Prescribed Performance Fault-Tolerant Tracking Control of Uncertain Robot Manipulators with Integral Sliding Mode

Abstract

:1. Introduction

- (i)

- (ii)

- Different from previous approaches [45], the assumption of the inertia matrix being known in advance is eliminated. This cannot be assumed in practical applications.

- (iii)

- In comparison with the SMCs [19,23,26,34], the reaching phase is eliminated for the proposed approach, and the prescribed transient convergence rate and steady-state tracking precision are guaranteed by the proposed approach. Moreover, the chattering of the SMC is restrained by utilizing the ISM with prescribed performance.

2. Preliminaries

3. Problem Statement

- Case 1. When , no actuator faults happen in the robot control system.

- Case 2. When , the actuator partially loses its effectiveness. For example, implies the actuator loses effectiveness.

4. Transformed Tracking Errors Development

4.1. PPF Introduction

4.2. Prescribed Tracking Errors Development

5. PPF Tracking Control Development

5.1. Error System Development

5.2. Control Development

5.3. Stability Analysis

- Step 1: Stability analysis without reaching phase

- Step 2: Stability analysis in sliding phase

6. Simulation Results and Discussions

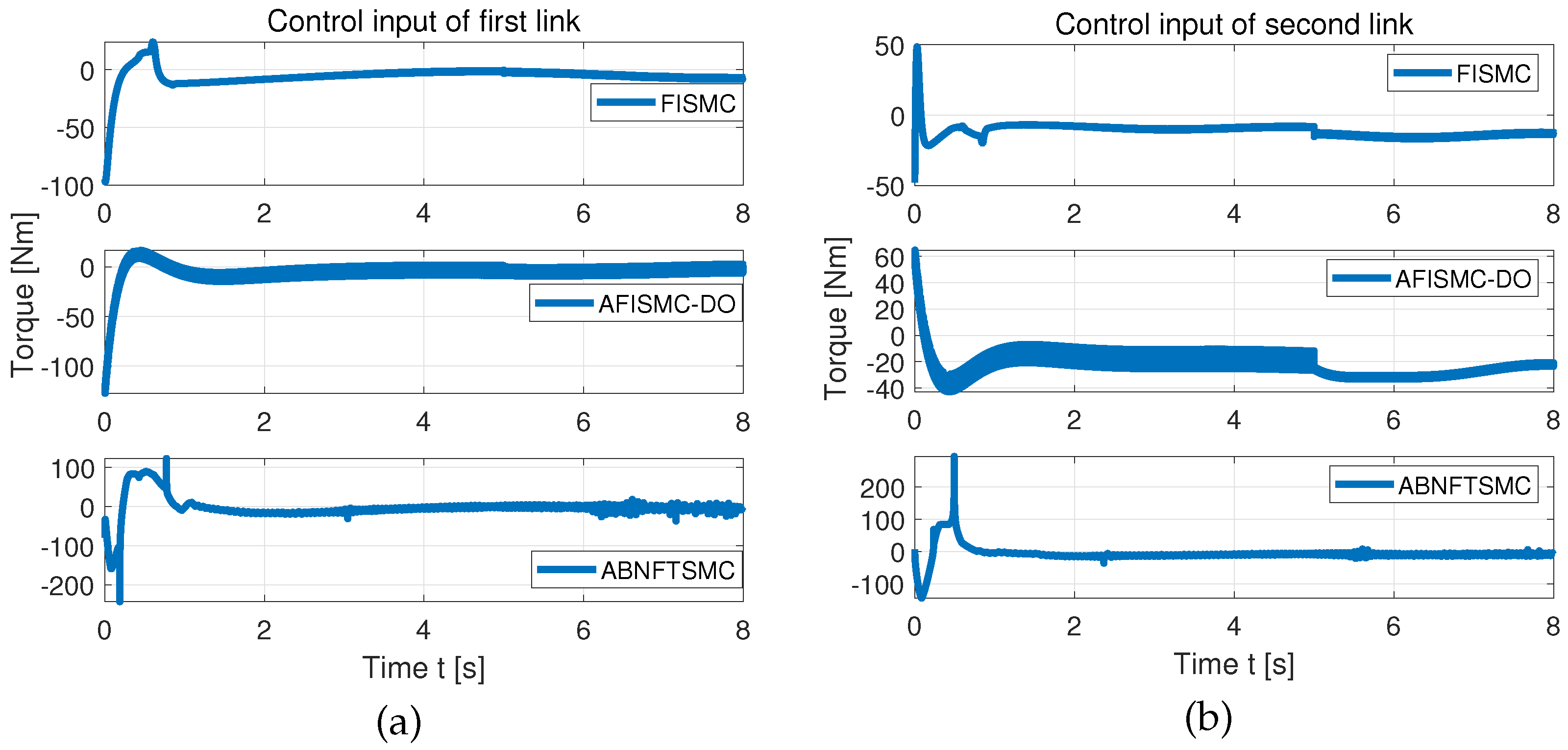

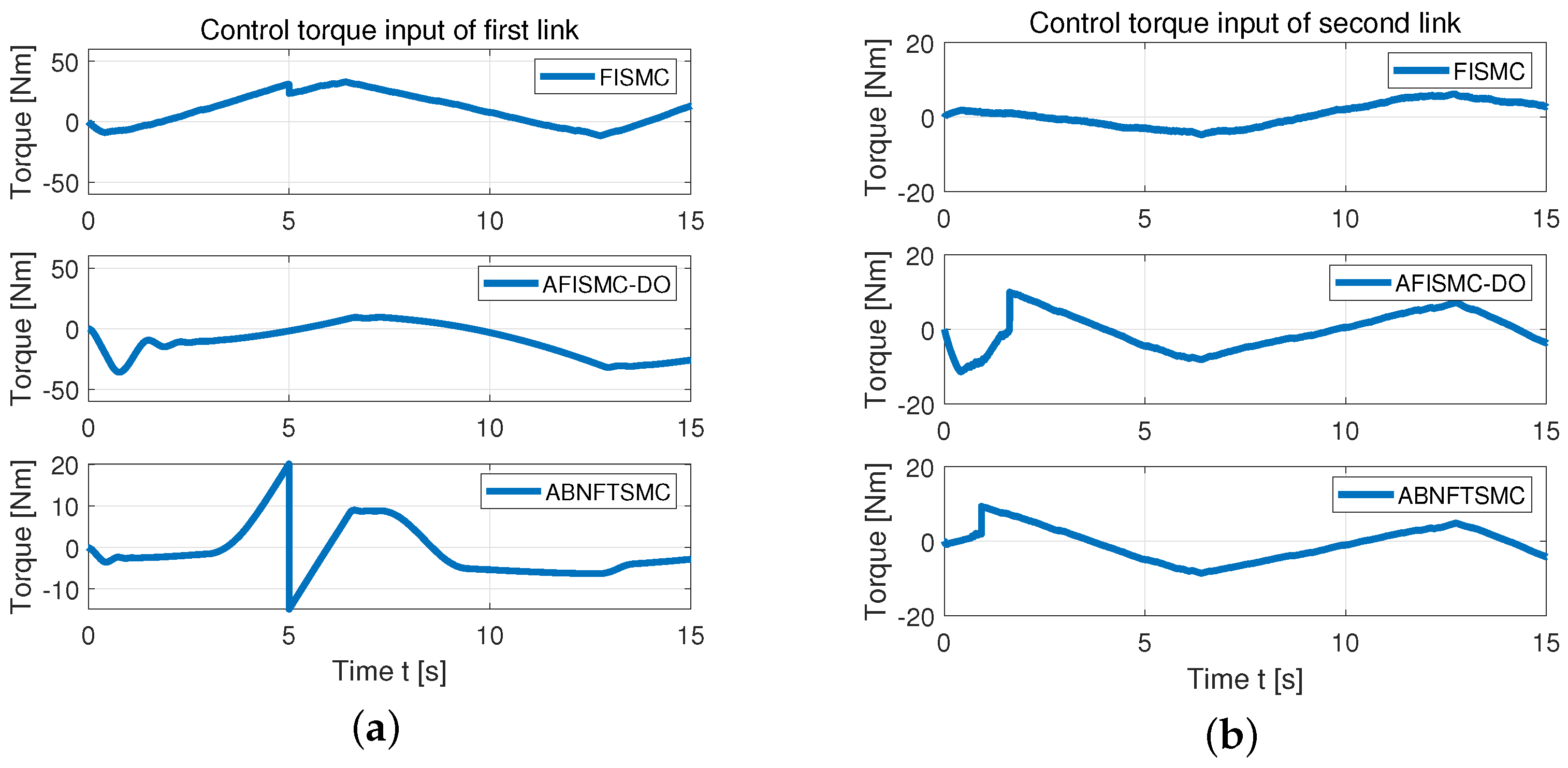

6.1. Tracking Performance Compared with AFISMC-DO and ABNFTSMC

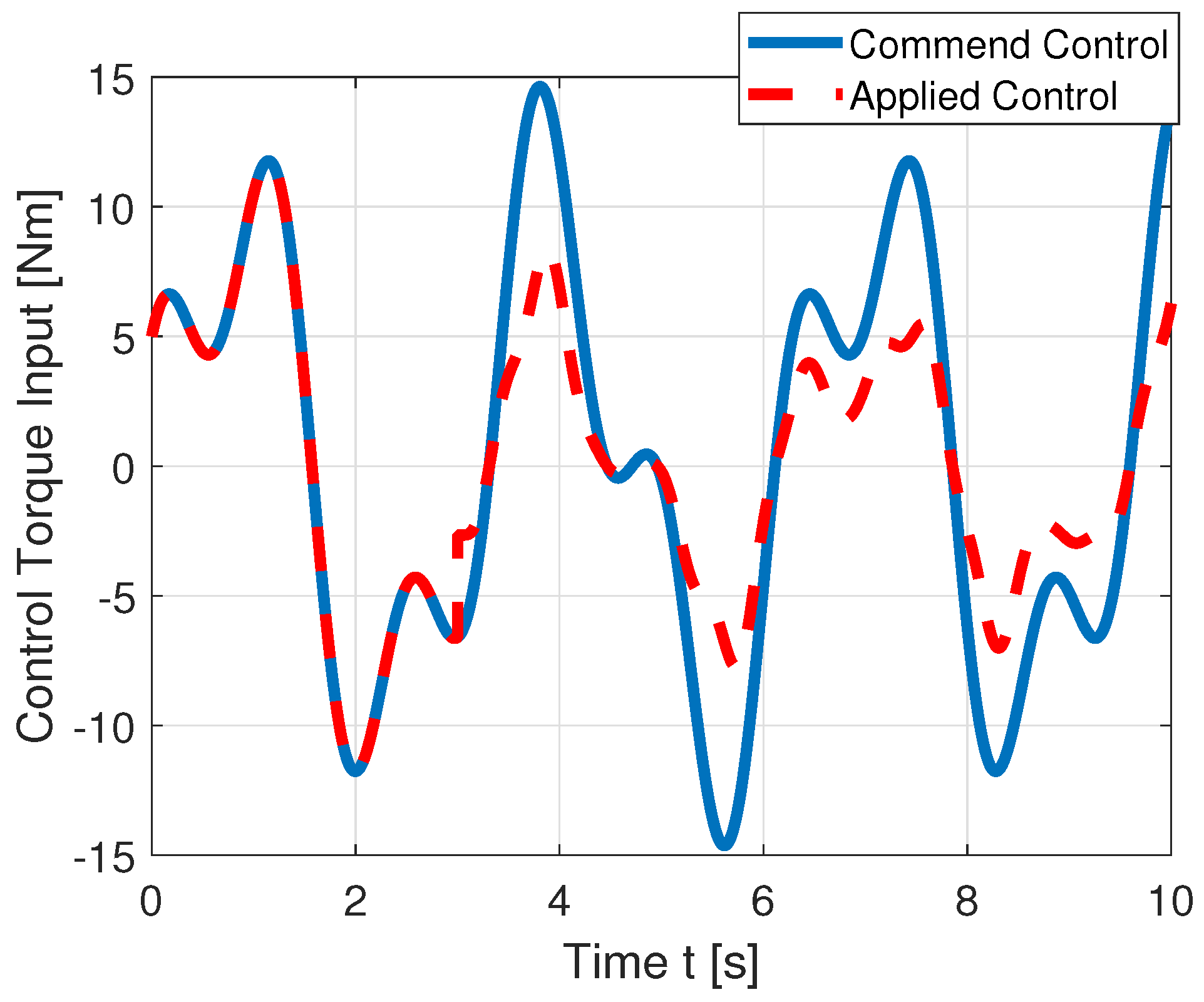

6.2. Tracking Performance with/without Actuator Faults

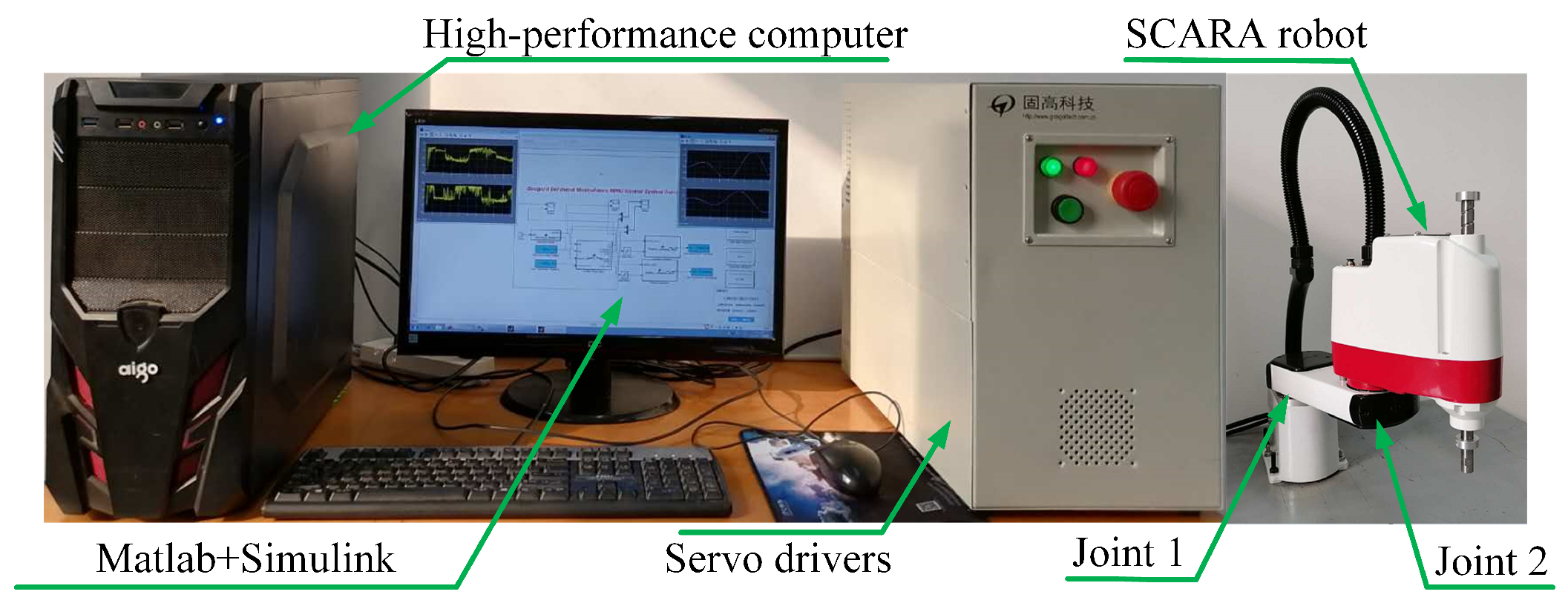

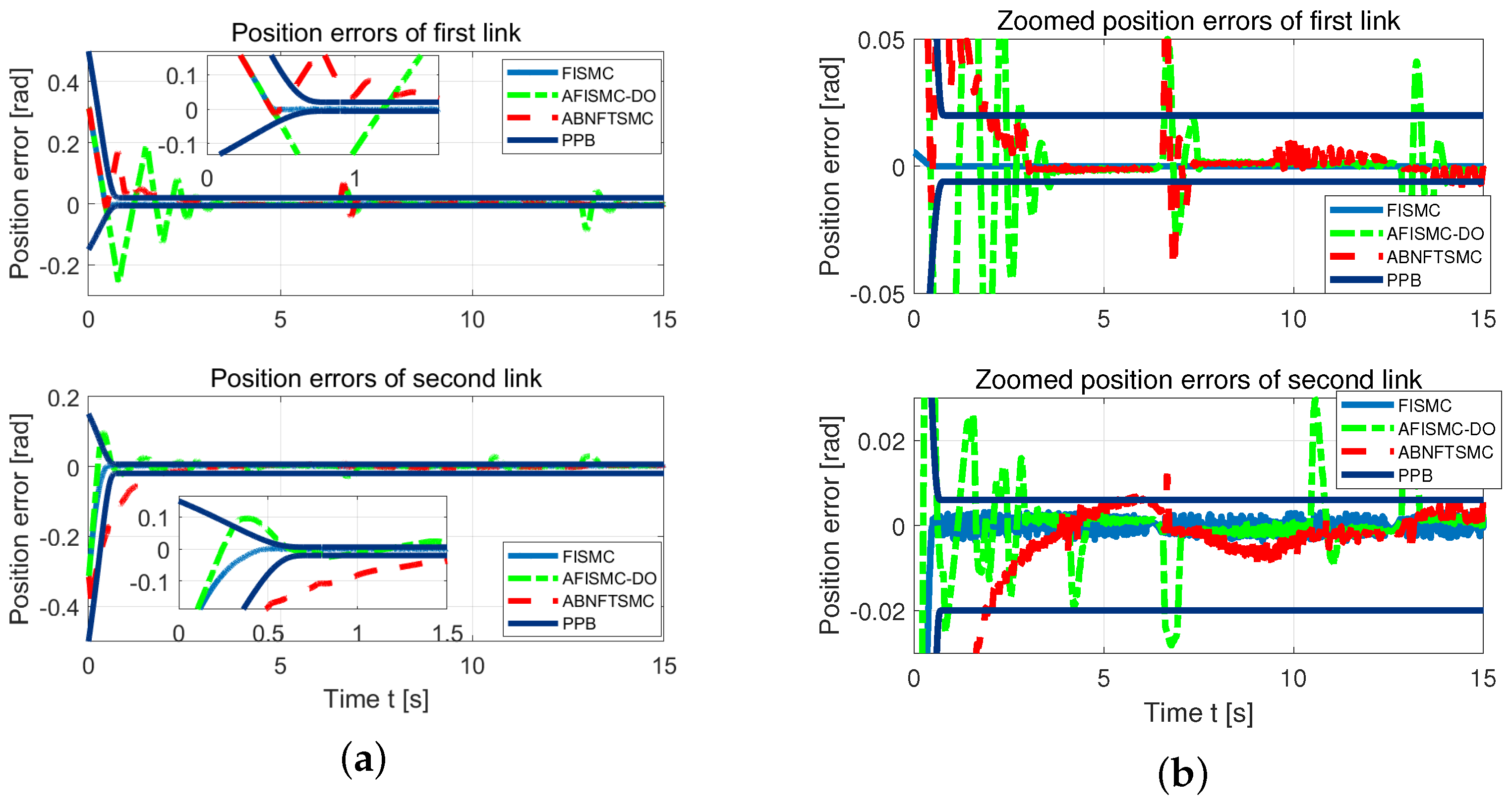

7. Experimental Comparison

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Yu, H.; Shen, J.H.; Joos, K.M.; Simaan, N. Calibration and integration of b-mode optical coherence tomography for assistive control in robotic microsurgery. IEEE/ASME Trans. Mechatron. 2016, 21, 2613–2623. [Google Scholar] [CrossRef]

- Xiao, B.; Yin, S.; Kaynak, O. Tracking control of robotic manipulators with uncertain kinematics and dynamics. IEEE Trans. Ind. Electron. 2016, 63, 6439–6449. [Google Scholar] [CrossRef]

- Lee, J.Y.; Jin, M.; Chang, P.H. Variable PID gain tuning method using backstepping control with time-delay estimation and nonlinear damping. IEEE Trans. Ind. Electron. 2014, 61, 6975–6985. [Google Scholar] [CrossRef]

- Lee, J.; Chang, P.H.; Jamisola, R.S. Relative impedance control for dual-arm robots performing asymmetric bimanual tasks. IEEE Trans. Ind. Electron. 2013, 61, 3786–3796. [Google Scholar] [CrossRef]

- Islam, S.; Liu, X.P. Robust sliding mode control for robot manipulators. IEEE Trans. Ind. Electron. 2010, 58, 2444–2453. [Google Scholar] [CrossRef]

- Jie, W.; Yudong, Z.; Yulong, B.; Kim, H.H.; Lee, M.C. Trajectory tracking control using fractional-order terminal sliding mode control with sliding perturbation observer for a 7-DOF robot manipulator. IEEE/ASME Trans. Mechatron. 2020, 25, 1886–1893. [Google Scholar] [CrossRef]

- Jin, M.; Kang, S.H.; Chang, P.H.; Lee, J. Robust control of robot manipulators using inclusive and enhanced time delay control. IEEE/ASME Trans. Mechatron. 2017, 22, 2141–2152. [Google Scholar] [CrossRef]

- Van, M. An enhanced robust fault tolerant control based on an adaptive fuzzy PID-nonsingular fast terminal sliding mode control for uncertain nonlinear systems. IEEE/ASME Trans. Mechatron. 2018, 23, 1362–1371. [Google Scholar] [CrossRef]

- Nguyen, N.P.; Mung, N.X.; Thanh Ha, L.N.N.; Huynh, T.T.; Hong, S.K. Finite-time attitude fault tolerant control of quadcopter system via neural networks. Mathematics 2020, 8, 1541. [Google Scholar] [CrossRef]

- Li, Y.; Liang, H. Robust finite-time control algorithm based on dynamic sliding mode for satellite attitude maneuver. Mathematics 2022, 10, 111. [Google Scholar] [CrossRef]

- Gang, C.; Wang, P.; Zhenyu, W.; Jiajun, T.; Huosheng, H.; Donghai, W.; Hao, C.; Lvyuan, Z. Modeling of swimming posture dynamics for a beaver-like robot. Ocean Eng. 2019, 29, 1396–1417. [Google Scholar]

- Chen, G.; Zhao, Z.; Wang, Z.; Tu, J.; Hu, H. Swimming modeling and performance optimization of a fish-inspired underwater vehicle (FIUV). Ocean Eng. 2023, 271, 113748. [Google Scholar] [CrossRef]

- Shen, G.; Xia, Y.; Ma, D.; Zhang, J. Adaptive sliding-mode control for Mars entry trajectory tracking with finite-time convergence. Int. J. Robust Nonlinear Control 2019, 29, 1249–1264. [Google Scholar] [CrossRef]

- Ma, Z.; Huang, P. Adaptive neural-network controller for an uncertain rigid manipulator with input saturation and full-order state constraint. IEEE Trans. Cyber. 2020, 52, 2907–2915. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Zhang, L.; Hou, Y.; Tang, D.; Liu, H. Implementation of Adaptive Fault-Tolerant Tracking Control for Robot Manipulators with Integral Sliding Mode; Wiley Online Library: Hoboken, NJ, USA, 2023. [Google Scholar]

- Ji, P.; Li, C.; Ma, F. Sliding Mode Control of Manipulator Based on Improved Reaching Law and Sliding Surface. Mathematics 2022, 10, 1935. [Google Scholar] [CrossRef]

- Najafi, A.; Vu, M.T.; Mobayen, S.; Asad, J.H.; Fekih, A. Adaptive barrier fast terminal sliding mode actuator fault tolerant control approach for quadrotor UAVs. Mathematics 2022, 10, 3009. [Google Scholar] [CrossRef]

- Slotine, J.J.E.; Li, W. Applied Nonlinear Control; Prentice Hall: Englewood Cliffs, NJ, USA, 1991; Volume 199. [Google Scholar]

- Feng, Y.; Yu, X.; Man, Z. Non-singular terminal sliding mode control of rigid manipulators. Automatica 2002, 38, 2159–2167. [Google Scholar] [CrossRef]

- Yu, S.; Yu, X.; Shirinzadeh, B.; Man, Z. Continuous finite-time control for robotic manipulators with terminal sliding mode. Automatica 2005, 41, 1957–1964. [Google Scholar] [CrossRef]

- Alipour, M.; Malekzadeh, M.; Ariaei, A. Practical fractional-order nonsingular terminal sliding mode control of spacecraft. ISA Trans. 2022, 128, 162–173. [Google Scholar] [CrossRef]

- Wang, Y.; Li, B.; Yan, F.; Chen, B. Practical adaptive fractional-order nonsingular terminal sliding mode control for a cable-driven manipulator. Int. J. Robust Nonlinear Control 2019, 29, 1396–1417. [Google Scholar] [CrossRef]

- Polyakov, A. Nonlinear feedback design for fixed-time stabilization of linear control systems. IEEE Trans. Autom. Control 2011, 57, 2106–2110. [Google Scholar] [CrossRef]

- Polyakov, A.; Efimov, D.; Perruquetti, W. Robust stabilization of MIMO systems in finite/fixed time. Int. J. Robust Nonlinear Control 2016, 26, 69–90. [Google Scholar] [CrossRef]

- Cao, W.J.; Xu, J.X. Nonlinear integral-type sliding surface for both matched and unmatched uncertain systems. IEEE Trans. Autom. Control 2004, 49, 1355–1360. [Google Scholar] [CrossRef]

- Wang, Y.; Xia, Y.; Li, H.; Zhou, P. A new integral sliding mode design method for nonlinear stochastic systems. Automatica 2018, 90, 304–309. [Google Scholar] [CrossRef]

- Niu, Y.; Ho, D.W.; Lam, J. Robust integral sliding mode control for uncertain stochastic systems with time-varying delay. Automatica 2005, 41, 873–880. [Google Scholar] [CrossRef]

- Jiang, B.; Karimi, H.R.; Kao, Y.; Gao, C. A novel robust fuzzy integral sliding mode control for nonlinear semi-Markovian jump T–S fuzzy systems. IEEE Trans. Fuzzy Syst. 2018, 26, 3594–3604. [Google Scholar] [CrossRef]

- Shao, K. Nested adaptive integral terminal sliding mode control for high-order uncertain nonlinear systems. Int. J. Robust Nonlinear Control 2021, 31, 6668–6680. [Google Scholar] [CrossRef]

- Li, J.; Zhai, D. A descriptor regular form-based approach to observer-based integral sliding mode controller design. Int. J. Robust Nonlinear Control 2021, 31, 5134–5148. [Google Scholar] [CrossRef]

- Lee, J.; Chang, P.H.; Jin, M. Adaptive integral sliding mode control with time-delay estimation for robot manipulators. IEEE Trans. Ind. Electron. 2017, 64, 6796–6804. [Google Scholar] [CrossRef]

- Ferrara, A.; Incremona, G.P. Design of an integral suboptimal second-order sliding mode controller for the robust motion control of robot manipulators. IEEE Trans. Control Syst. Technol. 2015, 23, 2316–2325. [Google Scholar] [CrossRef]

- Qin, J.; Ma, Q.; Gao, H.; Zheng, W.X. Fault-tolerant cooperative tracking control via integral sliding mode control technique. IEEE/ASME Trans. Mechatron. 2017, 23, 342–351. [Google Scholar] [CrossRef]

- Van, M.; Ge, S.S.; Ren, H. Robust fault-tolerant control for a class of second-order nonlinear systems using an adaptive third-order sliding mode control. IEEE Trans. Syst. Man Cyber. Syst. 2016, 47, 221–228. [Google Scholar] [CrossRef]

- Huang, H.; He, W.; Li, J.; Xu, B.; Yang, C.; Zhang, W. Disturbance observer-based fault-tolerant control for robotic systems with guaranteed prescribed performance. IEEE Trans. Cyber. 2020, 52, 772–783. [Google Scholar] [CrossRef] [PubMed]

- Van, M.; Kang, H.J.; Suh, Y.S.; Shin, K.S. A robust fault diagnosis and accommodation scheme for robot manipulators. Int. J. Control Autom. Syst. 2013, 11, 377–388. [Google Scholar] [CrossRef]

- He, X.; Wang, Z.; Qin, L.; Zhou, D. Active fault-tolerant control for an internet-based networked three-tank system. IEEE Trans. Control Syst. Tech. 2016, 24, 2150–2157. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, H.; Tang, D.; Hou, Y.; Wang, Y. Adaptive fixed-time fault-tolerant tracking control and its application for robot manipulators. IEEE Trans. Ind. Electron. 2021, 69, 2956–2966. [Google Scholar] [CrossRef]

- Karayiannidis, Y.; Doulgeri, Z. Model-free robot joint position regulation and tracking with prescribed performance guarantees. Robo. Autonom. Syst. 2012, 60, 214–226. [Google Scholar] [CrossRef]

- Bechlioulis, C.P.; Rovithakis, G.A. Robust adaptive control of feedback linearizable MIMO nonlinear systems with prescribed performance. IEEE Trans. Autom. Control 2008, 53, 2090–2099. [Google Scholar] [CrossRef]

- Bechlioulis, C.P.; Rovithakis, G.A. Prescribed performance adaptive control for multi-input multi-output affine in the control nonlinear systems. IEEE Trans. Autom. Control 2010, 55, 1220–1226. [Google Scholar] [CrossRef]

- Jing, Y.; Liu, Y.; Zhou, S. Prescribed performance finite-time tracking control for uncertain nonlinear systems. J. Syst. Sci. Complex. 2019, 32, 803–817. [Google Scholar] [CrossRef]

- Yang, P.; Su, Y. Proximate fixed-time prescribed performance tracking control of uncertain robot manipulators. IEEE/ASME Trans. Mechatron. 2021, 27, 3275–3285. [Google Scholar] [CrossRef]

- Hao, L.Y.; Park, J.H.; Ye, D. Integral sliding mode fault-tolerant control for uncertain linear systems over networks with signals quantization. IEEE Trans. Neural Netw. Learn. Syst. 2016, 28, 2088–2100. [Google Scholar] [CrossRef] [PubMed]

- Van, M.; Ge, S.S. Adaptive fuzzy integral sliding-mode control for robust fault-tolerant control of robot manipulators with disturbance observer. IEEE Trans. Fuzzy Syst. 2020, 29, 1284–1296. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, L.; Wang, Z.; Xia, Y. Continuous finite-time control for uncertain robot manipulators with integral sliding mode. IET Control Theory Appl. 2018, 12, 1621–1627. [Google Scholar] [CrossRef]

- Zhu, W.H. Comments on “Robust tracking control for rigid robotic manipulators”. IEEE Trans. Autom. Control 2000, 45, 1577–1580. [Google Scholar] [CrossRef]

- Van, M.; Mavrovouniotis, M.; Ge, S.S. An adaptive backstepping nonsingular fast terminal sliding mode control for robust fault tolerant control of robot manipulators. IEEE Trans. Syst. Man. Cybern. Syst. 2018, 49, 1448–1458. [Google Scholar] [CrossRef]

- Sciavicco, L.; Siciliano, B. Modelling and Control of Robot Manipulators; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

| Controller | |||

|---|---|---|---|

| FISMC | |||

| ABNFTSMC | |||

| AFISMC-DO |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Hou, Y.; Liu, H.; Tang, D.; Li, L. Prescribed Performance Fault-Tolerant Tracking Control of Uncertain Robot Manipulators with Integral Sliding Mode. Mathematics 2023, 11, 2430. https://doi.org/10.3390/math11112430

Zhang L, Hou Y, Liu H, Tang D, Li L. Prescribed Performance Fault-Tolerant Tracking Control of Uncertain Robot Manipulators with Integral Sliding Mode. Mathematics. 2023; 11(11):2430. https://doi.org/10.3390/math11112430

Chicago/Turabian StyleZhang, Liyin, Yinlong Hou, Hui Liu, Dafeng Tang, and Long Li. 2023. "Prescribed Performance Fault-Tolerant Tracking Control of Uncertain Robot Manipulators with Integral Sliding Mode" Mathematics 11, no. 11: 2430. https://doi.org/10.3390/math11112430

APA StyleZhang, L., Hou, Y., Liu, H., Tang, D., & Li, L. (2023). Prescribed Performance Fault-Tolerant Tracking Control of Uncertain Robot Manipulators with Integral Sliding Mode. Mathematics, 11(11), 2430. https://doi.org/10.3390/math11112430