Technical Efficiency and Productivity Growth of Crude Palm Oil: Variation across Years, Locations, and Firm Sizes in Indonesia

Abstract

1. Introduction

2. Methodology

2.1. Material

2.2. Methodology

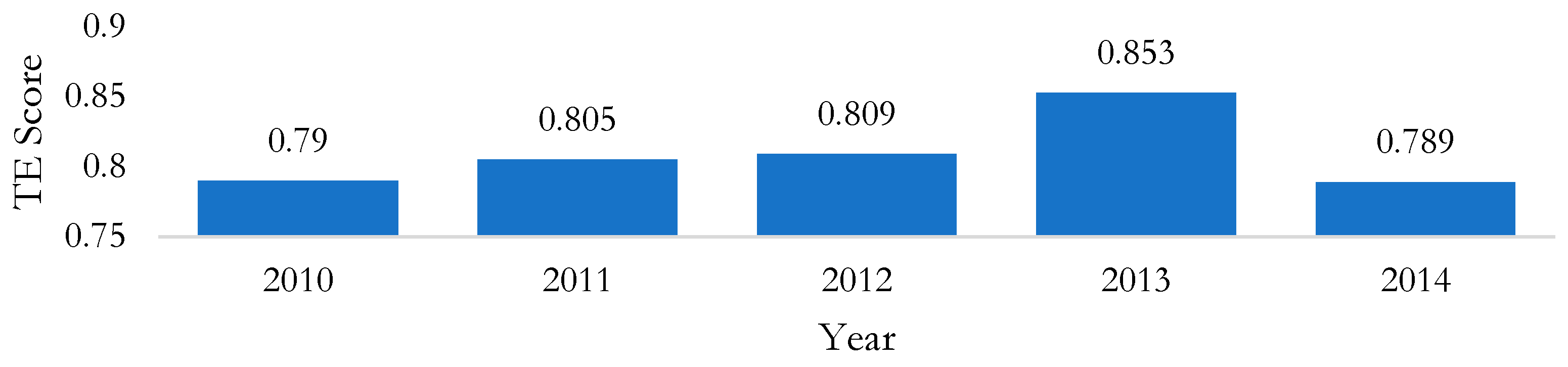

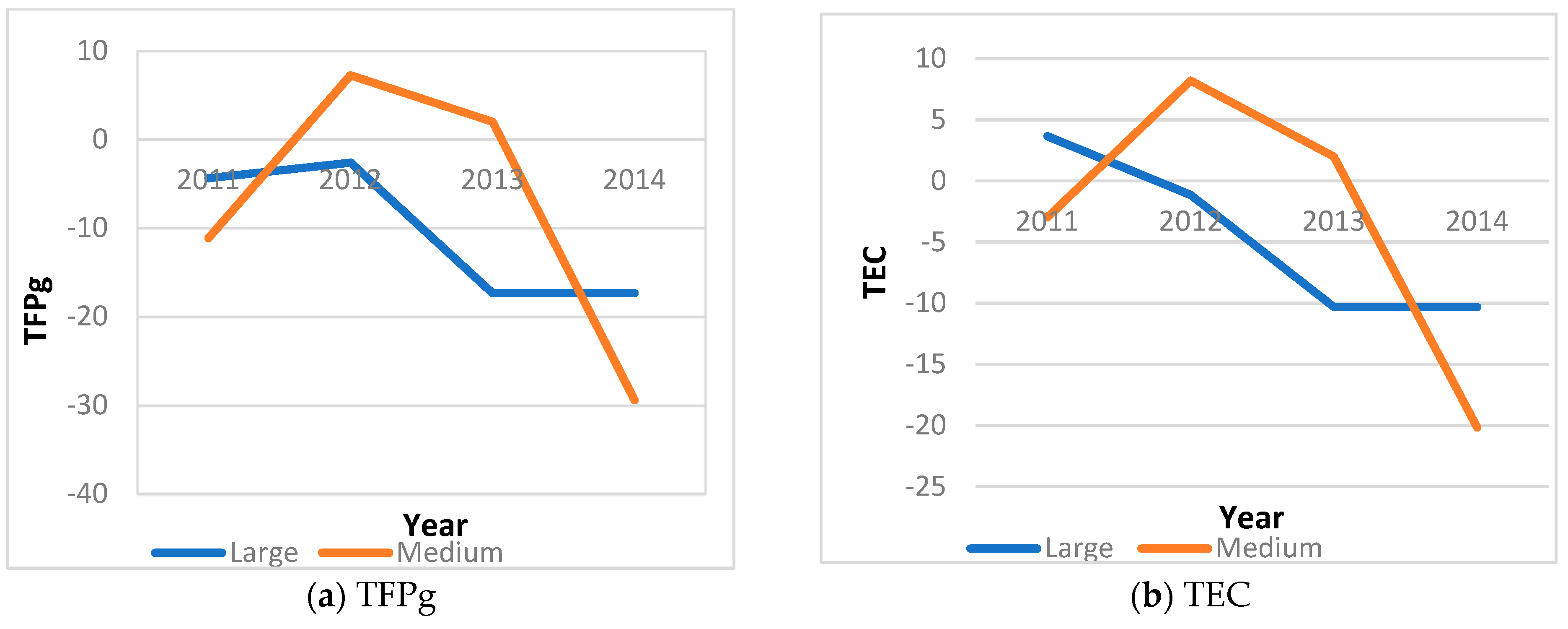

3. Results

4. Discussion

5. Conclusions

6. Limitation and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

| 1 | We only include energy and materials as intermediate inputs due to the availability of in Statistics Indonesia’s data. |

References

- Aigner, Dennis, Charles Albert Knox Lovell, and Peter Schmidt. 1977. Formulation and Estimation of Stochastic Frontier Production Function Models. Journal of Econometrics 6: 21–37. [Google Scholar] [CrossRef]

- Amin, Azharuddin Mohd. 2010. An Analysis Technical Efficiency and Total Factor Productivity (TFP) Growth of the Indonesian Food Manufacturing Industry. Paper presented at International Seminar, Economic Regional Development, Law and Governance in Malaysia and Indonesia, Riau, Indonesia, June 7–9. [Google Scholar]

- Anam, M. Khairul, and Suhartini Suhartini. 2020. Efficiency of Palm Oil Companies in Indonesia: A DEA Approach. Habitat 31: 55–63. [Google Scholar] [CrossRef]

- Arora, Nitin, and Preeti Lohani. 2017. Does Foreign Direct Investment Spillover Total Factor Productivity Growth? A Study of Indian Drugs and Pharmaceutical Industry. Benchmarking: An International Journal 24: 1937–55. [Google Scholar] [CrossRef]

- Banda, Héctor Salgado, and Lorenzo Ernesto Bernal Verdugo. 2011. Multifactor Productivity and Its Determinants: An Empirical Analysis for Mexican Manufacturing. Journal of Productivity Analysis 36: 293–308. [Google Scholar] [CrossRef]

- Battese, George Edward, and Timothy James Coelli. 1988. Prediction of Firm-Level Technical Efficiencies with a Generalized Frontier Production Function and Panel Data. Journal of Econometrics 38: 387–99. [Google Scholar] [CrossRef]

- Battese, George Edward, and Timothy James Coelli. 1992. Frontier Production Functions, Technical Efficiency and Panel Data: With Application to Paddy Farmers in India. Journal of Productivity Analysis 3: 153–69. [Google Scholar] [CrossRef]

- Battese, George Edward, and Timothy James Coelli. 1995. A Model for Technical Inefficiency Effects in a Stochastic Frontier Production Function for Panel Data. Empirical Economics 20: 325–32. [Google Scholar] [CrossRef]

- Comin, Diego. 2010. Total Factor Productivity. In Economic Growth. Edited by Steven N. Durlauf and Lawrence E. Blume. London: Palgrave Macmillan UK, pp. 260–63. [Google Scholar] [CrossRef]

- Dhawan, Rajeev. 2001. Firm size and productivity differential: Theory and evidence from a panel of US firms. Journal of Economic Behavior & Organization 44: 269–93. [Google Scholar]

- Dvouletý, Ondřej, and Ivana Blažková. 2021. Exploring Firm-Level and Sectoral Variation in Total Factor Productivity (TFP). International Journal of Entrepreneurial Behavior & Research 27: 1526–47. [Google Scholar] [CrossRef]

- Earthworm. 2020. Tata Cara Penggunaan Sistem Pekerja Harian Lepas Di Perusahaan Kelapa Sawit. Available online: https://www.earthworm.org/uploads/files/Tatacara-Penggunaan-Pekerja-Harian-Lepas.pdf (accessed on 2 December 2021).

- Esquivias, Miguel Angel, and Samuel Kharis Harianto. 2020. Does Competition and Foreign Investment Spur Industrial Efficiency: Firm-Level Evidence from Indonesia. Heliyon 6: e04494. [Google Scholar] [CrossRef]

- Greene, William. 2005a. Fixed and Random Effects in Stochastic Frontier Models. Journal of Productivity Analysis 23: 7–32. [Google Scholar] [CrossRef]

- Greene, William. 2005b. Reconsidering Heterogeneity in Panel Data Estimators of the Stochastic Frontier Model. Journal of Econometrics 126: 269–303. [Google Scholar] [CrossRef]

- Halkos, George Emmanuel, and Nickolaos G. Tzeremes. 2007. Productivity efficiency and firm size: An empirical analysis of foreign owned companies. International Business Review 16: 713–31. [Google Scholar] [CrossRef]

- Hu, Xiaotian, and Xiaopeng Yin. 2022. Do stronger intellectual property rights protections raise productivity within the context of trade liberalization? Evidence from China. Economic Modelling 110: 105791. [Google Scholar] [CrossRef]

- Ikhsan, Mohamad. 2007. Total Factor Productivity Growth in Indonesian Manufacturing: A Stochastic Frontier Approach. Global Economic Review 36: 321–42. [Google Scholar] [CrossRef]

- Indonesian Palm Oil Association. 2022. Tanpa Minyak Sawit, Neraca Perdagangan Indonesia Selalu Defisit. Gabungan Pengusaha Kelapa Sawit Indonesia, April. Available online: https://gapki.id/news/20878/tanpa-minyak-sawit-neraca-perdagangan-indonesia-selalu-defisit (accessed on 5 May 2022).

- Jondrow, James, Charles Albert Knox Lovell, Ivan S. Materov, and Peter Schmidt. 1982. On the estimation of technical inefficiency in the stochastic frontier production function model. Journal of Econometrics 19: 233–38. [Google Scholar] [CrossRef]

- Kumbhakar, Subal C. 1987. The Specification of Technical and Allocative Inefficiency in Stochastic Production and Profit Frontiers. Journal of Econometrics 34: 335–48. [Google Scholar] [CrossRef]

- Kumbhakar, Subal C. 1990. Production Frontiers, Panel Data, and Time-Varying Technical Inefficiency. Journal of Econometrics 46: 201–11. [Google Scholar] [CrossRef]

- Lee, Young Hoon, and Peter Schmidt. 1993. A Production Frontier Model with Flexible Temporal Variation in Technical Efficiency. In The Measurement of Productive Efficiency: Techniques and Applications. Edited by Harold O’Neil Fried, Charles Albert Knox Lovell and Shelton Spencer Schmidt. Oxford: Oxford University Press, pp. 237–55. [Google Scholar]

- Margono, Heru, and Subhash Chandra Sharma. 2006. Efficiency and Productivity Analyses of Indonesian Manufacturing Industries. Journal of Asian Economics 17: 979–95. [Google Scholar] [CrossRef]

- Meeusen, Wim, and Julien van Den Broeck. 1977. Efficiency Estimation from Cobb-Douglas Production Functions with Composed Error. International Economic Review 18: 435–44. [Google Scholar] [CrossRef]

- Nasution, Aswin, Fajri Fajri, and Sofyan. 2015. Analisa Pola Produksi Kelapa Sawit Dan Keseimbangannya Terhadap Pabrik Kelapa Sawit Di Pantai Barat Aceh. Jurnal Agrisep 16: 70–76. [Google Scholar] [CrossRef]

- Nieto, María Jesús, and Lluís Santamaria. 2010. Technological Collaboration: Bridging the Innovation Gap between Small and Large Firms. Journal of Small Business Management 48: 44–69. [Google Scholar] [CrossRef]

- Pitt, Mark M., and Lung Fei Lee. 1981. The Measurement and Sources of Technical Inefficiency in the Indonesian Weaving Industry. Journal of Development Economics 9: 43–64. [Google Scholar] [CrossRef]

- Rifin, Amzul. 2010. The Effect of Export Tax on Indonesia’s Crude Palm Oil (CPO) Export Competitiveness. Asean Economic Bulletin 27: 173. [Google Scholar] [CrossRef]

- Rifin, Amzul. 2017. Efisiensi Perusahaan Crude Palm Oil (CPO) Di Indonesia. Jurnal Manajemen Dan Agribisnis 14: 103–108. [Google Scholar] [CrossRef][Green Version]

- Sari, Dyah Wulan. 2019. The Potential Horizontal and Vertical Spillovers from Foreign Direct Investment on Indonesian Manufacturing Industries. Economic Papers 38: 299–310. [Google Scholar] [CrossRef]

- Sari, Dyah Wulan, Haura Azzahra Tarbiyah Islamiya, Wenny Restikasari, and Emi Salmah. 2021. The Source of Output Growth: Productivity Performance in the Indonesian Crude Palm Oil Industry. Journal of Southwest Jiaotong University 56: 405–18. [Google Scholar] [CrossRef]

- Sari, Dyah Wulan, Noor Aini Khalifah, and Suyanto Suyanto. 2016. The Spillover Effects of Foreign Direct Investment on the Firms’ Productivity Performances. Journal of Productivity Analysis 46: 199–233. [Google Scholar] [CrossRef]

- Scherer, Frederic Michael. 1991. Changing perspectives on the firm size problem. In Innovation and Technological Change: An International Comparison. Edited by Zoltan J. Acs and David B. Audretsch. Ann Arbor: University of Michigan Press, pp. 24–38. [Google Scholar]

- Schmidt, Peter, and Robin Christopher Sickles. 1984. Production Frontiers and Panel Data. Journal of Business and Economic Statistics 2: 367–74. [Google Scholar]

- Setiawan, Maman, and Ernie Tisnawati Sule. 2020. Technical Efficiency and Its Determinants of the State-Owned Enterprises in the Indonesian Manufacturing Industry. International Journal of Economics and Management 14: 331–42. [Google Scholar]

- Suroso, Arif Imam, Hansen Tandra, Mukhamad Najib, and Yusman Syaukat. 2020. Firm Performance Factors and Efficiency of Indonesian Palm Oil Companies. Jurnal Manajemen Dan Agribisnis 17: 227–38. [Google Scholar] [CrossRef]

- Suyanto, Suyanto, Yenny Sugiarti, and Idfi Setyaningrum. 2021. Clustering and firm productivity spillovers in Indonesian manufacturing. Heliyon 7: e06504. [Google Scholar] [CrossRef] [PubMed]

- Utterback, James M. 1994. Mastering the Dynamics of Innovation: How Companies Can Seize Opportunities in the Face of Technological Change. Boston: Harvard Business School Press, p. 68. [Google Scholar]

- Wang, Hung-jen, and Chia-wen Ho. 2010. Estimating Fixed-Effect Panel Stochastic Frontier Models by Model Transformation. Journal of Econometrics 157: 286–96. [Google Scholar] [CrossRef]

- World Bank. 2020. Research and Development Expenditure (% of GDP) Indonesia. Available online: https://data.worldbank.org/indicator/GB.XPD.RSDV.GD.ZS (accessed on 7 December 2021).

- Yasin, Mohammad Zeqi. 2021. Technical Efficiency and Total Factor Productivity Growth of Indonesian Manufacturing Industry: Does Openness Matter? Studies in Microeconomics 10: 1–30. [Google Scholar] [CrossRef]

- Yeo, Yeongjun, and Chansoo Park. 2022. Does Firm Size Matter? Decomposing Korean Firms’ Productivity Growth Based on a Stochastic Frontier Approach and Its Policy Implications. Asian Journal of Technology Innovation 3: 1–25. [Google Scholar] [CrossRef]

- Yuniartha, Lidya. 2021. Konsumsi Minyak Sawit Domestik Tumbuh 3.6% Tahun Lalu. Kontan. February 4. Available online: https://industri.kontan.co.id/news/konsumsi-minyak-sawit-domestik-tumbuh-36-tahun-lalu (accessed on 28 December 2021).

| Variable | Unit | 2010 | 2011 | 2012 | 2013 | 2014 | |

|---|---|---|---|---|---|---|---|

| Output (Y) | Billion Rupiah | Mean | 488.968 | 719.184 | 700.218 | 790.220 | 580.551 |

| Std. Dev | 977.892 | 1511.323 | 1435.908 | 3014.861 | 2850.227 | ||

| Capital (K) | Billion Rupiah | Mean | 9.574 | 14.287 | 15.389 | 19.088 | 136.997 |

| Std. Dev | 23.309 | 35.104 | 44.763 | 97.881 | 1069.036 | ||

| Labor (L) | Workers | Mean | 291.867 | 303.700 | 310.874 | 297.007 | 299.249 |

| Std. Dev | 457.494 | 630.855 | 656.225 | 549.791 | 663.593 | ||

| Material (M) | Billion Rupiah | Mean | 310.906 | 496.481 | 478.865 | 554.444 | 333.426 |

| Std. Dev | 530.538 | 1042.153 | 965.570 | 2588.200 | 1183.289 | ||

| Energy (E) | Billion Rupiah | Mean | 21.730 | 31.243 | 30.823 | 28.140 | 21.917 |

| Std. Dev | 63.746 | 84.170 | 91.291 | 77.992 | 119.710 |

| Hicks-Neutral (df = 4) | No Technological Progress

(df = 6) | Cobb Douglas

(df = 17) | Decision | |

|---|---|---|---|---|

| Translog (Baseline) | 143.9 | 143.2 | 1148.0 | Translog |

| 13.2 | 31.9 | 6.4 |

| Variable | Translog | Hicks-Neutral | No Technological Progress | Cobb Douglas |

|---|---|---|---|---|

| 0.0972 *** | 0.0510 *** | 0.0501 *** | 0.0493 *** | |

| (0.0000235) | (0.000225) | (0.0000461) | (0.00000754) | |

| 0.0768 *** | 0.0859 *** | 0.0833 *** | 0.0859 *** | |

| (0.0000227) | (0.0000352) | (0.0000322) | (0.0000168) | |

| 0.179 *** | 0.188 *** | 0.189 *** | 0.206 *** | |

| (0.0000302) | (0.000109) | (0.0000690) | (0.00000901) | |

| 0.527 *** | 0.564 *** | 0.560 *** | 0.447 *** | |

| (0.0000282) | (0.000236) | (0.0000740) | (0.0000146) | |

| 0.0448 *** | −0.0000645 | −0.000528 *** | ||

| (0.0000192) | (0.000145) | (0.0000244) | ||

| −0.00472 *** | −0.0118 *** | −0.00903 *** | ||

| (0.0000201) | (0.0000347) | (0.0000252) | ||

| 0.201 *** | 0.185 *** | 0.183 *** | ||

| (0.0000480) | (0.000157) | (0.0000738) | ||

| 0.421 *** | 0.408 *** | 0.405 *** | ||

| (0.0000360) | (0.000153) | (0.0000661) | ||

| 0.0174 *** | 0.0128 *** | 0.0132 *** | ||

| (0.0000191) | (0.0000499) | (0.0000258) | ||

| 0.0428 *** | 0.0486 *** | 0.0526 *** | ||

| (0.0000212) | (0.000104) | (0.0000272) | ||

| −0.102 *** | −0.0611 *** | −0.0669 *** | ||

| (0.0000160) | (0.000140) | (0.0000224) | ||

| 0.0150 *** | 0.0115 *** | 0.0121 *** | ||

| (0.0000172) | (0.0000546) | (0.0000251) | ||

| −0.0123 *** | −0.0208 *** | −0.0157 *** | ||

| (0.0000157) | (0.0000380) | (0.0000324) | ||

| −0.287 *** | −0.283 *** | −0.281 *** | ||

| (0.0000291) | (0.000108) | (0.0000648) | ||

| −0.0288 *** | −0.00222 *** | |||

| (0.0000244) | (0.0000948) | |||

| −0.0204 *** | ||||

| (0.0000360) | ||||

| −0.0299 *** | ||||

| (0.0000141) | ||||

| −0.00624 *** | ||||

| (0.0000116) | ||||

| −0.00265 *** | ||||

| (0.0000164) | ||||

| 0.0441 *** | ||||

| (0.0000130) | ||||

| −2.827 *** | −2.773 *** | −2.773 *** | −2.396 *** | |

| (0.0387) | (0.0387) | (0.0387) | (0.0387) | |

| −32.15 | −29.41 *** | −31.57 ** | −35.85 | |

| (26.58) | (8.955) | (12.28) | (69.25) | |

| Log-likelihood Ratio | 1101.5 | 1029.58 | 1029.9 | 527.5 |

| Year | |||||

|---|---|---|---|---|---|

| 2010 | 0.141 | 0.081 | 0.181 | 0.467 | 0.870 |

| 2011 | 0.108 | 0.079 | 0.163 | 0.526 | 0.875 |

| 2012 | 0.072 | 0.072 | 0.153 | 0.583 | 0.880 |

| 2013 | 0.049 | 0.065 | 0.167 | 0.604 | 0.885 |

| 2014 | 0.073 | 0.077 | 0.218 | 0.527 | 0.895 |

| 2010–2014 | 0.085 | 0.074 | 0.177 | 0.544 | 0.882 |

| Year | TFPg | TEC | TC | SEC |

|---|---|---|---|---|

| 2010–2011 | −5.097 | 3.176 | −3.231 | −5.041 |

| 2011–2012 | −0.877 | 0.736 | −1.156 | −0.458 |

| 2012–2013 | 3.853 | 3.767 | −1.495 | 1.581 |

| 2013–2014 | −16.860 | −9.285 | −8.032 | 0.457 |

| 2010–2014 | −5.191 | −0.831 | −3.664 | −0.696 |

| No | Province | Number of Observation | TFP | TEC | TC | SEC |

|---|---|---|---|---|---|---|

| 1 | Naggroe Aceh Darussalam | 60 | −5.54 | −1.40 | −3.44 | −0.70 |

| 2 | North Sumatera | 488 | −5.40 | −1.23 | −3.41 | −0.75 |

| 3 | West Sumatra | 76 | −5.24 | −1.17 | −3.27 | −0.81 |

| 4 | Riau | 476 | −5.19 | −1.12 | −3.26 | −0.81 |

| 5 | Jambi | 96 | −5.17 | −1.15 | −3.25 | −0.77 |

| 6 | South Sumatra | 52 | −5.19 | −1.22 | −3.24 | −0.73 |

| 7 | Bengkulu | 16 | −5.09 | −1.03 | −3.23 | −0.83 |

| 8 | Lampung | 36 | −5.13 | −1.07 | −3.23 | −0.84 |

| 9 | Bangka Belitung Island | 40 | −4.23 | −0.36 | −2.94 | −0.93 |

| 10 | Riau Island | 8 | −24.93 | −18.93 | −5.96 | −0.04 |

| 11 | DKI Jakarta | 16 | −1.89 | 3.27 | −4.13 | −1.04 |

| 12 | West Java | 24 | 1.18 | 2.33 | −3.38 | 2.22 |

| 13 | Central Java | 4 | −2.73 | −5.50 | −4.12 | 6.88 |

| 14 | East Java | 24 | −3.51 | −3.44 | −3.84 | 3.76 |

| 15 | Banten | 8 | −16.55 | −11.68 | −5.11 | 0.24 |

| 16 | West Kalimantan | 60 | −5.80 | −0.73 | −4.64 | −0.43 |

| 17 | Central Kalimantan | 108 | −4.66 | −0.30 | −3.64 | −0.72 |

| 18 | South Kalimantan | 40 | −4.46 | −1.58 | −3.85 | 0.97 |

| 19 | East Kalimantan | 32 | −7.72 | −1.54 | −4.64 | −1.55 |

| 20 | Central Sulawesi | 12 | 4.56 | 9.81 | −5.70 | 0.45 |

| 21 | South Sulawesi | 8 | 9.07 | 19.85 | −6.07 | −4.71 |

| 22 | West Sulawesi | 20 | −2.36 | 1.37 | −3.14 | −0.59 |

| 23 | West Papua | 8 | 10.50 | 19.09 | −2.93 | −5.66 |

| 24 | Papua | 12 | −6.92 | −2.29 | −4.83 | 0.21 |

| Total | 1724 | −5.51 | −1.29 | −3.42 | −0.81 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azzahra Tarbiyah Islamiya, H.; Wulan Sari, D.; Zeqi Yasin, M.; Restikasari, W.; Shaari, M.S.; Devis Susandika, M. Technical Efficiency and Productivity Growth of Crude Palm Oil: Variation across Years, Locations, and Firm Sizes in Indonesia. Economies 2022, 10, 303. https://doi.org/10.3390/economies10120303

Azzahra Tarbiyah Islamiya H, Wulan Sari D, Zeqi Yasin M, Restikasari W, Shaari MS, Devis Susandika M. Technical Efficiency and Productivity Growth of Crude Palm Oil: Variation across Years, Locations, and Firm Sizes in Indonesia. Economies. 2022; 10(12):303. https://doi.org/10.3390/economies10120303

Chicago/Turabian StyleAzzahra Tarbiyah Islamiya, Haura, Dyah Wulan Sari, Mohammad Zeqi Yasin, Wenny Restikasari, Mohd Shahidan Shaari, and Mochamad Devis Susandika. 2022. "Technical Efficiency and Productivity Growth of Crude Palm Oil: Variation across Years, Locations, and Firm Sizes in Indonesia" Economies 10, no. 12: 303. https://doi.org/10.3390/economies10120303

APA StyleAzzahra Tarbiyah Islamiya, H., Wulan Sari, D., Zeqi Yasin, M., Restikasari, W., Shaari, M. S., & Devis Susandika, M. (2022). Technical Efficiency and Productivity Growth of Crude Palm Oil: Variation across Years, Locations, and Firm Sizes in Indonesia. Economies, 10(12), 303. https://doi.org/10.3390/economies10120303