Surface Quality of Metal Parts Produced by Laser Powder Bed Fusion: Ion Polishing in Gas-Discharge Plasma Proposal

Abstract

1. Introduction

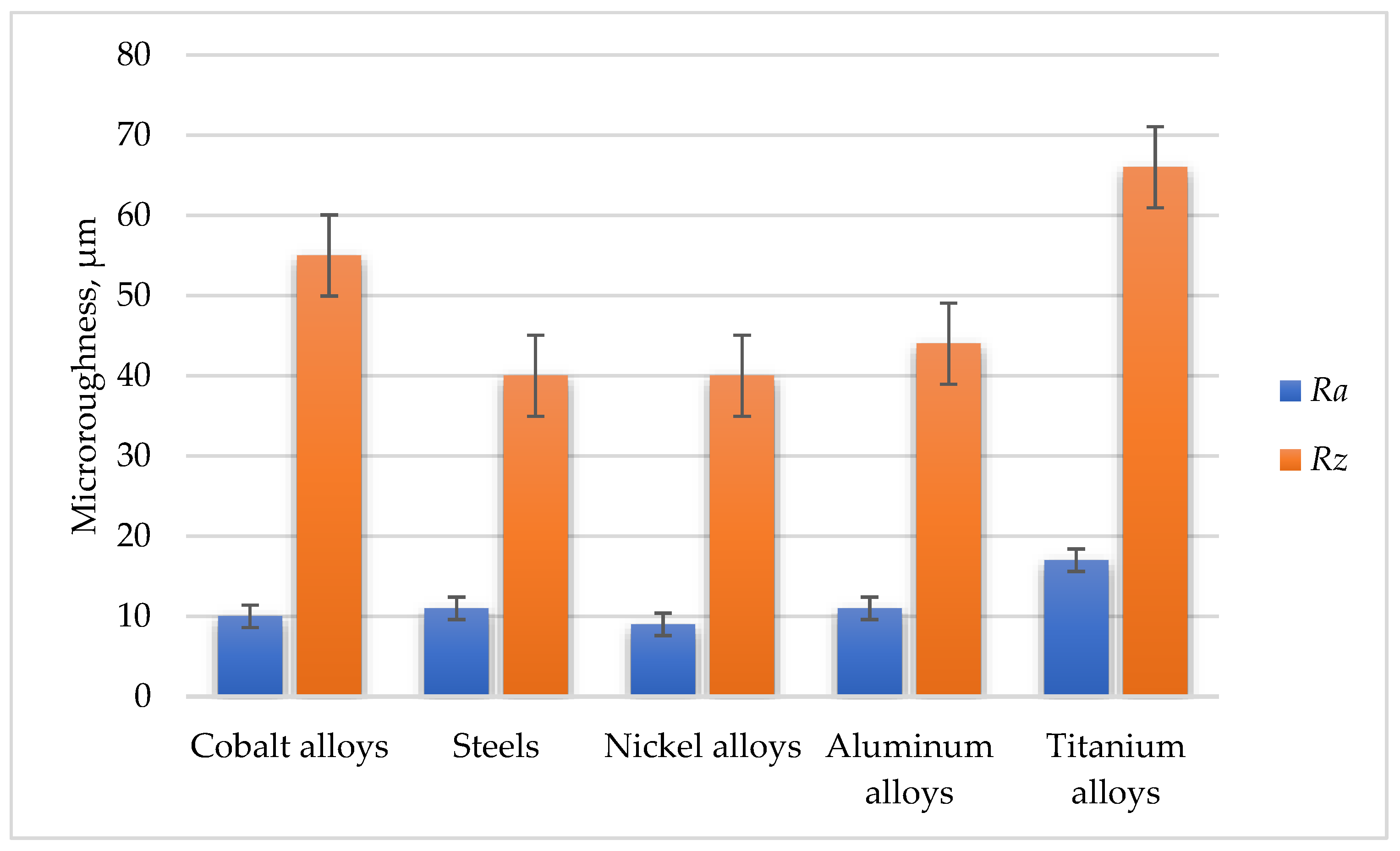

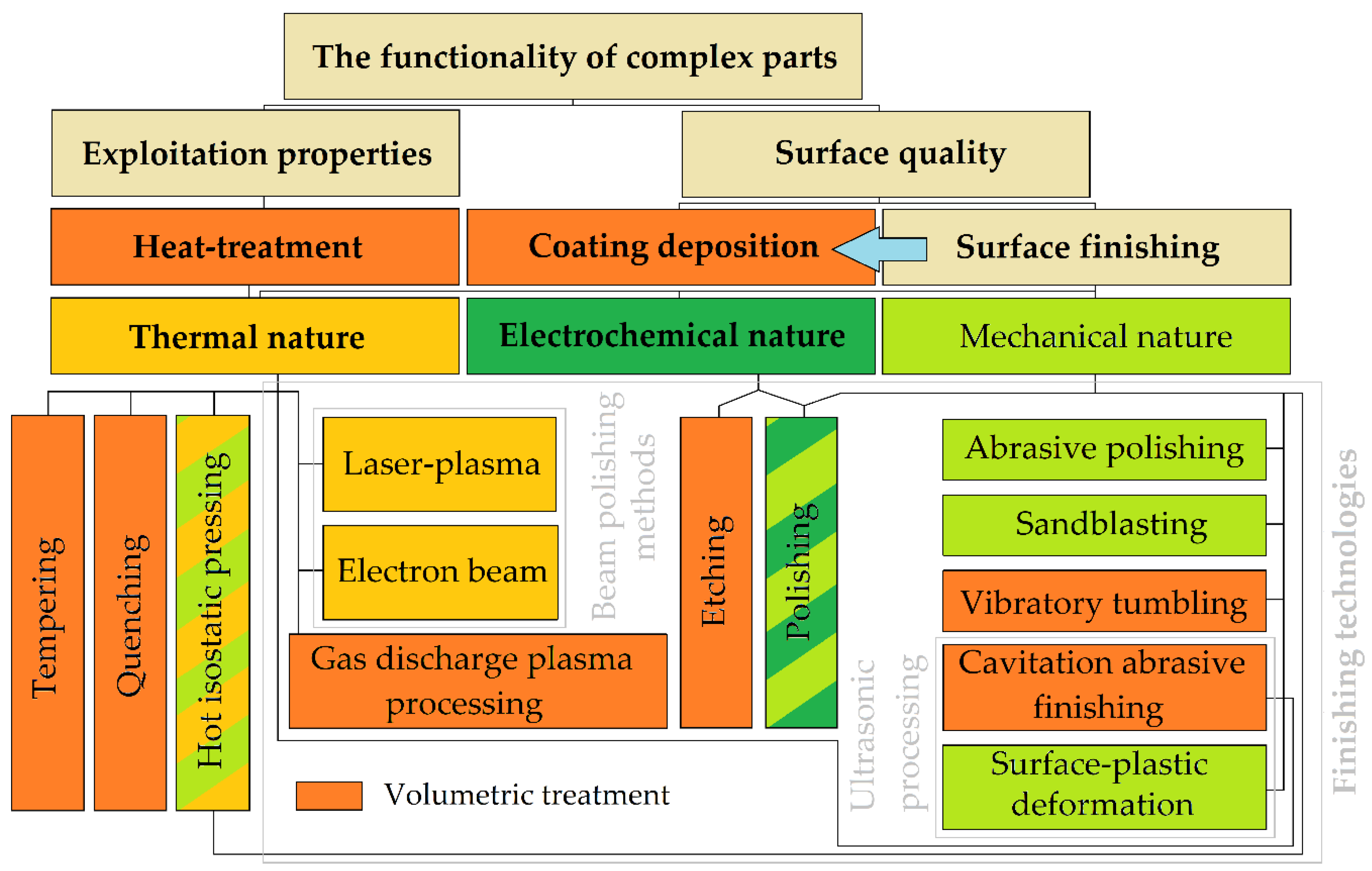

- Determining particularities in the surface quality problem (surface properties and roughness parameters) of metal parts produced by additive manufacturing methods from various metallic alloys—steels, cobalt, nickel, aluminum, and titanium alloys in the context of airspace industry application,

- Classification existed methods to improve exploitation properties and surface quality of the parts produced by laser additive manufacturing,

- Analyses of the last achievement in implementing finishing technologies depending on its nature—thermal, electrochemical, mechanical, and combined methods,

- Determining finishing methods that were not covered by the experimental research for additively manufactured parts but have a potentially valuable impact on surface quality,

- Developing the technological principles of ion polishing in gas-discharge plasma for finishing laser additively manufactured parts to improve their surface quality in the context of resistance to abrasive wear.

2. Problem Statement

2.1. Prospects and Surface Quality Problem

- The ability to produce high-precision parts for the needs of medicine, jewelry, and even watch production [42].

2.2. Research Methodology

3. Analyses of Surface Finishing Methods

3.1. Mechanical Methods

3.2. Electrochemical Methods

3.3. Beam Polishing Methods

3.4. Ion Polishing Methods

4. Development of Ion Polishing Principles

5. Discussion

- -

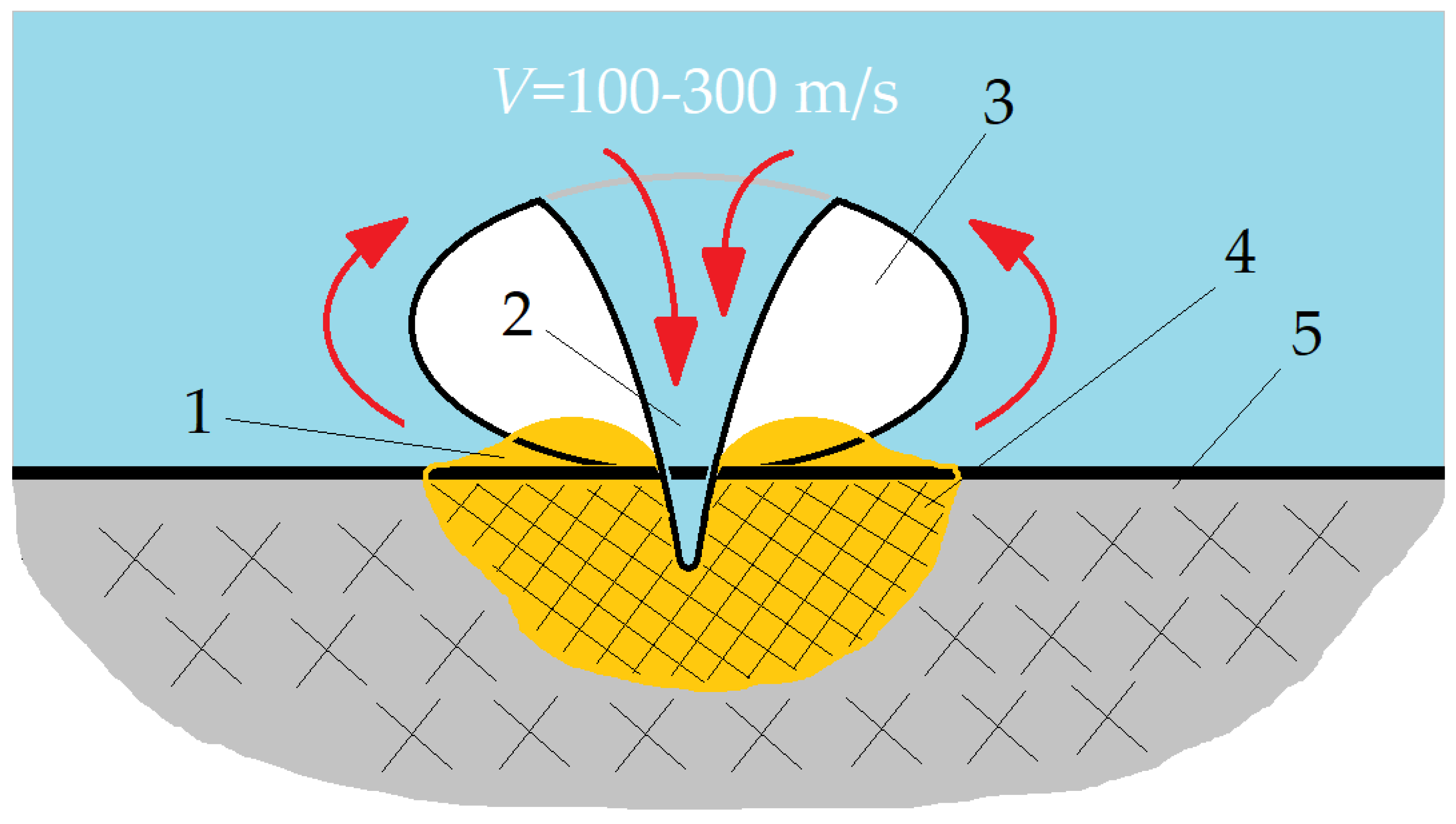

- Explosive ablation of surface protrusions when voltage pulses with an amplitude up to 30 kV and a width of 0.001–1 μs are applied to a detail immersed in the plasma;

- -

- Polishing with a concentrated beam of fast neutral argon atoms at a large angle of incidence to the surface of the part moved in the chamber using a positioning device;

- -

- Coating deposition on the part surface upon sputtering with argon ions of solid magnetron targets and/or the evaporation of a liquid metal magnetron target heated by ions.

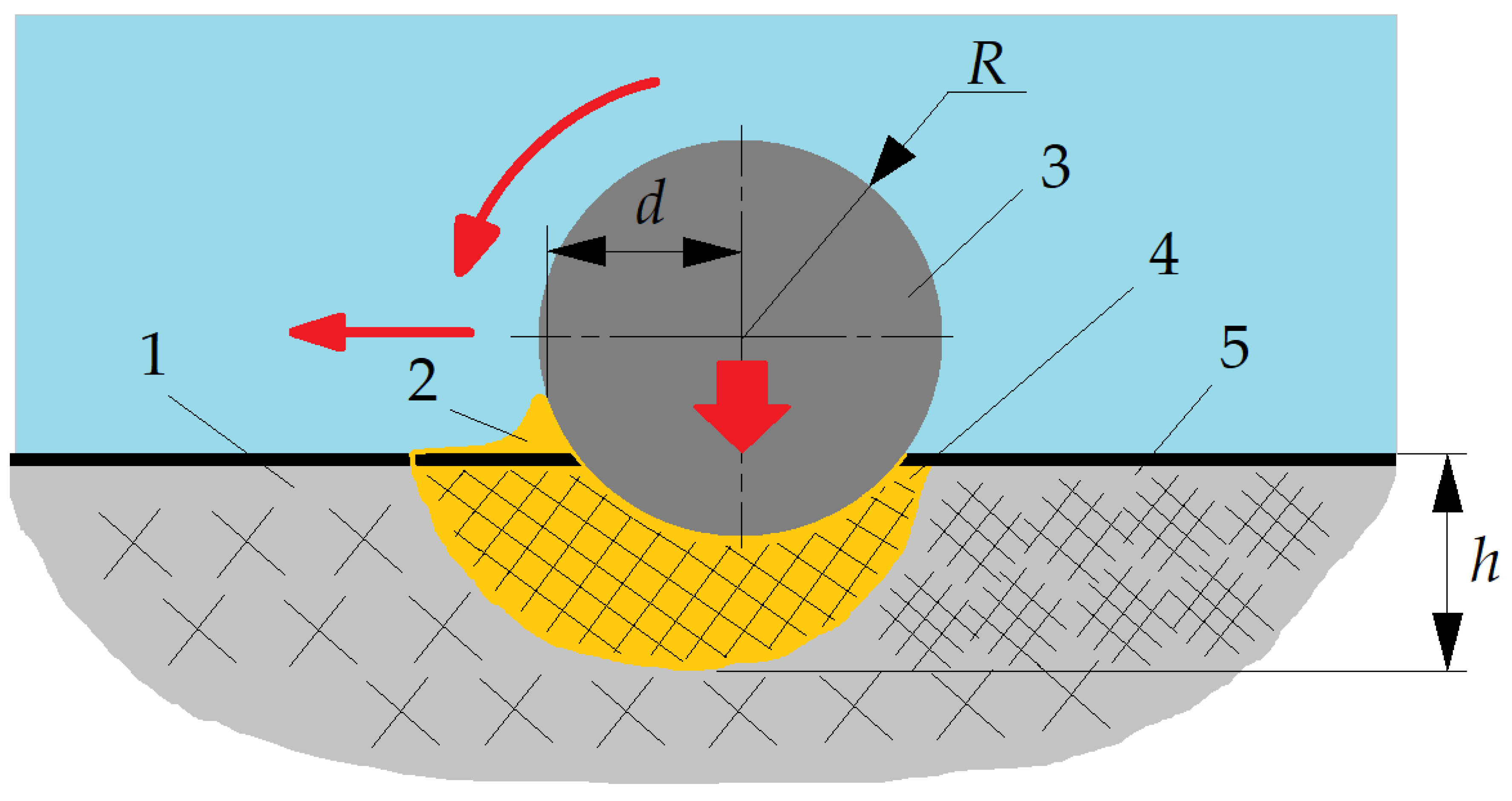

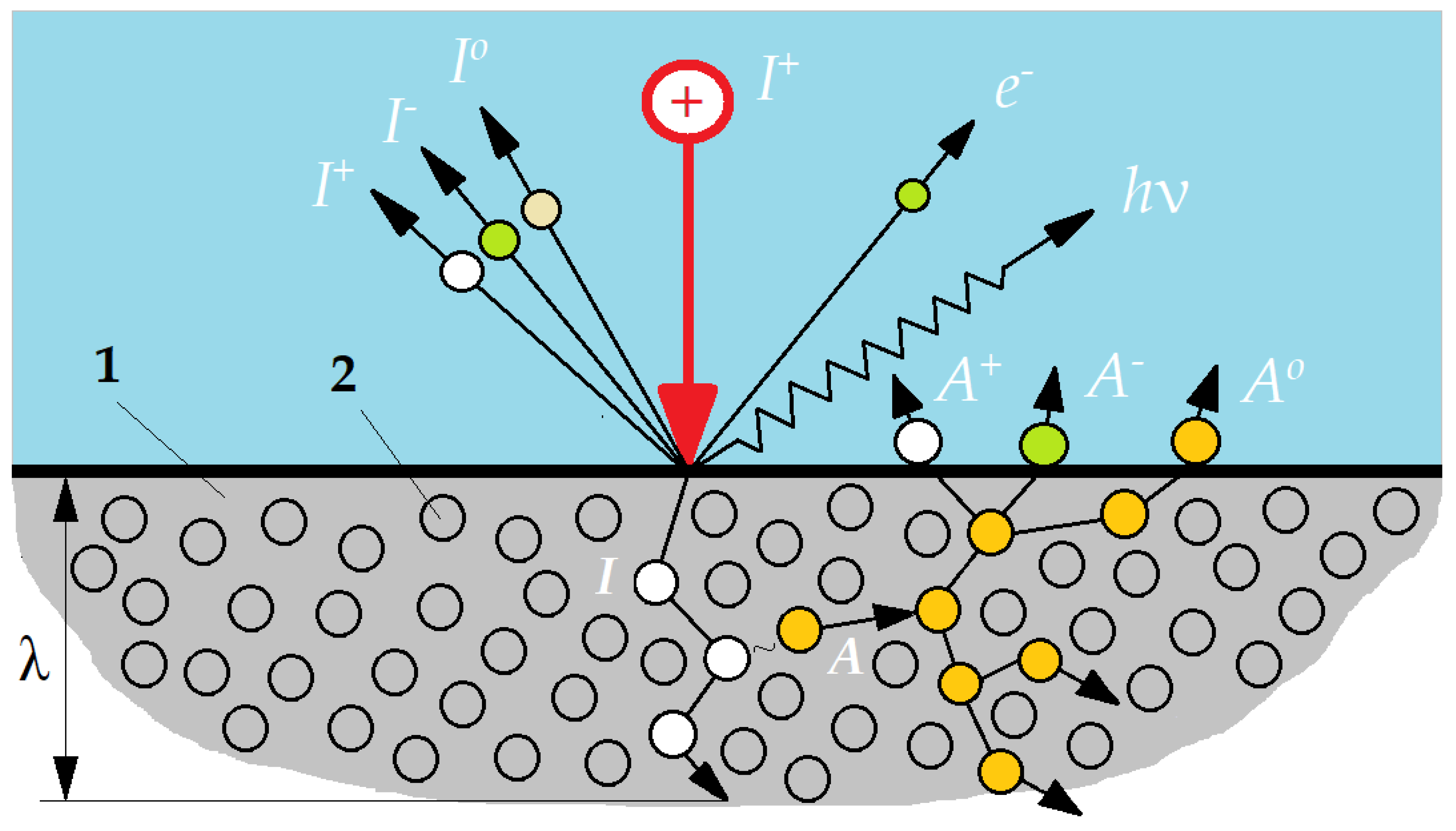

- Removal of powder particles 40–100 µm in size used in the manufacture of the part and protruding on its surface, which is responsible for the initial roughness parameter Ra (Arithmetic Mean Deviation) of 30 µm and surface porosity, by explosive ablation of surface protrusions when microsecond pulses of negative voltage up to 30 kV are applied to the part immersed in the plasma.

- Polishing with a concentrated beam of ions and/or fast argon atoms at an angle of incidence greater than 60° of the surface of the part moved in a vacuum chamber using a positioning device.

- Coating deposition on the surface of a part immersed in a dense metal plasma obtained by the evaporation of liquid metal magnetron targets.

6. Conclusions

- removal granules from the surfaces of the parts with the size that primarily used in additive manufacturing of 40–100 µm and achieving roughness parameter Ra (Arithmetic Mean Deviation) of 30 µm by microsecond pulses of negative voltage up to 30 kV are applied to the part immersed in the plasma;

- polishing the surface with concentrated ions or fast argon atoms under angle exceeds 60°;

- coating deposition by the evaporation of liquid metal magnetron targets.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sova, A.; Doubenskaia, M.; Grigoriev, S.; Okunkova, A.; Smurov, I. Parameters of the Gas-Powder Supersonic Jet in Cold Spraying Using a Mask. J. Therm. Spray Technol. 2013, 22, 551–556. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Bertrand, P.; Antonenkova, G.; Grigoriev, S.; Smurov, I. Use of track/layer morphology to develop functional parts by selectivelaser melting. J. Laser Appl. 2013, 25, 052003. [Google Scholar] [CrossRef]

- Klein, T.; Schnall, M. Control of macro-/microstructure and mechanical properties of a wire-arc additive manufactured aluminum alloy. Int. J. Adv. Manuf. Technol. 2020, 108, 235–244. [Google Scholar] [CrossRef]

- Shen, C.; Liss, K.D.; Reid, M.; Pan, Z.X.; Hua, X.M.; Li, F.; Mou, G.; Huang, Y.; Dong, B.S.; Luo, D.Z. Effect of the post-production heat treatment on phase evolution in the Fe3Ni-FeNi functionally graded material: An in-situ neutron diffraction study. Intermetallics 2021, 129, 107032. [Google Scholar] [CrossRef]

- Khmyrov, R.S.; Protasov, C.E.; Grigoriev, S.N.; Gusarov, A.V. Crack-free selective laser melting of silica glass: Single beads and monolayers on the substrate of the same material. Int. J. Adv. Manuf. Technol. 2016, 85, 1461–1469. [Google Scholar] [CrossRef]

- Khmyrov, R.S.; Grigoriev, S.N.; Okunkova, A.A.; Gusarov, A.V. On the possibility of selective laser melting of quartz glass. Phys. Procedia 2014, 56, 345–356. [Google Scholar] [CrossRef][Green Version]

- Grigoriev, S.; Tarasova, T.; Gusarov, A.; Khmyrov, R.; Egorov, S. Possibilities of Manufacturing Products from Cermet Compositions Using Nanoscale Powders by Additive Manufacturing Methods. Materials 2019, 12, 3425. [Google Scholar] [CrossRef] [PubMed]

- Bunnell, D.E.; Bourell, D.L.; Beaman, J.B.; Marcus, H.L. Fundamentals of liquid phase sintering during selective laser sintering. In Processing and Fabrication of Advanced Materials IV, Proceedings of the Symposium on Processing and Fabrication of Advanced Materials IV, Cleveland, OH, USA, 29 October–2 November 1995; Srivatsan, T.S., Moore, J.J., Eds.; Minerals, Metals & Materials Society: Warrendale, PA, USA, 1996; pp. 17–26. [Google Scholar]

- Alsulami, M.; Mortazavi, M.; Niknam, S.A.; Li, D.S. Design complexity and performance analysis in additively manufactured heat exchangers. Int. J. Adv. Manuf. Technol. 2020, 110, 865–873. [Google Scholar] [CrossRef]

- Wanjara, P.; Gholipour, J.; Watanabe, E.; Watanabe, K.; Sugino, T.; Patnaik, P.; Sikan, F.; Brochu, M. High Frequency Vibration Fatigue Behavior of Ti6Al4V Fabricated by Wire-Fed Electron Beam Additive Manufacturing Technology. Adv. Mater. Sci. Eng. 2020, 2020, 1902567. [Google Scholar] [CrossRef]

- Sotov, A.V.; Agapovichev, A.V.; Smelov, V.G.; Kokareva, V.V.; Dmitrieva, M.O.; Melnikov, A.A.; Golanov, S.P.; Anurov, Y.M. Investigation of the IN-738 superalloy microstructure and mechanical properties for the manufacturing of gas turbine engine nozzle guide vane by selective laser melting. Int. J. Adv. Manuf. Technol. 2020, 107, 2525–2535. [Google Scholar] [CrossRef]

- Tarasova, T.V.; Nazarov, A.P.; Shalapko, Y.I. Abrasive and fretting wear resistance of refractory cobalt alloy specimens manufactured by the method of selective laser melting. J. Frict. Wear 2014, 35, 365–373. [Google Scholar] [CrossRef]

- Tarasova, T.V.; Gusarov, A.V.; Protasov, K.E.; Filatova, A.A. Effect of Thermal Fields on the Structure of Corrosion-Resistant Steels Under Different Modes of Laser Treatment. Met. Sci. Heat Treat. 2017, 59, 433–440. [Google Scholar] [CrossRef]

- Nowotny, S.; Tarasova, T.V.; Filatova, A.A.; Dolzhikova, E.Y. Methods for Characterizing Properties of Corrosion-Resistant Steel Powders Used for Powder Bed Fusion Processes. Mater. Sci. Forum 2016, 876, 1–7. [Google Scholar] [CrossRef]

- Gavrin, V.N.; Kozlova, Y.P.; Veretenkin, E.P.; Logachev, A.V.; Logacheva, A.I.; Lednev, I.S.; Okunkova, A.A. Reactor target from metal chromium for “pure” high-intensive artificial neutrino source. Phys. Part. Nucl. Lett. 2016, 13, 267–273. [Google Scholar] [CrossRef]

- Volosova, M.A.; Gurin, V.D. Influence of vacuum-plasma nitride coatings on contact processes and a mechanism of wear of working surfaces of high-speed steel cutting tool at interrupted cutting. J. Frict. Wear 2013, 34, 183–189. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Gurin, V.D.; Volosova, M.A.; Cherkasova, N.Y. Development of residual cutting tool life prediction algorithm by processing on CNC machine tool. Materialwiss. Werkstofftech. 2013, 44, 790–796. [Google Scholar] [CrossRef]

- Metel, A.; Grigoriev, S.; Melnik, Y.; Panin, V.; Prudnikov, V. Cutting Tools Nitriding in Plasma Produced by a Fast Neutral Molecule Beam. Jpn. J. Appl. Phys. 2011, 50, 08JG04. [Google Scholar] [CrossRef]

- Fang, Z.C.; Wu, Z.L.; Huang, C.G.; Wu, C.W. Review on residual stress in selective laser melting additive manufacturing of alloy parts. Opt. Laser Technol. 2020, 129, 106283. [Google Scholar] [CrossRef]

- Acevedo, R.B.O.; Kantarowska, K.; Santos, E.C.; Fredel, M.C. Residual stress measurement techniques for Ti6Al4V parts fabricated using selective laser melting: State of the art review. Rapid Prototyp. J. 2020. [Google Scholar] [CrossRef]

- Vermilion, M.L.D.; de Oliveira, T.T.; Kreve, S.; Batalha, R.L.; de Oliveira, D.P.; Pauly, S.; Bolfarini, C.; Bachmann, L.; dos Reis, A.C. Analysis of the mechanical and physicochemical properties ofTi-6Al-4 Vdiscs obtained by selective laser melting and subtractive manufacturing method. J. Biomed. Mater. Res. Part B 2020. [Google Scholar] [CrossRef]

- Cardoso, R.M.; Kalinke, C.; Rocha, R.G.; dos Santos, P.L.; Rocha, D.P.; Oliveira, P.R.; Janegitz, B.C.; Bonacin, J.A.; Richter, E.M.; Munoz, R.A.A. Additive-manufactured (3D-printed) electrochemical sensors: A critical review. Anal. Chim. Acta 2020, 1118, 73–91. [Google Scholar] [CrossRef] [PubMed]

- Gokuldoss Prashanth, K.; Scudino, S.; Eckert, J. Tensile Properties of Al-12Si Fabricated via Selective Laser Melting (SLM) at Different Temperatures. Technologies 2016, 4, 38. [Google Scholar] [CrossRef]

- Kim, J.; Wakai, A.; Moridi, A. Materials and manufacturing renaissance: Additive manufacturing of high-entropy alloys. J. Mater. Res. 2020, 35, 19963–19983. [Google Scholar] [CrossRef]

- Wang, J.; Liu, S.; Fan, Y.; He, Z.R. A short review on selective laser melting of H13 steel. Int. J. Adv. Manuf. Technol. 2020, 108, 2453–2466. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y. Laser powder bed fusion for metal additive manufacturing: Perspectives on recent developments. Virtual Phys. Prototyp. 2020, 15, 359–370. [Google Scholar] [CrossRef]

- Volosova, M.A.; Fyodorov, S.V.; Opleshin, S.; Mosyanov, M. Wear Resistance and Titanium Adhesion of Cathodic Arc Deposited Multi-Component Coatings for Carbide End Mills at the Trochoidal Milling of Titanium Alloy. Technologies 2020, 8, 38. [Google Scholar] [CrossRef]

- Cruz, N.; Martins, M.I.; Domingos Santos, J.; Gil Mur, J.; Tondela, J.P. Surface Comparison of Three Different Commercial Custom-Made Titanium Meshes Produced by SLM for Dental Applications. Materials 2020, 13, 2177. [Google Scholar] [CrossRef] [PubMed]

- Kuzin, V.V.; Grigoriev, S.N.; Fedorov, M.Y. Role of the thermal factor in the wear mechanism of ceramic tools. Part 2: Microlevel. J. Frict. Wear. 2015, 36, 40–44. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Gerlich, A.P. Potentials and strategies of solid-state additive friction-stir manufacturing technology: A critical review. J. Manuf. Process. 2018, 36, 77–92. [Google Scholar] [CrossRef]

- Kalender, M.; Kilic, S.F.; Ersoy, S.; Bozkurt, Y.; Salman, S. Additive Manufacturing and 3D Printer Technology in Aerospace Industry. In Proceedings of the 9th International Conference on Recent Advances in Space Technologies (RAST), Istanbul, Turkey, 11–14 June 2019; IEEE: New York, NY, USA, 2019; pp. 689–695. [Google Scholar]

- Camacho, D.D.; Clayton, P.; O’Brien, W.J.; Seepersad, C.; Juenger, M.; Ferron, R.; Salamone, S. Applications of additive manufacturing in the construction industry—A forward-looking review. Autom. Constr. 2018, 89, 110–119. [Google Scholar] [CrossRef]

- Chekurov, S.; Salmi, M.; Verboeket, V.; Puttonen, T.; Riipinen, T.; Vaajoki, A. Assessing industrial barriers of additively manufactured digital spare part implementation in the machine-building industry: A cross-organizational focus group interview study. J. Manuf. Technol. Manag. 2021. [Google Scholar] [CrossRef]

- Land, P.; Crossley, R.; Branson, D.; Ratchev, S. Technology Review of Thermal Forming Techniques for use in Composite Component Manufacture. SAE Int. J. Mater. Manuf. 2016, 9, 81–89. [Google Scholar] [CrossRef]

- Liu, J.; Jalalahmadi, B.; Guo, Y.B.; Sealy, M.P.; Bolander, N. A review of computational modeling in powder-based additive manufacturing for metallic part qualification. Rapid Prototyp. J. 2018, 24, 1245–1264. [Google Scholar] [CrossRef]

- Bambach, M.; Sizova, I.; Sydow, B.; Hemes, S.; Meiners, F. Hybrid manufacturing of components from Ti-6Al-4V by metal forming and wire-arc additive manufacturing. J. Mater. Process. Technol. 2020, 282, 116689. [Google Scholar] [CrossRef]

- Echsel, M.; Springer, P.; Huembert, S. Production and planned in-orbit qualification of a function-integrated, additive manufactured satellite sandwich structure with embedded automotive electronics. CEAS Space J. 2020. [Google Scholar] [CrossRef]

- Hafenstein, S.; Hitzler, L.; Sert, E.; Öchsner, A.; Merkel, M.; Werner, E. Hot Isostatic Pressing of Aluminum–Silicon Alloys Fabricated by Laser Powder-Bed Fusion. Technologies 2020, 8, 48. [Google Scholar] [CrossRef]

- Salman, O.O.; Funk, A.; Waske, A.; Eckert, J.; Scudino, S. Additive Manufacturing of a 316L Steel Matrix Composite Reinforced with CeO2 Particles: Process Optimization by Adjusting the Laser Scanning Speed. Technologies 2018, 6, 25. [Google Scholar] [CrossRef]

- Saroia, J.; Wang, Y.; Wei, Q.; Lei, M.J.; Li, X.P.; Guo, Y.; Zhang, K. A review on 3D printed matrix polymer composites: Its potential and future challenges. Int. J. Adv. Manuf. Technol. 2020, 106, 1695–1721. [Google Scholar] [CrossRef]

- Protasov, C.E.; Khmyrov, R.S.; Grigoriev, S.N.; Gusarov, A.V. Selective laser melting of fused silica: Interdependent heat transfer and powder consolidation. Int. J. Heat Mass Transf. 2017, 104, 665–674. [Google Scholar] [CrossRef]

- Hartmann, C.; Lechner, P.; Himmel, B.; Krieger, Y.; Lueth, T.C.; Volk, W. Compensation for Geometrical Deviations in Additive Manufacturing. Technologies 2019, 7, 83. [Google Scholar] [CrossRef]

- Shulunov, V.R. Several advantages of the ultra high-precision additive manufacturing technology. Int. J. Adv. Manuf. Technol. 2016, 85, 1941–1945. [Google Scholar] [CrossRef]

- Okunkova, A.; Peretyagin, P.; Vladimirov, Y.; Volosova, M.; Torrecillas, R.; Fedorov, S.V. Laser-beam modulation to improve efficiency of selecting laser melting for metal powders. Proc. SPIE 2014, 9135, 913524. [Google Scholar]

- Gusarov, A.V.; Grigoriev, S.N.; Volosova, M.A.; Melnik, Y.A.; Laskin, A.; Kotoban, D.V.; Okunkova, A.A. On productivity of laser additive manufacturing. J. Mater. Process. Technol. 2018, 261, 213–232. [Google Scholar] [CrossRef]

- Metel, A.S.; Stebulyanin, M.M.; Fedorov, S.V.; Okunkova, A.A. Power Density Distribution for Laser Additive Manufacturing (SLM): Potential, Fundamentals and Advanced Applications. Technologies 2019, 7, 5. [Google Scholar] [CrossRef]

- Canaday, H. Making 3D-printed parts for Boeing 787s. Aerospace Am. 2018, 56, 18–21. [Google Scholar]

- Jelaca, M.S.; Boljevic, A. Critical Success Factors and Negative Effects of Development—The Boeing 787 Dreamliner. Strateg. Manag. 2016, 21, 30–39. [Google Scholar]

- Rutkowski, M. Safety as an Element of Creating Competitive Advantage among Airlines Given the Example of The Airbus A350 XWB and The Boeing 787 Dreamliner Aircraft. Sci. J. Sil. Univ. Technol. Ser. Transp. 2020, 108, 201–212. [Google Scholar] [CrossRef]

- Giannis, S. Testing and Analysis Building Block Approach: Evaluation of the Performance of the Integrated Lattice Fuselage Section. SAMPE J. 2016, 52, 22–33. [Google Scholar]

- Kelkar, R.; Andreaco, A.; Ott, E.; Groh, J. Alloy 718: Laser Powder Bed Additive Manufacturing for Turbine Applications. In Minerals Metals & Materials Series, Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives: Energy, Aerospace, And Industrial Applications, Champion, PA, USA, 17–21 September 2000; Ott, E., Liu, X., Andersson, J., Bi, Z., Bockenstedt, K., Dempster, I., Groh, J., Heck, K., Jablonski, P., Kaplan, M., et al., Eds.; Springer International Publishing AG: Cham, Switzerland, 2018; pp. 53–68. [Google Scholar]

- Schanz, J.; Hofele, M.; Hitzler, L.; Merkel, M.; Riegel, H. Laser Polishing of Additive Manufactured AlSi10Mg Parts with an Oscillating Laser Beam. Adv. Struct. Mater. 2016, 61, 159–169. [Google Scholar]

- Yang, T.; Liu, T.T.; Liao, W.H.; MacDonald, E.; Wei, H.L.; Chen, X.Y.; Jiang, L.Y. The influence of process parameters on vertical surface roughness of the AlSi10Mg parts fabricated by selective laser melting. J. Mater. Process. Technol. 2019, 266, 26–36. [Google Scholar] [CrossRef]

- Krawczyk, M.B.; Królikowski, M.A.; Grochała, D.; Powałka, B.; Figiel, P.; Wojciechowski, S. Evaluation of Surface Topography after Face Turning of CoCr Alloys Fabricated by Casting and Selective Laser Melting. Materials 2020, 13, 2448. [Google Scholar] [CrossRef] [PubMed]

- Texier, D.; Copin, E.; Flores, A.; Lee, J.; Terner, M.; Hong, H.U.; Lours, P. High temperature oxidation of NiCrAlY coated Alloy 625 manufactured by selective laser melting. Surf. Coat. Technol. 2020, 398, 126041. [Google Scholar] [CrossRef]

- Antanasova, M.; Kocjan, A.; Hocevar, M.; Jevnikar, P. Influence of surface airborne-particle abrasion and bonding agent application on porcelain bonding to titanium dental alloys fabricated by milling and by selective laser melting. J. Prosthet. Dent. 2020, 123, 491–499. [Google Scholar] [CrossRef]

- Yu, J.; Kim, D.; Ha, K.; Jeon, J.B.; Lee, W. Strong feature size dependence of tensile properties and its microstructural origin in selectively laser melted 316L stainless steel. Mater. Lett. 2020, 275, 128161. [Google Scholar] [CrossRef]

- Zhao, Y.Z.; Sun, J.; Guo, K.; Li, J.F. Investigation on the effect of laser remelting for laser cladding nickel based alloy. J. Laser Appl. 2019, 31, UNSP 022512. [Google Scholar] [CrossRef]

- Jeyaprakash, N.; Yang, C.H. Microstructure and Wear Behaviour of SS420 Micron Layers on Ti-6Al-4V Substrate Using Laser Cladding Process. Trans. Indian Inst. Met. 2020, 73, 1527–1533. [Google Scholar] [CrossRef]

- Kotoban, D.; Grigoriev, S.; Okunkova, A.; Sova, A. Influence of a shape of single track on deposition efficiency of 316L stainless steel powder in cold spray. Surf. Coat. Technol. 2017, 309, 951–958. [Google Scholar] [CrossRef]

- Smolenska, H.; Konczewicz, W.; Bazychowska, S. The Impact of Material Selection on Durability of Exhaust Valve Faces of a Ship Engine—A Case Study. Adv. Sci. Technol. Res. J. 2020, 14, 165–174. [Google Scholar]

- du Plessis, A.; Yadroitsev, I.; Yadroitsava, I.; Le Roux, S.G. X-Ray Microcomputed Tomography in Additive Manufacturing: A Review of the Current Technology and Applications. 3D Print. Addit. Manuf. 2018, 5, 227–247. [Google Scholar] [CrossRef]

- Matache, G.; Vladut, M.; Paraschiv, A.; Condruz, R.M. Edge and corner effects in selective laser melting of IN 625 alloy. Manuf. Rev. 2020, 7, 8. [Google Scholar] [CrossRef]

- Bashevskaya, O.S.; Bushuev, S.V.; Poduraev, Y.V.; Mel’nichenko, E.A.; Shcherbakov, M.I.; Garskov, R.V. Use of Infrared Thermography for Evaluating Linear Dimensions of Subsurface Defects. Meas. Tech. 2017, 60, 457–462. [Google Scholar] [CrossRef]

- Bashevskaya, O.S.; Bushuev, S.V.; Nikitin, A.A.; Romash, E.V.; Poduraev, Y.V. Assessment of Surface Roughness Using Curvature Parameters of Peaks and Valleys of the Profile. Meas. Tech. 2017, 60, 128–133. [Google Scholar] [CrossRef]

- Valente, E.H.; Gundlach, C.; Christiansen, T.L.; Somers, M.A.J. Effect of Scanning Strategy During Selective Laser Melting on Surface Topography, Porosity, and Microstructure of Additively Manufactured Ti-6Al-4V. Appl. Sci. 2019, 9, 5554. [Google Scholar] [CrossRef]

- Luongo, A.; Falster, V.; Doest, M.B.; Ribo, M.M.; Eiriksson, E.R.; Pedersen, D.B.; Frisvad, J.R. Microstructure Control in 3D Printing with Digital Light Processing. Comput. Graph. Forum 2020, 39, 347–359. [Google Scholar] [CrossRef]

- Johnson, A.R.; Procopio, A.T. Low cost additive manufacturing of microneedle masters. 3D Print. Med. 2019, 5, 2. [Google Scholar] [CrossRef]

- Covarrubias, E.E.; Eshraghi, M. Effect of Build Angle on Surface Properties of Nickel Superalloys Processed by Selective Laser Melting. JOM 2018, 70, 336–342. [Google Scholar] [CrossRef]

- Bashevskaya, O.S.; Bushuev, S.V.; Ilyukhin, Y.V.; Kovalskiy, M.G.; Mel’nichenko, E.A.; Romash, E.V.; Poduraev, Y.V. Comparative Analysis of Thermal Deformations in Structural Elements of Measurement Stands and Supports. Meas. Tech. 2015, 58, 760–765. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, H.; Li, Z.; Wu, Y.; Xiao, Y.; Chen, Z.; Zhong, S.; Wang, H. Strategy of Residual Stress Determination on Selective Laser Melted Al Alloy Using XRD. Materials 2020, 13, 451. [Google Scholar] [CrossRef]

- Wan, H.Y.; Luo, Y.W.; Zhang, B.; Song, Z.M.; Wang, L.Y.; Zhou, Z.J.; Li, C.P.; Chen, G.F.; Zhang, G.P. Effects of surface roughness and build thickness on fatigue properties of selective laser melted Inconel 718 at 650 degrees C. Int. J. Fatigue 2020, 137, 105654. [Google Scholar] [CrossRef]

- Jamshidi, P.; Aristizabal, M.; Kong, W.; Villapun, V.; Cox, S.C.; Grover, L.M.; Attallah, M.M. Selective Laser Melting of Ti-6Al-4V: The Impact of Post-processing on the Tensile, Fatigue and Biological Properties for Medical Implant Applications. Materials 2020, 13, 2813. [Google Scholar] [CrossRef] [PubMed]

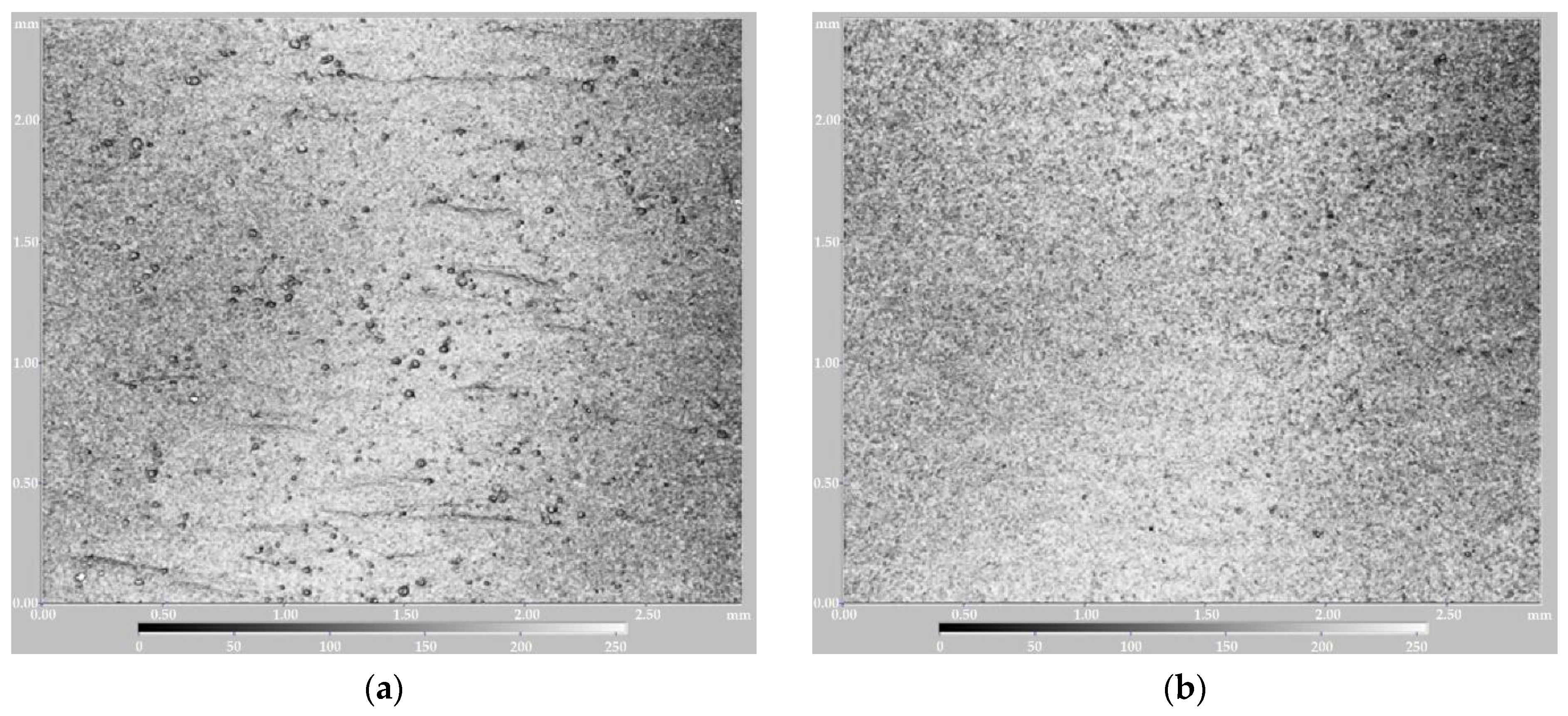

- Grigoriev, S.N.; Metel, A.S.; Tarasova, T.V.; Filatova, A.A.; Sundukov, S.K.; Volosova, M.A.; Okunkova, A.A.; Melnik, Y.A.; Podrabinnik, P.A. Effect of Cavitation Erosion Wear, Vibration Tumbling, and Heat Treatment on Additively Manufactured Surface Quality and Properties. Metals 2020, 10, 1540. [Google Scholar] [CrossRef]

- Gola, A.M.; Ghadamgahi, M.; Ooi, S.W. Microstructure evolution of carbide-free bainitic steels under abrasive wear conditions. Wear 2017, 376, 975–982. [Google Scholar] [CrossRef]

- Bankowski, D.; Spadlo, S. Vibratory Machining Effect on the Properties of the Aluminum Alloys Surface. Arch. Foundry Eng. 2017, 17, 19–24. [Google Scholar] [CrossRef][Green Version]

- Niemczewski, B. A Comparison of Ultrasonic Cavitation Intensity in Liquids. Ultrasonics 1980, 18, 107–110. [Google Scholar] [CrossRef]

- Landau, L.D.; Lifshitz, E.M. Hydrodynamic Fluctuations. Soviet Phys. JETP-USSR 1957, 5, 512–513. [Google Scholar]

- Endo, H. Thermodynamic Consideration of the Cavitation Mechanism in Homogeneous Liquids. J. Acoust. Soc. Am. 1994, 95, 2409–2415. [Google Scholar] [CrossRef]

- Wang, Q. Local energy of a bubble system and its loss due to acoustic radiation. J. Fluid Mech. 2016, 797, 201–230. [Google Scholar] [CrossRef]

- Pelekasis, N.A.; Tsamopoulos, J.A. Bjerknes Forces between 2 Bubbles.1. Response to a Step Change in Pressure. J. Fluid Mech. 1993, 254, 467–499. [Google Scholar] [CrossRef]

- Makarov, P.V. Mathematical theory of evolution of loaded solids and media. Phys. Mesomech. 2008, 11, 213–227. [Google Scholar] [CrossRef]

- Gusev, A.I.; Shveikin, G.P. Energy of Elastic Lattice Deformation in Formation of Solid-Solutions of Transition-Metal Carbides and Nitrides. Inorg. Mater. 1976, 12, 1283–1286. [Google Scholar]

- Alekseev, A.A.; Strunin, B.M. Change of Elastic Energy of Crystal during Its Plastic-Deformation. Fizika Tverdogo Tela 1975, 17, 1457–1459. [Google Scholar]

- Akhmedzhanov, R.A.; Zelenskii, I.V.; Gushchin, L.A.; Nizov, V.A.; Nizov, N.A.; Sobgaida, D.A. Observation of Coherent Population Trapping in Ensembles of Diamond NV-Centers under Ground-State Level Anticrossing Conditions. Opt. Spectrosc. 2019, 127, 260–264. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Tarasova, T.V.; Filatova, A.A.; Sundukov, S.K.; Volosova, M.A.; Okunkova, A.A.; Melnik, Y.A.; Podrabinnik, P.A. Influence of Postprocessing on Wear Resistance of Aerospace Steel Parts Produced by Laser Powder Bed Fusion. Technologies 2020, 8, 73. [Google Scholar] [CrossRef]

- Shmakov, V.A. Surface Quality of Small Components after Ultrasonic Abrasive Machining. Russ. Eng. J. 1976, 56, 33–34. [Google Scholar]

- Isobe, H.; Tsuji, S.; Hara, K.; Ishimatsu, J. Improvement of Removal Rate of Tape Lapping by Applying Fluid with Ultrasonic Excited Cavitation. Int. J. Autom. Technol. 2021, 15, 65–73. [Google Scholar] [CrossRef]

- Bolmatov, D.; Soloviov, D.; Zhernenkov, M.; Zav’yalov, D.; Mamontov, E.; Suvorov, A.; Cai, Y.Q.; Katsaras, J. Molecular Picture of the Transient Nature of Lipid Rafts. Langmuir 2020, 36, 4887–4896. [Google Scholar] [CrossRef] [PubMed]

- Caupin, F.; Anisimov, M.A. Thermodynamics of supercooled and stretched water: Unifying two-structure description and liquid-vapor spinodal. J. Chem. Phys. 2019, 151, 034503. [Google Scholar] [CrossRef] [PubMed]

- Lyashchenko, A.K.; Zasetskii, A.Y. Structural transition to electrolyte-water solvent and changes in the molecular dynamics of water and properties of solutions. J. Struct. Chem. 1998, 39, 694–703. [Google Scholar] [CrossRef]

- Tan, K.L.; Yeo, S.H. Surface finishing on IN625 additively manufactured surfaces by combined ultrasonic cavitation and abrasion. Addit. Manuf. 2020, 31, 100938. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, J.; Liew, P.J. Material Removal in Ultrasonic Abrasive Polishing of Additive Manufactured Components. Appl. Sci. 2019, 9, 5359. [Google Scholar] [CrossRef]

- Tan, K.L.; Yeo, S.H. Surface modification of additive manufactured components by ultrasonic cavitation abrasive finishing. Wear 2017, 378–379, 90–95. [Google Scholar] [CrossRef]

- Grechnikov, F.V.; Surudin, S.V.; Erisov, Y.A.; Kuzin, A.O.; Bobrovskiy, I.N. Influence of Material Structure Crystallography on its Formability in Sheet Metal Forming Processes. IOP Conf. Ser. Mater. Sci. Eng. 2018, 286, UNSP 012021. [Google Scholar] [CrossRef]

- Dong, G.; Marleau-Finley, J.; Zhao, Y.F. Investigation of electrochemical post-processing procedure for Ti-6Al-4V lattice structure manufactured by direct metal laser sintering (DMLS). Int. J. Adv. Manuf. Technol. 2019, 104, 3401–3417. [Google Scholar] [CrossRef]

- Rotty, C.; Mandroyan, A.; Doche, M.-L.; Monney, S.; Hihn, J.Y.; Rouge, N. Electrochemical Superfinishing of Cast and ALM 316L Stainless Steels in Deep Eutectic Solvents: Surface Microroughness Evolution and Corrosion Resistance. J. Electrochem. Soc. 2019, 166, C468–C478. [Google Scholar] [CrossRef]

- Hryniewicz, T.; Rokosz, K.; Rokicki, R. Electrochemical and XPS studies of AISI 316L stainless steel after electropolishing in a magnetic field. Corros. Sci. 2008, 50, 2676–2681. [Google Scholar] [CrossRef]

- Ni, X.; Zhang, L.; Wu, W.; Song, J.; He, B.B.; Zhu, D.X. Improved Surface Properties for Nanotube Growth on Selective Laser Melted Porous Ti6Al4V Alloy via Chemical Etching. Int. J. Electrochem. Sci. 2019, 14, 5679–5689. [Google Scholar] [CrossRef]

- Xu, W.; Ma, L.; Chen, Y.; Liang, H. Mechano-oxidation during cobalt polishing. Wear 2018, 416, 36–43. [Google Scholar] [CrossRef]

- Chirkov, A.M.; Rybalko, A.P.; Rogal’skij, J.I.; Sedoj, E.A.; Merkukhin, A.V.; Borisov, N.V. Method of Laser-Plasma Polishing of Metallic Surface. RU Patent 2 381 094, 10 February 2010. [Google Scholar]

- Marinin, E.A.; Chirkov, A.M.; Gavrilov, G.N.; Fetisov, G.P.; Chernyshov, D.A.; Kurganova, Y.A. Experimental Evaluation of the Methods of Laser Cementation of Low-Alloy Tool Steels. Russ. Metall. 2018, 13, 1259–1263. [Google Scholar] [CrossRef]

- Koval, N.N.; Teresov, A.D.; Ivanov, Y.F.; Petrikova, E.A. Pulse Electron-Beam Metal Product Surface Polishing Method. RU Patent 2 619 5434, 16 May 2017. [Google Scholar]

- Teresov, A.D.; Ivanov, Y.F.; Petrikova, E.A.; Koval, N.N. Structure and Properties of VT6 Alloy Obtained by Layered Selective Sintering of a Powder. Russ. Phys. J. 2017, 60, 1367–1372. [Google Scholar] [CrossRef]

- Uglov, V.V.; Krutsilina, E.A.; Shymanski, V.I.; Kuleshov, A.K.; Koval, N.N.; Ivanov, Y.F. Heat Transfer in Surface Layer of a T15k6 Heterogeneous Hard Alloy under Pulsed High-Energy Irradiation. Russ. Phys. J. 2020, 63, 693–698. [Google Scholar] [CrossRef]

- Lober, L.; Flache, C.; Petters, R.; Kuhn, U.; Eckert, J. Comparison of different post processing technologies for SLM generated 3161 steel parts. Rapid Prototyp. J. 2013, 19, 173–179. [Google Scholar] [CrossRef]

- Gordon, E.R.; Shokrani, A.; Flynn, J.M.; Goguelin, S.; Barclay, J.; Dhokia, V.A. Surface Modification Decision Tree to Influence Design in Additive Manufacturing. In Smart Innovation Systems and Technologies, Proceedings of the 3rd International Conference on Sustainable Design and Manufacturing (SDM), Chania, Greece, 4–6 April 2016; Setchi, R., Howlett, R.J., Liu, Y., Theobald, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; Volume 52, pp. 423–434. [Google Scholar]

- Gatto, A.; Bassoli, E.; Denti, L.; Sola, A.; Tognoli, E.; Comin, A.; Porro, J.A.; Cordovilla, F.; Angulo, I.; Ocana, J.L. Effect of Three Different Finishing Processes on the Surface Morphology and Fatigue Life of A357.0 Parts Produced by Laser-Based Powder Bed Fusion. Adv. Eng. Mater. 2019, 21, 1801357. [Google Scholar] [CrossRef]

- Kudrya, V.P.; Maishev, Y.P. Applications of the Technology of Fast Neutral Particle Beams in Micro-and Nanoelectronics. Mikroelektronika 2018, 47, 51–63. [Google Scholar] [CrossRef]

- Vlcak, P.; Fojt, J.; Drahokoupil, J.; Brezina, V.; Sepitka, J.; Horazdovsky, T.; Miksovsky, J.; Cerny, F.; Lebeda, M.; Haubner, M. Influence of surface pre-treatment with mechanical polishing, chemical, electrochemical and ion sputter etching on the surface properties, corrosion resistance and MG-63 cell colonization of commercially pure titanium. Mater. Sci. Eng. C 2020, 115, 111065. [Google Scholar] [CrossRef] [PubMed]

- Grigoriev, S.; Metel, A. Plasma-and Beam-Assisted Deposition Methods. In Nanostructured Thin Films and Nanodispersion Strengthened Coatings; NATO Science Series II: Mathematics, Physics and Chemistry; Voevodin, A.A., Shtansky, D.V., Levashov, E.A., Moore, J.J., Eds.; Springer: Dordrecht, The Netherlands, 2004; Volume 155, pp. 147–154. [Google Scholar] [CrossRef]

- Isakova, Y.I.; Prima, A.I.; Pushkarev, A.I. A Conical Ion Diode with Self-Magnetic Insulation of Electrons. Instrum. Exp. Tech. 2019, 62, 506–516. [Google Scholar] [CrossRef]

- Ghyngazov, S.A.; Zhu, X.P.; Pushkarev, A.I.; Egorova, Y.I.; Matrenin, S.V.; Kostenko, V.A.; Zhang, C.C.; Lei, M.K. Surface Modification of ZrO2-3Y(2)O(3) with Highintensity Pulsed N2+ Ion Beams. Russ. Phys. J. 2020, 63, 176–179. [Google Scholar] [CrossRef]

- Metel, A.; Bolbukov, V.; Volosova, M.; Grigoriev, S.; Melnik, Y. Source of metal atoms and fast gas molecules for coating deposition on complex shaped dielectric products. Surf. Coat. Technol. 2013, 225, 34–39. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Melnik, Y.A.; Metel, A.S.; Panin, V.V. Broad beam source of fast atoms produced as a result of charge exchange collisions of ions accelerated between two plasmas. Instrum. Exp. Tech. 2009, 52, 602–608. [Google Scholar] [CrossRef]

- Suhara, M.; Matsuzaka, N.; Fukumitsu, M.; Okumura, T. Characterization of argon fast atom beam source and application to mesa etching process for GaInP/GaAs triple-barrier resonant tunneling diodes. In Proceedings of the 18th International Microprocesses and Nantechnology Conference, Tokyo, Japan, 26–28 October 2005; Institute of Pure Applied Physics: Tokyo, Japan, 2006; Volume 45, pp. 5504–5508. [Google Scholar]

- Grigoriev, S.N.; Melnik, Y.A.; Metel, A.S.; Panin, V.V.; Prudnikov, V.V. A compact vapor source of conductive target material sputtered by 3-keV ions at 0.05-Pa pressure. Instrum. Exp. Tech. 2009, 52, 731. [Google Scholar] [CrossRef]

- Musil, J.; Jaroš, M. Plasma and floating potentials in magnetron discharges. J. Vac. Sci. Technol. A 2017, 35, 060605. [Google Scholar] [CrossRef]

- Anders, A. Tutorial: Reactive high power impulse magnetron sputtering. J. Appl. Phys. 2017, 121, 171101. [Google Scholar] [CrossRef]

- Berlin, E.V.; Grigoriev, V.Y. Features of super-high-speed deposition of copper by a magnetron operating in target vapors on dielectric substrates. In Proceedings of the 11th International conference of a “Films and Coatings—2013”, Saint Petersburg, Russia, 6–8 May 2013; pp. 104–106. [Google Scholar]

- Shandrikov, M.V.; Artamonov, I.D.; Bugaev, A.S.; Oks, E.M.; Oskomov, K.V.; Vizir, A.V. Deposition of Cu-films by a planar magnetron sputtering system at ultra-low operating pressure. Surf. Coat. Technol. 2020, 389, 125600. [Google Scholar] [CrossRef]

- Shandrikov, M.V.; Bugaev, A.S.; Oks, E.M.; Vizir, V.; Yushkov, G.Y. Ion mass-to-charge ratio in planar magnetron plasma with electron injections. J. Phys. D Appl. Phys. 2018, 51, 415201. [Google Scholar] [CrossRef]

- Markov, A.B.; Yakovlev, E.V.; Shepel’, D.A.; Petrov, V.I.; Bestetti, M. Liquid-Phase Surface Alloying of Copper with Stainless Steel Using Low-Energy, High-Current Electron Beam. Russ. Phys. J. 2017, 60, 1455–1460. [Google Scholar] [CrossRef]

- Volosova, M.A.; Grigor’ev, S.N.; Kuzin, V.V. Effect of titanium nitride coating on stress structural inhomogeneity in oxide-carbide ceramic. Part 4. Action of heat flow. Refract. Ind. Ceram. 2015, 56, 91–96. [Google Scholar] [CrossRef]

- Maishev, Y.P.; Shevchuk, S.L.; Kudrya, V.P. Formation of fast neutral beams and their using for selective etching. Proc. SPIE 2014, 9440, UNSP 94400K. [Google Scholar]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.A.; Panin, V.V. Filling the vacuum chamber of a technological system with homogeneous plasma using a stationary glow discharge. Plasma Phys. Rep. 2009, 35, 1058–1067. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.A.; Bolbukov, V.P. Characteristics of a fast neutral atom source with electrons injected into the source through its emissive grid from the vacuum chamber. Instrum. Exp. Tech. 2012, 55, 288–293. [Google Scholar] [CrossRef]

- Mesyats, G.A.; Proskurovsky, D.I.; Yankelevich, E.B.; Tregubov, V.F. Observation of micro-tip regeneration and the cathode polishing at nanosecond pulses of explosive emission current. Rep. USSR Acad. Sci. 1976, 227, 1335–1337. [Google Scholar]

- Zhong, Z.W. Advanced polishing, grinding and finishing processes for various manufacturing applications: A review. Mater. Manuf. Process. 2020, 35, 1279–1303. [Google Scholar] [CrossRef]

- Sagbas, B. Post-Processing Effects on Surface Properties of Direct Metal Laser Sintered AlSi10Mg Parts. Met. Mater. Int. 2020, 26, 143–153. [Google Scholar] [CrossRef]

- Lazarenko, B.R.; Lazarenko, N.I. Electric Spark Machining of Metals in Water and Electrolytes (Elektroiskrovaya Obrabotka Metallov V Vode I Elektrolitakh). Surf. Eng. Appl. Electrochem. (Elektronnaya Obrabotka Materialov) 1980, 1, 5–8. [Google Scholar]

- Danilov, I.; Hackert-Oschätzchen, M.; Zinecker, M.; Meichsner, G.; Edelmann, J.; Schubert, A. Process Understanding of Plasma Electrolytic Polishing through Multiphysics Simulation and Inline Metrology. Micromachines 2019, 10, 214. [Google Scholar] [CrossRef] [PubMed]

- Afanasiev, Y.V.; Chichkov, B.N.; Demchenko, N.N.; Isakov, V.A.; Zavestovskaya, I.N. Ablation of metals by ultrashort laser pulses: Theoretical modeling and computer simulations. Proc. SPIE 2000, 3885, 266–274. [Google Scholar]

- Sobol’, O.V.; Andreev, A.A.; Grigoriev, S.N.; Gorban’, V.F.; Volosova, M.A.; Aleshin, S.V.; Stolbovoy, V.A. Physical characteristics, structure and stress state of vacuum-arc tin coating, deposition on the substrate when applying high-voltage pulse during the deposition. Probl. Atom. Sci. Technol. 2011, 4, 174–177. [Google Scholar]

- Aleshin, N.P.; Grigor’ev, M.V.; Shchipakov, N.A.; Krys’ko, N.V.; Krasnov, I.S.; Prilutskii, M.A.; Smorodinskii, Y.G. On the Possibility of Using Ultrasonic Surface and Head Waves in Nondestructive Quality Checks of Additive Manufactured Products. Russ. J. Nondestruct. 2017, 53, 830–838. [Google Scholar] [CrossRef]

- Metel, A.; Bolbukov, V.; Volosova, M.; Grigoriev, S.; Melnik, Y. Equipment for deposition of thin metallic films bombarded by fast argon atoms. Instrum. Exp. Tech. 2014, 57, 345–351. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Metel, A.S.; Grigoriev, S.N.; Tarasova, T.V.; Melnik, Y.A.; Volosova, M.A.; Okunkova, A.A.; Podrabinnik, P.A.; Mustafaev, E.S. Surface Quality of Metal Parts Produced by Laser Powder Bed Fusion: Ion Polishing in Gas-Discharge Plasma Proposal. Technologies 2021, 9, 27. https://doi.org/10.3390/technologies9020027

Metel AS, Grigoriev SN, Tarasova TV, Melnik YA, Volosova MA, Okunkova AA, Podrabinnik PA, Mustafaev ES. Surface Quality of Metal Parts Produced by Laser Powder Bed Fusion: Ion Polishing in Gas-Discharge Plasma Proposal. Technologies. 2021; 9(2):27. https://doi.org/10.3390/technologies9020027

Chicago/Turabian StyleMetel, Alexander S., Sergey N. Grigoriev, Tatiana V. Tarasova, Yury A. Melnik, Marina A. Volosova, Anna A. Okunkova, Pavel A. Podrabinnik, and Enver S. Mustafaev. 2021. "Surface Quality of Metal Parts Produced by Laser Powder Bed Fusion: Ion Polishing in Gas-Discharge Plasma Proposal" Technologies 9, no. 2: 27. https://doi.org/10.3390/technologies9020027

APA StyleMetel, A. S., Grigoriev, S. N., Tarasova, T. V., Melnik, Y. A., Volosova, M. A., Okunkova, A. A., Podrabinnik, P. A., & Mustafaev, E. S. (2021). Surface Quality of Metal Parts Produced by Laser Powder Bed Fusion: Ion Polishing in Gas-Discharge Plasma Proposal. Technologies, 9(2), 27. https://doi.org/10.3390/technologies9020027