A Particle Reinforced Gradient Honeycomb Sandwich Panel for Broadband Sound Insulation

Abstract

1. Introduction

2. Theory

2.1. Equivalent Parameters of Particle Reinforced Composites

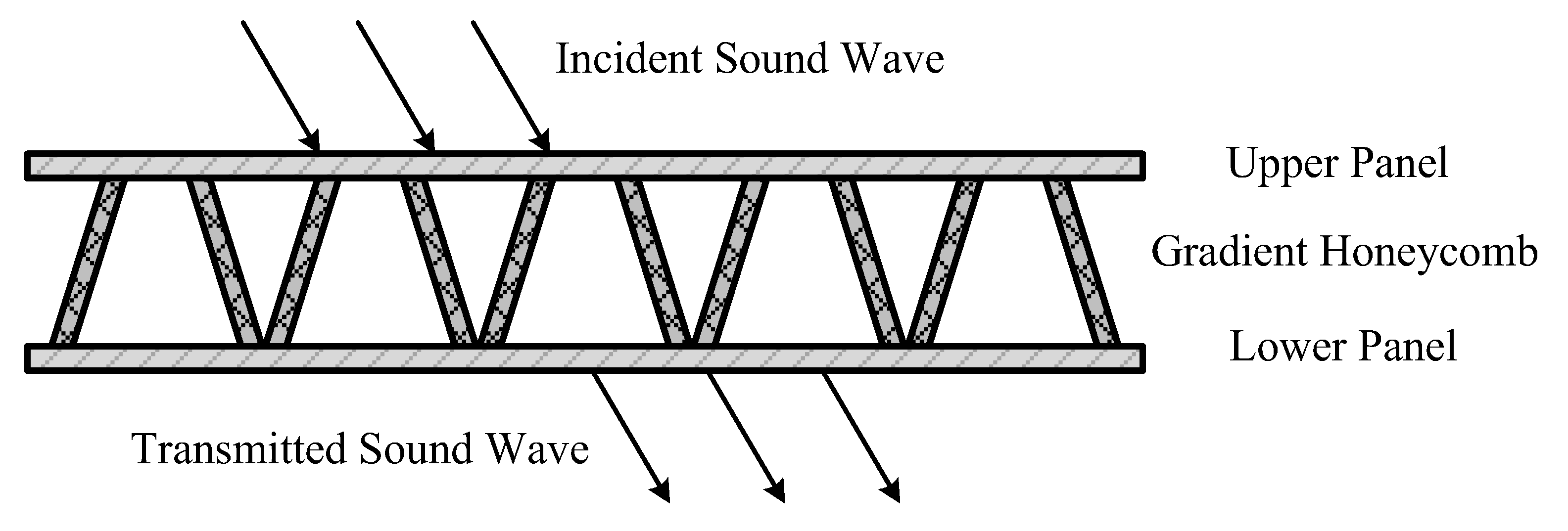

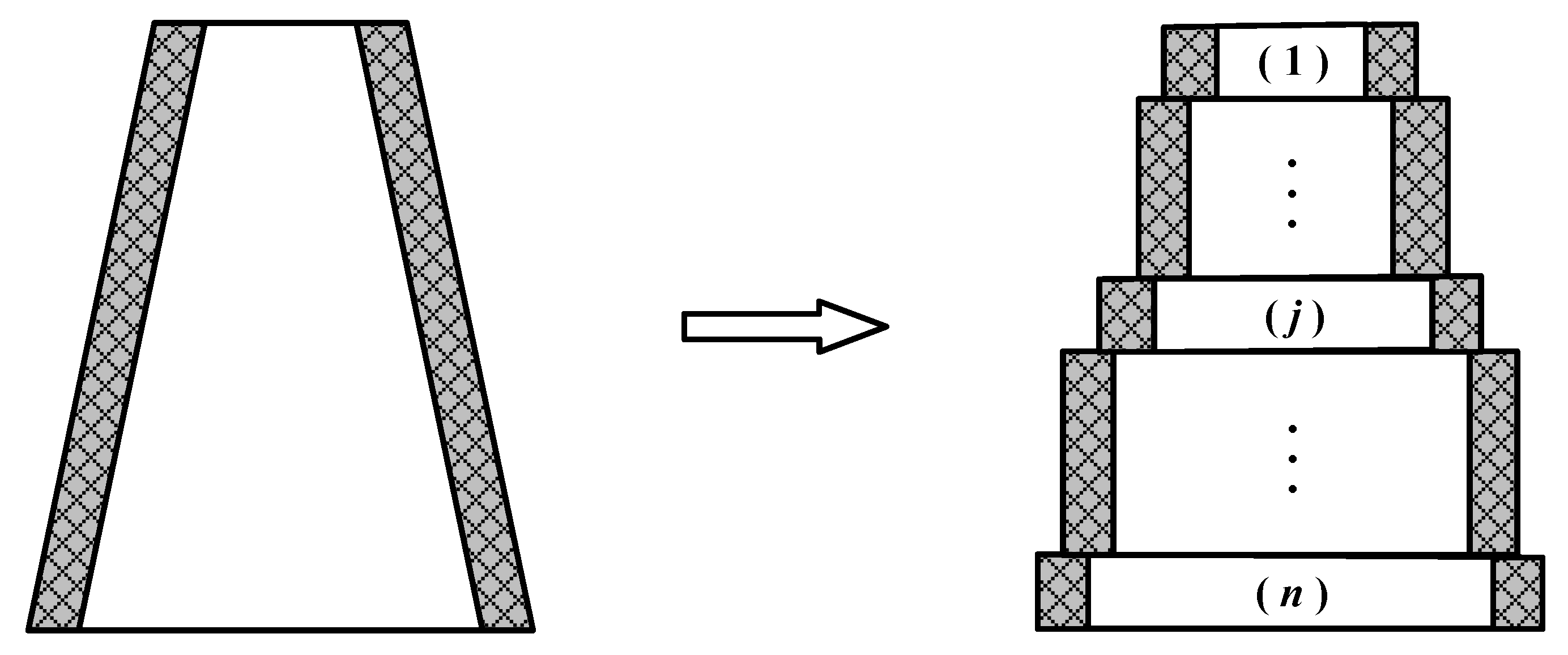

2.2. Sound Insulation Theory of Honeycomb Sandwich Panel

3. Foundation and Validation of Theoretical Analysis

3.1. Parameter Characteristics and Preconditions of Model Application

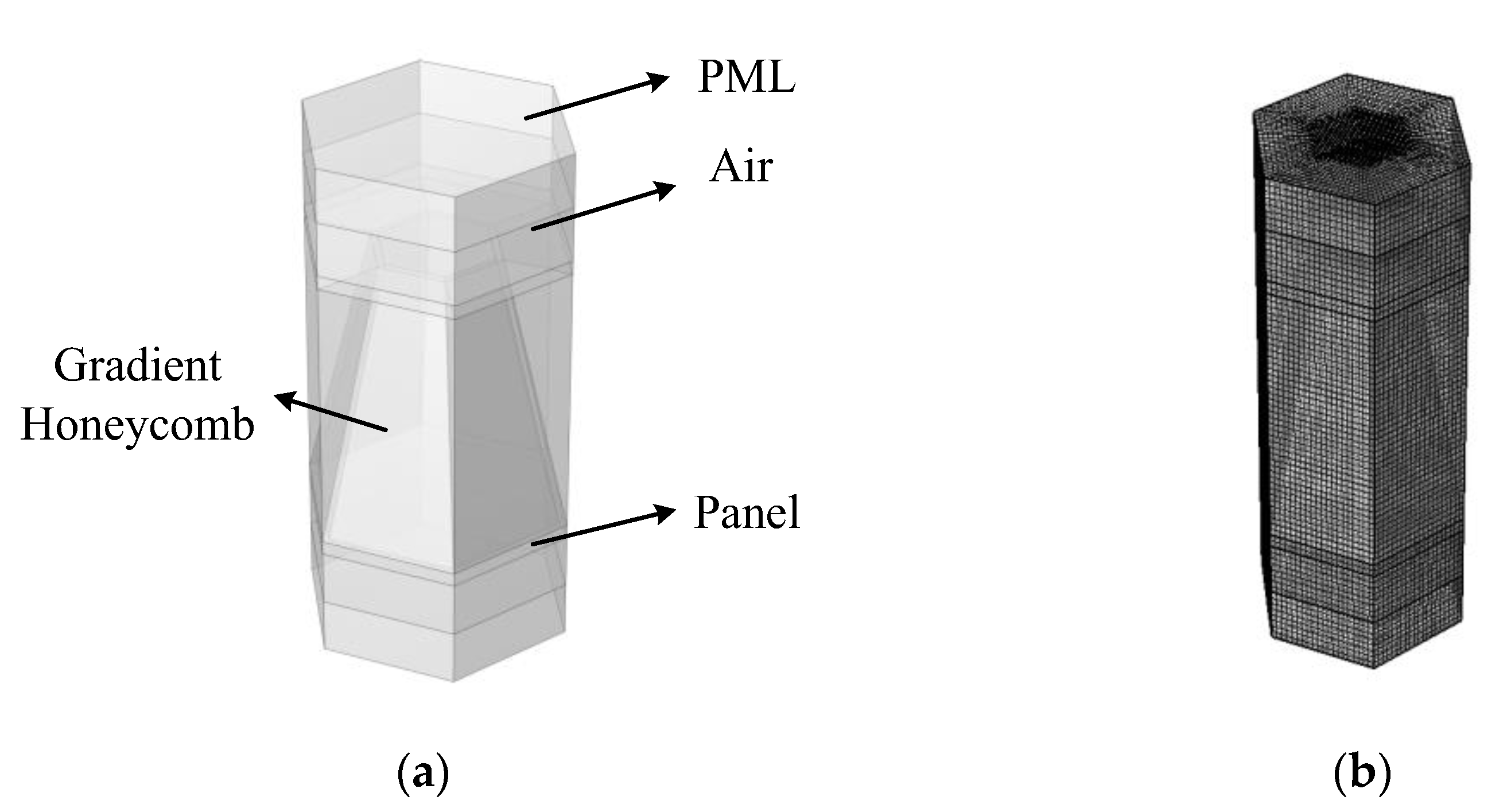

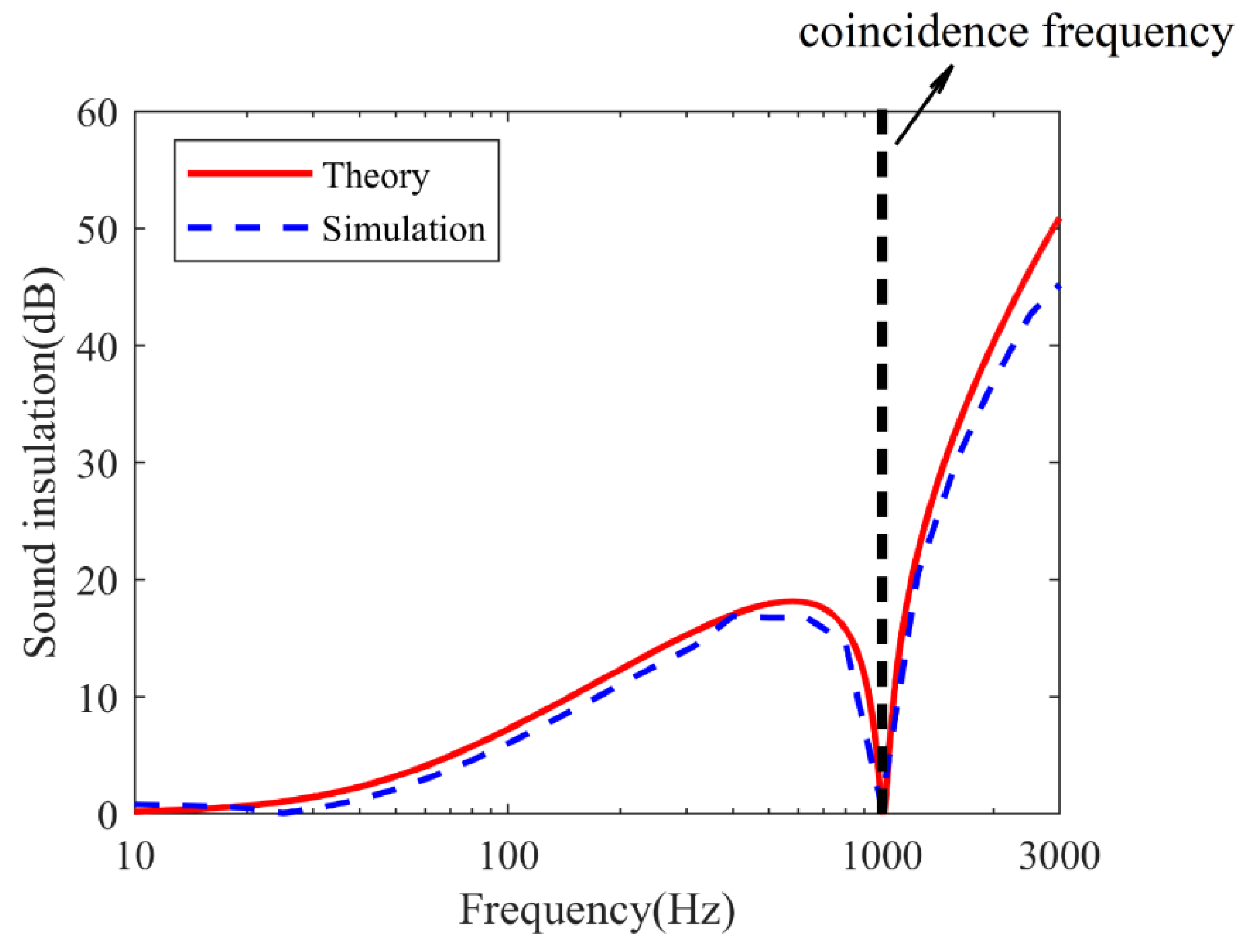

3.2. Model Validation

4. Parameter Research and Discussion

4.1. Influence of Geometric Parameters of Honeycomb

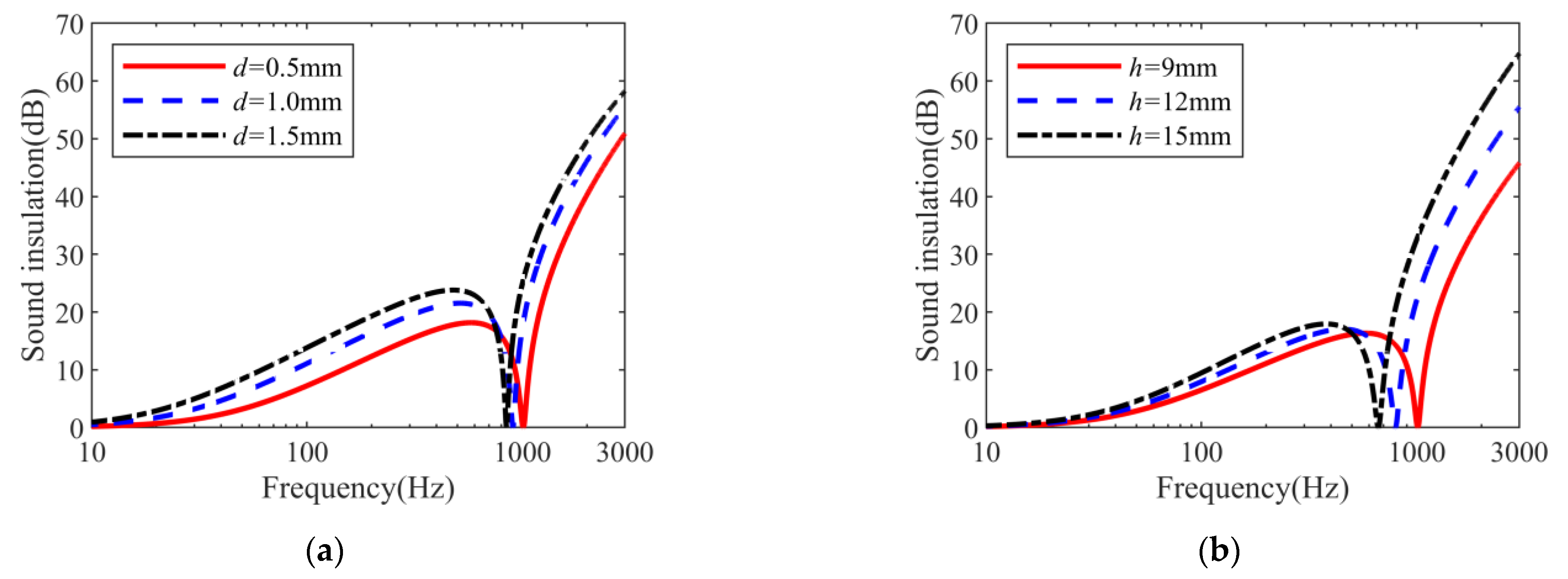

4.1.1. Effects of Panel Thickness and Core Height

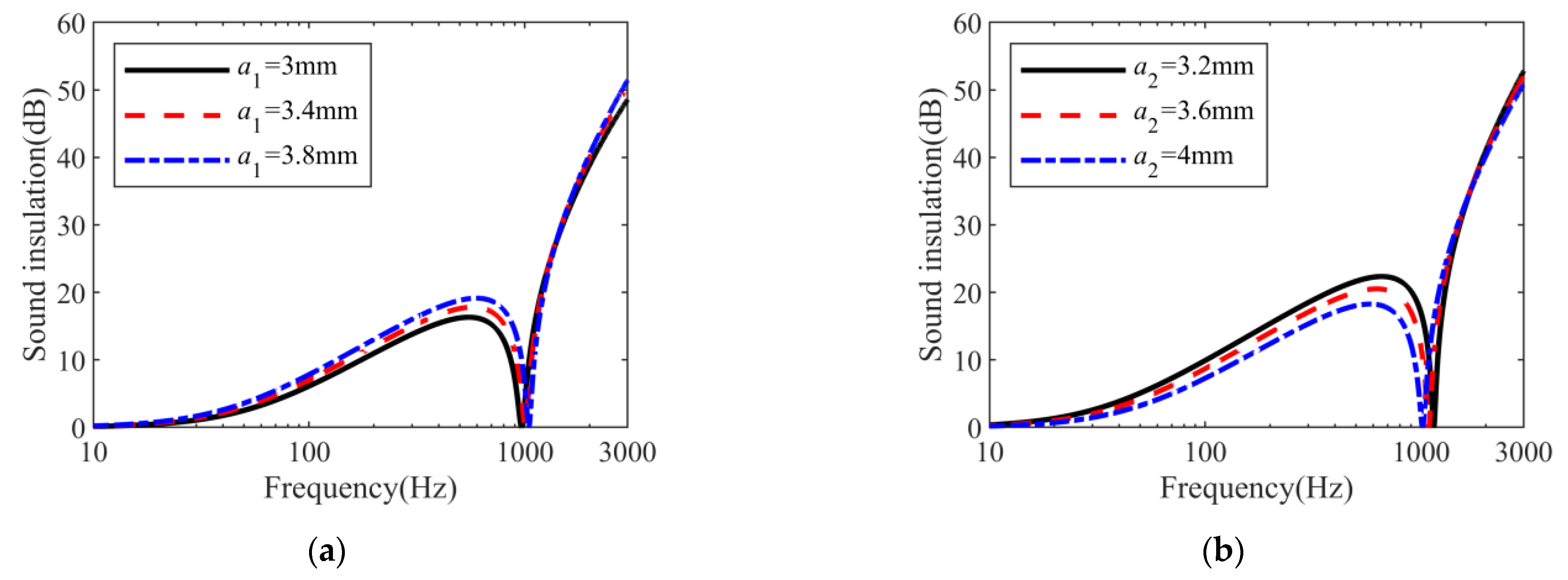

4.1.2. Effects of Honeycomb Side Length

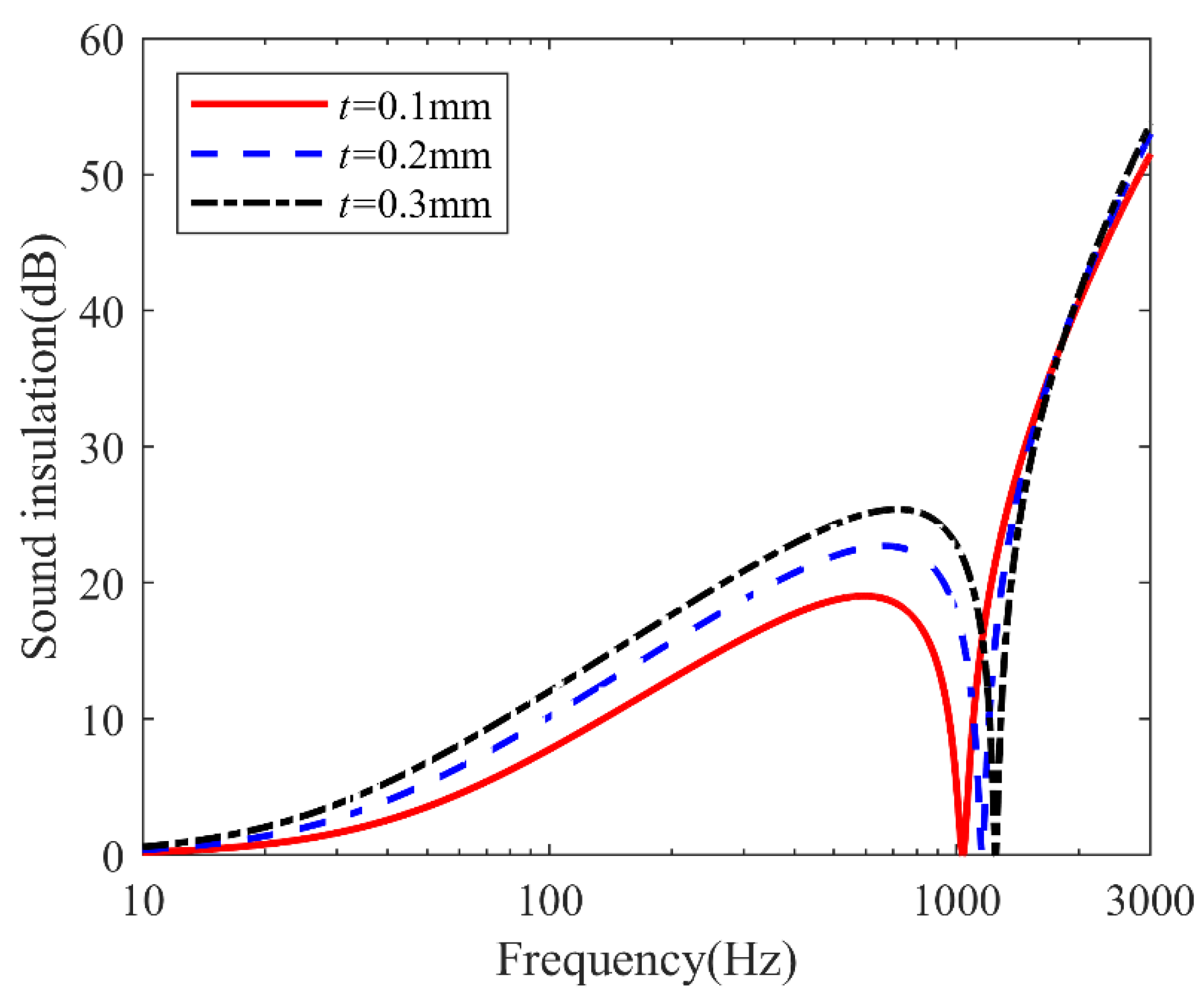

4.1.3. Effects of Honeycomb Wall Thickness

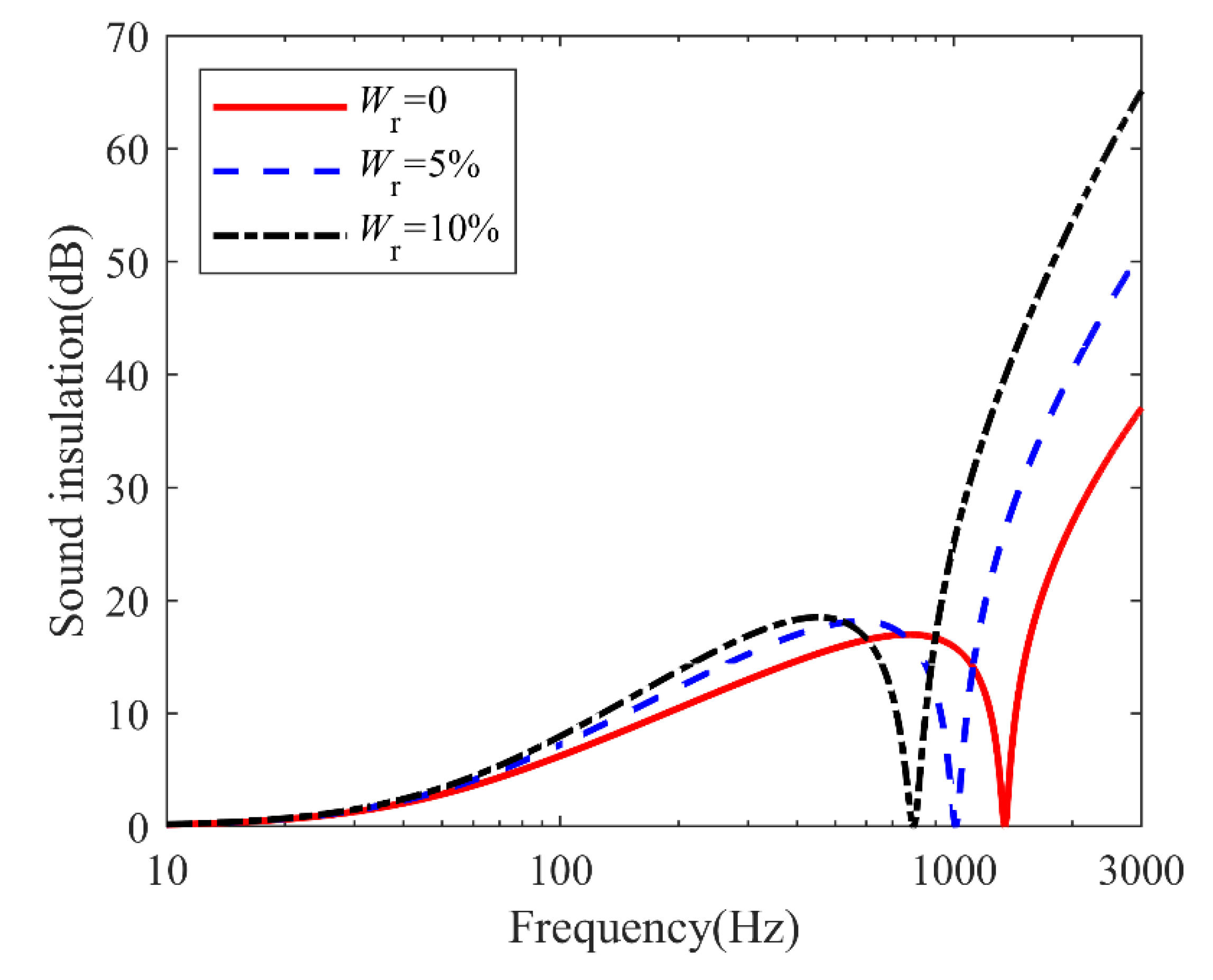

4.2. Influence of Particle Mass Fraction of Reinforcement

4.3. Sound Insulation and Light Weight

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| PML | Perfectly Matched Layer |

| GFRP | Glass Fiber Reinforced Polymer |

| FRP | Fiber Reinforced Plastic |

| STL | Sound Transmission Loss |

| E | Young’s modulus of particle reinforced composites |

| v | Poisson’s ratio of particle reinforced composites |

| K | bulk modulus of particle reinforced composites |

| G | shear modulus of particle reinforced composites |

| Vr | volume fraction of reinforcement particles |

| Wr | mass fraction of reinforcement particles |

| d | surface thickness of panel |

| h | core height |

| t | honeycomb wall thickness |

| a1 | minimum honeycomb side length |

| a2 | maximum honeycomb side length |

| ϕ | scalar displacement potential function |

| φ | vector displacement potential function |

| wx | vibration displacement function in x direction |

| wz | vibration displacement function in z direction |

| vx | vibration velocity in x direction |

| vz | vibration velocity in z direction |

| Tx | stress in x direction |

| Tz | stress in z direction |

| kz | wave vector in z direction |

| Sc | area matrix of each sublayer |

| τ | transmission coefficient |

| τ’ | sound intensity transmission coefficient |

| TL | sound insulation loss |

| f | coincidence frequency |

References

- Zhang, Z.; Wang, J.; Li, Z.; Zhang, X. Broadband Sound Insulation and Dual Equivalent Negative Properties of Acoustic Metamaterial with Distributed Piezoelectric Resonators. Materials 2022, 15, 4907. [Google Scholar] [CrossRef] [PubMed]

- Kaidouchi, H.; Kebdani, S.; Slimane, S.A. Vibro-acoustic analysis of the sound transmission through aerospace composite structures. Mech. Adv. Mater. Struct. 2022, 1–11. [Google Scholar] [CrossRef]

- Lee, Y.Y. Modified Elliptic Integral Approach for the Forced Vibration and Sound Transmission Analysis of a Nonlinear Panel Backed by a Partitioned Cavity. Mathematics 2022, 10, 984. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, W.L.; Wang, S.K. Overview of the application of composite honeycomb sandwich structure in civil aircraft. Fiber Compos. 2021, 38, 73–77. [Google Scholar]

- Ashby, M.F.; Gibson, L.J. Cellular Solids: Structure and Properties; Press Syndicate of the University of Cambridge: Cambridge, UK, 1997; pp. 175–231. [Google Scholar]

- Kumar, S.; Feng, L.; Orrenius, U. Predicting the sound transmission loss of honeycomb panels using the wave propagation approach. Acta Acust. United Acust. 2011, 97, 869–876. [Google Scholar] [CrossRef]

- Wang, C.N.; Tang, M.J.; Tse, C.C. Application of Biot theory in analyzing the sound insulation characteristic of honeycomb sandwich panels. J. Mech. 2007, 23, 23–30. [Google Scholar] [CrossRef]

- Qi, C.; Jiang, F.; Yang, S. Advanced honeycomb designs for improving mechanical properties: A review. Compos. Part B Eng. 2021, 227, 109393. [Google Scholar] [CrossRef]

- Li, M. Study on Nonlinear Deformation Mechanical Behavior of Gradient Aluminum Alloy Honeycomb Metal; Lanzhou University of Technology: Lanzhou, China, 2021. [Google Scholar]

- Mazloomi, M.S.; Ranjbar, M.; Boldrin, L.; Scarpa, F.; Patsias, S.; Ozada, N. Vibroacoustics of 2D gradient auxetic hexagonal honeycomb sandwich panels. Compos. Struct. 2018, 187, 593–603. [Google Scholar] [CrossRef]

- Li, Q.; Yang, D. Mechanical and acoustic performance of sandwich panels with hybrid cellular cores. J. Vib. Acoust. 2018, 140, 061016. [Google Scholar] [CrossRef]

- Ye, J.; Chu, C.; Zhai, Z.; Wang, Y.; Shi, B.; Qiu, Y. The interphase influences on the particle-reinforced composites with periodic particle configuration. Appl. Sci. 2017, 7, 102. [Google Scholar] [CrossRef]

- Sideridis, E. The influence of particle distribution and interphase on the thermal expension coefficient of particulate composites by the use of a new model. Compos. Interfaces 2016, 23, 277–287. [Google Scholar] [CrossRef]

- Adachi, T.; Yamada, Y.; Ishii, Y. Interphase-layer effect on deformation of silicone rubber filled with nanosilica particles. J. Appl. Polym. Sci. 2018, 116, 8145–8153. [Google Scholar] [CrossRef]

- Benvenise, Y. Effective Thermal Conductivity of Composites with a Thermal Contact Resistance between the Constituents: Nondilute Case. J. Appl. Phys. 1987, 61, 2840–2843. [Google Scholar] [CrossRef]

- Mori, T.; Tanaka, K. Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 1973, 21, 571–574. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, Q. Vibro-acoustic analysis of functionally graded graphene-reinforced nanocomposite laminated plates under thermal-mechanical loads. Eng. Struct. 2019, 186, 345–355. [Google Scholar] [CrossRef]

- Zhao, S.; Zhao, Z.; Yang, Z.; Ke, L.; Kitipornchai, S.; Yang, J. Functionally graded graphene reinforced composite structures: A review. Eng. Struct. 2020, 210, 110339. [Google Scholar] [CrossRef]

- Koizumi, M. FGM activities in Japan. Compos. Part B Eng. 1997, 28, 1–4. [Google Scholar] [CrossRef]

- Xu, Z.C. Research on Vibro Acoustic Modeling Theory and Characteristics of Functionally Graded Nano Reinforced Plate Structure. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, 2021. [Google Scholar]

- Cervenka, P.; Challande, P. A new efficient algorithm to compute the exact reflection and transmission factors for plane waves in layered absorbing media (liquids and solids). J. Acoust. Soc. Am. 1991, 89, 1579–1589. [Google Scholar] [CrossRef]

- Ogam, E.; Fellah, Z.E.A.; Ogam, G. Identification of the mechanical moduli of closed-cell porous foams using transmitted acoustic waves in air and the transfer matrix method. Compos. Struct. 2016, 135, 205–216. [Google Scholar] [CrossRef]

- He, Z.Y.; Zhao, Y.F. Fundamentals of Acoustics Theory; National Defense Industry Press: Beijing, China, 1981. [Google Scholar]

- Zhang, Z.; Huang, Y.; Huang, Q. Low-frequency broadband absorption of underwater composite anechoic coating with periodic subwavelength arrays of shunted piezoelectric patches. Compos. Struct. 2019, 216, 449–463. [Google Scholar] [CrossRef]

- Caviglia, G.; Morro, A. Wave propagation and reflection-transmission in a stratified viscoelastic solid. Int. J. Solids Struct. 2012, 49, 567–575. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, G.; Wu, X.; Jiang, R.; Li, S. A Particle Reinforced Gradient Honeycomb Sandwich Panel for Broadband Sound Insulation. Mathematics 2023, 11, 502. https://doi.org/10.3390/math11030502

Shi G, Wu X, Jiang R, Li S. A Particle Reinforced Gradient Honeycomb Sandwich Panel for Broadband Sound Insulation. Mathematics. 2023; 11(3):502. https://doi.org/10.3390/math11030502

Chicago/Turabian StyleShi, Geman, Xiaoxun Wu, Renjie Jiang, and Shande Li. 2023. "A Particle Reinforced Gradient Honeycomb Sandwich Panel for Broadband Sound Insulation" Mathematics 11, no. 3: 502. https://doi.org/10.3390/math11030502

APA StyleShi, G., Wu, X., Jiang, R., & Li, S. (2023). A Particle Reinforced Gradient Honeycomb Sandwich Panel for Broadband Sound Insulation. Mathematics, 11(3), 502. https://doi.org/10.3390/math11030502