. IEEE Eng. Manag. Rev. 2019, 47, 36. [Google Scholar] [CrossRef]

- Cai, S.; Wang, X.; Zhao, Y. Revenue Model of Supply Chain by Internet of Things Technology. IEEE Access 2019, 7, 4091–4100. [Google Scholar]

- Tian, F. An Agri-Food Supply Chain Traceability System for China Based on RFID Amp; Blockchain Technology. In Proceedings of the 2016 13th International Conference on Service Systems and Service Management (ICSSSM), Kunming, China, 24–26 June 2016; pp. 1–6. [Google Scholar]

- Tan, W.C.; Sidhu, M.S. Review of RFID and IoT Integration in Supply Chain Management. Oper. Res. Perspect. 2022, 9, 100229. Available online: https://www.sciencedirect.com/science/article/pii/S2214716022000070 (accessed on 1 January 2022). [CrossRef]

- Francisco, K.; Swanson, D. The Supply Chain Has No Clothes: Technology Adoption of Blockchain for Supply Chain Transparency. Logistics 2018, 2, 2. [Google Scholar] [CrossRef]

- Mohammadi, T.; Sajadi, S.M.; Najafi, S.E.; Taghizadeh Yazdi, M. Optimizing Smart Supply Chain with Vendor Managed Inventory through the Internet of Things. Ind. Manag. J. 2022, 14, 458–483. [Google Scholar]

- Singh, S.; Kumar, M.; Verma, O.P.; Kumar, R.; Gill, S.S. An IIoT based secure and sustainable smart supply chain system using sensor networks. Trans. Emerg. Telecommun. Technol. 2023, 34, e4681. [Google Scholar] [CrossRef]

- Singh, A.K.; Raza, Z. A framework for IoT and blockchain based smart food chain management system. Concurr. Comput. Pract. Exp. 2023, 35, e7526. [Google Scholar] [CrossRef]

- Alabi, M.O.; Ngwenyama, O. Food security and disruptions of the global food supply chains during COVID-19: Building smarter food supply chains for post COVID-19 era. Br. Food J. 2023, 125, 167–185. [Google Scholar] [CrossRef]

- Nanda, S.K.; Panda, S.K.; Dash, M. Medical supply chain integrated with blockchain and IoT to track the logistics of medical products. Multimed. Tools Appl. 2023, 82, 32917–32939. [Google Scholar] [CrossRef]

- Khan, Y.; Su’ud, M.B.M.; Alam, M.M.; Ahmad, S.F.; Ahmad, A.Y.A.B.; Khan, N. Application of Internet of Things (IoT) in Sustainable Supply Chain Management. Sustainability 2023, 15, 694. [Google Scholar] [CrossRef]

- Hu, H.; Xu, J.; Liu, M.; Lim, M.K. Vaccine supply chain management: An intelligent system utilizing blockchain, IoT and machine learning. J. Bus. Res. 2023, 156, 113480. [Google Scholar] [CrossRef]

- Jayashri, N.; Rampur, V.; Gangodkar, D.; Abirami, M.; Balarengadurai, C.; Kumar, A. Improved block chain system for high secured IoT integrated supply chain. Meas. Sens. 2023, 25, 100633. [Google Scholar] [CrossRef]

- Mantravadi, S.; Srai, J.S. How Important are Digital Technologies for Urban Food Security? A Framework for Supply Chain Integration using IoT. Procedia Comput. Sci. 2023, 217, 1678–1687. [Google Scholar] [CrossRef]

- Nagarajan, S.M.; Deverajan, G.G.; Chatterjee, P.; Alnumay, W.; Muthukumaran, V. Integration of IoT based routing process for food supply chain management in sustainable smart cities. Sustain. Cities Soc. 2022, 76, 103448. [Google Scholar] [CrossRef]

- Bhat, S.A.; Huang, N.-F.; Sofi, I.B.; Sultan, M. Agriculture-Food Supply Chain Management Based on Blockchain and IoT: A Narrative on Enterprise Blockchain Interoperability. Agriculture 2022, 12, 40. [Google Scholar] [CrossRef]

- Santhi, A.R.; Muthuswamy, P. Influence of Blockchain Technology in Manufacturing Supply Chain and Logistics. Logistics 2022, 6, 15. [Google Scholar] [CrossRef]

- Kaur, A.; Singh, G.; Kukreja, V.; Sharma, S.; Singh, S.; Yoon, B. Adaptation of IoT with Blockchain in Food Supply Chain Management: An Analysis-Based Review in Development, Benefits and Potential Applications. Sensors 2022, 22, 8174. [Google Scholar] [CrossRef]

- Kumar, S.; Raut, R.D.; Agrawal, N.; Cheikhrouhou, N.; Sharma, M.; Daim, T. Integrated blockchain and internet of things in the food supply chain: Adoption barriers. Technovation 2022, 118, 102589. [Google Scholar] [CrossRef]

- Kavisankar, L.; Sivakumar, V.; Balachander, T.; Mukesh Krishnan, M.B.; Deeban Chakravarthy, V.; Selvin Paul Peter, J.; Balasubramani, S. An Efficient Trust-Based Supply Chain Management Framework Utilizing the Internet of Things and Blockchain Technology. In Implementing and Leveraging Blockchain Programming; Rawal, B.S., Manogaran, G., Poongodi, M., Eds.; Springer Nature: Singapore, 2022; pp. 149–160. [Google Scholar] [CrossRef]

- Srivastava, A.; Dashora, K. Application of blockchain technology for agrifood supply chain management: A systematic literature review on benefits and challenges. Benchmarking Int. J. 2022, 29, 3426–3442. [Google Scholar] [CrossRef]

- Ali, S.B. Industrial Revolution 4.0 and Supply Chain Digitization. South Asian J. Soc. Rev. 2022, 1, 21–41. [Google Scholar] [CrossRef]

- Zhu, X.N.; Peko, G.; Sundaram, D.; Piramuthu, S. Blockchain-Based Agile Supply Chain Framework with IoT. Inf. Syst. Front. 2021, 24, 563–578. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, Z.; Wang, H.; Yi, Y.; Zhang, Y. Optimization of monitoring network system for Eco safety on Internet of Things platform and environmental food supply chain. Comput. Commun. 2020, 151, 320–330. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. A Supply Chain Transparency and Sustainability Technology Appraisal Model for Blockchain Technology. Int. J. Prod. Res. 2020, 58, 2142–2162. [Google Scholar] [CrossRef]

- Jiang, W. An Intelligent Supply Chain Information Collaboration Model Based on Internet of Things and Big Data. IEEE Access 2019, 7, 58324–58335. [Google Scholar] [CrossRef]

- Rejeb, A.; Keogh, J.G.; Treiblmaier, H. Leveraging the Internet of Things and Blockchain Technology in Supply Chain Management. Futur. Internet 2019, 11, 161. [Google Scholar] [CrossRef]

- Pundir, A.K.; Jagannath, J.D.; Chakraborty, M.; Ganpathy, L. Technology Integration for Improved Performance: A Case Study in Digitization of Supply Chain with Integration of Internet of Things and Blockchain Technology. In Proceedings of the 2019 IEEE 9th Annual Computing and Communication Workshop and Conference (CCWC), Las Vegas, NV, USA, 7–9 January 2019; pp. 170–176. [Google Scholar] [CrossRef]

- Mohan, T. Improve Food Supply Chain Traceability Using Blockchain. Master’s Thesis, College of Engineering, The Graduate School, The Pennsylvania State University, State College, PA, USA, 2018. [Google Scholar]

- Mirjalili, S.; Saremi, S.; Mirjalili, S.M.; Coelho, L.D.S. Multi-objective grey wolf optimizer: A novel algorithm for multi-criterion optimization. Expert Syst. Appl. 2016, 47, 106–119. [Google Scholar] [CrossRef]

- Bhesdadiya, R.H.; Trivedi, I.N.; Jangir, P.; Jangir, N.; Kumar, A. An NSGA-III algorithm for solving multi-objective economic/environmental dispatch problem. Cogent Eng. 2016, 3, 1269383. [Google Scholar] [CrossRef]

- Kumawat, I.R.; Nanda, S.J.; Maddila, R.K. Multi-objective whale optimization. In Proceedings of the TENCON 2017—2017 IEEE Region 10 Conference, Penang, Malaysia, 5–8 November 2017; pp. 2747–2752. [Google Scholar]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).