Post-Processing of 3D-Printed Polymers

Abstract

:1. Introduction

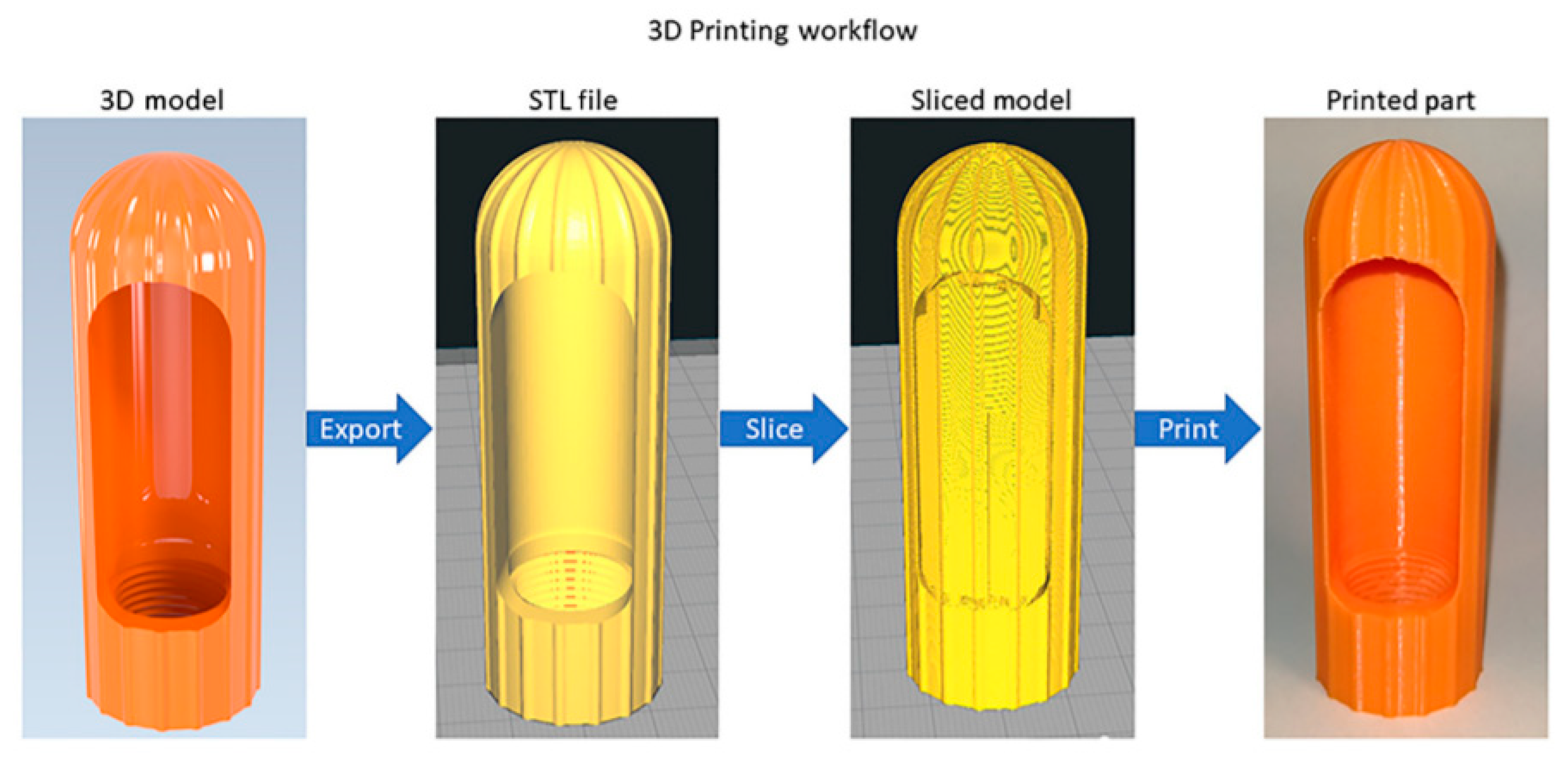

2. Additive Manufacturing (AM) Overview

History

3. Review of Common 3D Printing Technologies

3.1. Material Extrusion

3.2. Vat Photopolymerization

3.3. Powder Bed Fusion (PBF)

3.4. Material Jetting

3.5. Binder Jetting

4. Commonly-Used 3D Printing Materials

4.1. Acrylonitrile Butadiene Styrene (ABS)

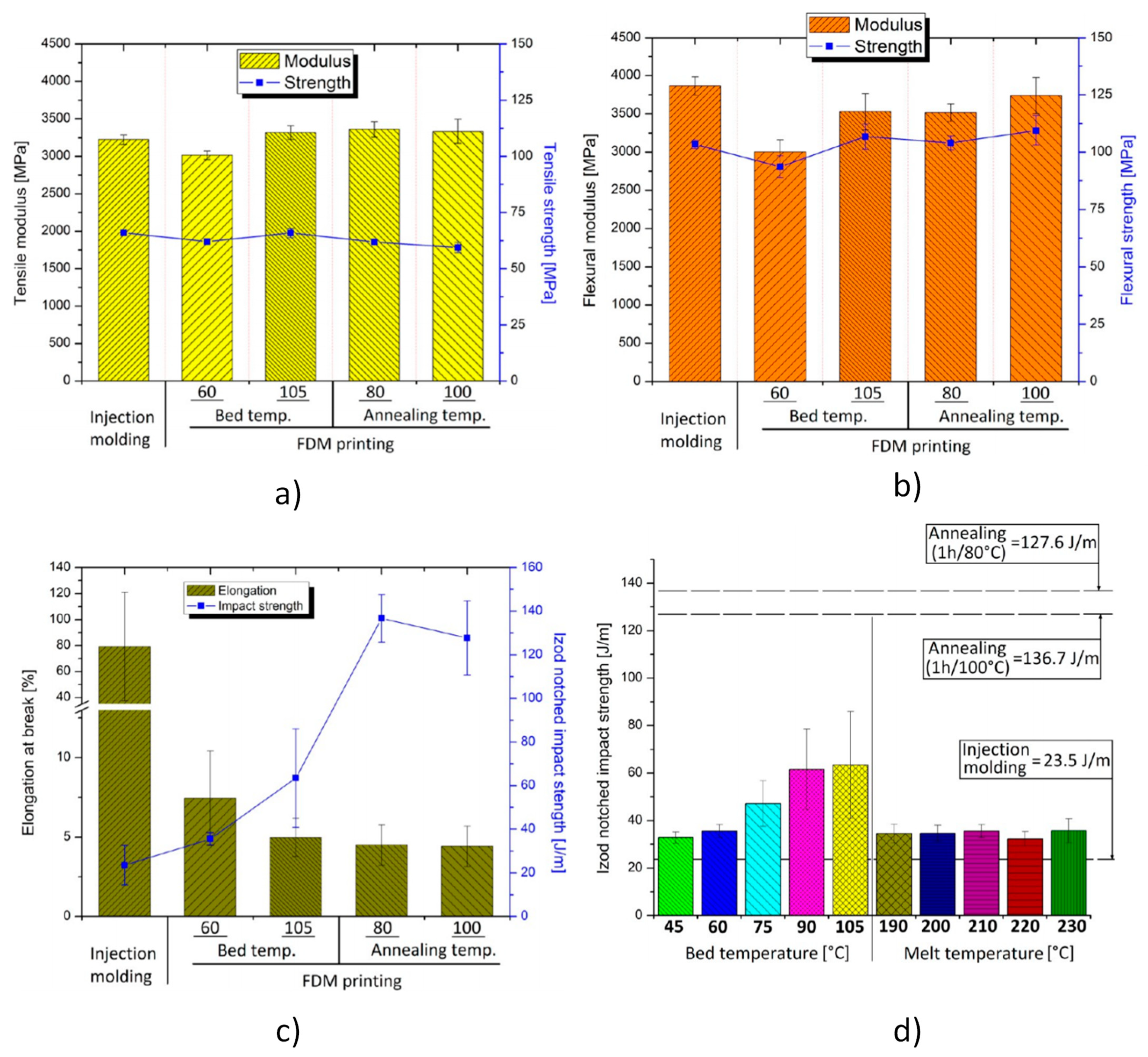

4.2. Polylactic Acid or PLA

4.3. Polycarbonate or PC

4.4. Polyethylene Terephthalate Glycol (PETG)

4.5. Polyether Ether Ketone or PEEK

4.6. Nylon or Polyamide

4.7. Thermoset Epoxy and Acrylate Resins

5. Post-Processing Techniques for 3D-Printed Polymers

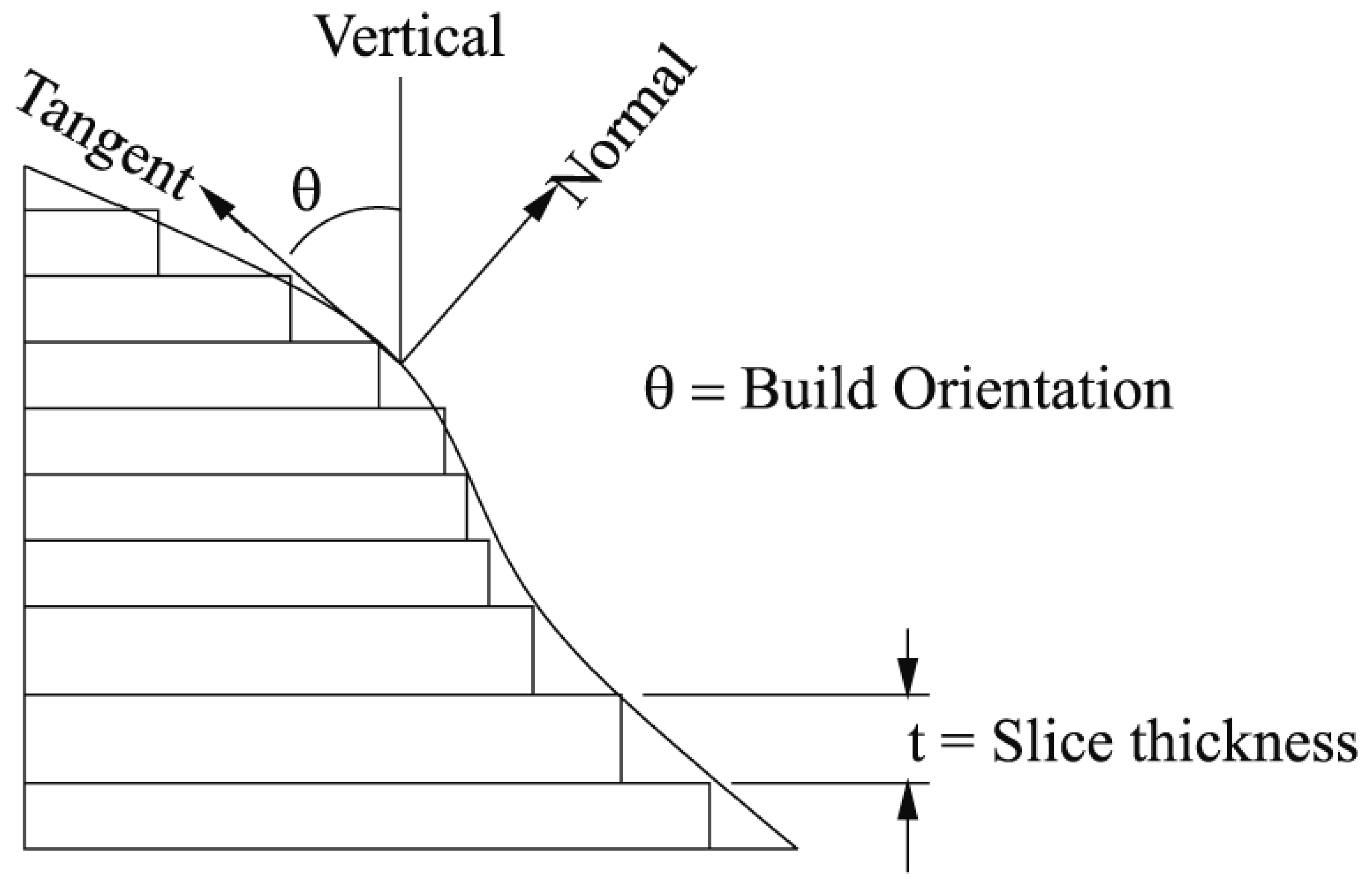

5.1. Fused Deposition Modeling (FDM)

- (1)

- Material Support Removal. Material support removal, which is considered as the most basic form of post-processing, is done through the elimination of complicated support materials. This process does not require any specialized tool beyond using simple needle-nose pliers or flush cutters [109]. This is simply done by cutting, shaving, or deburring excess material. Moreover, although it can be time-consuming and labor-intensive, it does not alter the overall geometry of the part [113]. This process however sometimes leaves marks on the surface of the part. To do away with this process, some 3D printers have both AM and SM (machining or polishing combined). Some 3D printers have dual extruders where a water-soluble support (e.g., polyvinyl alcohol, or PVA) is extruded by the second extruder head [116]. PVA is simply removed by dissolution in water solvent. Material support removal is done not only on fused deposition modelling prints but also for parts produced with other printing technologies.

- (2)

- Sanding or Surface Polishing. Sanding is done after the supports have been removed. In this process, a 3D part is smoothened using a sander/sandpaper to remove any obvious imperfections [38]. It is recommended that one uses increasing grades of sandpaper (i.e., 100, 240, 400, 600, 1500, and 2000), sanding the print with a larger grade paper first to remove bumps and scratches. While this method may produce a desirable texture, it is difficult to apply for intricate surfaces or low glass transition (Tg) polymers [111].

- (3)

- Gap Filling. This uses inexpensive materials on the market to at least protect and give an aesthetic effect on an FDM print surface. Due to toolpath constraints and other reasons, gaps may be formed from incompletely printed layers. Gap filling is simply filling the voids and gaps with epoxy/fillers. A filler may be used for larger gaps which will require additional sanding to remove excess material [38].

- (4)

- Coating. This is the use of any paint or resin formulation available which would improve the aesthetic of the print. Painting may be done manually by using an air spray or brush. As with the other post-processing methods listed above, this method is very simple to apply [109]. Figure 3 shows 3D-printed specimens which have been coated to investigate its effect on strength and stiffness of the material, the results of the study showed adequate mechanical properties for some applications (especially non-load bearing) [117]. Two types of coating polymers were used, namely, polyurethane elastomer and liquid silicone. The details are provided in the reference. Both these products are commonly used in outdoor waterproofing.

- (5)

- Polymer Coating. While coating is usually done using spray paints and other formulations for aesthetic purposes, direct polymer coating, on the other hand, is found to increase the adhesion of 3D printing materials on textile fabrics by initially coating the latter with a soluble polymer layer (dissolved or melt polymer). One of its advantages is that adhesion can be substantially enhanced without significantly changing the haptic properties and the bending stiffness of a fabric. Plastisols are solutions of polymers which require solvent evaporation after coating. Epoxy resins are thermoset polymer coatings that involve curing. Figure 4 shows 3D printed ABS and cotton fabrics coated with various polymers [118].

- (1)

- Cold Welding. Solvent and other chemical substances can also be used to weld broken parts of ABS materials. For instance, the use of acetone solvent will not change the color of the print surface as much as other glues. Once dried, the joint will exhibit the properties of bulk ABS, making further finishing more uniform and simple [121].

- (2)

- Vapor Smoothing. The usual method of post-processing an ABS-printed object involves the use of solvents to dissolve its surface layer. Acetone is usually used as a solvent for ABS vapor smoothing [122]. It involves the 3D-printed object/material being exposed to saturated acetone vapors in a closed environment (generally in a glass enclosure). The vapors condense on the outer layer of the print, resulting in the fading of layer lines. This process indirectly smoothens the outer layer of the print, giving it a shiny look [111]. However, this method affects the object’s dimensional accuracy, as the amount of material being removed cannot be controlled. Note also that some solvents are more toxic, and therefore proper precautions must be taken when using this post-processing technique. In addition, improvised apparatus/materials may also be used in post-processing techniques such as ABS vapor smoothing, as long as certain properties of the polymer, such as heating temperature, are considered. Figure 5 shows an improvised setup for vapor smoothing/polishing as reported by Tuazon et al., wherein the authors observed a significant effect of this post-processing technique on the impact behavior of 3D-printed ABS parts [16].

- -

- Dip Coating. This is a post-processing method done by dip coating the FDM 3D-printed parts into food-grade polyurethane or epoxy resin, or an FDA approved PTFE, acting as food-safe coatings and sealants to reduce the risk of bacteria build-up and particle migration.

5.2. Stereolithography (SLA)

SLA Materials and Post-Processing

- (1)

- Washing. After 3D printing, parts are usually slimy, due to the uncured resin still being attached to the surface of printed parts. Isopropyl alcohol (IPA) and water are commonly used for washing [50].

- (2)

- (3)

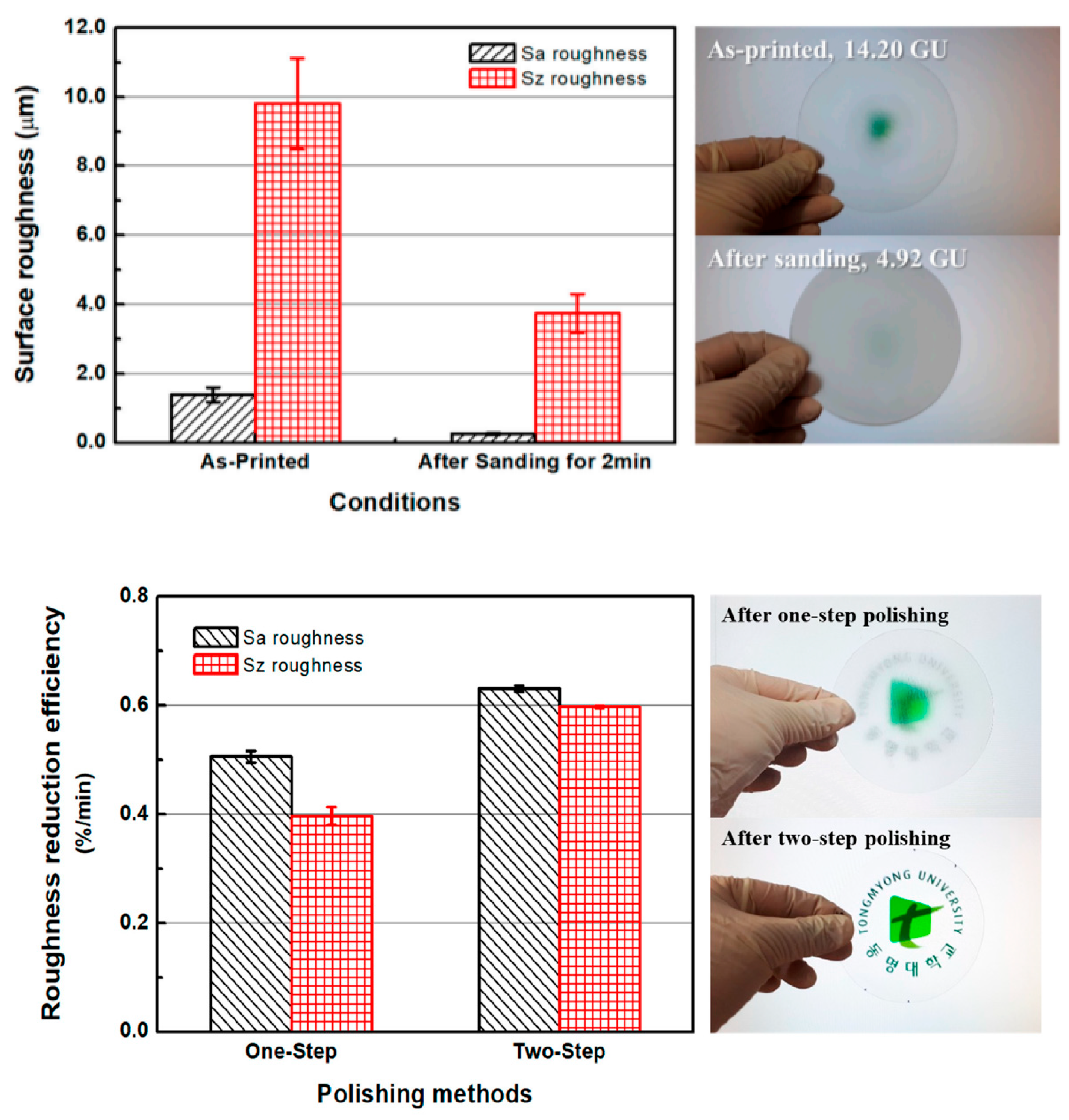

- Wet sanding/mechanical polishing. Sanding of the support nibs can be done in flat surfaces. Because the surface can only be sanded at the support nibs, the overall geometry of the parts will not be affected [125,126]. Wet sanding provides a smooth surface finish, making it ideal for complex geometries. However, it has lower accuracy on the supported side, and the use of water while sanding may result in some light spots on the 3D prints [125].

- (4)

- Chemical mechanical polishing (CMP). This is a hybrid process that flattens the surface of a material through a mechanical material removal method and chemical surface reactions. This method uses abrasive particles located on the real contact area (RCA) between the material to be polished and a polishing pad [127]. In their experiments, Son et al. used two polishing methods to reduce the surface roughness and increase the glossiness of SLA-printed ABS-like resin. In the one-step polishing case, only CMP was directly applied to the sample, while in the two-step polishing case, the sample (disc) was first polished for 2 min using sandpaper (#2000) before CMP was performed. Polishing using sandpaper was done to quickly remove the waviness on the surface of the material. After this two-step process, the disc was cleaned with PVA brush scribing and then air-dried. It took a significant amount of time to remove the waviness on the surface of the disk in the case of the one-step polishing. However, in the case of the two-step polishing, the surface roughness was reduced more quickly, and the glossiness increased relatively faster. Figure 7 demonstrates the surface roughness assessments of 3D-printed ABS-like resin [127].

- (5)

- (6)

- Spray paint (clear UV protective acrylic). This is done by spray-painting the model to help conceal layer lines. This reduces the need to sand the unsupported side of the model. The varnish may also protect the model from yellowing by limiting UV exposure. It has a clear finish that also offers UV protection. However, it increases the overall dimension and may result in an ‘orange peel’ effect on the surface [125].

5.3. Selective Laser Sintering (SLS)

SLS Materials and Post-Processing

- (1)

- (2)

- Dyeing. Dyeing is a fast and cost-effective method to color SLS 3D-printed parts. Dyeing is ideal for SLS 3D-printed parts due to their porosity. The dyeing process starts by immersing the 3D-printed part in the dyeing tank, which contains the dye and an auxiliary agent. The part is then gradually dyed through the circulation of the dyeing cylinder [132,134].

- (3)

- Spray paint or lacquering. Spray painting or lacquer coating (clear coat or varnish) may be used for SLS 3D-printed parts. Various finishes could be achieved via lacquering, e.g., metallic sheen or high gloss. Lacquer coatings may increase water tightness, improve surface hardness, increase wear resistance, and limit smudges and marks on the surface of the 3D-printed part [132].

- (4)

- Waterproof Treatment. Coatings may be applied to enhance the inherent water-resistant properties of SLS 3D-printed parts. The surface of the part may be covered by dip-dyeing, spraying, or even coating with a layer of epoxy resin. Vinyl-acrylates and silicones have been reported to provide excellent results [132,133,134].

- (5)

- Roller polishing. This is a rough polishing process which may provide a smooth finish on the surface of nylon 3D-printed parts. Roller polishing starts by putting a small stone or a steel ball in a drum, the drum then vibrates at a high frequency to provide the grinding effect. This process results in the rounding of sharp edges and may also affect part dimension (to a small degree). This process therefore is not recommended to be used for parts with complicated functions and fine details [134].

5.4. Other Finishing Methods

- (1)

- Physical vapor deposition (PVD) is a process wherein the surface of the 3D-printed part is coated with a metal or ceramic material by ionizing the atoms of the coating material. This process does not require any medium to transfer the coating but is usually done under a vacuum. These coatings change the surface characteristics, producing a more robust part against wear, friction, heat, chemicals, etc. [136].

- (2)

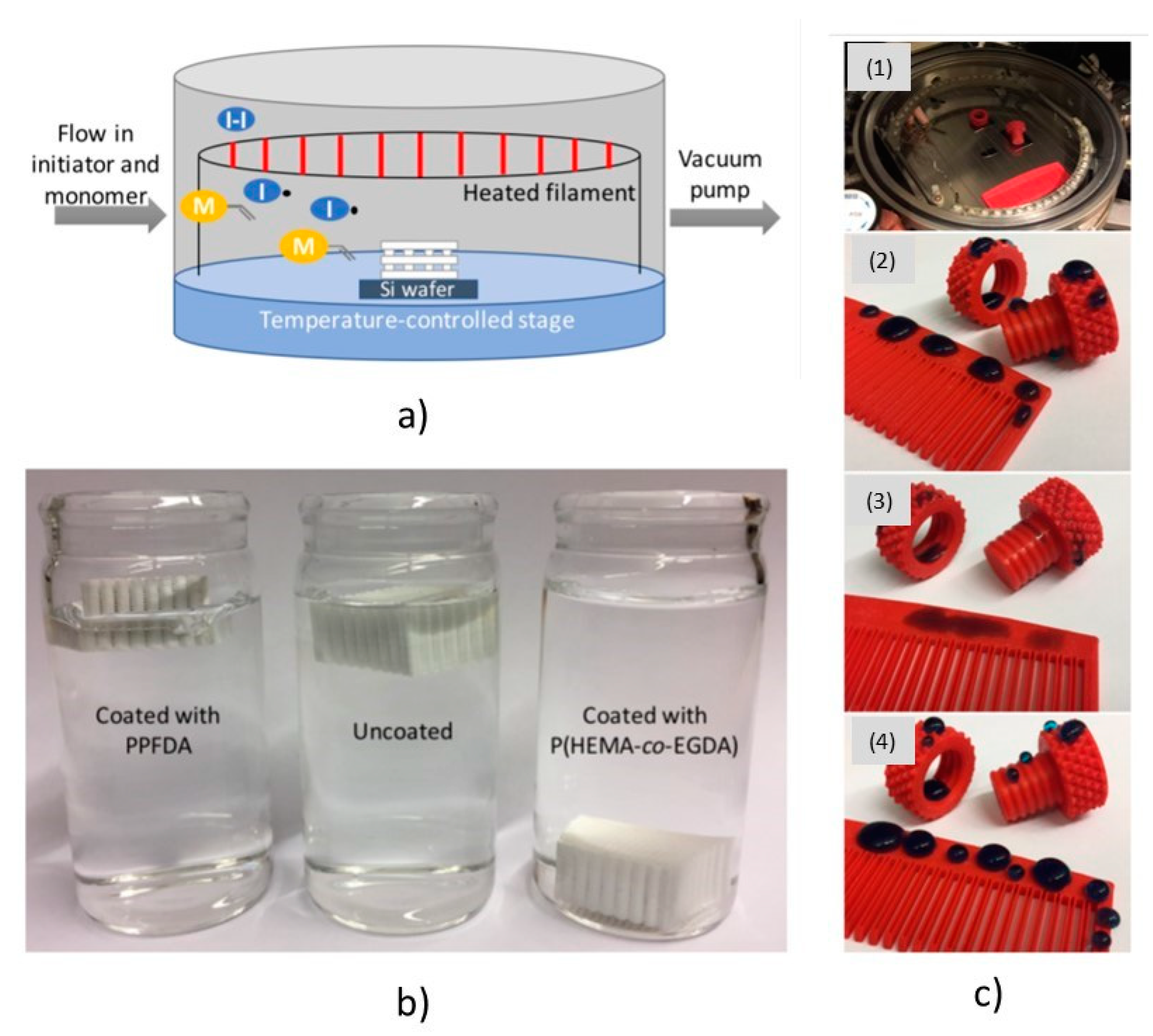

- Chemical vapor deposition (CVD) is a method where the surface properties of common 3D printing polymers can be functionalized, thereby allowing the bulk properties of 3D-printed objects (e.g., strength) can be manipulated/designed separately from surface properties. In one study [137], the filament temperature and substrate temperature were varied and the parts were coated via CVD (hydrophilic and hydrophobic polymers were used as a coating). Figure 10a shows a schematic of the initiated chemical vapor deposition (iCVD) process used to coat 3D-printed PLA and ABS parts/substrates. The 3D-printed substrate (white) was placed on a silicon wafer piece and then on a temperature-controlled stage. Poly(1H,1H,2H,2H-perfluorodecyl acrylate) (PPFDA), which is hydrophobic, and poly((2-hydroxyethyl methacrylate)-co-(ethylene glycol diacrylate)) (P(HEMA-co-EGDA)), which is hydrophilic, were deposited onto the substrates. Figure 10b shows an uncoated PLA object which is floating in water. Because the uncoated PLA is hydrophobic, the pores of the lattice did not get wet and remained filled with air, thereby reducing the density of the lattice and preventing it from sinking. In the same way, the object coated with PPFDA also floated because its enhanced hydrophobicity also caused its pores to not get wet, and therefore were filled with air. On the contrary, the object coated with P(HEMA-co-EGDA) sank in the water, because it absorbed water into its pores due to its hydrophilicity. This sample was soaked in water for 3 days and was then dried and placed again into the water, where it again sank. This experiment demonstrated that its hydrophilicity may be retained. These results showed that these functionalized 3D-printed parts may be used in microfluidics and tissue scaffolds [137]. Moreover, in another experiment, 3D-printed parts were coated with a hydrophilic polymer and then with a hydrophobic polymer. The parts/substrates were printed with ABS material. Different parts, such as a bolt, nut, and comb were all coated using the iCVD process (Figure 10c-1. It can be seen in Figure 10c-2 that the uncoated ABS part surfaces were hydrophobic. These parts were first coated with the hydrophilic P(HEMA-co-EGDA) and were readily wetted (Figure 10c-3). After which, the parts were coated with PPFDA, and it can be observed that the surfaces regained hydrophobicity (Figure 10c-4). These experiments show that different surfaces of 3D-printed parts can be tuned using the iCVD process.

- (3)

- Electroplating is the process of depositing a thin layer/coating on the surface of another part for functional or decorative purposes through the electro-deposition process. Indeed, 3D-printed parts manufactured using SLA, FDM, Polyjet, and others, may be electroplated with different metallic alloys. In such a case, the surface would have enhanced properties, such as improved electrical properties, increased strength, improved heat deflection, better chemical resistance, aesthetic value, and a smooth finish [138,139,140].

- (4)

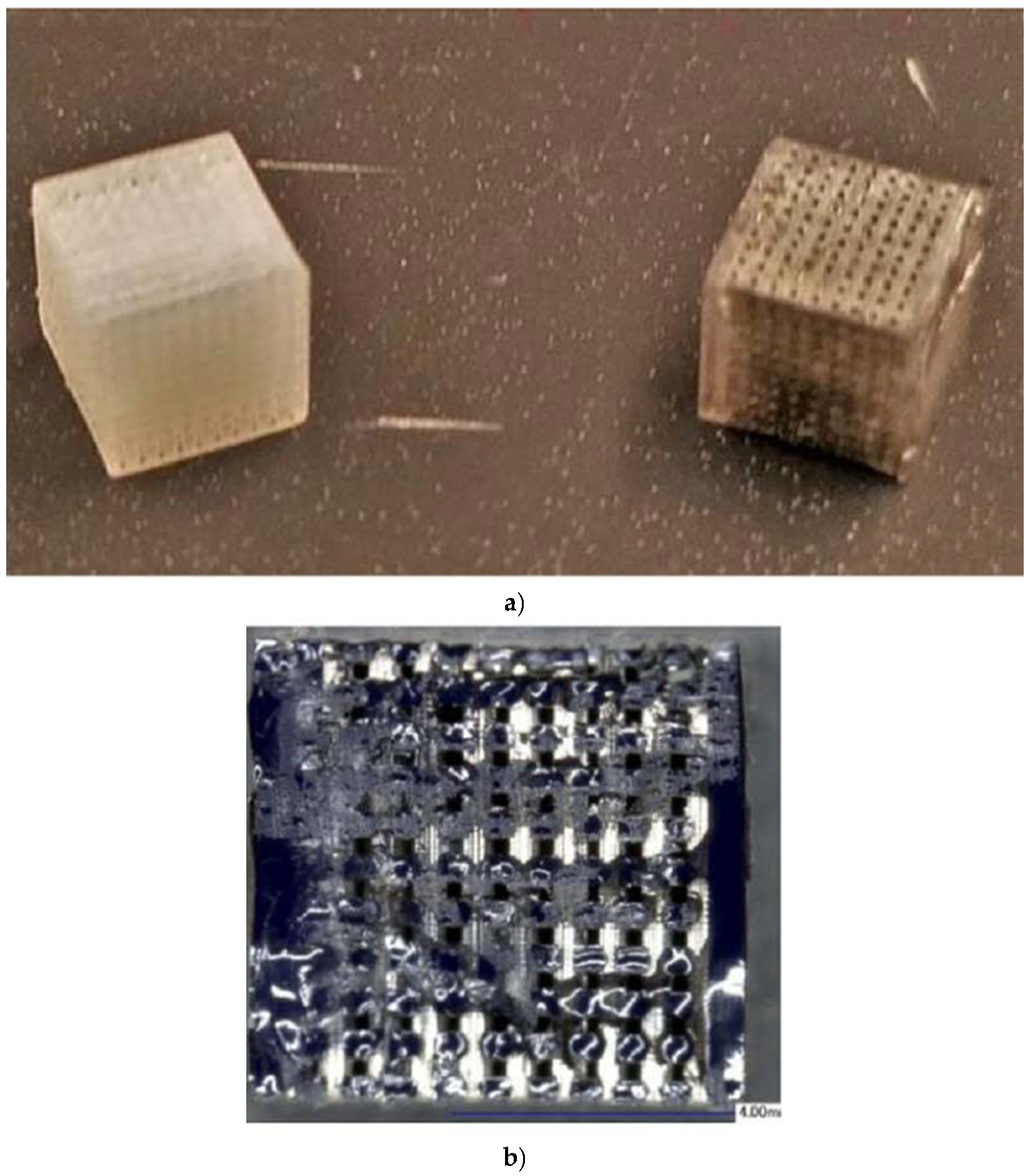

- Electroless deposition or plating, also known as autocatalytic deposition of metals, is the uniform coating of thick metallic layers on the surface of non-conductive parts (substrates) through the reduction of metallic ions from a liquid electrolyte. In some papers, 3D-printed parts via stereolithography used this method to coat nickel platinum, copper, and palladium metallic materials. Moreover, the researchers observed that the resulting parts with functionalized surfaces may be used in the fields of electronics such as MEMS, microrobots, metamaterials, as well as other chemical and mechanical engineering systems [141,142]. Jones et al. [141] plated palladium onto 3D-printed photopolymers via electroless deposition. The authors printed cubes containing logpile lattices and a cylinder containing cubic lattices. Autodesk Ember 3D printer and PR48/PR57 were used in the experiments. The cubes were 5 mm along an edge and had 200 μm pores. The cylinders were 200 mm in length and 2 mm in diameter, the cubic lattice was composed of 150 μm pores. The plating lasted for 1 h under moderate stirring. The substrate was washed with deionized water and was air dried. Figure 11a shows a photopolymer cube before (left) and after (right) plating. The cross-sectional image of the plated SLA-printed cube, demonstrating full internal metallization, is shown in Figure 11b. The adhesion strength, film brightness, and plating rate were comparable with other thermoplastic materials printed via FDM. Internal plating of photopolymers could be easily achieved compared with FDM-printed parts, specifically polycarbonate [141]. These results show that 3D metal-polymer composite parts can be easily and effectively produced using 3D printing and a simple electroless deposition method (essentially creating a functional metal surface on high-resolution polymer substrates). With this, functional 3D parts utilizing mechanical, electrical, thermal, and catalytic properties may be developed.

- (5)

- Post-processing to protect from electrostatic discharge (ESD). Many electric/electronics devices require component materials to be electrostatic discharge (ESD) safe in order to prevent damage from the buildup of electric potential (static discharge). Usually, several post-processing methods are applied, namely: (1) Painting/coating; (2) Covering with conductive tape; (3) Wrapping with aluminum-coated or carbon-filled films [143,144]. Some companies have developed ESD-safe 3D printing materials, which eliminates the need for post-processing [137,138].

- (6)

- Post-processing for 4D printing. Nadgorny et al. reported on the FDM 3D printing of parts using an ABS filament followed by quaternization post-processing with 1-bromoethane (BE) and then cross-linking with 1,4-dibromobutane (DBB). Moreover, the post-processing of soaking the 3D-printed model in a bath of silver nitrate (AgNO3) and then the catalyzed reduction of 4-Nitrophenol allowed for the functionalization of the surface of the 3D-printed model with silver (Ag) and then the tuning of the pH-responsive swelling of the model [145]. Bodaghi et al. used a compressed water jet to remove the hydrophilic gel Sup705 sacrificial material from the structure, consisting of TangoBlackPlus (fiber) and VeroWhitePlus (matrix) [146]. In order to improve the interlayer adhesion, reduce anisotropy, and strengthen the parts of FDM 3D-printed parts, Shaffer et al. introduced crosslinks among the polymer chains. Ionizing radiation was used to expose 3D-printed copolymer blends [147].

5.5. Comparison of Different Post-Processing Techniques

6. Cost and Benefits of Post-Processing

6.1. Estimated Labor Cost for Post-Processing

6.2. Estimated Time Impact for Post-Processing

7. Future Prospects

8. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. Manuf. Technol. 2016, 65, 737–760. [Google Scholar] [CrossRef] [Green Version]

- Trends in 3D Printing Among Manufacturers: A Survey of Manufacturing Decision Makers. Available online: https://cdn2.hubspot.net/hubfs/362383/Jabil-3D-Printing-Report.pdf?t= (accessed on 5 August 2021).

- Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Hernandez, D.D. Factors affecting dimensional precision of consumer 3D printing. Int. J. Aviat. Aeronaut. Aerosp. 2015, 2, 2. [Google Scholar] [CrossRef] [Green Version]

- Dizon, J.R.C.; Valino, A.D.; Souza, L.R.; Espera, A.H.; Chen, Q.; Advincula, R.C. Three-dimensional-printed molds and materials for injection molding and rapid tooling applications. MRS Commun. 2019, 9, 1267–1283. [Google Scholar] [CrossRef]

- De Leon, A.C.; Chen, Q.; Palaganas, N.B.; Palaganas, J.O.; Manapat, J.; Advincula, R.C. High performance polymer nanocomposites for additive manufacturing applications. React. Funct. Polym. 2016, 103, 141–155. [Google Scholar] [CrossRef]

- Manapat, J.; Mangadlao, J.D.; Tiu, B.D.B.; Tritchler, G.C.; Advincula, R.C. High-Strength Stereolithographic 3D Printed Nanocomposites: Graphene Oxide Metastability. ACS Appl. Mater. Interfaces 2017, 9–11, 10085–10093. [Google Scholar] [CrossRef] [PubMed]

- Knell, T. What Is Additive Manufacturing? Available online: https://www.spotlightmetal.com/what-is-additive-manufacturing-a-796337/ (accessed on 5 August 2021).

- Espera, A.H.; Dizon, J.R.C.; Chen, Q.; Advincula, R.C. 3D-printing and advanced manufacturing for electronics. Prog. Addit. Manuf. 2019, 4, 245–267. [Google Scholar] [CrossRef]

- Advincula, R.C.; Dizon, J.R.C.; Chen, Q.; Niu, I.; Chung, J.; Kilpatrick, L.; Newman, R. Additive Manufacturing for COVID-19: Devices, Materials, Prospects and Challenges. MRS Commun. 2020, 10, 413–427. [Google Scholar] [CrossRef]

- Tijing, L.D.; Dizon, J.R.C.; Ibrahim, I.; Nisay, A.R.N.; Shon, H.K.; Advincula, R.C. 3D printing for membrane separation, desalination and water treatment. Appl. Mater. Today 2020, 18, 100486. [Google Scholar] [CrossRef]

- Tijing, L.D.; Dizon, J.R.C.; Cruz, G.C., Jr. 3D-Printed Absorbers for Solar-Driven Interfacial Water Evaporation: A Mini-Review. Adv. Sustain. Sci. Eng. Technol. 2021, 3, 0210103. [Google Scholar] [CrossRef]

- Wei, P.; Leng, H.; Chen, Q.; Advincula, R.C.; Pentzer, E. Reprocessable 3D-Printed Conductive Elastomeric Composite Foams for Strain and Gas Sensing. ACS Appl. Polym. Mater. 2019, 1, 885–892. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Chen, Q.; Valino, A.D.; Advincula, R.C. Thermo-mechanical and swelling properties of three-dimensional-printed poly (ethylene glycol) diacrylate/silica nanocomposites. MRS Commun. 2019, 9, 209–217. [Google Scholar] [CrossRef]

- Valino, A.D.; Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Messman, J.; Advincula, R.C. Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog. Polym. Sci. 2019, 98, 101162. [Google Scholar] [CrossRef]

- Tuazon, B.J.; Espino, M.T.; Ryan, J.; Dizon, C. Investigation on the Effects of Acetone Vapor-Polishing to Fracture Behavior of ABS Printed Materials at Different Operating Temperature. Mater. Sci. Forum. 2020, 1005, 141–149. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Valino, A.D.; Souza, L.R.; Espera, A.H.; Chen, Q.; Advincula, R.C. 3D Printed Injection Molds Using Various 3D Printing Technologies. Mater. Sci. Forum. 2020, 1005, 150–156. [Google Scholar] [CrossRef]

- Delda, R.N.M.; Tuazon, B.J.; Dizon, J.R.C. Assessment of Interfacial Adhesion of Adhesively Bonded 3D-Printed Thermoplastics. Mater. Sci. Forum. 2020, 1005, 157–165. [Google Scholar] [CrossRef]

- Espino, M.T.; Tuazon, B.J.; Robles, G.S.; Dizon, J.R.C. Application of Taguchi Methodology in Evaluating the Rockwell Hardness of SLA 3D Printed Polymers. Mater. Sci. Forum. 2020, 1005, 166–173. [Google Scholar] [CrossRef]

- Andres, N. Development of Solar-Powered Water-Pump with 3D Printed Impeller. Open Eng. J. 2021, 11, 249–253. [Google Scholar] [CrossRef]

- Diego, J.R.R.; Martinez, D.W.; Robles, G.S.; Dizon, J.R.C. Development of Smartphone-Controlled Hand and Arm Exoskeleton for Persons with Disability. Open Eng. J. 2020, 11, 161–170. [Google Scholar] [CrossRef]

- De Leon, A.C.; Rodier, B.J.; Bajamundi, C.; Espera, A., Jr.; Wei, P.; Kwon, J.G.; Williams, J.; Ilijasic, F.; Advincula, R.C.; Pentzer, E. Plastic Metal-Free Electric Motor by 3D Printing of Graphene-Polyamide Powder. ACS Appl. Energy Mater. 2018, 1, 1726–1733. [Google Scholar] [CrossRef]

- Advincula, R.C.; Dizon, J.R.C.; Caldona, E.B.; Siacor, J.F.D.C.; Maalihan, R.D.; Espera, A.H. On the Progress of 3D-Printed Hydrogels for Tissue Engineering. MRS Commun. 2021, 1–15. [Google Scholar] [CrossRef]

- Quality Management and Quality Assurance The Prerequisite for Success in Additive Manufacturing. Available online: https://www.eos.info/en/industrial-3d-printing/3d-printing-quality-assurance (accessed on 6 August 2021).

- Chen, Q.; Mangadlao, J.D.; Wallat, J.; de Leon, A.; Pokorski, J.K.; Advincula, R.C. 3D Printing Biocompatible Polyurethane/Poly(lactic acid)/Graphene Oxide Nanocomposites: Anisotropic Properties. ACS Appl. Mater. Interfaces 2017, 9, 4015–4023. [Google Scholar] [CrossRef] [PubMed]

- Palaganas, N.B.; Mangadlao, J.D.; de Leon, A.C.C.; Palaganas, J.O.; Pangilinan, K.D.; Lee, Y.J.; Advincula, R.C. 3D Printing of Photocurable Cellulose Nanocrystal Composite for Fabrication of Complex Architectures via Stereolithography. ACS Appl. Mater. Interfaces 2017, 39, 34314–34324. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Cao, P.-F.; Advincula, R.C. Mechanically Robust, Ultraelastic Hierarchical Foam with Tunable Properties via 3D Printing. Adv. Funct. Mater. 2018, 28, 1800631. [Google Scholar] [CrossRef]

- Espera, A.H., Jr.; Valino, A.D.; Palaganas, J.O.; Souz, L.; Chen, Q.; Advincula, R.C. 3D Printing of a Robust Polyamide-12-Carbon Black Composite via Selective Laser Sintering: Thermal and Electrical Conductivity. Macromol. Mater. Eng. 2019, 304, 1800718. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, J.; Ren, J.; Rong, L.; Cao, F.; Advincula, R.C. 3D Printed Multifunctional, Hyperelastic Silicone Rubber Foam. Adv. Funct. Mater. 2019, 29, 1900469. [Google Scholar] [CrossRef]

- Palaganas, J.; de Leon, A.C.; Mangadlao, J.; Palaganas, N.; Mael, A.; Lee, Y.J.; Yian Lai, H.; Advincula, R. Facile Preparation of Photocurable Siloxane Composite for 3D Printing. Macromol. Mater. Eng. 2017, 302, 1600477. [Google Scholar] [CrossRef]

- How to Improve Aesthetic and Mechanical Properties of FDM 3D Printed Parts. Available online: https://www.javelin-tech.com/blog/2019/06/mechanical-properties-fdm-3d-printed-parts/ (accessed on 5 August 2021).

- Grimm, T. 3D Printing: The Impact of Post-Processing. Available online: https://www.techbriefs.com/component/content/article/tb/pub/features/articles/33589 (accessed on 5 August 2021).

- Momeni, F.; Hassani, S.M.M.; Liu, N.X.; Ni, J. A review of 4D printing. Mater. Des. 2017, 122, 42–79. [Google Scholar] [CrossRef]

- Zhou, J.; Sheiko, S.S. Reversible shape-shifting in polymeric materials. J. Polym. Sci. Part B Polym. Phys. 2016, 54, 1365–1380. [Google Scholar] [CrossRef] [Green Version]

- Tibbits, S. 4D printing: Multi-material shape change. Arch. Des. 2014, 84, 116–121. [Google Scholar] [CrossRef]

- Albright, B. Post-Processing 3D Printed Prototypes Getting to the Finished Part. Available online: https://www.digitalengineering247.com/article/post-processing-3d-printed-prototypes/ (accessed on 5 August 2021).

- Enhancing Aesthetic & Functional Properties of 3D Print. Available online: https://www.azom.com/article.aspx?ArticleID=17987 (accessed on 5 August 2021).

- Chen, A. 4 Vital Things on Post-Processing 3D Printed Parts. Available online: https://www.cmac.com.au/blog/4-vital-things-post-processing-3d-printed-parts (accessed on 5 August 2021).

- Molitch-Hou, M. Overview of additive manufacturing process. Addit. Manuf. Mater. Process. Quantif. Appl. 2018, 9780128121559, 1–38. [Google Scholar] [CrossRef]

- Zivanovic, S.T.; Popovic, M.D.; Vorkapic, N.M.; Pjevic, M.D.; Slavkovic, N.R. An overview of rapid prototyping technologies using subtractive, additive and formative processes. FME Trans. 2020, 48, 246–253. [Google Scholar] [CrossRef]

- Jiménez, M.; Romero, L.; Domínguez, I.A.; Espinosa, M.D.M.; Domínguez, M. Domínguez Additive Manufacturing Technologies: An Overview about 3D Printing Methods and Future Prospects. Complexity 2019, 2019, 1–30. [Google Scholar] [CrossRef] [Green Version]

- Kocovic, P. 3D Printing and Its Impact on the Production of Fully Functional Components: Emerging Research and Opportunities; IGI Global: Hershey, PA, USA, 2017. [Google Scholar] [CrossRef]

- Husar, B.; Hatzenbichler, M.; Mironov, V.; Liska, R.; Stampfl, J.; Ovsianikov, A. Photopolymerization-based additive manufacturing for the development of 3D porous scaffolds. Biomater. Bone Regen. Nov. Tech. Appl. 2014, 9780857098047, 149–201. [Google Scholar] [CrossRef]

- Chakravorty, D. 3D Printing Support Structures—The Ultimate Guide. Available online: https://all3dp.com/1/3d-printing-support-structures/ (accessed on 5 August 2021).

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies. Addit. Manuf. Technol. 2015, 978-1-4939-2113-3, 1–15. [Google Scholar] [CrossRef]

- De Leon, A.C.; da Silva, Í.G.; Pangilinan, K.D.; Chen, Q.; Caldona, E.B.; Advincula, R.C. High performance polymers for oil and gas applications. React. Funct. Polym. 2021, 162, 104878. [Google Scholar] [CrossRef]

- Chen, Q.; Sukmanee, T.; Rong, L.; Yang, M.; Ren, J.; Ekgasit, S.; Advincula, R. A Dual Approach in Direct Ink Writing of Thermally Cured Shape Memory Rubber Toughened Epoxy. ACS Appl. Polym. Mater. 2020, 2, 5492–5500. [Google Scholar] [CrossRef]

- Alexandrea, P. The Complete Guide to Stereolithography(SLA) in 3D Printing. 3D Native. Available online: https://www.3dnatives.com/en/stereolithography-explained100420174/ (accessed on 5 August 2021).

- Manapat, J.Z.; Chen, Q.; Ye, P.; Advincula, R.C. 3D Printing of Polymer, Nanocomposites via Stereolithography. Macromol. Mater. Eng. 2017, 32, 1600553. [Google Scholar] [CrossRef]

- Guide to Stereolithography (SLA) 3D Printing in 2019. Available online: https://formlabs.com/asia/blog/ultimate-guide-to-stereolithography-sla-3d-printing/ (accessed on 5 August 2021).

- Latouche, M. SLA 3D Printing Materials Compare. Available online: https://www.hubs.com/knowledge-base/sla-3d-printing-materials-compared/ (accessed on 5 August 2021).

- Goodridge, R.; Ziegelmeier, S. Powder bed fusion of polymers. Laser Addit. Manuf. Mater. Des. Technol. Appl. 2017, 9780081004333, 181–204. [Google Scholar] [CrossRef]

- Varotsis, A.B. Introduction to SLS 3D Printing. Available online: https://www.hubs.com/knowledge-base/introduction-sls-3d-printing/ (accessed on 5 August 2021).

- Varotsis, A.B. Introduction to Binder Jetting 3D Printing. Available online: https://www.hubs.com/knowledge-base/introduction-binder-jetting-3d-printing/ (accessed on 5 August 2021).

- Engstrom, D.S. Additive Manufacturing Research Group: Binder Jetting. Available online: https://www.lboro.ac.uk/research/amrg/about/the7categoriesofadditivemanufacturing/binderjetting/ (accessed on 5 August 2021).

- Zhang, H.; Cai, L.; Golub, M.; Zhang, Y.; Yang, X.; Schlarman, K.; Zhang, J. Tensile, Creep, and Fatigue Behaviors of 3D-Printed Acrylonitrile Butadiene Styrene. J. Mater. Eng. Perform. 2018, 27, 57–62. [Google Scholar] [CrossRef] [Green Version]

- Aldousiri, B.; Shalwan, A.; Chin, C.W. A review on tribological behaviour of natural reinforced composites. J. Reinf. Plast. Compos. 2018, 37, 349–353. [Google Scholar] [CrossRef]

- Selvamani, S.K.; Samykano, M.; Subramaniam, S.R.; Ngui, W.K.; Kadirgama, K.; Kanagaraj, G.; Idris, M.S. 3D printing: Overview of ABS evolvement. AIP Conf. Proc. 2019, 2059, 020041. [Google Scholar] [CrossRef]

- Gokhare, V.G.; Raut, D.N.; Shinde, D.K. A Review paper on 3D-Printing Aspects and Various Processes Used in the 3D-Printing. Int. J. Eng. Res. Technol. 2017, 6, 953–958. [Google Scholar]

- Begum, S.A.; Rane, A.V.; Kanny, K. Applications of compatibilized polymer blends in automobile industry. Compat. Polym. Blends Micro Nano Scale Phase Morphol. Interphase Charact. Prop. 2019, 978-0-12-816006-0, 563–593. [Google Scholar] [CrossRef]

- Omnexus, Acrylonitrile Butadiene Styrene (ABS) and Its Features. 2021. Available online: https://omnexus.specialchem.com/selection-guide/acrylonitrile-butadiene-styrene-abs-plastic (accessed on 12 July 2021).

- Harris, A.M.; Lee, E.C. Improving Mechanical Performance of Injection Molded PLA by Controlling Crystallinity. J. Appl. Polym. Sci. 2008, 107, 2246–2255. [Google Scholar] [CrossRef]

- Benwood, C.; Anstey, A.; Andrzejewski, J.; Misra, M.; Mohanty, A.K. Improving the Impact Strength and Heat Resistance of 3D Printed Models: Structure, Property, and Processing Correlationships during Fused Deposition Modeling (FDM) of Poly(Lactic Acid). ACS Omega 2018, 3, 4400–4411. [Google Scholar] [CrossRef]

- Hagen, R. Polylactic Acid. Polym. Sci. A Compr. Ref. 2012, 10, 231–236. [Google Scholar] [CrossRef]

- Yang, Z.; Peng, H.; Wang, W.; Liu, T. Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J. Appl. Polym. Sci. 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Wittbrodt, B.; Pearce, J.M. The effects of PLA color on material properties of 3-D printed components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef] [Green Version]

- Avérous, L. Polylactic acid: Synthesis, properties and applications. Polylactic Acid Synth. Prop. Appl. 2012, 9780080453163, 1–340. [Google Scholar] [CrossRef]

- Avérous, L. Polylactic acid: Synthesis, properties and applications. In Monomers, Polymers and Composites from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2008; pp. 433–450. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef] [Green Version]

- Yang, T.C. Effect of extrusion temperature on the physico-mechanical properties of unidirectional wood fiber-reinforced polylactic acid composite (WFRPC) components using fused depositionmodeling. Polymers 2018, 10, 976. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lopes, M.S.; Jardini, A.L.; Filho, R.M. Poly (lactic acid) production for tissue engineering applications. Procedia Eng. 2012, 42, 1402–1413. [Google Scholar] [CrossRef] [Green Version]

- Tommaso, P.G.C.; Filippo, R. Castrovinci Andrea, A Perspective on Polylactic Acid-Based Polymers Use for Nanoparticles Synthesis and Applications. Front. Bioeng. Biotechnol. 2019, 7, 259. [Google Scholar] [CrossRef]

- Carlota, V. All You Need to Know about Polycarbonate (PC) for 3D Printing. Available online: https://www.3dnatives.com/en/polycarbonate-pc-for-3d-printing-110220204/ (accessed on 5 August 2021).

- Polycarbonate. Available online: https://www.simplify3d.com/support/materials-guide/polycarbonate/ (accessed on 5 August 2021).

- de la Colina-Martínez, A.L.; Martínez-Barrera, G.; Barrera-Díaz, C.E.; ávila-Córdoba, L.I.; Ureña-Núñez, F. Characterization of recycled polycarbonate from electronic waste and its use in hydraulic concrete: Improvement of compressive performance. Adv. Concr. Constr. 2017, 5, 563–573. [Google Scholar] [CrossRef]

- Martínez, A.L.d.; Barrera, G.M.; Díaz, C.E.B.; Córdoba, L.I.Á.; Núñez, F.U.; Hernández, D.J.D. Recycled polycarbonate from electronic waste and its use in concrete: Effect of irradiation. Constr. Build. Mater. 2019, 201, 778–785. [Google Scholar] [CrossRef]

- Konstantinou, I.; Vosniakos, G.C. Rough-cut fast numerical investigation of temperature fields in selective laser sintering/melting. Int. J. Adv. Manuf. Technol. 2018, 99, 29–36. [Google Scholar] [CrossRef]

- Burr, E. Polycarbonate (PC) 3D Printing—All You Need to Know. Available online: https://all3dp.com/2/polycarbonate-pc-3d-printing-all-you-need-to-know/ (accessed on 5 August 2021).

- Online, Polycarbonates. Available online: https://www.essentialchemicalindustry.org/polymers/polycarbonates.html (accessed on 17 July 2021).

- Guessasma, S.; Belhabib, S.; Nouri, H. Printability and tensile performance of 3D printed polyethylene terephthalate glycol using fused deposition modelling. Polymers 2019, 11, 1220. [Google Scholar] [CrossRef] [Green Version]

- Latko-Durałek, P.; Dydek, K.; Boczkowska, A. Thermal, Rheological and Mechanical Properties of PETG/rPETG Blends. J. Polym. Environ. 2019, 27, 2600–2606. [Google Scholar] [CrossRef] [Green Version]

- Nieto, D.M.; López, V.C.; Molina, S.I. Large-format polymeric pellet-based additive manufacturing for the naval industry. Addit. Manuf. 2018, 23, 79–85. [Google Scholar] [CrossRef]

- Instincts, M. Structure of PETG. Available online: https://www.molinstincts.com/structure/PETG-cstr-CT1103556678.html (accessed on 17 July 2021).

- Velisaris, C.N.; Seferis, J.C. Crystallization kinetics of polyetheretherketone (peek) matrices. Polym. Eng. Sci. 1986, 26, 1574–1581. [Google Scholar] [CrossRef]

- Jones, D.P.; Leach, D.C.; Moore, D.R. Mechanical properties of poly(ether-ether-ketone) for engineering applications. Polymer 1985, 26, 1385–1393. [Google Scholar] [CrossRef]

- Rae, P.J.; Brown, E.N.; Orler, E.B. The mechanical properties of poly(ether-ether-ketone) (PEEK) with emphasis on the large compressive strain response. Polymer 2007, 48, 598–615. [Google Scholar] [CrossRef]

- Arzak, A.; Eguiazábal, J.I.; Nazábal, J. Phase behaviour and mechanical properties of poly(ether ether ketone)-poly(ether sulphone) blends. J. Mater. Sci. 1991, 26, 5939–5944. [Google Scholar] [CrossRef]

- Najeeb, S.; Zafar, M.S.; Khurshid, Z.; Siddiqui, F. Applications of polyetheretherketone (PEEK) in oral implantology and prosthodontics. J. Prosthodont. Res. 2016, 60, 12–19. [Google Scholar] [CrossRef] [PubMed]

- Database, P. Polyaryletherketones. Available online: https://polymerdatabase.com/polymerclasses/Polyetherketonetype.html (accessed on 17 July 2021).

- Polyamide (PA, Nylon). Available online: https://3dgence.com/filaments/polyamide/Certified (accessed on 5 August 2021).

- Carlota, V. All You Need to Know about Nylon for 3D Printing. Available online: https://www.3dnatives.com/en/nylon-3d-printing-guide-120320204/ (accessed on 5 August 2021).

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J.M. Laser sintering of polyamides and other polymers. Prog. Mater. Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- Rahim, T.N.A.T.; Abdullah, A.M.; Akil, H.M.; Mohamad, D.; Rajion, Z.A. Preparation and characterization of a newly developed polyamide composite utilising an affordable 3D printer. J. Reinf. Plast. Compos. 2015, 34, 1628–1638. [Google Scholar] [CrossRef]

- Byju’s, Nylon—Structure, Properties, Uses. Available online: https://byjus.com/chemistry/nylon/ (accessed on 17 July 2021).

- Jin, F.L.; Li, X.; Park, S.J. Synthesis and application of epoxy resins: A review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Petrović, J.M.; Bekrić, D.Ž.; Vujičić, I.A.T.; Dimić, I.D.; Putić, S.S. Microstructural characterization of glass-epoxy composites subjected to tensile testing. Acta Period. Technol. 2013, 44, 151–162. [Google Scholar] [CrossRef] [Green Version]

- Salmoria, G.V.; Ahrens, C.H.; Fredel, M.; Soldi, V.; Pires, A.T.N. Stereolithography somos 7110 resin: Mechanical behavior and fractography of parts post-cured by different methods. Polym. Test. 2005, 24, 157–162. [Google Scholar] [CrossRef]

- Sushma, R.; Vande, A.; Malvika, R.; Abhijeet, K.; Pronob, S. A Comparative Study of the Mechanical Properties of Clear and Pink Colored Denture Base Acrylic Resins. Ann. Afr. Med. 2018, 17, 178. [Google Scholar] [CrossRef]

- Huang, B.; Weng, Z.; Sun, W. Study on the properties of DSM SOMOS 11120 type photosensitive resin for stereolithography materials. Adv. Mater. Res. 2011, 233–235, 194–197. [Google Scholar] [CrossRef]

- Zguris, Z. How Mechanical Properties of Stereolithography 3D Prints are Affected by UV Curing. Available online: https://3d.formlabs.com/mechanical-properties-of-uv-cured-3d-prints/ (accessed on 5 August 2021).

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Weng, Z.; Zhou, Y.; Lin, W.; Senthil, T.; Wu, L. Structure-property relationship of nano enhanced stereolithography resin for desktop SLA 3D printer. Compos. Part A Appl. Sci. Manuf. 2016, 88, 234–242. [Google Scholar] [CrossRef]

- Henriques, B.; Pinto, P.; Silva, F.S.; Fredel, M.C.; Fabris, D.; Souza, J.C.M.; Carvalho, O. On the mechanical properties of monolithic and laminated nano-ceramic resin structures obtained by laser printing. Compos. Part B Eng. 2018, 141, 76–83. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M.J. 3D printing with polymers: Challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef]

- 3D Printers and 3D Printing: Technologies, Processes and Techniques. Available online: https://www.sculpteo.com/en/3d-printing/3d-printing-technologies/ (accessed on 5 August 2021).

- Kumar, A.; Verma, S.; Jeng, J.Y. Supportless Lattice Structures for Energy Absorption Fabricated by Fused Deposition Modeling. 3D Print. Addit. Manuf. 2020, 7, 85–96. [Google Scholar] [CrossRef]

- Kumar, A.; Collini, L.; Daurel, A.; Jeng, J.Y. Design and additive manufacturing of closed cells from supportless lattice structure. Addit. Manuf. 2020, 33, 101168. [Google Scholar] [CrossRef]

- Chohan, J.S.; Singh, R. Post Treatment for Super Finishing of 3d Printed Thermosetting Polymers Based Functional Prototypes. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2021; p. 9780128035818. [Google Scholar] [CrossRef]

- What is Post-Processing in 3D Printing? Available online: https://www.beamler.com/post-processing-3d-printing/ (accessed on 5 August 2021).

- 3D Printing Post Processing. Available online: https://bigrep.com/post-processing/ (accessed on 15 February 2021).

- FDM 3D Printing Post-Processing: An Overview for Beginners and Professionals. Available online: https://www.prozix.com/fdm-3d-printing-post-processing-an-overview-for-beginners-and-professionals/ (accessed on 24 August 2021).

- Cassaignau, A. Make Beautiful 3D Prints: Understanding the Layer Thickness. Available online: https://www.sculpteo.com/blog/2015/07/29/make-beautiful-3d-prints-understanding-the-layer-thickness/#:~:text=3D (accessed on 28 January 2020).

- Moradi, M.; Moghadam, M.K.; Shamsborhan, M.; Bodaghi, M.; Falavandi, H. Post-processing of FDM 3d-printed polylactic acid parts by laser beam cutting. Polymers 2020, 12, 550. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pandey, P.M.; Reddy, N.V.; Dhande, S.G. Slicing procedures in layered manufacturing: A review. Rapid Prototyp. J. 2003, 9, 274–288. [Google Scholar] [CrossRef] [Green Version]

- Palermo, E. Fused Deposition Modeling: Most Common 3D Printing Method. Live Sci. 2013, 19, 2013. [Google Scholar]

- The Widest Material Choice on the Market|Ultimaker. Available online: https://ultimaker.com/materials (accessed on 28 January 2020).

- Miguel, M.; Leite, M.; Ribeiro, A.M.R.; Deus, A.M.; Reis, L.; Vaz, M.F. Failure of polymer coated nylon parts produced by additive manufacturing. Eng. Fail. Anal. 2019, 101, 485–492. [Google Scholar] [CrossRef]

- Unger, L.; Scheideler, M.; Meyer, P.; Harland, J.; Görzen, A.; Wortmann, M.; Dreyer, A.; Ehrmann, A. Increasing Adhesion of 3D Printing on Textile Fabrics by Polymer Coating premazom. Tekstilec 2018, 61, 265–271. [Google Scholar] [CrossRef]

- Carlota, V. How to Optimise Post-Processing in 3D Printing: Experts Give Their Advice. Available online: https://www.3dnatives.com/en/optimise-post-processing-3d-printing-expert-advice-220820195/#! (accessed on 28 January 2020).

- What is ABS Material? Available online: https://www.plasticextrusiontech.net/resources/what-is-abs-material/ (accessed on 20 February 2021).

- Armstrong, C. Post Processing for FDM Printed Parts. Available online: https://www.3dhubs.com/knowledge-base/post-processing-fdm-printed-parts/#weld (accessed on 6 August 2021).

- Gad, S.E. Methyl ethyl ketone. In Encyclopedia of Toxicology; Elsevier: Amsterdam, The Netherlands, 2005; pp. 77–79. [Google Scholar]

- Jorgenson, L. How Annealing Makes Your 3D Prints Better. Available online: https://www.fargo3dprinting.com/annealing-makes-3d-prints-better/ (accessed on 6 August 2021).

- Bhandari, S.; Lopez-Anido, R.A.; Gardner, D.J. Enhancing the interlayer tensile strength of 3D printed short carbon fiber reinforced PETG and PLA composites via annealing. Addit. Manuf. 2019, 30, 100922. [Google Scholar] [CrossRef]

- Van der Steen, D. Post Processing for SLA Printed Parts. Available online: https://www.hubs.com/knowledge-base/post-processing-sla-printed-parts/ (accessed on 6 August 2021).

- Kategorii, B. Post-Processing in 3D Printing—How Do SLS, SLA and FDM Compare. Available online: https://www.sinterit.com/post-processing-in-3d-printing-how-do-sls-sla-and-fdm-compare/ (accessed on 4 March 2021).

- Son, J.; Lee, H. Preliminary study on polishing SLA 3D-printed ABS-like resins for surface roughness and glossiness reduction. Micromachines 2020, 11, 843. [Google Scholar] [CrossRef] [PubMed]

- Removing Support Marks. Available online: https://support.formlabs.com/s/article/Removing-Support-Marks?language=en_US (accessed on 9 October 2020).

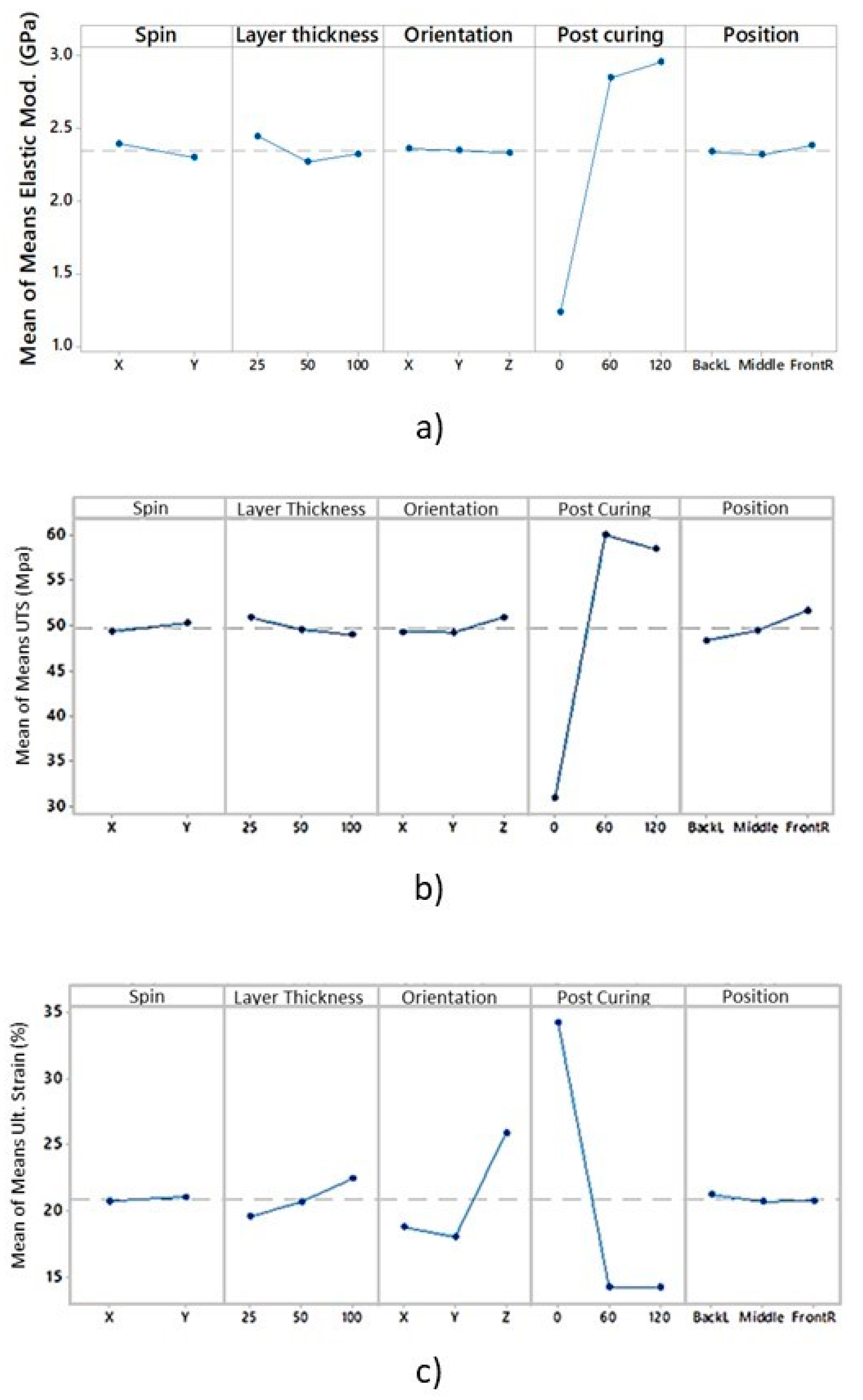

- Garcia, E.A.; Ayranci, C.; Qureshi, A.J. Material property-manufacturing process optimization for form 2 VAT-photo polymerization 3D printers. J. Manuf. Mater. Process. 2020, 4, 12. [Google Scholar] [CrossRef] [Green Version]

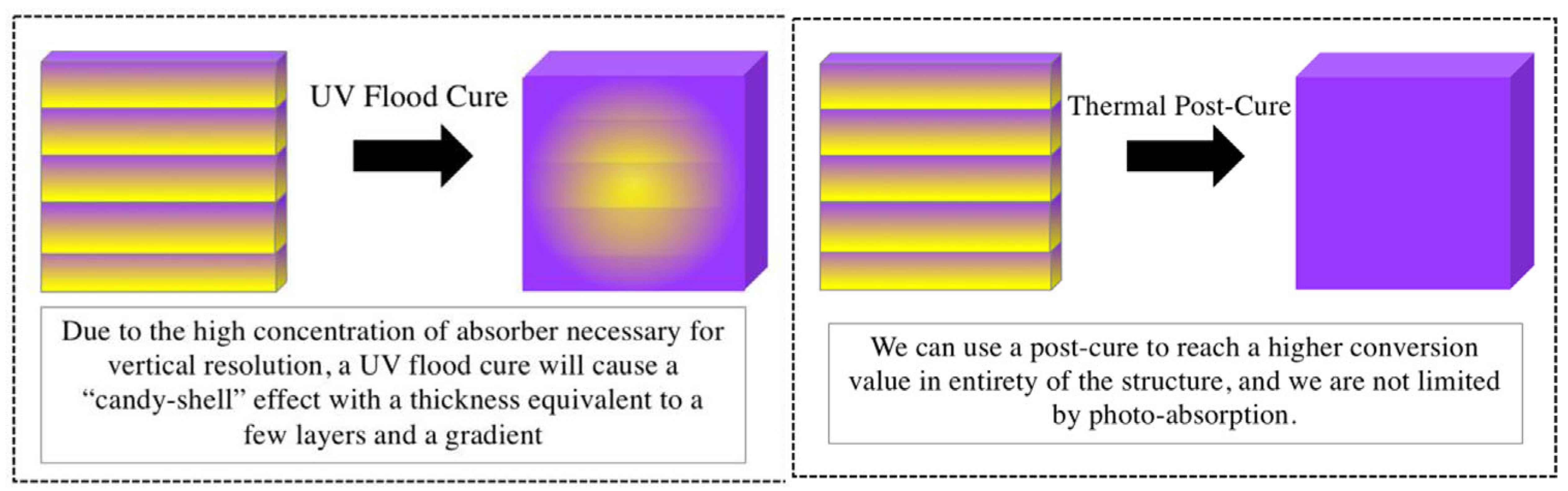

- Uzcategui, A.C.; Muralidharan, A.; Ferguson, V.L.; Bryant, S.J.; McLeod, R.R. Understanding and Improving Mechanical Properties in 3D printed Parts Using a Dual-Cure Acrylate-Based Resin for Stereolithography. Adv. Eng. Mater. 2018, 20, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Guide to Selective Laser Sintering (SLS) 3D Printing. Available online: https://formlabs.com/asia/blog/what-is-selective-laser-sintering/ (accessed on 6 August 2021).

- Redwood, B. Post Processing for SLS Printed Parts. Available online: https://www.hubs.com/knowledge-base/post-processing-sls-printed-parts/ (accessed on 6 August 2021).

- Adding the Perfect Finish to Your SLS Prints. Available online: https://amfg.ai/2017/05/24/perfect-finish-sls-prints/ (accessed on 6 August 2021).

- Common SLS Post Processing Method. Available online: https://www.sgproto.com/single-post/2019/07/20/Common-SLS-Post-Processing-Method (accessed on 6 August 2021).

- The PostProcess Solution for MJF & SLS Post-Printing. Available online: https://www.postprocess.com/mjf-sls/ (accessed on 6 August 2021).

- Fuges, C.M. PVD Coatings Solve Common 3D-Printed Mold and Part Problems. Available online: https://www.additivemanufacturing.media/articles/pvd-coatings-solve-common-3d-printed-mold-and-part-problems (accessed on 6 August 2021).

- Cheng, C.; Gupta, M. Surface functionalization of 3D-printed plastics via initiated chemical vapor deposition. Beilstein J. Nanotechnol. 2017, 8, 1629–1636. [Google Scholar] [CrossRef] [PubMed]

- Electroplating Goes Beyond Making FDM and PolyJet Parts Shine. Available online: https://www.stratasysdirect.com/manufacturing-services/finishing-assembly/electroplating-making-fdm-polyjet-parts-shine (accessed on 6 August 2021).

- Electroplating 3D Printed Parts for High-Performance Antennas. Available online: https://formlabs.com/asia/blog/electroplating-3d-printed-parts-high-performance-antennas/ (accessed on 6 August 2021).

- Electroplating 3D Printed Jewelry. Available online: https://www.instructables.com/Electroplating-3D-Printed-Jewelry/ (accessed on 6 August 2021).

- Jones, C.; Mills, B.; Nishimoto, R.; Beljonne, D. Electroless Deposition of Palladium on Macroscopic 3D-Printed Polymers with Dense Microlattice Architectures for Development of Multifunctional Composite Materials. J. Electrochem. Soc. 2017, 164, D8. [Google Scholar] [CrossRef]

- Bernasconi, R.; Credi, C.; Tironi, M.; Levi, M.; Magagnina, L. Electroless Metallization of Stereolithographic Photocurable Resins for 3D Printing of Functional Microdevices. J. Electrochem. Soc. 2017, 164, B3. [Google Scholar] [CrossRef]

- Stratasys Develops PEKK for ESD-Safe 3D Printed Space Components. Available online: https://omnexus.specialchem.com/news (accessed on 6 August 2021).

- Kohut, A. ESD-Safe Materials: A Beginner’s Guide. Available online: https://ultimaker.com/learn/esd-safe-materials-a-beginners-guide (accessed on 6 August 2021).

- Nadgorny, M.; Xiao, Z.; Chen, C.; Connal, L.A. Three-Dimensional printing of pH-Responsive and functional polymers on an affordable desktop printer. ACS Appl. Mater. 2016, 8, 28946. [Google Scholar] [CrossRef]

- Bodaghi, M.; Damanpack, A.; Liao, W. Self-expanding/shrinking structures by 4D printing. Smart Mater. Struct. 2016, 25, 105034. [Google Scholar] [CrossRef]

- Shaffer, S.; Yang, K.; Vargas, J.; di Prima, M.A.; Voit, W. On reducing anisotropy in 3D printed polymers via ionizing radiation. Polymer 2014, 55, 5969. [Google Scholar] [CrossRef]

- 3D Printing Post-Processing Techniques. Available online: https://www.makerbot.com/professional/post-processing/ (accessed on 5 August 2021).

- Post-Processing 3D Printed Objects. Available online: https://www.instructables.com/Post-Processing-3D-Printed-Objects/ (accessed on 7 August 2021).

- Available online: https://www.fictiv.com/articles/ultimate-guide-to-finishing-3d-printed-parts (accessed on 6 August 2021).

- Guide to Surface Finishing for 3D-Printed Parts. Available online: https://www.sharrettsplating.com/blog/guide-surface-finishing-3d-printed-parts/ (accessed on 6 August 2021).

- Tyson, E. How to Finish Your 3D Prints—Ultimate Guide to Filling, Priming, Sanding & Painting 3D Printed Parts. Available online: https://rigid.ink/blogs/news/how-to-finish-your-3d-prints (accessed on 6 August 2021).

- Post Processing of 3D Polymer Prints. Available online: http://edutechwiki.unige.ch/en/Post_processing_of_3D_polymer_prints (accessed on 6 August 2021).

- Post-Processing—Enabling Additive Manufacturing. Available online: https://amtil.com.au/post-processing-enabling-additive-manufacturing/ (accessed on 6 August 2021).

- How to Prime and Paint 3D Printed Parts. Available online: https://formlabs.com/asia/blog/how-to-prime-and-paint-3d-prints/ (accessed on 6 August 2021).

- Kumbhar, N.N.; Mulay, A.V. Post Processing Methods used to Improve Surface Finish of Products which are Manufactured by Additive Manufacturing Technologies: A Review. J. Inst. Eng. Ser. C 2018, 99, 481–487. [Google Scholar] [CrossRef]

- 3D Printing Post Processing Tricks—Make Your Prints Shine. Available online: https://pinshape.com/blog/3d-printing-post-processing-tricks-make-your-prints-shine/ (accessed on 5 August 2021).

- Gregurić, L. 3D Printing Post-Processing: 10 Easy Techniques. Available online: https://all3dp.com/2/fdm-3d-printing-post-processing-an-overview-for-beginners/ (accessed on 15 January 2021).

- Belter, J.T.; Dollar, A.M. Strengthening of 3D Printed Fused Deposition Manufactured Parts Using the Fill Compositing Technique. PLoS ONE 2015, 10, e0122915. [Google Scholar] [CrossRef] [PubMed]

- Can You Use Epoxy Coating on PLA Printed Objects. Available online: https://3dprintergeeks.com/epoxy-coating-pla-prints/ (accessed on 6 August 2021).

- Annino, R. Top 3 Ways to Smooth PLA Parts. Available online: https://blog.trimech.com/three-ways-to-smooth-pla-parts (accessed on 6 August 2021).

- Bernasconi, R.; Natale, G.; Levi, M.; Magagnin, L. Electroless Plating of PLA and PETG for 3D Printed Flexible Substrates. ECS Trans. 2015, 66, 23–35. [Google Scholar] [CrossRef]

- Jian, J.R.; Kim, T.; Park, J.S.; Wang, J.; Kim, W.S. High performance 3D printed electronics using electroless plated copper. AIP Adv. 2017, 7, 035314. [Google Scholar] [CrossRef] [Green Version]

- Rashad, A.; Mohamed-Ahmed, S.; Ojansivu, M.; Berstad, K.; Yassin, M.A.; Kivijarvi, T.; Heggset, E.B.; Syverud, K.; Mustafa, K. Coating 3D Printed Polycaprolactone Scaffolds with Nanocellulose Promotes Growth and Differentiation of Mesenchymal Stem Cells a Department c Department e Department. Biomacromolecules 2018, 19, 4307–4319. [Google Scholar] [CrossRef]

- The Essential Guide to Food Safe 3D Printing: Regulations, Technologies, Materials, and More. Available online: https://formlabs.com/asia/blog/guide-to-food-safe-3d-printing/ (accessed on 6 August 2021).

- Zhang, M.; Song, X.; Grove, W.; Hull, E.; Pei, Z.J.; Ning, F.; Cong, W. Carbon Nanotube Reinforced Fused Deposition Modeling Using Microwave Irradiation. In Proceedings of the International Manufacturing Science and Engineering Conference, American Society of Mechanical Engineers, Blacksburg, WV, USA, 27 June–1 July 2016. [Google Scholar]

- Saunders, S. Is This the Best Way to Manually Post-Process an FDM 3D Printed Part? Available online: https://3dprint.com/257738/researchers-explain-manual-post-processing-of-fdm-3d-printed-model/ (accessed on 6 August 2021).

- Basgul, C.; Yu, T.; MacDonald, D.W.; Siskey, R.; Marcolongo, M.; Kurtz, S.M. Does annealing improve the interlayer adhesion and structural integrity of FFF 3D printed PEEK lumbar spinal cages? J. Mech. Behav. Biomed. Mater. 2020, 102, 103455. [Google Scholar] [CrossRef]

- AM Post-Processing Cost Identified. Available online: https://www.materialstoday.com/additive-manufacturing/news/am-postprocessing-cost-identified/ (accessed on 10 November 2020).

- Gregurić, L. The Best 3D Printing Cost Calculators. Available online: https://all3dp.com/2/3d-printing-cost-calculator-great-websites/ (accessed on 6 August 2021).

| Material | Post-Processing Technique | Advantages | Disadvantages |

|---|---|---|---|

| All FDM thermo-plastics | Material Support Removal. Usually done for most 3D printing methods wherein the raft and generated supports are removed [38,109,111,121] | Shape consistency [121] | Unpolished print texture [121] |

| Greater flexibility of design [38,111] | Supports can damage the part during removal [109,111] | ||

| Use of minimal tools [111] | Can sometimes restrict the design freedom of the product [111] | ||

| Quick and easiest method of post-processing [109,111,121] | Incomplete removal of supports affect the accuracy/appearance of the print [121] | ||

| Dissolvable support removal. Soluble supports is dissolved by soaking the part in either water or another solution, leaving little to no marking or residue [111,121] | Applicable and is recommended for complex geometry prints [121] | When done incorrectly, may result to warping and bleaching of the print [121] | |

| Leaves a smooth surface on support marks [121] | Unpolished print texture [121] | ||

| Leakage may create small holes or divots on the print texture [121] | |||

| Sanding. Done by carefully sanding the surface of the model, using sanding paper with varying grit: from low to high for finishing [31,32,38,109,110,111,121,148,149,150,151,152] | Produces extremely smooth surface finish [38,110,121,151,152] | Labor and time intensive [38,109,151,152] | |

| Uses minimal tools [31,38,111] | Can affect health issues when excess fine materials are inhaled [111] | ||

| Minimal costs [111] | May produce an uneven texture [111] | ||

| Creates an effective additional room for post-processing such as painting [110,121,150] | Difficult for complex geometry prints [31,109,121,151,152] | ||

| May affect the accuracy of the part if sanding is aggressively done [121] | |||

| Polishing. Done after sanding by using a small amount of cloth to rub on the surface of the 3D prints in circular motion [111,121,149] | Improves print texture without warping any part [121] | Sometimes require sanding first to achieve the desired finish [121] | |

| Produces an aesthetical surface prints [111,121] | Requires proper safety precautions [111] | ||

| Cost-effective [121] | Paint/primer may not stick to the surface of the part after polishing [121] | ||

| Sandblasting. Done by spraying small particles (sand, glass balls, walnut shells, etc.) to remove layer lines [110] | Quick and easy to apply [110] | Not intended for small/weak objects [110] | |

| PLA and ABS | Hot Air Gun. Used to remove small filaments through the use of an air gun with several types of nozzles heated 50–650 °C [153] | Brings back color after sanding/filing [153] | Knowledge of using the right temperature is needed [153] |

| PLA | CO2 Laser Cutting. Done by cutting and shaping using CO2 laser [113] | May improve geometrical precision and dimensional accuracy [113] |

| Material | Post-Processing Technique | Advantages | Disadvantages |

|---|---|---|---|

| All FDM Thermo-plastics | Gap Filling. Done by filling the gaps (due to incomplete printing) with auto body filler. Additional sanding may be needed once dry [38,109,121,148] | Epoxies are easily primed and sanded making an additional room for post-processing [121] | Some filling materials may dry opaquely which results in discoloration on the surface of the print [121] |

| No surface discolorations [121] | May require additional sanding for better texture [121] | ||

| Priming and Painting. A thin layer of the primer may be coated to ensure details of the prints are not altered/covered before finally putting a paint according to preferred aesthetics. [31,109,110,111,121,148,149,153,154,155] | Increase aesthetical factors [110,111,121,155] | Paint and primer can be bulky on the surface prints [121] | |

| The visual appearance of the final product has complete flexibility [111,121] | Relatively time-consuming [111,155] | ||

| Can be costly in terms of the number of materials used [111,121] | |||

| Aluminum Filled Epoxy Resin as Filler. This filler can work for small hole or voids which can be easily managed. [121,156] | An outer protective “shell” may be provided around the print [121] | Surface layer lines may still be visible [121] | |

| Excessive use of epoxy may affect the fine details of the print [121] | |||

| Improved surface texture up to 83.85% [156] | |||

| Metal Plating. Done by coating the 3D-printed plastic with a thin layer of conductive paint. After allowing the conductive coating to dry, sanding may be necessary to ensure a smooth surface finish. [121,151] | Increases strength of the plastic part [121,151] | Relatively costly [121] | |

| As the coating is very thin, tolerances may be maintained if the plating is correctly done [121] | Too many safety precautions are needed [121] | ||

| Extremely smooth surface finish [121,151] | |||

| Applying Metallic Powder and Epoxy. Done by mixing clear gloss epoxy with metallic powder [157] | Quick, cost-effective alternative with convincing metallic finish on the surface of the part. [157] | Too much powder added will result to rough texture and leafed gold look [157] | |

| Hydro Dipping. Done by applying printed graphic designs to solid objects using special water transfer paper [158] |

|

| |

|

|

| Material | Post-Processing Technique | Advantages | Disadvantages |

|---|---|---|---|

| ABS | Electroplating. Done by depositing a thin layer of metal (e.g., gold, silver, nickel, or chromium) to the print surface making it look shinier while providing a wear-resistant and hard surface with reflective properties [31,111] | Significantly enhances the look, feel, and surface properties of a part [111] | Expensive, complex, and requires a lot of skill [111] |

| Increases strength and durability of the part [31,111] | |||

| Many outsourcing options exist for electroplating [111] | |||

| PLA and ABS | Polymer Coating of Textile Fabrics. Done by melting the polymers and coating it to the textile fabric [118] | Significantly increases the adhesion between the textile fabric and polymer [118] | |

| Two-part Epoxy Solution Method. Consists of a resin and a hardener mixed together in an aluminum foil plate until they form a smooth, miscible blend that will then make the part smooth and glossy [157,159] | Very shiny smooth finish, and makes parts strong and durable [157,159] | ||

| PLA | Epoxy Coating. Done by allowing the print part to soak in the epoxy liquid for about 20–25 mins which is enough duration to seep the liquid into holes [150,160,161] | Due to its chemical properties, the resultant coating is usually solvent-resistant, durable, and tough [150] | Potential health risk [150] |

| PLA and PETG | Electroless Plating of Cu and NiP. Done by coating Cu and NiP bath on the surface of the prints using temperatures similar to the glass transition temperatures of the polymers [162,163] | Coatings have good adhesion to the substrate [162] | PETG adhesion should be high enough to prevent partial delamination (especially) on flexible substrates [162] |

| Polycaprolactone (PCL) | Cellulose Nanofibrils Material (CNF) Coating. Cellulose nanofibril material (CNF) is coated on the scaffold. This may improve the surface properties of the print [164] | May enhance cell attachment, proliferation and osteogenic differentiation [164] | High cost of manufacturing [164] |

| May improve the performance of 3D-printed PCL scaffolds (which may be applicable for bone tissue engineering) [164] | Complex procedures required for purification [164] | ||

| PLA, nylon-6, PP, PET, co-polyester, HIPS, and PET, some brands of PEI, ASA, and ABS | Food Safe Coatings and Sealants (food-grade epoxy or polyurethane resin). Done by dip coating the parts with a food grade polyurethane or resin epoxy to prevent bacteria build-up [165] | Reduces the risk of bacteria build-up and particle migration [165] | Coating does not always guarantee food safety for prolonged use [165] |

| Material | Post-Processing Technique | Advantages | Disadvantages |

|---|---|---|---|

| ABS | Cold Welding. Manually clamping two printed parts by brushing lightly with acetone to be chemically bonded. [121] | Acetone will not change the surface color of the 3D-printed part [121] | Can be a weaker bond on some parts [121] |

| The joint may copy the properties of ABS after drying (natural look) [121] | Too much acetone may dissolve parts unintentionally [121] | ||

| Microwave Treatment. Melts the ABS thermoplastic matrix near the CNTs—improves inter-layer adhesion. [3,166] | Stronger layer adhesion, tensile and flexural properties [3,166] | ||

| Chemical Post-Processing Treatment. (Acetone, Ester and Chloride Solvent) [3,110,111,156,167] | Improves texture appearance [3,156] | Time difficulties may vary accordingly which can result in deformation and alteration of parts [3,111] | |

| Acetone vapor-polishing. Done by dissolving the liquid/acetone in order to have a concentrated atmosphere of the vapor that will eventually develop the smooth effects on the print. [16,31,109,111,121,152,153] | Better interlayer adhesion of ABS material when used at the right operating temperature. [16,109,153] | May affect the dimensional accuracy of the part [109,111] | |

| Reduces the capacity of ABS 3D-printed material to withstand higher operating temperature [16] | |||

| The relatively cheap cost of acetone makes this post-processing cost-effective. [111] | Too many safety precautions [109,111,153]. May require constant observation and a well-ventilated area [109,111] | ||

| PET-G | Annealing. Done by subjecting parts under varying temperatures and time. [124] | Increases the interlayer tensile strength when given appropriate temperature [124] | |

| Increases the interlayer Young’s Modulus by 1.65 times compared to unannealed composite, as well as 32 times compared to annealed 3D-printed polymer. [124] | |||

| 64% increase in interlayer Strain-to-failure of 3D-printed amorphous part [124] | |||

| PLA | Annealing. Done by subjecting specimens into varying temperatures and time [124] | Doubles the interlayer tensile strength if annealed at an appropriate temperature [124] | |

| Increases the Interlayer Young’s Modulus by 1.48% than unannealed 3D-printed composite [124] | |||

| 49% increase in interlayer Strain-to-failure of semi-crystalline composite [124] | |||

| Gluing (Anabond). Gluing the parts together to form a larger build. [111,148] | Simple and relatively cheap process [111] | Bond is not too strong [111] | |

| PEEK | Annealing. Annealing above the glass transition temperature (200–300° C) [168] | May enhance the interlayer adhesion in some printing conditions [168] | Undesired porosity may form during the 3D printing process [168] |

| Material | Post-Processing Technique | Advantages | Disadvantages |

|---|---|---|---|

| Durable and General-Purpose Resin | Basic Support Removal. [38,125,154] | Gives complete control over the finish [38,125] | Sometimes not aesthetically pleasing and requires a high skill level to achieve a clean finish [125] |

| Shape consistency [125] | |||

| Sanding of Support Nibs [125] | Smooth finish that hides surface imperfections [125] | Sometimes result in uneven texture (due to non-uniform sanding) [125] | |

| May not be aesthetically appealing (e.g., on clear resin) [125] | |||

| Wet Sanding [38,125] | Excellent smooth finish [38,125] | Lower accuracy on the supported side [125] | |

| Ideal for complex geometries [38,125] | May produce white/light spots on the print [125] | ||

| Mineral Oil Finish [38,125] | May result in a semi-transparent finish for clear resins [125] | Paint may not adhere well to the surface [38,125] | |

| Spray paint (clear UV protective acrylic) [125] | Clear finish on complex geometries for clear resin [125] | Typically results in an ‘orange peel’ effect on the surface | |

| Offers UV protection [125] | Shape accuracy and consistency [125] | ||

| Not suited on moving parts [125] | |||

| UV Post-curing [3] | May improve the mechanical strength of the part due to the complete curing of remaining resin [3] | ||

| Post-curing at a higher temperature may lead to shorter curing time resulting to higher strength of the part. [3] | |||

| Microwave Curing [3] | Small effect on the strength/stiffness of [3] | ||

| Conventional Heating [3] | Results to higher strength compared to UV Post-curing and microwave techniques. [3] | ||

| Vibratory Bowl Abrasion Finishing [156] | Nice surface finish in a short amount of time with improvement of around 74%. [156] | ||

| Ultrasonic Abrasion Finishing [156] | May improve the surface of the parts [156] | ||

| Smart Part Washer [109] | Automates the washing process [109] | ||

| Formwash/Formcure [3,109] | Automates washing/curing processes [3,109] | ||

| Somos Resin | UV Post-curing and Thermal Post-curing (Combination of both) [3] | Optimal thermal, mechanical and electrical properties. [3] | |

| Clear Resin | Polished to clear transparent finish [125] | Clear finish (similar to glass) [125] | Labor-intensive [125] |

| Smooth surface [125] | May not be employed for parts with complex geometries [125] | ||

| Standard Clear Resin | UV Curing [100,109,129,154] | Accounts for 73% of the specimen mechanical behavior [129] | Different temperatures are recommended for different types of resin. [100] |

| Material | Post-Processing Technique | Advantages | Disadvantages |

|---|---|---|---|

| SLS Materials (Nylon and Polyamide) | Standard Finish [38,132,154] | Smooth finish [38] | Limited color options (typically white) [132] |

| Shape accuracy and consistency [38,132] | |||

| Cost effective [132] | |||

| Media tumbled (vibro polish) [132] | Excellent smooth finish [132] | Not suitable for complex geometries [132] | |

| Multiple parts can be done at the same time [132] | Removes sharp edges which may alter part geometry [132] | ||

| Removes sharp edges [132] | |||

| Dyeing [38,132] | Multiple ranges of color options [132] | The penetration of the dye may only be ~0.5 mm deep [132] | |

| Will not affect part dimensions [132] | |||

| Multiple parts may be dyed altogether [132] | |||

| Cheaper compared to other coloring methods [38,132] | Will not result in a glossy finish [132] | ||

| Very much applicable for complex geometries [132] | |||

| Spray paint or lacquering [132,153] | Improves mechanical properties [132] | Labour intensive if many parts will be coated [132] | |

| May result in a glossy smooth clear or colored surface [132] | Impacts overall part dimensions [132] | ||

| Improves UV protection [132] | Requires good surface preparation (all loose powder should be removed) [132] | ||

| Watertightness [132] | Further improves water resistance [132] | Coatings are usually thick and may affect shape accuracy and consistency [132] | |

| Improves mechanical strength [132] | |||

| Metal coating [38,132] | Improves functionality and strength [38,132] | Increases lead time, costly, requires high level of skill [132] | |

| Aesthetically parts will have a metal finish [132] | |||

| Allows for electrical conductivity [38,132] | Available types of metals are limited [132] | ||

| Excellent surface finish may be achieved [132] | |||

| Vibratory Grinding [156] | Parts without complex structure are readily amenable [156] | ||

| Sintering [3] | May improve mechanical properties [3] | Obvious shrinkage often takes place [3] | |

| Infiltration [3] | Shrinkage may be avoided. It is also possible to generate higher density parts. [3] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dizon, J.R.C.; Gache, C.C.L.; Cascolan, H.M.S.; Cancino, L.T.; Advincula, R.C. Post-Processing of 3D-Printed Polymers. Technologies 2021, 9, 61. https://doi.org/10.3390/technologies9030061

Dizon JRC, Gache CCL, Cascolan HMS, Cancino LT, Advincula RC. Post-Processing of 3D-Printed Polymers. Technologies. 2021; 9(3):61. https://doi.org/10.3390/technologies9030061

Chicago/Turabian StyleDizon, John Ryan C., Ciara Catherine L. Gache, Honelly Mae S. Cascolan, Lina T. Cancino, and Rigoberto C. Advincula. 2021. "Post-Processing of 3D-Printed Polymers" Technologies 9, no. 3: 61. https://doi.org/10.3390/technologies9030061

APA StyleDizon, J. R. C., Gache, C. C. L., Cascolan, H. M. S., Cancino, L. T., & Advincula, R. C. (2021). Post-Processing of 3D-Printed Polymers. Technologies, 9(3), 61. https://doi.org/10.3390/technologies9030061