1. Introduction

Most machine elements work in lubricated environments. Generally, the usage of lubrication allows a decrease in frictional losses in contacts and, thus, an increase in their durability. When such lubricated contacts are mathematically modeled, the rheology of the lubricant is considered to be Newtonian or non-Newtonian. The former case is significantly simpler and a lot of studies for the cases of homogeneous material and coated solids [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10] were dedicated to it. The latter case is more complex, but it better corresponds to the real behavior of lubricants because polymeric additives make their behavior significantly non-Newtonian, which allows for a distinctly different lubricant behavior at low and high shear stresses. Different rheological models for lubricant behavior were used to catch various aspects of real lubricant behavior such as lubricant relaxation time, etc. An overview and analysis of different fluid rheological models is given in [

11,

12]. One of the simplest rheological models of non-Newtonian lubricant behavior among generalized Newtonian fluids [

13] is the Ree–Eyring model [

14,

15,

16]. Some studies of fluids with complex non-Newtonian rheology were presented in [

17,

18,

19,

20,

21,

22].

Experimental data show that lubricant viscosity depends not only on pressure but also on lubricant shear stress and velocity [

23]. The actual behavior of polymer-formulated lubricant flowing through narrow gaps is most accurately described by the Giesekus rheological model [

12,

24,

25]. The Giesekus model differs from the Maxwell, Jeffris, Oldroyd A and B, etc., rheological models by the presence of a nonlinear term determined by the mobility factor

and stress state of the fluid. It provides the opportunity to take into account the degree to which the fluid viscosity is dependent on the shear stress in the fluid. In particular, this model allows for proper accounting of relatively high viscosity for low and relatively low viscosity for high shear stresses in the fluid. The model takes into account four parameters of the fluid: the relaxation time, the viscosities of base oil and polymeric additive and the mobility factor. If the mobility factor is set to zero, then the Giesekus model turns into the convected Maxwell model [

11,

12]. The Giesekus model is nonlinear and, therefore, more complex for analysis. A relatively simple case of a fluid with Giesekus rheology flowing between two parallel surfaces is considered in [

26,

27]. In [

28], the analysis of a lightly loaded trust bearing lubricated by a fluid with the Giesekus rheology was performed by the perturbation methods. However, the presence of convective terms and the base oil were not taken into account.

The present paper is the continuation of the series of the author’s studies of hydro- and elastohydrodynamic problems for Newtonian [

29,

30] and non-Newtonian [

13] lubricating fluids including the study of a lightly loaded trust bearing lubricated with a fluid with the Giesekus rheology [

31]. Also, the authors previously considered a similar but more simple problem under the condition when the mobility factor

is significantly greater than the ratio of the characteristic gap between the surfaces and length of the contact [

32]. In this case, in a two-term asymptotic solution, the inertia terms can be neglected. The first two terms of asymptotic representation for contact pressure with respect to the small parameter

are obtained in the analytical form. Numerical analysis of the obtained relationships for contact pressure, lubrication film thickness, lubricant flux, friction, contact energy loss, etc., as functions of the input parameters of the Giesekus model is performed. Some applications of perturbation methods to steady problems similar to the one used are described in [

33,

34].

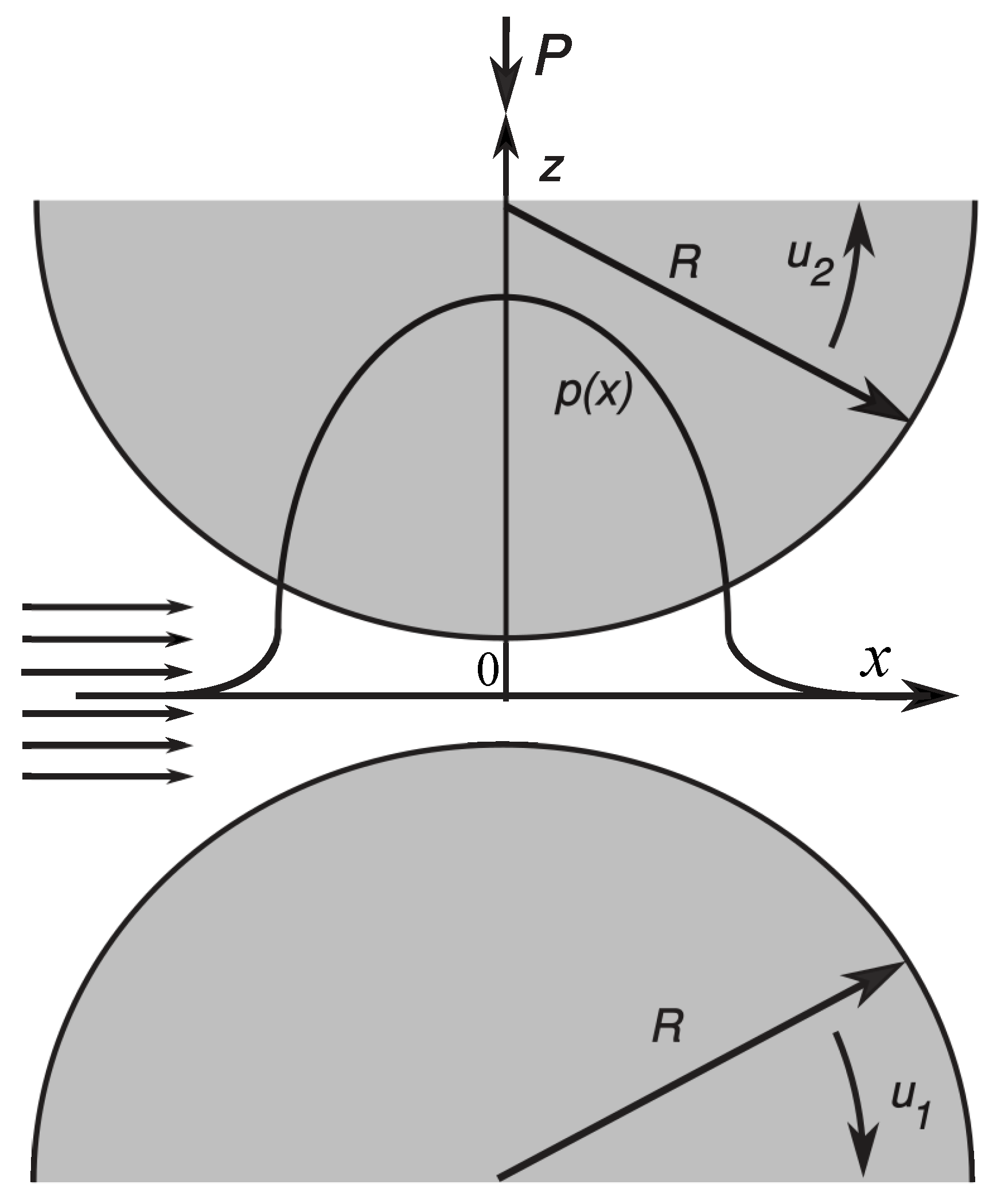

2. Formulation of the Lubrication Problem and General Description of the Analysis Applied

Let us consider a steady plane problem for a lubricated contact of two parallel infinite cylinders of the radius

R (see

Figure 1), both of which are made of rigid materials (the case of cylinders of different radii is considered at the end of the paper). It is assumed that the lubricant is described by the Giesekus model [

12] with a constant viscosity

and relaxation time

. The

x-axis of the coordinate system is directed along the contact and perpendicular to the cylinder axes, the

y-axis is directed along the cylinder axes, and the

z-axis is perpendicular to both

x- and

y-axes. A continuous lubricant layer separates the cylinders which steadily roll and slide with the surface linear speeds

and

in the direction of the

x-axis. The upper cylinder is subjected to the normal load

P along the

z-axis. The lubricant velocity components are represented by functions

, and

. Due to the problem geometry,

Therefore, the problem parameters are independent of

y and the motion equations of such a fluid are as follows [

13,

29].

In addition to that, one needs to consider the continuity equation. It is assumed that the fluid is incompressible, i.e.,

. That leads to the continuity equation

In this case, the stress tensor components are as follows

where

p is the pressure and

and

are the additional stress components acting in the corresponding directions. These tensor components satisfy the Giesekus fluid model which is a certain generalization of the Maxwell model and takes into account the degree to which the additive polymeric molecules follow the lubricant flow. The rheological equations are as follows [

12]

where

is the full stress tensor while

and

are the solvent and polymer stress tensors, respectively,

and

are the constant solvent and polymer dynamic viscosities,

is the deformation tensor,

is the constant relaxation time, and

is the dimensionless constant mobility factor describing the degree of the alignment of polymeric molecules with the lubricant flow,

.

In (

4), the following definitions of the tensor operators

and

[

12] are used

and [

12]

It is necessary to impose some boundary conditions on the components

u and

w of the lubricant velocity on the surfaces of the contacting solids. It is assumed that the no-slip and no-penetration conditions are valid on the solid boundaries. The contact is considered to be concentrated, i.e.,

(where

and

are the characteristic contact sizes along the

x- and

z-axes) or equivalently

, where

is the gap between the cylinder surfaces at point

x. Using the above boundary conditions will take the form

It will be shown later that in the simplified formulation the function of pressure

p is independent of the variable

z. Therefore, under pressure, one can impose the boundary conditions stemming from the fact that at the contact boundaries the fluid pressure

p is equal to the atmospheric one and, therefore, can be neglected. To avoid cavitation at the exit from the contact [

13], the boundary conditions on

p have the form

where

and

are the coordinates of the inlet and exit points of the contact.

In addition to that, it is required that the stress

from (

3) supports the normal load

P applied to the cylinder, i.e.,

Being interested in a two-term asymptotic problem solution in

, in (

9) and (

10), it is assumed that the two-term asymptotic expansion of pressure

in

(i.e., a linear function of

) is independent of

z. That assumption is confirmed later for small

up to the order of

, i.e., in the asymptotic expansion of

p in

, terms

and

are independent of

z, while terms

depend on both

x and

z.

The goal is to determine the contact pressure , the gap between the two cylinders , the coordinate of the exit point from the lubricated contact , the components of the tensor in the fluid, etc. Typically, the point of entrance in the lubricated contact, i.e., the coordinate of the inlet point , is known, and it is determined by the amount of lubricant supplied to the contact. The region where the problem solution is searched is bounded by and as well as by and . Out of these four boundaries of the region, three are unknown, i.e., , , and are unknown. One needs to find a perturbation solution to the above-determined problem in the case when . In this case, and are just slightly perturbed values of the exit point and gap realized in a lubricated contact with Newtonian fluid, i.e., when .

The general case of

will be considered. Here,

is a nonnegative constant. This case allows us to take into account some of the convective as well as major and minor dissipative terms of the equations. Also, it allows us to consider the limiting cases

and

by correspondingly taking

and

.

3. Simplification of the Rheological Equations and the Equations of Lubricant Motion

It was shown that the problem solution should be searched for not in the original

independent variables but in slightly modified ones

. It is due to the fact that the exit

and upper

and lower

boundaries of the lubricated contact are perturbed ones of the corresponding boundaries

and

of the contact lubricated by a Newtonian fluid (for

). Therefore, let us assume that

where

and

will be determined as a part of the problem solution. Then, the problem can be projected on the region

by introducing the following new independent variables

When

and

with the precision of

, one obtains

and

, respectively, and vice versa (see (

12) and (

13)). The actual definition of the new variable

can be taken as

, which varies between

and

.

As it was shown earlier, this projection of the original problem onto the region

is also dictated by the asymptotic expansion of the boundary conditions on pressure

at the exit point

[

31,

32].

Let us consider the solution form which should be used in this case. One needs to modify integration and differentiation operators while converting the problem from variables

to variables

as follows (see (

12) and (

13))

Let us consider an arbitrary sufficiently smooth function

which has to be expanded asymptotically in

. Then, based on (

12) and (

13), one has [

31,

32]

where

and the derivative of

f with respect to

and

are also taken for

. Therefore, the solution of the problem one will search using the Taylor expansions of the unknown functions such as

,

,

, etc., about

and

, retaining just the first two terms of the expansions as well as taking into account the sample expansion (

15) and the perturbed expressions for

and

from (

12) and (

13).

In the form the problem is formulated above it is very complex for any analytical analysis except the perturbation method. Therefore, the first goal is to simplify Equations (

1)–(

8) and to reduce them to much simpler equations which would allow for an analytical solution and derivation of analogs of the Reynolds equation. One needs to retain only the terms of higher orders of magnitude. As it was mentioned earlier, due to the fact that the thickness of the lubrication layer is much smaller than the extent of the lubricated contact, one has a small parameter

. Also, let

and

be the characteristic velocities of the lubricating fluid in the directions of the

x- and

z-axes. Then, the following scaling of the equations can be introduced

where

is the characteristic value of the lubricant viscosity. For simplicity, in the further analysis, the primes at the dimensionless variables are dropped.

By introducing the above scaling in the continuity Equation (

2), one obtains

To retain both terms in Equation (

17), one needs to assume that

Then, Equation (

17) becomes

Introducing scaling (

16) in Equations (

1) and (

3)–(

6) leads to equations

where

is the local Reynolds number.

Let us assume that not only

but also

, and

The latter assumption makes the rheological equations solvable. Otherwise, for

,

, these equations do not have a reasonable solution.

Then, Equations (

20)–(

22) can be simplified. Based on the example of function

expansion for

, one needs to search the problem solution in the form

where

,

,

,

,

,

,

,

,

and

,

,

,

,

,

,

,

are the unknown main and first-order approximations of the corresponding functions while the gap

between two contact rigid solids and functions

and

are described by the equations (see (

12))

where

,

is the a priori unknown lubrication film thickness at the exit point

,

is the effective curvature radius of the contacting solids,

and

,

,

, and

are unknown components of the perturbed solution.

Substituting (

12) and (

15) and using (

14) in Equations (

19)–(

22), taking into account (

11), and expanding all equations in

for the first two terms of each of the above expansions, one obtains equations

as well as the solutions for the tensor components as follows

Here, the approximation of the continuity Equation (

19) for the main terms of

u and

w is used in the form

Equations (

29)–(

31) show that functions

and

are independent of

, i.e.,

and

. That supports the form (

26) in which

will be searched as well as the choice of the boundary and additional conditions imposed on pressure

p in the form (

9) and (

10).

4. Derivation of the Lubricant Velocity Components and

Before solving the continuity Equation (

19) and equations of motion (

29), one needs to determine the boundary conditions imposed on

, and

. To do that, let us take conditions (

7) and (

8) and substitute into them the expansions from (

26). Expanding the obtained boundary conditions in

, one obtains the boundary conditions for the main and first-order approximations of

u and

w in the form

Now, one can turn to solving Equations (

19) and (

29). Solving the first equation in (

29) with boundary conditions from (

34) and taking into account that

is independent of

, one finds that

An asymptotic expansion of the continuity equation in

produces Equation (

33) and a similar equation

for

and

. Let us integrate Equation (

33) with respect to

from

to

which leads to

A similar analysis for

produces the expression

However, the solution to the latter equation does not represent a significant interest as

is not involved in any relationships for the first-order approximations of functions

, etc., and it will not be considered in detail.

Using (

36) in (

37), one obtains

To show that this expression for

satisfies the second boundary condition from (

35) at

, it is sufficient to use the Reynolds equation of order zero (see below Equation (

44)).

Now, let us determine

. Keeping in mind that

and

are independent of

and using the third equation in (

29) and the third and fourth boundary conditions in (

34) as well as the representation of

from (

26), one obtains

5. Reynolds Equations and Their Analysis

Based on the above analysis, let us derive the zero- and first-order Reynolds equations. Integrating the continuity Equation (

2) with respect to

z from

to

, using the boundary conditions (

7) and (

8) as well as changing the order of integration and differentiation leads to the equation

which will lead to the necessary Reynolds equations. Using (

14) and the asymptotic representations of

u from (

26) and

h from (

27) and (

28) and expanding (

41) in

, one derives the zero-order Reynolds equation

and the first-order Reynolds equation

Substituting the expression for

from (

36) into (

42) leads to the zero-order Reynolds equation which is just the traditional Reynolds equation for a Newtonian fluid

Similarly, substituting

, and

from (

36), (

40), and (

26) into (

42), one derives the first-order Reynolds equation

which takes into account the presence of polymeric additive in the lubricant.

Now, let us determine the boundary and additional conditions for

and

. Substituting the representation for

from (

26) in (

9) and expanding them in

leads to the boundary conditions on

and

in the form

Let us introduce dimensionless variables (

16) in (

10) which will result in the equation

Taking into account that

and that

(see (

30) and (

31)), and taking into account (

14), (

24) and (

25), and expanding this integral condition in

and integrating by parts produces equations

Now, one can finally formulate the specific boundary value problems for the zero-order Reynolds equation, i.e., for the given values of

, and

, one needs to solve Equations (

44), (

46) and (

49), and the first equation in (

28) for

, and

while for the first-order Reynolds equation for the given values of

and main solution

, and

, one needs to solve Equations (

45), (

47) and (

50), and the second equation in (

28) for

, and

. Let us use the dimensionless variables (

16) more convenient for the analysis of hydrodynamic lubrication problems [

29] by assuming that

and

Here,

is a dimensionless constant dependent on some of the problem input data,

a and

c are the dimensionless coordinates of the contact inlet and exit points, respectively,

,

is the slide-to-roll ratio,

is the main term of the dimensionless lubrication film thickness at the exit from the contact,

Q is the lubricant volume flux through the gap between the contact solids,

is the additional pressure which in the dimensional form is given by

,

and

which are the friction forces acting on the surfaces of the two cylinders, respectively, which in the dimensional form are equal to

, while

E is the loss of energy in the contact, which in the dimensional form is

. In the dimensionless form, these formulas have the following form (primes are omitted)

Obviously,

, i.e., it is independent of

.

In these dimensionless variables, the small parameter

involved in (

23) is determined as follows

(see (

51) and (

52)).

By introducing the dimensionless variables from (

52), one obtains the following dimensionless problems for the Reynolds equation of the zero-order

and the following dimensionless problem for the Reynolds equation of the first-order

Equation (

58) describe the lubrication process by a Newtonian fluid [

13,

29] and their solution has the form

where the unknown constants

and

satisfy the following system of algebraic equations [

13,

29]

Double integration of the Reynolds equation from (

59) with its boundary and additional condition leads to the solution

where the unknowns

and

are determined from the system of two linear algebraic equations

In (

60)–(

64), the following integrals—

, and

—are used

The solution of the nonlinear system (

61) for

and

can be found iteratively using Newton’s method. To start the iteration process, an initial approximation of the solution should be chosen according to [

13,

29].

Therefore, the approach to solution of the problem is first to solve the system (

61) for

and

and then to solve the linear system (

63) and (

64) for

and

. Having the values of

, and

allows to analytically calculate the functions of pressure

and gap

as well as the exit lubrication film thickness

and the exit coordinate

. In addition, from Formulas (

53)–(

56), one can find the friction forces

, the energy loss

E in the contact, the lubricant volume flux

Q, and the additional pressure

.

Using integrals , and , the problem solution can be calculated analytically. However, due to the fact that the formulas are sufficiently complex for manual calculations, it is advisable to use some quadrature formulas (for example, the trapezoid rule) for calculation of some of the integrals, for example, the integrals for , etc.

6. Examples of Some Specific Lubrication Problem Solutions and Discussion

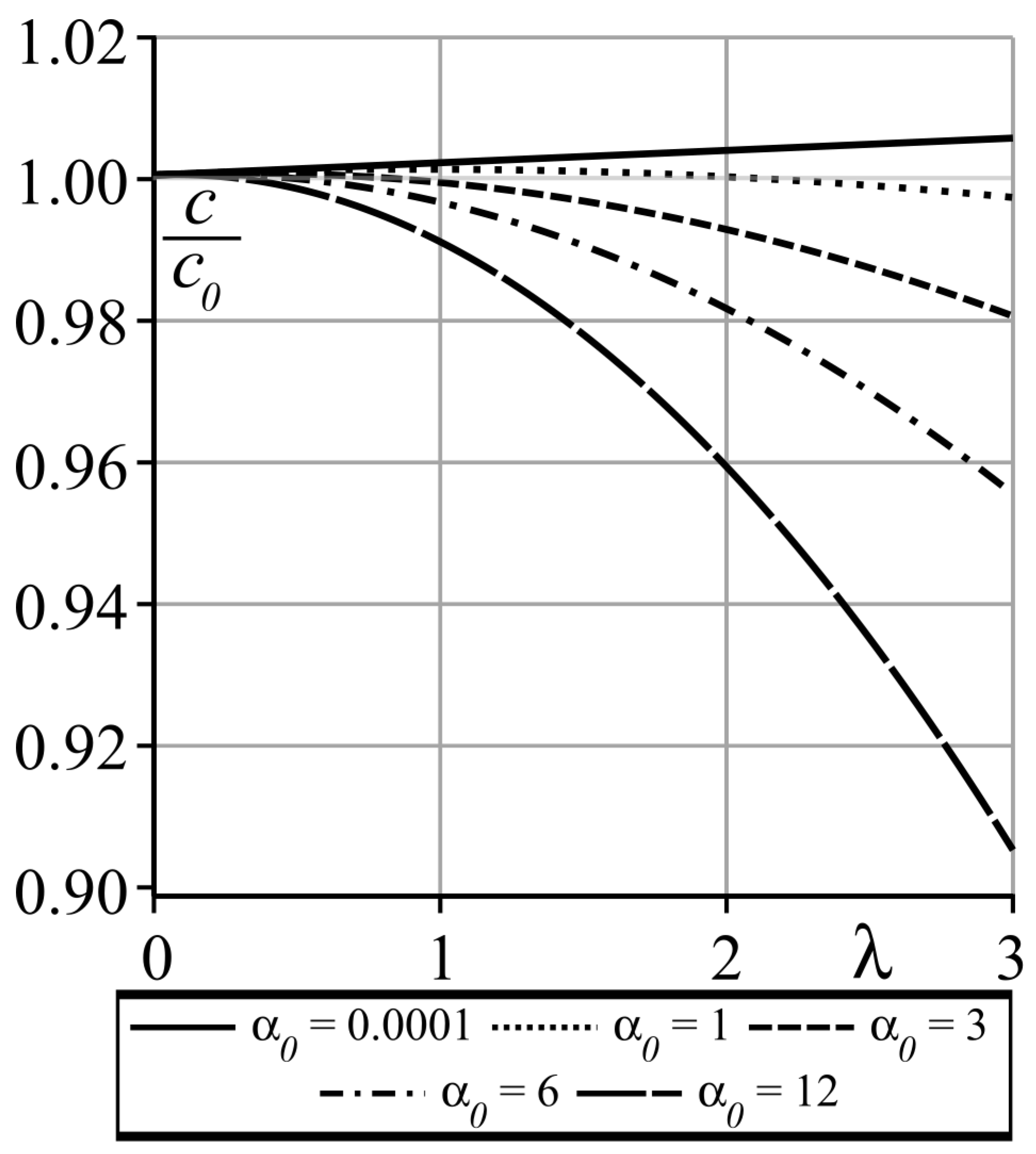

Now, let us consider some results which can be extracted from the obtained approximate solutions. It will always be assumed that . The basic set the following values: , m, N/m, N·s/m2, kg/ m3, , m/s, , , and will be taken. Below, all figures are presented in the dimensionless variables.

Figure 2 represents the plots of contact pressure in the lubricated contact obtained for different values of

and

. For

and

, the pressure distribution is very close to the one for the corresponding Newtonian fluid (see [

13,

29]). It is clear from these graphs that the maximum of the contact pressure tends to increase with the growth in

and

, while the size of the contact region tends to decrease due to decrease in

c (see

Figure 3). The variations in the contact pressure distribution compared to the corresponding Newtonian one remain insignificant for small values of the mobility factor

even for a relatively large lubricant relaxation time

. However, for relatively large values of the mobility factor

, the former variations in pressure

and exit coordinate

c become significant.

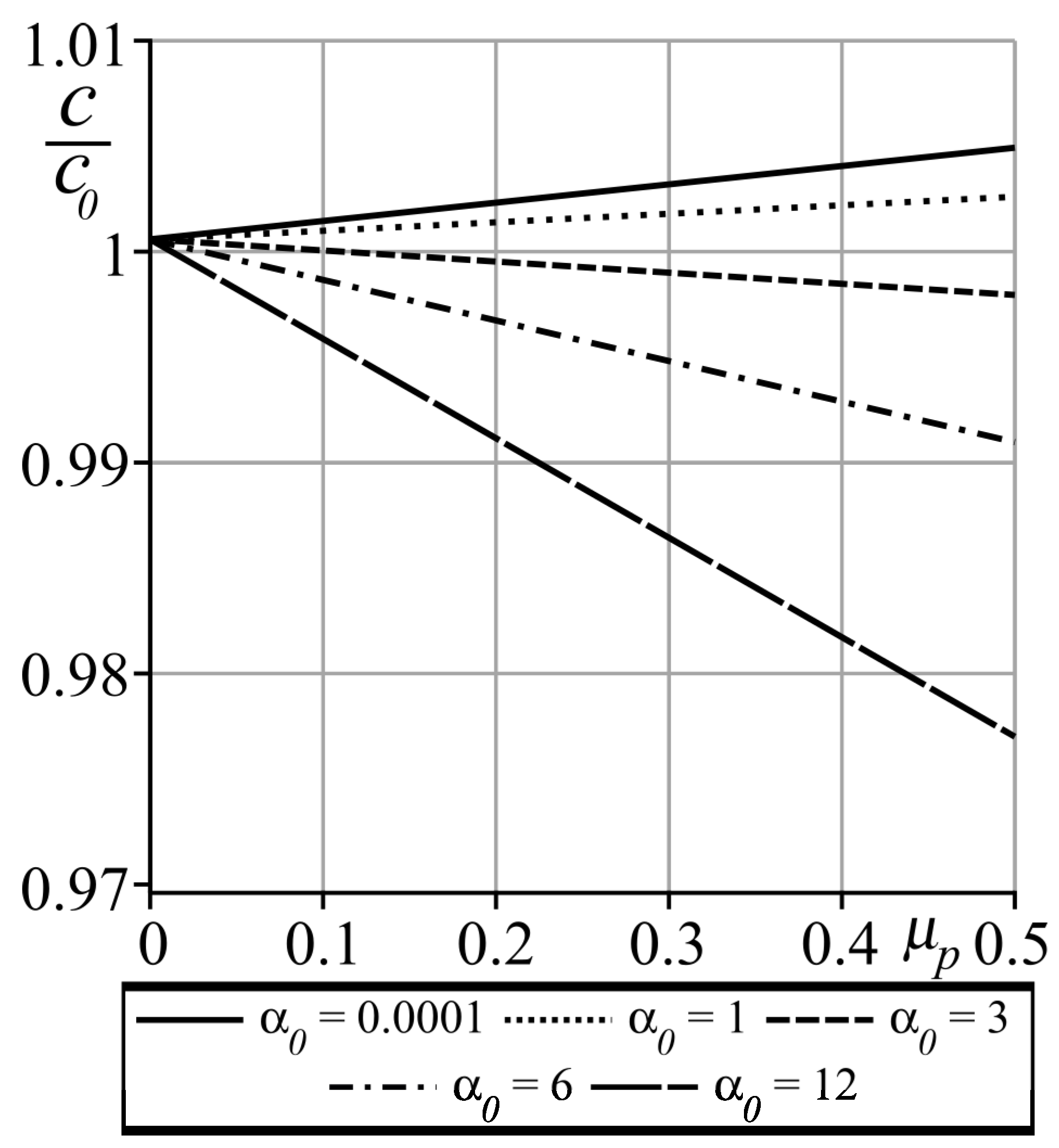

Figure 4 shows the dependence of the exit coordinate

c on the lubricant additive viscosity

, which qualitatively (being linear) resembles the dependence of

c on

from

Figure 3 which is nonlinear.

For , the Giesekus model becomes the convected Maxwell model and the value of the exit coordinate c tends slightly to increase with increase in both and .

The dependence of the exit film thickness

on the lubrication relaxation time

and lubricant additive viscosity

is represented in

Figure 5 and

Figure 6, which show beneficial (increasing) behavior of

with increase in

, and

. The only difference is in whether it happens linearly or nonlinearly. A similar behavior of the minimum lubrication film thickness

is shown in

Figure 7 and

Figure 8.

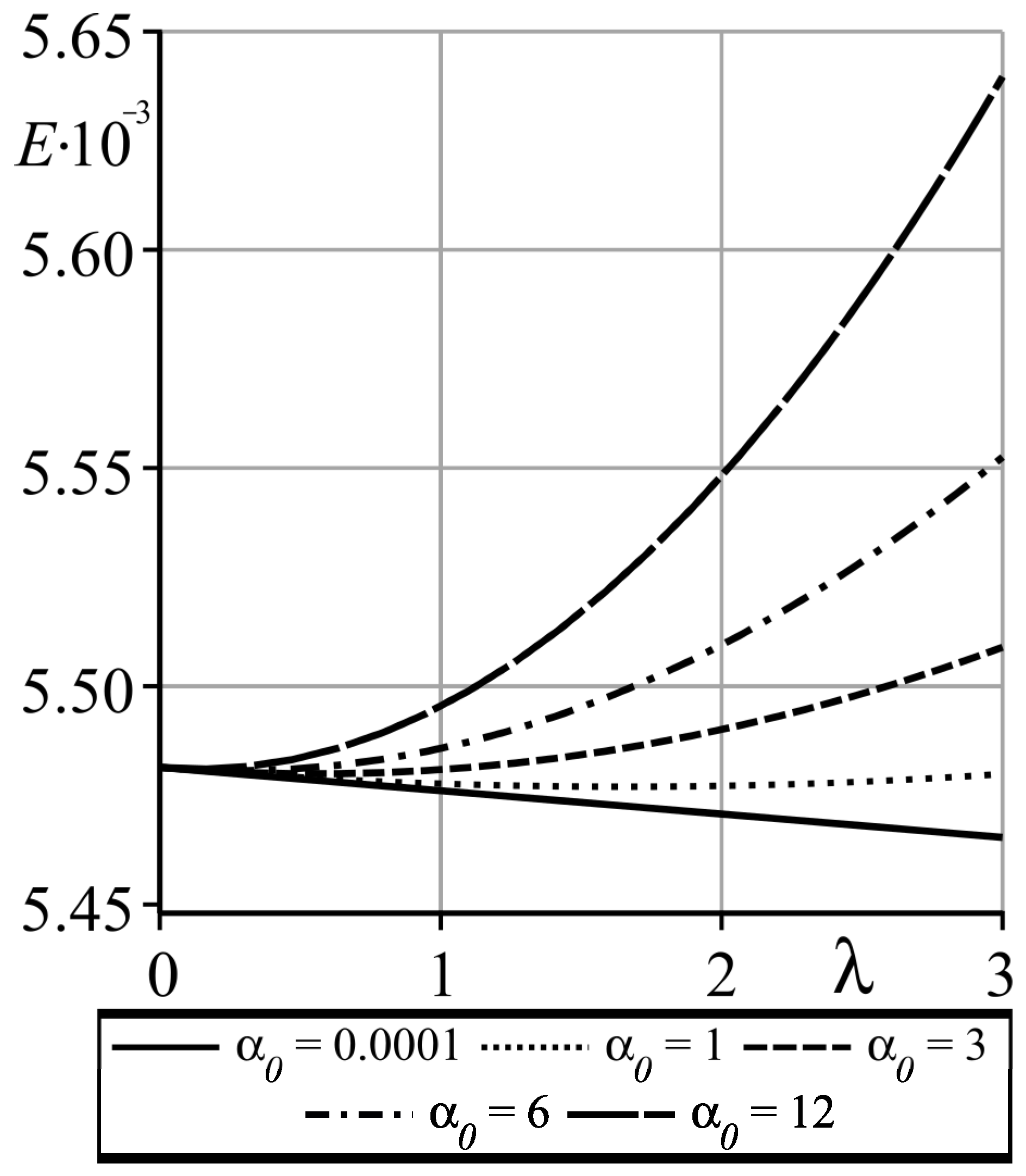

As it is clear from

Figure 9 and

Figure 10, depending on the value of the mobility factor

, the friction force

may display an increasing or decreasing behavior with

and

. Specifically, for smaller values of

, the friction force

decreases with

and

, while for larger values of

, the friction force

monotonically increases with

and

. A similar behavior exhibits the energy loss in the contact

E presented in

Figure 11. The fact that the exit lubrication film thickness

always is greater than in the corresponding case of a Newtonian fluid and that one can pick the mobility factor

value for which the friction force

and energy loss

E are just a bit higher than in the case of a Newtonian liquid provides an opportunity to optimize the lubricant design to increase lubrication film thickness and, at the same time, to practically not increase the frictional and energy losses. For example, for

and

, it is possible to achieve an increase in the minimum lubrication film thickness

by about

while the friction

and energy

E losses would increase by about only

compared to the lubricant with the corresponding Newtonian rheology.

The behavior of the lubricant flux

Q as a function of the lubricant relaxation time

and lubricant additive viscosity

are depicted in

Figure 12 and

Figure 13, and its behavior resembles the behavior of the exit film thickness

from

Figure 5 and

Figure 6.

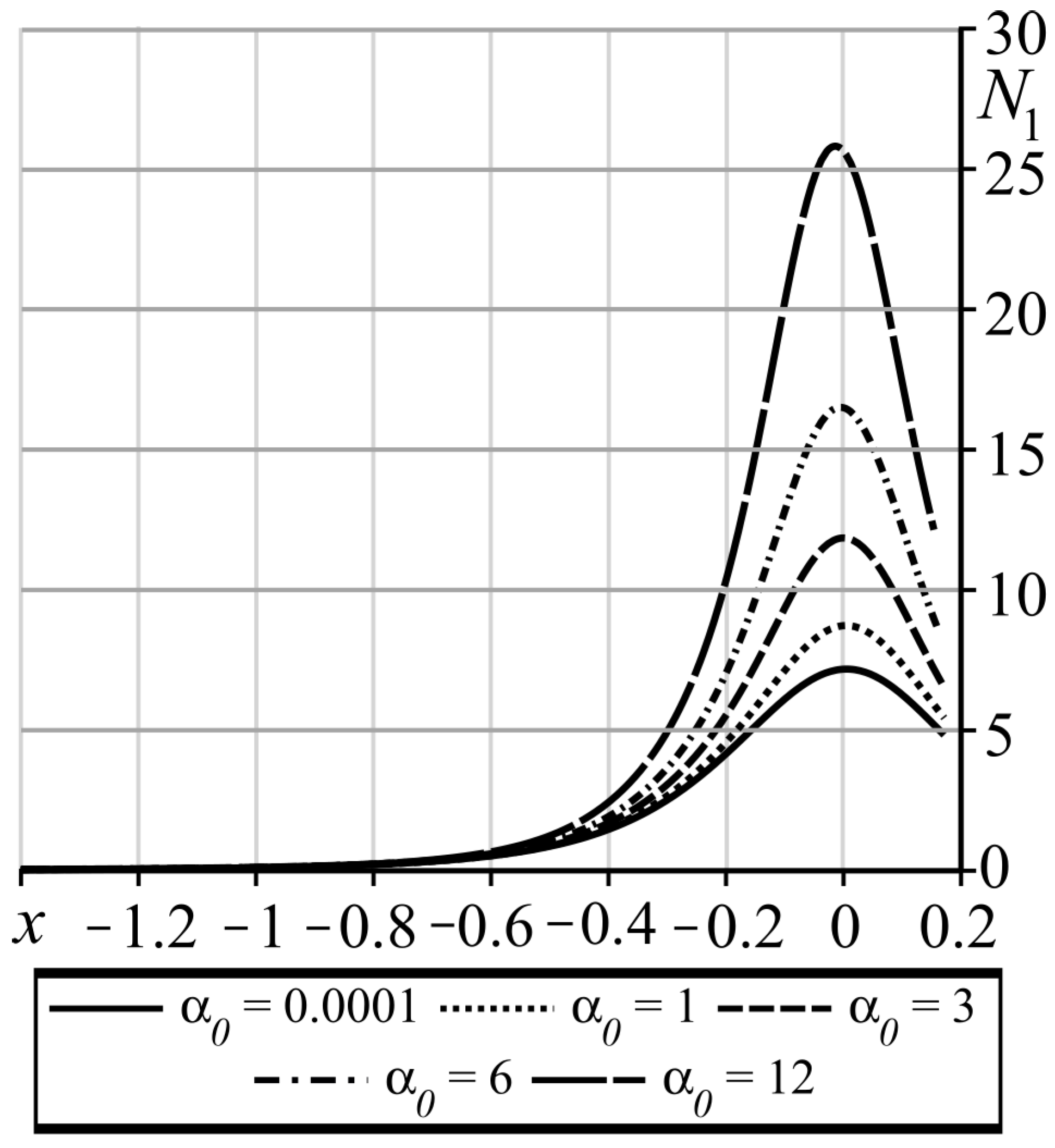

Some graphs of the additional pressure distribution

versus

x for

are presented in

Figure 14 and

Figure 15. In a sense, the behavior of

resembles the behavior of

from

Figure 2.

7. One Problem Generalization

In the above analysis, a lubrication problem for two parallel cylinders of the same radius has been considered. Now, let us briefly consider the generalization of this problem on the case of two parallel cylinders with different radii

and

. Then, in the same coordinate system as before, all equations of the problem formulation remain the same as before except for the boundary conditions for the lubricant velocity components, which now look as follows

and the equilibrium condition

where

and

are the cylinder surfaces which are represented by equations

where

is the effective radius of the cylinders,

.

The analysis of the system of these equations is conducted for

in the manner similar to the one used above, but in (

13), the variable

z remained intact. The assumptions (

11) and (

23) regarding

and

remain the same. Then, using the same dimensionless variables as in (

16) and asymptotic representations of solution components in which terms proportional to

are omitted, one obtains Equations (

29)–(

32), in which terms proportional to

are omitted. To derive the expressions for

, and

, one needs to use asymptotic boundary conditions (

34) and (

35) following from (

66) and (

67), in which

on the lower and upper surfaces should be replaced by

and

, respectfully.

After that, the expressions for

, and

have the form

The Reynolds equations of the first and second order are derived from the equation (for comparison, see (

41))

Using the obtained asymptotic solution representations, one derives the zero-order Reynolds equation

and the first-order Reynolds equation

Substitution of the expressions for

and

from (

71) and (

73) into (

75) and (

76) leads to precisely the same Reynolds Equations (

44) and (

45) with boundaries (

46) and (

47) and additional conditions (

49) and (

50) derived for the case of cylinders of the same radius

R; however, in this case,

. The rest of the analysis is identical with the one conducted above for the case of cylinders of the same radius

R.

Formulas for the friction forces

and energy loss

E obviously become transformed to the following ones