2. Literature Review

Sanahuja investigated the sources of non-value-added issues (waste) within the education environment, focusing on subjects within the STEAM sector [

4]. The overall aim of the work was to highlight the non-value-added issues within the teaching of STEAM subjects and recommend suitable measures to either minimize or eliminate these waste sources. Sanahuja differentiates between Lean teaching and Lean education, with the former focusing on the transmission of educational information from the teacher to the student in a classroom environment, and the latter focusing on the implementation of Lean initiatives in an educational system, thus ‘making it work as a Lean enterprise’ [

4]. The study concludes that the conversion of Lean thinking into the education system begins with Lean teaching, as this is fundamental to the overall education system and only relies on the commitment and motivation of the teachers. On the other hand, the implementation of Lean education requires the involvement of many people and layers of management, thus having limitations. In order to maximize the adoption of Lean teaching, the teacher must continually be up to date with developing methodologies and technologies (such as virtual learning environments) to maximize the motivation and engagement of students, whilst also portraying the ability to outline abstract concepts. Likewise, the continual improvement demonstrated by Lean thinking within an educational context is promoted through the involvement of students and the critical input the students can have on Lean teaching, such as the ‘design and progress of their own learning’ [

4]. This aspect of Lean teaching develops a ‘model of cooperative and collaborative learning’ [

3], thus creating a fluid classroom environment between the student and teacher.

A Lean management framework, relating to non-value-added issues in HEIs, was outlined by Klein et al. in an academic report based on a Brazilian Higher Education Institution (HEI) [

6]. The aim of the study was to investigate the non-value-added issues (waste) within a Brazilian HEI, whilst applying an Analytical Hierarchy Process (AHP) to categorize and identify the definite sources of waste in an educational context that can be prioritized and developed to ‘optimize efforts to create value for final users’ [

6]. The results of the AHP, in relation to the eight waste sources on the main campus base, implies that the loss of knowledge (boasting a priority weight of 34.1%) and overprocessing (boasting a priority weight of 19.9%) are the key sources of waste within the education system, whilst transportation was considered the least important, with a priority weight of 2.3%. The quantitative prioritization of the non-value-added issues provides a framework of Lean implementation that will have the most considerable effect on the quality of teaching and learning in the Brazilian HEI. Sub-criteria of each of the eight waste sources were explored: motion, transportation, inventory, defects, overproduction, waiting, overprocessing, loss of knowledge. This outlined specific examples of the non-value-added issues within each category, thus allowing a framework to be devised, illustrating the key waste sources in the HEI that require optimization.

A comparative study, published by Kemp and Grieve, investigated the difference between online and face to face learning in relation to students’ academic marks and uncovered students’ preferences regarding the teaching environment [

7]. The study found that, in terms of academic marks, there were no significant difference between online and face to face teaching. However, the overall preference of students was face to face teaching, due to the increased level of engagement. The results indicated that, although online learning promoted flexibility and convenience, students valued the increased levels of engagement possible in face to face discussions. Whilst the overall consensus suggested face to face teaching was superior, it was found that different activities resulted in different preferences. The results showed that students preferred completing written activities online, due to the convenience and reduced distraction from peers, whilst also noting that online teaching provides students with more time to think. On the other hand, the majority of students preferred discussion activities to be carried out in a face to face environment, due to students being able to interact more easily, thus improving engagement and learning capabilities.

In order to successfully implement a Lean philosophy into the education system, a thorough analysis of the eight prime wastes is required to define sub-wastes. The definition of sub-wastes within an HEI allows a Lean transformation to occur, as recommendations can be suggested to counter the sub-wastes and reduce the number of non-value-added issues, thereby increasing the efficiency and effectiveness of learning. The implementation of 22 sub-wastes were investigated by Kazancoglu and Ozkan-Ozen in a business school (with the participation of numerous departments) [

8], with the aim of suggesting a multistage model. The application of a multistage model that defines the potential for Lean transformation within the business school includes the use of multicriteria decision making (MCDM) techniques, an evaluation laboratory (DEMATEL) and a fuzzy decision making trial [

8]. The ordered matrix representation of the sub-criteria allows HEIs to evaluate the most effective route for eliminating or minimizing the largest non-value-added issues. Kazancoglu et al. found that the dominant waste sources were repeated tasks, excessive amounts of information and errors leading to communication issues. Consequently, the results of this study correlate to some of the findings in the study written by Klein et al. [

6], who also found that overprocessing (i.e., excessive amount of information) was a key non-value-added issue. This study can be utilized as a reference for the adoption of a Lean philosophy into any HEI with the definition, analysis and categorization of the eight primary wastes and subsequent sub-wastes.

The underdeveloped application of LSS within HEIs has led to confusion regarding its relevance to the education sector, due to the use of manufacturing terminology [

1], which leads to a lack of understanding from senior executives, thus decreasing the motivation to utilize the tools and techniques LSS offers. Without commitment from the leaders of the educational organization, the implementation of LSS will fail, as the process requires clear communication channels and an attitude of continuous improvement. Furthermore, ‘the strategy of achieving Leanness is not clear to many senior executives’ (Mathaisel and Comm, 2000) as a result of a lack of education in relation to the numerous benefits Lean has in the non-manufacturing industries [

9]. The opinions expressed in this study are reflected in another study composed by Waterbury (Waterbury, 2015) that outlined the difficulties of using a Lean approach in higher education, and the consequent lessons learned. Through the investigation of the use of a Lean approach in seven colleges and universities in the USA, Theresa Waterbury found that one college struggled with the scheduling of projects that required the input of multiple departments. This supports Anthony et al.’s conclusion that effective communication channels within the HEI are vital for successful Lean implementation. Moreover, both studies account for the need for motivated leaders that strive for continuous improvement through the implementation of Lean, and are patient with the process. Indeed, Waterbury found that three universities expressed their difficulties with allocating enough time to the Lean program whilst also maintaining their daily responsibilities. A recommendation made in this study to counter this barrier was the adoption of careful and effective planning: ‘adequate planning time decreased the time spent reacting to preventable issues’ [

10]. The reliability of the study written by Waterbury is higher than that of Anthony et al., due to the practical investigation carried out by the former, as opposed to the theoretical research carried out in the latter.

According to Petrusch et al., the adoption rate of Lean thinking within educational institutions in Brazil is very low [

11], despite the country being ranked fifth in regards to the number of publications about the Lean approach by country [

12]. There is also evidence that Lean thinking in HEIs across Brazil, the UK and the USA is not adequately implemented; only the teaching of Lean is being carried out. Moreover, many educational institutions do not adopt continuous improvement processes that create organizational change; rather, they focus on process improvements [

13]. Petrusch et al. found that applied Lean thinking within HEIs has not led to a clear pathway to maintain the philosophy, thus decreasing the chance of continuous improvement. The slow adoption rates of Lean thinking in the education sector may be due to the difficulty of implementation, in comparison to the manufacturing sector, as much work is required to ‘encourage the engagement of all employees’ [

13]. The conclusion of this study states that, in order to successfully implement a Lean philosophy, HEIs are required to pave their ‘own management system to a more holistic application of Lean thinking’ [

13].

Whilst Petrusch et al. express the lack of Lean thinking in HEIs, Alves et al. express the importance of Lean education and the need for its successful application [

14]. The promotion of Lean education is vital for future professionals that need to adopt ‘whole system-thinking, a sustainable conscious and ethical behavior’ in response to the development of the fourth industrial revolution [

14]. The use of a Lean philosophy in education is essential to create competent professionals that consider sustainability and aim for continuous improvement—vital attributes in the age of climate change and the global concerns of impacts arising from industrial activities [

15]. The results of the workshops conducted in this study highlighted that only 10% of participants were familiar with Lean education and only 12% taught Lean principles in educational institutions. This supports Petrusch et al.’s claim that the implementation of Lean thinking in education is very low in general. This study demonstrates that a lack of knowledge in Lean education is the primary reason for the scarcity of its implementation in HEIs, as the majority of participants in the workshop only referenced Lean thinking in relation to the industry and manufacturing sectors.

To summarize, the transfer of Lean thinking from the manufacturing sector to the education sector, in particular to HEIs, has profound effects on the productivity and engagement of students, as well as the efficiency of teaching methodologies and techniques. Lean thinking creates an educational environment that aims for continuous improvement, through the reduction of non-value-added wastes and collaborative, heterogenous learning, as implied by Bhat et al. [

16]. However, the successful introduction of Lean thinking methodologies into HEIs is only effective when the entire organization adopts the idea, as efficient channels of communication are required between departments. This means that the managers of HEIs need to accept Lean thinking as a way to continuously improve the education system, and must see it as a long term investment instead of a ‘phase’. The application of Lean thinking will improve the quality of graduate professionals who can respond to dynamic industrial environments, whilst also engaging with sustainability issues [

14]. Lean thinking methodologies, such as 5S, have the ability to change educational environments that promote organization and waste reduction, which develops student productivity, engagement and satisfaction [

17,

18]. The literature review exposed a void of research focusing on the effect Lean thinking can have on the engagement of students who learn through online and hybrid teaching methods. This research is of particular importance in 2021, due to the closure of schools and HEIs that has led to the majority of students in the UK, and across the world, learning through online and hybrid methods. This study will focus on the identification of non-value-added issues within online, hybrid and face to face teaching methods at the University of Northampton as an example, and will recommend suitable actions to either minimize or prohibit these waste sources.

3. Methodology

The primary aim of this research was to identify the most common non-value-added issues within varying teaching environments, including online, hybrid and face to face. The study focuses on identifying the non-value-added issues that have the greatest effect on the engagement of final year engineering students at the University of Northampton. By comparing the results of online, hybrid and face to face teaching, conclusions can be made based on which non-value-added issues are present in each teaching environment, and how each method can be adapted to improve both the engagement of students and the standard of teaching. In order to highlight the waste sources, a questionnaire was completed by students online. The questionnaire accounted for the non-value-added issues within online, hybrid and face to face teaching, which were ranked from 1 to 5 based on their effect on student engagement (with 1 representing no effect and 5 representing the largest effect). The participants of this study have already experienced face to face, online and hybrid teaching; thus, the results of this study will be reliable and comparable.

In total, the number of respondents amounted to 27 (out of the 38 questionnaires given out). However, a minority (3 out of 27) were incomplete and were removed from the study. The data were extrapolated from each completed questionnaire and placed into a MATLAB script in matrix form. This increased the efficiency of calculating the mean result, element by element, for each non-value-added issue within the three teaching environments. The ‘mean’ function was employed in the MATLAB code to calculate the mean of the matrix’s element by element. The resultant 28 x 3 matrix demonstrated the mean result for the 24 questionnaires for each waste source in online, hybrid and face to face teaching. The resultant matrix was converted into Excel format, and a graphical representation of the results was created, which illustrated the non-value-added issues that had the greatest effect on student engagement in an online, hybrid and face to face teaching–learning environment.

The use of questionnaires in this particular study is an efficient and time focused method of gaining quantitative results that can be interpreted to suit the aim of the study. In addition, the data collection method allows the study to cover numerous non-value-added issues that may account for the lack of engagement in varied teaching–learning environments. This increases the scope of the study, whilst allowing more accurate recommendations to be made. Qualitative data were not taken into account in this study, as numerical analysis was required to uncover the highest mean result of the data, thus enabling recommendations to be made that will have the greatest effect on student engagement within online, hybrid and face to face teaching. The use of a questionnaire for identifying non-value-added issues in this study is advantageous, as it provides first hand experiences from students regarding the effect certain waste sources have on student engagement. Whilst the application of interviews in this area of research can be advantageous to provide specific examples of non-value-added issues, such as the studies carried out by Klein et al. [

6] and Waterbury [

10], the use of questionnaires is suitable for this study as the method is an efficient and simple way to obtain results during a global pandemic.

4. Results

The application of Lean thinking into an educational context at the University of Northampton led to the accumulation of the non-value-added issues that have the greatest negative effect on student engagement within online, hybrid and face to face teaching environments. The assemblage of the results from the collected questionnaires led to the formation of multiple 28 × 3 matrices, indicating each student’s opinion on how each specific waste affects engagement with each teaching method. The mean matrix was calculated element by element on MATLAB to represent the average effect score for each non-value-added issue and each teaching environment. The average matrix is represented in

Table 1. This allows for the easy identification of the waste sources that have the greatest effect on student engagement.

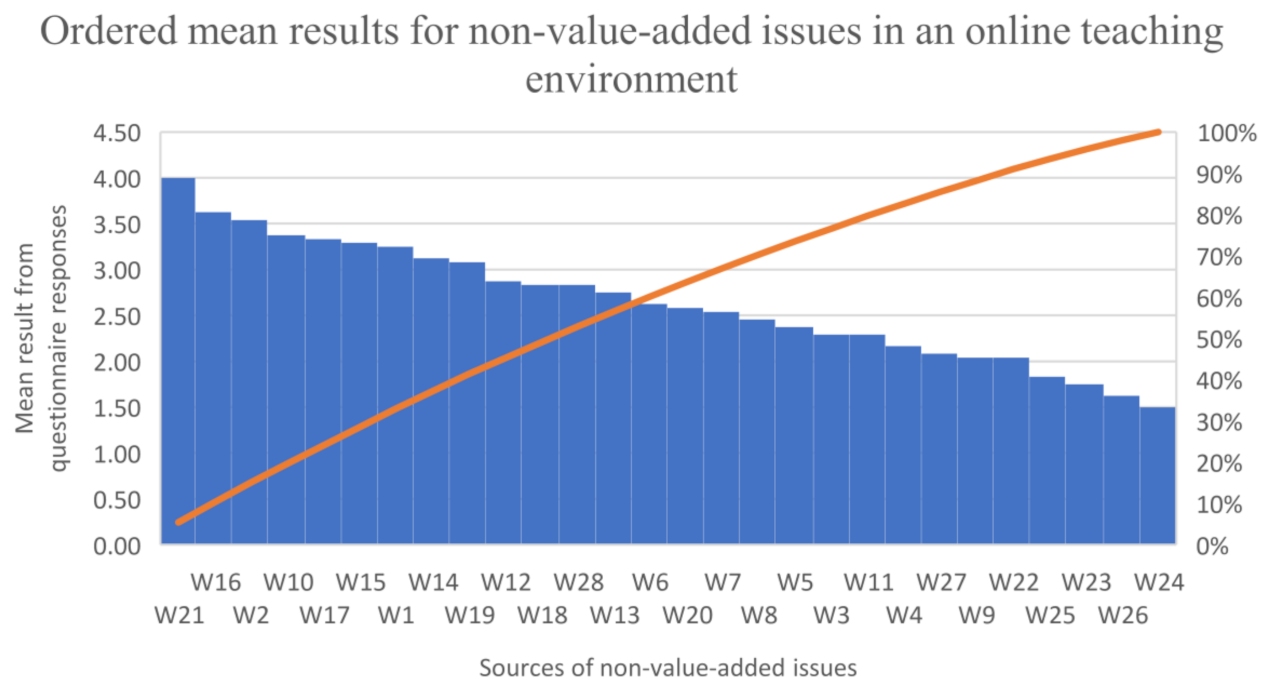

As highlighted in

Figure 1, the results show that the use of online teaching methods has a more profound effect on student engagement on the whole, due to the blue data having a greater mean value in comparison to hybrid and face to face teaching. The mean of means for online is 2.647, whereas the mean of means for hybrid and face to face teaching methods are 2.580 and 2.546, respectively; thus further highlighting the overall negative effect online teaching has on student engagement. Online teaching boasts a maximum mean value of 4.00 (corresponding to ‘unused lab equipment’), whereas the lowest mean value is 1.50 (corresponding to ‘scattered departments across campuses’). The online teaching environment indicates a range of 2.50, whereas the range for hybrid and face to face teaching are 1.00 and 1.54, respectively. This is supported by the varied standard deviations of online, hybrid and face to face teaching environments (0.65, 0.23 and 0.42, respectively).

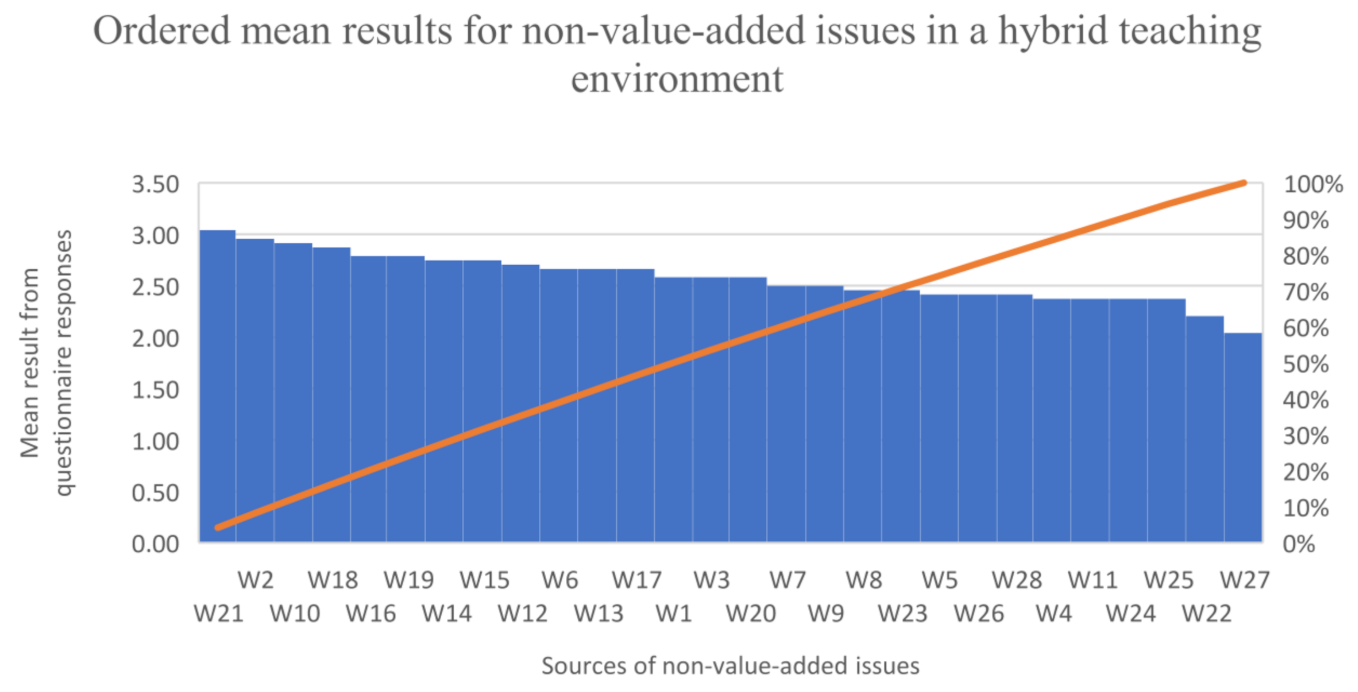

From the mean results (

Figure 2,

Figure 3 and

Figure 4), the top five non-value-added issues from each teaching environment can be determined, thus highlighting the area of each that needs improving through Lean adoption to increase the engagement of students. It was found that, for online and hybrid teaching, the largest waste source that affected student engagement was unused lab equipment (a sub-criterion for inventory waste), whereas the largest waste source for face to face was being late to lectures due to traffic (a sub-criterion to the motion waste). Whilst face to face teaching had no relation to the online and hybrid teaching environments, the top five waste sources for online and hybrid were very similar, as shown in

Table 2. Unused lab equipment, however, is a more significant waste source in online learning than in hybrid learning, due to the mean value being 4.00 for online learning and 3.04 for hybrid learning. This highlights a correlation between hybrid and online learning that can be applied to Lean thinking to increase the engagement of students in both environments simultaneously. The top five non-value-added issues for each teaching environment are described in

Table 2. In relation to the eight traditional waste elements described by the Lean methodology, the most common non-value-added issue that has the greatest effect on student engagement in face to face teaching environments is motion. Three out of the top five priority waste elements for face to face teaching relate to motion. Consequently, it is easier to locate and recommend suitable measures that will have the greatest effect on inhibiting or reducing this type of waste source. This is not the case for both online and hybrid teaching environments. Both hybrid and online teaching environments had a different waste criterion for each of the top five non-value-added issues, thus increasing the difficulty of suggesting suitable recommendations that maximize student engagement. In order to combat this issue, a list will be presented to show the top 10 priority waste sources.

The top 10 priority waste criteria clearly indicate the most notable waste factor for each teaching environment. In regard to face to face teaching, the waste factor that has the most significant effect on student engagement is motion, accounting for a total of 33.33% of the top 10 waste sources. On the other hand, unused talent was the primary non-value-added issue (in relation to student engagement) for hybrid and online teaching environments, boasting overall percentages of 33.33% and 30%, respectively. These results enable recommendations to be made that focus on improving the non-value-added issues stated previously, as well as teaching efficiency and student engagement in each teaching environment.

5. Discussion

The aim of this research was to investigate the effect of differing teaching environments on student engagement at the University of Northampton, and to provide comparisons between the most significant non-value-added issues in each, by applying the Lean methodology. Through the implementation of Lean thinking into an educational context, recommendations can be suggested that may improve both student engagement and teaching efficiency. The results indicate that the employment of an online teaching environment has the largest negative impact on student engagement when compared to hybrid and face to face teaching. The most common non-value-added issues within online and hybrid teaching were unused lab equipment, communication problems and the limited contribution from students in discussion activities, whereas the most common non-value-added issues within face to face teaching were scattered departments across campus, students’ line of sight being blocked and the transition from one lecture to another. In relation to the eight conventional Lean wastes, the most significant factor in face to face teaching was motion. However, for both hybrid and online teaching environments, unused talent was the factor that had the most significant effect on student engagement. These results highlight the key areas where waste sources have the largest impact on student engagement in different teaching environments. Thus, recommendations can be made to improve the teaching environment for students at the University of Northampton.

The conclusion of this research indicates the advantage of using a face to face teaching environment in comparison to hybrid and online methods, due to the results shown in

Figure 1. The engagement of students is lower in an online teaching environment, which can have profound effects on student motivation and their attitudes towards the module content, as was suggested by Mcfarland and Hamilton [

19]. Decreased motivation and attitude in an online environment may severely impact the student’s ability to learn. Thus, Lean thinking can be applied to improve both student motivation and attitudes. However, this study also discovered flaws in face to face teaching that have an effect on student engagement. The largest waste source within face to face teaching is motion, which is a factor that has limited effect within online teaching. The most significant waste sources within face to face teaching have no correlation with the most significant waste sources in online and hybrid teaching, as shown in

Table 3. Although, when compared to online teaching, hybrid teaching demonstrates very similar waste sources that have the greatest impact on student engagement. As a result, further focus can be applied to the improvement of online teaching methods through the employment of Lean thinking.

The literature relating to the comparison of online, face to face and hybrid teaching methods through Lean techniques is limited. Thus, the research carried out in this study is unique and provides first hand experimental data linking Lean thinking to the improvement of teaching environments at the University of Northampton. However, multiple studies outline waste sources in HEIs without specifying the teaching environment. A research article published by Sanahuja expresses the need for continual improvement, aided by a Lean methodology, through the input of students [

4]. In relation to online and hybrid teaching, unused talent was the waste factor that had the largest effect on student engagement, thus supporting the claim that student involvement in lectures develops continual improvement through a Lean approach. The utilization of Kaizen ensures continual improvement in an institution that is constantly adapting alongside continuously changing market conditions [

20].

Whilst the results of this study imply that motion is the largest non-value-added issue in face to face teaching, Klein et al. published a study stating that loss of knowledge is the most significant waste source [

6]. The contradicting results may be due to geographical location, as the HEI studied by Klein et al. was situated in Brazil, where the education system may be somehow different to the education system in the UK. This may lead to the prioritization of waste factors other than those that are more relevant in the UK. Furthermore, Klein et al. studied the waste sources on a satellite campus, which are smaller and less populated than the main campus, meaning motion will not be as much of an issue as it is at the University of Northampton.

The results of this study correlate with the findings published by Kemp and Grieve [

7], who stated that online learning prohibited the level of engagement required for discussions. This conclusion links with the predominant waste factor in online learning being unused talent found in this research study, where limited contribution from students in discussion activities boasted a mean value of 3.63, indicating a significant effect on student engagement. Furthermore, a key waste factor found in this study for face to face teaching was the frequent distraction of peers, which represented a mean value of 2.96. Kemp and Grieve discovered that students preferred completing written activities in an online setting, due to the reduced distraction from peers. This correlation suggests that the level of student engagement can be tailored to fit the activity at hand, with predominant discussion activities being held in a face to face environment, and written activities being completed online. A teaching environment that designates key activities to specific environments may have a profound effect on students’ engagement, and could lead to more productive students, thus limiting waste sources. The comparison of this study and the study published by Kemp and Grieve can be seen as reliable, despite this study focusing on quantitative results and Kemp and Grieve’s focus on qualitative results. Both studies include students that have experienced both online and face to face teaching. Thus, the results provide first hand experiences of factors that affect student engagement.

6. Recommendations

By analysing and interpreting the results from the questionnaires, suitable recommendations can be suggested to increase student engagement and productivity by reducing or inhibiting the top priority waste sources through Lean thinking. Such recommendations may be implemented in the varying teaching environments employed by HEIs to increase the standard of education provided. Due to the varying top priority waste sources found in relation to online, hybrid and face to face teaching environments, differing recommendations must be made to accommodate for the top priority wastes in each environment.

6.1. Online Teaching–Learning Environment

Regarding the online teaching–learning environment, the most significant waste factor was found to be unused talent, which included sub-criteria examples such as ‘limited contribution from students in discussion activities’ and ‘limited time for research activities’. The former can be improved through the introduction of interactive activities during the online lectures, as opposed to students solely listening to the teacher. Such interactive activities may include students taking turns, on a weekly basis, to introduce a concept that relates to the planned content. Whilst this will elevate the interaction between the students and the teacher, it also remedies the issue regarding the limited time for research activities. Collaborative learning may also improve the engagement levels of students during online classes. Collaborative learning could be implemented in online teaching environments through the employment of breakout rooms, which enable students to converse and focus on a problem/question as a team. The emphasis on feedback from the breakout rooms will place the required pressure on the students to collaborate and engage in the task at hand. Through the application of team based, collaborative activities in an online setting, students increase their ‘cognitive interest and positive attitude towards the whole learning process,’ as suggested by Sumtsova [

21].

Other non-value-added issues within online teaching include unused lab equipment, which is particularly relevant to engineering students due to the hands-on approach used in numerous modules. A lack of practical engineering knowledge may have profound effects on future graduate students in the workplace. However, this waste source can be minimised through the introduction of live online lab sessions carried out by a technician. Practical apparatus, such as Arduino packages and soldering equipment, could be handed out to students, resulting in greater engagement during online lab sessions as they can follow along. The added expense for the university providing the necessary equipment to students may be compensated by the reduced overhead costs at the university, such as lighting and heating bills. ‘Communication issues’ was also a high priority waste source in online teaching, which may account for the lack of feedback during lecture content in relation to students’ questions. A key problem online teaching presents for the lecturer is the balancing act between delivering the module content and ensuring all questions are answered, although this is not always possible. A recommendation to overcome this non-value-added issue may be to employ a dual screen system that the lecturer uses, with one screen displaying the lecture content and the other displaying the chat box. This will increase the likelihood of student questions being answered during the lecture instead of waiting to the end.

Automation and the use of smart apps for some activities (such as the registration service during online lectures) would significantly reduce wasted time at the start of lectures. Students join the lecture at different times; thus, the attendance code needs to be re-emphasised at the start of the lecture, which both wastes time and stalls the commencement of the lecture. By employing automated software/apps that read a student’s login credentials and automatically logs their attendance when they join (or leave) the virtual session, the streamlining of online lectures will be developed. Consequently, students will have more time to engage in lecture content as opposed to waiting on attendance codes.

6.2. Face to Face Teaching–Learning Environment

With reference to face to face teaching, the primary non-value-added issue that affected student engagement the most was motion. Within motion, the most significant sub-criteria were ‘being late to lectures due to traffic’ and ‘students’ line of sight being obstructed. Although the former is an external factor that cannot be controlled within the university, the latter can be inhibited through the utilization of lecture halls with graded seating arrangements, thus maximising students’ vision towards the lecturer and lecture content. Due to the limited capacity of lecture halls at some HEIs, prioritising lectures/modules that are based solely on theoretical content is key, whilst allocating normal lecture rooms to collaborative modules and lectures that require interaction.

‘Scattered departments across campus’ and ‘transition from one lecture to another’ were key non-value-added issues within face to face teaching that led to wasted time between lectures. In order to minimise the transition from one lecture to another, and thus lower the significance of scattered departments across campus, an AI timetabling software could be deployed at the institution. This would enable departments to schedule lectures in a more time-efficient layout, leading to different lectures taking place within a close proximity of each other. As a result, less time will be wasted by the movement of students from one lecture to another. The advantage of using timetabling software over manual scheduling is that the reliability of the schedule is increased, due to the lack of human involvement; thus, there is a lower chance of human error. Furthermore, the software may have the ability to rank various scheduling scenarios to come to the best conclusion that suits all modules. This process would be very time consuming if carried out manually, as it is dealing with large quantities of data and multi-objective optimizations must be considered. Introducing an approach to minimize the movement of students between lectures will reduce motion waste significantly.

6.3. Hybrid Teaching–Learning Environment

Whilst the hybrid teaching environment accommodates for all student preferences, waste sources are present that significantly affect student engagement. The majority of non-value-added issues within online teaching correlate with hybrid teaching, as shown in the results section. Thus, the recommendations suggested above are applicable to both teaching–learning environments. However, hybrid teaching presents differing cases within each waste source. For example, ‘communication problems’ is a key waste in hybrid teaching, which originates from the lack of interaction between the lecturer and online and face to face students. This presents a huge task for the lecturer to provide engaging activities for both online and face to face students, and leads to questions from online students being unanswered, due to the primary focus on face to face students. This non-value-added issue can be inhibited through the implementation of a moderator who focuses on answering questions from online students and provides further support to the lecturer and students. Furthermore, the use of a hybrid teaching environment is an underdeveloped method and has few long-term implementations in universities, hence further training may be required for the lecturer to develop the necessary skills needed to deliver lecture content in multiple teaching–learning environments simultaneously (i.e., online and face to face).

6.4. Limitations and Further Study

Multiple limitation factors within this study were encountered that may inhibit the reliability and accuracy of the results and interpretations. The sample size was relatively small in this study and, therefore, may not present an accurate conclusion that represents all engineering students at HEIs. Moreover, as the application of Lean in HE and the hybrid learning–teaching environment is relatively new, there is limited research in this field. As a result, it was difficult to provide an extensive comparative analysis of the results found in this study with those in the other literature in order to increase the reliability of the study. The use of subjective data may also inhibit the reliability of the study, as the questionnaires can be manipulated by personal opinion. The use of objective data that utilizes exam results, student attendance and assignment grades could pose a more accurate study that considers these factors and relates them to student engagement in online, hybrid and face to face settings.

In the future, this study could be developed through the broadening of the sample size to students from other subject areas and other HEIs to gain a more in-depth analysis of which non-value-added issues are present. This will provide more reliable results due to the increased sample size, and will allow further and more accurate recommendations to be made.

6.5. Conclusions

To conclude, the aim of this study was to evaluate the sources of non-value-added issues within online, hybrid and face to face teaching environments that affected student engagement through the application of a Lean methodology, and to provide informed and practical recommendations that could be used to inhibit or reduce the waste sources found in the research. The results implied that online teaching resulted in the greatest sources of waste that significantly affected student engagement when compared to hybrid and face to face teaching. The most significant Lean waste within both online and hybrid teaching environments was found to be unused talent, whereas the predominant Lean waste within face to face teaching was motion. Through the identification of Lean waste sources in online, hybrid and face to face teaching, practical recommendations were made to improve student engagement and provide a more efficient learning experience at HEIs. The results of this study contribute to the limited literature focusing on the comparative analysis of differing teaching environments with respect to Lean thinking implementation. Overall, the practical recommendations outlined in this study do have the ability to reduce the frequency of waste sources in online, hybrid and face to face teaching, consequently leading to greater student engagement and improving the standard of the teaching–learning environment.