Abstract

The advent of Industry 4.0 is changing the role of human labour towards a more supportive function in the production system, requiring new digital-, technical-, interdisciplinary-, collaborative- and communicative competencies. This challenges educational institutions to develop new teaching activities and materials to address ever emerging needs. To address this, this paper presents an Educational Framework to support educators in developing new teaching activities and study material for Industry 4.0. The model distinguishes itself from other educational design models by combining an iterative approach toward problem-solving, with the concept of authentic task design, as the core elements. Based on 14 pilot cases, it is concluded that educational framework have increased the educational activities in the areas in focus.

1. Introduction

Information and communication technologies have led to new industry opportunities [1,2,3], often referred to as the fourth industrial revolution or, in short Industry 4.0. The core concept of Industry 4.0 can be described as machines and products autonomously exchanging information, self-configuring and self-organising, leading to flexible, modular, intelligent, and cyber-physical production environments [1]. This transformation towards smart machinery and new capabilities also set new requirements for work tasks, operators and technicians [4,5].

As a result, the role of human labour in the manufacturing industry is also changing. Human labour is changing towards a more supportive role in the production system rather than directly involved in the production processes, e.g., assembling the products [6,7,8]. Consequently, employees need new technical-, interdisciplinary-, collaborative- and communicative competencies [6,8]. Traditionally, many educational programs within the technical fields have focused almost exclusively on developing technical skills and much less on social and interpersonal skills [9,10], which is found to be a requirement for Industry 4.0 and is supported by recent studies [11] and reports from the world economic forum [12]. To address the new role of human labour, educational institutions within the technical fields must develop new teaching activities and materials. However, the needs, teaching method and approach for making these changes are unclear, as Industry 4.0 is a broad, alternating, and complex area. Hence, there is a need to support the educators in handling the complexity and uncertainty [13].

Since Japan launched its fifth science and technology basic plan in 2016, the term Society 5.0 has emerged as a way of complementing the societal aspects of the Industry 4.0 era, aiming for a prosperous human-centric society [14]. EU’s initiative “Industry 5.0” rests upon the Society 5.0 objectives and values, however pointing out the industry’s role in the transition. Our understanding is that Industry 5.0 is based on the Industry 4.0 technologies and address the societal and organizational consequences of the Industry 4.0 paradigm as well as needs stemming from sustainability issues and the society through political objectives [15]. Our question is what will the consequences for the learning of professions be as the society moves towards the Society 5.0 “super smart society” [14,16].

The research into this issue is still somewhat meagre, but there are a few aspects that have bearing upon our project. Ref. [17] points out several characteristics of Society 5.0 learning needs: students’ ability to think critically, deductively, and inductively. They also state that students must learn faster and to a high extent through practical experience and underline the need for social competences and a high degree of reflexivity. This supports the claim for Industry 4.0 learning needs, and enhance the need for social skills, reflexivity and experiential learning [18,19].

Approaches to these challenges have been identified on the institutional level [13], identification of needed skills [10], and with a focus on learning mechanisms [20]. However, all of these approaches are descriptive in the sense that they describe the optimal learning setting, yet remain unclear on prescribing a path towards it. Several descriptive approaches to teaching the skills required for Industry 4.0 has been presented, most notably the learning factory [21,22] and teaching factory [23,24] approaches. However, Enke et al. criticises these models for their technology-centric approach [25], where the didactic dimension has been underdeveloped compared to mature technical and operational models. Hence, the learning design for technical education still needs improvement.

Traditionally, learning activities have been developed by the educator, by various models, e.g., SMTTE [26] or the Relational model [27]. Newer approaches involve co-creation, which can be used to create a design for the learning activity [28]. However, a prescriptive approach for educators on how to develop learning activities targeting Industry 4.0 does still call for new approaches, due to the complexity and changing requirements within the field.

This research aims to propose an educational framework that educators can use to guide educators in designing learning and teaching materials for a complex and changing environment while considering the didactic challenges. To define the framework, this article answers the following research question: What should an educational framework address to make it relevant for Industry 4.0, and how can such a framework contribute to better educational targeting of Industry 4.0?

The article describes the relationship between industrial development and the corresponding learning processes within technical training and education. This is followed by a conceptual discussion of how the current situation of Industry 4.0 affects education. Based on this, the Educational Framework is developed. This is followed by an empirical test of the framework, including a discussion on its contribution and further research.

2. The Development of Learning Processes towards Industry 4.0

Industrial development has historically significantly affected educational programmes’ shape, content, pedagogics and didactics [22]. The most notable success criteria for educational programmes is whether graduates from such programmes will be able to fulfil the future needs in the labour market, hence providing the basis for continued growth and prosperity of the society. Understanding the development of needs in the labour market is an essential guide for creating new approaches and methods for developing teaching material and activities [23].

Historically, the Swedish scholar Lennart Nilsson studied the Swedish public system for vocational education and training (VET) through a comprehensive examination of public documents directing and describing the sector [29,30]. The time scope of the study was from the end of the guild-based education in 1846 to 1980. The study resulted in many interesting findings, including the strong relationship between the organisation and activities in vocational schools and the industry they supported. Based on their findings, Nilsson identified the following defining dimensions to describe the relation:

- Planning of work (learning “unit” and training direction). Nilsson found that the working tasks were the core element for planning in the industry and that this was the fact in VET. When the industry moved from the craft-based paradigm of the industrial revolution to mass production, the planning focus moved from a holistic view of the tasks to a method-centric view; how can the tasks be divided and arranged to achieve the highest productivity? This was the case in VET as well. A system was established where the students moved from workstation to workstation, studying divided and adapted tasks. One station focused on the clutch in the car mechanic training, and the next was the differential. The system is still very much alive; the lab equipment suppliers for VET still deliver ready-made “learning stations” with adapted artificial learning tasks for any VET sector.

- The organisational structure. Nilsson found that how school learning activities were organised mimicked the organisational structure of the work in the industry. The prevailing industrial paradigm following the second world war was scientific management, as described by Frederic Taylor. This was also the model for the Training Within Industry (TWI) system that was highly successful as workplace-based training during WW2. Nilsson found that the Swedish VET was highly influenced by this system and organised their activities by individual learning stations self-contained with tools, materials, and manuals in an assembly line fashion.

- Character of the tasks. The adaption of the working (learning) tasks in industry and VET is also closely connected. When the industry transformed from the craft-based paradigm to the fordistic era, the tasks moved from holistic tasks to create value for the customer to a divided instrumental task designed to fit into the worker’s spot on the assembly line. In VET the tasks moved to mock-up tasks designed to learn a small part of a whole system.

- Work mode. This describes whether the working/learning tasks are solved individually or as a team. In the craft-inspired industrial era, a team working mode was prevalent; when the station-based model of the mass-production era entered the VET workshops, the individual mode gained ground as the students rotated between the stations.

- Nature of communication. This feature describes the characteristics for communication of work/task-related communication in the work/learning space. With the introduction of the learning stations, the communication moved from oral communication between the manager/teacher to written instructions. The TWI system had a system for conveying the needed information based on structured lists of “steps” and “key points”, a more instrumental way of communication. You can find the reminiscence of this in today’s eLearning provision.

If we accept the significance of the relation between the industrial paradigm and the educational mode in vocational and professional training according to Nilsson and along the dimensions he proposed, we may deduct characterising features of learning activities, objectives, and outcomes for Industry 4.0.

The basic planning unit is the task of manufacturing highly customised products. In training, this translates to a holistic relation to the finalised authentic products and the system(s) needed to manufacture them. Thus, the learning tasks are to create a final product, not tasks adapted for learning a reduced part of a divided learning outcome. The task is also situated in an authentic context of manufacturing systems and machines, such as one can find in the learning factories, which recently have experienced increased popularity [22]. However, authentic can also be understood in a broader sense, as a problem with a real-world context [31], which allows the learner to relate the new knowledge to their existing knowledge [32].

The organisational structure is characterised by highly integrated, flexible, autonomous and automated production facilities, where the machines and systems communicate both independently of humans and with humans. Due to the high flexibility, Industry 4.0 opens for a cost-effective production of small, customised manufacturing runs, while virtual testing and simulations aid the transition from one product (variant) to another. Some of the tasks are performed in virtual workspaces complementing the physical processes. Humans perform tasks where human capabilities are needed and aid the machines’ operations [33].

The structure requires a holistic approach to the complete value chain of the operation, which demands interdisciplinary oversight and competence from the workers and professionals in the manufacturing industry. The work mode is task-oriented, highly autonomous and conducted in inter-disciplinary teams and/or networks covering all domains needed to solve the tasks. Summarily, a new educational design tool needs to address the three following areas:

- An offset in context, which ensures industrial authenticity.

- A task-based learning approach that enables multidisciplinary group work.

- A design-inspired approach toward problem-solving, where understanding the context and applying an iterative process are key elements.

3. Methods

The research has been conducted as an engaged scholarship [34,35], adding to the quality of higher technical education, as well as providing new knowledge within technical education. To achieve this, a three-step approach was applied. This can also be seen graphically in Figure 1.

Figure 1.

Flow of the applied three-step method.

- Background analysis of industrial needs: A background analysis, enquiring industrial stakeholders about the current and future skill requirements for working with Industry 4.0. In total, 94 stakeholders gave their input, rooted in the industrial needs and matching educational capabilities.

- Development of educational framework and training concept: A theoretical foundation, the educational framework, and the training concept for educators was developed based on the input from the first analysis. It was developed among the project partners following an iterative approach. The elements of Table 1 and the industrial analysis were considered together with the theory presented in this paper.

Table 1. An overview of which characteristics education and instruction had during the four industrial paradigms.

Table 1. An overview of which characteristics education and instruction had during the four industrial paradigms. - Educational pilots for framework testing: The educators evaluated the educational framework through 14 educational pilots, in five European countries, with a total of 450 students. They developed a new educational activity of 5–30 ECTS points (course to full semester), targeting EQF levels 5–7 (higher education), with industry 4.0 scope.

These three activities were evaluated in correspondence with the Framework for Evaluation in Design Science Research for research evaluation [36], which describes that problems with high human factors should be evaluated formatively in a natural environment after a few artificial tests:

- The background analysis was performed partly from the literature and partly from interviews with stakeholders. All partnering institutions surveyed 10+ relevant stakeholders from their countries. It is reported in a separate publication [11].

- The concept was evaluated formatively by educators from six higher education institutions. This increased quality and was a test in a more naturalistic environment. The training material is published at https://fagskolene.online/courses/teffic-pedagogical-framework-for-industry-4-0/?lang=en (accessed on 21 September 2022).

- The educators who conducted the 14 pilots performed both summative (learning outcome) and formative (reactions to the course) evaluations of the courses [36]. This was done as a combination between the institution’s existing evaluation procedures and course-specific activities composed of the educators. After the course, the gains and challenges were reported to the Transforming Educational programs For Future Industry 4.0 Capabilities (TEFFIC) project management. The compiled evaluation can be found at www.teffic.eu or https://www.ucviden.dk/da/projects/transforming-educational-programmes-for-future-industry-40-capabi (accessed on 21 September 2022).

The evaluations was carried out at the individual institutions according to their quality insurance guidelines. At all institutions, this included both questioner data as well as open-ended evaluation at the end of the courses. These evaluations were collected by the educators conducting the educational activities, and processed into an evaluation collecting the learning goals, a learning activity description, and the positive and negative quantitative data as well as any qualitative assessments from the local quality insurance system.

To investigate whether the proposed educational framework meets the demands presented in Table 1, the collected evaluations among educators and students are analysed regarding the four Kirkpatrick levels: reactions, learning, transfer, and performance. Trends that do not fall within these four categories will be described [37]. This analysis was conducted as a Gioia analysis, where the qualitative results from the evaluations was grouped first based on the words used by the individual evaluators, and afterwards towards the four Kirkatrick levels [38].

4. The Educational Framework

As described, both the focus on context and tasks and the agility of the design process are vital elements of an educational framework for Industry 4.0. Hence, the framework development presented in this paper started with a focus on these three elements.

Nilsson [29,30,39] argued that professional and vocational skills and competence are consequences of the human’s task-related professions. It implies that the tasks dictate the obtained competencies [29,30,39]. This realisation is at the core of the Educational Framework. One of their major discoveries was that reducing the tasks according to the training within industry principles led to decreased learning outcomes and dropout from the study programmes. These findings support the application of authentic holistic tasks at the core of the learning process. This strategy is supported by contemporary research [40,41]. Merrill [42] later developed an instructional theory named ’First principles of instruction’, which give explicit guidance on ensuring a higher learning outcome, taking a point of departure in a task-centred approach. A prominent feature of Merrill’s theory is that it places the task as the central element in the learning process. It resonates well with Nilsson’s work, as he argued that the task is imperative, developing teaching activities and material. Accordingly, a learning process based on the ’First principles of instruction’ places the core task at the centre and relates all learning activities. This describes the organisational structure predicted in Table 1, where interdisciplinary groups work on authentic tasks relevant to future employment. Furthermore, the tasks are where the Industry 4.0 context is materialised by using industrial relevant technologies as both case and learning vessel, as described in, e.g., the learning factory literature [22].

The approach embedded in the model is based on agility, as having an agile approach has proven to hold some measurable advantages over traditional educational development methods regarding handling the ambiguous definitions and complexity of the situation [43]. The agile approach allows understanding of the situation to evolve through the process, which is fundamental when the problem at hand is not fully understood from the beginning. This becomes even more relevant when the problem is a dynamic and adaptable authentic task, as described in Table 1. Hence, the solution and understanding of the problem are co-developed through an iterative process [44].

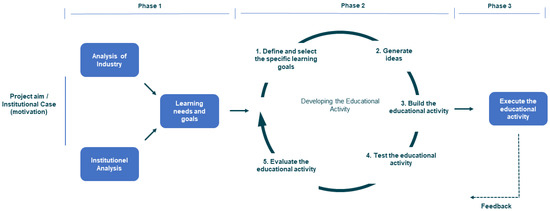

The model (see Figure 2) aims to combine a holistic approach to developing teaching activities and material (identifying and analysing the needs and boundaries), focusing on the detailed development of the activities/material (the circle). Moreover, the overall agile approach is combined with a task-centred principle, as task-centred models, e.g., authentic task design, have provided significant learning outcomes within technical educational programmes, creating a natural setting [31,45].

Figure 2.

The Educational Framework.

The model’s core is the iterative approach toward developing the teaching activities, represented as a circle with five steps in the model (Phase 2—see Figure 2). The other two key phases are, (Phase 1), the initial analysis leading to the learning needs and boundaries, and (Phase 3), the execution of the educational activities, including feedback. Below is a short introduction.

The initial analysis establishes the learning needs and boundaries. Based on the results of the analysis, activities and materials are developed. Afterwards, the educator executes the activities in collaboration with the students. Finally, the activities and materials developed are evaluated by both the educator, student, and potentially also peers.

4.1. Phase 1

An analysis is conducted to identify any gap between industry needs and educational capabilities to ensure that the general learning goals are supported by practice. The analysis results in a set of learning needs, boundaries and opportunities within the higher education organisation. This initial analysis can serve as the foundation for several educational activities related to an educational programme. The analysis should not be conducted before developing an educational activity but should be updated regularly to ensure its relevance. The analysis framework must be adjusted to the specific situation, educational program, and educational organisation(s). However, the one used in TEFFIC (The Erasmus+ project co-funding the development of the Educational Framework) can be used as inspiration for developing a focused framework [11].

Phase 1 result in a set of learning needs and goals, combined with the institutional capabilities, which are the boundaries for meaningful educational activities targeting the industry.

4.2. Phase 2

The iterative development of education consists of five steps, see Figure 1. In the following, the process of each of the underlying steps is described in greater detail.

- Define and Select the Specific Learning Goals;

- Generate Ideas;

- Build the Educational Activity;

- Test the Educational Activity;

- Evaluate the Proposed Educational Activity.

The educational activity is ready for use if it meets the learning goals. If not, the activity must be redesigned.

The choices regarding educational technologies, infrastructure, and resources must be considered in this phase. The initial mapping of educational capabilities revealed that many institutions had access to learning management systems, augmented and virtual reality devices, learning factory equipment and simulational software [11]. The learning management systems allow for several didactical approaches, such as blended learning and flipped classroom. These, and other locally available learning technologies must be evaluated iteratively, as suggested in this phase, as it finds potential flaws in the learning design.

Phase 2 results in a learning design which can be taken into the education and be executed among the students. This includes both what, when, where and how to learn, and which infrastructure is needed.

4.3. Phase 3

The execution uses the developed educational activity as a plan, which is the overall reality check for the plan. After the program’s execution, several types of feedback can be obtained. This feedback targets the execution, the planned activity, the learning goals, the learning needs and the industry. Several methods can be used to obtain feedback, including interviews, questionnaires, and workshops. The educators’ reflections are also crucial in this process, as the educators and the students are participating in the educational activity at different premises. The test approach must be adjusted to the specific situation, educational program, and educational organisation(s).

The feedback acquired in phase 3 comes in several forms, and serves purposes in both phase 1 and 2: Feedback towards students’ reactions to the course and learning outcome targets in phase 2. If the students find the learning activity to be poorly organised, if learning goals are missed, or if positive outcomes need to be maintained, this is used in the following design cycle.

Phase 1 is influenced by graduates’ feedback on using the acquired skills and how these can aid the choice of learning needs and goals. Likewise, feedback from the industry can be added to new industrial and institutional analyses.

5. Learning Activities and Their Characteristics

The 14 developed learning activities, their contents and results can be seen in Table 2. Note that 5 of the educational activities were second iterations of the same educational activity, and hence received feedback from the first iteration.

Table 2.

The 14 conducted educational pilots. Two numbers marked pilot with two iterations.

These learning activities all provided the desired results learning wise, implying that the educational framework is use-able for planning technical higher education.

6. Learning Outcome and Educational Characteristics

The evaluation of the 14 pilots can be aggregated into five themes; the four Kirkpatrick levels (1) reactions, (2) learning, (3) transfer, (4) performance [37], and given the circumstances of this case (COVID-19), a fifth theme is added; (5) external circumstances.

The majority of students in all pilots reported positive reactions to the organisation and content of the education. The pilots where the participating institutions performed course satisfaction evaluations, the results showed a 75–85% satisfaction with the courses. This is on par with, or above, the European average before the COVID-19 pandemic of 77% [46]. The students were explicit that they appreciated the cases and mini-projects, as well as the video and podcast material. They also reported that the educational material was well made, and that it fits the style and content of the courses. The high degree of blended learning allowed asynchronous watching of video lectures and listening to podcasts, to which the students reacted positively. All of this contributed to a higher motivation among the students. A few students noted that the open-ended problems were frustrating, which was the only reoccurring complaint about the courseware. This implies that the organisation of the learning, as described in Table 1, provides the students with a satisfying learning environment.

In addition to the positive reactions to the course, the learning outcome was also high. In one pilot, a student noted that everyone seemed to be able to contribute with their cases afterwards and that this aided the discussion. The ability to revisit video and audio material also aided previously failed students, who highlighted this as a significant improvement compared to traditional auditorium lectures. The reflective dimension of most pilots also aided new insights. When reflective questions were part of the preparation for the day, students came better prepared for discussing the topic. The students put in much effort, combined with the authentic tasks they solved: all pilots meet their learning goals. Positive reactions regarding relevancy and motivation can explain this effect. Furthermore, the broader understanding of, e.g., business or digitalisation was also improved during the activities. Some students also reported that abstract content became more accessible and relevant through the authentic cases, helping them understand it better. This implies that the learning outcome from the structure, task type and work mode in Table 1 have fitted for the subjects.

The transfer from the explicit pilots into the general practice of the students was also seen in the evaluations. After some of the pilots, the students were asked to identify further learning requirements and pointed towards different techniques to master or knowledge to obtain. As mentioned, the students could identify further learning goals, both within the application of the learned skills and knowledge within their projects, as well as new skills to acquire. They became more aware of digital tools and solutions, and in the pilots with integrated interdisciplinarity, they also increased their understanding of other related disciplines. This transfer was also seen in some of the semester projects, which tended to be more digitally-minded than previous semesters. This support that the educational framework targets the characteristics of industry 4.0 education, as described in Table 1. The students’ performance upon graduation was not evaluated within the project’s timeframe, but students reported confidence in job readiness and ability to perform within the topic of the pilots.

While all the above is positive, many students noted adverse effects from COVID-19 (external circumstances), where hardware, internet connections, organisation and social interaction became challenged. All of this might overshadow potential negative feedback, as in general, well-planned and conducted courses suited for blended learning worked well. Hence, the results should be understood in that context, where minor drawbacks of the planned courses could have been eliminated under other circumstances.

With offset in these themes, it can be seen how this approach can enhance industrial learning for targeting the industry in the 4.0 movement, as described in Table 1. As seen from the learning outcome of the 14 pilots, the nature of communication (both digital and analogue, synchronous and asynchronous) enhanced the learning and, at the same time, added the technologically augmented dimension. Along the same lines, the physical and virtual tasks are also presented in this framework and support learning outcomes and transfer. The autonomous and group-oriented tasks also seem to have increased both positive reactions to the pilots and learning outcomes.

7. Discussion and Conclusions

As the industry turns ever more complex, it alters the educational setting that prepares tomorrow’s workers for the industry. Hence, methods and tools for targeting this change can aid educational institutions’ transition towards educating for Industry 4.0. To guide educational institutions, this paper presents an agile educational framework that combines a process model with analysis and an iterative building phase with the task-centric approach of authentic task design. The task-centric and agile education approaches have prevailed individually within education. By proposing this combination, we presented a tool that can enhance the students’ knowledge by keeping the content up to date compared to the complex industry and by providing the student with authentic problem-solving abilities. Nilsson’s [29,30,39] analysis of the learning associated with the earlier industrial paradigms suggests that the educational settings affect the amplitude of learning and what is learned. Hence, the learning approach should fit the desired learning outcome in the teaching approach and have a relevant, authentic task. A known catch regarding authentic tasks is that minor details can draw too much attention. Hence, Enke et al. argue that the authentic task should not wander into details, as this leads to many technical-centric learning activities having less than optimal learning design. If tasks focus too heavily on a few technical aspects, they can leave more general perspectives behind [25]. The iterative approach presented in this paper can limit this wandering, as the iterations will identify this. If the technical details are too pronounced, this can be adjusted in the next iteration.

The analysis shows that the industry requests ever-increasing competencies outside the traditional technical domains, the student’s learning, personal, and interdisciplinary skills gain further traction. This Educational Framework supports this by suggesting multidisciplinary student groups. As suggested by Prensky, this work targets several fundamental learning areas: creative thinking, problem-solving, system thinking, mindset, innovation, collaboration, and communication (Prensky, 2014). Neither of these competencies are necessarily required to perform a specific industrial task. As they are not core competencies, they aid the overall task solving. Hence, they are contextual competencies [9] that can aid the worker in everyday tasks.

While this educational framework provides tools for designing new educational activities for educators in higher education, specifically for learning Industry 4.0 skills, then the educational framework should be tested in other contexts where multidisiplinarity is key, and learnings can be supported by authentic task design. In addition, future work should specify two things: (1) Deeper case studies, which can provide details on how to use the framework and why it works, along with (2) test in further education, an other important area for industry 4.0 competence development. A limitation to the study is found in its uses in areas with a more strict requirements for what the learning outcome should be, such as law or healthcare, meaning that the everchanging nature of the task-centric educational framework cannot support this material, but the methods and guides created could still be used to improve the teaching methods.

The proposed Educational Framework is a tool for educators to create educational content targeting future industries, which have in this study been tested across various European countries. According to cultural studies [47], this multidisciplinary way of working is culturally fitting these countries, however, exploring how the adoption and use of the educational framework can be used across countries is highly relevant. This aligns well with the call for a Industry 5.0 or Society 5.0 agenda [14].

Author Contributions

Conceptualization, L.C., T.E.H. and E.S.L.; Methodology, L.C., E.S.L., A.H.L. and J.H.K.; Validation, All authors on respective institutions; Formal Analysis, J.G., L.C. and T.E.H.; Data Curation, J.G.; Writing—Original Draft Preparation, L.C., E.S.L. and T.E.H.; Writing—Review & Editing, C.S., A.H.L., T.D.B. and T.O.; Visualization, E.S.L.; Supervision, A.H.L. and T.D.B.; Project Administration, E.S.L.; Funding Acquisition, E.S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Erasmus+ grant number 2018-1-DK01-KA203-047093.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data can be found at on www.teffic.eu (accessed on 21 September 2022).

Acknowledgments

The Educational Framework presented in this article is developed as part of the activities in the TEFFIC project (Transforming Educational Programmes For Future Industry 4.0 Capabilities). The project has been co-founded by EU through Erasmus+ programme (Project Reference: 2018-1-DK01-KA203-047093). More information about the TEFFIC project can be found on www.teffic.eu (accessed on 21 September 2022).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kagermann, H.; Wahlster, W.; Helbig, J. Securing the Future of German Manufacturing Industry: Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0; Final Report of the Industrie 4.0 Working Group; Forschungsunion: Berlin, Germany, 2013; pp. 1–84. [Google Scholar]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Nunes, M.L.; Pereira, A.C.; Alves, A.C. Smart products development approaches for Industry 4.0. Procedia Manuf. 2017, 13, 1215–1222. [Google Scholar] [CrossRef]

- Romero, D.; Stahre, J. Towards The Resilient Operator 5.0: The Future of Work in Smart Resilient Manufacturing Systems. Procedia CIRP 2021, 104, 1089–1094. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Operator 5.0: A survey on enabling technologies and a framework for digital manufacturing based on extended reality. J. Mach. Eng. 2022, 22, 43–69. [Google Scholar] [CrossRef]

- Romero, D.; Bernus, P.; Noran, O.; Stahre, J.; Fast-Berglund, A. The operator 4.0: Human cyber-physical systems and adaptive automation towards human-automation symbiosis work systems. In IFIP International Conference on Advances in Production Management Systems; Springer: Cham, Switzerland, 2016; pp. 677–686. [Google Scholar]

- Nelles, J.; Kuz, S.; Mertens, A.; Schlick, C.M. Human-centered design of assistance systems for production planning and control: The role of the human in Industry 4.0. In Proceedings of the 2016 IEEE International Conference on Industrial Technology (ICIT), Taipei, Taiwan, 14–17 March 2016; pp. 2099–2104. [Google Scholar]

- Fareri, S.; Fantoni, G.; Chiarello, F.; Coli, E.; Binda, A. Estimating Industry 4.0 impact on job profiles and skills using text mining. Comput. Ind. 2020, 118, 103222. [Google Scholar] [CrossRef]

- van Laar, E.; van Deursen, A.J.; van Dijk, J.A.; de Haan, J. The relation between 21st-century skills and digital skills: A systematic literature review. Comput. Hum. Behav. 2017, 72, 577–588. [Google Scholar] [CrossRef]

- Pontes, J.; Geraldes, C.A.S.; Fernandes, F.P.; Sakurada, L.; Rasmussen, A.L.K.; Christiansen, L.; Hafner-Zimmermann, S.; Delaney, K.; Leitao, P. Relationship between Trends, Job Profiles, Skills and Training Programs in the Factory of the Future. In Proceedings of the 9th International Conference on Information Technology: IoT and Smart City, Guangzhou, China, 22–25 December 2021; pp. 1–6. [Google Scholar]

- Mahmood, K.; Otto, T.; Kristensen, J.H.; Lassen, A.H.; Brunø, T.D.; Schou, C.; Christiansen, L.; Laursen, E.S. Analysis of Industry 4.0 Capabilities: A perspective of Educational Institutions and Needs of Industry. In Proceedings of the 8th Changeable, Agile, Reconfigurable, and Virtual Production Conference (CARV2021), Aalborg, November 2021; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- What Are the Top 10 Job Skills for the Future?|World Economic Forum. Available online: https://www.weforum.org/agenda/2020/10/top-10-work-skills-of-tomorrow-how-long-it-takes-to-learn-them/ (accessed on 21 September 2022).

- Mian, S.H.; Salah, B.; Ameen, W.; Moiduddin, K.; Alkhalefah, H. Adapting Universities for Sustainability Education in Industry 4.0: Channel of Challenges and Opportunities. Sustainability 2020, 12, 6100. [Google Scholar] [CrossRef]

- Onday, O. Japan’s society 5.0: Going beyond industry 4.0. Bus. Econ. J. 2019, 10, 1–6. [Google Scholar]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Michael. Online training: The application of the Society 5.0 concept. IOP Conf. Ser. Earth Environ. Sci. 2021, 729, 012105. [Google Scholar] [CrossRef]

- Sajidan, S.; Saputro, S.; Perdana, R.; Atmojo, I.R.W.; Nugraha, D.A. Development of Science Learning Model towards Society 5.0: A Conceptual Model. J. Phys. Conf. Ser. 2020, 1511, 012124. [Google Scholar] [CrossRef]

- Cotet, G.B.; Balgiu, B.A.; Zaleschi, V. Assessment procedure for the soft skills requested by Industry 4.0. In Proceedings of the MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2017; Volume 121, p. 7005. [Google Scholar]

- Motyl, B.; Baronio, G.; Uberti, S.; Speranza, D.; Filippi, S. How will change the future engineers’ skills in the Industry 4.0 framework? A questionnaire survey. Procedia Manuf. 2017, 11, 1501–1509. [Google Scholar] [CrossRef]

- Paravizo, E.; Chaim, O.C.; Braatz, D.; Muschard, B.; Rozenfeld, H. Exploring gamification to support manufacturing education on industry 4.0 as an enabler for innovation and sustainability. Procedia Manuf. 2018, 21, 438–445. [Google Scholar] [CrossRef]

- Abele, E.; Flum, D.; Strobel, N. A Systematic Approach for Designing Learning Environments for Energy Efficiency in Industrial Production. Procedia Manuf. 2017, 9, 9–16. [Google Scholar] [CrossRef]

- Abele, E.; Metternich, J.; Tisch, M. Learning Factories; Springer: Cham, Switzerland, 2019; pp. 239–243. [Google Scholar] [CrossRef]

- Mavrikios, D.; Georgoulias, K.; Chryssolouris, G. The Teaching Factory Paradigm: Developments and Outlook. Procedia Manuf. 2018, 23, 1–6. [Google Scholar] [CrossRef]

- Chryssolouris, G.; Mavrikios, D.; Rentzos, L. The teaching factory: A manufacturing education paradigm. Procedia Cirp 2016, 57, 44–48. [Google Scholar] [CrossRef]

- Enke, J.; Glass, R.; Metternich, J. Introducing a Maturity Model for Learning Factories. Procedia Manuf. 2017, 9, 1–8. [Google Scholar] [CrossRef]

- Felip, F.; Navarro, J.; Martín, S.; García, M. Competences for collaboration and knowledge sharing in digital society—A case study with an erasmus intensive programme. In Proceedings of the INTED2014 Proceedings, Valencia, Spain, 10–12 March 2014; pp. 5562–5569. [Google Scholar]

- Ponte, P.; Smit, B.H. A strategy for practice-based education and research: Built on experiences in educating vocational teachers. In The Quality of Practitioner Research; Brill: Leiden, The Netherlands, 2007; pp. 97–114. [Google Scholar] [CrossRef]

- Pors, A.L.K.; Bennyson, R.; Laursen, E.S.; Geraldes, C.A.; Leitão, P.; Sheridan, I.; Christiansen, L. Co-design of technical upskilling training program through early stakeholder involvement. In Proceedings of the 19th International Conference on Cooperative Design, Visualisation and Engineering, Online, 25–28 October 2022. [Google Scholar]

- Nilsson, L. Yrkesutbildning i Nutidshistoriskt Perspektiv: Yrkesutbildningens Utveckling Från Skråväsendets Upphörande 1846 till 1980-Talet Samt Tankar om Framtida Inriktning [Vocational Training in a Historical Perspective: The Development of Vocational Training Fro; Acta Universitatis Gothoburgensis: Göteborg, Sweden, 1981. [Google Scholar]

- Nilsson, L. Vocational Education: An Historical Analysis. Ph.D. Thesis, Göteborg University, Göteborg, Sweden, 1982. [Google Scholar]

- Herrington, J.; Reeves, T.C.; Oliver, R.; Woo, Y. Designing authentic activities in web-based courses. J. Comput. High. Educ. 2004, 16, 3–29. [Google Scholar] [CrossRef]

- Oakley, B. A Mind for Numbers: How to Excel at Math and Science (Even If You Flunked Algebra); Tarcher, J.P., Ed.; Penguin: New York, NY, USA, 2014. [Google Scholar]

- Weiss, A.; Wortmeier, A.K.; Kubicek, B. Cobots in Industry 4.0: A Roadmap for Future Practice Studies on Human-Robot Collaboration. IEEE Trans. Hum.-Mach. Syst. 2021, 51, 335–345. [Google Scholar] [CrossRef]

- Mathiassen, L. Designing Engaged Scholarship: From Real-World Problems to Research Publications. Engaged Manag. Rev. 2017, 1, 2. [Google Scholar] [CrossRef]

- Van De Ven, A.H. Engaged Scholarship: A Guide for Organizational and Social Engaged Scholarship Diamond Model; Oxford University Press on Demand: New York, NY, USA, 2007. [Google Scholar]

- Venable, J.; Pries-Heje, J.; Baskerville, R. FEDS: A Framework for Evaluation in Design Science Research. Eur. J. Inf. Syst. 2017, 25, 77–89. [Google Scholar] [CrossRef]

- Kaufman, R.; Others, A. What Works and What Doesn’t: Evaluation beyond Kirkpatrick. Perform. Instr. 1996, 35, 8–12. [Google Scholar] [CrossRef]

- Gioia, D.A.; Corley, K.G.; Hamilton, A.L. Seeking Qualitative Rigor in Inductive Research: Notes on the Gioia Methodology. Organ. Res. Methods 2012, 16, 15–31. [Google Scholar] [CrossRef]

- Nilsson, L. Den Glömda Arbetsuppgiften. I Samverkan Mellan Skola Och Arbetsliv. Om Möjligheterna Med Lärande i Arbete. [The Forgotten Job Assignments. In Collaboration between School and Work. On Possibilities with Learners at Work]; Regeringskanseliet: Stockholm, Sweden, 2000; pp. 227–264. [Google Scholar]

- Christiansen, L.; Georgsen, M.; Hvidsten, T.E.; Skov, E. Reflective Practice-based Learning Across Technical Educational Disciplines. In Proceedings of the European Conference on Reflective Practice-Based Learning 2021, Aalborg, Denmark, 1–3 November 2021. [Google Scholar]

- Hvidsten, T.; Vangen, F.J.; Laursen, E.S.; Christiansen, L. Sustainability issues across educational disciplines in learning factories. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Merrill, M.D. A Pebble-in-the-Pond Model For Instructional Design. Perform. Improv. 2015, 54, 42–48. [Google Scholar] [CrossRef]

- López-Alcarria, A.; Olivares-Vicente, A.; Poza-Vilches, F. A systematic review of the use of agile methodologies in education to foster sustainability competencies. Sustainability 2019, 11, 2915. [Google Scholar] [CrossRef]

- Schön, D.A. Educating the Reflective Practitioner; Jossey-Bass Higher Education Series; Jossey-Bass: San Francisco, CA, USA, 1987. [Google Scholar]

- Reeves, T.C.; Herrington, J.; Oliver, R. Authentic Activities and Online Learning. In Proceedings of the HERDSA 2002 Quality Conversations, Perth, Australia, 7–10 July 2002. [Google Scholar]

- Internationa English Language Testing System; Studyportals; Student Satisfaction; Technical Report; Studyportals B.V.: Eindhoven, The Netherlands, 2019.

- Hofstede, G. Dimensionalizing cultures: The Hofstede model in context. Online Read. Psychol. Cult. 2011, 2, 2307–2919. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).