Bilevel Optimal Sizing and Operation Method of Fuel Cell/Battery Hybrid All-Electric Shipboard Microgrid

Abstract

1. Introduction

2. Problem Statement

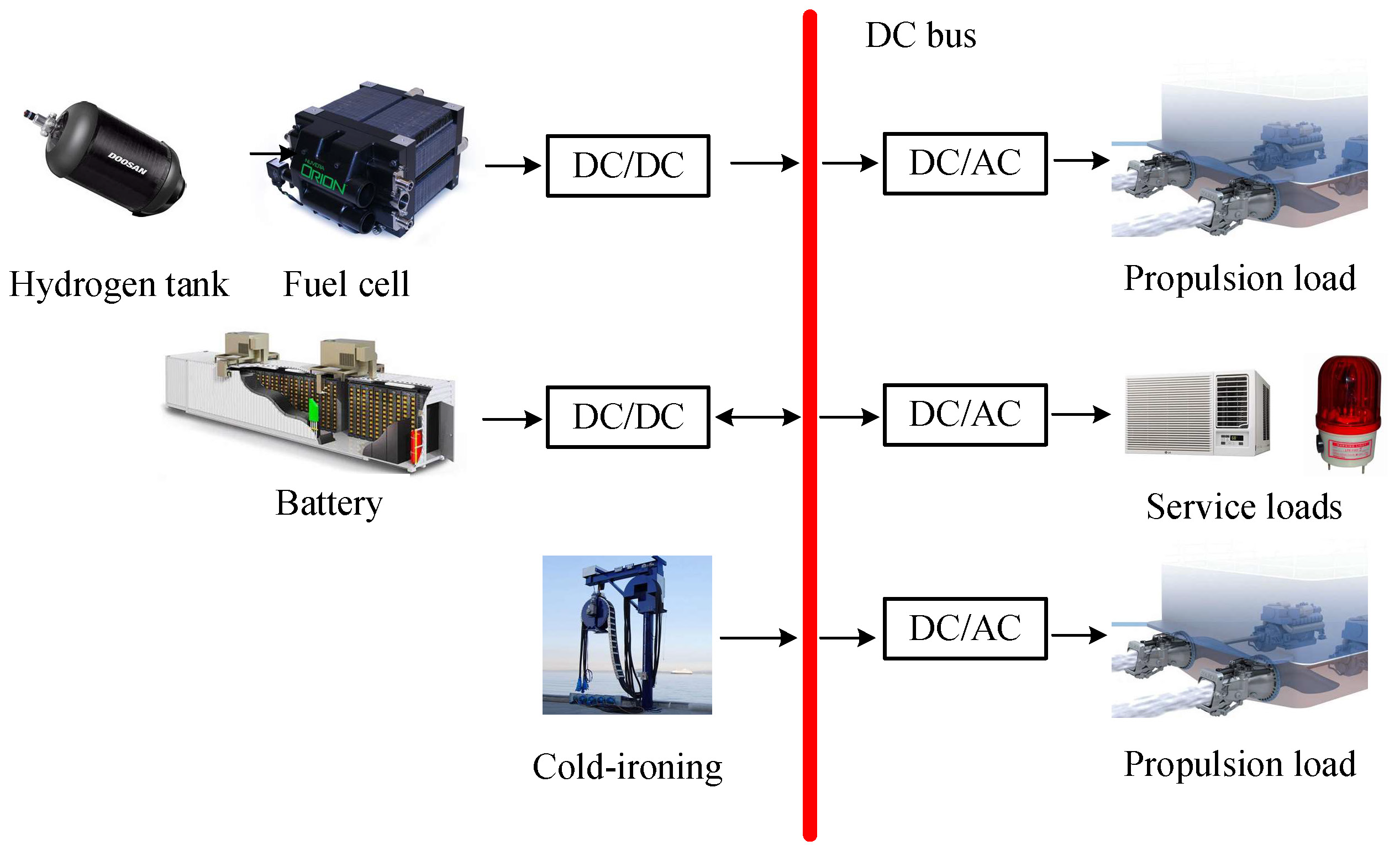

2.1. Topology of the AES

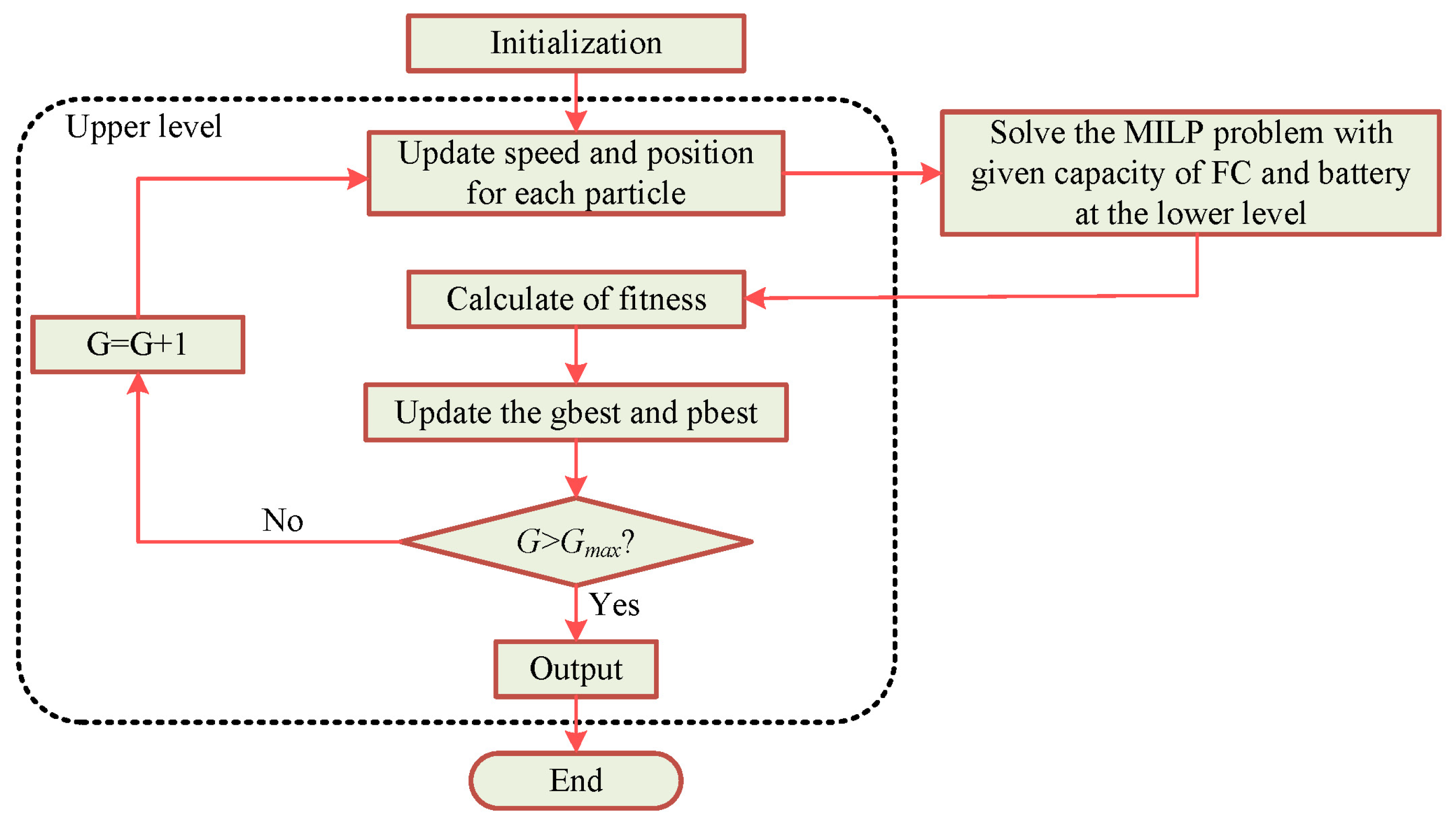

2.2. Framework of Proposed Method

3. Mathematical Modeling

3.1. AES Voyage Model

3.2. Hydrogen Fuel Cell Operation Model

4. Problem Formulation

4.1. Upper Level

4.1.1. Objective Function

4.1.2. Constraints

4.2. Lower Level

4.2.1. Objective Function

4.2.2. Constraints

- Power Balance Constraint

- 2.

- Fuel Cell Output Power Constraint

- 3.

- Fuel Cell Ramp Rate Constraint

- 4.

- Tank Capacity Constraint

- 5.

- Battery Charging and Discharging Power Constraint

- 6.

- Battery Capacity Constraint

- 7.

- SOC Constraint

- 8.

- System Reserve Constraint

- 9.

- Cold Ironing Power Constraint

- 10.

- AES sailing Speed Constraint

- 11.

- Voyage Constraint

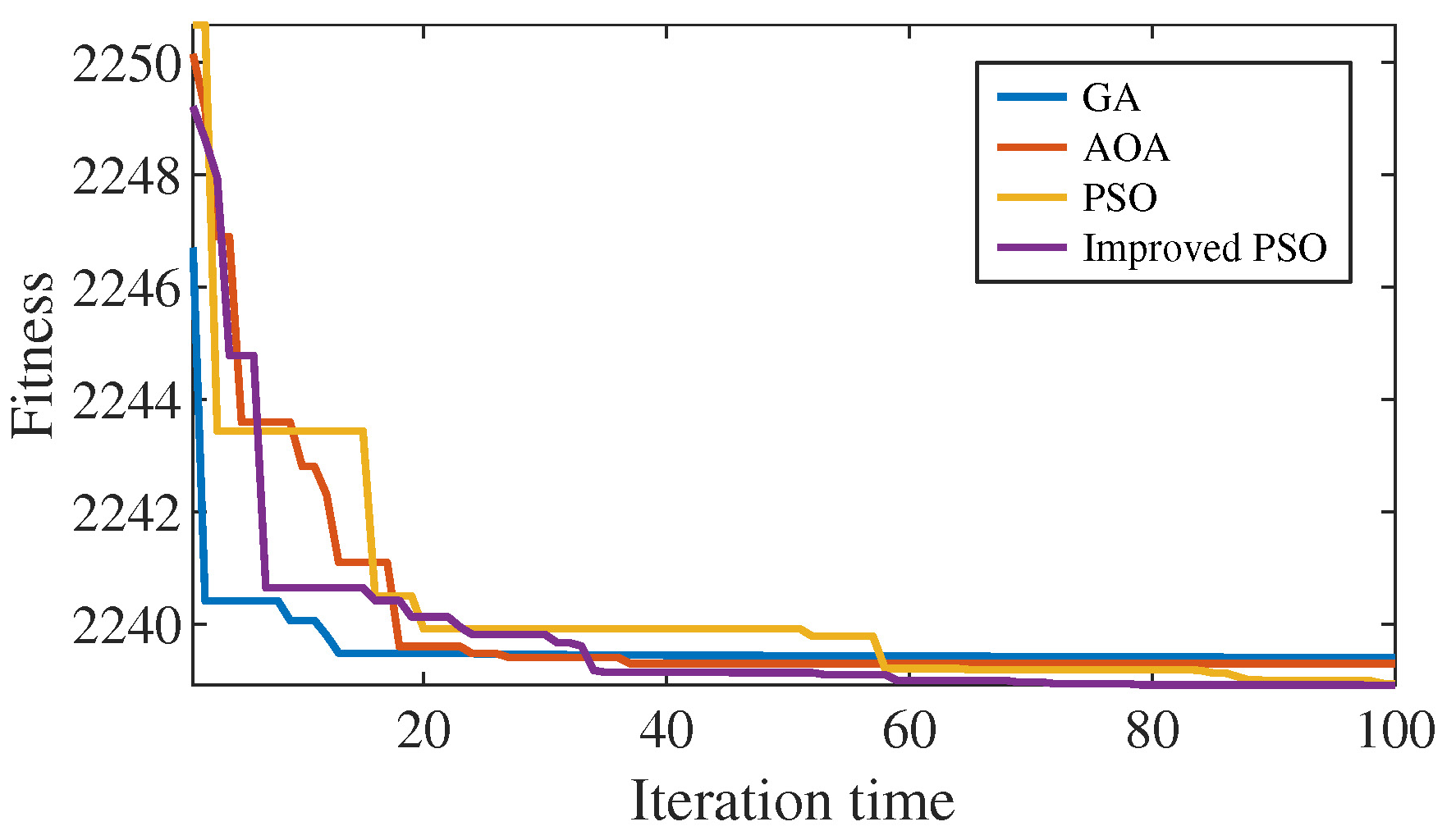

5. Solution Algorithm

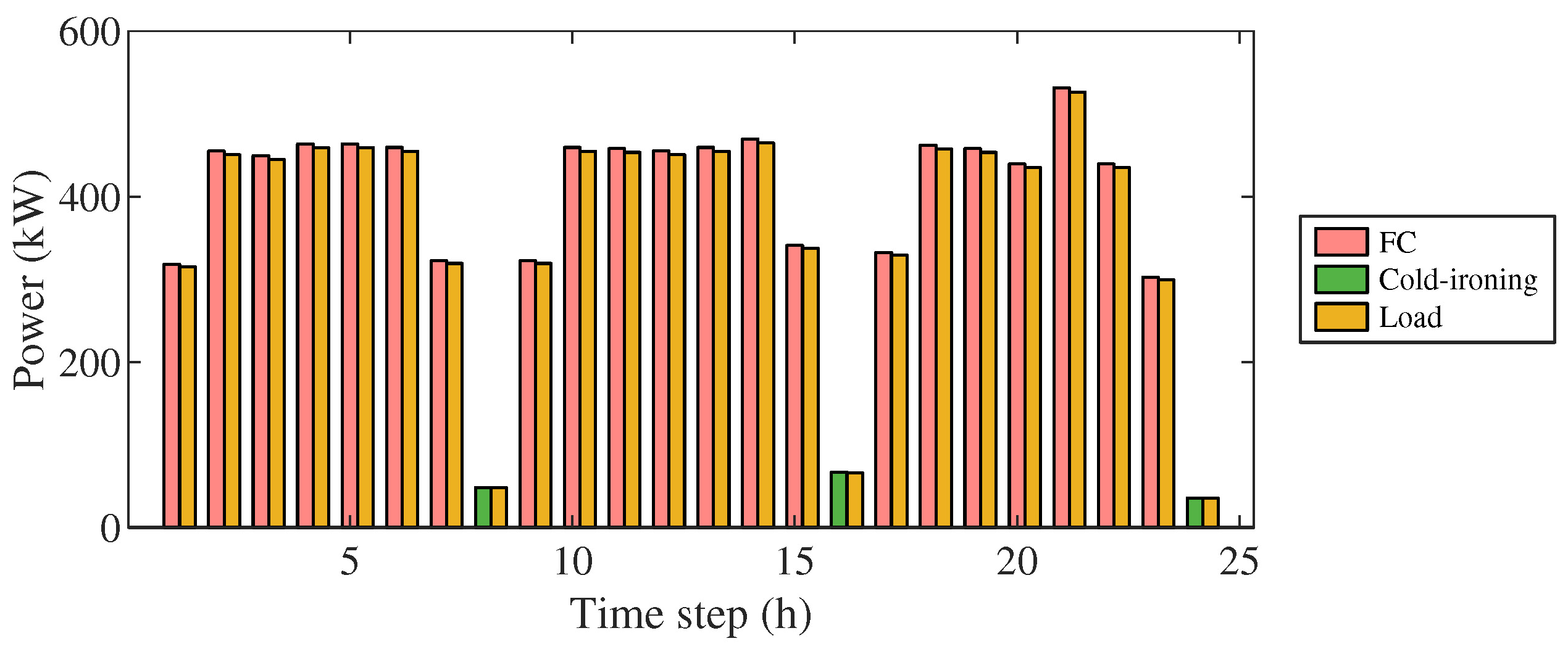

6. Case Study

6.1. System Configuration

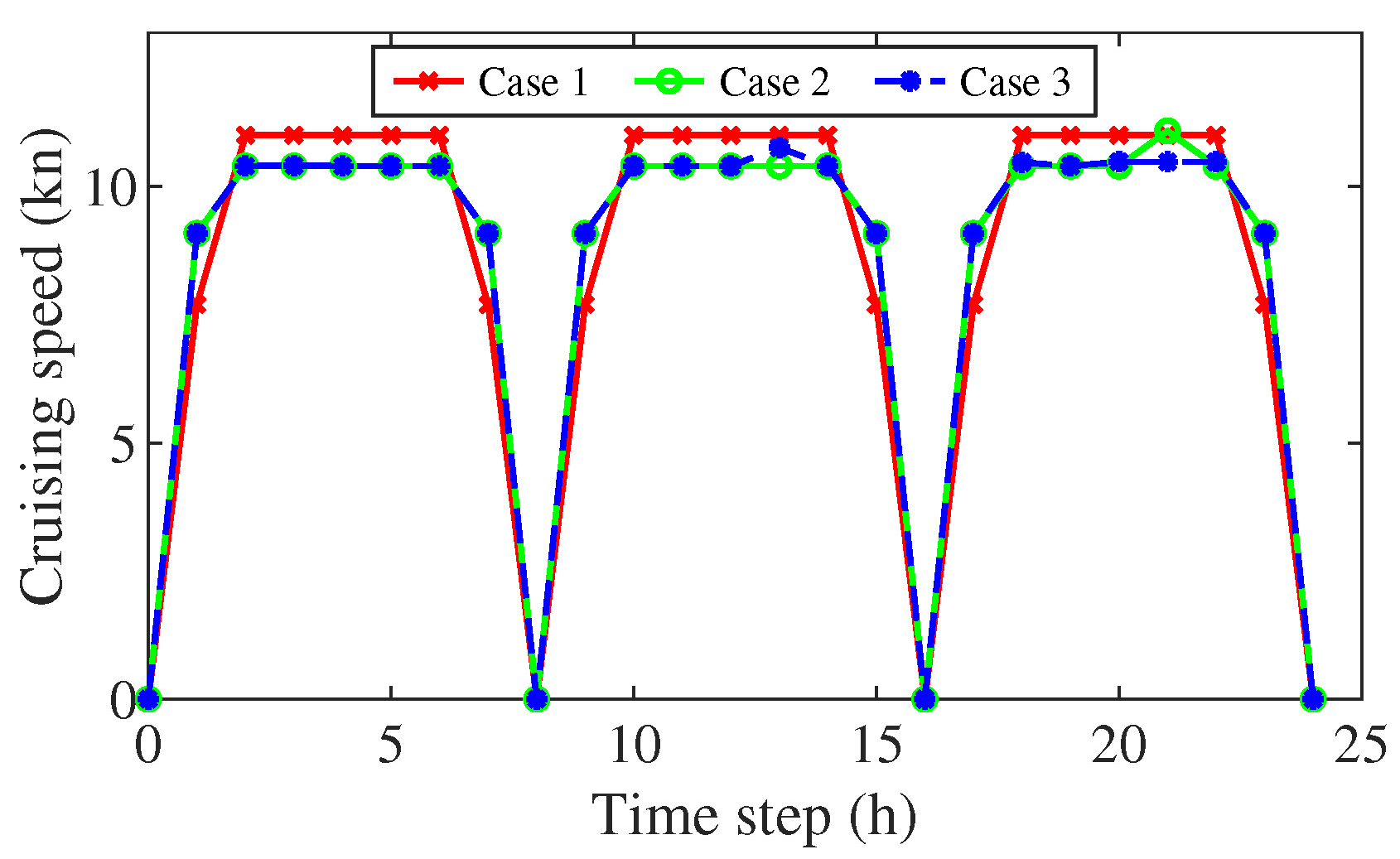

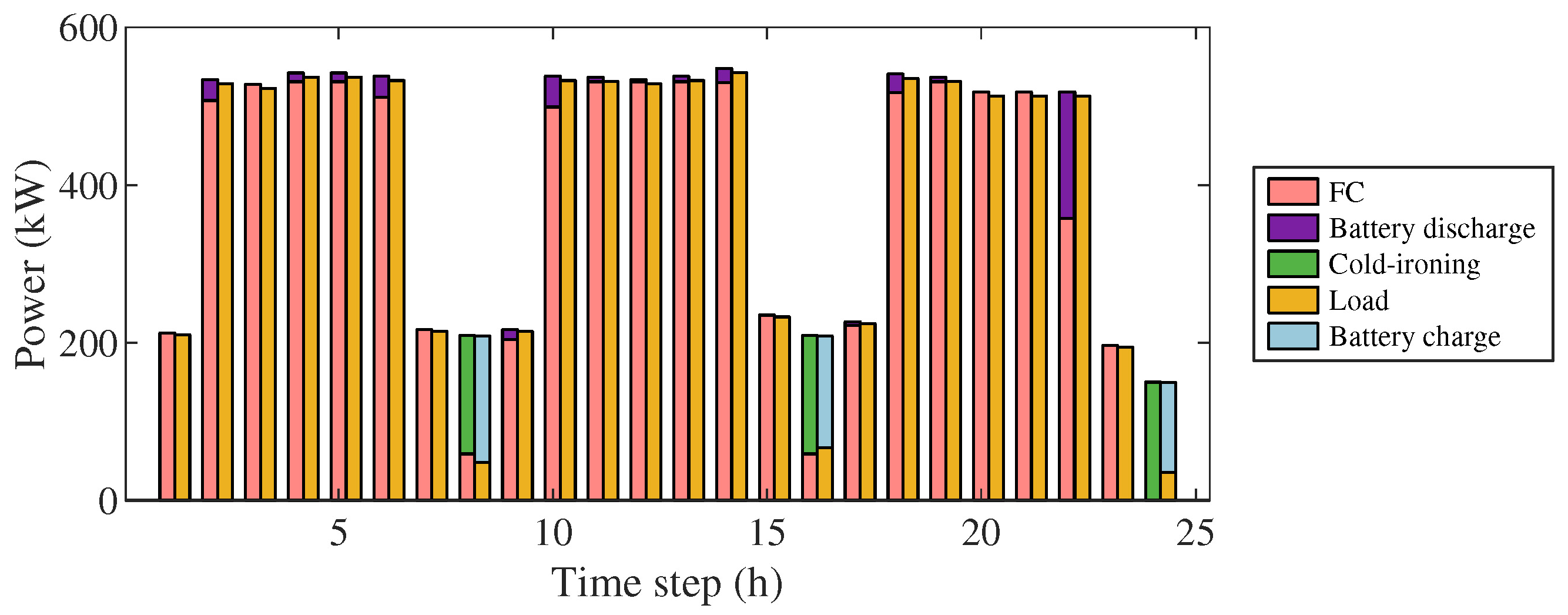

6.2. Optimization Results

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Faber, J.; Hanayama, S.; Zhang, S.; Pereda, P.; Comer, B.; Hauerhof, E.; Schim van der Loeff, W.; Smith, T.; Zhang, Y.; Kosaka, H.; et al. Fourth IMO GHG Study 2020; Technical report; International Maritime Organization (IMO): London, UK, 2020. [Google Scholar]

- Balcombe, P.; Brierley, J.; Lewis, C.; Skatvedt, L.; Speirs, J.; Hawkes, A.; Staffell, I. How to Decarbonise International Shipping: Options for Fuels, Technologies and Policies. Energy Convers. Manag. 2019, 182, 72–88. [Google Scholar] [CrossRef]

- Joung, T.H.; Kang, S.G.; Lee, J.K.; Ahn, J. The IMO initial strategy for reducing Greenhouse Gas(GHG) emissions, and its follow-up actions towards 2050. J. Int. Marit. Safety Environ. Aff. Shipp. 2020, 4, 1–7. [Google Scholar] [CrossRef]

- Gray, N.; McDonagh, S.; O’Shea, R.; Smyth, B.; Murphy, J.D. Decarbonising Ships, Planes and Trucks: An Analysis of Suitable Low-Carbon Fuels for the Maritime, Aviation and Haulage Sectors. Adv. Appl. Energy 2021, 1, 100008. [Google Scholar] [CrossRef]

- Al-Enazi, A.; Okonkwo, E.C.; Bicer, Y.; Al-Ansari, T. A Review of Cleaner Alternative Fuels for Maritime Transportation. Energy Rep. 2021, 7, 1962–1985. [Google Scholar] [CrossRef]

- Wan, Z.; el Makhloufi, A.; Chen, Y.; Tang, J. Decarbonizing the International Shipping Industry: Solutions and Policy Recommendations. Mar. Pollut. Bull. 2018, 126, 428–435. [Google Scholar] [CrossRef]

- Jin, Z.; Sulligoi, G.; Cuzner, R.; Meng, L.; Vasquez, J.C.; Guerrero, J.M. Next-Generation Shipboard DC Power System: Introduction Smart Grid and dc Microgrid Technologies into Maritime Electrical Netowrks. IEEE Electrif. Mag. 2016, 4, 45–57. [Google Scholar] [CrossRef]

- Geertsma, R.; Negenborn, R.; Visser, K.; Hopman, J. Design and Control of Hybrid Power and Propulsion Systems for Smart Ships: A Review of Developments. Appl. Energy 2017, 194, 30–54. [Google Scholar] [CrossRef]

- Nuchturee, C.; Li, T.; Xia, H. Energy Efficiency of Integrated Electric Propulsion for Ships—A Review. Renew. Sustain. Energy Rev. 2020, 134, 110145. [Google Scholar] [CrossRef]

- Nguyen, H.P.; Hoang, A.T.; Nizetic, S.; Nguyen, X.P.; Le, A.T.; Luong, C.N.; Chu, V.D.; Pham, V.V. The electric propulsion system as a green solution for management strategy of CO2 emission in ocean shipping: A comprehensive review. Int. Trans. Electr. Energy Syst. 2021, 31, e12580. [Google Scholar] [CrossRef]

- Fang, S.; Xu, Y.; Li, Z.; Zhao, T.; Wang, H. Two-Step Multi-Objective Management of Hybrid Energy Storage System in All-Electric Ship Microgrids. IEEE Trans. Veh. Technol. 2019, 68, 3361–3373. [Google Scholar] [CrossRef]

- Xing, H.; Stuart, C.; Spence, S.; Chen, H. Fuel Cell Power Systems for Maritime Applications: Progress and Perspectives. Sustainability 2021, 13, 1213. [Google Scholar] [CrossRef]

- Lotrič, A.; Sekavčnik, M.; Pohar, A.; Likozar, B.; Hočevar, S. Conceptual Design of an Integrated Thermally Self-Sustained Methanol Steam Reformer—High-Temperature PEM Fuel Cell Stack Manportable Power Generator. Int. J. Hydrogren Energy 2017, 42, 16700–16713. [Google Scholar] [CrossRef]

- Pohar, A.; Hočevar, S.; Likozar, B.; Levec, J. Synthesis and Characterization of Gallium-Promoted Copper—Ceria Catalyst and Its Application for Methanol Steam Reforming in a Packed Bed Reactor. Catal. Today 2015, 256, 358–364. [Google Scholar] [CrossRef]

- Rubin, K.; Pohar, A.; Dasireddy, V.D.; Likozar, B. Synthesis, Characterization and Activity of CuZnGaOx Catalysts for the Water–Gas Shift (WGS) Reaction for H2 Production and CO Removal after Reforming. Fuel Process. Technol. 2018, 169, 217–225. [Google Scholar] [CrossRef]

- Shakeri, N.; Zadeh, M.; Bremnes Nielsen, J. Hydrogen Fuel Cells for Ship Electric Propulsion: Moving toward Greener Ships. IEEE Electrif. Mag. 2020, 8, 27–43. [Google Scholar] [CrossRef]

- Banaei, M.; Rafiei, M.; Boudjadar, J.; Khooban, M.H. A Comparative Analysis of Optimal Operation Scenarios in Hybrid Emission-Free Ferry Ships. IEEE Trans. Transp. Electrif. 2020, 6, 318–333. [Google Scholar] [CrossRef]

- Letafat, A.; Rafiei, M.; Sheikh, M.; Afshari-Igder, M.; Banaei, M.; Boudjadar, J.; Khooban, M.H. Simultaneous Energy Management and Optimal Components Sizing of a Zero-Emission Ferry Boat. J. Energy Storage 2020, 28, 101215. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Liang, X.; Huang, B. Event-Triggered-Based Distributed Cooperative Energy Management for Multienergy Systems. IEEE Trans. Ind. Inform. 2019, 15, 2008–2022. [Google Scholar] [CrossRef]

- Shang, C.; Srinivasan, D.; Reindl, T. Economic and Environmental Generation and Voyage Scheduling of All-Electric Ships. IEEE Trans. Power Syst. 2016, 31, 4087–4096. [Google Scholar] [CrossRef]

- Huang, Y.; Lan, H.; Hong, Y.Y.; Wen, S.; Fang, S. Joint Voyage Scheduling and Economic Dispatch for All-Electric Ships with Virtual Energy Storage Systems. Energy 2020, 190, 116268. [Google Scholar] [CrossRef]

- Fang, S.; Gou, B.; Wang, Y.; Xu, Y.; Shang, C.; Wang, H. Optimal Hierarchical Management of Shipboard Multibattery Energy Storage System Using a Data-Driven Degradation Model. IEEE Trans. Transp. Electrif. 2019, 5, 1306–1318. [Google Scholar] [CrossRef]

- Wen, S.; Zhao, T.; Tang, Y.; Xu, Y.; Zhu, M.; Fang, S.; Ding, Z. Coordinated Optimal Energy Management and Voyage Scheduling for All-Electric Ships Based on Predicted Shore-Side Electricity Price. IEEE Trans. Ind. Appl. 2021, 57, 139–148. [Google Scholar] [CrossRef]

- Fang, S.; Xu, Y.; Li, Z.; Ding, Z.; Liu, L.; Wang, H. Optimal Sizing of Shipboard Carbon Capture System for Maritime Greenhouse Emission Control. IEEE Trans. Ind. Appl. 2019, 55, 5543–5553. [Google Scholar] [CrossRef]

- Wen, S.; Zhao, T.; Tang, Y.; Xu, Y.; Zhu, M.; Huang, Y. A Joint Photovoltaic-Dependent Navigation Routing and Energy Storage System Sizing Scheme for More Efficient All-Electric Ships. IEEE Trans. Transp. Electrif. 2020, 6, 1279–1289. [Google Scholar] [CrossRef]

- Zhao, T.; Qiu, J.; Wen, S.; Zhu, M. Efficient Onboard Energy Storage System Sizing for All-Electric Ship Microgrids via Optimized Navigation Routing under Onshore Uncertainties. IEEE Trans. Ind. Appl. 2022, 58, 1664–1674. [Google Scholar] [CrossRef]

- Banaei, M.; Ghanami, F.; Khooban, M.H.; Boudjadar, J. Cost-effective control of Roll-on/Roll-off Emission-Free Ships. In Proceedings of the 2021 25th International Conference on Methods and Models in Automation and Robotics (MMAR), Miedzyzdroje, Poland, 23–26 August 2021; IEEE: Toulouse, France, 2021; pp. 315–320. [Google Scholar]

- Banaei, M.; Boudjadar, J.; Dragičević, T.; Khooban, M.H. Cost Effective Operation of a Hybrid Zero-Emission Ferry Ship. In Proceedings of the 2020 IEEE 11th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Dubrovnik, Croatia, 28 September–1 October 2020; IEEE: Toulouse, France, 2020; pp. 23–28. [Google Scholar]

- Letafat, A.; Rafiei, M.; Ardeshiri, M.; Sheikh, M.; Banaei, M.; Boudjadar, J.; Khooban, M.H. An Efficient and Cost-Effective Power Scheduling in Zero-Emission Ferry Ships. Complexity 2020, 2020, 6487873. [Google Scholar] [CrossRef]

- Han, J.; Charpentier, J.F.; Tang, T. An Energy Management System of a Fuel Cell/Battery Hybrid Boat. Energies 2014, 7, 2799–2820. [Google Scholar] [CrossRef]

- Wang, X.; Shipurkar, U.; Haseltalab, A.; Polinder, H.; Claeys, F.; Negenborn, R.R. Sizing and Control of a Hybrid Ship Propulsion System Using Multi-Objective Double-Layer Optimization. IEEE Access 2021, 9, 72587–72601. [Google Scholar] [CrossRef]

- Pan, X.; Zhu, X.; Zhao, F. More Environmental Sustainability Routing and Energy Management for All Electric Ships. Front. Energy Res. 2022, 9, 821236. [Google Scholar] [CrossRef]

- Urbanucci, L. Limits and Potentials of Mixed Integer Linear Programming Methods for Optimization of Polygeneration Energy Systems. Energy Procedia 2018, 148, 1199–1205. [Google Scholar] [CrossRef]

- Angelo, J.S.; Krempser, E.; Barbosa, H.J. Differential evolution for bilevel programming. In Proceedings of the 2013 IEEE Congress on Evolutionary Computation, Cancun, Mexico, 20–23 June 2013; IEEE: Toulouse, France, 2013; pp. 470–477. [Google Scholar]

- Kanellos, F.D. Optimal Power Management with GHG Emissions Limitation in All-Electric Ship Power Systems Comprising Energy Storage Systems. IEEE Trans. Power Syst. 2014, 29, 330–339. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95—International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; IEEE: Toulouse, France, 1995; Volume 4, pp. 1942–1948. [Google Scholar]

- Shi, Y.; Eberhart, R. A modified particle swarm optimizer. In Proceedings of the 1998 IEEE International Conference on Evolutionary Computation Proceedings, Anchorage, AK, USA, 4–9 May 1998; IEEE: Toulouse, France, 1998; pp. 69–73. [Google Scholar]

- Yan, X.; Wang, K.; Yuan, Y.; Jiang, X.; Negenborn, R.R. Energy-Efficient Shipping: An Application of Big Data Analysis for Optimizing Engine Speed of Inland Ships Considering Multiple Environmental Factors. Ocean. Eng. 2018, 169, 457–468. [Google Scholar] [CrossRef]

- Ahmed, E.M.; Rathinam, R.; Dayalan, S.; Fernandez, G.S.; Ali, Z.M.; Abdel Aleem, S.H.E.; Omar, A.I. A Comprehensive Analysis of Demand Response Pricing Strategies in a Smart Grid Environment Using Particle Swarm Optimization and the Strawberry Optimization Algorithm. Mathematics 2021, 9, 2338. [Google Scholar] [CrossRef]

- Yu, H.; Gao, Y.; Wang, L.; Meng, J. A Hybrid Particle Swarm Optimization Algorithm Enhanced with Nonlinear Inertial Weight and Gaussian Mutation for Job Shop Scheduling Problems. Mathematics 2020, 8, 1355. [Google Scholar] [CrossRef]

- Holland, J.H. Adaptation in Natural and Artificial Systems; University of Michigan Press: Ann Arbor, MI, USA, 1975. [Google Scholar]

- Hashim, F.A.; Hussain, K.; Houssein, E.H.; Mabrouk, M.S.; Al-Atabany, W. Archimedes Optimization Algorithm: A New Metaheuristic Algorithm for Solving Optimization Problems. Appl. Intell. 2021, 51, 1531–1551. [Google Scholar] [CrossRef]

| Item | Parameter of Upper Level |

|---|---|

| = 40 $/kW, = 17.8 $/kWh, = 17.8 $/kW | |

| = 40,000 h, = 1460 times | |

| = 300 kW, = 800 kWh, = 800 kW | |

| Voyage | =1 h, T = 24 h |

| = 11 knots, = 0.346, = 3, = 0.7, = 18%, = 1% | |

| = {2, …, 6, 10, …, 14, 18, …, 22}, = {1, 7, 9, 15, 17, 23}, = {8, 16, 24} | |

| Fuel cell and Hydrogen tank | , , = 450 kg, = 0.03 kg/kWh, = 5 $/kg |

| = 0.9, = 0.1, = 50%, = −50%, = 15%, = 10% | |

| Battery | = 0.9, = 0.8, = 85%, = 100%, = 1%, = 0.5 |

| Cold ironing | = 150 kW, |

| Item | Case 1 | Case 2 | Case 3 |

|---|---|---|---|

| Maximum power of FC (kW) | 591 | 683 | 501 |

| Maximum capacity of battery (kWh) | 243 | - | 243 |

| Maximum power of battery (kW) | 161 | - | 152 |

| Investment cost of FC ($) | 23,640 | 27,320 | 20,040 |

| Investment cost of battery ($) | 7191.2 | - | 7031 |

| Total investment cost ($) | 30,831.2 | 27,320 | 27,071 |

| Daily investment cost of FC ($) | 13.59 | 14.34 | 11.52 |

| Daily investment cost of battery ($) | 14.78 | - | 14.45 |

| Total daily investment cost ($) | 28.37 | 14.34 | 25.97 |

| Daily consumed mass of (L) | 455.01 | 446.11 | 430.90 |

| Daily operation cost of ($) | 2275.04 | 2230.57 | 2154.50 |

| Daily operation cost of cold ironing ($) | 58.50 | 20.97 | 58.47 |

| Total daily operation cost ($) | 2333.54 | 2251.54 | 2212.98 |

| Total daily cost ($) | 2361.91 | 2265.88 | 2238.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, H.; Yang, X. Bilevel Optimal Sizing and Operation Method of Fuel Cell/Battery Hybrid All-Electric Shipboard Microgrid. Mathematics 2023, 11, 2728. https://doi.org/10.3390/math11122728

Jin H, Yang X. Bilevel Optimal Sizing and Operation Method of Fuel Cell/Battery Hybrid All-Electric Shipboard Microgrid. Mathematics. 2023; 11(12):2728. https://doi.org/10.3390/math11122728

Chicago/Turabian StyleJin, Hao, and Xinhang Yang. 2023. "Bilevel Optimal Sizing and Operation Method of Fuel Cell/Battery Hybrid All-Electric Shipboard Microgrid" Mathematics 11, no. 12: 2728. https://doi.org/10.3390/math11122728

APA StyleJin, H., & Yang, X. (2023). Bilevel Optimal Sizing and Operation Method of Fuel Cell/Battery Hybrid All-Electric Shipboard Microgrid. Mathematics, 11(12), 2728. https://doi.org/10.3390/math11122728