Solving the Flying Sidekick Traveling Salesman Problem by a Simulated Annealing Heuristic

Abstract

:1. Introduction

- An improved MILP model for the FSTSP is formulated. The model is more compact and effective than the existing model of Murray and Chu [26].

- A simulated annealing algorithm is developed for the FSTSP. The proposed SA features a new solution representation and a new operator specifically designed for the FSTSP. It outperforms the iterative local search for the FSTSP and is competitive with the hybrid genetic algorithm for the FSTSP.

2. Literature Review

3. Problem Description and Mathematical Model

- (1)

- The drone cannot be launched from the ending depot.

- (2)

- Each delivery point must be drone-eligible and not the drone’s launching point.

- (3)

- Each rendezvous point must be either the ending depot or a customer site, and the travel time of the drone should be within its endurance.

- (1)

- The drone can carry at most one package on each trip.

- (2)

- The drone can perform multiple delivery trips.

- (3)

- The truck performs at most one route.

- (4)

- The distance metric is the same for the truck and the drone. More specifically, both the truck and the drone travel between nodes via the street network.

- (5)

- The time needed to dispatch the drone from the truck is SL (for loading a package and replacing the battery).

- (6)

- The time needed for the truck to receive the drone is SR.

- (7)

- The drone can be dispatched or received only at the depot and customer nodes.

- (8)

- Both the truck and the drone must wait for the other if it first arrives at the rendezvous point (a customer site or depot). Receiving time SR and waiting time are included in the flying time.

- (9)

- When the drone is dispatched from the depot, it does not need the preparation time SL. The drone can be dispatched after the truck has left the depot.

- (10)

- Every customer is serviced exactly once either by the drone or the truck.

- Decision Variables

| Binary variable. 1 if the truck travels from node i to node j; 0 otherwise. | |

| Binary variable. 1 if the drone is dispatched at node , flies from node i to node , and then returns to node ; 0 otherwise. | |

| Arrival time of the truck at node . | |

| Arrival time of the drone at node . | |

| Load of the truck when it traverses arc . | |

| Auxiliary binary decision variable that equals 1 if for every . | |

| Completion time. |

- Objective Function

- Constraints

4. Simulated Annealing Heuristic for the FSTSP

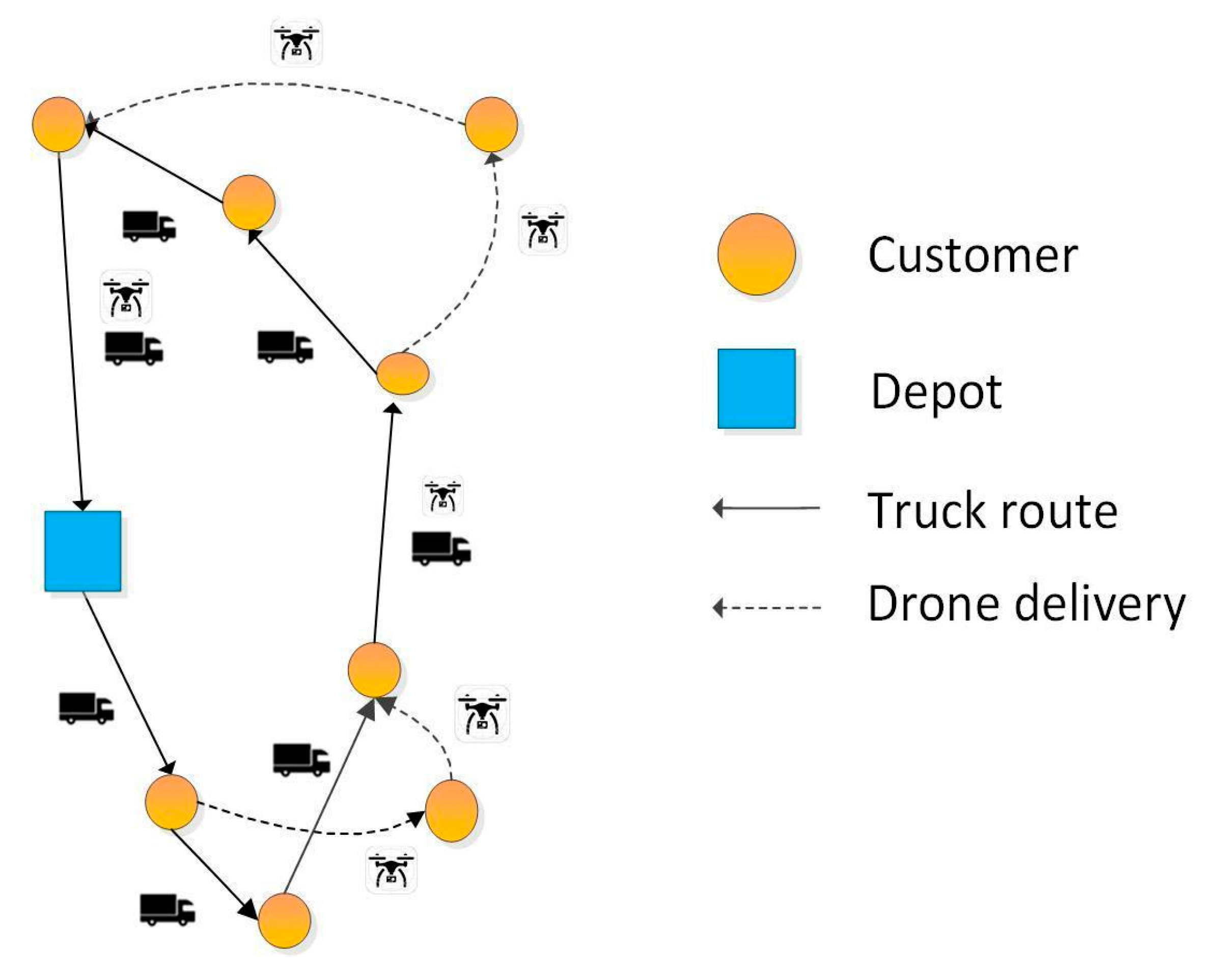

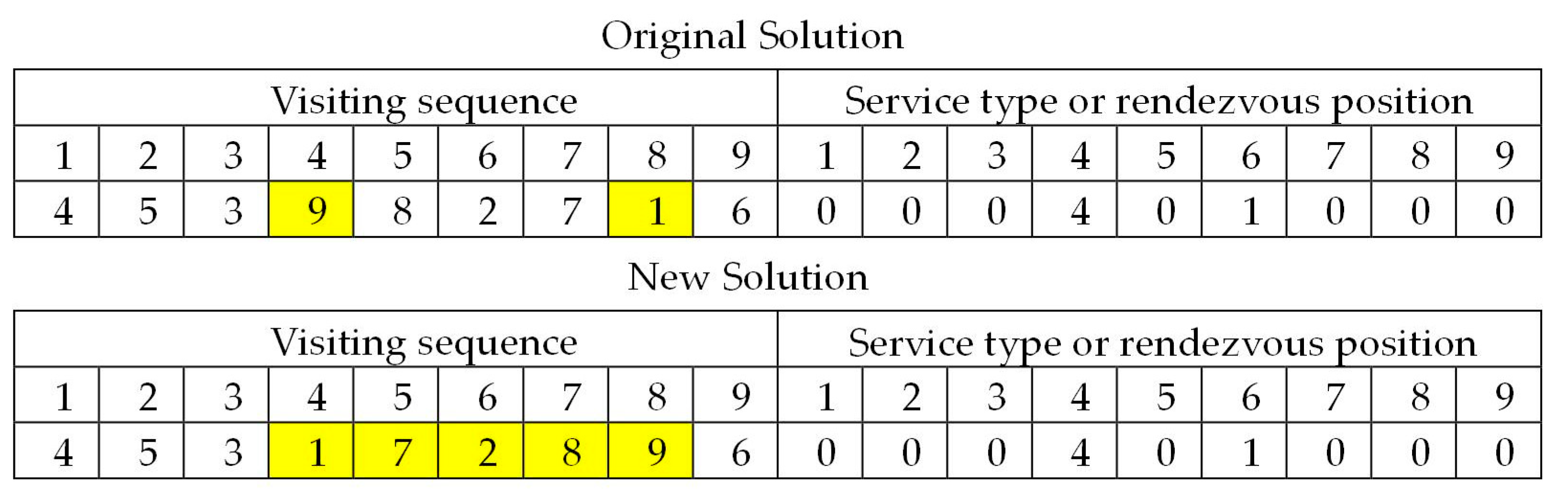

4.1. Solution Representation

4.2. Illustration of Solution Representation

4.3. Neighborhood

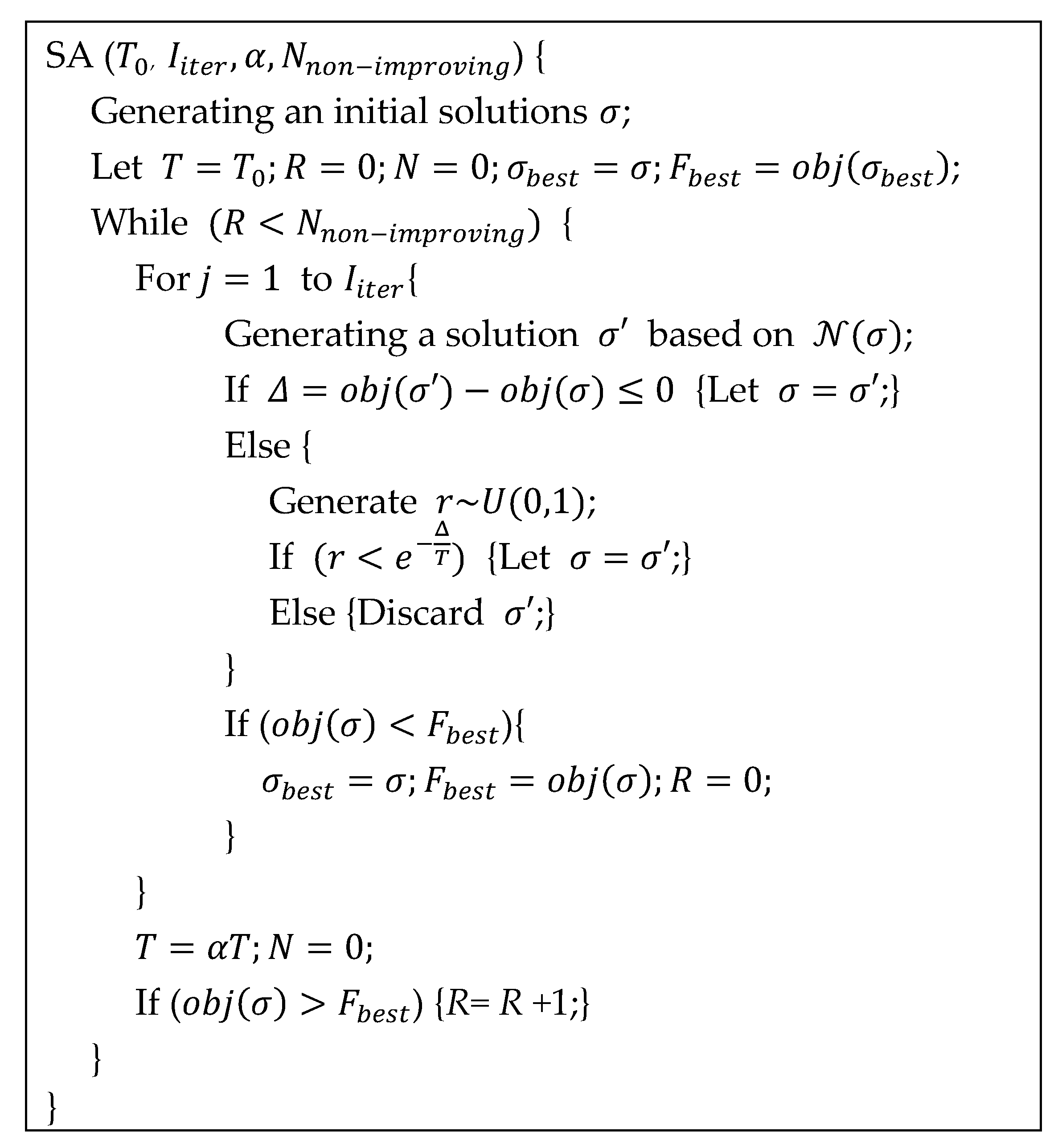

4.4. Parameter Setting and the SA Procedure

5. Experimental Results

5.1. Test Problems

5.2. Parameter Selection

5.3. Results and Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rougès, J.-F.; Montreuil, B. Crowdsourcing delivery: New interconnected business models to reinvent delivery. In Proceedings of the 1st International Physical Internet Conference, Québec City, QC, Canada, 28–30 May 2014; pp. 1–19. [Google Scholar]

- Joerss, M.; Schröder, J.; Neuhaus, F.; Klink, C.; Mann, F. Parcel Delivery: The Future of Last Mile. Available online: https://bdkep.de/files/bdkep-dateien/pdf/2016_the_future_of_last_mile.pdf (accessed on 1 August 2023).

- Tang, L.; Shao, G. Drone remote sensing for forestry research and practices. J. For. Res. 2015, 26, 791–797. [Google Scholar] [CrossRef]

- Kopaska, J. Drones—A Fisheries Assessment Tool? Fisheries 2014, 39, 319. [Google Scholar] [CrossRef]

- Veroustraete, F. The rise of the drones in agriculture. EC Agric. 2015, 2, 325–327. [Google Scholar]

- Oruc, B.E.; Kara, B.Y. Post-disaster assessment routing problem. Transp. Res. Part B Methodol. 2018, 116, 76–102. [Google Scholar] [CrossRef]

- Rabta, B.; Wankmüller, C.; Reiner, G. A drone fleet model for last-mile distribution in disaster relief operations. Int. J. Disaster Risk Reduct. 2018, 28, 107–112. [Google Scholar] [CrossRef]

- Barmpounakis, E.N.; Vlahogianni, E.I.; Golias, J.C. Unmanned Aerial Aircraft Systems for transportation engineering: Current practice and future challenges. Int. J. Transp. Sci. Technol. 2016, 5, 111–122. [Google Scholar] [CrossRef]

- Campbell, J.F.; Corberán, Á.; Plana, I.; Sanchis, J.M. Drone arc routing problems. Networks 2018, 72, 543–559. [Google Scholar] [CrossRef]

- Li, M.; Zhen, L.; Wang, S.; Lv, W.; Qu, X. Unmanned aerial vehicle scheduling problem for traffic monitoring. Comput. Ind. Eng. 2018, 122, 15–23. [Google Scholar] [CrossRef]

- Scott, J.; Scott, C. Drone Delivery Models for Healthcare. In Proceedings of the 50th Hawaii International Conference on System Sciences, Hilton Waikoloa Village, HI, USA, 4–7 January 2017. [Google Scholar] [CrossRef]

- Scott, J.E.; Scott, C.H. Models for drone delivery of medications and other healthcare items. Int. J. Healthc. Inf. Syst. Inform. 2019, 13, 20–34. [Google Scholar] [CrossRef]

- Wohlsen, M. The Next Big Thing You Missed: Amazon‘s Delivery Drones Could Work—They Just Need Trucks. Available online: https://www.wired.com/2014/06/the-next-big-thing-you-missed-delivery-drones-launched-from-trucks-are-the-future-of-shipping/ (accessed on 1 August 2023).

- France-Presse, A. Amazon Unveils Futuristic Drone Delivery Plan. Available online: https://www.industryweek.com/supply-chain/article/21961746/amazon-unveils-futuristic-drone-delivery-plan (accessed on 1 August 2023).

- Cuthbertson, A. Australia Post to Launch Drone Delivery Service. Available online: http://www.newsweek.com/australia-post-drone-delivery-service-drones-449442 (accessed on 13 November 2019).

- Hern, A. DHL launches first commercial drone ‘parcelcopter’delivery service. Guardian 2014, 25, 2014. [Google Scholar]

- Heath, N. Project Wing: A Cheat Sheet on Alphabet’s Drone Delivery Project. Available online: https://www.techrepublic.com/article/project-wing-a-cheat-sheet/ (accessed on 1 August 2023).

- Lithia, F. UPS Tests Residential Delivery via Drone Launched from Atop Package Car. Available online: https://www.pressroom.ups.com/pressroom/ContentDetailsViewer.page (accessed on 1 August 2023).

- Agatz, N.; Bouman, P.; Schmidt, M. Optimization approaches for the traveling salesman problem with drone. Transp. Sci. 2018, 52, 965–981. [Google Scholar] [CrossRef]

- Chang, Y.S.; Lee, H.J. Optimal delivery routing with wider drone-delivery areas along a shorter truck-route. Expert Syst. Appl. 2018, 104, 307–317. [Google Scholar] [CrossRef]

- Jeong, H.Y.; Song, B.D.; Lee, S. Truck-drone hybrid delivery routing: Payload-energy dependency and no-fly zones. Int. J. Prod. Econ. 2019, 214, 220–233. [Google Scholar] [CrossRef]

- Karak, A.; Abdelghany, K. The hybrid vehicle-drone routing problem for pick-up and delivery services. Transp. Res. Part C Emerg. Technol. 2019, 102, 427–449. [Google Scholar] [CrossRef]

- Kitjacharoenchai, P.; Ventresca, M.; Moshref-Javadi, M.; Lee, S.; Tanchoco, J.M.; Brunese, P.A. Multiple traveling salesman problem with drones: Mathematical model and heuristic approach. Comput. Ind. Eng. 2019, 129, 14–30. [Google Scholar] [CrossRef]

- Poikonen, S.; Golden, B.; Wasil, E.A. A branch-and-bound approach to the traveling salesman problem with a drone. Inf. J. Comput. 2019, 31, 335–346. [Google Scholar] [CrossRef]

- Sacramento, D.; Pisinger, D.; Ropke, S. An adaptive large neighborhood search metaheuristic for the vehicle routing problem with drones. Transp. Res. Part C Emerg. Technol. 2019, 102, 289–315. [Google Scholar] [CrossRef]

- Murray, C.C.; Chu, A.G. The flying sidekick traveling salesman problem: Optimization of drone-assisted parcel delivery. Transp. Res. Part C Emerg. Technol. 2015, 54, 86–109. [Google Scholar] [CrossRef]

- Dell’Amico, M.; Montemanni, R.; Novellani, S. Drone-assisted deliveries: New formulations for the flying sidekick traveling salesman problem. Optim. Lett. 2021, 15, 1617–1648. [Google Scholar] [CrossRef]

- Roberti, R.; Ruthmair, M. Exact methods for the traveling salesman problem with drone. Transp. Sci. 2021, 55, 315–335. [Google Scholar] [CrossRef]

- Schermer, D.; Moeini, M.; Wendt, O. A branch-and-cut approach and alternative formulations for the traveling salesman problem with drone. Networks 2020, 76, 164–186. [Google Scholar] [CrossRef]

- De Freitas, J.C.; Penna, P.H.V. A randomized variable neighborhood descent heuristic to solve the flying sidekick traveling salesman problem. Electron. Notes Discret. Math. 2018, 66, 95–102. [Google Scholar] [CrossRef]

- Yurek, E.E.; Ozmutlu, H.C. A decomposition-based iterative optimization algorithm for traveling salesman problem with drone. Transp. Res. Part C Emerg. Technol. 2018, 91, 249–262. [Google Scholar] [CrossRef]

- De Freitas, J.C.; Penna, P.H.V. A variable neighborhood search for flying sidekick traveling salesman problem. Int. Trans. Oper. Res. 2020, 27, 267–290. [Google Scholar] [CrossRef]

- Ha, Q.M.; Deville, Y.; Pham, Q.D.; Hà, M.H. On the min-cost Traveling Salesman Problem with Drone. Transp. Res. Part C Emerg. Technol. 2018, 86, 597–621. [Google Scholar] [CrossRef]

- Ha, Q.M.; Deville, Y.; Pham, Q.D.; Hà, M.H. A hybrid genetic algorithm for the traveling salesman problem with drone. J. Heuristics 2020, 26, 219–247. [Google Scholar] [CrossRef]

- Ha, Q.M.; Vu, D.M.; Le, X.T.; Hoang, M.H. The traveling salesman problem with multi-visit drone. J. Comput. Sci. Cybern. 2021, 37, 465–493. [Google Scholar] [CrossRef]

- Ferrandez, S.M.; Harbison, T.; Weber, T.; Sturges, R.; Rich, R. Optimization of a truck-drone in tandem delivery network using k-means and genetic algorithm. J. Ind. Eng. Manag. 2016, 9, 374–388. [Google Scholar] [CrossRef]

- Wang, X.; Poikonen, S.; Golden, B. The vehicle routing problem with drones: Several worst-case results. Optim. Lett. 2017, 11, 679–697. [Google Scholar] [CrossRef]

- Wang, Z.; Sheu, J.-B. Vehicle routing problem with drones. Transp. Res. Part B Methodol. 2019, 122, 350–364. [Google Scholar] [CrossRef]

- Ulmer, M.W.; Thomas, B.W. Same-day delivery with heterogeneous fleets of drones and vehicles. Networks 2018, 72, 475–505. [Google Scholar] [CrossRef]

- Schermer, D.; Moeini, M.; Wendt, O. A matheuristic for the vehicle routing problem with drones and its variants. Transp. Res. Part C Emerg. Technol. 2019, 106, 166–204. [Google Scholar] [CrossRef]

- Schermer, D.; Moeini, M.; Wendt, O. A hybrid VNS/Tabu search algorithm for solving the vehicle routing problem with drones and en route operations. Comput. Oper. Res. 2019, 109, 134–158. [Google Scholar] [CrossRef]

- Bruni, M.E.; Khodaparasti, S. A variable neighborhood descent matheuristic for the drone routing problem with beehives sharing. Sustainability 2022, 14, 9978. [Google Scholar] [CrossRef]

- Sah, B.; Gupta, R.; Bani-Hani, D. Analysis of barriers to implement drone logistics. Int. J. Logist. Res. Appl. 2021, 24, 531–550. [Google Scholar] [CrossRef]

- Chung, S.H.; Sah, B.; Lee, J. Optimization for drone and drone-truck combined operations: A review of the state of the art and future directions. Comput. Oper. Res. 2020, 123, 105004. [Google Scholar] [CrossRef]

- Pasha, J.; Elmi, Z.; Purkayastha, S.; Fathollahi-Fard, A.M.; Ge, Y.E.; Lau, Y.Y.; Dulebenets, M.A. The drone scheduling problem: A systematic state-of-the-art review. IEEE Trans. Intell. Transp. Syst. 2022, 23, 14224–14247. [Google Scholar] [CrossRef]

- Daud, S.M.S.M.; Yusof, M.Y.P.M.; Heo, C.C.; Khoo, L.S.; Singh, M.K.C.; Mahmood, M.S.; Nawawi, H. Applications of drone in disaster management: A scoping review. Sci. Justice 2022, 62, 30–42. [Google Scholar] [CrossRef]

- Kirkpatrick, S.; Gelatt Jr, C.D.; Vecchi, M.P. Optimization by simulated annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef]

- Metropolis, N.; Rosenbluth, A.W.; Rosenbluth, M.N.; Teller, A.H.; Teller, E. Equation of state calculations by fast computing machines. J. Chem. Phys. 1953, 21, 1087–1092. [Google Scholar] [CrossRef]

- Alfaro-Ayala, J.A.; López-Núñez, O.A.; Gómez-Castro, F.; Ramírez-Minguela, J.; Uribe-Ramírez, A.; Belman-Flores, J.; Cano-Andrade, S. Optimization of a solar collector with evacuated tubes using the simulated annealing and computational fluid dynamics. Energy Convers. Manag. 2018, 166, 343–355. [Google Scholar] [CrossRef]

- Ferreira, K.M.; de Queiroz, T.A. Two effective simulated annealing algorithms for the location-routing problem. Appl. Soft Comput. 2018, 70, 389–422. [Google Scholar] [CrossRef]

- Lin, S.-W.; Yu, V.F. Solving the team orienteering problem with time windows and mandatory visits by multi-start simulated annealing. Comput. Ind. Eng. 2017, 114, 195–205. [Google Scholar] [CrossRef]

- Matai, R. Solving multi objective facility layout problem by modified simulated annealing. Appl. Math. Comput. 2015, 261, 302–311. [Google Scholar] [CrossRef]

- Pérez-Sánchez, M.; Sánchez-Romero, F.J.; López-Jiménez, P.A.; Ramos, H.M. PATs selection towards sustainability in irrigation networks: Simulated annealing as a water management tool. Renew. Energy 2018, 116, 234–249. [Google Scholar] [CrossRef]

- Milenkovic, M.; Milosavljevic, N.; Bojovic, N.; Val, S. Container flow forecasting through neural networks based on metaheuristics. Oper. Res. 2021, 21, 965–997. [Google Scholar] [CrossRef]

- Abdeljaoued, M.A.; Saadani, N.E.; Bahroun, Z. Heuristic and metaheuristic approaches for parallel machine scheduling under resource constraints. Oper. Res. 2020, 20, 2109–2132. [Google Scholar] [CrossRef]

| Experiment No. | ARPD for FSTSP | ||||

|---|---|---|---|---|---|

| 1 | 1.0 | 5000 L * | 0.900 | 5 | 1.0586 |

| 2 | 1.0 | 10,000 L | 0.925 | 10 | 0.8969 |

| 3 | 1.0 | 15,000 L | 0.950 | 15 | 0.8168 |

| 4 | 1.0 | 20,000 L | 0.975 | 20 | 0.7168 |

| 5 | 1.5 | 5000 L | 0.925 | 15 | 0.8259 |

| 6 | 1.5 | 10,000 L | 0.900 | 20 | 0.8041 |

| 7 | 1.5 | 15,000 L | 0.975 | 5 | 0.7427 |

| 8 | 1.5 | 20,000 L | 0.950 | 10 | 0.6790 |

| 9 | 2.0 | 5000 L | 0.950 | 20 | 0.7698 |

| 10 | 2.0 | 10,000 L | 0.975 | 15 | 0.7032 |

| 11 | 2.0 | 15,000 L | 0.900 | 10 | 0.7255 |

| 12 | 2.0 | 20,000 L | 0.925 | 5 | 0.7428 |

| 13 | 2.5 | 5000 L | 0.975 | 10 | 0.8806 |

| 14 | 2.5 | 10,000 L | 0.950 | 5 | 0.8466 |

| 15 | 2.5 | 15,000 L | 0.925 | 20 | 0.6737 |

| 16 | 2.5 | 20,000 L | 0.900 | 15 | 0.7009 |

| Level | ||||

|---|---|---|---|---|

| 1 | 0.8723 | 0.8837 | 0.8223 | 0.8477 |

| 2 | 0.7629 | 0.8127 | 0.7848 | 0.7955 |

| 3 | 0.7353 | 0.7396 | 0.7780 | 0.7617 |

| 4 | 0.7754 | 0.7099 | 0.7608 | 0.7411 |

| Range | 0.1369 | 0.1739 | 0.0615 | 0.1066 |

| Rank | 2 | 1 | 4 | 3 |

| Method | Average RDP for the Best Solution among 10 Runs | Max. RDP for 72 Benchmark Problems | # of BKS Attained |

|---|---|---|---|

| IP | 2.072% | 14.083% | 32 |

| Savings ! | 3.604% | 18.300% | 21 |

| Nearest ! | 6.215% | 21.315% | 12 |

| Sweep | 11.807% | 36.803% | 1 |

| HGA | 0.008% | 0.569% | 71 |

| ILS | 0.000% | 0.000% | 72 |

| SA | 0.000% | 0.000% | 72 |

| MILPMC | 0.000% | 30.486% | 31 |

| MILPNew | 0.000% | 4.186% | 57 |

| No. | IP | Savings | Nearest | Sweep | HGA | ILS | SA | MILPMC | MILPnew | No. | IP | Savings | Nearest | Sweep | HGA | ILS | SA | MILPMC | MILPnew |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 56.468 | 56.709 | 57.992 | 57.992 | 56.468 | 56.468 | 56.468 | 56.468 | 56.468 | 37 | 49.996 | 49.996 | 50.030 | 58.378 | 49.422 | 49.422 | 49.422 | 51.922 | 49.422 |

| 2 | 50.573 | 50.813 | 52.625 | 52.096 | 50.573 | 50.573 | 50.573 | 52.096 | 52.690 | 38 | 49.470 | 49.470 | 49.470 | 54.493 | 49.204 | 49.204 | 49.204 | 49.204 | 49.204 |

| 3 | 53.207 | 55.351 | 53.207 | 57.367 | 53.207 | 53.207 | 53.207 | 53.207 | 53.207 | 39 | 62.796 | 62.796 | 64.270 | 69.147 | 62.576 | 62.222 | 62.222 | 65.624 | 62.222 |

| 4 | 47.311 | 53.761 | 47.311 | 51.471 | 47.311 | 47.311 | 47.311 | 47.311 | 47.311 | 40 | 62.270 | 62.270 | 62.270 | 68.183 | 62.004 | 62.004 | 62.004 | 62.270 | 62.004 |

| 5 | 53.687 | 53.687 | 53.687 | 56.395 | 53.687 | 53.687 | 53.687 | 53.687 | 53.687 | 41 | 42.799 | 46.367 | 51.599 | 44.253 | 42.533 | 42.533 | 42.533 | 44.253 | 42.799 |

| 6 | 53.687 | 53.687 | 53.687 | 56.241 | 53.687 | 53.687 | 53.687 | 53.687 | 54.241 | 42 | 42.799 | 46.367 | 50.015 | 44.253 | 42.533 | 42.533 | 42.533 | 44.253 | 42.799 |

| 7 | 67.464 | 67.464 | 67.464 | 80.958 | 67.464 | 67.464 | 67.464 | 67.464 | 67.464 | 43 | 43.342 | 43.342 | 43.369 | 52.503 | 43.076 | 43.076 | 43.076 | 43.076 | 43.076 |

| 8 | 66.487 | 66.487 | 66.487 | 80.726 | 66.487 | 66.487 | 66.487 | 66.487 | 66.487 | 44 | 43.342 | 43.342 | 43.369 | 52.503 | 43.076 | 43.076 | 43.076 | 43.076 | 43.297 |

| 9 | 51.149 | 51.390 | 51.172 | 51.172 | 50.551 | 50.551 | 50.551 | 50.551 | 51.634 | 45 | 49.204 | 49.204 | 49.470 | 56.347 | 49.204 | 49.204 | 49.204 | 49.204 | 49.204 |

| 10 | 51.149 | 51.149 | 51.149 | 51.149 | 44.835 | 44.835 | 44.835 | 45.835 | 44.835 | 46 | 49.204 | 49.204 | 49.470 | 54.423 | 49.204 | 49.204 | 49.204 | 49.204 | 49.204 |

| 11 | 45.176 ! | 47.601 | 45.176 ! | 46.576 | 47.311 | 47.311 | 47.311 | 47.601 | 47.601 | 47 | 62.004 | 62.004 | 64.270 | 69.881 | 62.004 | 62.004 | 62.004 | 62.004 | 62.004 |

| 12 | 45.863 | 47.601 | 45.863 | 46.576 | 43.602 | 43.602 | 43.602 | 47.601 | 44.285 | 48 | 62.004 | 62.004 | 62.830 | 64.404 | 62.004 | 62.004 | 62.004 | 62.004 | 62.004 |

| 13 | 49.581 | 49.581 | 49.581 | 49.581 | 49.581 | 49.581 | 49.581 | 51.887 | 49.581 | 49 | 69.586 | 69.586 | 82.280 | 79.760 | 69.586 | 69.586 | 69.586 | 69.586 | 69.586 |

| 14 | 47.791 | 47.791 | 47.791 | 48.369 | 46.621 | 46.621 | 46.621 | 46.621 | 46.621 | 50 | 55.493 | 55.493 | 59.413 | 57.251 | 55.493 | 55.493 | 55.493 | 57.251 | 55.493 |

| 15 | 62.381 | 62.381 | 62.381 | 75.983 | 62.381 | 62.381 | 62.381 | 64.687 | 62.381 | 51 | 72.146 | 74.740 | 86.043 | 86.605 | 72.146 | 72.146 | 72.146 | 72.146 | 72.146 |

| 16 | 60.591 | 60.591 | 60.591 | 69.247 | 59.416 | 59.416 | 59.416 | 59.776 | 59.416 | 52 | 58.053 | 58.053 | 64.054 | 76.009 | 58.053 | 58.053 | 58.053 | 58.053 | 58.053 |

| 17 | 46.254 | 46.254 | 46.276 | 46.276 | 42.416 | 42.416 | 42.416 | 45.985 | 42.996 | 53 | 77.344 | 82.083 | 91.763 | 91.304 | 77.344 | 77.344 | 77.344 | 77.344 | 77.344 |

| 18 | 46.254 | 46.254 | 46.254 | 46.254 | 42.416 | 42.416 | 42.416 | 42.416 | 42.416 | 54 | 69.900 | 70.853 | 74.773 | 74.454 | 68.431 | 68.431 | 68.431 | 69.175 | 69.431 |

| 19 | 42.416 | 47.601 | 42.416 | 46.576 | 41.729 | 41.729 | 41.729 | 43.093 | 41.729 | 55 | 90.144 | 94.883 | 104.563 | 105.104 | 90.144 | 90.144 | 90.144 | 90.144 | 90.144 |

| 20 | 42.416 | 47.601 | 42.416 | 46.576 | 41.729 | 41.729 | 41.729 | 41.729 | 41.729 | 56 | 82.700 | 83.653 | 89.654 | 88.947 | 82.700 | 82.700 | 82.700 | 82.700 | 82.700 |

| 21 | 42.896 | 42.896 | 42.896 | 48.369 | 42.896 | 42.896 | 42.896 | 48.214 | 42.896 | 57 | 55.493 | 55.493 | 61.707 | 57.251 | 54.973 | 54.973 | 54.973 | 63.247 | 55.302 |

| 22 | 42.896 | 42.896 | 42.896 | 48.369 | 42.896 | 42.896 | 42.896 | 42.896 | 42.896 | 58 | 53.980 | 53.980 | 54.252 | 53.741 | 51.929 | 51.929 | 51.929 | 53.447 | 52.093 |

| 23 | 56.696 | 56.696 | 56.696 | 76.983 | 56.273 | 56.273 | 56.273 | 61.569 | 56.273 | 59 | 58.053 | 60.530 | 64.054 | 64.054 | 55.209 | 55.209 | 55.209 | 64.702 | 55.209 |

| 24 | 55.696 | 55.696 | 55.696 | 59.653 | 55.696 | 55.696 | 55.696 | 55.696 | 55.696 | 60 | 57.088 | 57.088 | 53.837 | 60.249 | 52.329 | 52.329 | 52.329 | 52.329 | 52.329 |

| 25 | 49.430 | 53.890 | 55.111 | 53.044 | 49.430 | 49.430 | 49.430 | 49.430 | 49.430 | 61 | 69.009 | 64.409 ! | 68.489 | 70.650 | 65.523 | 65.523 | 65.523 | 67.770 | 65.523 |

| 26 | 46.886 | 48.340 | 54.952 | 48.340 | 46.886 | 46.886 | 46.886 | 48.723 | 46.886 | 62 | 64.841 | 64.409 | 65.010 | 65.105 | 60.743 | 60.743 | 60.743 | 60.743 | 61.886 |

| 27 | 50.708 | 52.133 | 57.591 | 58.628 | 50.708 | 50.708 | 50.708 | 50.708 | 50.708 | 63 | 80.809 | 77.209 ! | 81.289 | 86.777 | 78.323 | 78.323 | 78.323 | 83.700 | 78.323 |

| 28 | 46.423 | 46.423 | 47.543 | 58.582 | 46.423 | 46.423 | 46.423 | 46.423 | 46.423 | 64 | 74.686 | 73.967 | 77.209 | 80.809 | 72.967 | 72.967 | 72.967 | 74.686 | 74.686 |

| 29 | 56.102 | 56.102 | 62.331 | 71.426 | 56.102 | 56.102 | 56.102 | 56.102 | 56.102 | 65 | 49.049 | 49.049 | 54.658 | 50.009 | 45.931 | 45.931 | 45.931 | 59.321 | 45.931 |

| 30 | 56.102 | 56.102 | 57.060 | 57.102 | 53.933 | 53.933 | 53.933 | 53.933 | 55.223 | 66 | 49.049 | 49.049 | 54.658 | 50.009 | 45.931 | 45.931 | 45.931 | 47.250 | 46.740 |

| 31 | 69.902 | 69.902 | 76.131 | 81.606 | 69.902 | 69.902 | 69.902 | 69.902 | 69.902 | 67 | 47.935 | 55.524 | 54.481 | 64.155 | 46.935 | 46.935 | 46.935 | 61.240 | 47.935 |

| 32 | 68.902 | 68.902 | 74.717 | 71.757 | 68.397 | 68.397 | 68.397 | 68.397 | 68.902 | 68 | 47.935 | 53.555 | 52.481 | 60.249 | 46.935 | 46.935 | 46.935 | 48.865 | 47.935 |

| 33 | 43.533 | 49.787 | 45.950 | 44.987 | 43.533 | 43.533 | 43.533 | 45.358 | 43.533 | 69 | 61.886 | 57.382 | 60.476 | 60.744 | 56.395 | 56.395 | 56.395 | 67.435 | 56.395 |

| 34 | 43.533 | 46.358 | 50.979 | 44.987 | 43.533 | 43.533 | 43.533 | 46.590 | 43.533 | 70 | 61.886 | 57.382 | 57.265 | 60.744 | 56.395 | 56.395 | 56.395 | 56.395 | 57.382 |

| 35 | 44.076 | 44.076 | 45.040 | 50.876 | 43.949 | 56.468 | 43.949 | 44.076 | 44.076 | 71 | 74.686 | 69.195 | 73.276 | 75.436 | 69.195 | 69.195 | 69.195 | 83.700 | 69.195 |

| 36 | 44.076 | 44.076 | 44.076 | 47.900 | 43.810 | 50.573 | 43.810 | 44.076 | 43.810 | 72 | 73.894 | 69.195 | 69.195 | 80.809 | 69.195 | 69.195 | 69.195 | 69.195 | 69.195 |

| Method | Average RDP for the Best Solution among 10 Runs | Average RDP for the Average Solution among 10 Runs | # of BKS Obtained | Average Computing Time (Min) |

|---|---|---|---|---|

| HGA | 0.258% | 0.812% | 27 | 2.66 |

| ILS | 0.720% | 2.915% | 16 | 1.59 |

| SA | 0.261% | 1.043% | 29 | 2.52 |

| Inst. | BKS | ILS | HGA | SA | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Best | Gap | Ave. | Gap | Time (m) | Best | Gap | Ave. | Gap | Time (m) | Best | Gap | Ave. | Gap | Time (m) | ||

| B1 | 115.59 | 115.65 | 0.05 | 116.43 | 0.73 | 0.76 | 115.72 | 0.11 | 118.45 | 2.47 | 0.38 | 115.59 | 0.00 | 116.36 | 0.67 | 1.21 |

| B2 | 118.39 | 118.39 | 0.00 | 118.39 | 0.00 | 0.33 | 118.39 | 0.00 | 119.96 | 1.33 | 0.36 | 118.39 | 0.00 | 118.88 | 0.41 | 1.07 |

| B3 | 116.21 | 116.21 | 0.00 | 116.39 | 0.15 | 0.57 | 116.21 | 0.00 | 118.79 | 2.22 | 0.47 | 116.21 | 0.00 | 116.25 | 0.03 | 1.09 |

| B4 | 118.71 | 118.71 | 0.00 | 119.26 | 0.46 | 0.47 | 118.99 | 0.24 | 120.65 | 1.63 | 0.48 | 118.93 | 0.19 | 119.09 | 0.32 | 1.07 |

| B5 | 115.78 | 115.78 | 0.00 | 115.91 | 0.11 | 0.58 | 115.78 | 0.00 | 118.48 | 2.33 | 0.38 | 116.72 | 0.81 | 117.53 | 1.51 | 1.09 |

| B6 | 114.31 | 114.31 | 0.00 | 115.46 | 1.01 | 0.88 | 115.26 | 0.83 | 117.97 | 3.20 | 0.46 | 115.11 | 0.70 | 115.96 | 1.44 | 1.08 |

| B7 | 115.52 | 115.52 | 0.00 | 115.63 | 0.10 | 0.62 | 115.53 | 0.01 | 116.63 | 0.96 | 0.41 | 115.52 | 0.00 | 115.67 | 0.13 | 1.08 |

| B8 | 117.16 | 117.90 | 0.63 | 118.04 | 0.75 | 0.78 | 117.90 | 0.63 | 118.28 | 0.96 | 0.39 | 117.16 | 0.00 | 118.02 | 0.73 | 1.09 |

| B9 | 117.64 | 117.64 | 0.00 | 117.72 | 0.07 | 0.39 | 117.72 | 0.07 | 118.69 | 0.89 | 0.37 | 117.72 | 0.07 | 117.73 | 0.08 | 1.10 |

| B10 | 116.94 | 117.38 | 0.38 | 117.70 | 0.65 | 0.60 | 117.74 | 0.68 | 119.13 | 1.87 | 0.44 | 116.94 | 0.00 | 117.75 | 0.69 | 1.08 |

| C1 | 215.00 | 215.07 | 0.03 | 215.37 | 0.17 | 0.60 | 215.00 | 0.00 | 218.87 | 1.80 | 0.43 | 215.47 | 0.22 | 215.64 | 0.30 | 1.24 |

| C2 | 208.66 | 209.23 | 0.27 | 210.11 | 0.69 | 0.53 | 209.69 | 0.49 | 210.47 | 0.87 | 0.35 | 208.66 | 0.00 | 209.45 | 0.38 | 1.18 |

| C3 | 212.02 | 212.02 | 0.00 | 212.22 | 0.09 | 0.38 | 212.02 | 0.00 | 214.38 | 1.11 | 0.24 | 212.36 | 0.16 | 212.36 | 0.16 | 1.14 |

| C4 | 212.00 | 212.08 | 0.04 | 213.27 | 0.60 | 0.60 | 213.45 | 0.68 | 217.67 | 2.67 | 0.44 | 212.00 | 0.00 | 214.85 | 1.34 | 1.26 |

| C5 | 220.50 | 223.06 | 1.16 | 224.57 | 1.85 | 0.48 | 220.50 | 0.00 | 226.23 | 2.60 | 0.34 | 220.50 | 0.00 | 224.03 | 1.60 | 1.22 |

| C6 | 233.67 | 234.01 | 0.15 | 235.56 | 0.81 | 0.31 | 233.67 | 0.00 | 237.38 | 1.59 | 0.31 | 233.67 | 0.00 | 235.76 | 0.89 | 1.16 |

| C7 | 222.27 | 222.27 | 0.00 | 223.40 | 0.51 | 0.51 | 222.81 | 0.24 | 227.99 | 2.57 | 0.45 | 224.08 | 0.81 | 224.08 | 0.81 | 1.22 |

| C8 | 233.43 | 234.26 | 0.36 | 237.53 | 1.76 | 0.46 | 233.71 | 0.12 | 238.45 | 2.15 | 0.39 | 233.43 | 0.00 | 236.89 | 1.48 | 1.19 |

| C9 | 223.57 | 226.01 | 1.09 | 227.43 | 1.73 | 0.68 | 226.02 | 1.10 | 233.10 | 4.26 | 0.42 | 223.57 | 0.00 | 226.19 | 1.17 | 1.26 |

| C10 | 225.93 | 226.17 | 0.11 | 226.17 | 0.11 | 0.48 | 225.93 | 0.00 | 229.74 | 1.69 | 0.38 | 226.90 | 0.43 | 226.97 | 0.46 | 1.22 |

| D1 | 304.73 | 306.39 | 0.54 | 307.09 | 0.77 | 0.61 | 304.73 | 0.00 | 313.18 | 2.77 | 0.33 | 305.45 | 0.24 | 307.27 | 0.83 | 1.24 |

| D2 | 311.56 | 313.93 | 0.76 | 315.64 | 1.31 | 0.57 | 311.80 | 0.08 | 317.17 | 1.80 | 0.35 | 311.56 | 0.00 | 314.03 | 0.79 | 1.24 |

| D3 | 293.31 | 295.86 | 0.87 | 297.54 | 1.44 | 0.60 | 294.23 | 0.31 | 308.78 | 5.27 | 0.36 | 293.31 | 0.00 | 294.10 | 0.27 | 1.22 |

| D4 | 323.42 | 323.72 | 0.09 | 324.60 | 0.36 | 0.56 | 323.42 | 0.00 | 329.17 | 1.78 | 0.33 | 324.13 | 0.22 | 326.23 | 0.87 | 1.18 |

| D5 | 319.17 | 321.46 | 0.72 | 321.83 | 0.83 | 0.40 | 319.17 | 0.00 | 320.89 | 0.54 | 0.24 | 319.44 | 0.08 | 320.10 | 0.29 | 1.22 |

| D6 | 313.11 | 313.21 | 0.03 | 313.65 | 0.17 | 0.49 | 313.11 | 0.00 | 314.13 | 0.33 | 0.28 | 314.03 | 0.29 | 314.99 | 0.60 | 1.18 |

| D7 | 316.65 | 316.65 | 0.00 | 317.83 | 0.37 | 0.32 | 319.92 | 1.03 | 323.78 | 2.25 | 0.35 | 316.87 | 0.07 | 316.88 | 0.07 | 1.17 |

| D8 | 289.48 | 293.76 | 1.48 | 296.51 | 2.43 | 0.58 | 289.48 | 0.00 | 292.39 | 1.01 | 0.33 | 289.48 | 0.00 | 294.65 | 1.79 | 1.20 |

| D9 | 316.04 | 317.85 | 0.57 | 318.31 | 0.72 | 0.41 | 316.04 | 0.00 | 322.55 | 2.06 | 0.34 | 316.04 | 0.00 | 329.20 | 4.16 | 1.20 |

| D10 | 301.79 | 305.51 | 1.23 | 305.54 | 1.24 | 0.41 | 303.09 | 0.43 | 308.70 | 2.29 | 0.33 | 301.79 | 0.00 | 301.88 | 0.03 | 1.19 |

| Ave | 0.352 | 0.733 | 0.532 | 0.235 | 1.976 | 0.371 | 0.143 | 0.811 | 1.170 |

| Inst. | BKS | ILS | HGA | SA | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Best | Gap | Ave. | Gap | Time (m) | Best | Gap | Ave. | Gap | Time (m) | Best | Gap | Ave. | Gap | Time (m) | ||

| E1 | 187.67 | 187.67 | 0.00 | 188.32 | 0.35 | 3.60 | 188.46 | 0.42 | 189.89 | 1.18 | 2.89 | 188.73 | 0.56 | 188.87 | 0.64 | 3.72 |

| E2 | 187.21 | 187.21 | 0.00 | 188.01 | 0.43 | 5.60 | 187.59 | 0.20 | 189.62 | 1.29 | 3.53 | 187.82 | 0.33 | 188.61 | 0.75 | 3.56 |

| E3 | 188.09 | 188.09 | 0.00 | 188.89 | 0.43 | 4.58 | 188.54 | 0.24 | 190.26 | 1.15 | 2.75 | 188.87 | 0.41 | 189.58 | 0.79 | 3.60 |

| E4 | 186.23 | 186.23 | 0.00 | 186.99 | 0.41 | 4.69 | 187.32 | 0.59 | 188.78 | 1.37 | 2.61 | 186.51 | 0.15 | 187.06 | 0.45 | 3.57 |

| E5 | 187.71 | 187.71 | 0.00 | 188.26 | 0.29 | 4.06 | 188.30 | 0.31 | 190.07 | 1.26 | 2.13 | 188.20 | 0.26 | 188.89 | 0.63 | 3.62 |

| E6 | 189.16 | 189.16 | 0.00 | 189.44 | 0.15 | 4.84 | 189.83 | 0.35 | 192.11 | 1.56 | 2.63 | 189.67 | 0.27 | 191.85 | 1.42 | 3.60 |

| E7 | 189.95 | 190.39 | 0.23 | 190.89 | 0.49 | 3.84 | 190.68 | 0.38 | 192.16 | 1.16 | 3.01 | 189.95 | 0.00 | 190.46 | 0.27 | 3.60 |

| E8 | 189.02 | 189.02 | 0.00 | 189.54 | 0.28 | 4.22 | 189.46 | 0.23 | 190.85 | 0.97 | 3.10 | 189.14 | 0.06 | 189.43 | 0.22 | 3.59 |

| E9 | 189.07 | 189.76 | 0.36 | 189.94 | 0.46 | 4.00 | 189.07 | 0.00 | 190.55 | 0.78 | 2.29 | 189.07 | 0.00 | 189.78 | 0.38 | 3.59 |

| E10 | 188.96 | 189.45 | 0.26 | 189.91 | 0.50 | 3.40 | 188.96 | 0.00 | 190.00 | 0.55 | 1.96 | 189.20 | 0.13 | 189.49 | 0.28 | 3.52 |

| F1 | 322.94 | 322.94 | 0.00 | 326.10 | 0.98 | 5.73 | 328.19 | 1.63 | 337.49 | 4.51 | 3.08 | 323.31 | 0.11 | 325.93 | 0.93 | 4.16 |

| F2 | 308.15 | 308.74 | 0.19 | 310.89 | 0.89 | 5.24 | 311.50 | 1.09 | 319.35 | 3.63 | 2.95 | 308.15 | 0.00 | 312.68 | 1.47 | 4.03 |

| F3 | 309.67 | 309.67 | 0.00 | 313.55 | 1.25 | 5.61 | 317.51 | 2.53 | 330.40 | 6.69 | 2.84 | 314.07 | 1.42 | 321.48 | 3.81 | 4.01 |

| F4 | 311.37 | 311.37 | 0.00 | 314.96 | 1.15 | 6.06 | 316.86 | 1.76 | 323.86 | 4.01 | 2.66 | 312.29 | 0.30 | 316.90 | 1.78 | 3.99 |

| F5 | 313.51 | 314.82 | 0.42 | 317.83 | 1.38 | 6.57 | 318.52 | 1.60 | 332.07 | 5.92 | 2.84 | 313.51 | 0.00 | 318.11 | 1.47 | 4.09 |

| F6 | 294.38 | 294.38 | 0.00 | 297.47 | 1.05 | 4.70 | 296.65 | 0.77 | 313.77 | 6.59 | 3.08 | 295.34 | 0.33 | 297.14 | 0.94 | 4.00 |

| F7 | 311.41 | 311.41 | 0.00 | 316.15 | 1.52 | 4.92 | 316.94 | 1.78 | 329.39 | 5.77 | 2.70 | 311.47 | 0.02 | 313.54 | 0.68 | 4.10 |

| F8 | 323.74 | 323.74 | 0.00 | 326.40 | 0.82 | 5.21 | 329.22 | 1.69 | 336.00 | 3.79 | 2.87 | 324.60 | 0.27 | 327.52 | 1.17 | 4.04 |

| F9 | 315.04 | 315.56 | 0.17 | 318.47 | 1.09 | 4.66 | 316.69 | 0.52 | 326.71 | 3.70 | 3.18 | 315.04 | 0.00 | 317.25 | 0.70 | 3.83 |

| F10 | 312.37 | 312.70 | 0.11 | 315.13 | 0.88 | 3.94 | 321.89 | 3.05 | 327.84 | 4.95 | 3.00 | 312.37 | 0.00 | 314.20 | 0.59 | 3.32 |

| G1 | 413.52 | 417.92 | 1.06 | 425.19 | 2.82 | 4.45 | 416.70 | 0.77 | 437.84 | 5.88 | 2.43 | 413.52 | 0.00 | 417.08 | 0.86 | 4.25 |

| G2 | 389.46 | 389.64 | 0.05 | 390.14 | 0.17 | 2.40 | 394.82 | 1.38 | 405.97 | 4.24 | 2.85 | 389.46 | 0.00 | 390.96 | 0.39 | 4.14 |

| G3 | 411.47 | 411.47 | 0.00 | 415.14 | 0.89 | 4.90 | 418.44 | 1.69 | 433.66 | 5.39 | 3.04 | 423.59 | 2.95 | 429.28 | 4.33 | 4.24 |

| G4 | 429.47 | 433.09 | 0.84 | 435.56 | 1.42 | 4.67 | 443.99 | 3.38 | 457.26 | 6.47 | 2.71 | 429.47 | 0.00 | 435.83 | 1.48 | 4.00 |

| G5 | 419.94 | 421.05 | 0.26 | 422.49 | 0.61 | 4.48 | 423.99 | 0.96 | 435.99 | 3.82 | 2.38 | 419.94 | 0.00 | 424.61 | 1.11 | 4.05 |

| G6 | 415.46 | 415.46 | 0.00 | 420.84 | 1.29 | 5.51 | 420.91 | 1.31 | 436.48 | 5.06 | 2.87 | 421.30 | 1.41 | 426.96 | 2.77 | 4.21 |

| G7 | 409.24 | 409.31 | 0.02 | 412.14 | 0.71 | 5.21 | 414.10 | 1.19 | 433.60 | 5.95 | 2.71 | 409.24 | 0.00 | 411.58 | 0.57 | 4.18 |

| G8 | 402.76 | 406.51 | 0.93 | 407.89 | 1.27 | 5.08 | 411.63 | 2.20 | 426.55 | 5.91 | 2.84 | 402.76 | 0.00 | 417.30 | 3.61 | 4.11 |

| G9 | 428.16 | 428.16 | 0.00 | 435.75 | 1.77 | 5.91 | 434.75 | 1.54 | 453.15 | 5.84 | 3.31 | 438.40 | 2.39 | 440.99 | 3.00 | 3.92 |

| G10 | 426.82 | 426.82 | 0.00 | 430.94 | 0.97 | 5.40 | 437.87 | 2.59 | 453.32 | 6.21 | 2.92 | 426.96 | 0.03 | 430.17 | 0.78 | 3.44 |

| Ave | 0.16 | 0.89 | 4.78 | 1.21 | 3.85 | 2.81 | 0.38 | 1.27 | 3.87 |

| SA vs. | IP | Savings | Nearest | Sweep | HGA | ILS |

|---|---|---|---|---|---|---|

| Difference | 2.101 | 3.707 | 6.303 | 9.872 | 0.008 | 0.000 |

| Degree of freedom | 70 | 69 | 70 | 70 | 71 | 71 |

| t-value | −5.467 | −6.479 | −8.082 | −9.228 | −1.000 | NA |

| p-value | 0.000 | 0.000 | 0.000 | 0.000 * | 0.321 | NA |

| Best Obj. among 10 Runs | Average Obj. among 10 Runs | ||||

|---|---|---|---|---|---|

| SA vs. | HGA | ILS | SA vs. | HGA | ILS |

| Difference | 0.004 | −0.459 | Difference | 0.231 | −1.872 |

| Degree of freedom | 59 | 59 | Degree of freedom | 59 | 59 |

| t-value | 0.038 | −3.961 | t-value | 1.898 | −8.512 |

| p-value | 0.9702 | 0.0002 * | p-value | 0.0626 | 0.0000 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, V.F.; Lin, S.-W.; Jodiawan, P.; Lai, Y.-C. Solving the Flying Sidekick Traveling Salesman Problem by a Simulated Annealing Heuristic. Mathematics 2023, 11, 4305. https://doi.org/10.3390/math11204305

Yu VF, Lin S-W, Jodiawan P, Lai Y-C. Solving the Flying Sidekick Traveling Salesman Problem by a Simulated Annealing Heuristic. Mathematics. 2023; 11(20):4305. https://doi.org/10.3390/math11204305

Chicago/Turabian StyleYu, Vincent F., Shih-Wei Lin, Panca Jodiawan, and Yu-Chi Lai. 2023. "Solving the Flying Sidekick Traveling Salesman Problem by a Simulated Annealing Heuristic" Mathematics 11, no. 20: 4305. https://doi.org/10.3390/math11204305

APA StyleYu, V. F., Lin, S.-W., Jodiawan, P., & Lai, Y.-C. (2023). Solving the Flying Sidekick Traveling Salesman Problem by a Simulated Annealing Heuristic. Mathematics, 11(20), 4305. https://doi.org/10.3390/math11204305