Preventive Maintenance of k-out-of-n System with Dependent Failures

Abstract

1. Introduction, Motivation and Examples

1.1. Introduction

1.2. Examples

2. The Problem Set, Notations, and Assumptions

2.1. Notations and Assumptions

- —symbols of probability, expectation, and variation;

- is the series of component’s lifetimes, which are assumed to be independent identically distributed random variables;

- is their common cumulative distribution function (cdf) with their probability density function (pdf) and expectation

- The times of PM and the system repair for are supposed to be independent identically distributed random variables;

- are their cdf with mean values;

- It is assumed that the mean PM times are less than the mean repair time , and may or may not depend on the type of maintenance;

- j is the system state, where j means the number of failed components;

- is the set of the system states;

- After failure of the l-th component , the load on all others increases, which leads to a decrease in their residual lifetimes. It is modeled by compression of the residual components lifetime by some weight coefficient ;

- In the initial time epoch, the system is absolutely reliable, i.e., all its components are in the UP states and the initial system state is .

- After any system repair and its PM completion, the system became “as a new one”, i.e., returns to the zero state.

2.2. The Problem Statement

- —system working time during its regeneration cycle (see formal definition in Formula (13)).

- —system reliability function, and —mean time until the system fails (after the failure of k components).

- —cdf of PM start times for different strategies , and —their expectations

- The system availability , given by (3) for different PM strategies.

- An indicator of strategy preference criterion, which will be introduced later in the next section.

3. Process J and the Main Result

3.1. Process J

3.2. The Strategy Comparison

4. Distribution of PM Start and System Failure Times

4.1. Distribution of Order Statistics

4.2. Transformation of Order Statistics

4.3. Distribution of the Random Variables

- (i)

- its reliability function ;

- (ii)

- its mean lifetime ;

- (iii)

- availability factor for different PM strategies.

4.4. An Example: Exponential Distribution of Components Lifetimes

5. An Algorithm for the PM Strategies Comparison and Numerical Experiments

5.1. Algorithm

| Algorithm 1 General algorithm for calculation of the reliability function. |

Beginning. Determine: Integers , real , , distribution of the system components’ lifetime, its pdf, expectation a and coefficient of variation v. Step 1. Calculate parameters of cdf in terms of its expectation a and coefficient of variation v. Step 2. Taking into account the joint pdf of the first l order statistics calculate according to (28) the rv cdf

Step 3. Calculate the function and the mean time to the PM strategy beginning (mean time to the l-th component failure)

and the availability factor

Step 4. Compare the PM strategies by the criterion (15)

Stop. |

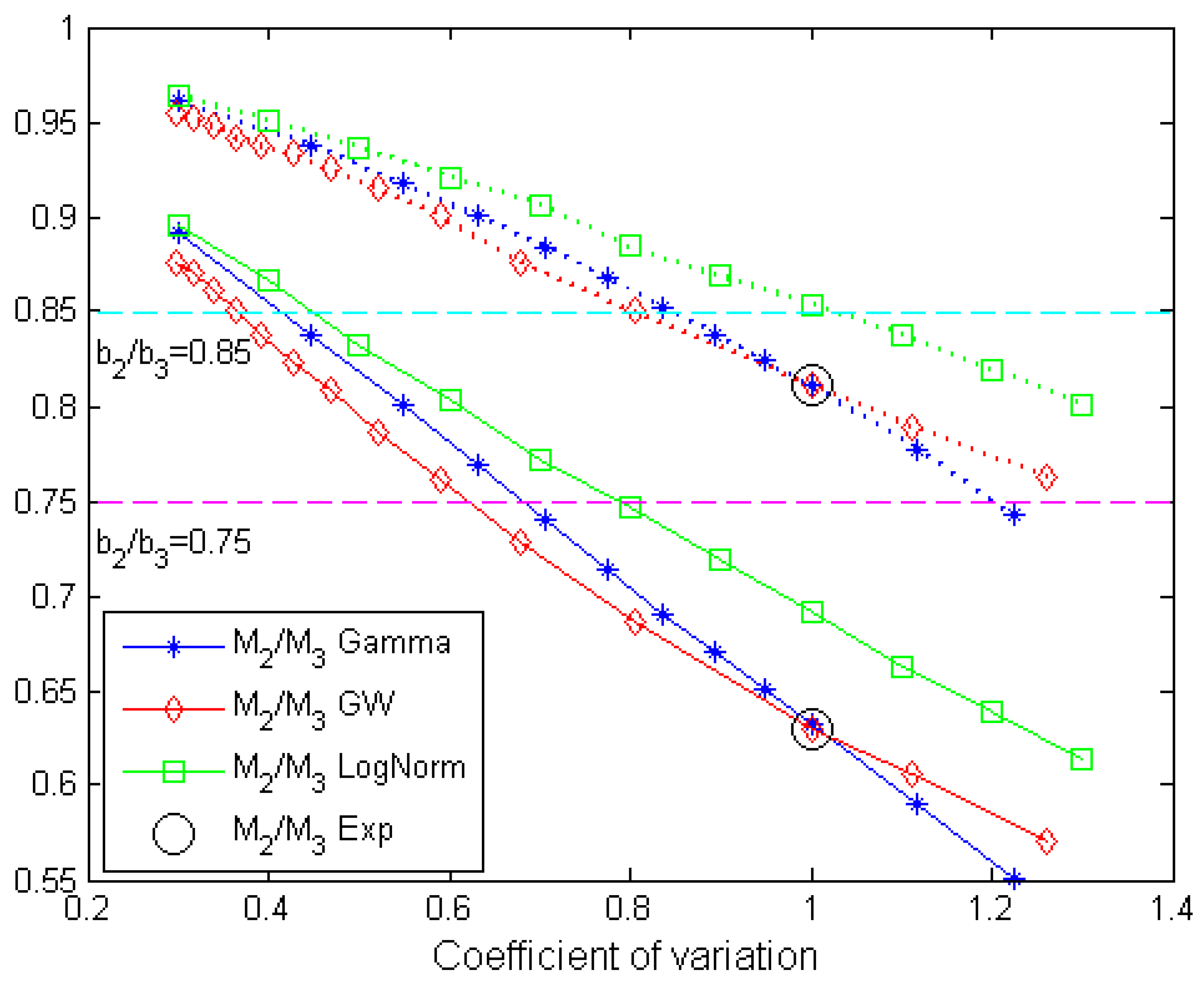

5.2. Numerical Experiments

5.3. An Example: Exponential Distribution

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PM | Preventive Maintenance |

| DM | Decision Maker |

| iid | independent and identically distributed |

| rv | random variable |

References

- Shepherd, D. k-out-of-n Systems. In Encyclopedia of Statistics in Quality and Reliability; John Wiley & Sons: Hoboken, NJ, USA, 2008; Available online: https://onlinelibrary.wiley.com/doi/pdf/10.1002/9780470061572.eqr342/ (accessed on 18 February 2022).

- Trivedi, K. Probability and Statistics with Reliability, Queuing and Computer Science Applications, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2016; Available online: https://onlinelibrary.wiley.com/doi/book/10.1002/9781119285441 (accessed on 18 February 2022).

- Chakravarthy, S.; Krishnamoorthy, A.; Ushakumari, P. A (k-out-of-n) reliability system with an unreliable server and Phase type repairs and services: The (N,T) policy. J. Appl. Math. Stoch. Anal. 2001, 14, 361–380. [Google Scholar] [CrossRef]

- Yuge, T.; Maruyama, M.; Yanagi, S. Reliability of a (k-out-of-n) system with common-cause failures using multivariate exponential distribution. Procedia Comput. Sci. 2016, 96, 968–976. [Google Scholar] [CrossRef]

- Zhang, T.; Xie, M.; Horigome, M. Availability and reliability of (k-out-of-(M+N)): Warm standby systems. Reliab. Eng. Syst. Saf. 2006, 91, 381–387. [Google Scholar] [CrossRef]

- Kuo, W.; Zuo, M. Optimal Reliability Modeling: Principles and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Wang, K.H.; Chen, W.L.; Yang, D.Y. Optimal management of the machine repair problem with working vacation: Newton’s method. Comput. Appl. Math. 2009, 233, 449–458. [Google Scholar] [CrossRef]

- Ke, J.C.; Hsu, Y.L.; Liu, T.H.; Zhang, Z.G. Computational analysis of machine repair problem with unreliable multi-repairmen. Comput. Oper. Res. 2013, 40, 848–855. [Google Scholar] [CrossRef]

- Wang, K.H.; Ke, J.B.; Ke, J.C. Profit analysis of the M/M/R machine repair problem with balking, reneging, and standby switching failures. Comput. Oper. Res. 2007, 34, 835–847. [Google Scholar] [CrossRef]

- Rykov, V.V.; Sukharev, M.G.; Itkin, V.Y. Investigations of k-out-of-n Systems Application Possibilities to Objects of Oil And Gas Industry. J. Mar. Sci. Eng. 2020, 8, 928. [Google Scholar] [CrossRef]

- Vishnevsky, V.M.; Kozyrev, D.V.; Rykov, V.V.; Nguyen, Z.F. Reliability Modeling of an unmanned high-altitude module of a tethered telecommunications platform. Inform. Technol. Comput. Syst. 2020, 4, 26–38. (In Russian) [Google Scholar] [CrossRef]

- Ying, C.; Qichao, M.; Ze, W.; Yingyi, L. Reliability analysis of k-out-of-n system with load-sharing and failure propagation effect. J. Syst. Eng. Electron. 2021, 32, 1221–1231. [Google Scholar] [CrossRef]

- Sharifi, M.; Taghipour, S.; Abhari, A. Inspection interval optimization for a k-out-of-n load sharing system under a hybrid mixed redundancy strategy. Reliab. Eng. Syst. Saf. 2021, 213, 107681. [Google Scholar] [CrossRef]

- Ahmadi, R. Reliability and maintenance modeling for a load-sharing k-out-of-n system subject to hidden failures. Comput. Ind. Eng. 2020, 150, 106894. [Google Scholar] [CrossRef]

- Nezakati, E.; Razmkhah, M. Reliability analysis of a load sharing k-out-of-n: F degradation system with dependent competing failures. Reliab. Eng. Syst. Saf. 2020, 203, 107076. [Google Scholar] [CrossRef]

- Rykov, V.; Ivanova, N.; Kozyrev, D.; Milovanova, T. On Reliability Function of a k-out-of-n System with Decreasing Residual Lifetime of Surviving Components after Their Failures. Mathematics 2022, 10, 4243. [Google Scholar] [CrossRef]

- Gertsbakh, I. Preventive Maintenance Models Based on the Lifetime Distribution. In Reliability Theory with Applications to Preventive Maintenance; Springer: Berlin/Heidelberg, Germany, 2000; pp. 67–106. [Google Scholar]

- Finkelstein, M.; Levitin, G. Preventive maintenance for homogeneous and heterogeneous systems. Appl. Stoch. Model. Bus. Ind. 2019, 35, 908–920. [Google Scholar] [CrossRef]

- Finkelstein, M.; Cha, J.H.; Levitin, G. On a new age-replacement policy for items with observed stochastic degradation. Qual. Reliab. Eng. Int. 2020, 36, 1132–1146. [Google Scholar] [CrossRef]

- Park, M.; Lee, J.; Kim, S. An optimal maintenance policy for k-out-of-n system without monitoring component. Qual. Technol. Qual. Manag. 2019, 16, 140–153. [Google Scholar] [CrossRef]

- Endharth, A.J.; Yun, W.Y.; Yamomoto, H. Preventive maintenance policy for linear-consequtive -k-out-of-n: F system. J. Oper. Res. Soc. Jpn. 2016, 59, 334–346. [Google Scholar]

- Hamdan, K.; Tavangar, M.; Asadi, M. Optimal preventive maintenance for repairable weighted k-out-of-n systems. Reliab. Eng. Syst. Safe 2021, 205, 107267. [Google Scholar] [CrossRef]

- Rezaei, E.; Jafary, B.; Fiondella, L. Optimal maintenance policies for linear consecutive k-out-of-n: F systems susceptible to dependent failures. Comput. Ind. Eng. 2022, 173, 108657. [Google Scholar] [CrossRef]

- Rykov, V.; Kochueva, O.; Farkhadov, M. Preventive Maintenance of a k-out-of-n System with Applications in Subsea Pipeline Monitoring. J. Mar. Sci. Eng. 2021, 9, 85. [Google Scholar] [CrossRef]

- Rykov, V.; Kochueva, O.; Rykov, Y. Preventive Maintenance of k-out-of-n System with Respect to Cost-Type Criterion. Mathematics 2021, 9, 2798. [Google Scholar] [CrossRef]

- Kala, Z. Quantification of Model Uncertainty Based on Variance and Entropy of Bernoulli Distribution. Mathematics 2022, 10, 3980. [Google Scholar] [CrossRef]

- Kala, Z. New Importance Measures Based on Failure Probability in Global Sensitivity Analysis of Reliability. Mathematics 2021, 9, 2425. [Google Scholar] [CrossRef]

- Rykov, V. On Reliability of Renewable Systems. In Reliability Engineering. Theory and Applications; Vonta, I., Ram, M., Eds.; CRC Press: Boca Raton, FL, USA, 2018; pp. 173–196. [Google Scholar]

- Rykov, V.; Kozyrev, D.; Filimonov, A.; Ivanova, N. On reliability function of a k-out-of-n system with general repair time distribution. Probab. Eng. Inf. Sci. 2020, 5, 1–18. [Google Scholar] [CrossRef]

- Vishnevsky, V.; Efrosinin, D.; Krishnamoorthy, A. Principles of Construction of Mobile and Stationary Tethered High-Altitude Unmanned Telecommunication Platforms of Long-Term Operation. In Communications in Computer and Information Science; Springer: Cham, Switzerland, 2018; Volume 919. [Google Scholar] [CrossRef]

- David, H.; Nagaraja, H. Order Statistics, 3rd ed.; John Wiley & Sons: New York, NY, USA, 2003. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rykov, V.; Kochueva, O. Preventive Maintenance of k-out-of-n System with Dependent Failures. Mathematics 2023, 11, 422. https://doi.org/10.3390/math11020422

Rykov V, Kochueva O. Preventive Maintenance of k-out-of-n System with Dependent Failures. Mathematics. 2023; 11(2):422. https://doi.org/10.3390/math11020422

Chicago/Turabian StyleRykov, Vladimir, and Olga Kochueva. 2023. "Preventive Maintenance of k-out-of-n System with Dependent Failures" Mathematics 11, no. 2: 422. https://doi.org/10.3390/math11020422

APA StyleRykov, V., & Kochueva, O. (2023). Preventive Maintenance of k-out-of-n System with Dependent Failures. Mathematics, 11(2), 422. https://doi.org/10.3390/math11020422