Abstract

The ability to accurately predict the shape of a transversely loaded hollow annular membrane is essential to the design of bending-free hollow annular shells of revolution, which requires a further improvement in the hollow annular membrane solution to meet the needs of this accurate prediction. In this paper, the large deflection problem of a transversely loaded hollow annular membrane is reformulated by simultaneously modifying the out-of-plane equilibrium equation and radial geometric equation, and a newer and more refined power series solution is derived. The reason why the classical radial geometry equation induces errors is revealed. The convergence and asymptotic behavior of the power series solution obtained is analyzed numerically. The newly derived solution is compared with the two previously derived solutions graphically, showing that the newly derived solution performs basically as well as expected. In addition, the anticipated use of the hollow and not-hollow annular membrane solutions for the design application of bending-free annular shells of revolution is discussed.

Keywords:

annular membrane; transverse loading; large deflection; power series solution; bending-free shell of revolution MSC:

74G10; 74K15

1. Introduction

Most membranes have the ability to exhibit large elastic deflections under lateral loading, which opens up the possibility for many technical applications such as blister tests [1,2,3], bulge tests [4,5,6], constrained blister tests [7,8,9,10], contact or non-contact capacitive pressure sensors [11,12,13,14], and especially deflection-based devices [15,16,17,18,19,20,21]. Essential to these technical applications is the ability to solve these problems of a large deflection of the membranes under lateral loading analytically and accurately. However, these large deflections often give rise to strong geometric nonlinearity, and these nonlinear differential equations often present analytical difficulties [22,23,24]. In the existing literature, annular membrane problems are less in evidence in comparison with circular membrane problems [25,26,27,28,29], but are often more difficult to deal with analytically due to the boundary conditions at the inner and outer edges which need to be satisfied simultaneously [30,31,32]. This paper is devoted to the further improvement in the analytical solution of a transversely loaded hollow annular membrane, aiming at providing a more accurate analytical solution for a specialized technical application of shell form-finding [33,34,35,36,37,38].

In an earlier work [31], we proposed the concept of a hollow annular membrane whose central empty region always keeps constant during transverse loading, for the determination of the shape (spatial geometry) of a hollow annular shell of revolution. Specifically, the inner edge of an annular membrane with a fixed outer edge is attached rigidly to a weightless stiff ring, to ensure that when the annular membrane is transversely loaded the central empty region within the inner edge always keeps constant and free from the action of the transverse loads during deflection, resulting in a hollow annular membrane structure. Similar to the hanging membrane method for shell designs proposed by Heinz Isler [36,37,38], the deflection shape of a transversely loaded hollow annular membrane, if inverted (flipped 180 degrees), can be used as the shape (spatial geometry) of, for instance, a concrete hollow annular shell of revolution. The hollow annular shell of revolution shaped by this method has only compression stresses, because the transversely loaded hollow annular membrane has only tension stresses. This is the so-called “shape-finding” or “form-finding” for bending-free shells [33,34,35,36,37,38]. Reducing the bending moment is very important for improving the stability of thin shells.

Before the concept of hollow annular membranes was proposed, only solid (not-hollow) annular membranes had been presented in the literature [30]. The so-called solid (not-hollow) annular membranes refer to the annular membrane structures whose outer edges are fixed and inner edges are attached rigidly to weightless stiff circular thin plates. The central region within the inner edge of a transversely loaded solid (not-hollow) annular membrane also always keeps constant during deflection, but is not empty and not free from the action of the transverse loads due to the weightless, stiff circular thin plate that is still subjected to the action of the transverse loads, and in particular is connected to the inner edge of the solid (not-hollow) annular membrane. Therefore, the difference between the hollow and solid (not-hollow) annular membranes is only that for the same outer and inner radius, the external load action withstood by a solid (not-hollow) annular membrane is greater than that withstood by its corresponding hollow annular membrane. This first suggests that under the same conditions (including outer and inner radius, transverse loads, etc.), the deflection shape of a solid (not-hollow) annular membrane is different from that of a hollow annular membrane. Secondly, it is very possible that by only adjusting the size of the loads applied, it is difficult to obtain two hollow and solid (not-hollow) annular membranes with the same geometric shape, if the other conditions are the same for the two annular membranes. This suggests that a hollow annular shell can be shaped only by a hollow annular membrane and never by a solid (not-hollow) annular membrane; otherwise, the original intention of “bending-free” will fall through due to the errors in geometric shape, and the reverse is also true. This is the reason why we proposed the concept of hollow annular membranes.

The closed-form solution of a hollow annular membrane under uniformly distributed transverse loads is derived originally by using an assumption of a small rotation angle of the membrane [31], while its second version [32] does not use the assumption of a small rotation angle of the membrane. The accuracy of the second version [32] has been greatly improved in comparison with the original version; however, as mentioned above, the shape errors have a significant influence on the shell form-finding. In other words, the accuracy of the closed-form solution of a transversely loaded hollow annular membrane determines the accuracy of the shell form-finding, and thus determines whether the bending moment will be present in the form-found hollow annular shell of revolution under service loads, which is very important for ensuring the stability of the shell. Although the finite element method is accurate and simple to obtain, it is not suitable for the shell form-finding where the structural parameters need to be adjusted arbitrarily. This is also the motivation for why this study further improves the power series solution of transversely loaded hollow annular membranes.

In this paper, two assumptions adopted in the classical radial geometric equation, which is used in the original and second versions [31,32], are further given up (see Section 3.1 for details), and a newer and more refined closed-form solution is presented. In the following section, the large deflection problem of a hollow annular membrane subjected to the action of uniformly distributed transverse loads is reformulated by simultaneously modifying the out-of-plane equilibrium equation and radial geometric equation, and is solved by using the power series method. In Section 3, some important issues are discussed, such as the reason why the classical radial geometric equation induces errors, the convergence of the power series solutions for stress and deflection obtained in Section 2, the asymptotic behavior from the obtained hollow annular membrane solution to the well-established circular membrane solution, the difference between hollow annular membrane solutions before and after improvement, and the difference in shell design between hollow and solid (not-hollow) annular membrane solutions. The concluding remarks are given in Section 4.

2. Membrane Equation and Solution

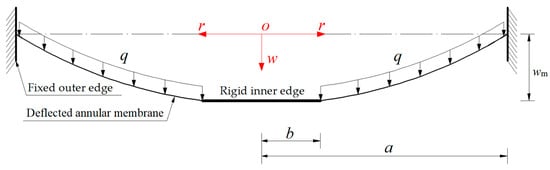

A transversely loaded hollow annular membrane structure is shown schematically in Figure 1. An initially flat annular membrane with outer radius a, inner radius b, thickness h, Poisson’s ratio v, and Young’s modulus of elasticity E, whose outer edge is rigidly fixed and inner edge is rigidly attached to a weightless stiff ring that is movable at the transverse direction perpendicular to the initially flat annular membrane, is subjected to a uniformly distributed transverse loads q, resulting in the transverse displacement (deflection) of the annular membrane. In Figure 1, the dash-dotted line represents the initially flat geometric middle plane of the annular membrane, the centroid of the initially flat geometric middle plane is coincident with the coordinate origin o of the introduced cylindrical coordinate system (r, φ, w), the polar coordinate plane (r, φ) is coincident with the plane in which the initially flat geometric middle plane is located, r is the radial coordinate variable, φ is the angle coordinate variable (not represented in Figure 1), w is the cylindrical coordinate variable (also representing the membrane deflections), and at the inner edge, the radial and circumferential displacement are rigidly constrained but the transverse displacement is not constrained.

Figure 1.

Sketch of a hollow annular membrane structure under the transverse uniform loads q.

The hollow annular membrane structures shown in Figure 1 differ from the traditional solid (not-hollow) annular membrane structures mainly because under the same inner radius b, outer radius a, thickness h, Young’s modulus of elasticity E, Poisson’s ratio v, and transverse loads q, the structural response of the former is smaller than that of the latter, because the annular membrane in the former is subjected to the action of π(a2−b2)q (since the central region within the inner edge of the former is empty and free from the action of the transverse loads q), while the annular membrane in the latter is subjected to the action of πa2q (since the inner edge of the latter is connected rigidly with a weightless, stiff circular thin plate that is still subjected to the action of the transverse loads q). This has a great influence on the out-of-plane equilibrium in the direction perpendicular to the polar plane (r, φ). The out-of-plane equilibrium equation may be established by taking a free body as shown in Figure 2.

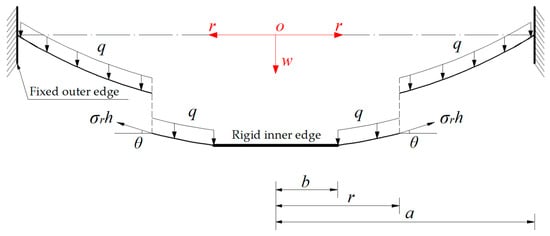

Figure 2.

A free body with radius r (b ≤ r ≤ a) removed from the deflected annular membrane.

A free body with radius r (b ≤ r ≤ a) is assumed to be taken out from the central region of the deflected annular membrane under the transverse loads q, to study its static problem of equilibrium under the joint action of the vertical (transverse) force π(r2 − b2)q produced by the loads q and the vertical force 2πrσrhsinθ produced by the membrane force σrh that is acting on the boundary r, as shown in Figure 2, where σr denotes the radial stress and θ denotes the slope angle of the deflected annular membrane. When the free body is in equilibrium, the resultant force in the vertical direction should be equal to zero, that is,

It can be found from Figure 2 that the slope at any point on the deflection curve can be expressed as tanθ = −dw/dr. Therefore, it can be recalled from trigonometric functions that

Therefore, after eliminating sinθ and tanθ from Equations (1) and (2), the out-of-plane equilibrium equation may finally be written as

The so-called “in-plane” refers to the plane parallel to the polar plane (r, φ), and the in-plane equilibrium equation may be established by taking out a wedge-shaped micro area element from the deflected annular membrane under the transverse loads q. If the circumferential stress is denoted by σt, then the in-plane equilibrium equation may be written as [31,32]

If the radial strain is denoted by er, the circumferential strain by et, and the radial displacement by u(r), then the geometric equations (the relationships between strain and displacement), which are used in [31,32] may be modified into the following forms (the detailed derivation is arranged in Section 3.1, to keep the formulation compact)

and

Moreover, the physical equations (the relationships between stress and strain) are still assumed to satisfy generalized Hooke’s law and are given by [31,32]

and

Equations (3) through (8) are six equations for solving σr, σt, er, et, u, and w, and the solution process is as follows. Eliminating er and et from Equations (5) through (8) yields

and

From Equations (9) and (10), the radial stress σr and circumferential stress σt can be expressed as

and

Furthermore, eliminating σt from Equations (4) and (10), one has

After substituting the u from Equation (13) into Equation (11), the consistency equation may be written as:

Equations (3), (4) and (14) are three equations for solving σr, σt, and w, and the boundary conditions to determine the specific solutions of σr, σt, and w are

and

After introducing the following dimensionless variables

Equations (3), (4), (13) through (17) can be transformed into the following dimensionless forms

and

In view of the stress and displacement being finite within α ≤ x ≤ 1, after introducing β = (1 + α)/2, Sr, and W can be expanded into the power series in powers of x − β, i.e., letting

and

Further, after introducing X = x − β, Equations (19), (22), (26) and (27) can be transformed into

and

By substituting Equations (30) and (31) into Equations (28) and (29) and letting all the coefficient sums of the X with like powers be equal to zero, a system of equations for determining the recurrence formulas for the power series coefficients ci and di can be obtained. The resulting recurrence formulas for ci (i = 2, 3, 4, …) and di (i = 1, 2, 3, …) are listed in Appendix A.

From Appendix A, it can be seen that the coefficients ci (i = 2, 3, 4, …) and di (i = 1, 2, 3, …) can be expressed into the polynomials with regard to the first two coefficients c0 and c1, i.e., the so-called undetermined constants. The remaining one coefficient d0 is another undetermined constant, but is a dependent one that is determined so long as the undetermined constants c0 and c1 are determined. By using the boundary conditions, Equations (23)–(25), the undetermined constants c0, c1, and d0 can be determined as follows. Substituting Equation (26) into Equations (23) and (24) yields

and

Equations (32) and (33) contain only c0 and c1, because the coefficients ci (i = 2, 3, 4, …) can be expressed into the polynomials with regard to c0 and c1. Therefore, the values of c0 and c1 can be determined by solving Equations (32) and (33) simultaneously. Then, substituting Equation (27) into Equation (25) yields

Therefore, the value of d0 can also be determined, because the values of the coefficients di (i = 1, 2, 3, …) can easily be determined with the known c0 and c1 (see Appendix A).

Finally, with the known c0 and c1, the coefficients ci (i = 0, 1, 2, 3, …) and di (i = 0, 1, 2, 3, …) can easily be determined, and hence the expressions of σr and w can be determined. As for the expressions of σt, er, et, and u, with the known expression of σr, the expression of σt can easily be determined by Equation (4), and with the known expressions of σr and σt, the expressions of er, et and u can also be easily determined by Equations (7), (8) and (10). The problem addressed here is thus solved analytically.

3. Results and Discussions

3.1. The Reason Why the Classical Geometric Equations Induce Errors

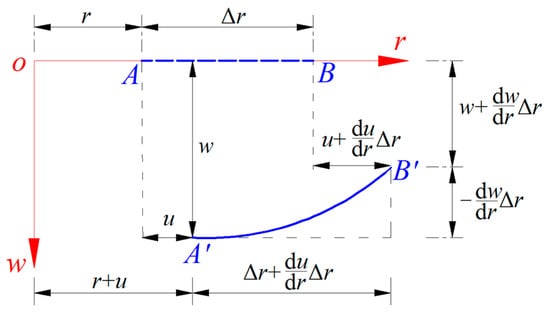

Comparing the geometric equations used here (Equations (5) and (6) in this paper) and the classical geometric equations used in [31,32] (Equations (5) and (6) in [31,32]), it can be observed that only the radial geometric equation, Equation (5), is different, while the circumferential geometric equation, Equation (6), is the same. The reason why the classical radial geometry equation is modified in this paper is that the classical radial geometry equation can induce errors, which is analyzed as follows. The so-called geometric equations refer to the analytical relationships between displacements and strains. The radial geometry equation can be derived by taking out an infinitely small (micro) radial line element (assumed to be the straight line of length Δr in Figure 3) from the initially flat annular membrane. After deformation, the initially flat micro radial straight line element is assumed to become the micro meridional curve in Figure 3.

Figure 3.

The geometrical relationship between the initial micro radial straight line element and the micro meridional curve that is derived from the deformation of .

Suppose that the radial and transverse displacements of the point A are denoted by u(r) and w(r), respectively. Then, the radial and transverse displacements of the point B may be denoted by u(r + Δr) and w(r + Δr), respectively. The u(r + Δr) and w(r + Δr) can be expanded into a Taylor series, and after ignoring the infinitely small higher order terms in Taylor expansion, they can be approximately expressed as the following forms

and

Therefore, the geometric dimensions marked on Figure 3 can be obtained, where u(r) and w(r) are abbreviated as u and w, respectively.

The radial line strain from the micro radial straight line element to the micro meridional curve (see Figure 3) may be written as, according to the definition of line strain

The classical radial geometric equation uses the assumption of , that is, the length change from the micro radial straight line element to the micro meridional curve is ignored. Then, based on the assumption of , Equation (37) can be changed to

Obviously, the length of the micro straight line can be used to approximately express the length of the micro curve (see Figure 3)

Therefore, from Equations (37) and (38), the radial line strain er may be written as

In Equation (40), the second term may be neglected in comparison with the first term . Therefore, the radial line strain er may finally be written as

Equation (41) is the classical radial geometric equation used in [31,32] (see Equation (5) in [31,32]).

It can clearly be seen from the above derivation that there are two places where the classical geometric equations can induce errors. One is through ignoring the length change from the micro radial straight line element to the micro meridional curve , and the other is via neglecting the second term in Equation (40). In fact, if the assumption of holds, then the radial line strain er should be equal directly to zero, so there is no need to derive Equation (38). On the other hand, it is hard to say whether can be neglected in comparison with ; they will probably be on the same order of magnitude. This is the reason why the classical radial geometry equation induces errors.

Incidentally, the radial geometry equation used in this paper is derived directly from Equations (37) and (39). Substituting Equation (39) into Equation (37) yields

This is the radial geometry equation used in this paper, i.e., Equation (5), where no assumptions are used here.

3.2. Convergence Analysis of Power Series Solutions

From Appendix A, it can be seen that the recursion formulas for the power series coefficients ci and di are too complicated, so the convergences of the power series solutions Sr and W have to be analyzed numerically. To this end, an annular membrane with outer radius a = 20 mm, inner radius b = 5 mm, thickness h = 0.2 mm, Young’s modulus of elasticity E = 7.84 MPa, Poisson’s ratio ν = 0.47, and subjected to the actions of q = 0.0008 Mpa and 0.15 Mpa, is used as a numerical example to illustrate how to carry out a convergence analysis of the power series solutions Sr and W. Here, the relevant dimensionless quantities are α = b/a = 0.25, β = (1 + α)/2 = 0.625, and Q = aq/Eh = 0.01020408 (when q = 0.0008 Mpa) and 1.91326531 (when q = 0.15 Mpa).

To numerically carry out a convergence analysis, all the infinite power series in Equations (32)–(34) have to be truncated and replaced with their nth partial sums, i.e.,

and

Then, assign values to the parameter n in Equations (43)–(45). Start with a small n value, say, n = 4. After eliminating ci (i = 2, 3, 4) and di (i = 1, 2, 3, 4) in Equations (43)–(45) by using the recurrence formulas in Appendix A, only the undetermined constants c0 and c1 are left in Equations (43) and (44), while Equation (45) also contains only the undetermined constants c0 and c1 in addition to the undetermined constant d0. Therefore, when n = 4, the values of the undetermined constants c0 and c1 can be determined by simultaneously solving Equations (43) and (44), and with the known c0 and c1, the value of the undetermined constant d0 can easily be determined by Equation (45). Next, continue the calculation of numerical values of c0, c1, and d0 with n = 5, and then with n = 6, …, until the calculated numerical values of c0, c1, and d0 are sufficiently saturated, as shown in Table 1 and Table 2. By the way, the calculation of numerical values of c0, c1 and d0 is usually not easy due to the complex recursion formulas for the power series coefficients in Appendix A. Obviously, the greater the value of the parameter n in Equations (43)–(45), the greater the difficulty of the numerical calculations, that is, the greater the time consumption of labor and computer.

Table 1.

The calculated numerical values of c0, c1 and d0 when q = 0.0008 MPa.

Table 2.

The calculated numerical values of c0, c1 and d0 when q = 0.15 Mpa.

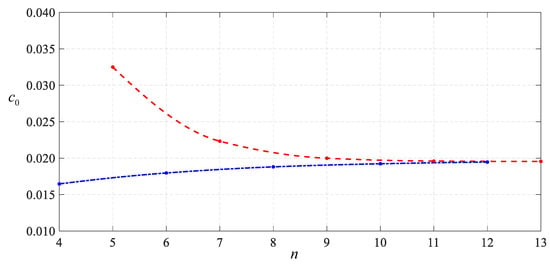

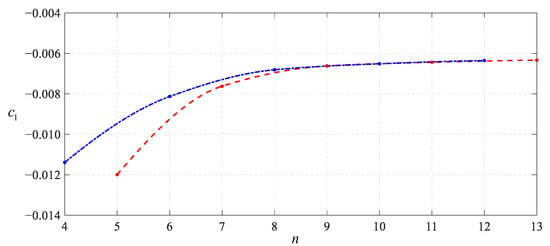

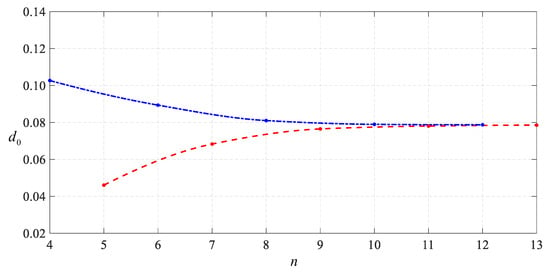

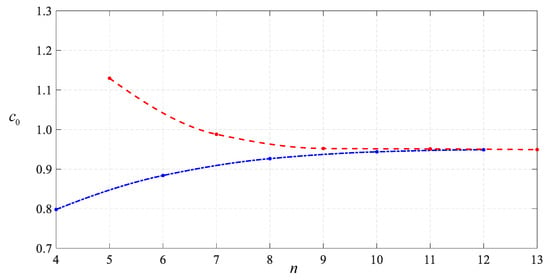

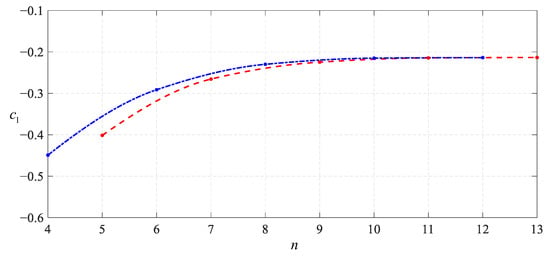

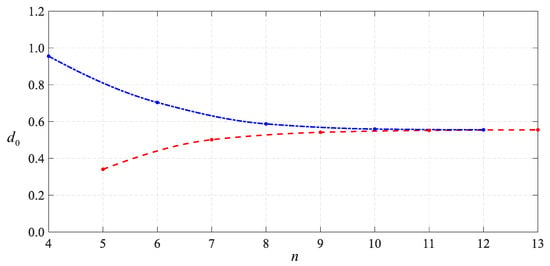

The degree to which the calculated numerical values of c0, c1, and d0 are fully saturated are shown in Figure 4, Figure 5, Figure 6, Figure 7, Figure 8 and Figure 9, which are plotted using the data in Table 1 and Table 2. It can be seen from Figure 4, Figure 5, Figure 6, Figure 7, Figure 8 and Figure 9 that the undetermined constants c0, c1, and d0 converge very well as the parameter n progressively increases. This suggests that the undetermined constants c0, c1, and d0 can, for q = 0.0008 MPa, take 0.01955117, −0.00633490, and 0.07853201 (the saturated values when n = 13 in Table 1), respectively, and for q = 0.15 MPa, take 0.94926763, −0.21357301, and 0.55497352 (the saturated values when n = 13 in Table 2), respectively.

Figure 4.

Variation in c0 with n when q = 0.0008 MPa, where the dashed line corresponds to the case where n is odd and the dash-dot line corresponds to the case where n is even.

Figure 5.

Variation in c1 with n when q = 0.0008 MPa, where the dashed line corresponds to the case where n is odd and the dash-dot line corresponds to the case where n is even.

Figure 6.

Variation in d0 with n when q = 0.0008 MPa, where the dashed line corresponds to the case where n is odd and the dash-dot line corresponds to the case where n is even.

Figure 7.

Variation in c0 with n when q = 0.15 MPa, where the dashed line corresponds to the case where n is odd and the dash-dot line corresponds to the case where n is even.

Figure 8.

Variation in c1 with n when q = 0.15 MPa, where the dashed line corresponds to the case where n is odd and the dash-dot line corresponds to the case where n is even.

Figure 9.

Variation in d0 with n when q = 0.15 MPa, where the dashed line corresponds to the case where n is odd and the dash-dot line corresponds to the case where n is even.

Now, we can use c0 = 0.01955117, c1 = −0.00633490, and d0 = 0.07853201 to analyze the convergences of the power series solutions of stress and deflection when q = 0.0008 MPa, and use c0 = 0.94926763, c1 = −0.21357301, and d0 = 0.55497352 to analyze the convergence of the power series solutions of stress and deflection when q = 0.15 MPa. The domain of the independent variable x is [α,1], i.e., [1/4,1]. Obviously, if the power series solutions converge at the two endpoints of the closed interval [1/4,1], they converge throughout the closed interval [1/4, 1]. Therefore, it is enough to analyze the convergences of the power series solutions of stress and deflection when x = α and x = 1.

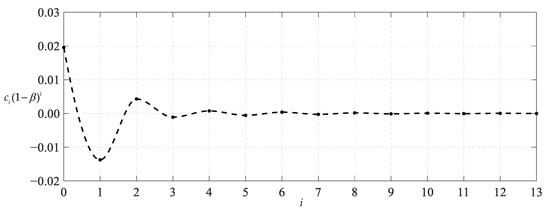

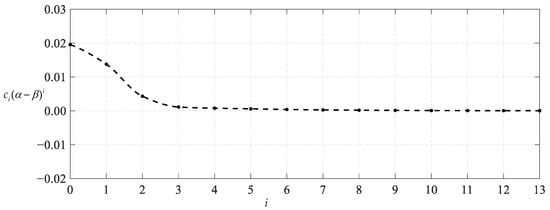

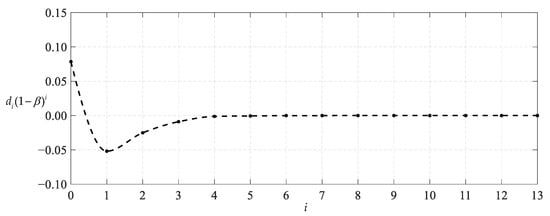

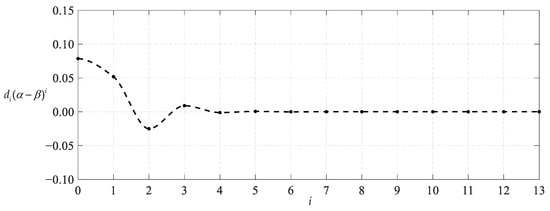

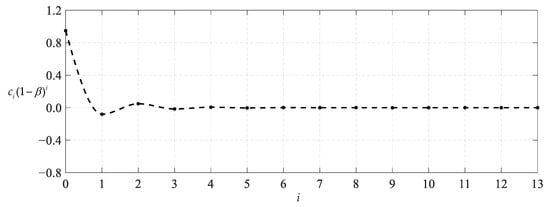

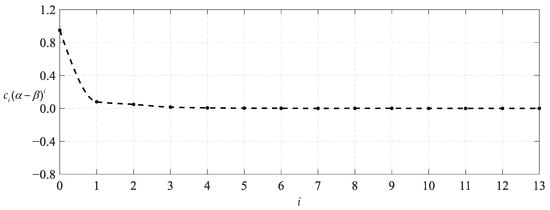

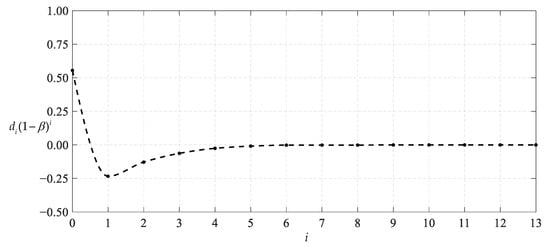

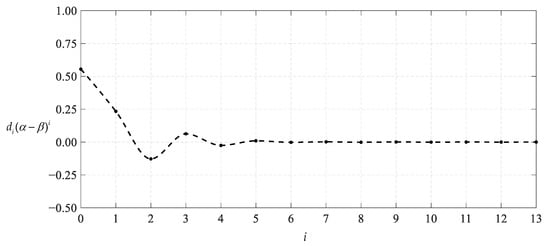

Table 3 and Table 4 (for q = 0.0008 Mpa) and Table 5 and Table 6 (for q = 0.15 Mpa) show the calculated numerical values of the ci(1 − β)I, ci(α − β)i, and di(1 − β)i, di(α − β)i in the expressions of stress and deflection solutions when x = 1 and x = α (see Equations (26) and (27)). The variations in ci(1–β)I, ci(α − β)i, di(1 − β)i, and di(α − β)i with i are shown in Figure 10, Figure 11, Figure 12 and Figure 13 (for q = 0.0008 MPa) and Figure 14, Figure 15, Figure 16 and Figure 17 (for q = 0.15 MPa). It can be seen from Figure 10, Figure 11, Figure 12 and Figure 13 and Figure 14, Figure 15, Figure 16 and Figure 17 that the power series solutions of stress and deflection converge at the two endpoints of the closed interval [1/4,1] for both q = 0.0008 MPa and q = 0.15 MPa. This suggests that when the uniformly distributed transverse loads q is between 0.0008 MPa and 0.15 MPa, the power series solutions of stress and deflection are convergent and usable.

Table 3.

The calculated numerical values of ci(1 − β)i and ci(α − β)i when q = 0.0008 MPa.

Table 4.

The calculated numerical values of di(1 − β)i and di(α − β)I when q = 0.0008 MPa.

Table 5.

The calculated numerical values of ci(1 − β)i and ci(α − β)i when q = 0.15 MPa.

Table 6.

The calculated numerical values of di(1 − β)i and di(α − β)i when q = 0.15 MPa.

Figure 10.

Variation in ci(1 − β)i with i when q = 0.0008 MPa.

Figure 11.

Variation in ci(α − β)i with i when q = 0.0008 MPa.

Figure 12.

Variation in di(1 − β)i with i when q = 0.0008 MPa.

Figure 13.

Variation in di(α − β)i with i when q = 0.0008 MPa.

Figure 14.

Variation in ci(1 − β)i with i when q = 0.15 MPa.

Figure 15.

Variation in ci(α − β)i with i when q = 0.15 MPa.

Figure 16.

Variation in di(1 − β)i with i when q = 0.15 MPa.

Figure 17.

Variation in di(α − β)i with i when q = 0.15 MPa.

3.3. Asymptotic Behavior from Annular Membrane Solution to Circular Membrane Solution

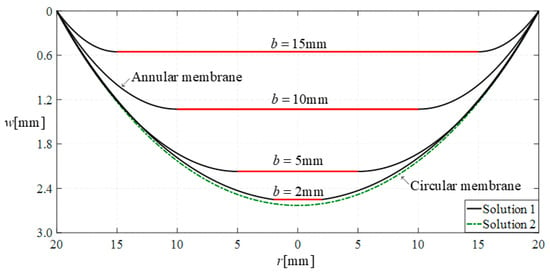

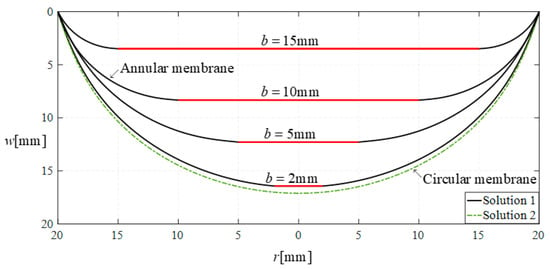

The reliability of the hollow annular membrane solution obtained in Section 2 can be verified in the following way. Obviously, the shape of an annular membrane with inner radius b and outer radius a can gradually approach the shape of a circular membrane with radius a as the inner radius b of the annular membrane gradually approaches zero, if the membrane thickness h, Poisson’s ratio v, Young’s modulus of elasticity E, and the uniformly distributed transverse loads q are the same. This can be used to check the reliability of the hollow annular membrane solution derived in Section 2. Figure 18 and Figure 19 show the asymptotic behavior when the uniformly distributed transverse loads q take 0.0008 MPa and 0.15 MPa: as the inner radius b of the hollow annular membrane with Young’s modulus of elasticity E = 7.84 MPa, Poisson’s ratio v = 0.47, thickness h = 0.2 mm, and outer radius a = 20 mm goes from 15 mm to 10 mm, then to 5 mm, and finally to 2 mm, its deflection curves gradually approach the deflection curve of the circular membrane with Young’s modulus of elasticity E = 7.84 MPa, Poisson’s ratio v = 0.47, thickness h = 0.2 mm and radius a = 20 mm. In Figure 18 and Figure 19, “Solution 1” refers to the annular membrane results calculated by using the hollow annular membrane solution derived in Section 2 in this paper. “Solution 2” refers to the circular membrane result calculated by using the circular membrane solution derived in [39]. Therefore, the fully asymptotic behaviors shown in Figure 18 and Figure 19 suggest that the hollow annular membrane solution derived in Section 2 is, to a certain extent, reliable.

Figure 18.

Sketch of the annular membrane with a gradually decreasing inner radius b gradually approaching the circular membrane under the same loads q = 0.0008 MPa, where “Solution 1” refers to the annular membrane results calculated by using the hollow annular membrane solution derived in Section 2 in this paper. “Solution 2” refers to the circular membrane result calculated by using the circular membrane solution derived in [39].

Figure 19.

Sketch of the annular membrane with a gradually decreasing inner radius b gradually approaching the circular membrane under the same loads q = 0.15 MPa, where the “Solution 1” refers to the annular membrane results calculated by using the hollow annular membrane solution derived in Section 2 in this paper; “Solution 2” refers to the circular membrane result calculated by using the circular membrane solution derived in [39].

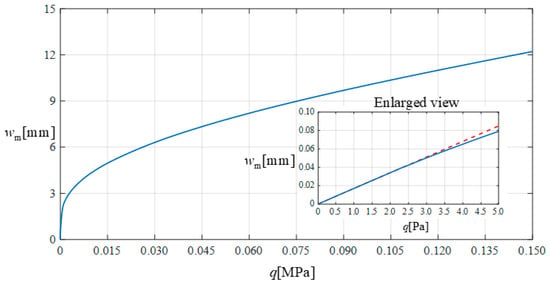

The usually so-called large deflection problems refer to the case where the maximum deflections of thin plates or membranes are greater than 1/5 of their thicknesses, and conversely, the case where the maximum deflections of thin plates or membranes are smaller than 1/5 of their thicknesses is usually called small deflection problems. The large deflection problems usually show effects of nonlinearity between loads and deflections while the small deflection problems usually show effects of linearity. Figure 20 shows the relationship between loads q and maximum deflections wm of the hollow annular membrane with E = 7.84 MPa, v = 0.47, a = 20 mm, b = 5 mm, and h = 0.2 mm. It can be seen from the enlarged view in Figure 20 that when wm < h/5 = 0.04 mm, the effect of linearity predominates, and when wm > h/5 = 0.04 mm, the effect of nonlinearity gradually predominates. In fact, such a effect from linear dominance to nonlinear dominance is not only true in thin-plate or membrane problems, but also in beam problems [40].

Figure 20.

The relationship between loads q and maximum deflections wm of the hollow annular membrane with E = 7.84 MPa, v = 0.47, a = 20 mm, b = 5 mm, and h = 0.2 mm.

3.4. Comparison between Hollow Annular Membrane Solutions before and after Improvement

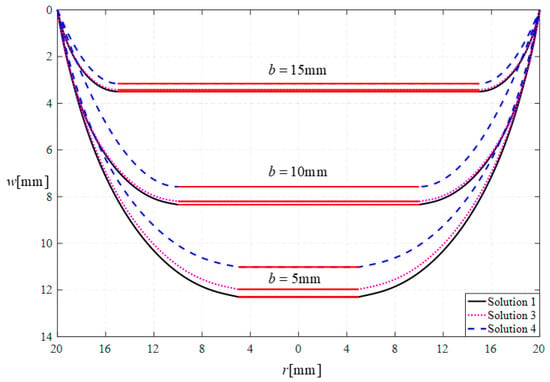

The deflection profiles of the hollow annular membrane with Young’s modulus of elasticity E = 7.84 MPa, Poisson’s ratio v = 0.47, thickness h = 0.2 mm, outer radius a = 20 mm, inner radius b = 15 mm, 10 mm, and 5 mm, and subjected to the action of q = 0.15 MPa are calculated by using the hollow annular membrane solutions before and after improvement, and compared with each other, as shown in Figure 21, where “Solution 1” refers to the results calculated by using the new hollow annular membrane solution derived in Section 2 in this paper, and ”Solution 3” refers to the results calculated by using the earlier hollow annular membrane solution derived in [32], and “Solution 4” refers to the results calculated by using the earliest hollow annular membrane solution derived in [31].

Figure 21.

The gradually increasing differences between the deflection profiles along with the gradually decreasing inner radius b of the hollow annular membrane when q = 0.15 MPa, where “Solution 1” refers to the deflection profiles calculated by using the new hollow annular membrane solution derived in Section 2 in this paper; “Solution 3” refers to the deflection profiles calculated by using the earlier hollow annular membrane solution derived in [32]; and “Solution 4” refers to the deflection profiles calculated by using the earliest hollow annular membrane solution derived in [31].

It can be seen from Figure 21 that the differences between the deflection profiles gradually increase as the inner radius b decreases from 15 mm to 10 mm, and then to 5 mm. This suggests that the previous improvement to the out-of-plane equilibrium equation (see reference [32] for details) has played a role in making the difference between “Solution 3” and “Solution 4”, while the difference between “Solution 1” and “Solution 3” is mainly due to the current improvement to the radial geometric equation in this paper. These differences, even subtle differences, can not be ignored if the hollow annular membrane solution is used for designing the so-called bending-free shells [33,34,35,36,37,38].

3.5. Difference in Shell Design between Hollow and Solid Annular Membrane Solutions

According to the hanging membrane method for shell designs proposed by Heinz Isler [36,37,38], the shape of a transversely loaded annular membrane, after inversion (flipped 180 degrees), can be used as the shape of, for instance, a concrete annular shell of revolution. The annular shell of revolution shaped by this method has only compression stresses, because the transversely loaded annular membrane has only tension stresses. This is the so-called “shape-finding” or “form-finding” for bending-free shells. Therefore, the accuracy of an annular membrane solution has a great influence on the shell form-finding, involving whether the form-found shell really has no bending moments under service loads.

Obviously, the choice of using a hollow annular membrane solution or using a solid (not-hollow) annular membrane solution has a greater, more obvious, and more significant effect on the shell form-finding, and the larger the inner radius b of the annular membrane, the greater the effect, involving the amount or size of the effective loads acting on the annular membrane. In the solid (not-hollow) annular membrane, its inner edge is connected rigidly with a weightless stiff circular thin plate that is still under the transverse loads q, while in the hollow annular membrane, the central region within its inner edge is empty and free from the action of the transverse loads q. Therefore, under the same conditions, the mechanical response of the hollow annular membrane is smaller than that of the corresponding solid (not-hollow) annular membrane.

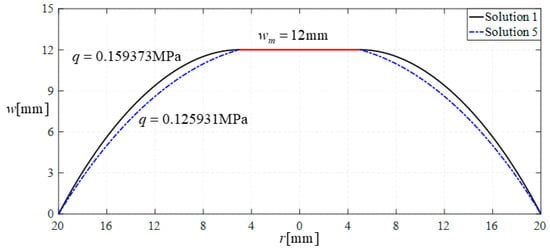

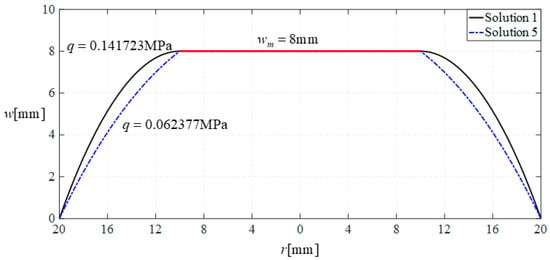

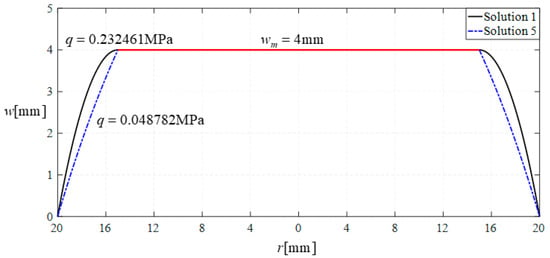

Figure 22 depicts the cross sections along the diameter of the inverted hollow and solid (not-hollow) annular membranes (represents the form-found annular shells), where the two annular membranes have the same Young’s modulus of elasticity E = 7.84 MPa, Poisson’s ratio v = 0.47, thickness h = 0.2 mm, outer radius a = 20 mm, inner radius b = 5 mm, maximum deflection wm = 12 mm (it should be called the maximum height of shells, but for convenience, is still called the maximum deflection), but are subjected to the transverse loads q = 0.159373 MPa (hollow) and q = 0.125931 MPa (not-hollow), respectively. The case depicted in Figure 23 differs from the case depicted in Figure 22 only in b = 10 mm, wm = 8 mm, q = 0.141723 MPa (hollow), and q = 0.062377 MPa (not-hollow), while the case depicted in Figure 24 differs from the case depicted in Figure 22 only in b = 15 mm, wm = 4 mm, q = 0.232461 MPa (hollow), and q = 0.048782 MPa (not-hollow). In Figure 22, Figure 23 and Figure 24, “Solution 1” refers to the results calculated by using the new hollow annular membrane solution derived in Section 2 in this paper, and ”Solution 5” refers to the results calculated by using the solid (not-hollow) annular membrane solution derived in [41].

Figure 22.

The cross sections along the diameter of the inverted hollow and solid (not-hollow) annular membranes with the same Young’s modulus of elasticity E = 7.84 MPa, Poisson’s ratio v = 0.47, thickness h = 0.2 mm, outer radius a = 20 mm, inner radius b = 5 mm, maximum deflection wm = 12 mm, but loaded by q = 0.159373 MPa (hollow) and q = 0.125931 MPa (not-hollow), respectively, where “Solution 1” refers to the results calculated by using the new hollow annular membrane solution derived in Section 2 in this paper, and ”Solution 5” refers to the results calculated by using the solid (not-hollow) annular membrane solution derived in [41].

Figure 23.

The cross sections along the diameter of the inverted hollow and solid (not-hollow) annular membranes with the same Young’s modulus of elasticity E = 7.84 MPa, Poisson’s ratio v = 0.47, thickness h = 0.2 mm, outer radius a = 20 mm, inner radius b = 10 mm, maximum deflection wm = 8 mm, but loaded by q = 0.141723 MPa (hollow) and q = 0.062377 MPa (not-hollow), respectively, where “Solution 1” refers to the results calculated by using the new hollow annular membrane solution derived in Section 2 in this paper, and “Solution 5” refers to the results calculated by using the solid (not-hollow) annular membrane solution derived in [41].

Figure 24.

The cross sections along the diameter of the inverted hollow and solid (not-hollow) annular membranes with the same Young’s modulus of elasticity E = 7.84 MPa, Poisson’s ratio v = 0.47, thickness h = 0.2 mm, outer radius a = 20 mm, inner radius b = 15 mm, maximum deflection wm = 4 mm, but loaded by q = 0.232461 MPa (hollow) and q = 0.048782 MPa (not-hollow), respectively, where “Solution 1” refers to the results calculated by using the new hollow annular membrane solution derived in Section 2 in this paper, and “Solution 5” refers to the results calculated by using the solid (not-hollow) annular membrane solution derived in [41].

It can be seen from Figure 22, Figure 23 and Figure 24 that in terms of the loads required to produce the same maximum deflection wm, the loads q applied to the hollow annular membrane is greater than the loads q applied to the solid (not-hollow) annular membrane, and the difference between the two load values increases as the inner radius b increases. This suggests that under the same conditions, the mechanical response of the hollow annular membranes is smaller than that of the corresponding solid (not-hollow) annular membranes, and the magnitude of the difference between the two depends on the magnitude of the inner radius b of the annular membranes.

On the other hand, however, the more important issue which can be observed from Figure 22, Figure 23 and Figure 24 is that for the same outer radius a, inner radius b, and maximum deflection wm, the shape of the inverted hollow annular membrane can never be the same as the shape of the inverted solid (not-hollow) annular membrane. This reminds us that the hollow bending-free annular shells can be shaped only by the inverted transversely loaded hollow annular membrane, and never by the inverted transversely loaded solid (not-hollow) annular membrane; otherwise, the original intention of “bending-free” will fall through due to the errors in the shapes found (in other words, the bending moment will be present in the form-found annular shells under service loads). The reverse is also true. The solid (not-hollow) bending-free annular shell can only be shaped using the inverted transversely loaded solid (not-hollow) annular membrane, for example, the case of designing an annular shell of revolution with a glass roof for natural overhead light.

4. Concluding Remarks

In this paper, the large deflection problem of a transversely loaded hollow annular membrane is reformulated by simultaneously modifying out-of-plane equilibrium equation and radial geometric equation, and the newer and more refined power series solutions for stress and deflection are derived. From this study, the following conclusions can be drawn.

The classical radial geometric equation, Equation (41), is derived based on two unreasonable assumptions (see Section 3.1 for details), and therefore should be discarded and replaced by the newly derived radial geometry equation, Equations (5) or (42).

The newly derived power series solutions for stress and deflection can meet the convergence requirements and have higher accuracy than the old solutions, which further strengthens the theoretical basis for shell form-finding.

The hollow annular shells of revolution can be shaped only by the inverted transversely loaded hollow annular membranes, and never by the inverted transversely loaded solid (not-hollow) annular membranes, and the reverse is also true. Otherwise, the original intention of “bending-free” will fall through due to the errors in the found shapes.

Author Contributions

Conceptualization, X.-T.H.; methodology, F.-Y.L. and X.-T.H.; validation, X.-T.H. and J.-Y.S.; writing—original draft preparation, F.-Y.L.; writing—review and editing, F.-Y.L. and X.-T.H.; visualization, F.-Y.L.; funding acquisition, J.-Y.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant No. 11772072).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

References

- Cao, Z.; Tao, L.; Akinwande, D.; Huang, R.; Liechti, K.M. Mixed-mode traction-separation relations between graphene and copper by blister tests. Int. J. Solids Struct. 2016, 84, 147–159. [Google Scholar] [CrossRef]

- Sun, J.Y.; Qian, S.H.; Li, Y.M.; He, X.T.; Zheng, Z.L. Theoretical study of adhesion energy measurement for film/substrate interface using pressurized blister test: Energy release rate. Measurement 2013, 46, 2278–2287. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, G.R.; Chen, Y.L.; Long, D.; Guan, Y.C.; Liu, L.Q.; Zhang, Z. Extended Hencky solution for the blister test of nanomembrane. Extrem. Mech. Lett. 2018, 22, 69–78. [Google Scholar] [CrossRef]

- Delfani, M.R. Nonlinear elasticity of monolayer hexagonal crystals: Theory and application to circular bulge test. Eur. J. Mech. A Solid. 2018, 68, 117–132. [Google Scholar] [CrossRef]

- Dai, Z.; Lu, N. Poking and bulging of suspended thin sheets: Slippage, instabilities, and metrology. J. Mech. Phys. Solids 2021, 149, 104320. [Google Scholar] [CrossRef]

- Gutscher, G.; Wu, H.C.; Ngaile, G.; Altan, T. Determination of flow stress for sheet metal forming using the viscous pressure bulge (VPB) test. J. Mater. Process Technol. 2004, 146, 1–7. [Google Scholar] [CrossRef]

- Napolitanno, M.J.; Chudnovsky, A.; Moet, A. The constrained blister test for the energy of interfacial adhesion. J. Adhes. Sci. Technol. 1988, 2, 311–323. [Google Scholar] [CrossRef]

- Zhu, T.T.; Müftü, S.; Wan, K.T. One-dimensional constrained blister test to measure thin film adhesion. J. Appl. Mech. T ASME 2018, 85, 054501. [Google Scholar] [CrossRef]

- Pervier, M.L.A.; Hammond, D.W. Measurement of the fracture energy in mode I of atmospheric ice accreted on different materials using a blister test. Eng. Fract. Mech. 2019, 214, 223–232. [Google Scholar] [CrossRef]

- Zhu, T.T.; Li, G.X.; Müftü, S.; Wan, K.T. Revisiting the constrained blister test to measure thin film adhesion. J. Appl. Mech. T ASME 2017, 84, 071005. [Google Scholar] [CrossRef]

- Meng, G.Q.; Ko, W.H. Modeling of circular diaphragm and spreadsheet solution programming for touch mode capacitive sensors. Sens. Actuators A 1999, 75, 45–52. [Google Scholar] [CrossRef]

- Lee, H.Y.; Choi, B. Theoretical and experimental investigation of the trapped air effect on air-sealed capacitive pressure sensor. Sens. Actuators A 2015, 221, 104–114. [Google Scholar] [CrossRef]

- Mishra, R.B.; Khan, S.M.; Shaikh, S.F.; Hussain, A.M.; Hussain, M. Low-cost foil/paper based touch mode pressure sensing element as artificial skin module for prosthetic hand. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020; pp. 194–200. [Google Scholar]

- Molla-Alipour, M.; Ganji, B.A. Analytical analysis of mems capacitive pressure sensor with circular diaphragm under dynamic load using differential transformation method (DTM). Acta Mech. Solida Sin. 2015, 28, 400–408. [Google Scholar] [CrossRef]

- Wang, J.; Lou, Y.; Wang, B.; Sun, Q.; Zhou, M.; Li, X. Highly sensitive, breathable, and flexible pressure sensor based on electrospun membrane with assistance of AgNW/TPU as composite dielectric layer. Sensors 2020, 20, 2459. [Google Scholar] [CrossRef] [PubMed]

- Lian, Y.S.; Sun, J.Y.; Zhao, Z.H.; Li, S.Z.; Zheng, Z.L. A refined theory for characterizing adhesion of elastic coatings on rigid substrates based on pressurized blister test methods: Closed-form solution and energy release rate. Polymers 2020, 12, 1788. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Sun, J.Y.; Shi, B.B.; Zhao, Z.H.; He, X.T. A theoretical study on an elastic polymer thin film-based capacitive wind-pressure sensor. Polymers 2020, 12, 2133. [Google Scholar] [CrossRef] [PubMed]

- Jindal, S.K.; Varma, M.A.; Thukral, D. Comprehensive assessment of MEMS double touch mode capacitive pressure sensor on utilization of SiC film as primary sensing element: Mathematical modelling and numerical simulation. Microelectron. J. 2018, 73, 30–36. [Google Scholar] [CrossRef]

- Shu, J.F.; Yang, R.R.; Chang, Y.Q.; Guo, X.Q.; Yang, X. A flexible metal thin film strain sensor with micro/nano structure for large deformation and high sensitivity strain measurement. J. Alloys Compd. 2021, 879, 160466. [Google Scholar] [CrossRef]

- Zhang, D.Z.; Jiang, C.X.; Tong, J.; Zong, X.Q.; Hu, W. Flexible Strain Sensor Based on Layer-by-Layer Self-Assembled Graphene/Polymer Nanocomposite Membrane and Its Sensing Properties. J. Electron. Mater. 2018, 47, 2263–2270. [Google Scholar] [CrossRef]

- Han, X.D.; Li, G.; Xu, M.H.; Ke, X.; Chen, H.Y.; Feng, Y.J.; Yan, H.P.; Li, D.T. Differential MEMS capacitance diaphragm vacuum gauge with high sensitivity and wide range. Vacuum 2021, 191, 110367. [Google Scholar] [CrossRef]

- Sun, J.-Y.; Zhang, Q.; Wu, J.; Li, X.; He, X.-T. Large Deflection Analysis of Peripherally Fixed Circular Membranes Subjected to Liquid Weight Loading: A Refined Design Theory of Membrane Deflection-Based Rain Gauges. Materials 2021, 14, 5992. [Google Scholar] [CrossRef] [PubMed]

- Moghaddam, B.P.; Tenreiro Machado, J.A. A computational approach for the solution of a class of variable-order fractional integro-differential equations with weakly singular kernels. Fract. Calc. Appl. Anal. 2017, 20, 1023–1042. [Google Scholar] [CrossRef]

- Mokhtary, P.; Moghaddam, B.P.; Lopes, A.M.; Tenreiro Machado, J.A. A computational approach for the non-smooth solution of non-linear weakly singular Volterra integral equation with proportional delay. Numer. Algorithms 2020, 83, 987–1006. [Google Scholar] [CrossRef]

- Hencky, H. On the stress state in circular plates with vanishing bending stiffness. Z. Angew. Math. Phys. 1915, 63, 311–317. [Google Scholar]

- Alekseev, S.A. Elastic circular membranes under the uniformly distributed loads. Eng. Corpus 1953, 14, 196–198. [Google Scholar]

- Chien, W.Z.; Wang, Z.Z.; Xu, Y.G.; Chen, S.L. The symmetrical deformation of circular membrane under the action of uniformly distributed loads in its central portion. Appl. Math. Mech. 1981, 2, 599–612. [Google Scholar]

- Huang, P.F.; Song, Y.P.; Li, Q.; Liu, X.Q.; Feng, Y.Q. A theoretical study of circular orthotropic membrane under concentrated load: The relation of load and deflection. IEEE Access 2020, 8, 126127–126137. [Google Scholar] [CrossRef]

- Zhang, C.H.; Fan, L.J.; Tan, Y.F. Sequential limit analysis for clamped circular membranes involving large deformation subjected to pressure load. Int. J. Mech. Sci. 2019, 155, 440–449. [Google Scholar] [CrossRef]

- Alekseev, S.A. Elastic annular membranes with a stiff centre under the concentrated force. Eng. Corpus 1951, 10, 71–80. [Google Scholar]

- Sun, J.Y.; Zhang, Q.; Li, X.; He, X.T. Axisymmetric large deflection elastic analysis of hollow annular membranes under transverse uniform loading. Symmetry 2021, 13, 1770. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, X.; He, X.-T.; Sun, J.-Y. Revisiting the Boundary Value Problem for Uniformly Transversely Loaded Hollow Annular Membrane Structures: Improvement of the Out-of-Plane Equilibrium Equation. Mathematics 2022, 10, 1305. [Google Scholar] [CrossRef]

- Bellés, P.; Ortega, N.; Rosales, M.; Andrés, O. Shell form-finding: Physical and numerical design tools. Eng. Struct. 2009, 31, 2656–2666. [Google Scholar] [CrossRef]

- Chiang, Y.-C.; Borgart, A. A form-finding method for membrane shells with radial basis functions. Eng. Struct. 2022, 251, 113514. [Google Scholar] [CrossRef]

- Sakai, Y.; Ohsaki, M.; Adriaenssens, S. A 3-dimensional elastic beam model for form-finding of bending-active gridshells. Int. J. Solids Struct. 2020, 193–194, 328–337. [Google Scholar] [CrossRef]

- Isler, H. New Shapes for Shells. Bull. IASS 1960, 8, C-3. [Google Scholar]

- Isler, H. New Shapes for Shells—Twenty years after. Bull. IASS 1979, 20, 9–26. [Google Scholar]

- Isler, H. Generating Shell Shapes by Physical Experiment. Bull. IASS 1993, 34, 53–63. [Google Scholar]

- Lian, Y.S.; Sun, J.-Y.; Zhao, Z.H.; He, X.-T.; Zheng, Z.L. A Revisit of the Boundary Value Problem for Föppl–Hencky Membranes: Improvement of Geometric Equations. Mathematics 2020, 8, 631. [Google Scholar] [CrossRef]

- Malikan, M.; Eremeyev, V.A. On Nonlinear Bending Study of a Piezo-Flexomagnetic Nanobeam Based on an Analytical-Numerical Solution. Nanomaterials 2020, 10, 1762. [Google Scholar] [CrossRef]

- Li, B.; Zhang, Q.; Li, X.; He, X.-T.; Sun, J.-Y. A Refined Closed-Form Solution for the Large Deflections of Alekseev-Type Annular Membranes Subjected to Uniformly Distributed Transverse Loads: Simultaneous Improvement of Out-of-Plane Equilibrium Equation and Geometric Equation. Mathematics 2022, 10, 2121. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).