Comparing Performance of 3D-Printed and Injection-Molded Fiber-Reinforced Composite Parts in Ring-Spinning Traveler Application

Abstract

:1. Introduction

2. Materials and Methods

2.1. Research Design

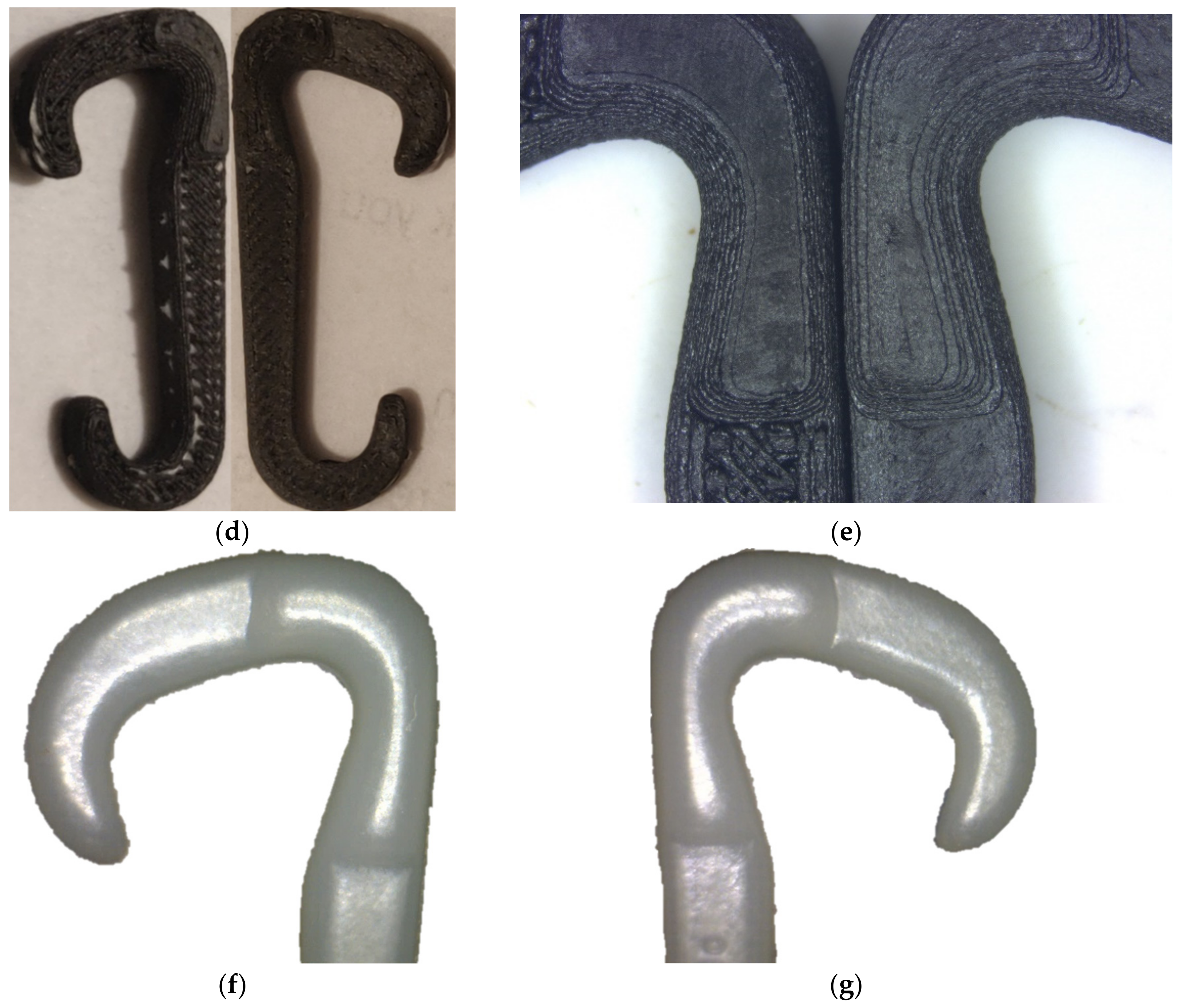

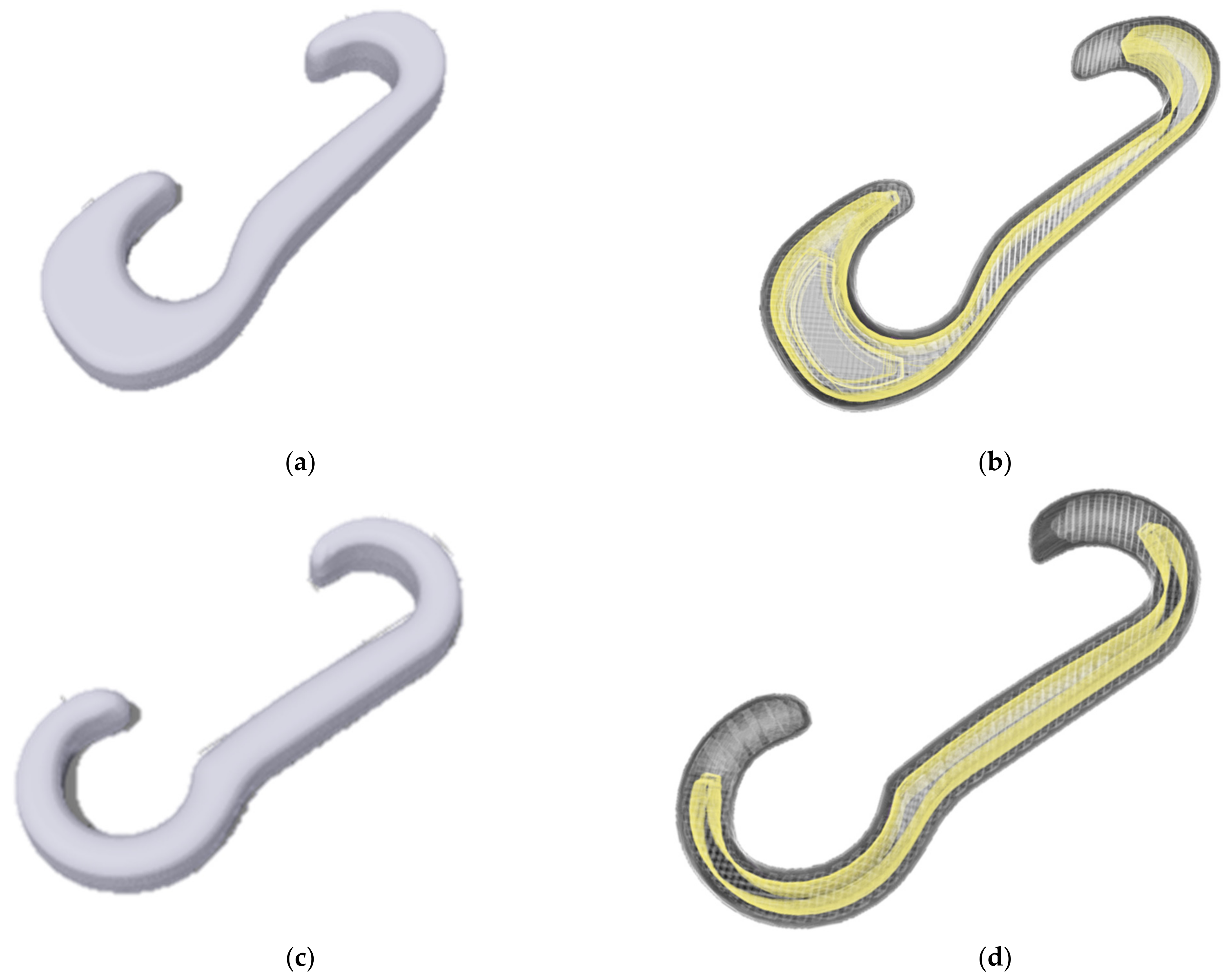

2.2. Fabrication of Ring-Spinning Travelers by 3DP

2.3. Quality and Performance Evaluation

3. Results and Discussion

3.1. Print Precision

3.2. Surface Finish

3.3. Wear Resistance

4. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hetrick, D.R.; Sanei, S.H.R.; Ashour, O.; Bakis, C.E. Charpy impact energy absorption of 3D printed continuous Kevlar reinforced composites. J. Compos. Mater. 2021, 55, 1705–1713. [Google Scholar] [CrossRef]

- Kabir, S.M.F.; Mathur, K.; Seyam, A.M. A critical review on 3D printed continuous fiber-reinforced composites: History, mechanism, materials and properties. Compos. Struct. 2020, 232, 111476. [Google Scholar] [CrossRef]

- Kabir, S.M.F.; Mathur, K.; Seyam, A.M. The Road to Improved Fiber-Reinforced 3D Printing Technology. Technologies 2020, 8, 51. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, J.; Liu, Z. Bending performance enhancement by nanoparticles for FFF 3D printed nylon and nylon/Kevlar composites. J. Compos. Mater. 2021, 55, 1017–1026. [Google Scholar] [CrossRef]

- Dewi, A.; Rante, H.; Basuki, A.; Pasila, F.; Lund, M. 3D Printing Process of Making a Smartphone Holder. E3S Web Conf. 2020, 188, 00003. [Google Scholar]

- Lee, J.; Kim, H.-C.; Choi, J.-W.; Lee, I.H. A review on 3D printed smart devices for 4D printing. Int. J. Precis. Eng. Manuf. Green Technol. 2017, 4, 373–383. [Google Scholar] [CrossRef]

- Nadgorny, M.; Ameli, A. Functional polymers and nanocomposites for 3D printing of smart structures and devices. ACS Appl. Mater. Interfaces 2018, 10, 17489–17507. [Google Scholar] [CrossRef]

- Van de Werken, N.; Tekinalp, H.; Khanbolouki, P.; Ozcan, S.; Williams, A.; Tehrani, M. Additively manufactured carbon fiber-reinforced composites: State of the art and perspective. Addit. Manuf. 2020, 31, 100962. [Google Scholar] [CrossRef]

- Azarov, A.; Latysheva, T.; Khaziev, A. Optimal Design of Advanced 3D Printed Composite Parts of Rocket and Space Structures. IOP Conf. Ser. Mater. Sci. Eng. 2020, 934, 012062. [Google Scholar]

- Rajs, R.; Palardy-Sim, M.; Renaud, G.; Jakubinek, M.; Shadmehri, F. Experimental testing, modeling, and simulation of 3d printed composite material for morphing wing application. In Proceedings of the Canadian Society for Mechanical Engineering International Congress 2020, Charlottetown, PE, Canada, 21–24 June 2020. [Google Scholar]

- Tasch, D.; Schagerl, M.; Wazel, B.; Wallner, G. Impact behavior and fractography of additively manufactured polymers: Laser sintering, multijet fusion, and hot lithography. Addit. Manuf. 2019, 29, 100816. [Google Scholar] [CrossRef]

- Taylor, R.M.; Niakin, B.; Lira, N.; Sabine, G.; Lee, J.; Conklin, C.; Advirkar, S. Design Optimization, Fabrication, and Testing of a 3D Printed Aircraft Structure Using Fused Deposition Modeling. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 1924. [Google Scholar]

- Toleos, L.R., Jr.; Luna, N.J.A.B.D.; Manuel, M.C.E.; Chua, J.M.R.; Sangalang, E.M.A.; So, P.C. Feasibility Study for Fused Deposition Modeling (FDM) 3D-Printed Propellers for Unmanned Aerial Vehicles. Int. J. Mech. Eng. Robot. Res. 2020, 9, 548–558. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Liu, T.; Cao, Y.; Li, D. 3D printing for continuous fiber reinforced thermoplastic composites: Mechanism and performance. Rapid Prototyp. J. 2017, 23, 209–215. [Google Scholar] [CrossRef]

- Su, X.; Liu, X.; Li, S. Research on mutual relationships of flange ring and traveler on ring spinning system. Int. J. Cloth. Sci. Technol. 2019, 31, 32–57. [Google Scholar] [CrossRef]

- Bains, P.S.; Grewal, J.S.; Sidhu, S.S.; Kaur, S. Wear between ring and traveler: A pin-on-disc mapping of various detonation gun sprayed coatings. Mater. Today Proc. 2017, 4, 369–378. [Google Scholar] [CrossRef]

- Hossain, M.; Abdkader, A.; Cherif, C.; Sparing, M.; Berger, D.; Fuchs, G.; Schultz, L. Innovative twisting mechanism based on superconducting technology in a ring-spinning system. Text. Res. J. 2014, 84, 871–880. [Google Scholar] [CrossRef] [Green Version]

- Carter, A. Nylon Travelers. Available online: https://www.abcarter.com/nylon-travelers/ (accessed on 20 January 2021).

- İpekçi, A.; Ekici, B. Experimental and statistical analysis of robotic 3D printing process parameters for continuous fiber reinforced composites. J. Compos. Mater. 2021, 55, 2545–2655. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Kumar, R.; Pruncu, C.I. Recent progress of reinforcement materials: A comprehensive overview of composite materials. J. Mater. Res. Technol. 2019, 8, 6354–6374. [Google Scholar] [CrossRef]

- Gendviliene, I.; Simoliunas, E.; Rekstyte, S.; Malinauskas, M.; Zaleckas, L.; Jegelevicius, D.; Bukelskiene, V.; Rutkunas, V. Assessment of the morphology and dimensional accuracy of 3D printed PLA and PLA/HAp scaffolds. J. Mech. Behav. Biomed. Mater. 2020, 104, 103616. [Google Scholar] [CrossRef]

- Çukul, D.; Beceren, Y. Yarn hairiness and the effect of surface characteristics of the ring traveller. Text. Res. J. 2016, 86, 1668–1674. [Google Scholar] [CrossRef]

- Hossen, J.; Saha, S.K. Selection of appropriate ring traveller number for different count of cotton hosiery yarn. Int. J. Eng. Technol. 2011, 11, 70–76. [Google Scholar]

- Usta, I.; Canoglu, S. Influence of ring traveller weight and coating on hairiness of acrylic and cotton yarns. Indian J. Fibre Text. Res. 2003, 28, 157–162. [Google Scholar]

- Kabir, S.M.F.; Mathur, K.; Seyam, A.M. Impact resistance and failure mechanism of 3D printed continuous fiber-reinforced cellular composites. J. Text. Inst. 2020, 112, 752–766. [Google Scholar] [CrossRef]

- Bains, P.S.; Grewal, J.S.; Sidhu, S.S.; Kaur, S.; Singh, G. Surface modification of ring-traveler of textile spinning machine for substantiality. Facta Univ. Ser. Mech. Eng. 2020, 18, 31–42. [Google Scholar] [CrossRef]

- Carter, A. Nylon Traverler Wear Pattern; Poster, Ed.; AB Carter: Gastonia, NC, USA, 2020. [Google Scholar]

- Xia, Z.; Xu, W. A review of ring staple yarn spinning method development and its trend prediction. J. Nat. Fibers 2013, 10, 62–81. [Google Scholar] [CrossRef]

- Hossain, M.; Abdkader, A.; Nocke, A.; Unger, R.; Krzywinski, F.; Hasan, M.; Cherif, C. Measurement methods of dynamic yarn tension in a ring spinning process. Fibres Text. East. Eur. 2016, 24, 36–43. [Google Scholar] [CrossRef]

- Shim, W.S.; Lee, H.; Lee, D.W. The interaction of moving yarns with stationary surfaces. Fibers Polym. 2013, 14, 164–171. [Google Scholar] [CrossRef]

- Prevorsek, D.; Chin, H. Intrinsic differences between Nylon 6 and Nylon 66 industrial fibers: Micromechanical and molecular analysis. Int. J. Polym. Mater. 1994, 25, 161–184. [Google Scholar] [CrossRef]

- Thread, S. The Difference between Nylon 6.6 and Nylon 6. Available online: https://www.servicethread.com/blog/the-difference-between-nylon-6.6-and-nylon-6#:~:text=In%20fact%2C%20its%20abrasion%20and,over%20Nylon%206’s%2040%2C000%20cycles (accessed on 28 January 2021).

- Gao, X.; Wang, L.; Hao, X. An improved Capstan equation including power-law friction and bending rigidity for high performance yarn. Mech. Mach. Theory 2015, 90, 84–94. [Google Scholar] [CrossRef]

| Ring-Spinning Travelers | G-77-C | J-102-C |

|---|---|---|

| Elaboration of nomenclature | Three parts, where the first part is a letter indicating the shape of the ring height around which the traveler rotates, the second part is number indicating the weight in grains per 10 nylon travelers, and the last part is again a letter indicating the shape of the traveler | |

| 3D image |  |  |

| Dimension, mm | Length (L): 27.11 Width (W): 13.14 Thickness (T): 3.556 | Length (L): 38.98 Width (W): 14.88 Thickness (T): 4.4958/2.921 |

| Application in yarn manufacturing | Polyester yarn | Nylon and polyester yarns |

| Injection-Molded Travelers | 3D-Printed Travelers | |||||

|---|---|---|---|---|---|---|

| G-77-C (Reinforced) | G-77-C) (Unreinforced) | G-77-C (Reinforced) | J-102-C (Reinforced) | |||

| Matrix | Materials | Nylon 6:6 | Nylon 6 | Onyx (Nylon 6 containing short carbon fiber) | Onyx (Nylon 6 containing short carbon fiber) | |

| Density, g/cm3 | 1.14 | 1.1 | 1.2 | 1.2 | ||

| Reinforcement | Materials | Short fiberglass | N/A * | Chopped carbon fiber | Chopped carbon fiber and continuous fiberglass | |

| Chopped carbon fiber | Pre-impregnated 400 continuous fiberglass filaments | |||||

| Density, g/cm3 | 2.59 | N/A | 2.10 | 2.10 | 2.15 | |

| Fiber length, µm | 263 ± 27 | N/A | 168 ± 37 | 168 ± 37 | Continuous | |

| Fiber weight fraction of the traveler, % | 33% | N/A | 18 | 34 (11% for chopped carbon fiber and 23% for continuous fiberglass) | ||

| Print Parameters | Ring-Spinning Travelers | ||

|---|---|---|---|

| G-77-C | G-77-C (Reinforced) | J-102-C (Reinforced) | |

| Build orientation | Flat * | Flat | Flat |

| Layer height, mm | 0.1 | 0.1 | 0.1 |

| Operating temperature, °C | 275 | 275 | 275 (plastic nozzle) 255 (fiber nozzle) |

| Fiber orientation | N/A | Along the print direction | Along the print direction (for short fiber) One concentric ring (for continuous fiber) |

| No. of wall layers (plastic) | 2 | 2 | 1 |

| No of plastic and fiber layers | 36 plastic layers | 36 plastic layers containing short carbon fiber | Total 45: 9 plastic layers containing short carbon fiber + 27 fiber layers with one concentric fiber ring + 9 plastic layers containing short carbon fiber |

| Use support | Yes | Yes | Yes |

| Criteria for Print Precision | Ring-Spinning Travelers | |||

|---|---|---|---|---|

| G-77-C | G-77-C (Reinforced) | J-102-C (Reinforced) | ||

| Dimensions, mm | Width (W) | 13.06 (±0.023 *) | 13.198 (±0.047) | 14.877 (±0.0647) |

| Thickness (T) | 3.537 (±0.017) | 3.604 (±0.0164) | 4.49 (±0.029) | |

| Weight, mg | Estimated weight (by Eiger) | 620 | 670 | 890 |

| Measured weight | 552 (±4.15) | 620 (±7.33) | 838 (±11.34) | |

| Target | 500 | 622 | 826 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kabir, S.M.F.; Mathur, K.; Seyam, A.-F.M. Comparing Performance of 3D-Printed and Injection-Molded Fiber-Reinforced Composite Parts in Ring-Spinning Traveler Application. Technologies 2021, 9, 75. https://doi.org/10.3390/technologies9040075

Kabir SMF, Mathur K, Seyam A-FM. Comparing Performance of 3D-Printed and Injection-Molded Fiber-Reinforced Composite Parts in Ring-Spinning Traveler Application. Technologies. 2021; 9(4):75. https://doi.org/10.3390/technologies9040075

Chicago/Turabian StyleKabir, S. M. Fijul, Kavita Mathur, and Abdel-Fattah M. Seyam. 2021. "Comparing Performance of 3D-Printed and Injection-Molded Fiber-Reinforced Composite Parts in Ring-Spinning Traveler Application" Technologies 9, no. 4: 75. https://doi.org/10.3390/technologies9040075

APA StyleKabir, S. M. F., Mathur, K., & Seyam, A.-F. M. (2021). Comparing Performance of 3D-Printed and Injection-Molded Fiber-Reinforced Composite Parts in Ring-Spinning Traveler Application. Technologies, 9(4), 75. https://doi.org/10.3390/technologies9040075