Study on the Reinforcement Mechanism of High-Energy-Level Dynamic Compaction Based on FDM–DEM Coupling

Abstract

1. Introduction

2. FDM–DEM Coupling Numerical Simulation

2.1. Project Overview

2.2. Foundation Treatment Scheme

2.3. FDM–DEM Coupling Technique

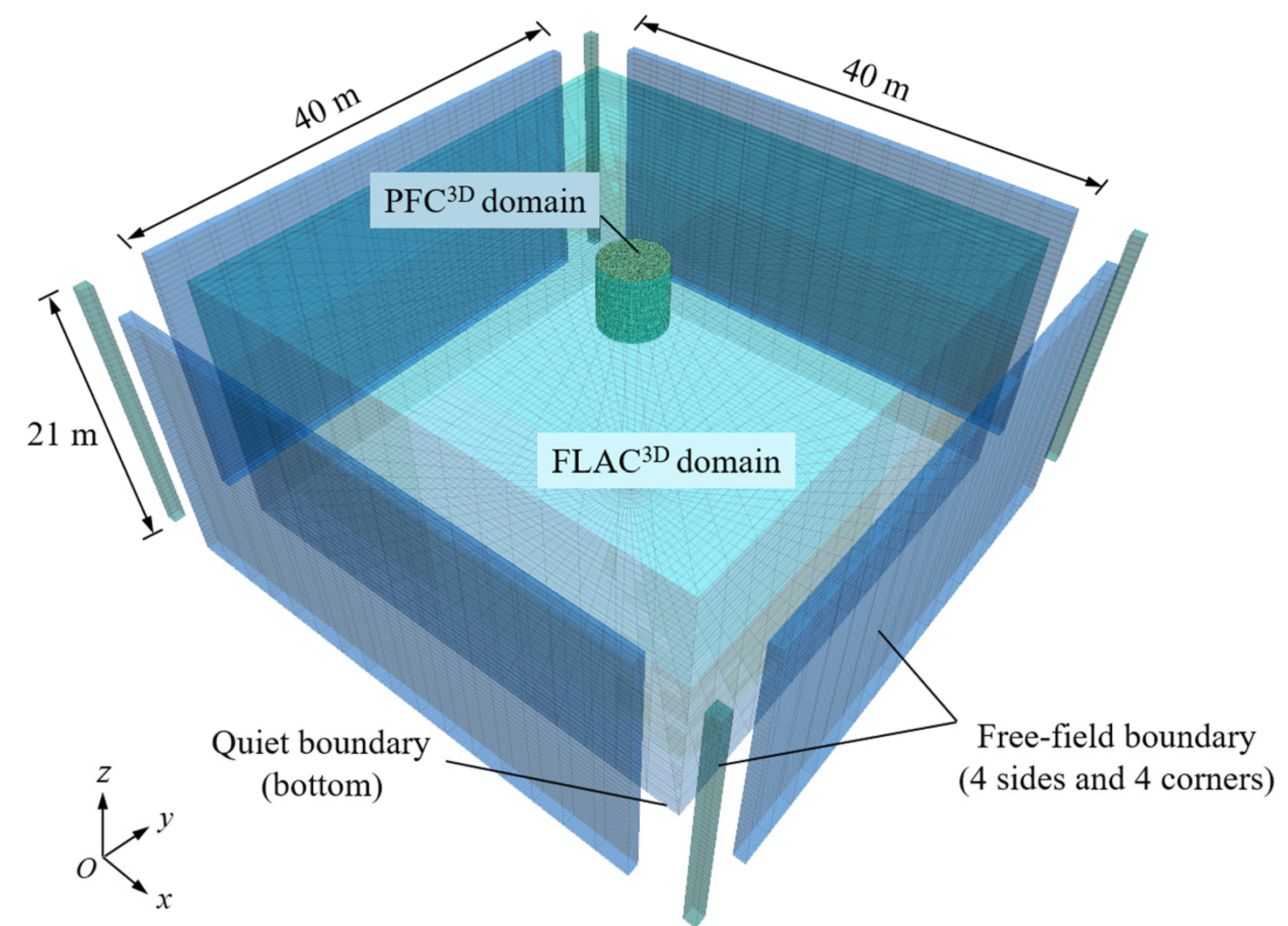

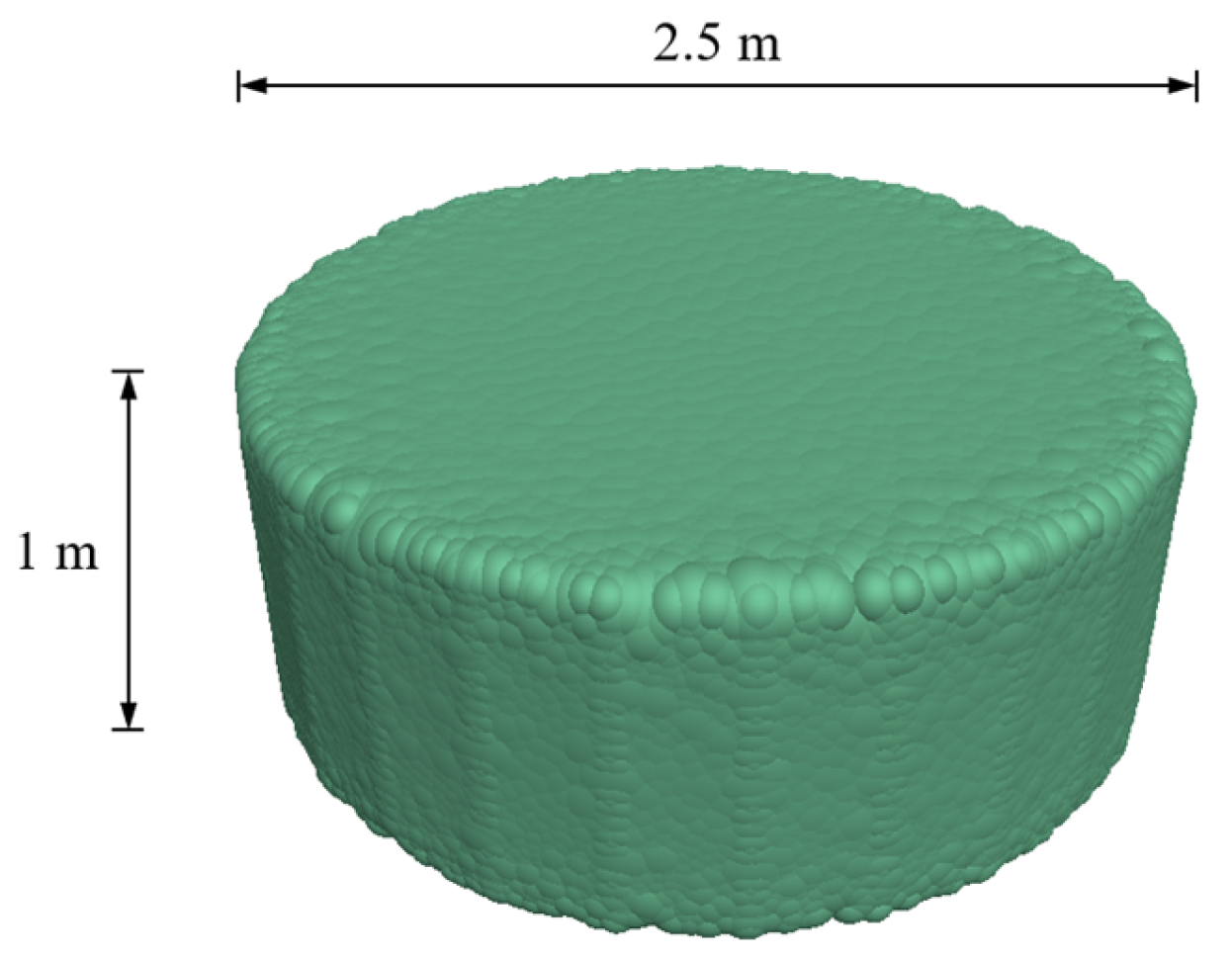

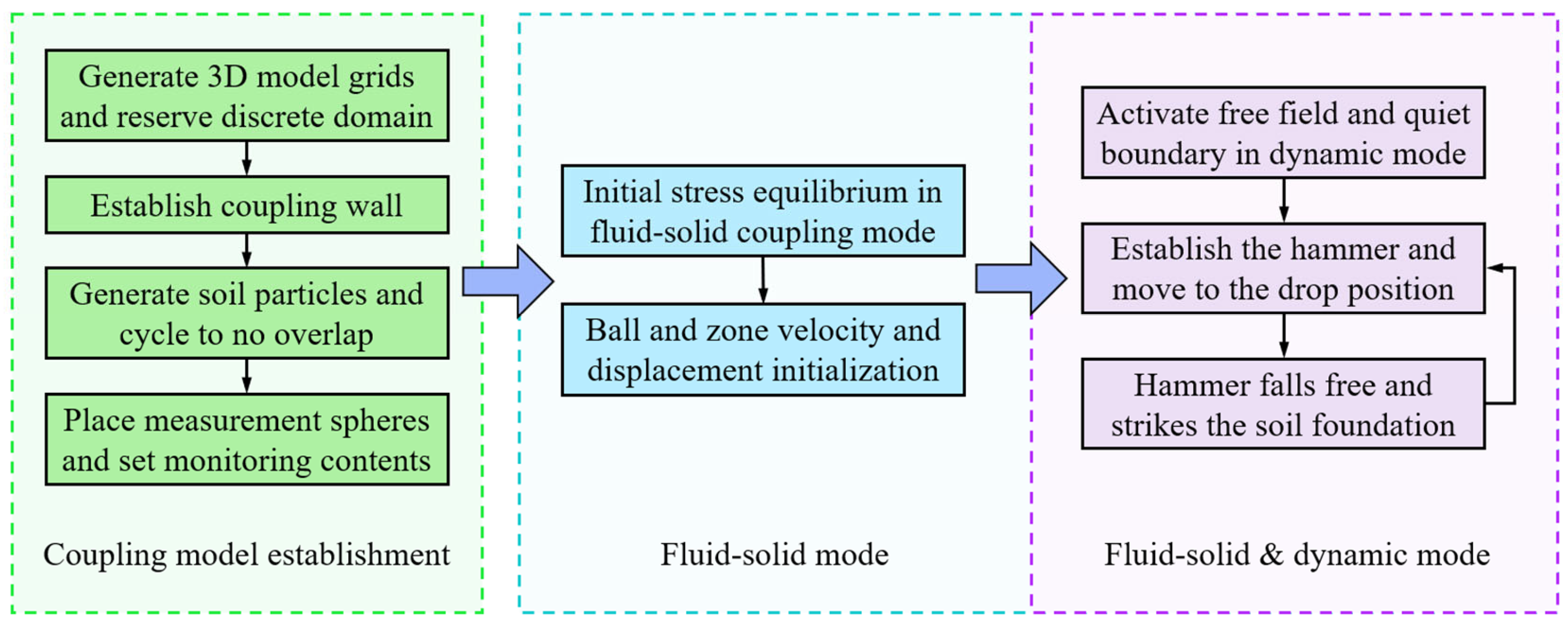

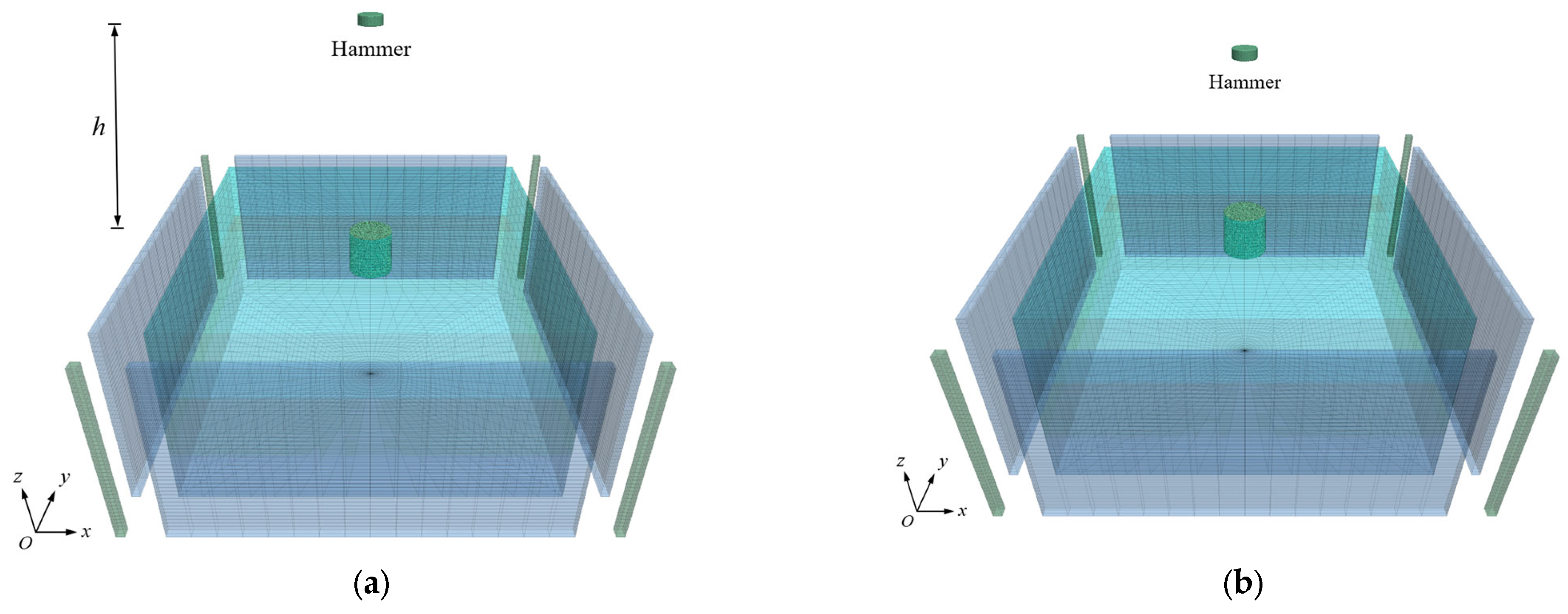

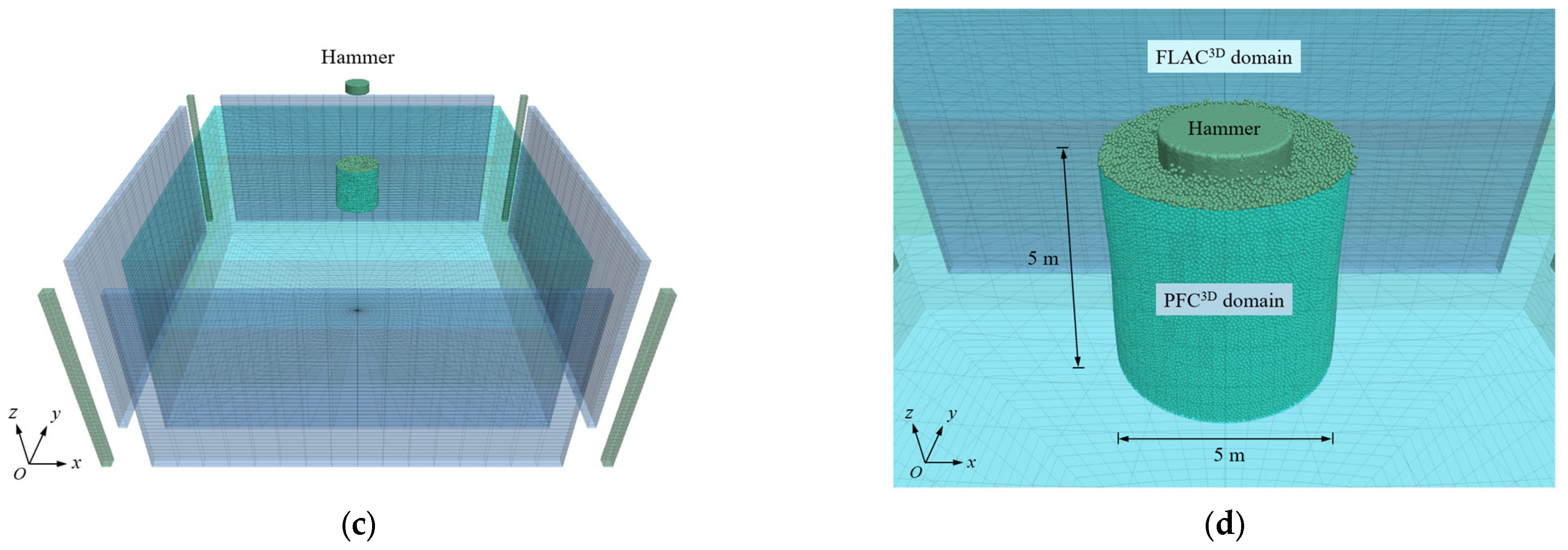

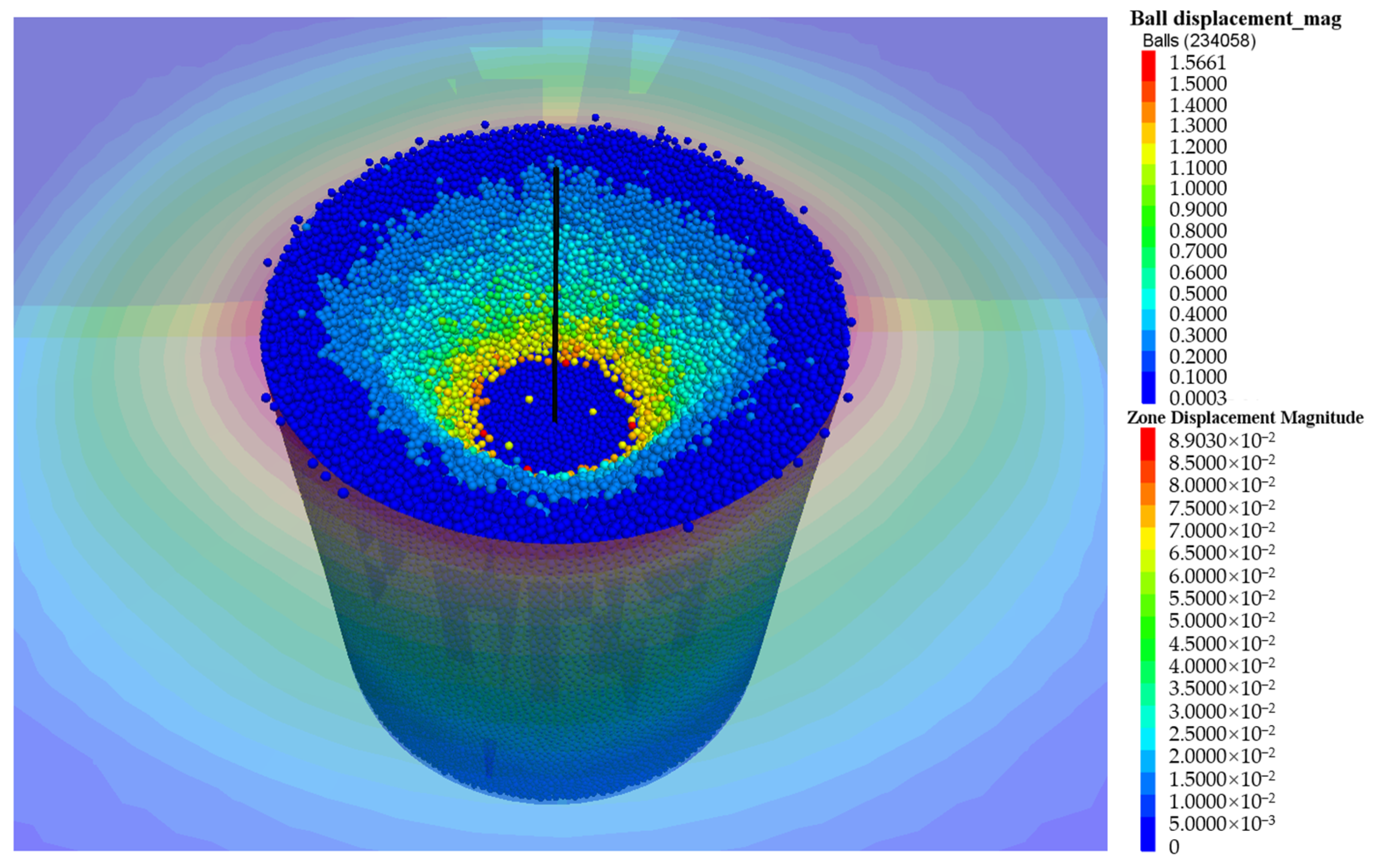

2.4. The 3D FDM–DEM Coupling Numerical Model

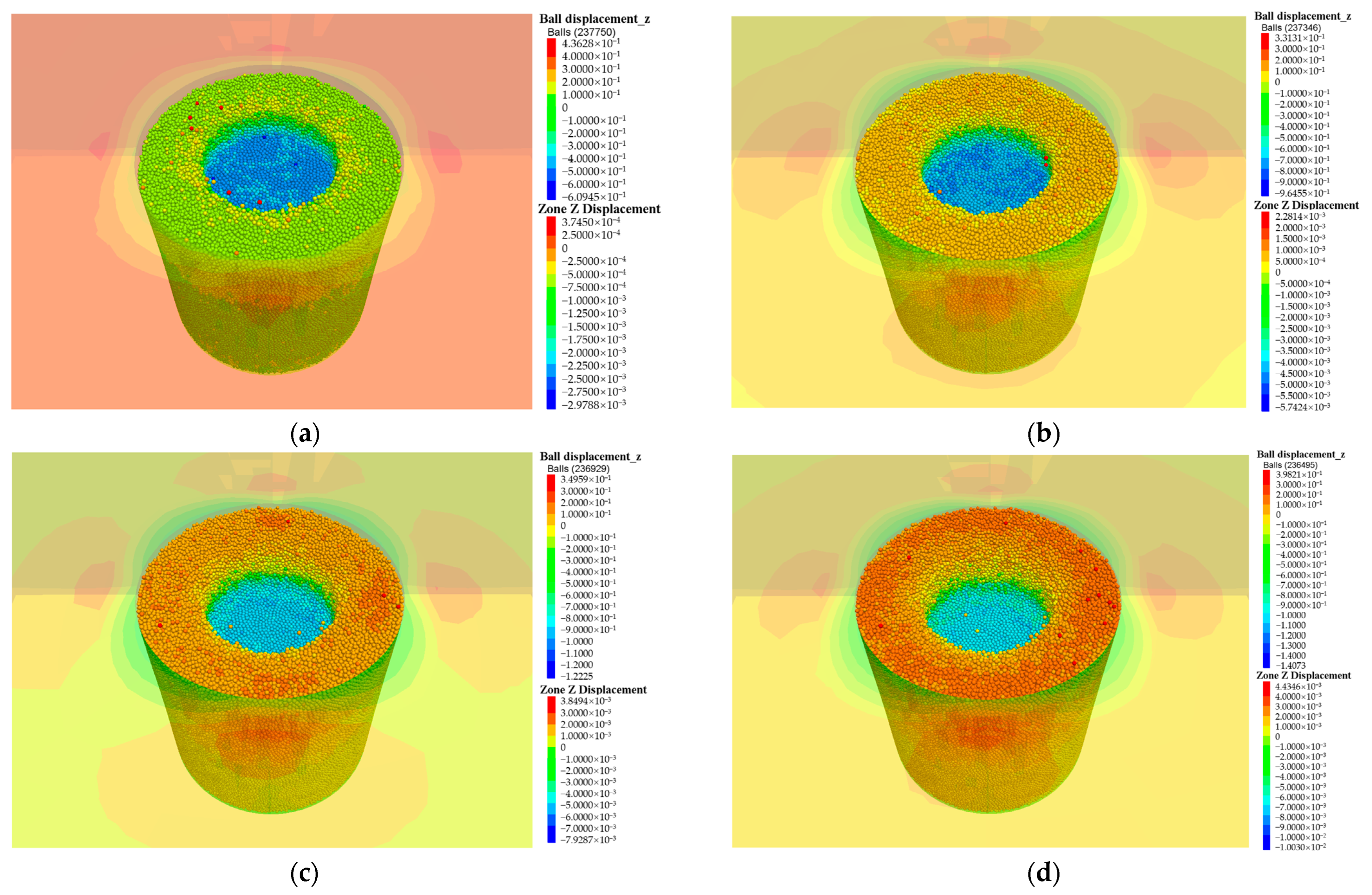

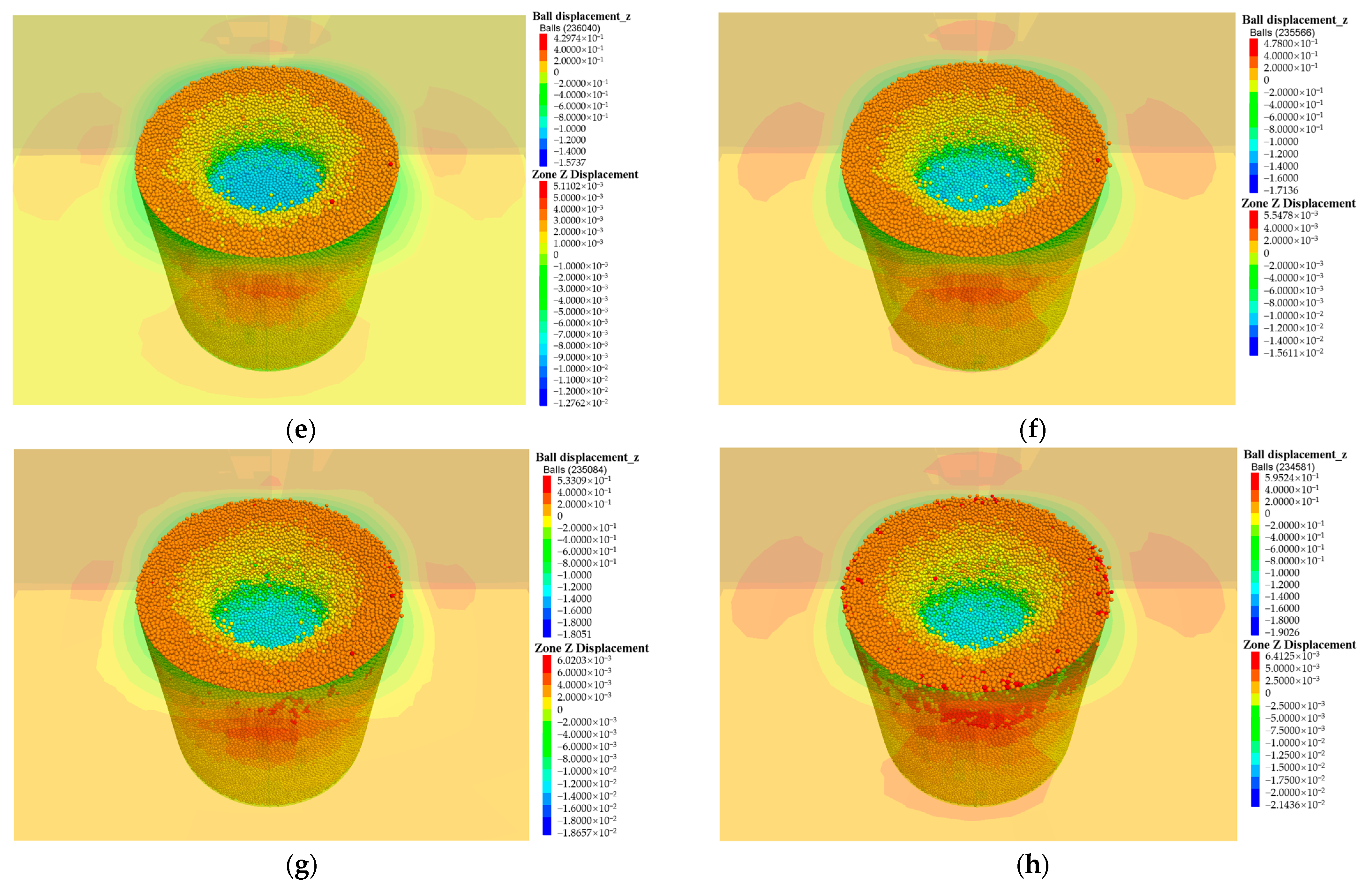

3. Numerical Analysis Results

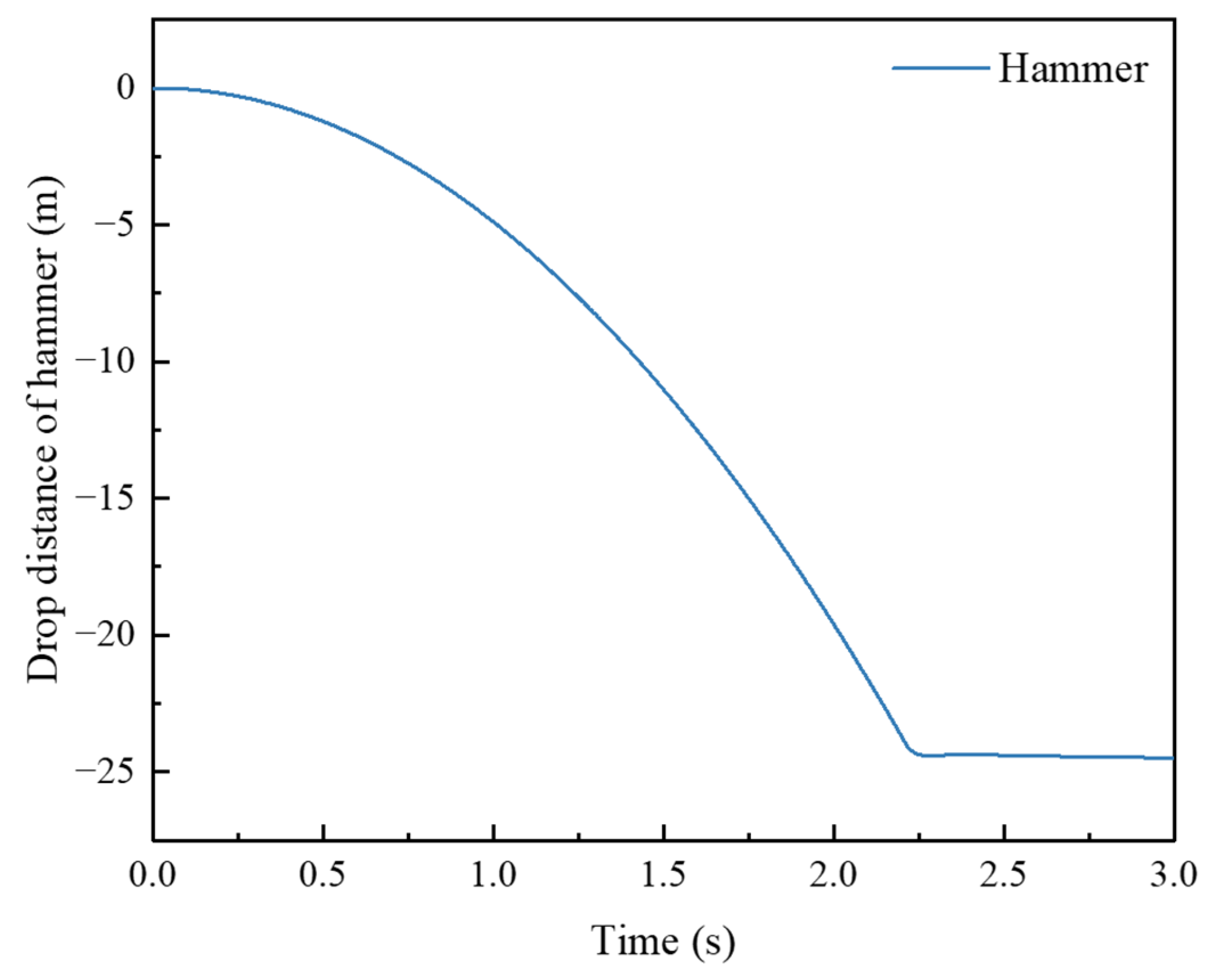

3.1. Crater Depth

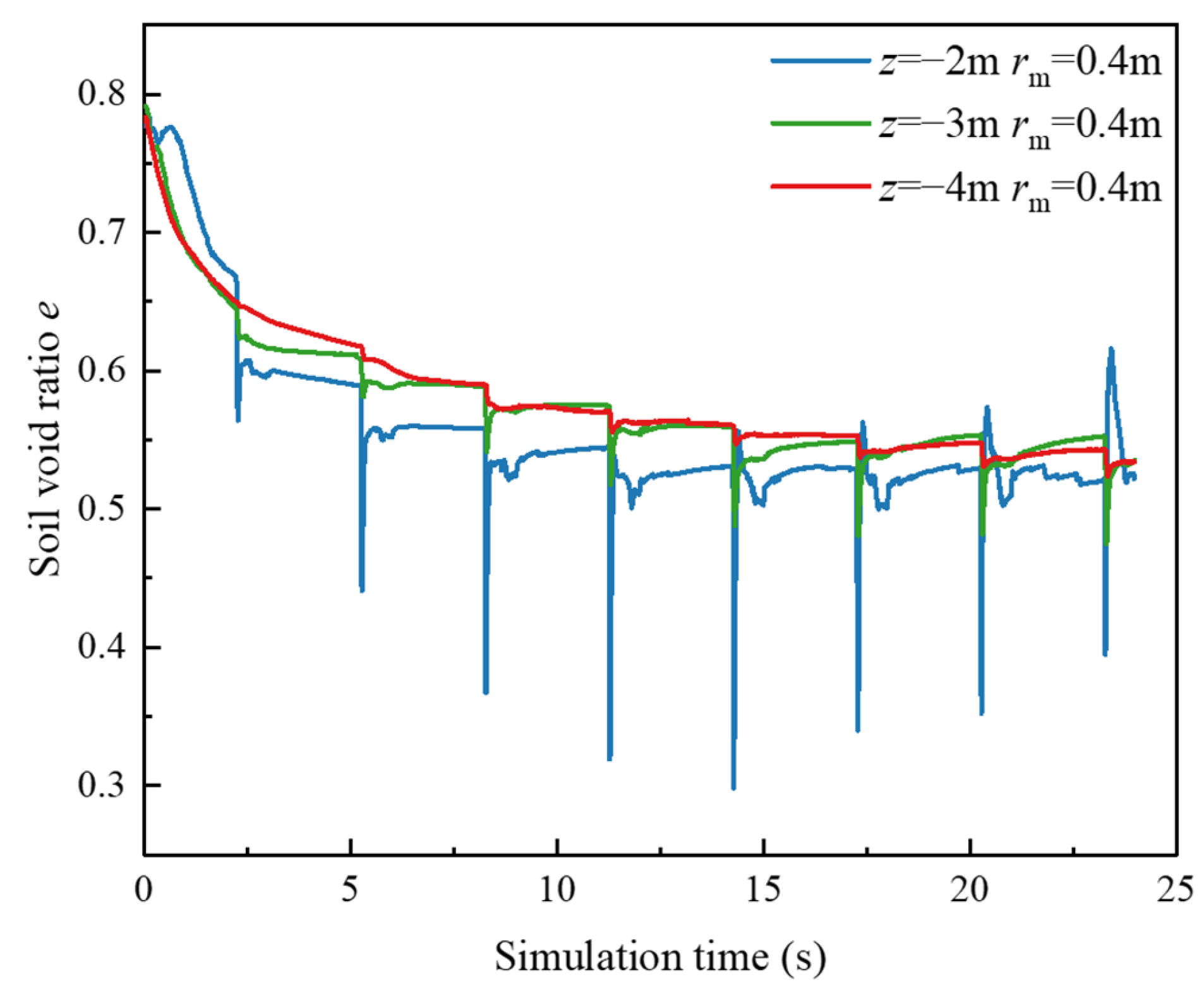

3.2. Soil Void Ratio

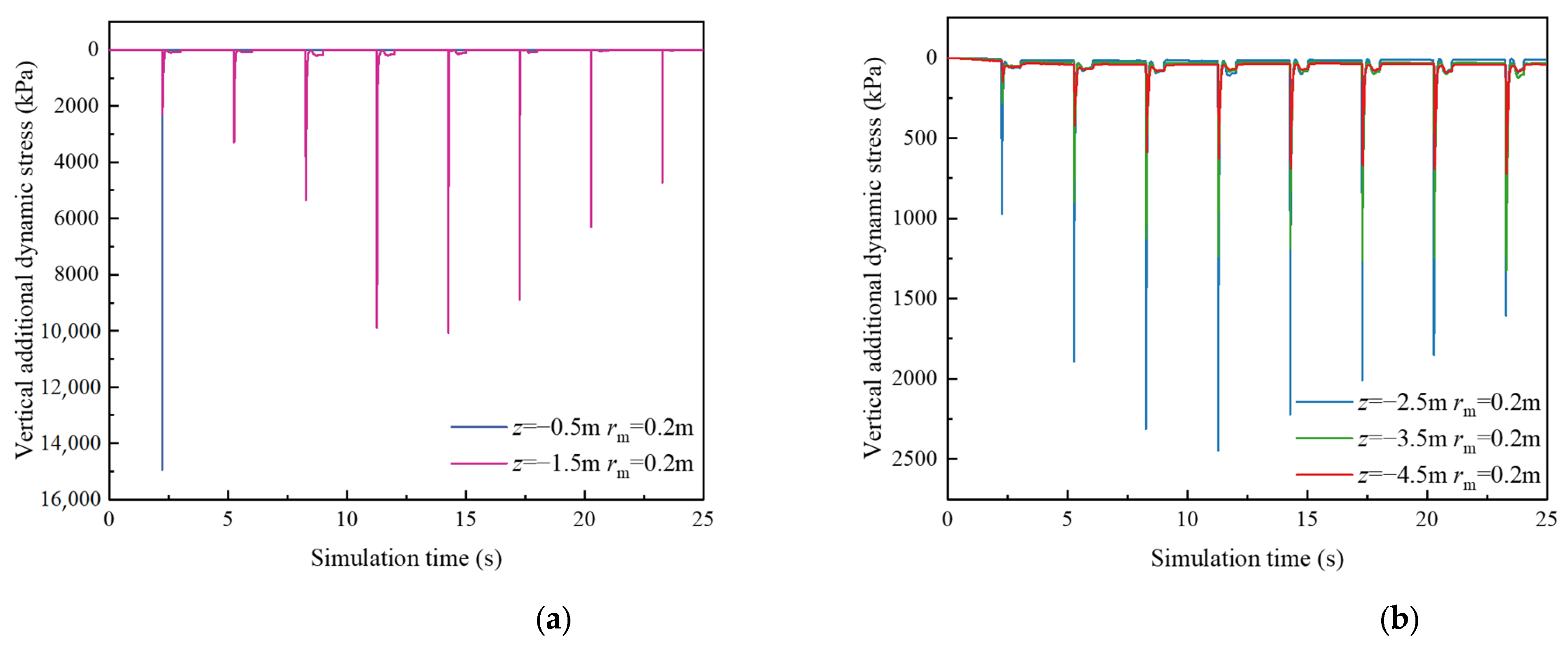

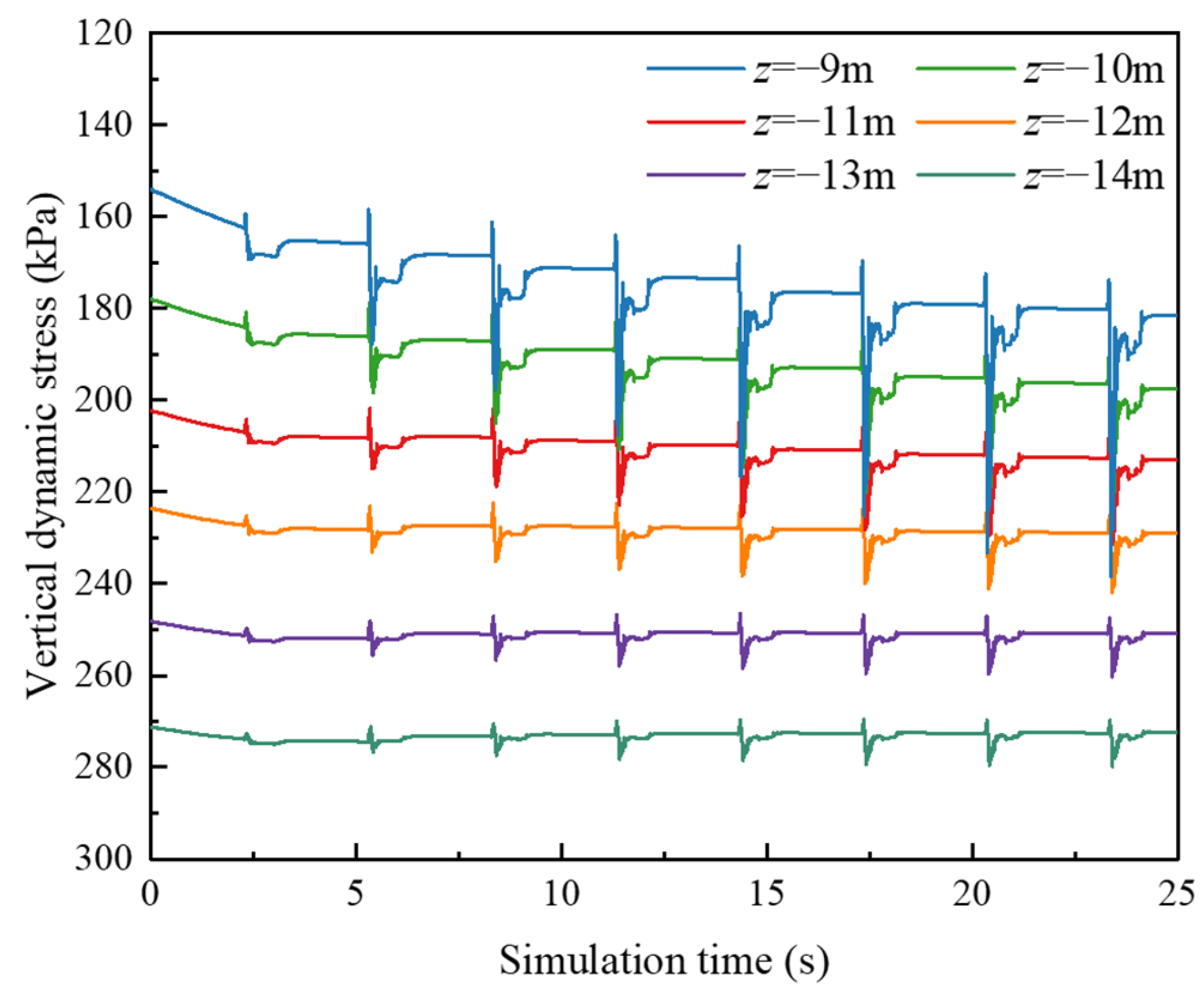

3.3. Vertical Additional Dynamic Stress

3.4. Pore Water Pressure

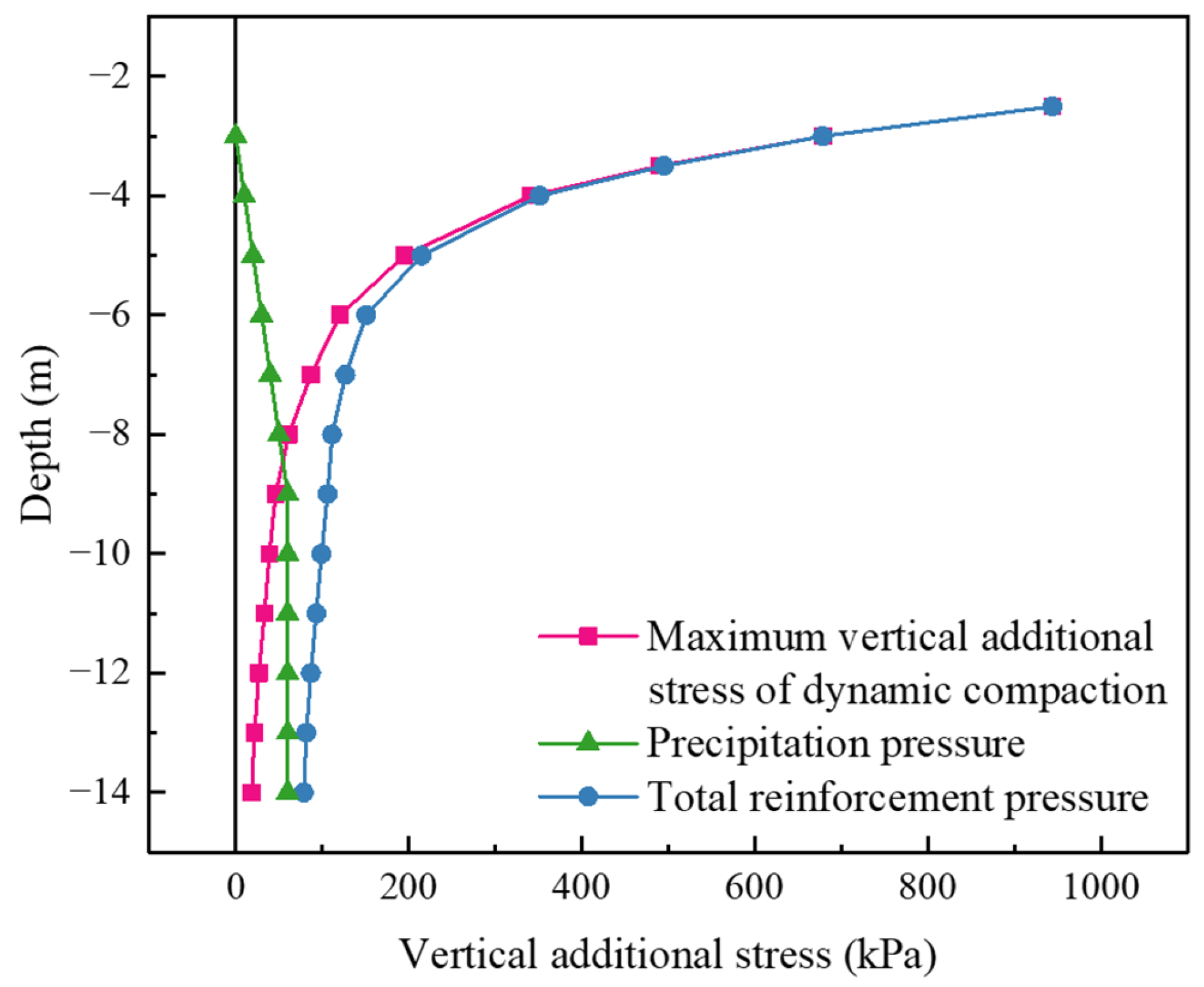

3.5. Total Reinforcement Pressure

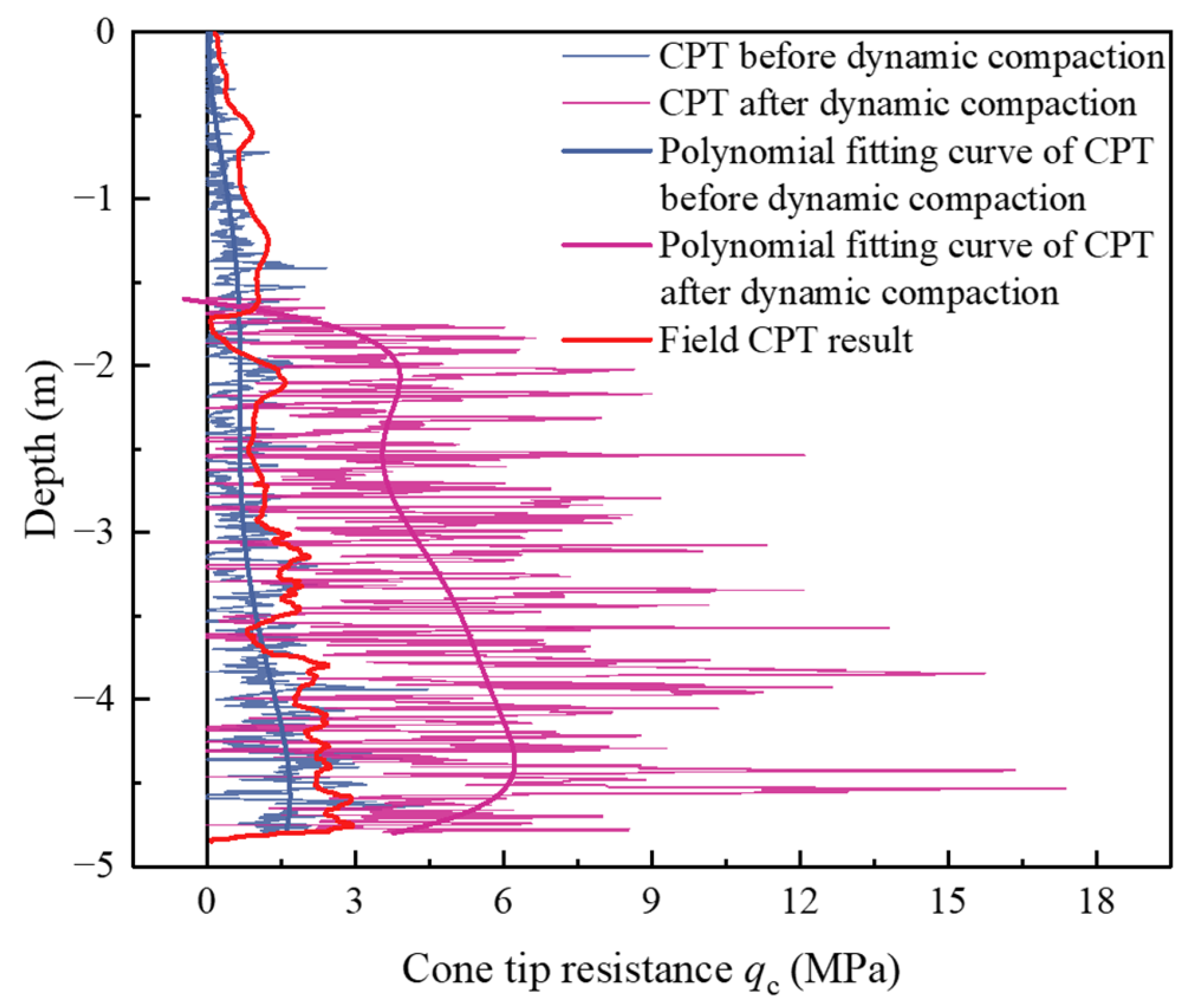

3.6. Simulated Static Cone Penetration Tests

4. Conclusions

- (a)

- The FDM–DEM coupling method was adopted to realize the three-dimensional refined modeling of continuum–discrete coupling, effectively enlarging the model size, reflecting local large deformation during DC, and improving the efficiency of numerical calculation. The 3D coupled model realized the comprehensive analysis of the mechanical behavior of the medium from the perspective of continuum and discrete macro–micro synergy. Meanwhile, a free field boundary and quiet boundary were applied to eliminate the influence of dynamic wave reflection, obtaining a higher calculation accuracy than that in previous studies.

- (b)

- The crater depth and the instant soil rebound at the crater bottom increased with the number of strikes. After removing the hammer, the soil rebound in the process of soil stabilization increased first and then decreased as the number of strikes increased. The soil settlement at the crater surface in the first strike was 460.7 mm, and the soil settlement at the crater surface in the last strike was 28.8 mm The total crater depth was 1669 mm after eight strikes of 8000 kN·m DC. Through polynomial fitting of the soil settlement curve, it could be found that the curvature gradually decreased, revealing that the foundation bearing capacity eventually tended to a stable value as a result of DC.

- (c)

- In the process of dynamic compaction, the soil void ratio decreased gradually and reached the minimum value at the moment of compaction. The final void ratio of granular soil could be reduced from 0.790 to 0.523. The vertical additional dynamic stress induced by DC was the fundamental reason resulting in foundation compaction, but the vertical additional dynamic stress attenuated rapidly along the depth. The effective reinforcement depth could be determined according to the fluctuation of vertical dynamic stress in different measurement spheres. The effective reinforcement depth of 8000 kN·m DC at this site was 11 m, which is in good agreement with the effective reinforcement depth of 11.42 m calculated using Menard’s modified formula.

- (d)

- Dewatering before dynamic compaction could reduce the increase in pore water pressure induced by vertical additional dynamic stress and improve the reinforcement effect. The superposition of dewatering pressure and vertical additional dynamic stress could compensate for the rapid attenuation of vertical additional dynamic stress along the depth direction to a certain extent. By comparing with the field CPT results, the rationality of the microscopic parameters of the model was verified, and the reliability of the CPT simulation was confirmed. The simulated CPT results demonstrate that the dynamic compaction could increase the modulus of soil foundation by about 3–5 times.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ménard, L.; Broise, Y. Theoretical and practical aspect of dynamic consolidation. Géotechnique 1975, 25, 3–18. [Google Scholar] [CrossRef]

- Feng, S.J.; Tan, K.; Shui, W.H.; Zhang, Y. Densification of desert sands by high energy dynamic compaction. Eng. Geol. 2013, 157, 48–54. [Google Scholar] [CrossRef]

- Zhang, R.Y.; Sun, Y.J.; Song, E.X. Simulation of dynamic compaction and analysis of its efficiency with the material point method. Comput. Geotech. 2019, 116, 103218. [Google Scholar] [CrossRef]

- Wang, W.; Chen, J.J.; Wang, J.H. Estimation method for ground deformation of granular soils caused by dynamic compaction. Soil Dyn. Earthq. Eng. 2017, 92, 266–278. [Google Scholar] [CrossRef]

- Zhou, C.; Jiang, H.G.; Yao, Z.Y.; Li, H.; Yang, C.J.; Chen, L.C.; Geng, X.Y. Evaluation of dynamic compaction to improve saturated foundation based on the fluid-solid coupled method with soil cap model. Comput. Geotech. 2020, 125, 103686. [Google Scholar] [CrossRef]

- Zhou, C.; Yang, C.J.; Qi, H.; Yao, K.; Yao, Z.Y.; Wang, K.; Ji, P.; Li, H. Evaluation on improvement zone of foundation after dynamic compaction. Appl. Sci. 2021, 11, 2156. [Google Scholar] [CrossRef]

- Yao, Z.Y.; Zhou, C.; Lin, Q.Q.; Yao, K.; Satchithananthan, U.; Lee, F.H.; Tang, A.M.; Jiang, H.G.; Pan, Y.T.; Wang, S.T. Effect of dynamic compaction by multi-point tamping on the densification of sandy soil. Comput. Geotech. 2022, 151, 104949. [Google Scholar] [CrossRef]

- Li, J.L.; Zhou, C.; Xin, G.F.; Long, G.X.; Zhang, W.L.; Li, C.; Zhuang, P.Z.; Yao, Z.Y. Study on reinforcement mechanism and reinforcement effect of saturated soil with a weak layer by DC. Appl. Sci. 2022, 12, 9770. [Google Scholar] [CrossRef]

- Abedini, F.; Rafiee-Dehkharghani, R.; Laknejadi, K. Mitigation of vibrations caused by dynamic compaction considering soil nonlinearity. Int. J. Civ. Eng. 2022, 20, 809–826. [Google Scholar] [CrossRef]

- Bradley, A.C.; Jaksa, M.B.; Kuo, Y.L. Finite element modelling of rolling dynamic compaction. Comput. Geotech. 2023, 157, 105275. [Google Scholar] [CrossRef]

- Paulmichl, I.; Furtmüller, T.; Adam, C.; Adam, D. Numerical simulation of the compaction effect and the dynamic response of an oscillation roller based on a hypoplastic soil model. Soil Dyn. Earthq. Eng. 2020, 132, 106057. [Google Scholar] [CrossRef]

- Chen, L.; Qiao, L.; Li, Q.W. Study on dynamic compaction characteristics of gravelly soils with crushing effect. Soil Dyn. Earthq. Eng. 2019, 120, 158–169. [Google Scholar] [CrossRef]

- Yao, K.; Rong, Y.; Yao, Z.Y.; Shi, C.Y.; Yang, C.J.; Chen, L.C.; Zhang, B.S.; Jiang, H.G. Effect of water level on dynamic compaction in silty ground of Yellow River alluvial plain. Arab. J. Geosci. 2022, 15, 126. [Google Scholar] [CrossRef]

- Sun, Y.W. Vertical additional dynamic stress propagation characteristics of silty foundation reinforced by dynamic compaction. J. Transp. Sci. Eng. 2023, accepted. [Google Scholar]

- Ma, Z.Y.; Dang, F.N.; Liao, H.J. Numerical study of the dynamic compaction of gravel soil ground using the discrete element method. Granul. Matter 2014, 16, 881–889. [Google Scholar] [CrossRef]

- Li, Y.Q.; Ma, Z.Y.; Yang, F. Numerical study on micro-reinforcement mechanism and environmental control of gravel soil under dynamic compaction. Arab. J. Geosci. 2021, 14, 2682. [Google Scholar] [CrossRef]

- Jia, M.C.; Yang, Y.; Liu, B.; Wu, S.H. PFC/FLAC coupled simulation of dynamic compaction in granular soils. Granul. Matter 2018, 20, 76. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, Y.; Ouyang, H.; Jiang, T.; Song, M.; Zhang, X. 3D continuum-discrete coupling modeling of soil-hammer interaction under dynamic compaction. J. Vibroeng. 2019, 21, 348–359. [Google Scholar] [CrossRef]

- Jia, M.C.; Liu, B.; Xue, J.F.; Ma, G.Q. Coupled three-dimensional discrete element–finite difference simulation of dynamic compaction. Acta Geotech. 2021, 16, 731–747. [Google Scholar] [CrossRef]

- Wang, W.; Wu, Y.J.; Wu, H.; Yang, C.Z.; Feng, Q.S. Numerical analysis of dynamic compaction using FEM-SPH coupling method. Soil Dyn. Earthq. Eng. 2021, 140, 106420. [Google Scholar] [CrossRef]

- Feng, S.J.; Du, F.L.; Chen, H.X.; Mao, J.Z. Centrifuge modeling of preloading consolidation and dynamic compaction in treating dredged soil. Eng. Geol. 2017, 226, 161–171. [Google Scholar] [CrossRef]

- Jia, M.C.; Cheng, J.X.; Liu, B.; Ma, G.Q. Model tests of the influence of ground water level on dynamic compaction. Bull. Eng. Geol. Environ. 2021, 80, 3065–3078. [Google Scholar] [CrossRef]

- Li, P.X.; Sun, J.Y.; Ge, X.S.; Zhang, M.; Wang, J.Y. Parameters of dynamic compaction based on model test. Soil Dyn. Earthq. Eng. 2023, 168, 107853. [Google Scholar] [CrossRef]

- Shen, M.F.; Martin, J.R.; Ku, C.S.; Lu, Y.C. A case study of the effect of dynamic compaction on liquefaction of reclaimed ground. Eng. Geol. 2018, 240, 48–61. [Google Scholar] [CrossRef]

- Wu, S.F.; Wei, Y.Q.; Zhang, Y.Q.; Cai, H.; Du, J.F.; Wang, D.; Yan, J.; Xiao, J.Z. Dynamic compaction of a thick soil-stone fill: Dynamic response and strengthening mechanisms. Soil Dyn. Earthq. Eng. 2020, 129, 105499. [Google Scholar] [CrossRef]

- Li, X.; Yang, H.; Zhang, J.Y.; Qian, G.P.; Yu, H.N.; Cai, J. Time-domain analysis of tamper displacement during dynamic compaction based on automatic control. Coatings 2021, 11, 1092. [Google Scholar] [CrossRef]

- Wei, Y.J.; Yang, Y.Y.; Wang, J.T.; Liu, H.C.; Li, J.G.; Jie, Y.X. Performance evaluation of high energy dynamic compaction on soil-rock mixture geomaterials based on field test. Case Stud. Constr. Mater. 2023, 18, e01734. [Google Scholar] [CrossRef]

- Wang, L.; Du, F.L.; Liang, Y.H.; Gao, W.S.; Zhang, G.Z.; Sheng, Z.Q.; Chen, X.S. A comprehensive in situ investigation on the reinforcement of high-filled red soil using the dynamic compaction method. Sustainability 2023, 15, 4756. [Google Scholar] [CrossRef]

- Wang, G.B.; Yin, Y.; Wang, J.N. Vibration safety evaluation and vibration isolation control measures for buried oil pipelines under dynamic compaction: A case study. Soil Dyn. Earthq. Eng. 2023, 167, 107783. [Google Scholar] [CrossRef]

- Alnaim, A.; AlQahtany, A.M.; Alshammari, M.S.; Al-Gehlani, W.A.G.; Alyami, S.H.; Aldossary, N.A.; Naseer, M.N. A systematic framework for evaluating the effectiveness of dynamic compaction (DC) technology for soil improvement projects using cone penetration test data. Appl. Sci. 2022, 12, 9686. [Google Scholar] [CrossRef]

- Yao, J.K.; Yue, M.; Ma, H.S.; Yang, C.W. Wave propagation characteristics and compaction status of subgrade during vibratory compaction. Sensors 2023, 23, 2183. [Google Scholar] [CrossRef]

- Gao, Q.Y.; Jin, Y.L.; Liu, Q.; Yan, P.; Zhang, H.Y.; Li, F.Y.; Wang, H. Monocular vision measurement technology applied in dynamic compaction ramming settlement monitoring. Measurement 2023, 216, 112941. [Google Scholar] [CrossRef]

- Wu, Z.X.; Lei, J.J.; Ye, C.P.; Yu, C.; Zhao, J.L. Coupled FDM-DEM simulations of axial compression tests on FRP-confined concrete specimens. Constr. Build. Mater. 2022, 351, 128885. [Google Scholar] [CrossRef]

- Zheng, Y.N.; Zheng, L.F.; Zhan, H.Y.; Huang, Q.F.; Jia, C.J.; Li, Z. Study on failure mechanism of soil–rock slope with FDM-DEM method. Sustainability 2022, 14, 17015. [Google Scholar] [CrossRef]

- Huang, K.; Sun, Y.W.; Kuang, X.L.; Huang, X.Q.; Liu, R.N.; Wu, Q.J. Study on the restraint effect of isolation pile on surface settlement trough induced by shield tunnelling. Appl. Sci. 2022, 12, 4845. [Google Scholar] [CrossRef]

- Huang, K.; Sun, Y.W.; Chen, X.S.; Deng, X.; Liu, R.N.; Wu, Q.J. Study on three-dimensional soil displacement characteristics in front of shield tunnel excavation face based on coupled FDM-DEM. China J. Highw. Transp. 2022; in press. [Google Scholar]

- Huang, Z.K.; Argyroudis, S.; Zhang, D.M.; Pitilakis, K.; Huang, H.W.; Zhang, D.M. Time-dependent fragility functions for circular tunnels in soft soils. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2022, 8, 04022030. [Google Scholar] [CrossRef]

- Huang, Z.K.; Zhang, D.M.; Pitilakis, K.; Tsinidis, G.; Huang, H.W.; Zhang, D.M.; Argyroudis, S. Resilience assessment of tunnels: Framework and application for tunnels in alluvial deposits exposed to seismic hazard. Soil Dyn. Earthq. Eng. 2022, 162, 107456. [Google Scholar] [CrossRef]

- Potyondy, D.O. Simulating stress corrosion with a bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 2007, 44, 677–691. [Google Scholar] [CrossRef]

- Feng, S.J.; Du, F.L.; Shi, Z.M.; Shui, W.H.; Tan, K. Field study on the reinforcement of collapsible loess using dynamic compaction. Eng. Geol. 2015, 185, 105–115. [Google Scholar] [CrossRef]

| Soil Layer | Soil Thickness hs (m) | Density γ (kg/m3) | Compression Modulus Es (MPa) | Poisson’s Ratio μ | Cohesion c (kPa) | Friction Angle φ (◦) | Void Ratio e | Permeability Coefficient k (cm/s) | SPT 1 |

|---|---|---|---|---|---|---|---|---|---|

| 1: granular soil | 7.5 | 1800 | 4.5 | 0.25 | 0.5 | 36 | 0.790 | - | - |

| 2: dredger fill | 7.5 | 1760 | 3.73 | 0.3 | 16.6 | 11.9 | 1.377 | 2.58 × 10−5 | 4.9 |

| 3: muddy silty clay with silty sand | 6 | 1840 | 3.58 | 0.3 | 15.3 | 5.8 | 1.042 | 1.92 × 10−6 | 3.7 |

| Contact Type | Effective Modulus (MPa) | Normal Bonding (Pa) | Shear Bonding (Pa) | Friction Angle (◦) | Friction Coefficient | Normal-to-Shear Stiffness Ratio |

|---|---|---|---|---|---|---|

| Ball–ball | 25.0 | 1.5 × 103 | 0.5 × 103 | 36 | 0.5 | 1.5 |

| Ball–wall | 25.0 | 1.5 × 104 | 5 × 103 | 36 | 0.3 | 1.5 |

| Ball–pebble | 25.0 | - | - | - | 0.3 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Huang, K.; Chen, X.; Zhang, D.; Lou, X.; Huang, Z.; Han, K.; Wu, Q. Study on the Reinforcement Mechanism of High-Energy-Level Dynamic Compaction Based on FDM–DEM Coupling. Mathematics 2023, 11, 2807. https://doi.org/10.3390/math11132807

Sun Y, Huang K, Chen X, Zhang D, Lou X, Huang Z, Han K, Wu Q. Study on the Reinforcement Mechanism of High-Energy-Level Dynamic Compaction Based on FDM–DEM Coupling. Mathematics. 2023; 11(13):2807. https://doi.org/10.3390/math11132807

Chicago/Turabian StyleSun, Yiwei, Kan Huang, Xiangsheng Chen, Dongmei Zhang, Xiaoming Lou, Zhongkai Huang, Kaihang Han, and Qijiang Wu. 2023. "Study on the Reinforcement Mechanism of High-Energy-Level Dynamic Compaction Based on FDM–DEM Coupling" Mathematics 11, no. 13: 2807. https://doi.org/10.3390/math11132807

APA StyleSun, Y., Huang, K., Chen, X., Zhang, D., Lou, X., Huang, Z., Han, K., & Wu, Q. (2023). Study on the Reinforcement Mechanism of High-Energy-Level Dynamic Compaction Based on FDM–DEM Coupling. Mathematics, 11(13), 2807. https://doi.org/10.3390/math11132807