Study on Overlying Strata Movement and Surface Subsidence of Coal Workfaces with Karst Aquifer Water

Abstract

:1. Introduction

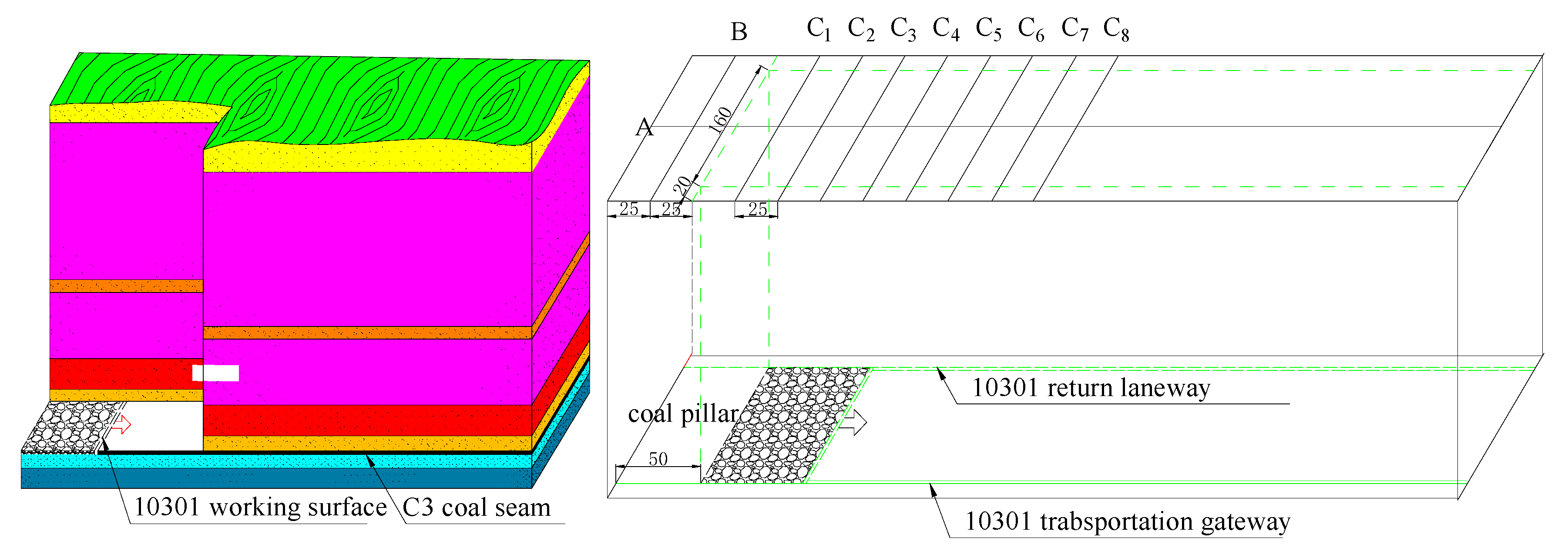

2. Numerical Simulation

2.1. Engineering Background

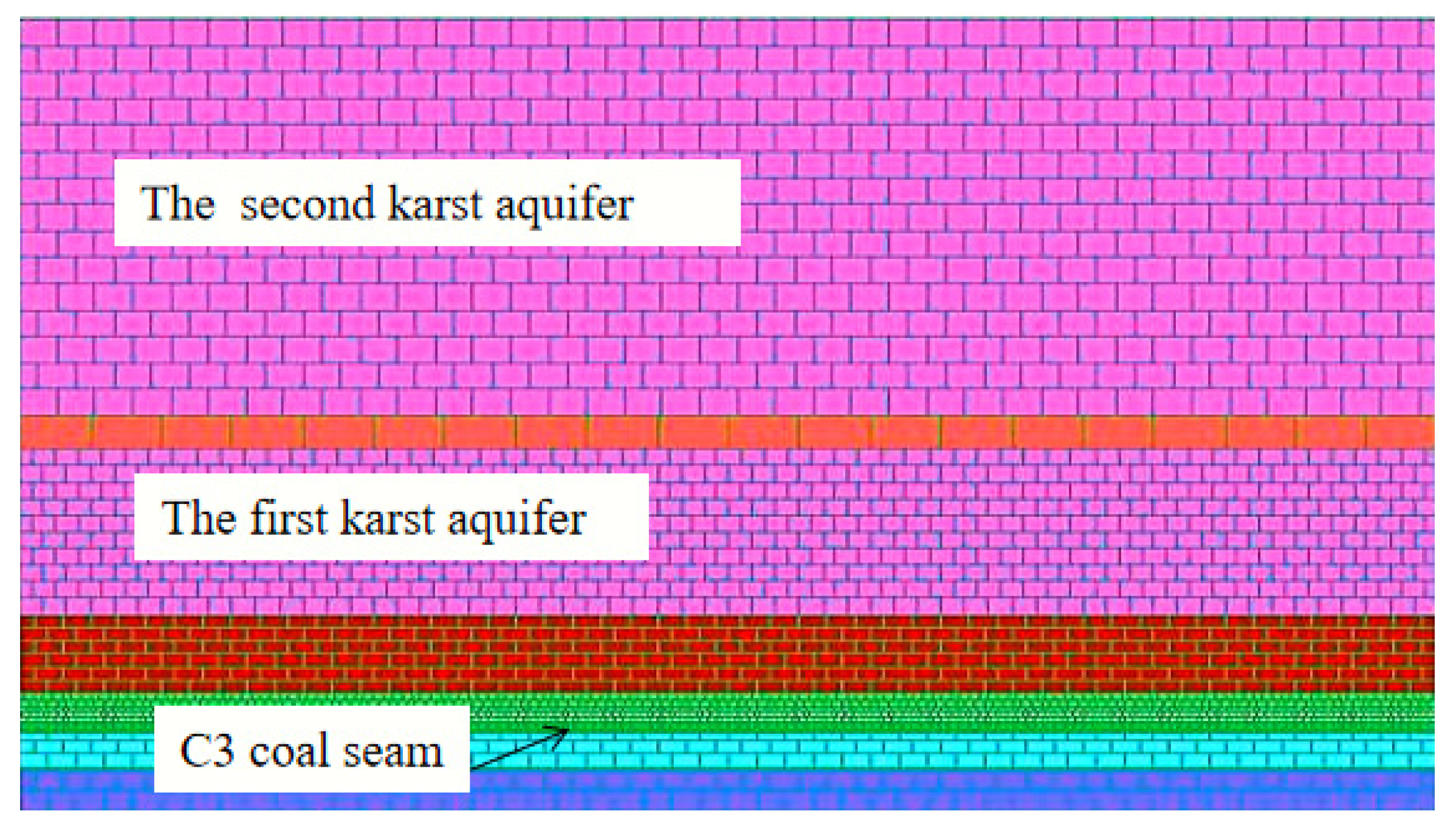

2.2. Model Establishment and Parameters Selection

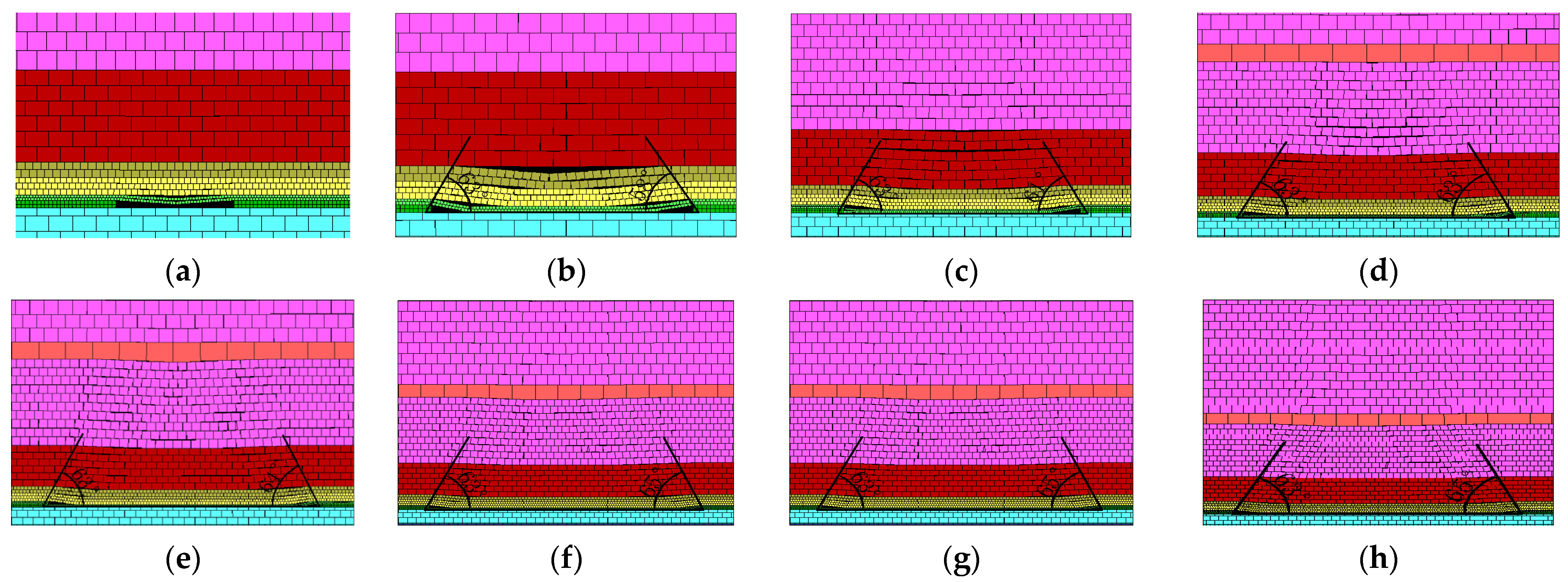

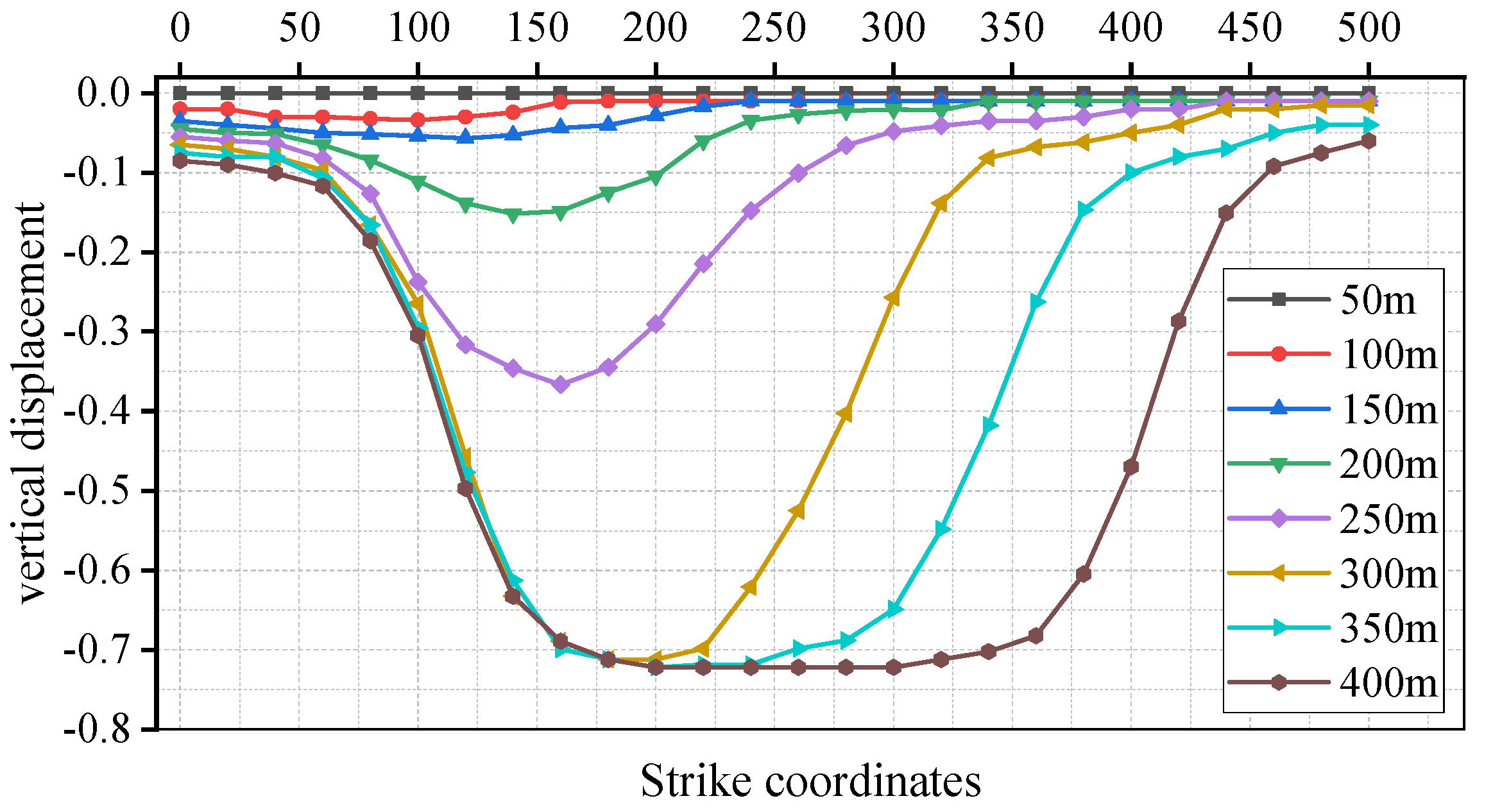

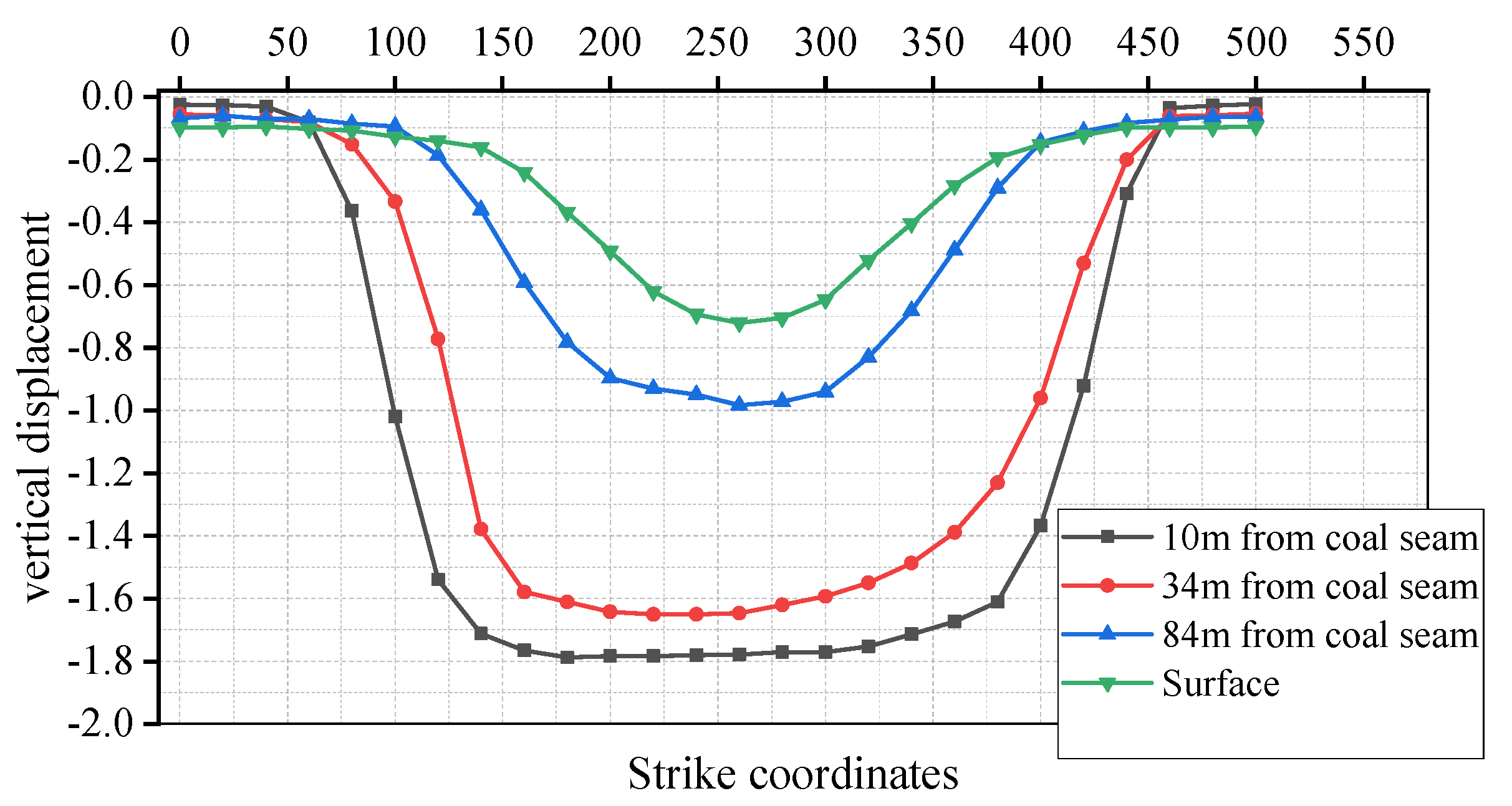

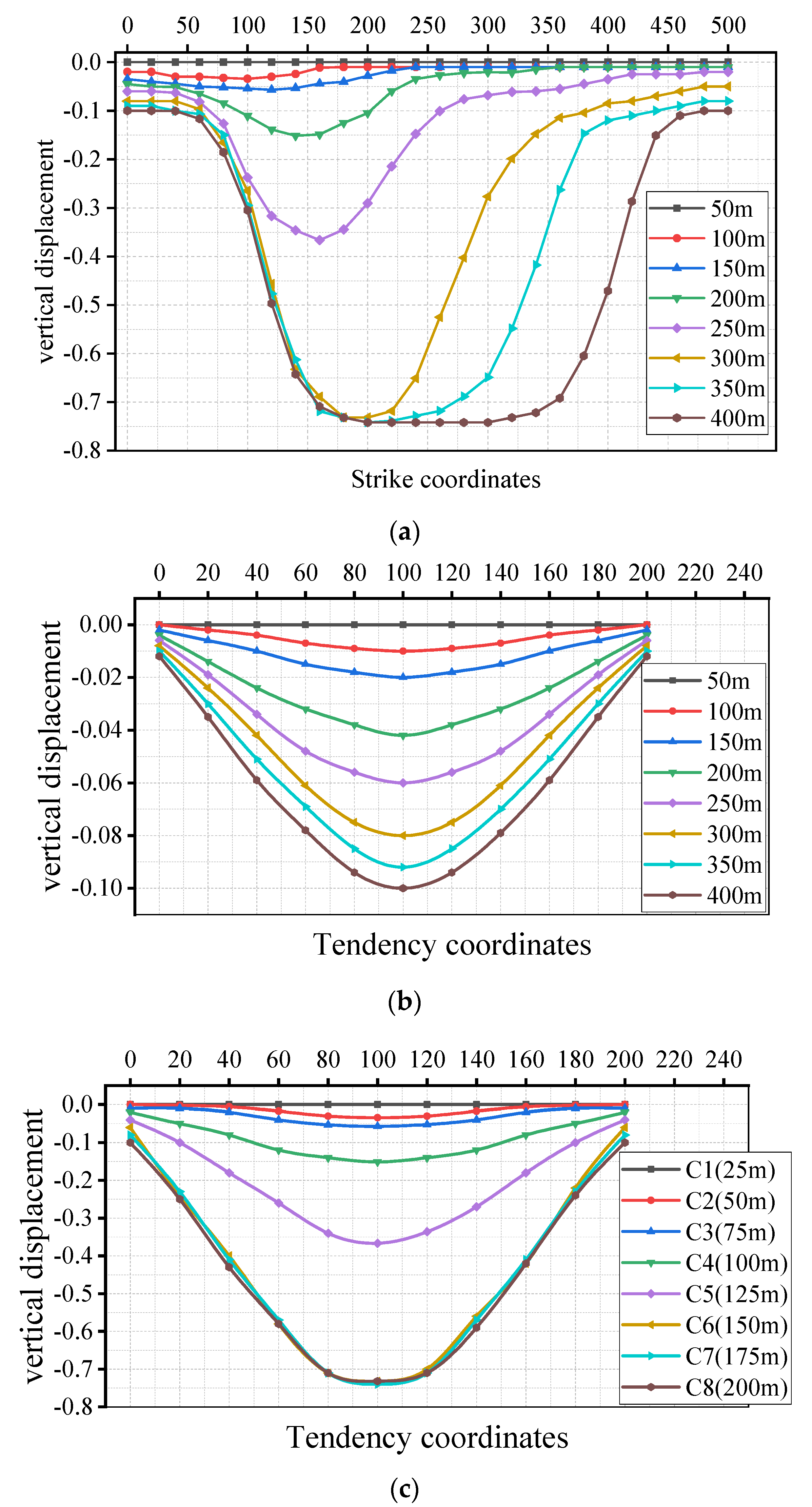

2.3. Overlying Strata Movement under the Condition of Karst Aquifer without Water

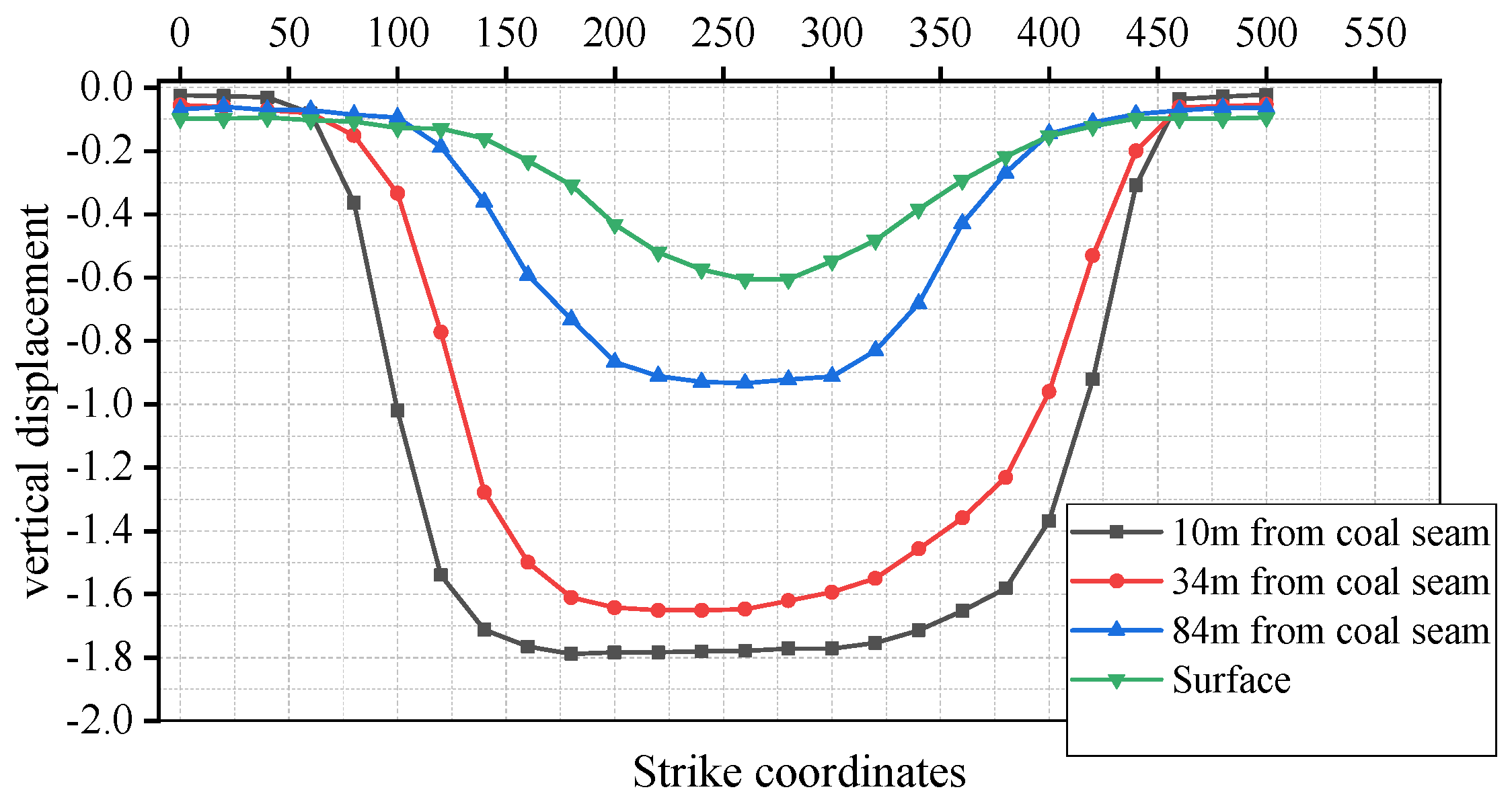

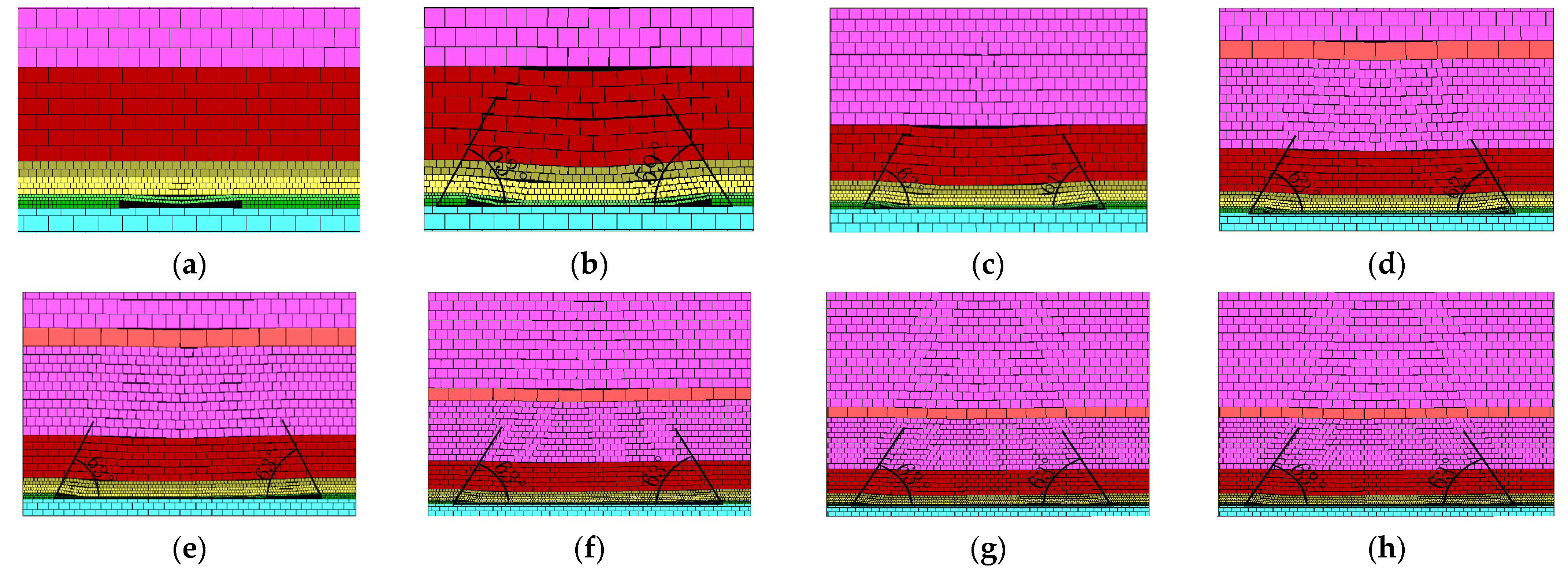

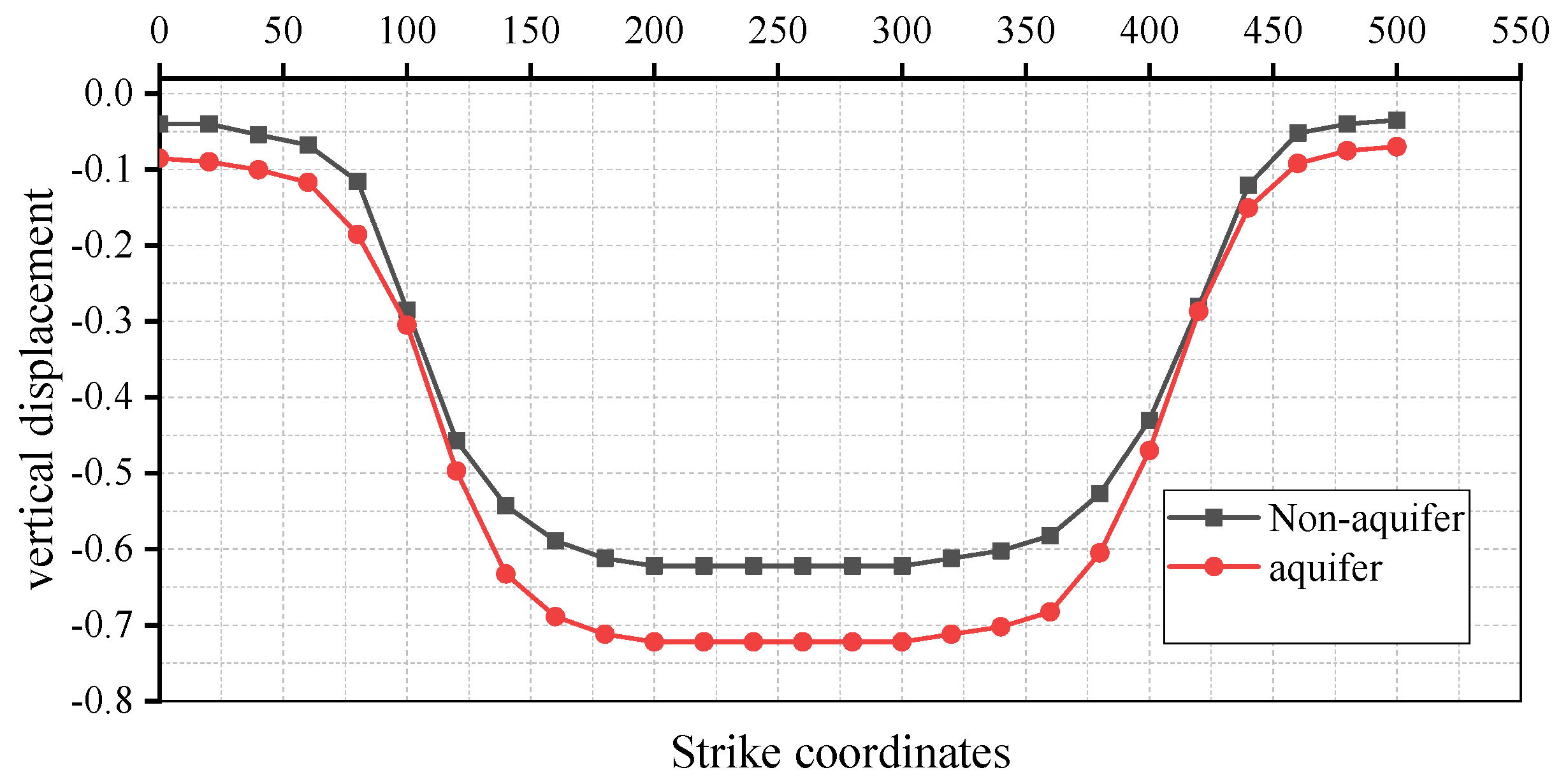

2.4. Overlying Strata Movement under the Condition of Karst Aquifer with Water

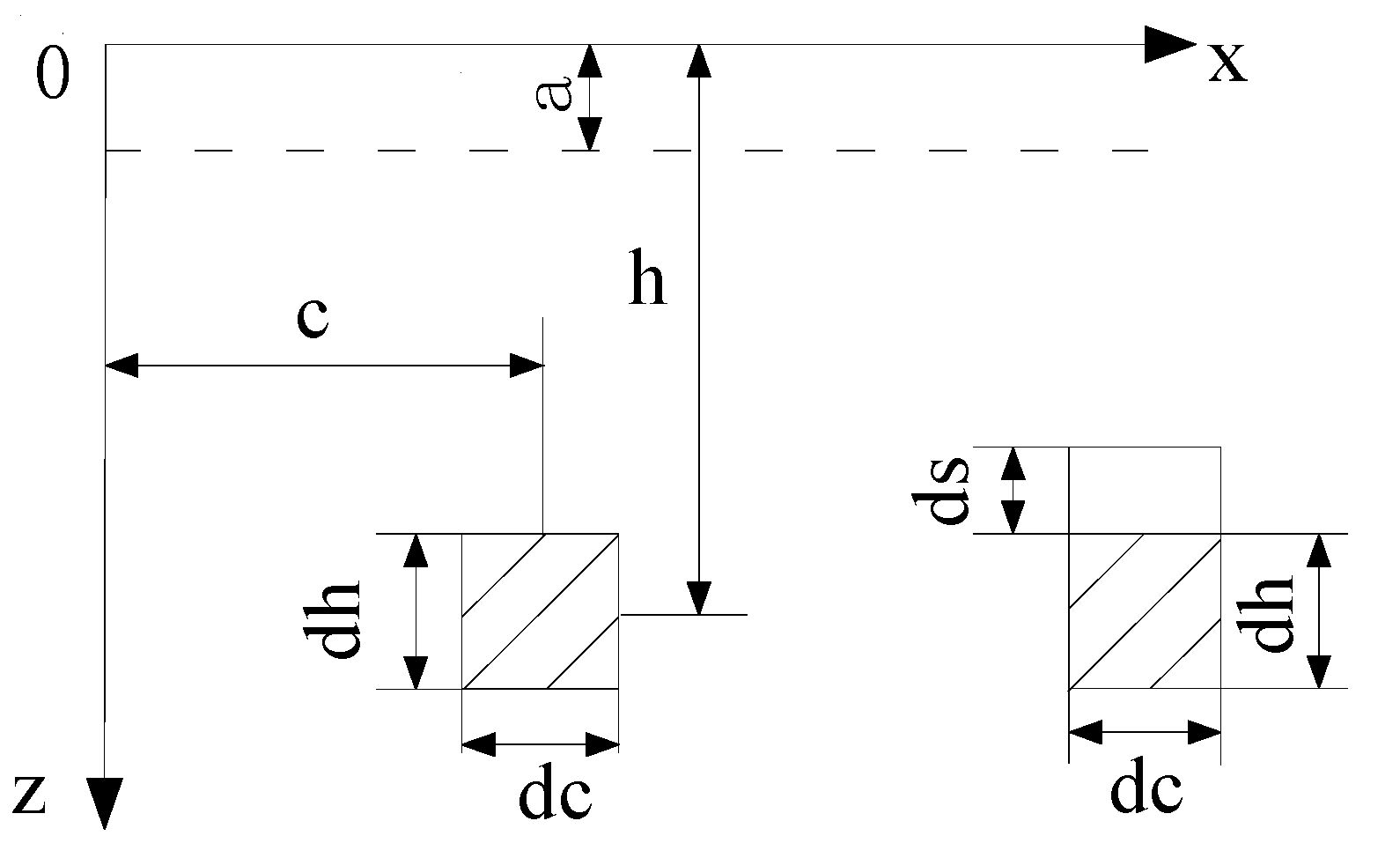

3. Theory Model of Surface Subsidence under the Condition of Karst Aquifer with Water

3.1. Calculation Model of Surface Subsidence Caused by Aquifer Drainage

3.2. Theoretical Calculation

4. Engineering Measurement and Analysis

4.1. Observation Scheme

4.2. Results and Analysis

5. Discussion

6. Conclusions

- (1)

- Compared with the karst aquifers without water, the movement and deformation characteristics of overburden for the karst aquifers with water drainage were quite different, while the collapse angle of overburden was roughly the same.

- (2)

- With the advance of the workface, the fracture caused by mining activities can penetrate to a karst aquifer and the water in the aquifer can flow to the workface along the fracture. The water drainage can decrease the osmotic pressure of aquifer, increase the effective stress of fractured limestone and the compression of aquifer, which can intensify the surface subsidence.

- (3)

- The maximum surface subsidence of mining area for the karst aquifer without water drainage was about 0.6 m, and the maximum surface subsidence of the mining area when considering water drainage was about 0.73 m. Therefore, the surface subsidence caused by drainage of multi-aquifer accounted for 17.8% of the total surface subsidence.

- (4)

- Based on the effective stress principle modified by the Biot coefficient αb, the axial deformation of aquifer with considering water drainage can be obtained, and the field-monitoring results of surface subsidence can also verify the accuracy of the theory-model results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Verma, A.; Mandal, S.K.; Singh, P.K. Trait of subsidence under high rate of coal extraction by longwall mining: Some inferences. Sadhana-Acad. Proc. Eng. Sci. 2021, 46, 216. [Google Scholar] [CrossRef]

- Qiang, Z.; Zhang, J.X.; Feng, J. Backfilling technology and strata behaviors in fully mechanized coal mining working face. Int. J. Min. Sci. Technol. 2012, 22, 151–157. [Google Scholar] [CrossRef]

- Xiong, Y.; Kong, D.; Cheng, Z.; Wu, G.; Zhang, Q. The Comprehensive Identification of Roof Risk in a Fully Mechanized Working Face Using the Cloud Model. Mathematics 2021, 9, 2072. [Google Scholar] [CrossRef]

- Lv, H.; Cheng, Z.; Dong, Y.; Zhang, J.; Ma, Y. Numerical simulation on the crack initiation and propagation of coal with combined defects. Struct. Eng. Mech. 2021, 79, 237–245. [Google Scholar] [CrossRef]

- Lv, H.; Cheng, Z.; Liu, F. Study on the mechanism of a new fully mechanical mining method for extremely thick coal seam. Int. J. Rock Mech. Min. Sci. 2021, 142, 104788. [Google Scholar] [CrossRef]

- Han, C.L.; Zhang, N.; Yang, H.Q. Superposed disturbance mechanism of sequential overlying strata collapse for gob-side entry retaining and corresponding control strategies. J. Cent. South Univ. 2018, 25, 2258–2271. [Google Scholar] [CrossRef]

- Liang, Q.H. Study of Numerical Simulation and Application on Thick-Alluvium Surface Subsidence. Ph.D. Thesis, Shandong University of Science and Technology, Qingdao, China, 2006. [Google Scholar]

- Xu, J.L.; Lian, G.M.; Zhu, W.B. Influence of the key strata in deep mining to mining subsidence. J. China Coal Soc. 2007, 32, 686–690. [Google Scholar]

- Singh, R.; Mandal, P.K.; Singh, A.K. Upshot of strata movement during underground mining of a thick coal seam below hilly terrain. Int. J. Rock Mech. Min. 2007, 45, 29–46. [Google Scholar] [CrossRef]

- Ramesh, P.S.; Ram, N.Y. Subsidence prediction method based on equivalent mining height theory for solid backfilling mining. Trans. Nonferr. Met. Soc. 2014, 24, 3302–3308. [Google Scholar] [CrossRef]

- Qin, Y.; Xue, J.Q.; Chen, B.Q. A model for extracting large deformation mining subsidence using D-InSAR technique and probability integral method. Trans. Nonferr. Met. Soc. 2014, 24, 1242–1247. [Google Scholar] [CrossRef]

- Ge, L.L.; Guo, J.T.; Ng, A.H.M. Numerical simulation of dynamic surface deformation based on DInSAR monitoring. Trans. Nonferr. Met. Soc. 2014, 24, 1248–1254. [Google Scholar] [CrossRef]

- Feng, W.P.; Xu, L.S. Fault parameters of the October 2008 Damxung M(w)6.3 earthquake from InSAR inversion and its tectonic implication. Chin. J. Geophys. 2010, 53, 1134–1142. [Google Scholar] [CrossRef]

- Soni, A.K.; K Singh, K.K.; Prakash, A.; Singh, K.B.; Chakraboraty, A.K. Shallow cover over coal mining: A case study of subsidence at Kamptee Colliery, Nagpur India. Bull. Eng. Geol. Environ. 2007, 66, 311–318. [Google Scholar] [CrossRef]

- Liu, X.L. Study on the Law of Dewater Settlement of Bottom Aquifer in Overburden. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2000. [Google Scholar]

- Zhang, D.S.; Fan, G.W.; Ma, L.Q.; Wang, X.F. Aquifer protection during longwall mining of shallow coal seams: A case study in the Shendong Coalfield of China. Int. J. Coal Geol. 2011, 86, 190–196. [Google Scholar] [CrossRef]

- Ma, R.Z. Research the Law of Surface Movement and Deformation of Multiple Mining under Confined Water Loss and Thick Unconsolidated Layers. Ph.D. Thesis, Anhui University of Science & Technology, Huainan, China, 2014. [Google Scholar]

- Li, Y.; Peng, S.S.; Zhang, J.W. Impact of longwall mining on groundwater above the longwall panel in shallow coal seams. Int. J. Min. Reclam. Env. 2016, 30, 295–311. [Google Scholar] [CrossRef]

- Nie, L.; Wang, H.F.; Xu, Y. Application of the arctangent function model in the prediction of ground mining subsidence deformation: A case study from Fushun City, Liaoning Province, China. B Eng. Geol. Environ. 2017, 76, 1383–1398. [Google Scholar] [CrossRef]

- Kong, D.; Cheng, Z.; Zheng, S. Study on the failure mechanism and stability control measures in a large-cutting-height coal mining face with a deep-buried seam. Bull. Eng. Geol. Environ. 2019, 78, 6143–6157. [Google Scholar] [CrossRef]

- Cheng, Z.; Li, L.; Zhang, Y. Laboratory investigation of the mechanical properties of coal-rock combined body. Bull. Eng. Geol. Environ. 2020, 79, 1947–1958. [Google Scholar] [CrossRef]

- Kong, D.; Pu, S.; Cheng, Z.; Wu, G.; Liu, Y. Coordinated Deformation Mechanism of the Top Coal and Filling Body of Gob-Side Entry Retaining in a Fully Mechanized Caving Face. Int. J. Geomech. 2021, 21, 04021030. [Google Scholar] [CrossRef]

- Kong, D.; Xiong, Y.; Cheng, Z.; Wang, N.; Wu, G.; Liu, Y. Stability analysis of coal face based on coal face-support-roof system in steeply inclined coal seam. Geomech. Eng. 2021, 25, 233–243. [Google Scholar] [CrossRef]

- Cheng, Z.; Yang, S.; Li, L.; Zhang, L. Support working resistance determined on top-coal caving face based on coal-rock combined body. Geomech. Eng. 2019, 19, 255–268. [Google Scholar] [CrossRef]

- Lv, H.; Tang, Y.; Zhang, L.; Cheng, Z.; Zhang, Y. Analysis for mechanical characteristics and failure models of coal specimens with non-penetrating single crack. Geomech. Eng. 2019, 17, 355–365. [Google Scholar] [CrossRef]

- Lou, J.; Gao, F.; Yang, J.; Ren, Y.; Li, J.; Wang, X.; Yang, L. Characteristics of evolution of mining-induced stress field in the longwall panel: Insights from physical modeling. Int. J. Coal Sci. Technol. 2021, 8, 938–955. [Google Scholar] [CrossRef]

- Cheng, Z.; Pan, W.; Li, X.; Sun, W. Numerical simulation on strata behaviours of TCCWF influenced by coal-rock combined body. Geomech. Eng. 2019, 19, 269–282. [Google Scholar] [CrossRef]

- He, G.Q.; Yang, L.; Ling, G.D. Mining Subsidence Science; China University of Mining and Technology Press: Xuzhou, China, 1991. [Google Scholar]

| Rock Type | Thickness (m) | Density (kg/m3) | Bulk /(GPa) | Shear /(GPa) | Internal Friction Angle /(°) | Cohesion /(MPa) | Tensile Strength /(MPa) | Permeability Coefficient /(pa−1s−1) | Initial Gap Width /(mm) | Residual Gap Width /(mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| Limestone | 110 m | 2800 | 5.57 | 4.53 | 38 | 11.4 | 6.7 | 110 | 0.2 | 0.05 |

| Mudstone | 10 m | 2700 | 2.86 | 1.4 | 39 | 2.8 | 2.48 | 83 | 0.01 | 0.005 |

| Changxing Limestone | 50 m | 2430 | 11.1 | 8.3 | 35 | 2.4 | 4.4 | 110 | 0.2 | 0.05 |

| Sandy mudstone | 24 m | 2250 | 10.2 | 6.1 | 30 | 1.8 | 3.2 | 83 | 0.01 | 0.005 |

| Mudstone | 4 m | 2550 | 5.8 | 3.2 | 30 | 1.2 | 3.25 | 83 | 0.01 | 0.005 |

| Sandy mudstone | 4.5 m | 2250 | 10.2 | 6.1 | 30 | 1.8 | 3.2 | 83 | 0.01 | 0.005 |

| Carbon mudstone | 1.5 m | 2450 | 3.2 | 2.8 | 30 | 0.7 | 1.8 | 83 | 0.01 | 0.005 |

| C3 Coal | 2 m | 1470 | 1.19 | 0.82 | 25 | 1.3 | 1.79 | 83 | 0.01 | 0.005 |

| Tonstein | 10 m | 2250 | 3.29 | 2.27 | 27 | 4.9 | 3.8 | 83 | 0.01 | 0.005 |

| C1 Coal | 1 m | 1470 | 1.19 | 0.82 | 25 | 1.3 | 1.79 | 83 | 0.01 | 0.005 |

| Mudstone | 13 m | 2550 | 5.8 | 3.2 | 30 | 1.2 | 3.25 | 83 | 0.01 | 0.005 |

| Water | - | 1000 | - | - | - | - | - | - | - | - |

| Advancing Distance of Working Face/m | Front Collapse Angle/° | Rear Collapse Angle/° |

|---|---|---|

| 100 | 58 | 63 |

| 150 | 61 | 63 |

| 200 | 63 | 63 |

| 250 | 64 | 63 |

| 300 | 65 | 63 |

| 350 | 65 | 63 |

| 400 | 65 | 63 |

| Advancing Distance of Working Face/m | Front Collapse Angle/° | Rear Collapse Angle/° |

|---|---|---|

| 100 | 59 | 63 |

| 150 | 61 | 63 |

| 200 | 62 | 63 |

| 250 | 63 | 63 |

| 300 | 63 | 63 |

| 350 | 63 | 63 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wu, G.; Liu, Y.; Cheng, Z. Study on Overlying Strata Movement and Surface Subsidence of Coal Workfaces with Karst Aquifer Water. Mathematics 2022, 10, 169. https://doi.org/10.3390/math10020169

Wang Y, Wu G, Liu Y, Cheng Z. Study on Overlying Strata Movement and Surface Subsidence of Coal Workfaces with Karst Aquifer Water. Mathematics. 2022; 10(2):169. https://doi.org/10.3390/math10020169

Chicago/Turabian StyleWang, Yuliang, Guiyi Wu, Yang Liu, and Zhanbo Cheng. 2022. "Study on Overlying Strata Movement and Surface Subsidence of Coal Workfaces with Karst Aquifer Water" Mathematics 10, no. 2: 169. https://doi.org/10.3390/math10020169

APA StyleWang, Y., Wu, G., Liu, Y., & Cheng, Z. (2022). Study on Overlying Strata Movement and Surface Subsidence of Coal Workfaces with Karst Aquifer Water. Mathematics, 10(2), 169. https://doi.org/10.3390/math10020169