Utilizing a Long Short-Term Memory Algorithm Modified by Dwarf Mongoose Optimization to Predict Thermal Expansion of Cu-Al2O3 Nanocomposites

Abstract

:1. Introduction

2. Machine Learning Models

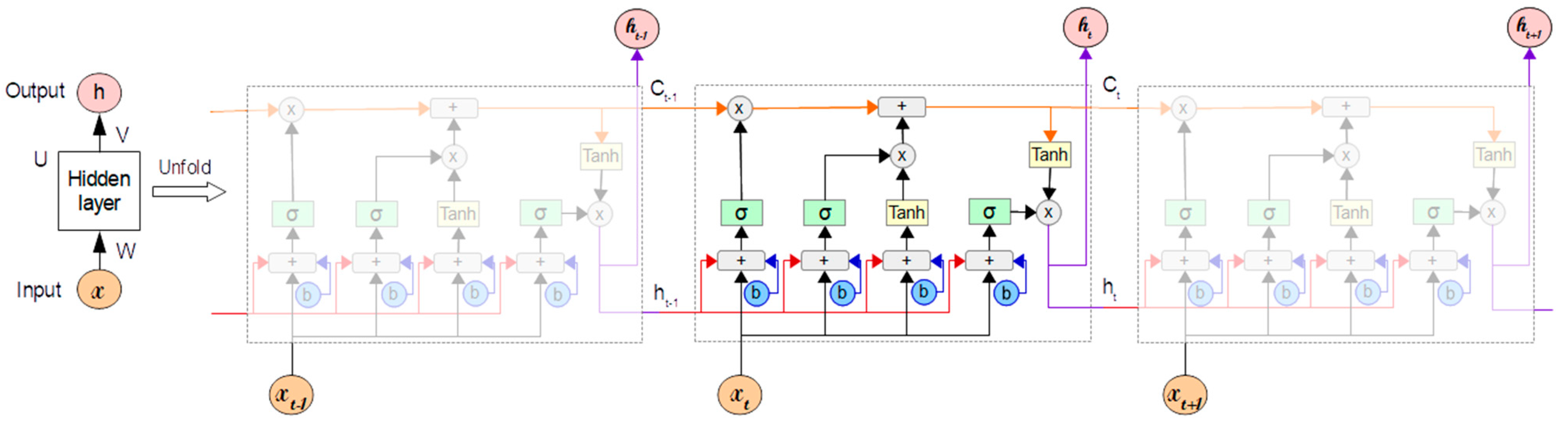

2.1. Long Short-Term Memory

2.2. Dwarf Mongoose Optimization Algorithm

2.2.1. Alpha Group

2.2.2. Scout Group

2.2.3. Babysitters Group

2.3. Proposed Model

2.4. Prediction of Thermal Expansion Using the Improved LSTM Model

3. Experiments

4. Results and Discussion

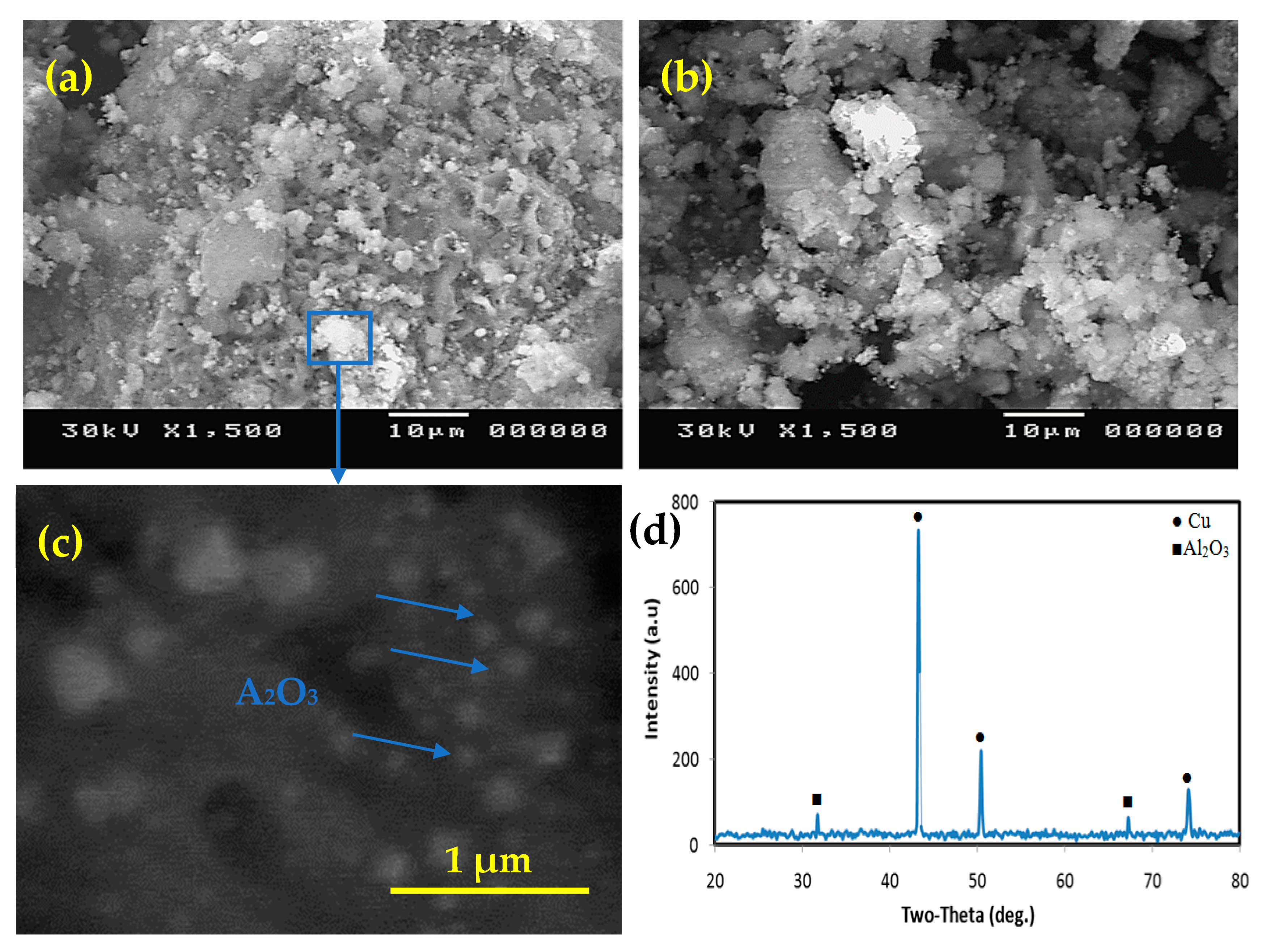

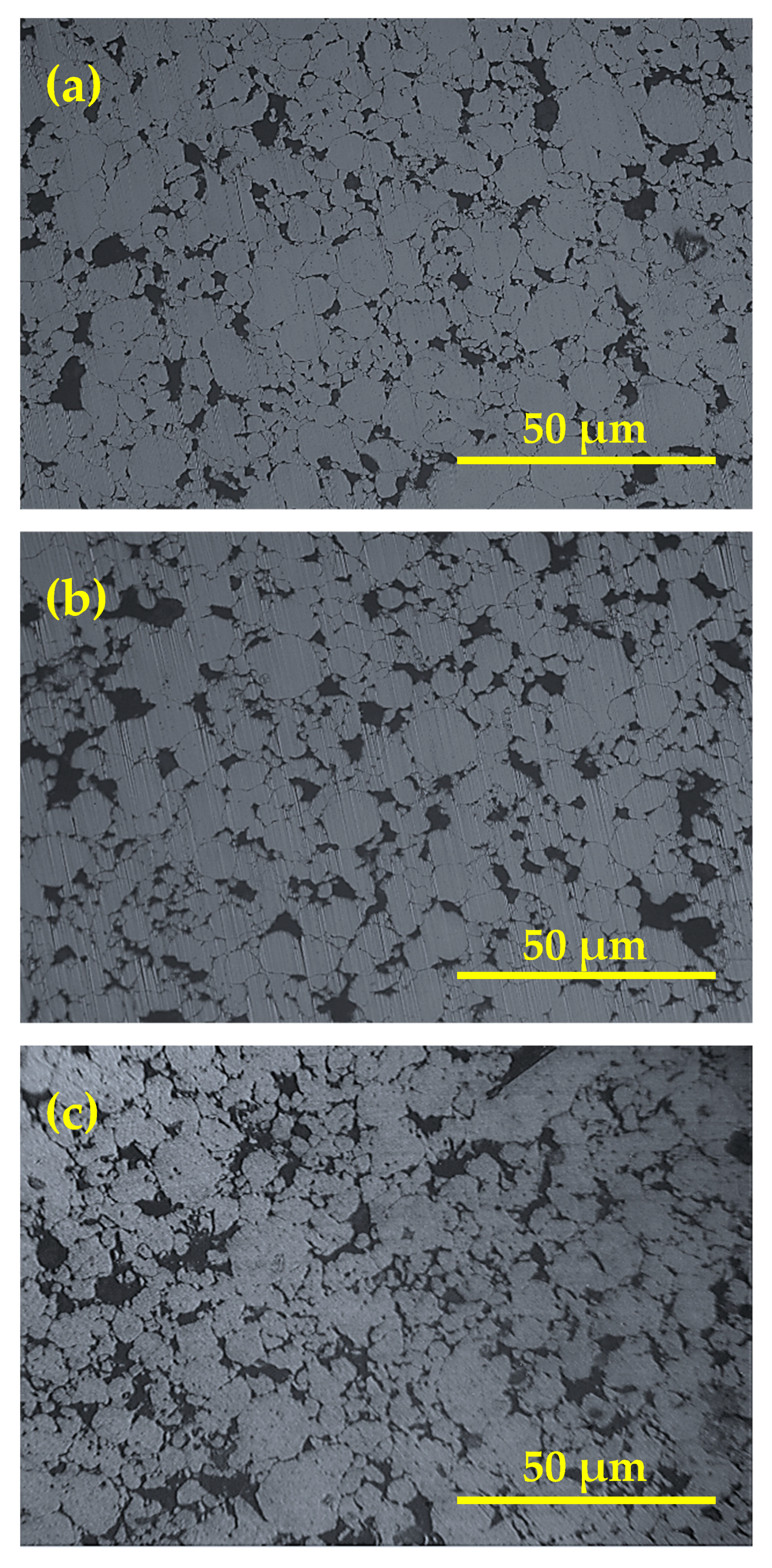

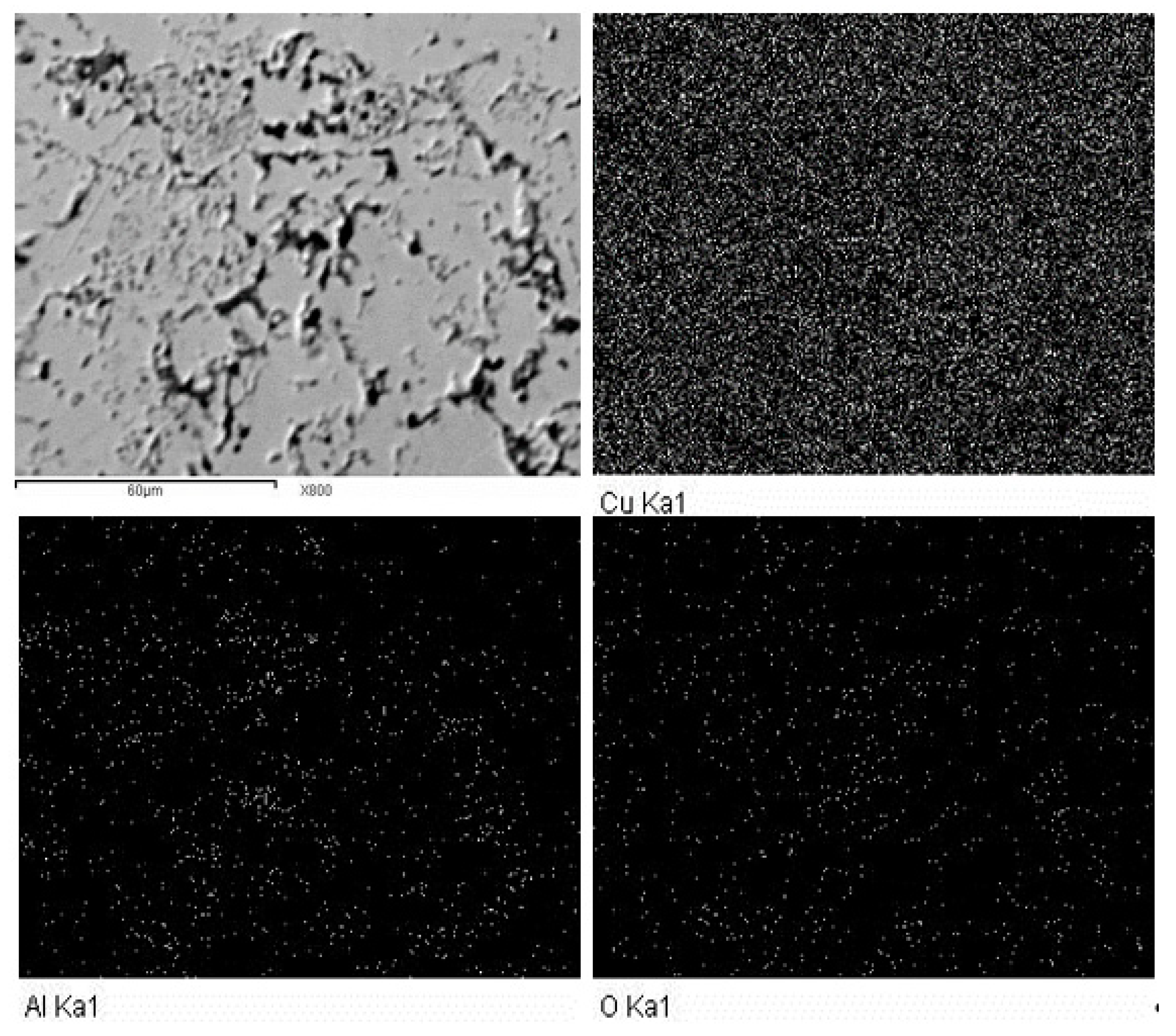

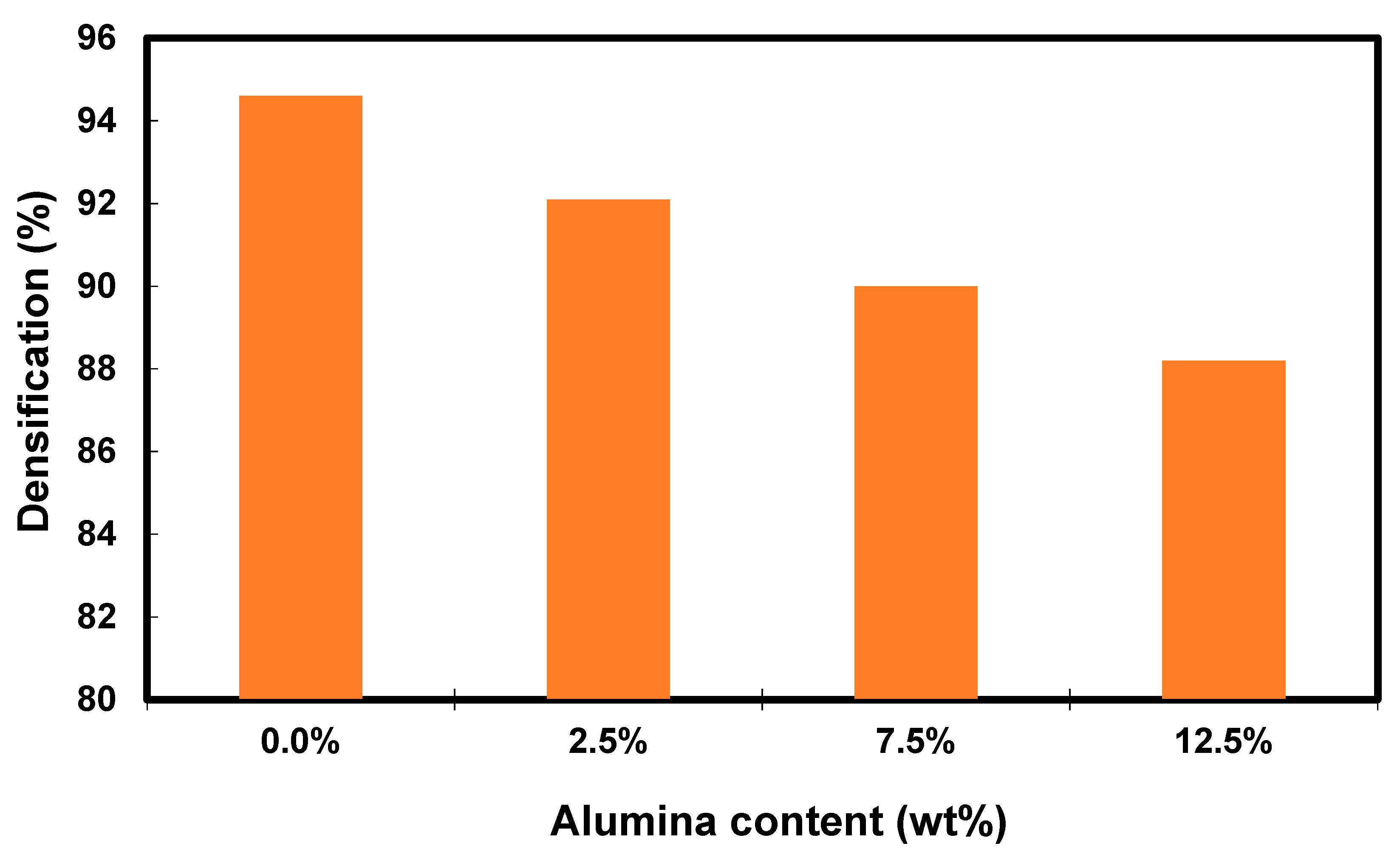

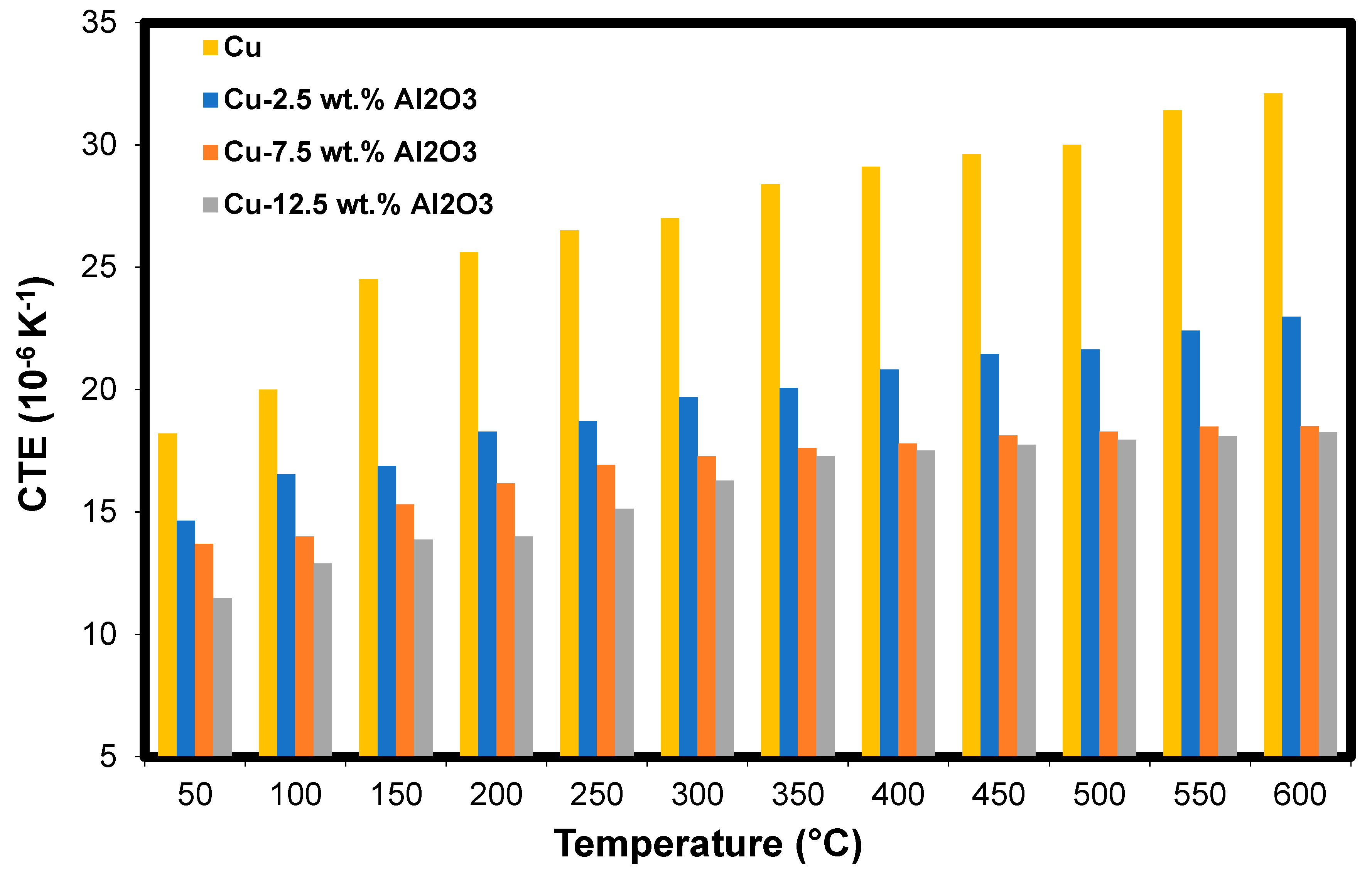

4.1. Structural and Thermal Properties

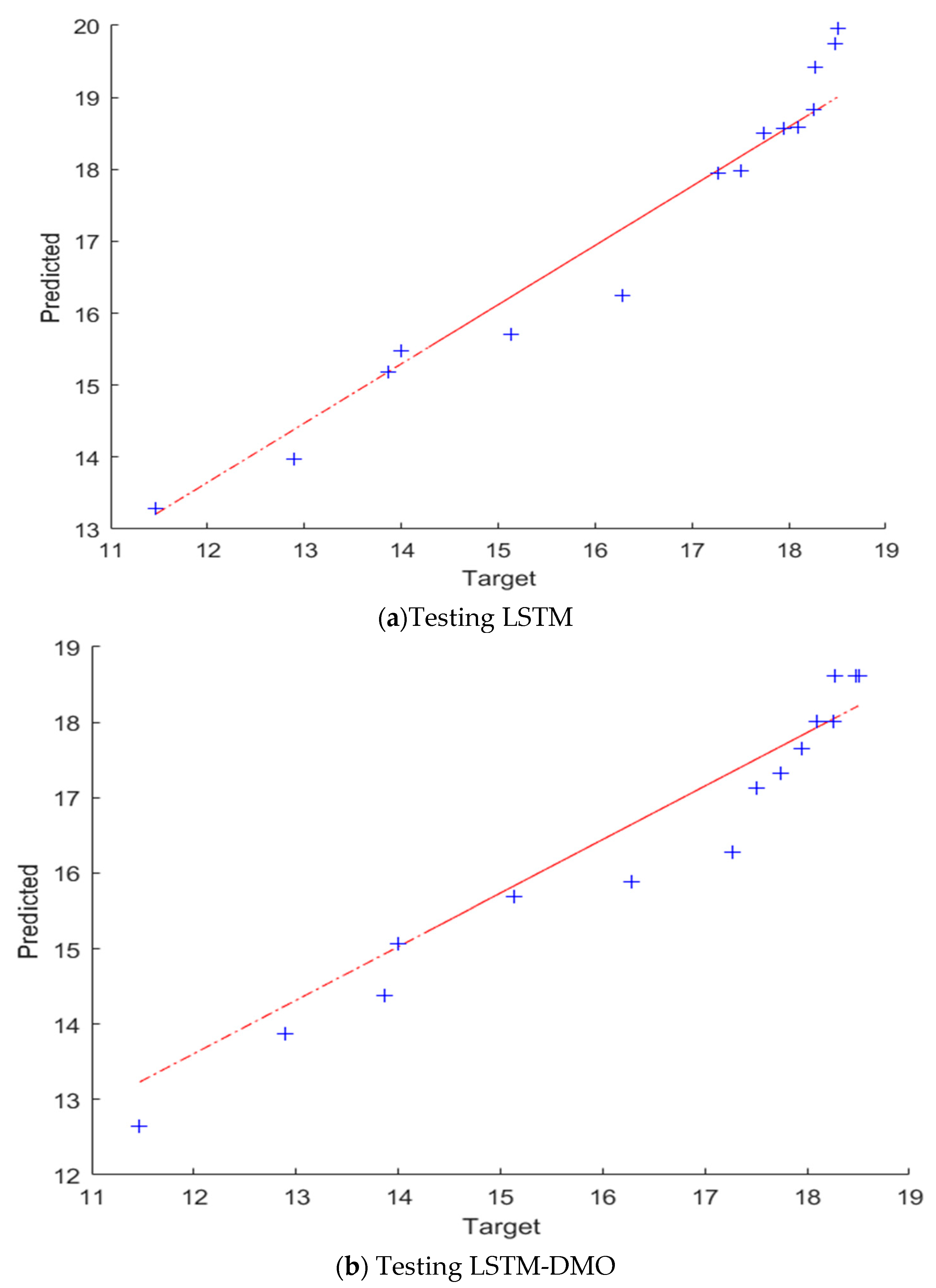

4.2. Prediction of Coefficient of Thermal Expansion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Algorithm A1 |

| Set the parameters of the algorithm: |

| Generate |

| For iter=1: max_iter |

| Compute the fitness of the mongoose |

| Set time counter |

| Determine the alpha using Equation (8) |

| obtain a candidate food position utilizing Equation (9) |

| Estimate new fitness of |

| Estimate sleeping mound using Equation (10) |

| Calculate the sleeping mound average value obtained using Equation (11). |

| Compute the movement vector using |

| Exchange babysitters , and set |

| Set bs position (Equation (7)) and compute fitness |

| Simulate the scout mongoose next position based on Equation (12). |

| Modernize best solution so far |

| End For |

| Return best solution |

| End |

References

- Casati, R.; Vedani, M. Metal Matrix Composites Reinforced by Nano-Particles—A Review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Kannan, C.; Ramanujam, R. Comparative study on the mechanical and microstructural characterization of AA 7075 nano and hybrid nanocomposites produced by stir and squeeze casting. J. Adv. Res. 2017, 8, 309–319. [Google Scholar] [CrossRef] [PubMed]

- Karabacak, A.H.; Çanakçı, A.; Erdemir, F.; Özkaya, S.; Çelebi, M. Effect of different reinforcement on the microstructure and mechanical properties of AA2024-based metal matrix nanocomposites. Int. J. Mater. Res. 2020, 111, 416–423. [Google Scholar] [CrossRef]

- Sadoun, A.M.; Najjar, I.M.R.; Abd-Elwahed, M.S.; Meselhy, A. Experimental study on properties of Al–Al2O3 nanocomposite hybridized by graphene nanosheets. J. Mater. Res. Technol. 2020, 9, 1470814717. [Google Scholar] [CrossRef]

- Varol, T.; Canakci, A. Microstructure, electrical conductivity and hardness of multilayer graphene/Copper nanocomposites synthesized by flake powder metallurgy. Met. Mater. Int. 2015, 21, 704–712. [Google Scholar] [CrossRef]

- Samal, C.; Parihar, J.; Chaira, D. The effect of milling and sintering techniques on mechanical properties of Cu–graphite metal matrix composite prepared by powder metallurgy route. J. Alloys Compd. 2013, 569, 95–101. [Google Scholar] [CrossRef]

- Abu-Oqail, A.; Ghanim, M.; El-Sheikh, M.; El-Nikhaily, A. Effects of processing parameters of tungsten–copper composites. Int. J. Refract. Met. Hard Mater. 2012, 35, 207–212. [Google Scholar] [CrossRef]

- Vettivel, S.; Selvakumar, N.; Leema, N.; Lenin, A. Electrical resistivity, wear map and modeling of extruded tungsten reinforced copper composite. J. Mater. Des. 2014, 56, 791–806. [Google Scholar] [CrossRef]

- Fathy, A.; Elkady, O.; Abu-Oqail, A. Synthesis and characterization of Cu-ZrO2 nanocomposite produced by thermochemical process. J. Alloys Compd. 2017, 719, 411–419. [Google Scholar] [CrossRef]

- Fathy, A.; Wagih, A.; Abu-Oqail, A. Effect of ZrO2 content on properties of Cu-ZrO2 nanocomposites synthesized by optimized high energy ball milling. J. Ceram. Int. 2019, 45, 2319–2329. [Google Scholar] [CrossRef]

- Zhang, X.; Lin, C.; Cui, S.; Li, Z. Characteristics of Nano-alumina Particles Dispersion Strengthened Copper Fabricated by Reaction Synthesis. Rare Met. Mater. Eng. 2016, 45, 893–896. [Google Scholar] [CrossRef]

- Tjong, S.; Lau, K. Tribological behaviour of SiC particle-reinforced copper matrix composites. Mater. Lett. 2000, 43, 274–280. [Google Scholar] [CrossRef]

- Guobin, L.; Jibing, S.; Quanmei, G.; Ru, W. Fabrication of the nanometer Al2O3/Cu composite by internal oxidation. J. Mater. Process. Technol. 2005, 170, 336–340. [Google Scholar] [CrossRef]

- Megahed, M.; Fathy, A.; Morsy, D.; Shehata, F. Mechanical Performance of glass/epoxy composites enhanced by micro-and nanosized aluminum particles. J. Ind. Text. 2019, 51, 68–92. [Google Scholar] [CrossRef]

- Sadoun, A.M.; Fathy, A. Experimental study on tribological properties of Cu–Al2O3 nanocomposite hybridized by graphene nanoplatelets. Ceram. Int. 2019, 45, 24784–24792. [Google Scholar] [CrossRef]

- Melaibari, A.; Fathy, A.; Mansouri, M.; Eltaher, M.A. Experimental and numerical investigation on strengthening mechanisms of nanostructured Al-SiC composites. J. Alloys Compd. 2019, 774, 1123–1132. [Google Scholar] [CrossRef]

- Sadoun, A.M.; Mohammed, M.M.; Fathy, A.; El-Kady, O.A. Effect of Al2O3 addition on hardness and wear behavior of Cu–Al2O3 electro-less coated Ag nanocomposite. J. Mater. Res. Technol. 2020, 9, 5024–5033. [Google Scholar] [CrossRef]

- Zhang, D.; Zhan, Z. Preparation of graphene nanoplatelets-copper composites by a modified semi-powder method and their mechanical properties. J. Alloys Compd. 2016, 658, 663–671. [Google Scholar] [CrossRef]

- Chu, K.; Jia, C. Enhanced strength in bulk graphene-copper composites. Phys. Status Solidi A 2014, 211, 184–190. [Google Scholar] [CrossRef]

- Fathy, A.; Elkady, O.; Abu-Oqail, A. Microstructure, mechanical and wear properties of Cu–ZrO2 nanocomposites. Mater. Sci. Technol. 2017, 33, 2138–2146. [Google Scholar] [CrossRef]

- Abd-Elwahed, M.S.; Ibrahim, A.F.; Reda, M.M. Effects of ZrO2 nanoparticle content on microstructure and wear behavior of titanium matrix composite. J. Mater. Res. Technol. 2020, 9, 8528–8534. [Google Scholar] [CrossRef]

- Abu-Oqail, A.A.; Wagih, A.; Fathy, O.; Elkady, A.; Kabeel, M. Effect of high energy ball milling on strengthening of Cu-ZrO2 nanocomposites. Ceram. Int. 2019, 45, 5866–5875. [Google Scholar] [CrossRef]

- Fathy, A. Investigation on microstructure and properties of Cu-ZrO2 nanocomposites synthesized by in situ processing. Mater. Lett. 2018, 213, 95–99. [Google Scholar] [CrossRef]

- Goli, P.; Ning, H.; Li, X.; Lu, C.Y.; Novoselov, K.S. Balandin, thermal properties of graphene-copper-graphene heterogeneous films. Nano Lett. 2014, 14, 1497–1503. [Google Scholar] [CrossRef]

- Wagih, A.; Abu-Oqail, A.; Fathy, A. Effect of GNPs content on thermal and mechanical properties of a novel hybrid Cu-Al2O3/GNPs coated Ag nanocomposite. Ceram. Int. 2019, 45, 1115–1124. [Google Scholar] [CrossRef]

- Allahkaram, S.R.; Golroh, S.; Mohammadalipour, M. Properties of Al2O3 nano-particle reinforced copper matrix composite coatings prepared by pulse and direct current electroplating. Mater. Des. 2011, 32, 4478–4484. [Google Scholar] [CrossRef]

- Tey, E.; Hashim, M.; Ismail, I. Characterization of Cu-Al2O3 and Ni-Al2O3 nanocomposites electrodeposited on copper substrate. Mater. Sci. Forum 2016, 846, 471–478. [Google Scholar] [CrossRef]

- Shehata, F.; Abdelhameed, M.; Fathy, A.; Elmahdy, M. Preparation and Characteristics of Cu-Al2O3 Nanocomposite. Open J. Met. 2011, 1, 25–33. [Google Scholar] [CrossRef] [Green Version]

- Lajevardi, S.; Shahrabi, T.; Szpunar, J. Synthesis of functionally graded nano Al2O3–Ni composite coating by pulse electrodeposition. Appl. Surf. Sci. 2013, 279, 180–188. [Google Scholar] [CrossRef]

- Ning, D.; Zhang, A.; Murtaza, M.; Wu, H. Effect of surfactants on the electrodeposition of Cu-TiO2 composite coatings prepared by jet electrodeposition. J. Alloys Compd. 2019, 777, 1245–1250. [Google Scholar] [CrossRef]

- Ďurišinová, K.; Ďurišin, J.; Orolínová, M. Al2O3-dispersion strengthened nanocrystalline copper. Powder Metall. Prog. 2006, 6, 75–80. [Google Scholar]

- Oh, S.-T.; Sekino, T.; Niihara, K. Effect of particle size distribution and mixing homogeneity on microstructure and strength of alumina/copper composites. Nanostruct. Mater. 1998, 10, 327–332. [Google Scholar] [CrossRef]

- Ritasalo, R.; Liua, X.; Söderberg, O.; Keski-Honkola, A.; Pitkänen, V.; Hannula, S.-P. The Microstructural Effects on the Mechanical and ThermalProperties of Pulsed Electric Current Sintered Cu-Al2O3 Composites. Procedia Eng. 2011, 10, 124–129. [Google Scholar] [CrossRef]

- Zhang, X.-H.; Li, X.-X.; Chen, H.; Li, T.-B.; Su, W.; Guo, S.-D. Investigation on microstructure and properties of Cu–Al2O3 composites fabricated by a novel in-situ reactive synthesis. Mater. Des. 2016, 92, 58–63. [Google Scholar] [CrossRef]

- Ramezanalizadeh, H. Fabrication and Characterization of an Al-Based Nanocomposite with High Specific Strength and Good Elongation Using Large Amount CMA Nanoparticles. J. Alloys Compd. 2020, 822, 153667. [Google Scholar] [CrossRef]

- Dhar, S.; Jena, A.; Patnaik, S.C.; Sahoo, S.K.; Tripathy, O. A Study on Microstructure and Mechanical Properties of Aluminium Matrix Composites with Micro-Sized Iron Fillers Produced by Powder Metallurgy Route. Mater. Today Proc. 2020, 33, 5617–5622. [Google Scholar] [CrossRef]

- Charan Nayak, K.; Kumar Pandey, A.; Date, P.P. Mechanical and Physical Characterization of Powder Metallurgy Based Aluminium Metal Matrix Hybrid Composite. Mater. Today Proc. 2020, 33, 5408–5413. [Google Scholar] [CrossRef]

- Saber, D.; Abd El-Aziz, K.; Fathy, A. Corrosion behavior of copper–alumina nanocomposites in different corrosive media. Int. J. Mech. Eng. 2016, 5, 1–10. [Google Scholar]

- Sadoun, A.M.; Mohammed, M.M.; Elsayed, E.M.; Meselhy, A.F.; El-Kady, O.A. Effect of nano Al2O3 coated Ag addition on the corrosion resistance and electrochemical behavior of Cu-Al2O3 nanocomposites. J. Mater. Res. Technol. 2020, 9, 4485–4493. [Google Scholar] [CrossRef]

- Rodrigues, I.; Guedes, M.; Ferro, A. Processing of Copper-Graphite-Alumina Powders by High-Energy Milling. In Proceedings of the PM2014 World Congress, 2014 World Conference on Powder Metallurgy, Orlando, FL, USA, 18–22 May 2014. [Google Scholar]

- Khatir, S.; Boutchicha, D.; Le Thanh, C.; Tran-Ngoc, H.; Nguyen, T.; Wahab, M.A. Improved ANN technique combined with Jaya algorithm for crack identification in plates using XIGA and experimental analysis. Theor. Appl. Fract. Mech. 2020, 107, 102554. [Google Scholar] [CrossRef]

- Zenzen, R.; Khatir, S.; Belaidi, I.; Le Thanh, C.; Wahab, M.A. A modified transmissibility indicator and Artificial Neural Network for damage identification and quantification in laminated composite structures. Compos. Struct. 2020, 248, 112497. [Google Scholar] [CrossRef]

- Wang, S.; Wang, H.; Zhou, Y.; Liu, J.; Dai, P.; Du, X.; Wahab, M.A. Automatic laser profile recognition and fast tracking for structured light measurement using deep learning and template matching. Measurement 2021, 169, 108362. [Google Scholar] [CrossRef]

- Fathy, A.; Megahed, A.A. Prediction of abrasive wear rate of in situ Cu–Al2O3 nanocomposite using artificial neural networks. Int. J. Adv. Manuf. Technol. 2012, 62, 953–963. [Google Scholar] [CrossRef]

- Raymond, S. Physics for Scientists and Engineers with Modern Physics, 3rd ed.; Saunders College Publishing: Forth Worth, TX, USA, 1983. [Google Scholar]

- Najjar, I.; Sadoun, A.; Alsoruji, G.S.; Elaziz, M.A.; Wagih, A. Predicting the mechanical properties of Cu–Al2O3 nanocomposites using machine learning and finite element simulation of indentation experiments. Ceram. Int. 2021, 48, 7748–7758. [Google Scholar] [CrossRef]

- Torabi, H.; Arghavanian, R. Investigations on the corrosion resistance and microhardness of Cu–10Sn/SiC composite manufactured by powder metallurgy process. J. Alloys Compd. 2019, 806, 99–105. [Google Scholar] [CrossRef]

- Abd-Elwahed, M.S.; Meselhy, A.F. Experimental investigation on the mechanical, structural and thermal properties of Cu–ZrO2 nanocomposites hybridized by graphene nanoplatelets. Ceram. Int. 2020, 46, 9198–9206. [Google Scholar] [CrossRef]

- Eltaher, M.; Wagih, A.; Melaibari, A.; Fathy, A.; Lubineau, G. Effect of Al2O3 particles on mechanical and tribological properties of Al–Mg dual-matrix nanocomposites. Ceram. Int. 2020, 46, 5779–5787. [Google Scholar] [CrossRef]

- Barakat, W.; Wagih, A.; Elkady, O.A.; Abuoqail, A.; Fathy, A.; El-Nikhaily, A. Effect of Al2O3 nanoparticles content and compaction temperature on properties of Al–Al2O3 coated Cu nanocomposites. Compos. Part B Eng. 2019, 175, 107140. [Google Scholar] [CrossRef]

- Shehata, F.; Fathy, A.; Abdelhameed, M.; Moustafa, S. Fabrication of copper–alumina nanocomposites by mechano-chemical routes. J. Alloys Compd. 2009, 476, 300–305. [Google Scholar] [CrossRef]

- Mohamed, A.; Mohammed, M.M.; Ibrahim, A.F.; El-Kady, O.A. Effect of nano Al2O3 coated Ag reinforced Cu matrix nanocomposites on mechanical and tribological behavior synthesis by P/M technique. J. Compos. Mater. 2020, 54, 4921–4928. [Google Scholar] [CrossRef]

- Wagih, A.; Fathy, A.; Sebaey, T.A. Experimental investigation on the compressibility of Al/Al2O3 nanocomposites. Int. J. Mater. Prod. Technol. 2016, 52, 312–332. [Google Scholar] [CrossRef]

- El-wazery, M.; El-Desouy, A.R.; Hameda, O.A.; Fathy, A.; Mansour, N.A. Electrical and mechanical performance of zirconia-nickel functionally graded materials. Int. J. Eng. 2013, 26, 375–382. [Google Scholar] [CrossRef]

- Hsieh, C.; Tuan, W. Thermal expansion behavior of a model ceramic–metal composite. Mater. Sci. Eng. A 2007, 460–461, 453–458. [Google Scholar] [CrossRef]

- Weber, L.; Tavangar, R. On the influence of active element content on the thermal conductivity and thermal expansion of Cu–X (X = Cr, B) diamond composites. Scr. Mater. 2007, 57, 988–991. [Google Scholar] [CrossRef]

| Training Set | Testing Set | |||

|---|---|---|---|---|

| LSTM | LSTM-DMO | LSTM | LSTM-DMO | |

| R2 | 0.9999 | 1.0000 | 0.936 | 0.995 |

| RMSE | 0.1817 | 0.0862 | 4.186 | 1.164 |

| MAE | 0.0515 | 0.0212 | 3.534 | 1.006 |

| Parameter | L = 0.6 | L = 0.3 | L = 0.9 | |||

|---|---|---|---|---|---|---|

| Set | Test | Train | Test | Train | Test | Train |

| R2 | 0.995 | 1.0000 | 0.9907 | 0.9966 | 0.9988 | 0.9963 |

| RMSE | 1.164 | 0.0862 | 1.788 | 1.2934 | 0.5779 | 1.3338 |

| MAE | 1.006 | 0.0212 | 1.6014 | 0.8319 | 0.5084 | 0.9179 |

| Parameter | = 2 | = 4 | = 1 | |||

| Set | Test | Train | Test | Train | Test | Train |

| R2 | 0.995 | 1.0000 | 0.9985 | 0.9974 | 0.9904 | 0.9948 |

| RMSE | 1.164 | 0.0862 | 0.6501 | 1.1348 | 1.8408 | 1.5919 |

| MAE | 1.006 | 0.0212 | 0.5896 | 0.6485 | 1.5992 | 1.0844 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadoun, A.M.; Najjar, I.R.; Alsoruji, G.S.; Wagih, A.; Abd Elaziz, M. Utilizing a Long Short-Term Memory Algorithm Modified by Dwarf Mongoose Optimization to Predict Thermal Expansion of Cu-Al2O3 Nanocomposites. Mathematics 2022, 10, 1050. https://doi.org/10.3390/math10071050

Sadoun AM, Najjar IR, Alsoruji GS, Wagih A, Abd Elaziz M. Utilizing a Long Short-Term Memory Algorithm Modified by Dwarf Mongoose Optimization to Predict Thermal Expansion of Cu-Al2O3 Nanocomposites. Mathematics. 2022; 10(7):1050. https://doi.org/10.3390/math10071050

Chicago/Turabian StyleSadoun, Ayman M., Ismail R. Najjar, Ghazi S. Alsoruji, Ahmed Wagih, and Mohamed Abd Elaziz. 2022. "Utilizing a Long Short-Term Memory Algorithm Modified by Dwarf Mongoose Optimization to Predict Thermal Expansion of Cu-Al2O3 Nanocomposites" Mathematics 10, no. 7: 1050. https://doi.org/10.3390/math10071050

APA StyleSadoun, A. M., Najjar, I. R., Alsoruji, G. S., Wagih, A., & Abd Elaziz, M. (2022). Utilizing a Long Short-Term Memory Algorithm Modified by Dwarf Mongoose Optimization to Predict Thermal Expansion of Cu-Al2O3 Nanocomposites. Mathematics, 10(7), 1050. https://doi.org/10.3390/math10071050