Abstract

The article elaborates upon a successful model of postgraduate studies on lean manufacturing. The subject of the research was nine editions of the Kaizen Academy postgraduate studies organized by the Warsaw University of Technology and the Kaizen Institute in the years 2009–2018, that still enjoys interest in the market. A detailed qualitative analysis of this case, followed by a comparative analysis with other post-graduate programs of this type on the national, European, and global level should make it possible to find what is necessary to launch and actively operate for a long time in the (considerably competitive) market of qualification raising programs related to Lean Management (critical success factors). The study has also identified the differences between a successful program, analyzed in detail, and other available programs described in the literature and on the Internet. This has been achieved through a structured analysis of thirty-nine postgraduate programs identified by querying scientific databases and the Google Internet search engine. Best practices and models of postgraduate education on Lean Management have been discussed, and the thirty-nine programs comprising the identified sample have been compared. Considering the very general level of the data available in terms of the organization of postgraduate programs, it has also been assessed if they follow constructivism and experiential learning paradigms. This has been achieved by including the industrial days/visit indicator in the comparison. Given its high value, it has been identified as a success factor of the postgraduate curriculum on Lean Management.

1. Introduction

1.1. Context and Main Purpose of the Study

- Lifelong Learning for Industry

Continuous improvement of employees’ qualifications is one of the most important factors affecting the competitiveness of the economy. What employees have at their disposal is a number of mechanisms enabling them to acquire new knowledge, including:

- Training related to employee onboarding at the workplace;

- training organized by enterprises;

- training organized by external entities;

- engineer’s, master’s, and doctoral studies.

- Postgraduate Studies

Postgraduate studies are an important element of the educational system, aimed at raising qualifications. First of all, they are dedicated to people who already have some professional experience. Students of such studies expect transfer of practical know-how in a narrow field of their choice, knowledge that they will be able to use in practice at their current or future work.

The Faculty of Production Engineering of the Warsaw University of Technology has extensive experience in the implementation of post-graduate studies and programs conducted in response to the needs of the industry. Among these programs, Kaizen Academy stands out as an exceptional case. Typically, the “life cycle” of such programs spans 3–4 editions. After nine editions, Kaizen Academy still enjoys interest in the market. A detailed analysis of this case, followed by a comparative analysis with other Polish post-graduate programs and a comparison with other foreign programs of this type, should make it possible to answer the following questions:

- What is necessary to launch and actively operate for a long time in the (considerably competitive) market of qualification raising programs related to Lean Management?

- What are the key success factors for such programs?

The purpose of this paper is to provide a case study of Kaizen Academy and to perform a qualitative comparative analysis with other similar postgraduate programs. The study was additionally supplemented with a comparison with the programs implemented by selected foreign entities. As part of this study, the authors have intended to answer the following questions:

- What other factors should be considered in addition to the program (content)?

- How do they (other factors) affect what is referred to as “market success” of the program?

- Lean Manufacturing/Lean Management

Lean manufacturing is a well-established philosophy aimed at improving an organization’s processes. The lean manufacturing paradigms and toolset were also widely adopted in other industries and services under the name of Lean Management (LM). The spectrum of lean techniques is broad. The core of the LM concept comprises the idea of value, value stream, and identification and elimination of all waste occurring in processes. Waste is everything that does not lead to the creation of value for customers (internal or external). There are seven types of waste which Ohno [1] defined when describing the Toyota Production System:

- Transportation;

- inventory;

- motion;

- waiting;

- overproduction;

- over-processing, and

- defects.

Several Massachusetts Institute of Technology (MIT) research teams analyzed, among other problems, the sources of Japanese carmakers’ competitive advantage over the American ones by focusing on the analysis and comparison of production systems [2,3,4]. Five generic rules/principles which describe lean thinking were discussed, i.e., value, value stream, flow, pull, and perfection. All processes can be characterized by three types of sub-processes or activities, i.e., value added, required but non-value added, and waste (non-value added). Later publications placed particular emphasis on people, from the perspective of both rules/principles [5] and waste—unused talent.

The LM toolset includes techniques and methods of different purposes [6], i.e.,:

- Identification and analysis of waste, e.g., causal diagrams, Value Stream Mapping (VSM);

- improvements implementation, e.g., Single Minute Exchange of Die (SMED), poka-yoke;

- process monitoring, e.g., andon, supermarket.

Methods and tools may have different purposes. Many of them are utilized not only in the LM concept, but also in other managerial approaches focused on process improvement.

Lean manufacturing and Lean Management are embodied in almost any managerial and industrial engineering curriculum. It is also widely used in management related topics in other engineering curricula. The topic considered in this study may be of interest to educators delivering postgraduate courses on Lean Management and related subjects, but also tutoring classes on similar issues under bachelor’s and master’s curricula. Therefore, the paper could also be interesting to individuals and employers considering training in this area.

1.2. State of the Art

The literature on the subject is dominated by publications concerning the methods and techniques used in the Lean and Kaizen teaching process, extending from conventional teaching methods to practical classes. The methods used most commonly are the following: Auditorium classes, guest speakers, simulations, games, case study analyses, study visits to enterprises, and inter-views with experts [7,8,9,10]. These methods are constantly being developed. There are also new methods emerging, such as problem-based learning [11,12].

In the literature review, a number of publications addressing the impact of the techniques used in study programs on the quality of teaching were identified [13,14,15,16]. Suarez-Barraza and Rodriguez-Gonzalez [15] analyzed the possibility of using the Kaizen approach while implementing the MBA (Master of Business Administration) program at a Mexican business school. They imply that using the Kaizen approach based on the Plan-Do-Check-Act (PDCA) cycle enables better learning results among students, measured by test results as well the outcomes of the dissertations prepared and defended by students in the final stage of their respective educational programs. Murman et al. [8] have presented a program developed by a consortium of 32 universities (US and UK), enterprises, and state administration entities. The program was dedicated to people with professional experience and constituted part of a large research program on the development and implementation of Lean techniques in the industry, known as LAI (Lean Advancement Initiative), coordinated by MIT.

The literature review revealed no results of curriculum research analyzed in a broader context of the organization of studies, going beyond teaching methods.

Postgraduate studies in their nature are dedicated to students with practical experience, who want to extend their knowledge in a specific field. Therefore, in such types of education, this implies application of the constructivist paradigm derived from Piaget’s [17] theory of cognitive development, which is widely adopted in higher education [18,19]. Given their nature, higher education in general, and specifically postgraduate studies, also require educational approaches like experiential learning and action learning, as traditional forms of teaching are characterized by low efficiency (“I hear and I forget. I see and I remember. I do and I understand” is a passage attributed to Confucius). This is particularly true for the topic under consideration, i.e., Lean Management, where the toolset is very broad, and not always are there strict application procedures. Managerial and industrial problems can usually be solved using diverse tools and approaches. Even application of the same tool may differ from case to case, and may also depend on the team involved. The common model of transmission of knowledge, where the existing fixed ideas are passed as ready-made patterns (often not for discussion with the learner), is no longer efficient, especially for studies where multiple approaches to the same problem are available.

Nowadays, the role of production and organizational learning (dating back to the 1920s and 1930s [20,21]) is of great importance, so education and training is a serious topic of interest in managerial sciences where postgraduate education on Lean Management is delivered. It is critical for postgraduate education to deliver specific knowledge which could be rapidly assimilated and applied in practice. Experiential learning has adopted the constructivist paradigm, assuming that social knowledge (created in the social environment, e.g., in a group of learners on the shop floor) should be created to enrich personal knowledge of a learner. Therefore, knowledge is created as a result of experience, as discussed by Dewey in his theory of experience, and gained by educators at higher education level [22]. Among the experiential learning models, Kolb’s [23] is the most cited one. It includes four cyclic and iterative stages (steps):

- Gaining concrete experience (doing some work);

- making observations on the job and drawing conclusions on the basis of past experience;

- assimilating observations and conclusions that become part of a new way of understanding and interpreting the significance (importance) of the experiments conducted—the work performed; thereby, individual hidden knowledge is being created;

- transforming this knowledge into “operational knowledge”, used in the implementation of further work and in new research works.

Similarly, action learning introduced by [24] makes it possible to significantly increase learning quality. This approach is widespread and very effective, not only in adult education, but also in a business community [25,26].

On the contrary, behavioral theories of teaching and learning are not applicable to postgraduate studies on Lean Management because the role of the learner’s subjective (personal) experience is ignored, while postgraduate students are often experienced managers. Therefore, postgraduate studies on management and engineering are characterized by a dominant role of the experiential learning approach [27,28]. This has become especially important considering the increasing role of blended and distant learning driven in recent months by the COVID-19 pandemic [29].

2. Materials and Methods

2.1. Procedure and Sample

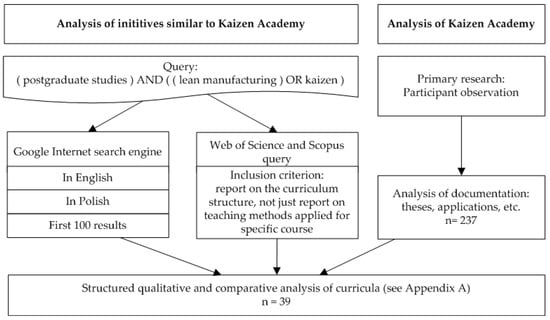

The research process is summarized and illustrated in Figure 1.

Figure 1.

Research procedure applied in the study.

The case study on which this paper is based was conducted in 2019, covering 9 editions of the Kaizen Academy postgraduate course organized by the Warsaw University of Technology (Faculty of Production Engineering) and the Kaizen Institute in the years 2009–2018. The total number of students forming the sample was 237, representing all program editions. The prerequisite for completing the post-graduate course with a certificate is to write and defend the final thesis. The course regulations admit that the final thesis can be prepared by teams of two.

Over the selected period of 2009–2018, all the final dissertations, application documents, and exam files were collected and archived. This constituted the database being considered during the presented study. The documents were used to obtain empirical data. The archived documentation was analyzed for each student to obtain the empirical data on the toolset used (dissertation), the industry of one’s employment (application file), one’s experience (application file), and the studying period (exam files).

Kaizen Academy is a two-semester post-graduate course which consists of 11 two-day sessions, comprising 235 h of classes in total (9 h per session day, on average), including a diploma seminar and an OH&S seminar. The Kaizen Academy lecturers are recruited from among consultants, practitioners, and academics. Its thematic scope focuses on Kaizen perceived as a concept of operational activity management, and it covers the foundations of many modern management systems, such as Just-in-Time (JiT), Lean Management, Total Quality Management, or Total Productive Maintenance. The range of subjects addressed during the studies includes problems related to material flow optimization, shortening of production cycles, inventory minimization, improvement of individual and team work, resource use streamlining, customer orientation, process approach, waste elimination, quality increase and continuous improvement, as well as team leadership and motivation. During the classes, numerous examples representing the area of manufacturing and service companies are used. The practical dimension of the course comprises preparation of the final thesis, being a case study of the improvement implemented in the student’s business. Each group consists of 16–18 people (in cases of a particularly large number of applicants, two groups were organized), and candidates are required to have completed at least one-year professional traineeship. The study was of a pilot nature, and its aim was to define basic statistics describing the sample, and on such a basis, to formulate working hypotheses for further statistical testing.

At the same time, with the study on Kaizen Academy itself, the research of similar initiatives was conducted, considering cases from all over the world. The goal of this research was to find other models of postgraduate studies related to Lean Manufacturing (and similar), which was assumed to constitute the basis for comparative analysis. For this purpose, the Web of Science database was queried for (postgraduate studies) AND ((lean manufacturing) OR kaizen). Three papers were included in further investigation. The excluded papers elaborated on teaching methods appropriate for teaching specific lean techniques, but did not describe the structure of the relevant curricula at any level. The same query was used in the Google web internet search engine. The first 100 results were analyzed, and ultimately 38 initiatives were found and included in further investigation. Finally, thirty-nine initiatives were compared, including 2 cases from the European Union, 3 from the UK, 1 case from the US, and 1 case from Australia.

Consequently, the goal of this article is of two-fold nature:

- Discussing best practices and models of postgraduate education on Lean Manufacturing; and

- comparing the Kaizen Academy initiative with other initiatives identified, and discussing some effectiveness characteristics of Kaizen Academy from the perspective of teaching results.

2.2. Data Collection Tools and Instruments

Both primary and secondary research methods were used during the study. The primary research component for the data collection was the participant observation conducted by the authors who were actively involved in all aspects of the postgraduate courses surveyed, and this primarily involved the following:

- Administration work: (1) Performed by the postgraduate course manager (including recruitment in particular), (2) performed by the postgraduate course secretary (including recruitment in particular);

- educational activity: (1) Under regular classes throughout a semester, including lectures, practical classes (projects, workshops, labs, exercises) as well as examination and verification of the learning progress, (2) under preparation of final (graduation) theses, in the supervisor’s role, (3) at final exams and the defense of the final (graduation) theses;

- participation in postgraduate courses in the student’s role.

The data concerning the Kaizen Academy case were collected as archived files of the full documentation required from students. The documentation analysis, i.e., the analysis of the graduation theses, final exams, and recruitment documents was of secondary nature. Such an approach was assumed to enable gathering information about the basic characteristics of the businesses analyzed in the final theses, as well as the characteristics of the Lean Manufacturing/Kaizen techniques, tools, and methods implemented while preparing the theses.

For the comparative analysis of other cases, a questionnaire was designed and applied to search and obtain the relevant data. Each website representing the sample identified in Section 2.1 was examined to find course characteristics considered by prospective students as the decision-making criteria. Those criteria were defined by way of ten expert interviews, where the latter included one former student, two postgraduate course administrators, two postgraduate course managers, and four teachers. The programs analyzed in the study have been summarized in the Table 1 below.

Table 1.

Summary of the programs analyzed.

Additional data included (Appendix A):

- Course imprint: Course name, educational organization’s name, city, country;

- course duration measured in the number of meetings, hours, semesters;

- practical dimension of the course measured in the number of industrial visits and industrial days; and

- course reputation and resulting prerequisites as proofs of the knowledge gained, described by the number and type of issued certificates.

2.3. Data Analysis

The data were analyzed qualitatively and quantitatively. The questionnaire for the comparative analysis (Appendix A) of the sample of thirty-nine initiatives mentioned in Section 2.2 was brainstormed by five experts in order to find the success factors of Kaizen Academy and discussed in depth.

Using the Kaizen Academy data, a number of basic quantitative analyses were performed. Individual types of the Lean Management methods/tools used by the students, particularly in the dissertations they prepared at the end of the program, were analyzed, and so was the popularity of specific Lean Management tools in individual years. Additionally, dependencies were analyzed between the program organization and the percentage of students who had completed the program (obtained a certificate or certificates). Since a data sample enabling statistical analyzes could not be obtained, the use of more advanced statistical analyzes was abandoned.

3. Results

3.1. Postgraduate Courses on Lean Manufacturing (and Related)

There are papers which concern teaching of Lean Manufacturing. However, there have only been a few attempts made to identify the specifics of postgraduate courses, as presented to the international scientific audience. Few papers have discussed teaching of Lean Manufacturing on the postgraduate academic level. Tortorella and Cauchick-Miguel [16,30] as well as Tortorella et al. [31] have discussed integration of two teaching approaches to enhance the Lean Manufacturing (LM) learning at postgraduate courses and to verify their effectiveness by comparing students’ performance and learning preferences. Their studies are focused on teaching effectiveness based on problem-based learning incorporated into traditional approaches. The idea of using problem-based learning, experiential learning, or related approaches, however, seems logical at the first glance. Tortorella and Cauchick-Miguel [16,30] as well as Tortorella et al. [31] have proved that it really is effective when applied to teaching LM, and that problem-based learning (PBL) may be an effective complementary method for LM learning. Their papers have also discussed associations between teaching methods and learning styles. However, the studies in question address the application of teaching approaches to specific Lean Management postgraduate courses, but they lack any details of the entire academic course model.

Selected universities from Poland were analyzed in consideration of how they delivered postgraduate courses on Lean Management. This analysis was supplemented with an analysis of selected courses from the UK, USA, EU, and Australia (see Appendix A).

An analysis of the relevant programs implies that participants of the postgraduate courses attach great importance to practical know-how and particularly to learning new tools which they could use in their business environment. Such courses are usually dedicated to specific methodologists (Lean, Kaizen, Six Sigma). An important element of postgraduate studies is the possibility of obtaining a diploma that is recognized in the business environment, besides the university graduation diploma itself.

3.2. Model of the Kaizen Academy Postgraduate Studies—Increasing Managerial Competencies through Practice

Managers know that in order to raise their companies to the world class, they need to master the art of process modeling and improvement. The Kaizen philosophy and methodology, which originated in Japan, has been successfully applied for continuous improvement in numerous Polish companies for many years. The process of continuous improvement by the small steps’ method leads to positive outcomes very quickly. Using simple means, without major investments, efficiency can be boosted in a short time. The effects of the improvement process will be increased efficiency of employees, machines, and equipment, material flow optimization, shortened lead times, stock minimization, greater customer and employee satisfaction, and consequently also culture transformation of the entire business.

Achieving these objectives is only possible through structured and methodological handling of all processes, and by making sure that employees are ready to participate in the never-ending process of continuous improvement. The basis for success is defining transparent goals for the company, establishing a clear operating concept, and then consistently implementing them in practice. In order to succeed in this effort, competent managers are needed to develop and then support these processes. This creates a need for new managerial qualifications.

Investment in knowledge is the best possible one. Every manager knows this. On account of the incredible development of new technologies and rapid changes taking place in the environment, the training of people responsible for the continuous improvement process has become particularly important. The ever-changing requirements make ongoing training necessary. What the continuous improvement process requires in particular is that the knowledge of process managers is continuously extended. The gist of the problem is that different schools and institutions usually offer theoretical knowledge only, while the market needs experienced practitioners almost instantly. There is no time to experiment in your own business. The process of education must proceed in parallel to the practice.

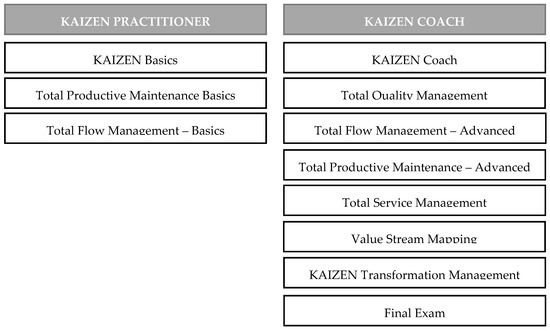

This need provided the grounds for the decision to use the Certified Kaizen College Program, developed in the first decade of the 21st century at the Kaizen Institute, as the subject matter backbone of the postgraduate courses organized by the Faculty of Production Engineering of the Warsaw University of Technology in partnership with Kaizen Institute Poland (Figure 2).

Figure 2.

Structure of the Kaizen Academy Program.

The Kaizen Academy Program is totally dependent on the practical requirements of the businesses represented by the students, or the practical requirements of the students themselves. It stands out as being oriented towards achieving a quick return on investment by the students/managers trained in this mode in the form of almost instantaneous transition of the methods learnt into the practice of production, or into another sphere. The minimum objective is to achieve savings corresponding to the training costs actually incurred. The Kaizen Academy program concludes with implementation tasks preceded by knowledge tests following each of the periodical course meeting. Every participant/student of the Kaizen Academy course is obliged to present their supervisor with a project based on the knowledge acquired through the course along with a statement of calculated savings and—once they have been approved—implement the project in the company. The implementation is monitored and consulted by the Kaizen Academy lecturers, providing the grounds for the course completion.

The Kaizen Academy program has been developed by practitioners for practitioners. The lecturers/practitioners tutoring the classes transfer the knowledge derived from their professional experience to the students, thus enhancing the teaching outcome through continuous exercises based on practical real-life examples. Presentations of managers invited from partner companies and practical study visits to a chosen business complement the course curriculum. Being oriented towards real processes, the course guarantees optimal knowledge transfer.

Such a large dosage of knowledge enhancing the students’ practical skills is supplemented with knowledge representing the area of methodological and social competences.

The structure of the Kaizen Academy program is based on three levels of competence building. The first practical competence level allows students to learn methods and techniques that come in handy when process flow is to be improved. Students become capable of using the qualifications they have acquired in a practical way in their respective businesses to achieve initial measurable effects. This level comprises three subjects:

- KAIZEN Basics. Students learn the origin, the principles, and the philosophy of Kaizen/Lean. Their waste awareness is sharpened through exercises both on site and under factory conditions. They are taught methods enabling them to systematically eliminate waste.

- Total Productive Maintenance Basics. Students learn the goals and objectives, as well as the structure of the TPM system, the major waste types of TPM, as well as the methods of autonomous maintenance. Having acquired this knowledge, the students can successfully implement TPM in their respective companies using Kaizen measures to eliminate disruptions in production and to understand the necessity of a solid data collection system to track and combat further disruptions (visual management).

- Total Flow Management Basics. Having completed the seminar, the students understand the goals and methods of the Just-in-Time philosophy. They learn how to analyze and design processes systematically. The newly learned methods enable them to adapt production to changing customer requirements and move toward the vision of an “inventory-free factory”.

The second competence level, i.e., the methodological one, turns a practitioner into a coach capable of taking over the role of a trainer in their business and transferring the freshly acquired knowledge on the methods and techniques of process improvement to others. They can also lead teams and conduct workshops for team-based problem solving. This level covers subjects such the following:

- KAIZEN Coach. Having attended the seminar, students are able to recognize the importance of education and training when implementing changes. Students learn how to manage teams targeted to improve process methods and techniques. They can also elaborate upon and implement changes capable of improving training and workshops.

- Total Quality Management (TQM). TQM seminars introduce students to comprehensive quality management. Special emphasis during seminars is put on the practical application of TQM tools. Thanks to a multi-stage game simulating production process, students have the opportunity to independently deploy individual TQM tools in the production process. The main assumption behind the seminar is the conviction of the role performed by an operational employee in building product quality.

- Total Flow Management Advanced. The seminar is intended to expand students’ knowledge on the issues related to optimization of material and information flow on both a production plant and a global scale, including a number of tools related to external logistics and flow management throughout the entire supply chain.

- Total Productive Maintenance Advanced. Students learn and practice further Kaizen/TPM®/Lean tools and methods to systematically reduce or completely eliminate loss and/or waste. Participants learn how TPM® and the zero-line principle work, and which steps are necessary to eliminate machine stops and reduce set times.

- Total Service Management. In the advanced seminar, the Kaizen methods previously learned are applied for process optimization in the office and service area. Students learn how to visualize and optimize processes, as well as how targets set for individual employees are derived from superordinate agreed targets, and develop skill profiles based on team boards.

- Value Stream Mapping. The seminar applies practical measures to teach how value stream mapping works and how to make business processes more transparent. Students learn to map the material and information flow in the company, to analyze key data, to identify potential, as well as to guide the manufacturing process from the current state to the target state.

- Kaizen Transformation Management. Students learn the Kaizen Management System. They are consequently able to provide thorough diagnostics, and to handle strategy development and implementation planning for a successful change process. Students successfully learn the methods and steps to implement Lean and change processes throughout an organization.

The third level of social competence goes beyond the basic scope of the course the academy offers, allowing students to claim the role of an independent expert in the area of process improvement and management, to coordinate all activities in this area, and to take responsibility for implementation of the Kaizen culture in the company. They are being prepared to independently stimulate and supervise the company improvement process on multiple levels. Graduates of the Kaizen Academy are privileged to benefit from additional workshops organized by the academy’s content partner and supplement their competences with whatever they are missing.

What makes the Kaizen Academy courses so unique is that the entire curriculum is basically covered on the ‘gemba’, i.e., on the location where the real value is created. The partner companies of Kaizen Institute Poland not only employ the Kaizen Academy graduates willingly, but it is also thanks to them that the training content is based on real-life examples from their everyday practice. There is no better way to learn than through practice. The knowledge acquired directly on the ‘gemba’ is passed on to students by practitioners representing the partner companies, and the teaching outcome is enhanced by lecturers/consultants based on their extensive international experience and best benchmarking examples. The course’s orientation towards real processes, complemented with new high-quality training materials, guarantees optimal knowledge transfer, which improves not only the practical competences of managers, but also their methodological and social competences.

Upon completion of the course, besides the prestigious graduation certificate issued by the Warsaw University of Technology, the Kaizen Academy graduates also receive applicable international certificates confirming their substantive competences in the field of Kaizen.

3.3. Insights from Kaizen Academy 2009–2018

The basic characteristics of the sample subject to the survey have been provided in Table 2.

Table 2.

Basic characteristics of the sample and exam/defense passing rates in a yearly breakdown.

The average number of implemented tools was 1.96 for large businesses and 1.83 for the medium-size ones. No major differences resulting from the ownership form and the capital type (Polish, foreign) were observed. What should be stressed is that the students attending the courses were predominantly representatives of large or medium-size manufacturing companies. Very rarely did they represent small enterprises and service companies.

A total of 237 cases were studied, out of which 181 were completed with implementations documented in the final theses defended. Ca. 70% of them represented large companies, 24% were medium-size ones, and small enterprises accounted for 6%. Domestic capital companies represented 48% of the population surveyed, while companies with foreign capital accounted for 52%. Privately-owned companies constituted 93% of the population surveyed, while state-owned companies—7%. More than 62% of the implementations concerned production and production-related areas (e.g., technology department, service and maintenance, workshop, warehouse of finished products, supplies, logistics, etc.). Among other areas of activity, (1) sales and commerce as well as (2) administration and accounting (both categories having no link with implementation in production) were represented by 5% of implementations each. Similarly, ca. 5% of the implementations pertained to the entire organization. Other implementations were performed in specific areas of activity of individual businesses, e.g., processing of requests (customer enquiries).

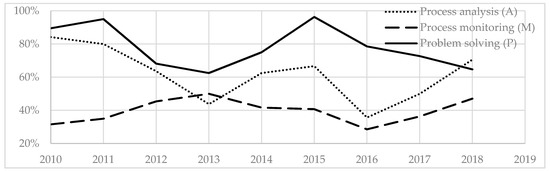

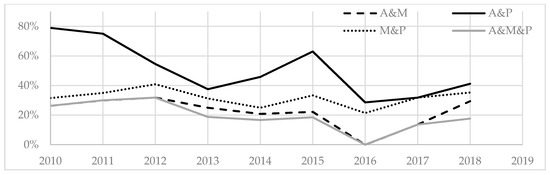

Based on the analysis of the above charts, it can be concluded that the most popular implementation projects among those successfully deployed were the ones with a dominant role of problem-solving tools (Figure 3 and Figure 4). They represented by far the highest percentage of cases. Additionally, this highlights the practical dimension of the final theses prepared by the course students. It should be noted that, according to the course assumptions, it would be desirable to use different types of tools within the framework of a single thesis (process analysis, process monitoring, and problem solving). What should also be considered as a positive phenomenon is the upward trend observed in terms of the use of the process monitoring tools. This may prove the growing importance of increasing the effectiveness of business processes.

Figure 3.

Types of tools according to groups (analysis, monitoring, problem solving) by year and trends (part 1).

Figure 4.

Types of tools according to groups (analysis, monitoring, problem solving) by year and trends (part 2).

One should also note that, in successive course editions, more emphasis was placed on an increasingly detailed presentation of the use of individual tools, and hence the smaller number of tools used in 2016 and 2018 compared to 2010, as depicted in the graph (Figure 3, Figure 4, Figure 5, Figure 6 and Figure 7). To a certain extent, this was because the requirements imposed on the students by their final thesis supervisors were more precise.

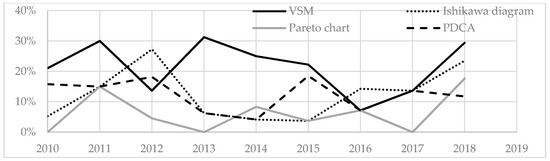

Figure 5.

Selected problem analyzing tools according to implementation year.

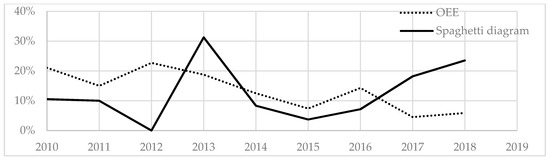

Figure 6.

Selected process monitoring tools according to implementation year.

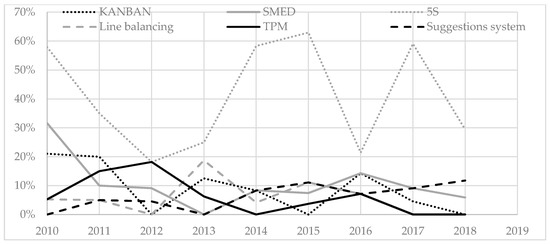

Figure 7.

Selected problem-solving tools used according to implementation year.

The predominant process monitoring tools were the Overall Equipment Effectiveness (OEE), typically related to the implementation of TPM components, and spaghetti diagrams, which are used for a wider array of processes (Figure 6).

The predominant problem analyzing tool discussed in the theses was Value Stream Mapping (VSM) (Figure 5). Also, simpler and more universal tools, such as the Ishikawa and Lorenzo-Pareto charts, were growing in popularity.

An analysis of the graphs implies that 5S is the tool which raised the highest interest (Figure 7). It is a relatively simple tool, but on the other hand, it provides the grounds for implementation of more advanced techniques and tools. An interesting phenomenon is the increasing interest in suggestion systems, which can be perceived as examples of what is commonly referred to as soft tools or awareness tools. It seems that implementation of such tools may indicate that businesses are undergoing a transformation in favor of greater awareness of the Lean/Kaizen principles.

4. Discussion

There are relatively few papers in the literature on the subject concerning comparative analyses of individual postgraduate courses on lean manufacturing/management. The publications usually focus on specific teaching techniques or curricula, while they lack comprehensive analysis of the organizational aspects of the studies. This is partly due to the diversity of formal requirements related to postgraduate studies in different countries, and even at individual higher education schools.

As a result of the research, the following groups of success factors were identified:

- Course content;

- organization of classes.

The course content must be monitored on an ongoing basis and evaluated in terms of both quality and convergence with the needs and expectations of students. The content should include a practical dimension as well. Another important element is the use of diverse methods and techniques for knowledge transfer. Auditorium classes alone, even with a very interesting curriculum, may not be enough. Particularly effective are the classes taking place directly in production facilities, when they are combined with study visits. An important component of any studies is the possibility of obtaining additional professional qualifications/certificates.

In addition to the knowledge transferred, it is also important to provide a platform for sharing experiences/ideas with graduates, for example by launching what is commonly referred to as the post-graduates’ club.

Thirty-nine postgraduate programs (from the whole world) on Lean Management were analyzed. The data available both in the scientific literature and in the internet are rather general and only partially depict the structure of the postgraduate programs. This may be due to some intellectual property issues. Postgraduate courses are commercial ventures which compete on the educational market, and as such, they require careful protection of know-how. However, this limits the possibility of finding best practices and analyzing successful courses, and makes it harder for students to make decisions on joining the given course as they cannot analyze the course details and can only rely on the reputation of the organization (academy, university, institute, faculty, business partners) or the staff (teachers and their achievements, guest speakers from the industry). This study goes beyond these limitations and extends the existing body of knowledge by supplementing it with the authors’ analysis of critical success factors of the Kaizen Academy course. This paper also enriches the literature by providing some new input which consists in comparing a relatively big set of courses and including details of the Kaizen Academy structure. The structure of Kaizen Academy, as presented in this paper, may serve to both educators and students. Educators may use it as a kind of signpost when designing, benchmarking, and improving their own initiatives. Students can make the most of it in the process of selection and decision making on whether or not to join a postgraduate course. They may analyze the course by searching for its features and success factors presented in this paper to increase the probability of joining a high quality postgraduate program. Such approach could be applied not only for Lean Management courses, but also for other types of postgraduate programs. It is postulated that each organization delivering postgraduate courses should present its curricula more comprehensively. This should enable students to make more sustainable choices, and ensure more fair competition in the educational market.

The great significance of workshops and industrial visits/days for this type of practical courses should be emphasized. Therefore, apart from price, which is surely the selection criterion for students, it is also advised to use data on practical activities as an important criterion. It is impossible to teach and train Lean Management without practice, which follows the Aristotelian learning-by-doing paradigm from “Nicomachean Ethics” [32]. “For the things we have to learn before we can do them, we learn by doing them.” Therefore, a hypothesis is constructed that successful postgraduate studies in the domain of managerial sciences require a design following the constructivist paradigms and application of the experiential learning principles. Additionally, the research question is what kind of Lean Management methods and tools are usually included in the postgraduate studies curricula. To confirm or decline this hypothesis and answer the question, the authors plan further research of both qualitative and quantitative nature (multiple case studies, structured interviews, and surveys).

An important element of postgraduate courses is a curriculum adapted to current market expectations. While only a few years ago most postgraduate programs offered knowledge in the scope of the so-called basic techniques (e.g., 5S), this is no longer sufficient nowadays, and students currently expect to receive knowledge concerning application of more advanced techniques and tools.

Many programs offer education which concludes with the graduate being granted one of the Six Sigma belts. According to the authors, this is a methodological mistake of these programs. Acquiring knowledge in the field of Six Sigma must be preceded by many months of industrial practice, including that which involves Lean, and cannot be offered under a single joint program.

5. Conclusions

The study discussed in this paper focused on qualitative comparative and some basic quantitative analyzes of the sample of postgraduate courses on Lean Management. The sample of thirty-nine courses was studied with particular attention paid to the Kaizen Academy case. The objective analysis was structured and focused on specific criteria. The set of criteria for comparison was defined by way of expert interviews. The comparison and in-depth case study of Kaizen Academy made it possible to identify factors and unique characteristics driving postgraduate courses on Lean Management towards being successful and sustaining for a long period on the market. The case study subject to analysis is one of its kind that has survived for a long period of a dozen years on the educational market, which is a competitive advantage in this area. Therefore, a comparison of the characteristics of this successful program and other programs led to finding the key success factors of postgraduate programs on Lean Management. It is the course’s practical dimension. It was also found that this practical dimension is strictly related to the experiential learning approach and embodies the constructivist paradigm in the course. The practical dimension was measured in the number of industrial visits and industrial days, being the most attractive way to practice Lean Management. Additionally, it is advised that the rest of classes (out of industrial sites) should also be conducted according to the experiential learning principle by applying games, project-based learning, and problem-based learning. It was also found that the critical factor to be sustained in the educational market is to continuously recognize the changing needs of students (which in this case are also the needs of companies) and to be flexible by adapting to these needs. Initially, these needs were more concentrated on basic and generic Lean Management tools, but nowadays the focus is increasingly often placed on advanced techniques and holistic concepts. Besides the comparative analysis, the case of Kaizen Academy has been addressed, and it can be used by other scholars as an inspiration to find practices that have worked for this successful program and to adapt such practices to their own curricula.

Based on the analysis performed, the authors have formulated the following observations concerning the organization of postgraduate studies and critical success factors of this venture.

- Kaizen Academy was founded 12 years ago and has already educated several hundred managers representing various industries from Poland and several EU countries. This state of matters results from the academy’s unique curriculum, which is clearly practice-oriented, follows the constructivist paradigm, and incorporates experiential and active learning approaches.

- Kaizen Academy is the only program in the sample subject to the study that offers eight days of classes under industrial conditions. One of the analyzed educational centers offers 10 days of classes in the field, but since they comprise an MBA course, it is hardly comparable to Kaizen Academy.

- Kaizen Academy offers a competitive price-to-quality ratio, especially considering the number of study visits to companies which are long-time partners of the academy, understanding the needs of practical knowledge transfer to postgraduate students.

- The available postgraduate studies are typically two semester courses, organized on a 2-day weekend meetings basis, typically held once or twice a month. Kaizen Academy offers 10 meetings of 18 h each (on the average), which is more than in the case of 80% of the competing courses, and adding the time required for the graduation project (235 h), it altogether translates into one of the most extensive LM courses delivered in Poland.

- Kaizen Academy offers three documents confirming the knowledge acquired, two of which are issued by the Kaizen Institute (internationally recognized), which makes it significantly easier for the course graduates to continue their professional development. Other programs offer certificates that are little recognized in the market, since they seem to have been created for marketing purposes only.

- Kaizen Academy is a joint program organized by a large and recognized consulting company in collaboration with a first-class state-administered technical university, which translates into a significant market advantage and makes it possible to gain highly qualified and acclaimed teaching staff.

Author Contributions

Conceptualization, A.B. and B.G.; methodology, B.G.; validation, A.B., L.B., M.B. (Mariusz Bednarek) and M.B. (Mariusz Bryke); formal analysis, A.B., B.G., L.B., M.B. (Mariusz Bednarek) and M.B. (Mariusz Bryke); investigation, A.B., L.B., M.B. (Mariusz Bednarek), and M.B. (Mariusz Bryke); resources, A.B. and L.B.; data curation, A.B. and L.B.; writing—original draft preparation, A.B. and B.G.; writing—review and editing, A.B., B.G., M.B. (Mariusz Bednarek), and M.B. (Mariusz Bryke); visualization, B.G.; supervision, M.B. (Mariusz Bednarek); project administration, A.B., M.B. (Mariusz Bednarek), and M.B. (Mariusz Bryke); internal funding acquisition, A.B., M.B. (Mariusz Bednarek) and M.B. (Mariusz Bryke). All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded proportionally by the Warsaw University of Technology (internal grant for employees dedicated to the discipline of management and quality sciences (A.B.)), WSB University, Kaizen Institute Poland, and Institute Industry 4.0.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Basic characteristics of postgraduate Lean Management courses and training schemes.

Table A1.

Basic characteristics of postgraduate Lean Management courses and training schemes.

| No. | Course Name | University | City Country | Meetings Hours Semesters | Industrial Visits | Industrial Days | Certificates |

|---|---|---|---|---|---|---|---|

| 0 | Kaizen Academy | Warsaw University of Technology | Warsaw Poland | 10 235 2 | 4 | 8 | 2 Kaizen practitioner Kaizen trainer |

| 1 | Lean Black Belt Strategy Expert | None, run by consultancy company | Warsaw Poland | 10 230 2 | 2 | 4 | 2 Lean Black Belt ® Lean Strategy Expert |

| 2 | Lean Management | Banking Academy in Gdansk | Gdansk Poland | 10 168 2 | 0 | 0 | 1 Free commercial training from industrial partner |

| 3 | Lean Management MBA | University of Business in Wroclaw | Wroclaw Poland | 10 240 2 | 6 | 10 | 3 Lean Leader Lean Coach Lean Manager |

| 4 | Lean Management In Services | University of Gdansk | Sopot Poland | 10 176 2 | 0 | 0 | 1 Postgraduate certificate (joint with Lean Management Sustainable Performance Improvement Network) |

| 5 | Lean Leader Academy—Effective Enterprise Management | Banking Academy in Katowice | Katowice Poland | 10 162 2 | 0 | 0 | 1 Lean Green Belt |

| 6 | Six Sigma Green Belt—Academy Of Process Management | Lazarski University | Warsaw Poland | 10 160 2 | 0 | 0 | 1 Green Belt Six Sigma |

| 7 | Lean Advanced—Academy Of Process Management | Lazarski University | Warsaw Poland | 10 160 2 | 0 | 0 | 0 |

| 8 | Lean Management—Managerial Postgraduate Studies | Wroclaw University of Economics and Business | Wroclaw Poland | 10 170 2 | 1 | No data | 0 |

| 9 | Managing Leaner Production | Rzeszow University of Technology | Wroclaw Poland | No data 240 2 | 0 | 0 | 0 |

| 10 | Lean Management and Lean Office | Jagiellonian University | Krakow Poland | 10 150 2 | 0 | 0 | 0 |

| 11 | Six Sigma—Managerial Postgraduate Studies | Wroclaw University of Economics and Business | Wroclaw Poland | 15 186 2 | 0 | 0 | 1 Green Belt Six Sigma |

| 12 | Lean Management in Production and Services | Wroclaw School of Banking | Wroclaw Poland | 10 160 2 | 0 | 0 | 0 |

| 13 | Lean Management | University of Humanities and Economics in Lodz | Lodz Poland | No data No data 2 | 1 | No data | 1 Green Belt Six Sigma |

| 14 | Quality Management in Theory and Practice (Lean Kaizen Six Sigma) | Poznan University of Technology | Poznan Poland | 10 200 2 | 0 | 0 | 0 |

| 15 | Poznan University of Economy and Business | Poznan University of Economics and Business | Poznan Poland | 14 168 2 | 1 | 1 | 1 Green Belt Six Sigma |

| 16 | WSB Chorzow | Poznan School of Banking, Faculty in Chorzow | Chorzow Poland | 9 162 2 | 1 | 1 | 1 Green Belt Six Sigma |

| 17 | Lean Manufacturing | Silesian University of Technology | Gliwice Poland | 13 200 2 | 0 | 0 | 1 Lean Manufacturing Specialist (external Research & Certification Unit ZETOM) |

| 18 | Lean Management Academy | Banking Academy in Dabrowa Gornicza | Dabrowa Gornicza Poland | No data 160 2 | 0 | 0 | 2 Yellow Belt Six Sigma Green Belt Six Sigma (IASSC) |

| 19 | TPM Champion—Maintenance in Practice | Lazarski University | Warsaw Poland | 10 No data 2 | 1 | 1 | 2 TPM Champion (LUQAM) ISO 14001 & ISO 45001 Internal Auditor (SwissCert) |

| 20 | Lean Sigma Expert For Services | Banking and Management Academy in Krakow | Krakow Poland | 10 No data 2 | 0 | 0 | 4 Green Belt Six Sigma (LUQAM) Green Belt Six Sigma (SwissCert) Lean Manufacturing Leader (LUQAM) Process mapping and modeling (LUQAM) |

| 21 | Lean Sigma Academy | Banking and Management Academy in Krakow | Krakow Poland | 10 No data 2 | 2 | 4 | 3 Green Belt Six Sigma (LUQAM) Green Belt Six Sigma (SwissCert) Lean Manufacturing Leader (LUQAM) Process mapping and modeling (LUQAM) |

| 22 | Lean in Services | Warsaw School of Economics | Warsaw Poland | 12 166 2 | 2 + 1 | 6 | International Kaizen Coach certificate |

| 23 | Lean Management | Banking and Management Academy in Poznan | Poznan Poland | 10 120 2 | 1 | 1 | 0 |

| 24 | Lean Management | Bialystok University of Technology | Bialystok Poland | 12 168 2 | 0 | No data, max. 1 | Internal certificates of industrial partners |

| 25 | Lean Six Sigma Black Belt | Gdansk University of Technology | Gdansk Poland | 18 188 2 | 0 | 0 | Black Belt Six Sigma (Loyola Marymount University Center for Technology Management in Poland) |

| 26 | Lean Management | University of Information Technology and Management in Rzeszow | Rzeszow Poland | No data 180 2 | 0 | 0 | 0 |

| 27 | Lean Six Sigma—Process Optimization | Banking Academy in Poznan | Poznan Poland | 10 160 2 | 0 | 0 | 0 |

| 28 | Lean Management | Banking Academy in Poznan | Poznan Poland | 10 160 2 | 0 | 0 | 0 |

| 29 | Lean Management | Katowice Business University | Katowice Poland | 9 176 2 | 0 | 0 | 0 |

| 31 | Lean Leader Academy | Banking Academy in Torun | Torun Poland | 10 152 2 | 0 | 0 | 0 |

| 32 | MSc Lean Six Sigma for Operational Excellence | Heriot Watt University, Edinburgh Business School | Edinburgh UK | No data No data Full time: 2 (MSc), 1.5 (Postgraduate diploma, 1 (certificate); Part-time: 4 (MSc), 2.5 (postgraduate diploma), 2 (certificate) | Included, but no data on details | 3 MSc in Lean Six Sigma for Operational Excellence | |

| 33 | MSc Lean and Agile Operations | University of Wales Trinity Saint David | Swansea UK | No data No data 2: full-time; 6: part-time | No data | MSc diploma | |

| 34 | MSc Lean Enterprise | University of Buckingham Business School | Buckingham UK | No data No data 2: part-time | No data | MSc diploma | |

| 35 | Dual MBA / MS in Lean Manufacturing | University of Michigan-Flint | Flint (MI) USA | No data No data Flexible studying scheme | No data | 2 diplomas: University of Michigan and Kettering University | |

| 36 | Lean Master Course | University of South Australia | Adelaide Australia | No data No data 2 × 5 days program face-to-face | No data | Postgraduate certificate | |

| 37 | Lean Manufacturing Engineer/Lean Manager Postgraduate Course | University of Debrecen, Faculty of Engineering | Debrecen Hungary | No data No data 2 | No data | Certificate Lean Manufacturing Engineer or Lean Manager | |

| 38 | Postgraduate Course in Lean Six Sigma Improvement Programs | Barcelona Tech | Barcelona Spain | No data No data 0.5 | No data | Black Belt Six Sigma | |

References

- Ohno, T. Toyota Production Systems: Beyond Large-Scale Production; Productivity Inc.: Portland, OR, USA, 1988. [Google Scholar]

- Womack, J.; Jones, D. Lean Thinking: Banish Waste and Create Wealth in Your Corporation; Simon & Schuster: New York, NY, USA, 1996. [Google Scholar]

- Womack, J.; Jones, D.; Roos, D. The Machine That Changed the World; Free Press: New York, NY, USA, 1990. [Google Scholar]

- Liker, J. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Oehmen, J. (Ed.) The Guide to Lean Enablers for Managing Engineering Programs; MIT-PMI-INCOSE: Cambridge, MA, USA, 2012. [Google Scholar]

- Gladysz, B.; Buczacki, A. Wireless Technologies for Lean Manufacturing—A Literature Review. Manag. Prod. Eng. Rev. 2018, 9, 20–34. [Google Scholar] [CrossRef]

- Torres, P.; Stephens, M. Improving production performance through lean manufacturing techniques & education in lean concepts. In Proceedings of the 2005 American Society for Engineering Education Annual Conference & Exposition; American Society for Engineering Education: Portland, OR, USA, 2005; Volume 10, pp. 1–27. [Google Scholar]

- Murman, E.; McManus, H.; Candido, J. Enhancing faculty competency in lean thinking bodies of knowledge. In Proceedings of the 3rd International CDIO Conference; CDIO: Cambridge, MA, USA, 2007; pp. 1–19. [Google Scholar]

- Hall, A.; Holloway, L. Application of lean concepts to the teaching of lean manufacturing. In Proceedings of the 2007 American Society for Engineering Education Annual Conference & Exposition; American Society for Engineering Education: Hawaii, HI, USA, 2008. [Google Scholar]

- Wan, H.; Liao, Y.; Kuriger, G. Redesigning a lean simulation game for more flexibility and higher efficiency. In Proceedings of the 2012 American Society for Engineering Education Annual Conference & Exposition; American Society for Engineering Education: San Antonio, TX, USA, 2012. [Google Scholar]

- Conger, S.; Miller, R. Problem-based learning applied to student consulting in a lean production course. J. High Educ. Theory Pract. 2014, 14, 81. [Google Scholar]

- Kanigolla, D.; Cudney, E.; Corns, S. Enhancing engineering education using project-based learning for lean and six sigma. Int. J. Lean Six Sigma 2014, 5, 45–61. [Google Scholar] [CrossRef]

- Bradley, J.; Willett, J. Cornell students participate in Lord Corporation’s Kaizen projects. Interfaces 2004, 34, 451–459. [Google Scholar] [CrossRef]

- Emiliani, M.L. Using Kaizen to improve graduate business school degree programs. Qual. Assur. Educ. 2005, 13, 37–52. [Google Scholar] [CrossRef]

- Suarez-Barraza, M.F.; Rodriguez-Gonzalez, F.G. Bringing Kaizen to the classroom: Lessons learned in an Operations Management course. Total Qual. Manag. Bus. Excell. 2018, 26, 1002–1016. [Google Scholar] [CrossRef]

- Tortorella, G.; Cauchick, M.P.A. Teaching lean manufacturing at a postgraduate level: Integrating traditional teaching methods and problem-based learning approach. Int. J. Lean Six Sigma 2018, 9, 301–323. [Google Scholar] [CrossRef]

- Piaget, J. Psychology and Epistemology: Towards a Theory of Knowledge; Grossman: New York, NY, USA, 1971. [Google Scholar]

- Alt, D. Contemporary constructivist practices in higher education settings and academic motivational factors. Aust. J. Adult Learn. 2016, 56, 354–399. [Google Scholar]

- O’Connor, K. Constructivism, curriculum and the knowledge question: Tensions and challenges for higher education. Stud. High. Educ. 2020. [Google Scholar] [CrossRef]

- Rohrbach, A. Economical Production of All-Metal Airplanes and Sea Planes. J. Soc. Automot. Eng. 1927, 20, 57–66. [Google Scholar]

- Wright, T.P. Factors Affecting the Cost of Airplanes. J. Aeronaut. Sci. 1936, 3, 122–128. [Google Scholar] [CrossRef]

- Kohli, W. Bringing Dewey into the Adult Higher Education Classroom. New Dir. Adult Contin. Educ. 2018, 158, 57–65. [Google Scholar] [CrossRef]

- Morris, T.H. Experiential learning—A systematic review and revision of Kolb’s model. Interact. Learn. Environ. 2019. [Google Scholar] [CrossRef]

- Revans, R. Action Learning in Practice; Gower Publishing Company: Burlington, UK, 1983. [Google Scholar]

- Waddil-DeWolfe, D. Adult Learning Orientations and Action Learning. Hum. Res. Dev. Rev. 2003, 2, 406–429. [Google Scholar]

- Ruane, M. Action learning in postgraduate executive management education: An account of practice. Action Learn. Res. Pract. 2016, 13, 272–280. [Google Scholar] [CrossRef]

- Eckhaus, E.; Klein, G.; Kanto, J. Experiential Learning in Management Education. J. Bus. Manag. Educ. 2017, 1, 42–56. [Google Scholar] [CrossRef]

- Gadola, M.; Chindamo, D. Experiential learning in engineering education: The role of student design competitions and a case study. Int. J. Mech. Eng. Educ. 2019, 47, 3–22. [Google Scholar] [CrossRef]

- Valverde-Berrocoso, J.; Garrido-Arroyo, M.D.C.; Burgos-Videla, C.; Morales-Cevallos, M.B. Trends in Educational Research about e-Learning: A Systematic Literature Review (2009–2018). Sustainability 2020, 12, 5153. [Google Scholar] [CrossRef]

- Tortorella, G.; Cauchick-Miguel, P.A. Combining traditional teaching methods and PBL for teaching and learning of lean manufacturing. IFAC-PapersOnLine 2018, 51, 915–920. [Google Scholar] [CrossRef]

- Tortorella, G.; Miorando, R.; Fettermann, D.; Mendoza, D. An empirical investigation on learning and teaching lean manufacturing. Educ. Train. 2020, 62, 339–354. [Google Scholar] [CrossRef]

- Ameriks, K.; Clarke, D.M. (Eds.) Aristotle: Nicomachean Ethics; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).