1. Introduction

Oil and natural gas are the main energy resources used for the development of modern society, and the exploitation and transportation of oil and gas require a large number of pipelines. However, pipelines are inevitably damaged by external force, corrosion, etc., and this high risk is generated from the beginning of the pipeline’s operation. Therefore, as a piece of engineering equipment that is highly invested in, the risk management for pipelines is very important. Although some preventive measures can be used for protection during the design, construction, and operation of the pipeline’s life cycle, such measures will gradually fail with the increase in service life and cannot guarantee the long-term safety of the pipeline. Therefore, pipeline risk assessment is a scientific management technology proposed to ensure the safe operation of the pipeline in the whole life cycle. The accuracy of risk assessment results depends on the design of the assessment method.

The earliest risk assessment method came from accidents in the process of industrialization [

1]. In the 1970s, nuclear power engineering began to introduce risk assessment, which eventually formed a complete risk management discipline [

2]. In the late 1980s, risk management was applied to equipment safety problems in the petrochemical field, especially for the risk management of oil and gas pipelines that are prone to accidents. For pipelines, risk assessment consists of conducting periodic risk assessments on oil and gas pipelines in the operation period and constantly improving defect factors identified in the assessment results according to the standards or requirements, then finally realizing the comprehensive management of the pipeline’s safety. Therefore, the risk assessment of the pipeline is actually a task that goes hand in hand with the pipeline’s life cycle. Its purpose is to ensure that the pipeline is within the scope of risk safety and to provide corresponding improvement and maintenance decisions.

For pipeline risk assessment, the American Society of Mechanical Engineers (ASME) first began to study the risk of pressure vessels [

3]. The American Petroleum Institute (API) published the API RP 580 normative standard of risk inspection technology that was formally proposed in 2002 [

4], which completely defines how to plan testing technology and plan based on risk factors. Pipeline safety expert W. Kent Muhlbauer wrote the authoritative pipeline risk management book, the

Pipeline Risk Management Manual, which is a summary of the theory and application of oil and gas pipeline risk assessment technology in the United States in the past decades [

5]. Canada began to pay attention to the research of risk assessment technologies of pipelines in the 1990s and put forward a number of future research topics [

6]. The HSC (Health and Safety Commission) of the UK developed the MISHAP software package for risk assessment and has achieved good practical results in using computer technology to carry out pipeline risk technology [

7]. After years of practical applications in various countries, it has been shown that the risk assessment of oil and gas pipelines can improve the safety of their operation, greatly reduce additional economic expenditure, reduce engineering disasters and environmental damage, and even maximize returns in social benefits, economic costs, and risks [

8]. For example, from 1987 to 1994, Amoco Corporation carried out regular risk assessments on its pipelines, which reduced the leakage rate from two-and-a-half times the industrial average to one-and-a-half times, and the company’s operating profit reached its highest level in 1994 [

9]. A large number of practical applications show that the risk assessment management of oil and gas pipelines is necessary, and the reasonable use of risk assessment technology has obvious benefits for pipeline safety operations, maintenance decision making, ecological safety, etc. [

10].

At present, the common methods used in risk assessment include the relative risk index method [

11], the probability analysis method [

12], the AHP (analytic hierarchy process) [

13], ETA (event tree analysis) [

14], the fuzzy comprehensive assessment method [

15], FTA (fault tree analysis) [

16], the risk matrix method [

17], etc. Although these methods have been applied in risk assessment, the quantitative risk assessment of oil and gas pipelines is still relatively lacking and needs to be further studied. Because there are many risk factors affecting pipelines, including pipe properties, transmission media, the external environment, operating conditions, and management approaches, etc., the risk factors will also affect each other. Meanwhile, as long-life equipment, the pipeline needs a lot of time and money to obtain all the risk factors’ sample information. Therefore, the most commonly used risk assessment methods are not suitable for the fitting of multiple risk indicators or are unable to process the risk information of small samples. As such, the common risk assessment methods are not practical for pipeline risk assessment. At present, many practical problems have been solved by combining fuzzy theory with multi-criteria decision making, such as quality performance indicator evaluation [

18], supplier selection [

19], platform partner evaluation [

20], etc.

In view of the current actual situation of pipeline operations, this paper constructs a risk indicator system for pipelines, calculates the indicator weight based on fuzzy theory, and combines this with the set pair analysis theory to propose a scientific quantitative risk assessment method for oil and gas pipelines. A large amount of risk indicator sample information can be obtained in a short time through the evaluation by experts [

21,

22], and it can solve the problem of less sample information regarding the pipeline. The set pair analysis method can realize the quantitative calculation of multiple indicators [

23,

24] with mathematical modeling to integrate the indicators’ information, and then effective decision making can be carried out.

Due to the large number of pipeline risk indicators, obtaining a large amount of indicator information will cost loads of time and money, which does not conform to the reality of management. The purpose of this paper is to obtain a more practical risk assessment method through mathematical modeling, which could meet the actual risk management requirements of pipeline engineering.

2. Failure Analysis and Risk Indicator System of Pipeline

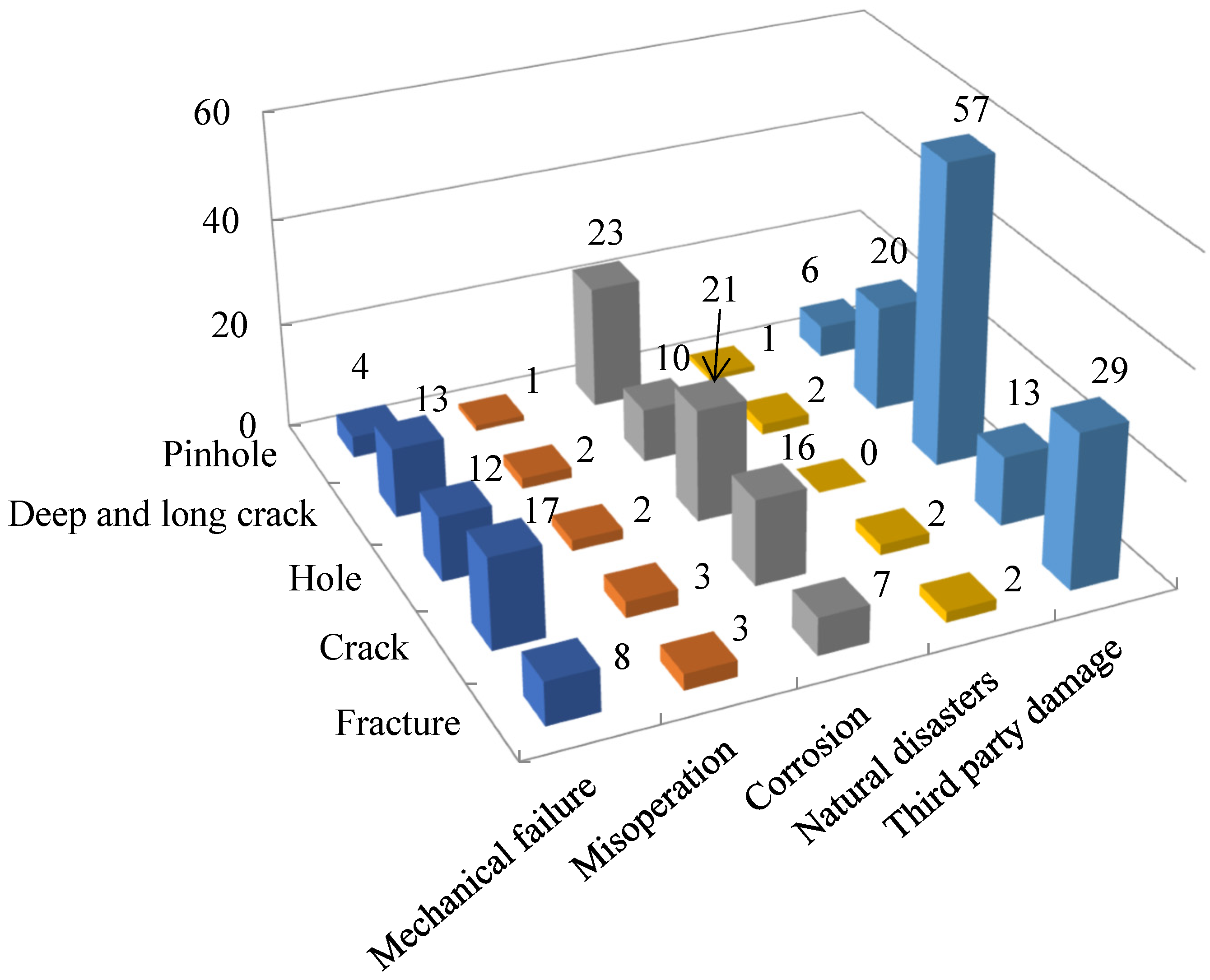

Oil and gas pipelines are usually buried in the ground across a wide area and face problems caused by complex geology and a harsh natural environment. Therefore, the pipeline will inevitably be damaged by external force, corrosion, or other problems in operation. The CONCAWE (Conservation of Clean Air and Water in Europe) summarized the leakage accidents of crude oil pipelines in Western Europe from 1971–2012, involving 156 pipelines with a total length of 36,251 km, for which 274 leakage accidents occurred [

25,

26,

27,

28]. According to the leakage diameter, the accident statistics are shown in

Figure 1.

The PHMSA (Pipeline and Hazardous Materials Safety Administration) of the United States conducted a statistical analysis of pipeline accidents from 1992 to 2012, including 5868 serious pipeline accidents [

29]. The PHMSA divides the accident causes into seven forms: corrosion, excavation damage, misoperation, material/welding/equipment failure, natural force damage, other external force damage, and other reasons, as shown in

Table 1.

Due to the frequent production and construction activities in China, third-party damage has become an important cause of pipeline accidents, followed by corrosion. Moreover, there are more and more pipelines in complex geological areas, and pipeline accidents caused by floods, landslides, earthquakes, and other geological disasters have begun to gradually increase. There have been 28 pipeline leakage accidents in China in the past decade, as shown in

Figure 2. Among them, there were 10 cases of pipeline damage caused by third-party damage, 7 cases caused by drilling and oil stealing, 3 cases caused by geological disasters, 2 cases caused by corrosion, 3 cases caused by equipment and materials, 1 case caused by improper operation, and 2 cases caused by unknown reasons.

According to the statistics of pipeline accidents in various countries, there are many causes leading to pipeline failure, including external interference, corrosion, material defects, mechanical damage, misoperation, and natural disasters. In conclusion, the analysis of the risk factors of pipelines needs to be comprehensive and save costs, so as to ensure correct and meaningful risk assessment results. The pipeline is a complex system, and the impacts of indicators on the system are different [

30]. Therefore, the difficulty of obtaining indicator information is also different [

31]. Therefore, the selection of indicators needs to be considered comprehensively: the obtainment of methods of indicator information should be operable, the impact on risk should be representative, and the final assessment of risk should be comprehensive. The selected indicators should be able to accurately reflect the risk status of the pipeline on a realizable basis.

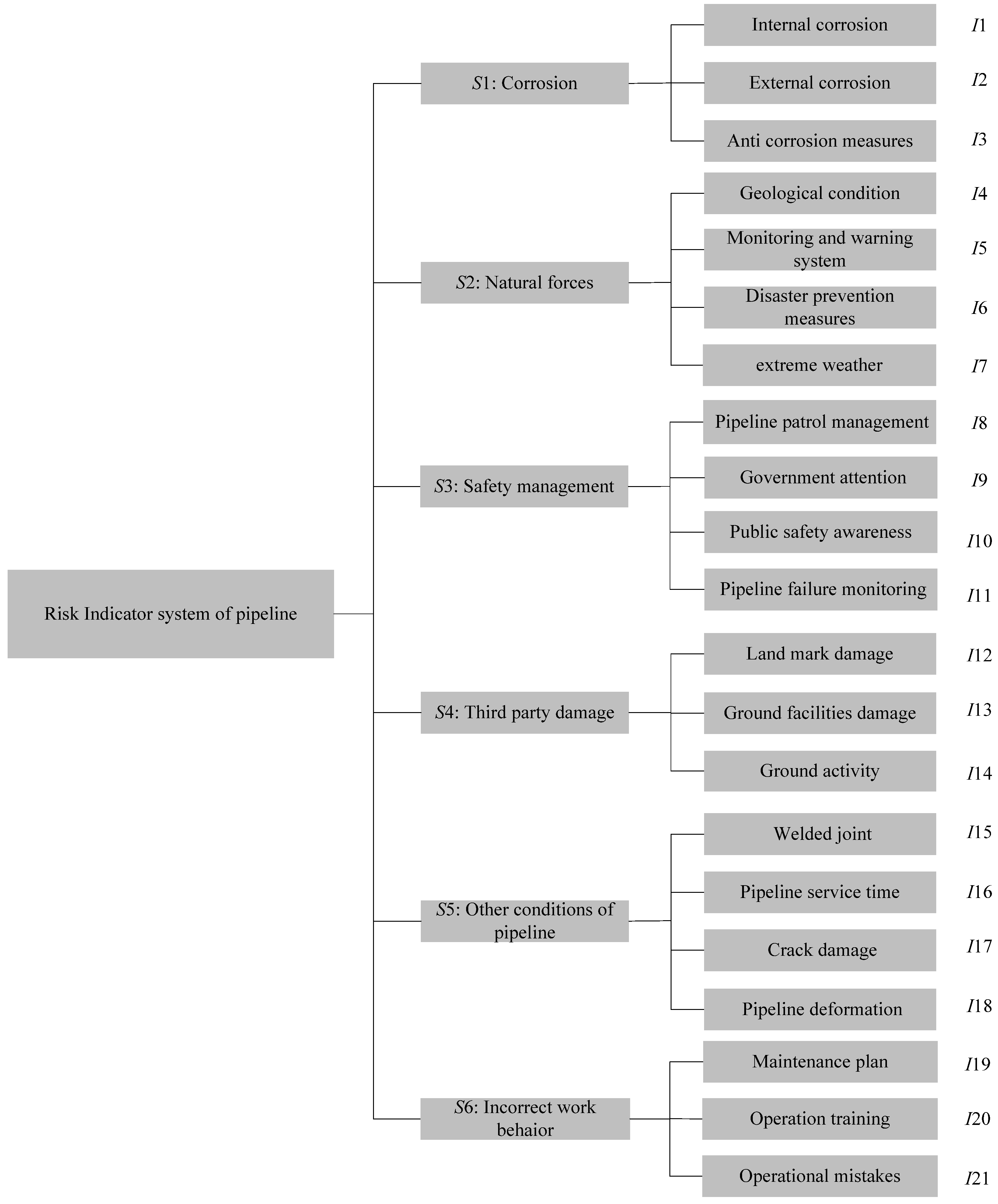

Therefore, based on the analysis of and reference to the classification of pipeline failure causes in various countries, this paper summarizes the risk indicators of pipelines into six secondary indicator sets: corrosion, third-party damage, natural forces, other conditions of the pipeline, incorrect work behavior, and safety management.

The classification of risk indicator sets is based on pipeline property damage, such as steel corrosion and cracks. Risks are caused by external factors, such as natural forces and third-party damage, as well as risks caused by incorrect operation and management, such as safety management and incorrect work behavior. Corrosion is the main form of damage to pipelines [

32]. Pipeline corrosion can be divided into internal corrosion and external corrosion. External corrosion is caused by external media such as the soil and atmosphere, and internal corrosion is caused by transmission media. Natural forces are the forces of natural factors. For instance, a landslide will cause displacement and cracking of pipelines [

33]. However, disasters caused by natural forces are usually sporadic and require high safety monitoring. Safety management includes the management measures taken to maintain safe operation during pipeline operation [

34]. Third-party damage is the damage caused by third-party activities to pipelines [

35]. For example, because of unclear ground markings, the pipeline may be exposed to the ground due to being wrongly excavated, and this will increase the risk of damage. Incorrect work behavior during pipeline operation will lead to pipeline damage. For instance, calculating the wrong delivery pressure will cause pipeline deformation. The incorrect work behavior is caused by many reasons, such as a lack of training for oil workers resulting in operational mistakes or the untimely maintenance of equipment resulting in failure. Other conditions of the pipeline include indicators that have a greater impact on pipeline safety, such as deformation, cracks, and weld joint [

36].

These 6 indicator sets include 21 tertiary indicators. The final risk assessment indicator system is shown in

Figure 3.

5. A Case Study

The Yujiaping-Haojiaping pipeline belongs to the Yanchang oilfield and stretches from the Xingzichuan oil production plant to the Yongping oil refinery, located in Yan’an City, Shaanxi Province, China (

Figure 5). The basic pipeline information is shown in

Table 2. The pipeline has been in operation for more than ten years, and it began to gradually form sudden damage. The sudden damage, such as leakage, seriously affects the normal transportation of oil and brings pressure to pipeline maintenance. (

Figure 6) Therefore, for the purpose of providing a reference to make maintenance decisions in advance, a risk assessment is now carried out for this pipeline.

5.1. Calculation of Risk Indicator Weight

The accurate assessment method must be based on the appropriate assessment information. The assessment information usually includes the assessment indicators and the assessment standard. The assessment indicators are listed in the

Section 2. For the assessment standard, the more the assessment levels there are, the more accurate the final assessment result will be. However, too many assessment levels will lead to complexity in the calculation in the assessment process, and it will also lead to complexity in the expression of the results from the qualitative assessment point of view. The psychologist George Miller [

59] proved that the number of levels for which a human can correctly distinguish things is between five and nine, and based on national standards [

60,

61]. This paper divides the safety of pipeline into 5 assessment levels:

L1 is extremely safe;

L2 is very safe;

L3 is relatively safe;

L4 is relatively unsafe;

L5 is particularly unsafe (can be understood as failure), and the score ranges are (0.9,1), (0.8,0.9), (0.7,0.8), (0.6,0.7), (0,0.6), respectively. The five assessment levels can reasonably reflect the different states of pipeline risk from serious to safe.

L1 and

L5 represent the most extreme state, and

L1 means that all the pipeline indicators are perfect without any need of improvement.

L5 means that the pipeline has great risks, cannot be operated, and needs maintenance.

L3 represents a stable safety state. In

L3, although there are some defect indicators, they do not affect the operation of the pipeline, and the defect indicators only need to be monitored regularly.

L2 is a safer state than

L3. Some defect indicators have been improved in

L2, but there are still a few defect indicators that cannot be further improved.

L4 indicates that at this time, the pipeline has some risk problems that need to be corrected. Although these problems will not affect the normal operation of the pipeline temporarily, they will further increase the risk of pipeline failure in the short term.

The assessment of indicators is also divided into six levels, and the vague values are constructed: V1 (0.9,1), V2 (0.8,0.9), V3 (0.6,0.8), V4 (0.4,0.6), V5 (0.2,0.3), V6 (0,0.2). Eight experts in pipeline safety management are invited to judge the indicators and give the vague values.

Taking the corrosion indicator as an example, the magnetic flux leakage detector (

Figure 7) is used to detect the corrosion data. The internal corrosion situation and external corrosion situation of the pipeline are shown in

Figure 8, and experts can give the vague value based on this corrosion information.

The vague value of other indicators can also be given by expert judgement based on the testing or recording data. Natural force indicators can be judged based on the recorded data of natural resource departments and meteorological departments. Safety management indicators, third-party damage indicators, and incorrect work behavior indicators can be judged based on the recorded data of the pipeline operation department. Other conditions of pipeline indicators can be judged based on the equipment detection data. The assessment vague values are given based on the six levels shown in

Table 3.

Based on vague values and Equation (10), the risk assessment matrix is:

Taking the first indicator of internal corrosion as an example, the consistency matrix is calculated by Equations (11) and (12):

where

, and the average similarity value of each expert can be calculated by Equation (13):

and

, so we can obtain the relative consistency value of each expert on internal corrosion:

Furthermore, the relative consistency measure matrix of indicators evaluated by experts is represented by:

The assessment vague value of all experts on internal corrosion in can be obtained:

Finally, the weight of internal corrosion is:

The weights of each indicator are calculated respectively, and the results are shown in the

Table 4.

5.2. Establishment of Set Pair Analysis for Pipeline Risk

The risk level and the indicator set are constituted as a set pair. The indicators corresponding to levels L1 to L5 are respectively defined as the identity, the difference trend to identity, the difference, the difference trend to opposite, and the opposite, and the number of indicators is S, F1, F2, F3, and P, respectively. The calculation steps of the five-element relational degree for the pipeline are as follows.

(1) Because the safety of the pipeline is divided into five assessment levels, the five-element relational degree according to the risk assessment level can be assessed with:

(2) The relation degree of each indicator is calculated based on the median value of each vague value. The calculation method is:

where

x is the median value of the vague value. Taking internal corrosion as an example, the median values of the vague value given by experts are (0.85, 0.95, 0.85, 0.7, 0.95, 0.7, 0.85, 0.95). The relational degrees of all experts calculated based on Equation (21) are shown in the

Table 5.

Combining the indicator weight 0.55258 (in

Table 4), the comprehensive relational degree of internal corrosion is calculated as:

5.3. Calculate the Relational Degree and Determine the Risk Level

By calculating the relational degree of all risk indicators, the five-element average relational degree of pipeline risk is calculated as:

Because the max value in {

S,

F1,

F2,

F3,

P} is less than 0.5, the principle of maximum membership cannot be used to determine the final risk level. Therefore, the risk level eigenvalue value is calculated based on Equation (9):

The risk level eigenvalue of the pipeline is calculated as 2.911, i.e., the risk level is

L3, which means the pipeline is relatively safe. This also indicates that the risk level of the pipeline is at

L3 but tends to

L2, that is, it is could attain level

L2 through improvement. The relational degree and level eigenvalues of the six indicator sets can be calculated as shown in

Table 6. Meanwhile, the assessment result also indicates that some indicators are not perfect. The calculation results of the risk level eigenvalue for each indicator are shown in

Table 7.

5.4. Analysis of Assessment Results

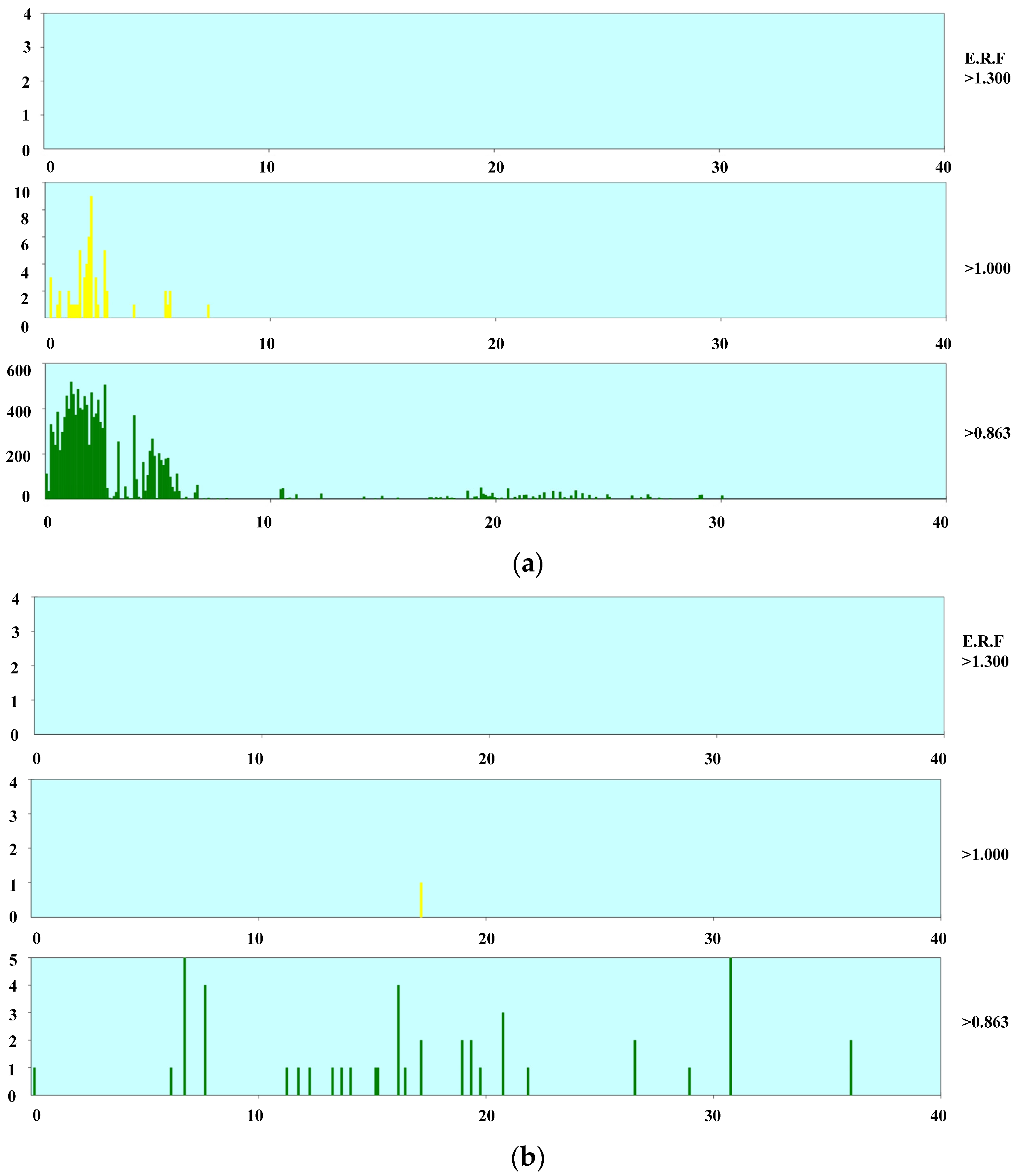

The risk eigenvalues of the indicator sets and indicators are shown in

Figure 9.

Figure 9a shows that the corrosion is at the

L2 level (i.e., very safe), and the natural forces, incorrect work behavior, third-party damage, and other conditions of pipeline are at the

L3 level (i.e., relatively safe).

Figure 9b shows that geological conditions, extreme weather, and public safety awareness are at the

L5 level (i.e., particularly unsafe), and service time, pipeline deformation, ground activity, and operation training are at the

L4 level (i.e., relatively unsafe). These indicators have an obvious influence on the safety of pipeline. Among these indicators, geological conditions, extreme weather, and service time are indicators that cannot be changed or modified from the perspective of management and can only be prevented in the form of periodic detection. Pipeline deformation needs to be focused on and monitored in time, and timely maintenance is necessary. However, public safety awareness, ground activity, and operation training awareness can be corrected and improved in a timely manner. By improving the three indicators, the safety of the pipeline can be greatly improved.

Other indicators affecting the risk are in line with the safety regulations and within the acceptable range of safety. However, with the increase in the pipeline’s operation time, the insecurity of these indicators will increase, and this will affect the overall safety. Therefore, targeted monitoring should be carried out according to the different risk levels. In particular, it is necessary point out that the impact of the risk of misoperation on the safety of the pipeline is controllable, which requires more strict control.

6. Conclusions

In this paper, set pair analysis theory is used to assess pipeline risk. Vague set theory is applied to calculate the weights of the identity, the difference, and the opposite. The calculation method takes into account the subjective influence of experts’ preferences and improves the accuracy and reasonableness of the assignment of weights. Meanwhile, to solve the problem that the risk level judgement with the maximum membership method is usually inconsistent with the actual situation, this paper uses the eigenvalue method to calculate the risk level and considers the influence of other relational degrees on the final result.

The risk indicators of pipelines are various and complex. In many cases, these indicators have a comprehensive effect and promote or inhibit to each other. Meanwhile, because the risk indicators are too numerous and studying all of them to obtain greater detailed information will take a lot of money and time, this is not suitable for actual engineering issues. Compared with traditional risk assessment methods, this paper proposes a new weight calculation method for the uncertainty of pipeline risk assessment indicators. Compared with other fuzzy expressions (e.g., fuzzy numbers), the vague value can express fuzzy information and comprehensively characterize the indicator information. It solves the uncertainty and hesitation of experts in judging risk indicators and renders the pipeline risk indicator weight calculation method more scientific. Compared with the traditional multi-criteria judgement method, the set pair analysis method connects the assessment indicators with the assessment criteria and can scientifically and quantitatively calculate the comprehensive judgment result of a large amount of indicator information. The assessment decision-making method proposed in this paper is to calculate the relational degree between indicators with all assessment levels, and this is reflected in the final assessment results. Other decision-making methods, for example, the TOPSIS method in [

18], included calculating the relationship between indicators with the best and worst assessment levels, which cannot reflect the membership degree to other risk assessment levels, and this will then lead to a certain error in the final evaluation results. Therefore, the assessment results in this paper are more comprehensive, stable, and accurate. The method proposed in this paper solves the problem of quantitative risk assessment for pipelines in the absence of indicator information and is more suitable for the situation in which there are only a small amount of sample data in the risk assessment.

Meanwhile, the assessment method proposed in this paper uses the multi-index assessment of pipeline risk for a single objective decision. The method not only realizes the quantification of risk assessment, but it also accurately reflects the comprehensive risk level for the pipeline and provides a new idea for the safety management of the pipeline. At the same time, the method can also locate the deficiencies of specific indicators, which is helpful for managers to make targeted improvements. The method has good practicability and is conducive to the long-term operation and management of pipelines, and it also provides a reference for other engineering projects’ risk assessments. However, the method relies too much on the experience, knowledge base, and judgement ability of experts, so it has a personal preference effect on the assessment results and does not exclusively use the indicators’ information. Therefore, it is necessary to further study the ways in which to combine the existing indicator information to form a more comprehensive assessment method.