Deviance and Pearson Residuals-Based Control Charts with Different Link Functions for Monitoring Logistic Regression Profiles: An Application to COVID-19 Data

Abstract

:1. Introduction

2. The GLM-Based Control Charts

3. Structure of the Control Charts

3.1. Logistic Regression Model-Based Control Chart Based on PR

3.2. Logistic Regression Model-Based Control Chart Based on DR

4. Monte Carlo Simulation Study

4.1. Performance Measures

4.2. Data Generation

4.3. Algorithm for Charting Constants

- Set the arbitrary value as a charting constant and set regression coefficients as and ;

- Generate 1000 observations of the input variable (x) from the uniform distribution;

- The mean of the logistic response variable () is determined for each observation using Equation (2);

- The response variable is generated from the Bernoulli distribution with parameter defined in step ii;

- Fit the logistic regression model and obtain the residuals DR and PR;

- For the control charts based on PR and DR, calculate the mean and standard error of DR and PR, respectively;

- Determine the UCL and LCL of each proposed control chart using steps (i) and (vi). Plot the PR and DR against their respective limits;

- To obtain specified , repeat steps i–vii, 10,000 times.

4.4. Results and Discussion

Monitoring and in Terms of ARL

5. Application: COVID-19 Deaths Profile Monitoring

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mahmood, T.; Xie, M. Models and monitoring of zero-inflated processes: The past and current trends. Qual. Reliab. Eng. Int. 2019, 35, 2540–2557. [Google Scholar] [CrossRef]

- Shewhart, W.A. Economic Control of Quality of Manufactured Product; Macmillan And Co., Ltd.: London, UK, 1931. [Google Scholar]

- Page, E.S. Continuous inspection schemes. Biometrika 1954, 41, 100–115. [Google Scholar] [CrossRef]

- Roberts, S.W. Control chart tests based on geometric moving averages. Technometrics 2000, 42, 97–101. [Google Scholar] [CrossRef]

- Zhu, J.; Lin, D.K. Monitoring the slopes of linear profiles. Qual. Eng. 2009, 22, 1–12. [Google Scholar] [CrossRef]

- Nelder, J.A.; Weddernburn, R.W.M. Generalized linear models. J. R. Stat. Soc. Ser. A 1972, 135, 370–384. [Google Scholar] [CrossRef]

- Skinner, K.R.; Montgomery, D.C.; Runger, G.C. Process monitoring for multiple count data using generalized linear model-based control charts. Int. J. Prod. Res. 2003, 41, 1167–1180. [Google Scholar] [CrossRef]

- Jearkpaporn, D.; Montgomery, D.C.; Runger, G.C.; Borror, C.M. Process monitoring for correlated gamma-distributed data using generalized-linear-model-based control charts. Qual. Reliab. Eng. Int. 2003, 19, 477–491. [Google Scholar] [CrossRef]

- Skinner, K.R.; Montgomery, D.C.; Runger, G.C. Generalized linear model-based control charts for discrete semiconductor process data. Qual. Reliab. Eng. Int. 2004, 20, 777–786. [Google Scholar] [CrossRef]

- Koosha, M.; Amiri, A. The effect of link function on the monitoring of logistic regression profiles. In Proceedings of the World Congress on Engineering 2011, London, UK, 6–8 July 2011. [Google Scholar]

- Shu, L.; Tsui, K.L.; Tsung, F. Regression Control Charts. Encyclopedia of Statistics in Quality and Reliability. 2008. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/9780470061572.eqr260 (accessed on 15 January 2023).

- Asgari, A.; Amiri, A.; Niaki, S.T.A. A new link function in GLM-based control charts to improve monitoring of two-stage processes with Poisson response. Int. J. Adv. Manuf. Technol. 2014, 72, 1243–1256. [Google Scholar] [CrossRef]

- Amiri, A.; Koosha, M.; Azhdari, A.; Wang, G. Phase I monitoring of generalized linear model-based regression profiles. J. Stat. Comput. Simul. 2015, 85, 2839–2859. [Google Scholar] [CrossRef]

- Amiri, A.; Yeh, A.B.; Asgari, A. Monitoring two-stage processes with binomial data using generalized linear model-based control charts. Qual. Technol. Quant. Manag. 2016, 13, 241–262. [Google Scholar] [CrossRef]

- Qi, D.; Wang, Z.; Zi, X.; Li, Z. Phase II monitoring of generalized linear profiles using weighted likelihood ratio charts. Comput. Ind. Eng. 2016, 94, 178–187. [Google Scholar] [CrossRef]

- Moheghi, H.R.; Noorossana, R.; Ahmadi, O. GLM profile monitoring using robust estimators. Qual. Reliab. Eng. Int. 2021, 37, 664–680. [Google Scholar] [CrossRef]

- Kinat, S.; Amin, M.; Mahmood, T. GLM-based control charts for the inverse Gaussian distributed response variable. Qual. Reliab. Eng. Int. 2020, 36, 765–783. [Google Scholar] [CrossRef]

- García-Bustos, S.; Zambrano, G. Control charts for health surveillance based on residuals of negative binomial regression. Qual. Reliab. Eng. Int. 2022, 38, 2521–2532. [Google Scholar] [CrossRef]

- Hakimi, A.; Amiri, A.; Kamranrad, R. Robust approaches for monitoring logistic regression profiles under outliers. Int. J. Qual. Reliab. Manag. 2017, 34, 494–507. [Google Scholar] [CrossRef]

- Kim, J.-M.; Ha, I.D. Deep learning-based residual control chart for count data. Qual. Eng. 2022, 34, 370–381. [Google Scholar] [CrossRef]

- Mahmood, T.; Iqbal, A.; Abbasi, S.A.; Amin, M. Efficient GLM-based control charts for Poisson processes. Qual. Reliab. Eng. Int. 2022, 38, 389–404. [Google Scholar] [CrossRef]

- Soleimani, P.; Asadzadeh, S. Effect of non-normality on the monitoring of simple linear profiles in two-stage processes: A remedial measure for gamma-distributed responses. J. Appl. Stat. 2022, 49, 2870–2890. [Google Scholar] [CrossRef]

- Yeganeh Chukhrova, N.; Johannssen, A.; Fotuhi, H. A network surveillance approach using machine learning based control charts. Expert Syst. Appl. 2023, 219, 119660. [Google Scholar] [CrossRef]

- Yu, J.; Liu, J. LRProb control chart based on logistic regression for monitoring mean shifts of auto-correlated manufacturing processes. Int. J. Prod. Res. 2011, 49, 2301–2326. [Google Scholar] [CrossRef]

- Khosravi, P.; Amiri, A. Self-Starting control charts for monitoring logistic regression profiles. Commun. Stat.-Simul. Comput. 2019, 48, 1860–1871. [Google Scholar] [CrossRef]

- Alevizakos, V.; Koukouvinos, C.; Lappa, A. Comparative study of the Cp and Spmk indices for logistic regression profile using different link functions. Qual. Eng. 2019, 31, 453–462. [Google Scholar] [CrossRef]

- Jahani, K.; Feili, H.; Ohadi, F. Phase II monitoring of the nominal logistic regression profiles based on Wald and Rao score test statistics (a case study in healthcare: Diabetic patients). Int. J. Product. Qual. Manag. 2019, 27, 161–176. [Google Scholar] [CrossRef]

- Amin, M.; Mahmood, T.; Kinat, S. Memory type control charts with inverse-Gaussian response: An application to yarn manufacturing industry. Trans. Inst. Meas. Control 2021, 43, 656–678. [Google Scholar] [CrossRef]

- Akhtar, H.; Akhtar, S.; Rahman, F.U.; Afridi, M.; Khalid, S.; Ali, S.; Akhtar, N.; Khader, Y.S.; Ahmad, H.; Khan, M.M. An overview of the treatment options used for the management of COVID-19 in Pakistan: Retrospective Observational Study. JMIR Public Health Surve. 2021, 7, e28594. [Google Scholar] [CrossRef]

- Royal College of Physicians. National Early Warning Score (NEWS): Standardising the Assessment of Acute Illness Severity in the NHS; Report of a Working Party; RCP: London, UK, 2012. [Google Scholar]

| PR | DR | ||||||

|---|---|---|---|---|---|---|---|

| logit | probit | c-log-log | cauchit | logit | probit | c-log-log | cauchit |

| 1.045 | 1.0443 | 1.0462 | 1.0443 | 1.045 | 1.0443 | 1.0456 | 1.0457 |

| PR | DR | |||||||

|---|---|---|---|---|---|---|---|---|

| logit | probit | c-log-log | cauchit | logit | probit | c-log-log | cauchit | |

| 0 | 201.56 | 199.99 | 200.97 | 200.92 | 200.24 | 199.68 | 199.13 | 199.49 |

| 0.04 | 117.87 | 121.46 | 129.14 | 121.95 | 119.01 | 124.69 | 111.15 | 125.00 |

| 0.08 | 53.93 | 56.15 | 62.80 | 61.25 | 55.93 | 55.25 | 55.08 | 66.47 |

| 0.12 | 24.00 | 23.96 | 26.20 | 22.28 | 21.57 | 22.76 | 20.85 | 21.42 |

| 0.16 | 7.67 | 7.56 | 9.29 | 7.96 | 8.59 | 7.33 | 10.29 | 8.10 |

| 0.2 | 4.07 | 4.21 | 3.75 | 3.75 | 3.38 | 3.83 | 3.67 | 3.81 |

| 0.24 | 2.53 | 2.71 | 2.62 | 2.50 | 2.50 | 2.94 | 3.09 | 2.55 |

| 0.28 | 2.58 | 2.42 | 2.41 | 2.49 | 2.48 | 2.44 | 2.41 | 2.44 |

| PR | DR | |||||||

|---|---|---|---|---|---|---|---|---|

| logit | probit | c-log-log | cauchit | logit | probit | c-log-log | cauchit | |

| 0 | 201.09 | 201.69 | 199.03 | 199.27 | 200.86 | 200.36 | 200.31 | 199.38 |

| 0.04 | 188.83 | 152.21 | 162.73 | 153.03 | 190.78 | 149.65 | 177.08 | 153.47 |

| 0.08 | 121.46 | 127.65 | 137.29 | 117.82 | 122.48 | 110.83 | 123.97 | 122.37 |

| 0.12 | 84.68 | 77.35 | 68.47 | 89.39 | 85.48 | 77.45 | 89.37 | 79.77 |

| 0.16 | 55.09 | 44.39 | 56.99 | 45.46 | 55.61 | 48.50 | 47.45 | 54.95 |

| 0.2 | 31.51 | 29.45 | 32.36 | 36.05 | 31.61 | 30.97 | 37.22 | 27.83 |

| 0.24 | 15.24 | 14.28 | 20.94 | 16.72 | 15.37 | 13.17 | 13.21 | 15.89 |

| 0.28 | 10.47 | 10.13 | 9.99 | 10.81 | 10.67 | 8.03 | 11.10 | 12.70 |

| PR | DR | |||||||

|---|---|---|---|---|---|---|---|---|

| logit | probit | c-log-log | cauchit | logit | probit | c-log-log | cauchit | |

| 0 | 199.28 | 201.73 | 199.61 | 201.54 | 199.68 | 199.49 | 200.05 | 199.36 |

| 0.04 | 52.19 | 59.56 | 51.04 | 58.92 | 63.32 | 62.33 | 60.67 | 64.53 |

| 0.08 | 8.29 | 8.20 | 8.47 | 6.99 | 8.58 | 8.31 | 8.72 | 9.16 |

| 0.12 | 2.81 | 2.60 | 2.88 | 2.54 | 2.40 | 2.50 | 2.58 | 2.75 |

| 0.16 | 2.48 | 2.47 | 2.51 | 2.49 | 2.53 | 2.52 | 2.53 | 2.50 |

| 0.2 | 2.63 | 2.61 | 2.64 | 2.59 | 2.61 | 2.62 | 2.62 | 2.65 |

| 0.24 | 2.80 | 2.79 | 2.77 | 2.82 | 2.76 | 2.78 | 2.71 | 2.70 |

| 0.28 | 2.95 | 2.89 | 2.95 | 2.95 | 2.84 | 2.94 | 2.94 | 2.93 |

| Physiological Parameters | 3 | 2 | 1 | 0 | 1 | 2 | 3 |

|---|---|---|---|---|---|---|---|

| Respiration Rate | ≤8 | 9–11 | 12–20 | 21–24 | ≥25 | ||

| Oxygen Saturations | ≤91 | 92–93 | 94–95 | ≥96 | |||

| Any Supplemental Oxygen | Yes | No | |||||

| Temperature | ≤35.0 | 35.1–36.0 | 36.1–38.0 | 38.1–39.0 | ≥39.1 | ||

| Systolic Blood Pressure | ≤90 | 91–100 | 101–110 | 111–219 | ≥220 | ||

| Heart Rate | ≤40 | 41–50 | 51–90 | 91–110 | 111–130 | ≥131 | |

| Level of Consciousness | Alert | Voice, Pain, or Unconscious |

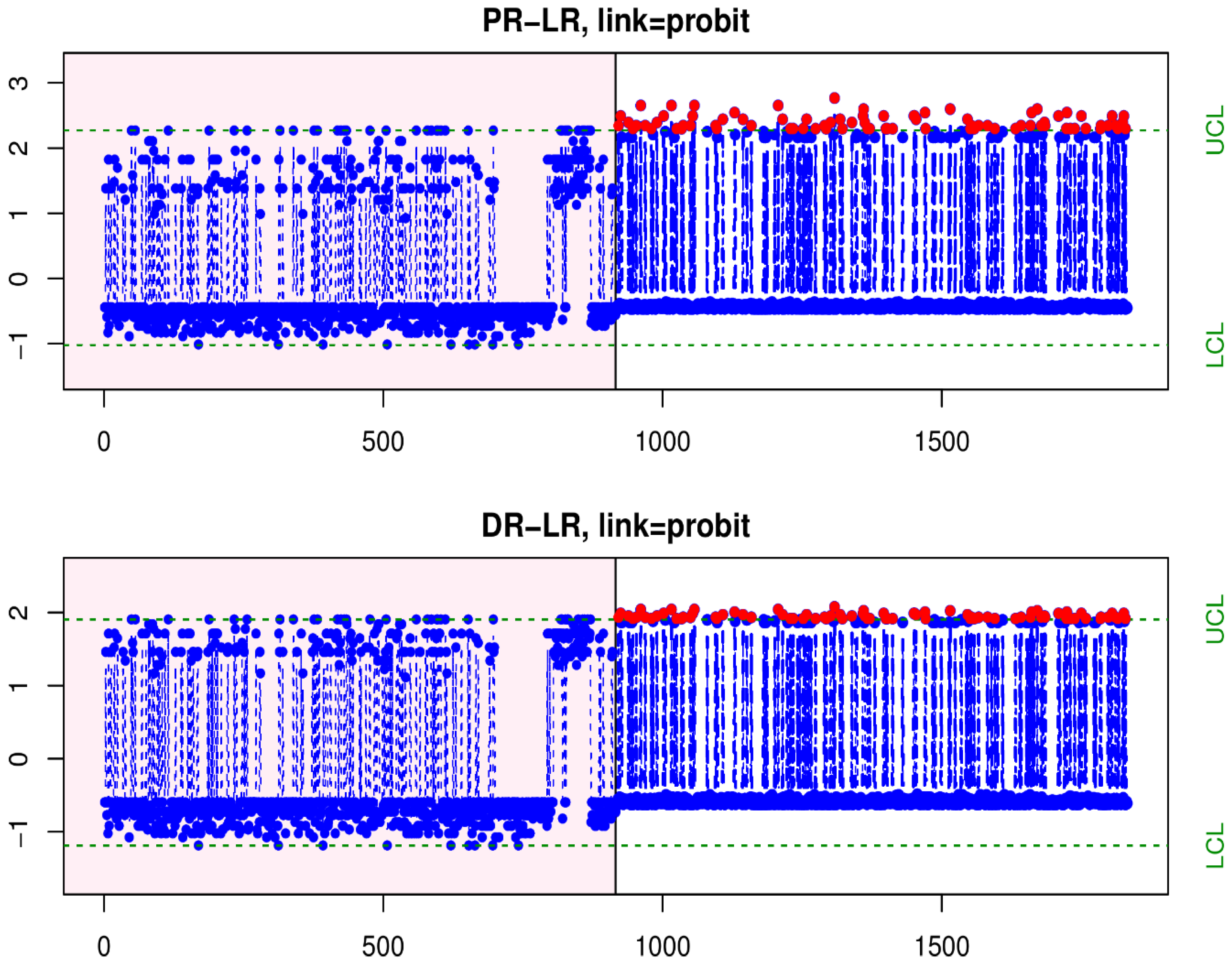

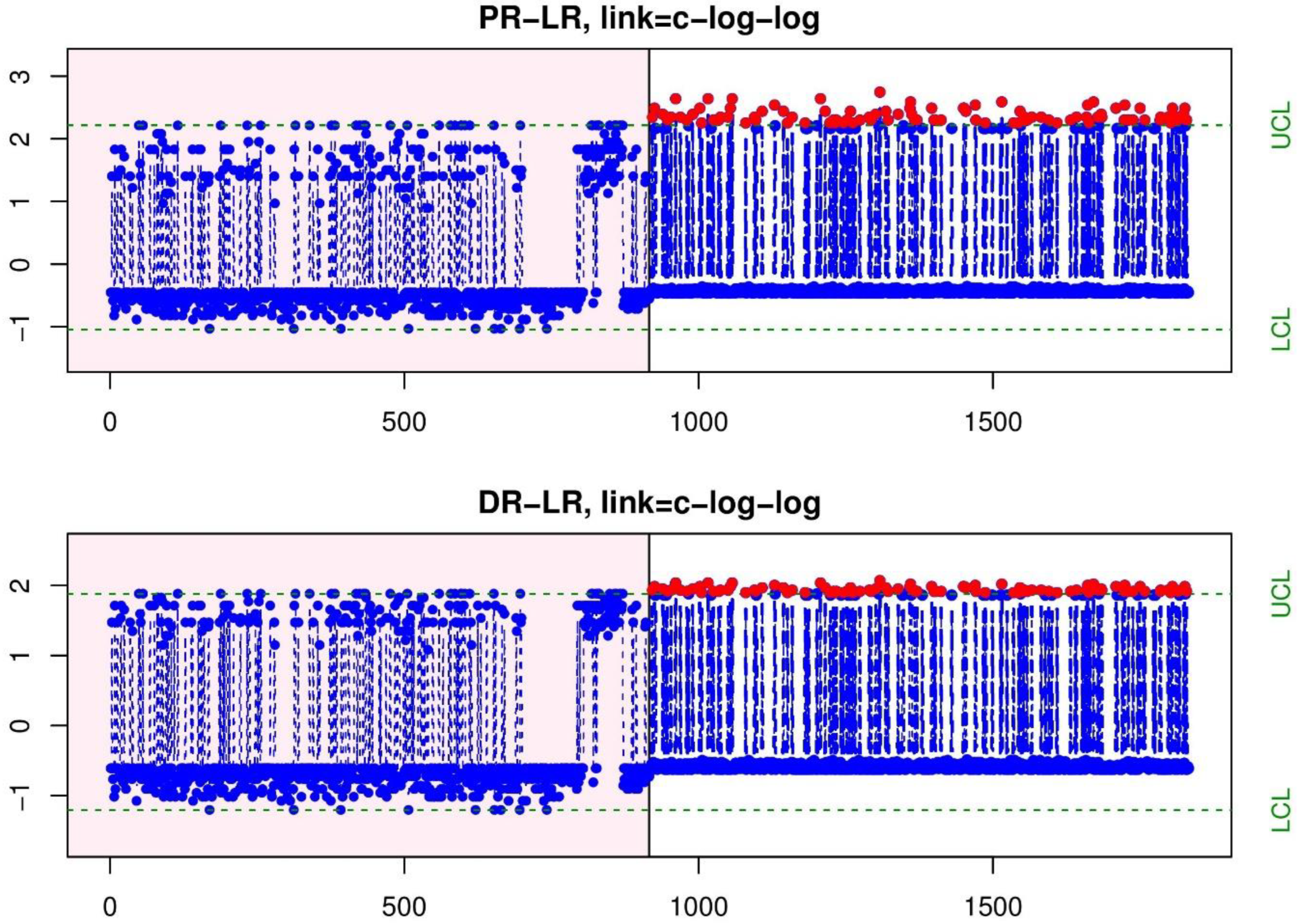

| Link Functions | logit | probit | c-log-log | cauchit | ||||

|---|---|---|---|---|---|---|---|---|

| Residuals | PR | DR | PR | DR | PR | DR | PR | DR |

| Mean | −0.0019 | −0.1476 | −0.0011 | −0.1468 | −0.0015 | −0.1473 | −0.0078 | −0.1529 |

| SD | 0.9971 | 1.0337 | 0.9979 | 1.034 | 0.9964 | 1.0345 | 0.9916 | 1.0352 |

| LCL | −1.0234 | −1.1939 | −1.0152 | −1.1873 | −1.0375 | −1.2051 | −1.0591 | −1.2222 |

| UCL | 2.256 | 1.899 | 2.277 | 1.9071 | 2.2192 | 1.8847 | 2.1154 | 1.8429 |

| OOC Signals | 83 | 97 | 83 | 83 | 97 | 97 | 144 | 144 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheema, M.; Amin, M.; Mahmood, T.; Faisal, M.; Brahim, K.; Elhassanein, A. Deviance and Pearson Residuals-Based Control Charts with Different Link Functions for Monitoring Logistic Regression Profiles: An Application to COVID-19 Data. Mathematics 2023, 11, 1113. https://doi.org/10.3390/math11051113

Cheema M, Amin M, Mahmood T, Faisal M, Brahim K, Elhassanein A. Deviance and Pearson Residuals-Based Control Charts with Different Link Functions for Monitoring Logistic Regression Profiles: An Application to COVID-19 Data. Mathematics. 2023; 11(5):1113. https://doi.org/10.3390/math11051113

Chicago/Turabian StyleCheema, Maryam, Muhammad Amin, Tahir Mahmood, Muhammad Faisal, Kamel Brahim, and Ahmed Elhassanein. 2023. "Deviance and Pearson Residuals-Based Control Charts with Different Link Functions for Monitoring Logistic Regression Profiles: An Application to COVID-19 Data" Mathematics 11, no. 5: 1113. https://doi.org/10.3390/math11051113

APA StyleCheema, M., Amin, M., Mahmood, T., Faisal, M., Brahim, K., & Elhassanein, A. (2023). Deviance and Pearson Residuals-Based Control Charts with Different Link Functions for Monitoring Logistic Regression Profiles: An Application to COVID-19 Data. Mathematics, 11(5), 1113. https://doi.org/10.3390/math11051113