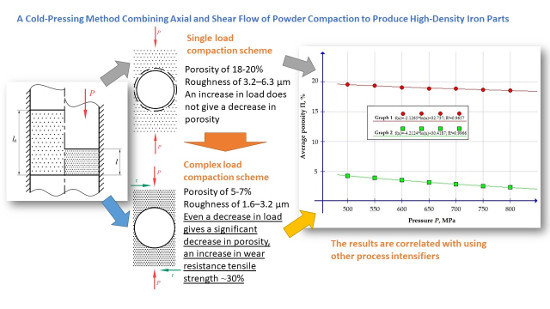

A Cold-Pressing Method Combining Axial and Shear Flow of Powder Compaction to Produce High-Density Iron Parts

Abstract

1. Introduction

2. Methods and Materials

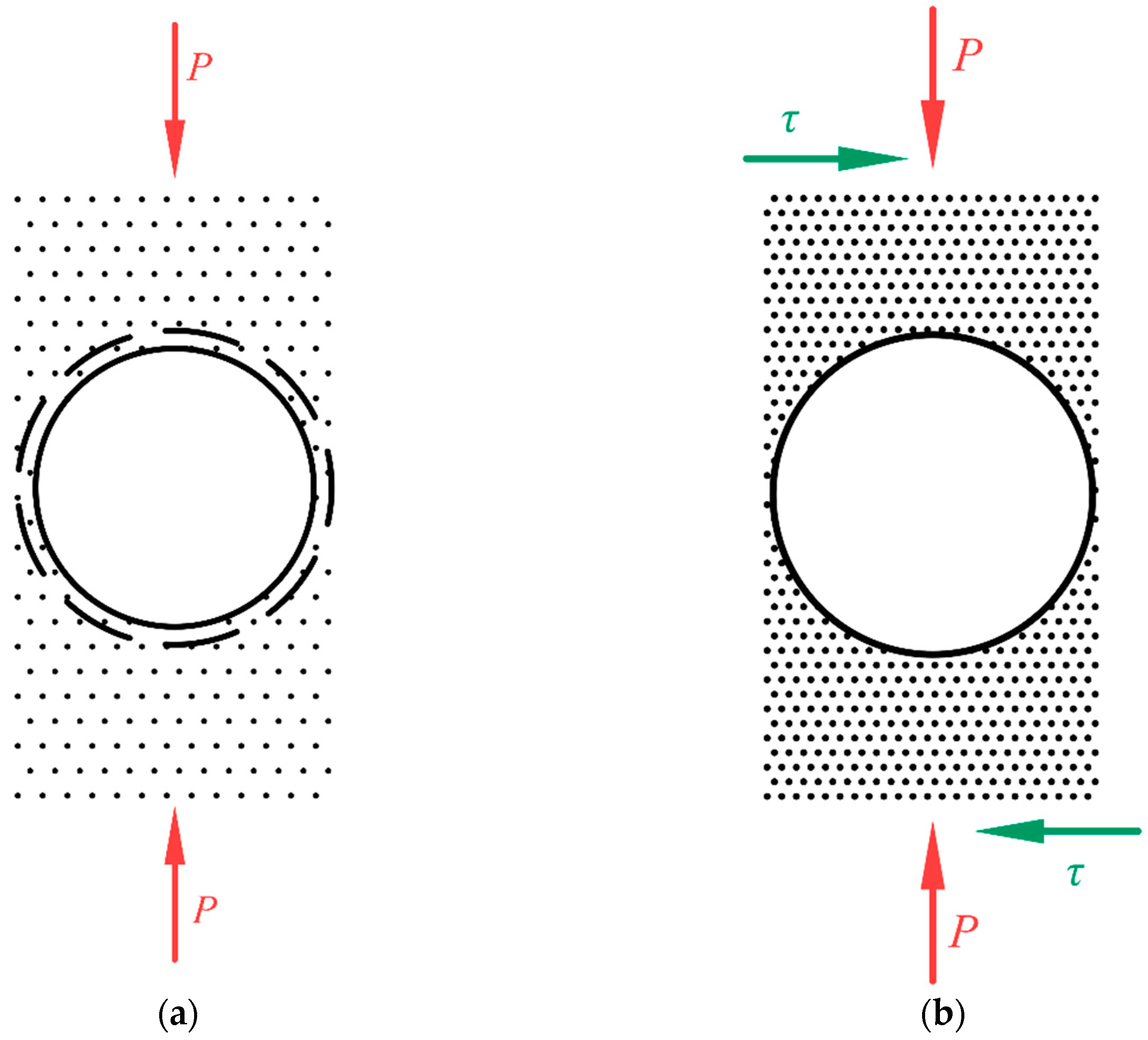

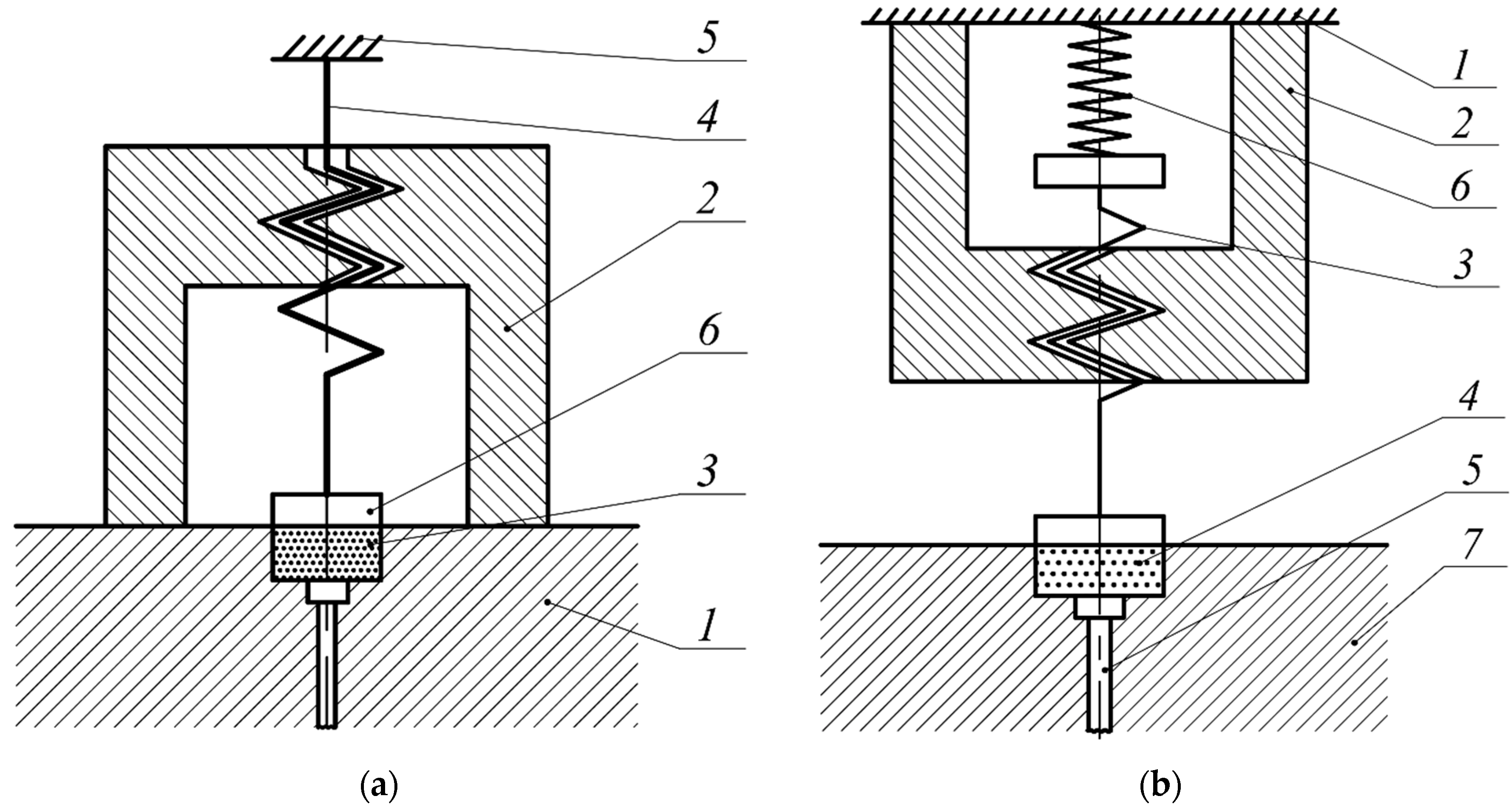

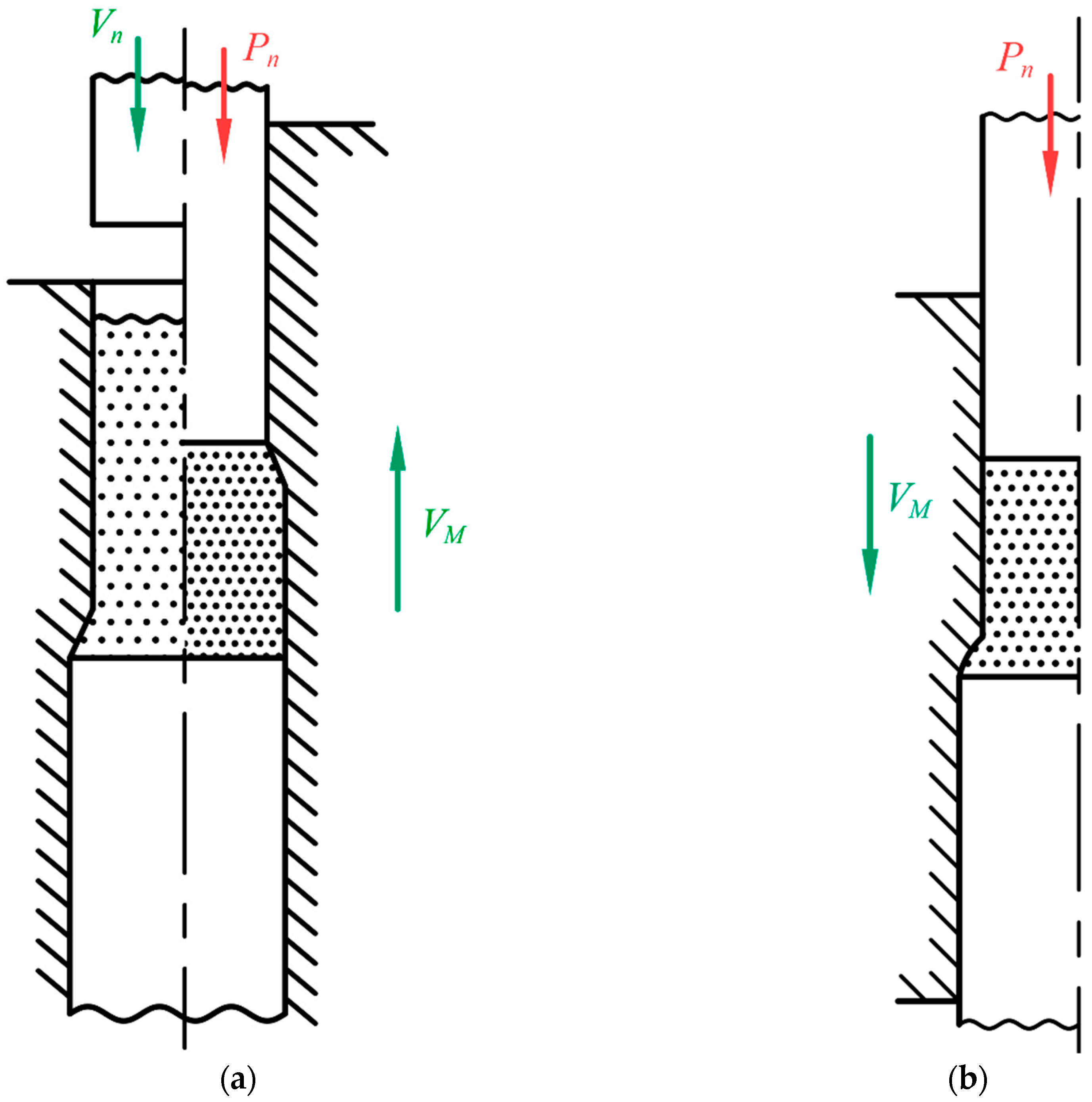

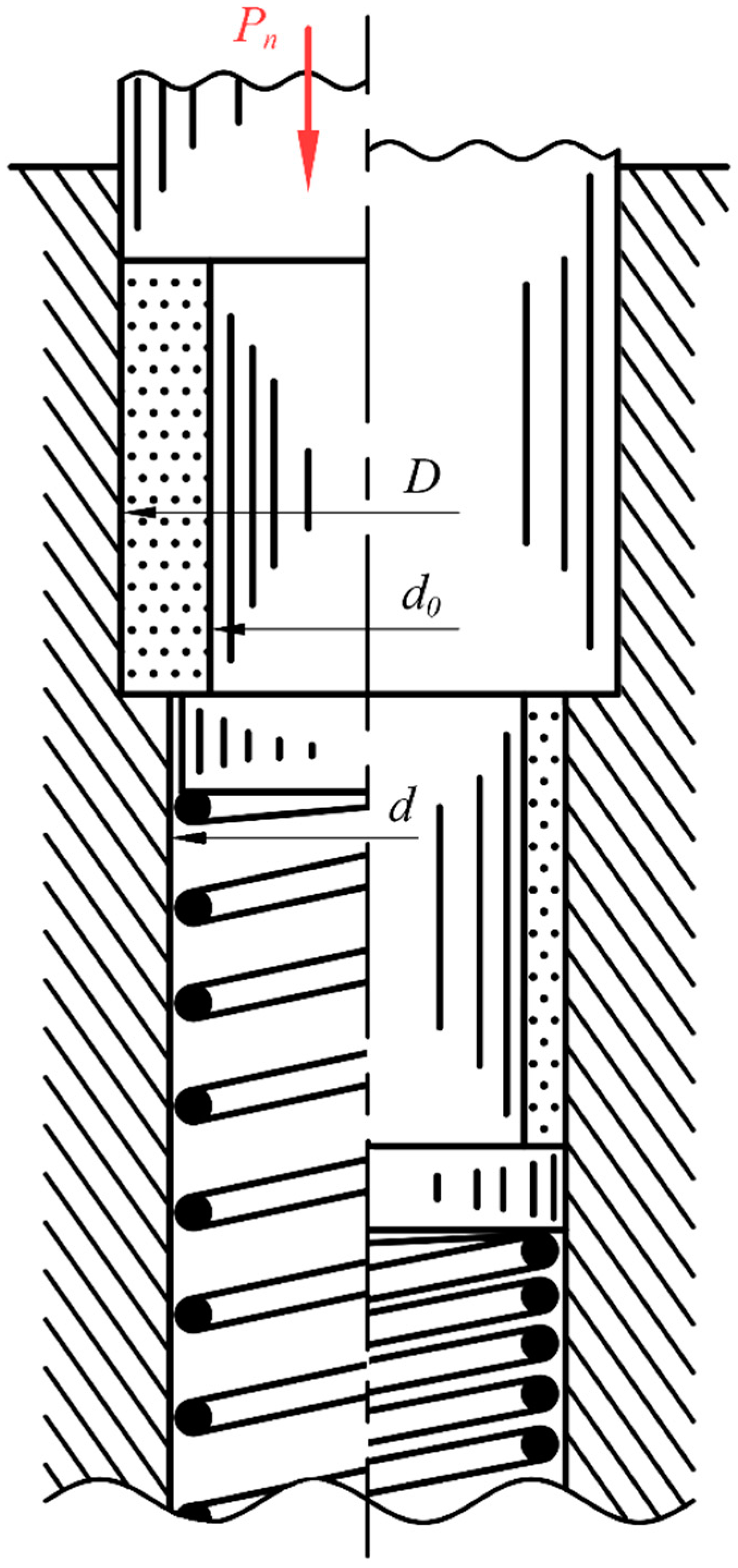

2.1. Developed Method of Complex Load

2.2. Coefficient of Friction

- The pair of “wall—powder workpiece”— the use of standard lubricants;

- between the particles of the powder—the use of a plasticizer introduced into the prepared powder mixture.

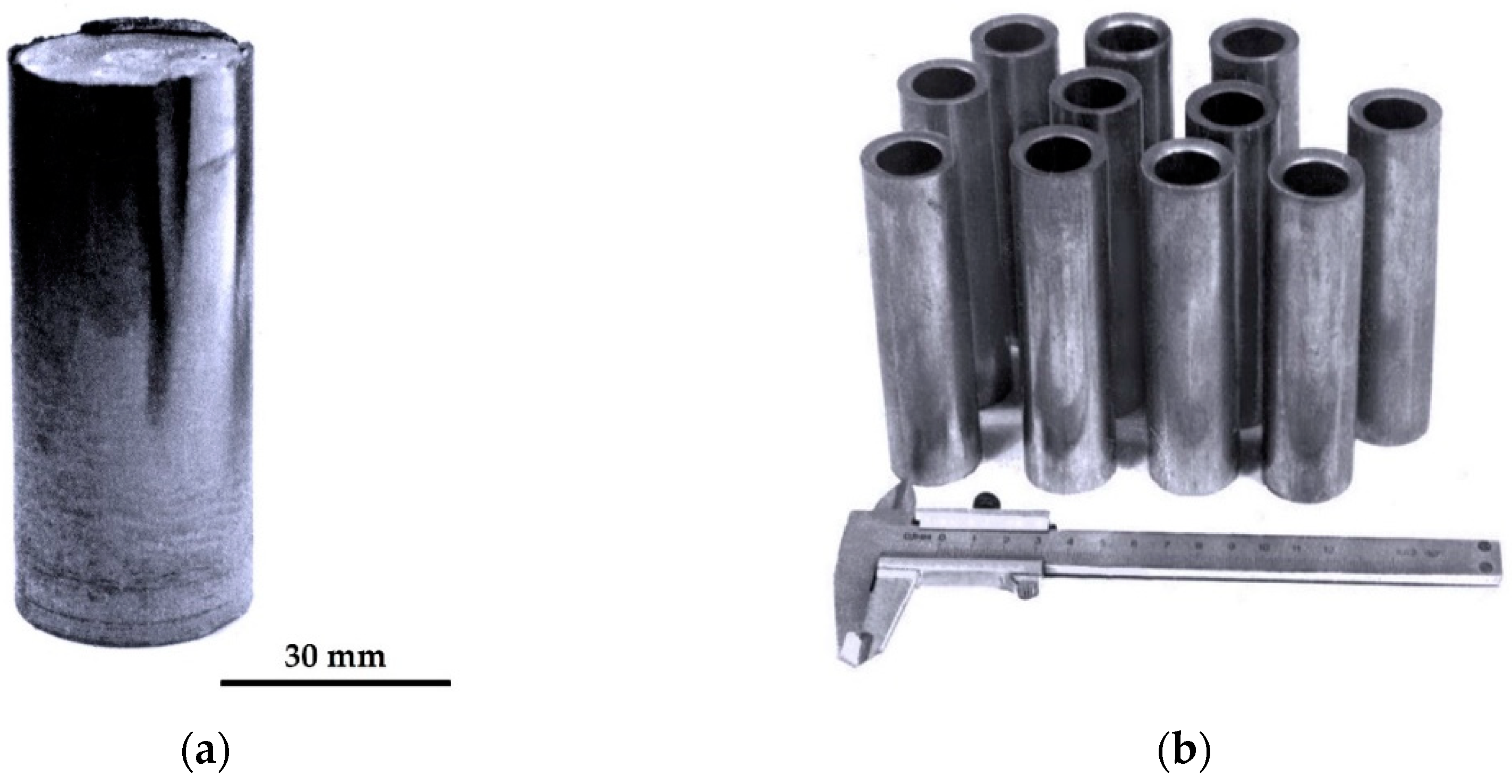

2.3. Material and Equipment

2.4. Characterization of the Samples

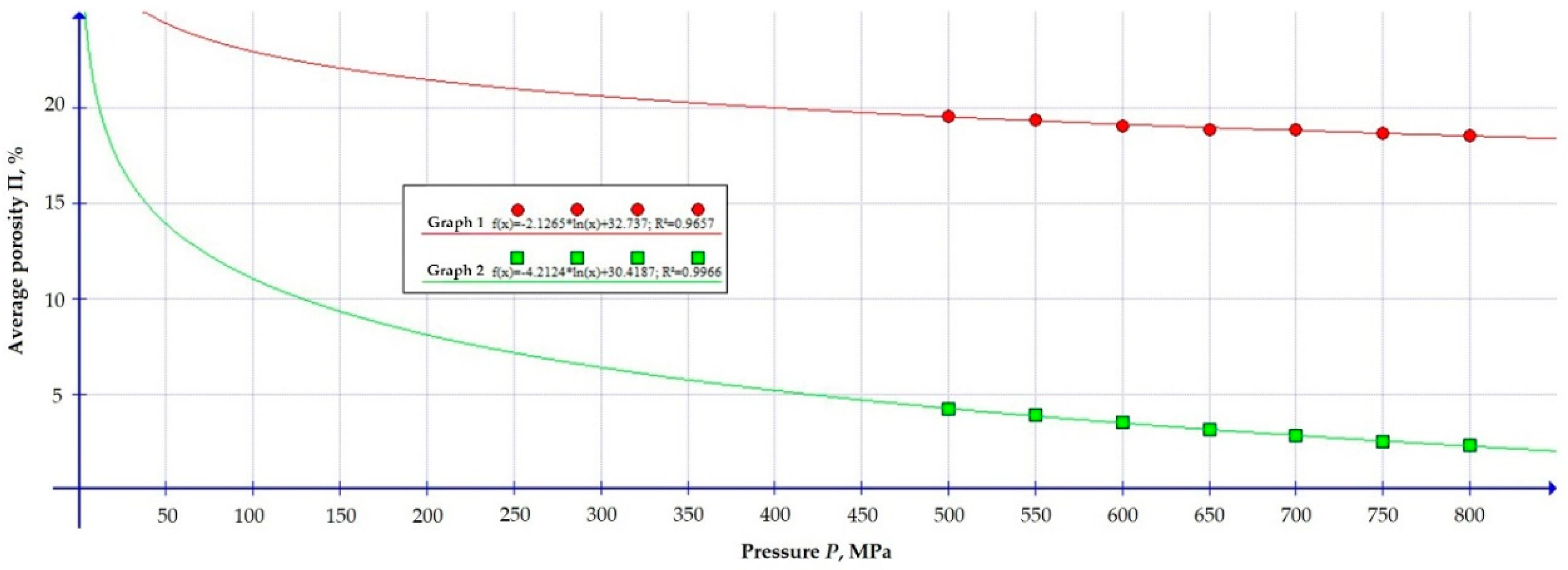

3. Results

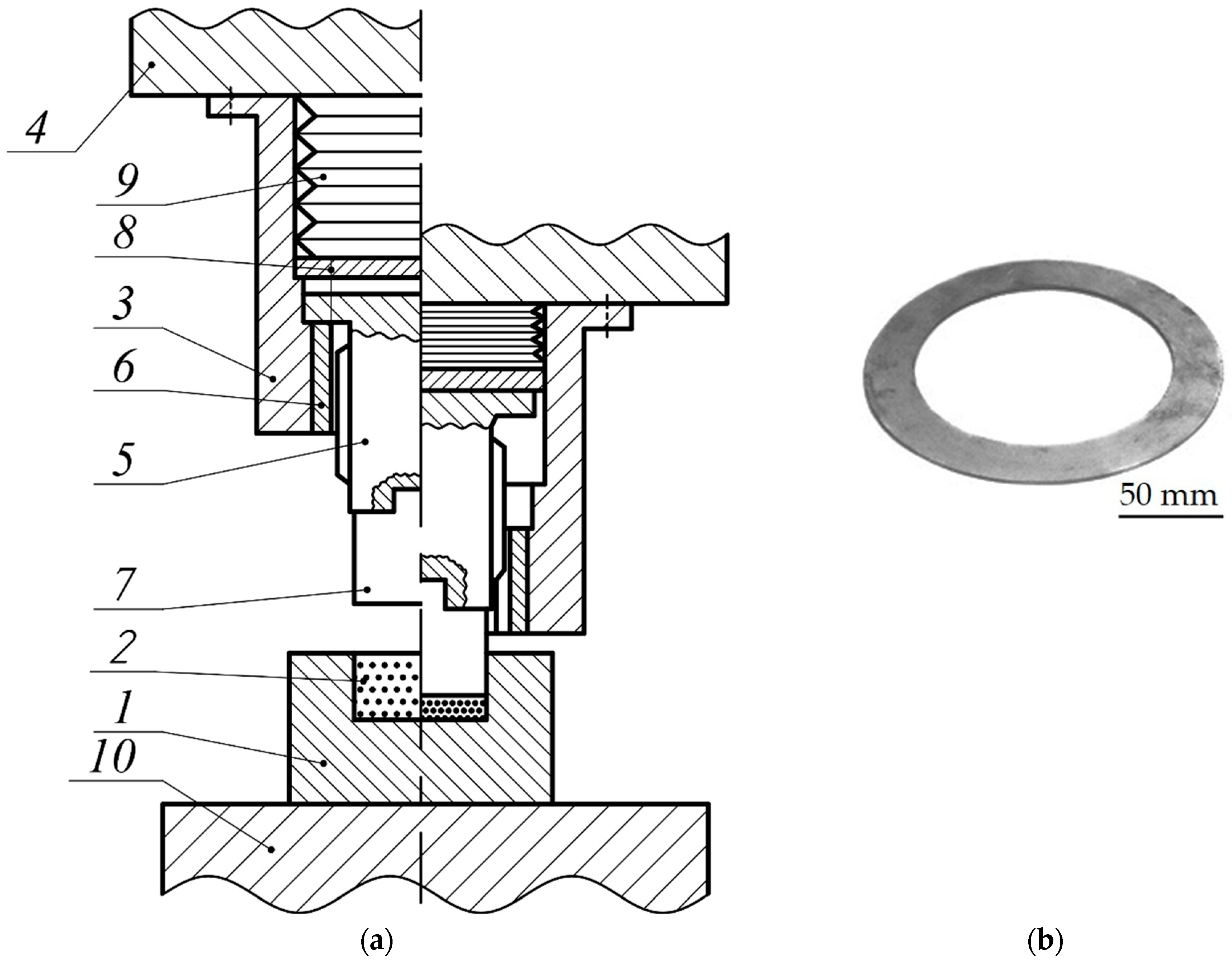

3.1. Manufacturing of Thin Round Parts

3.2. Manufacturing of Thick Round Parts

3.3. Extrusion and Lubrication of Preforms

4. Discussion

5. Conclusions

6. Patents

- Korobova, N.V.; Dmitriev, A.M.; Aksenenko, A.Yu. Stamp for Obtaining Cylindrical Metal Parts with a Homogeneous Short-Grain Structure from Bars; RU 2629576, 30.12.2015.

- Korobova, N.V.; Dmitriev, A.M.; Grigoriev, V.V.; Aksenenko, A.Yu. Device for Moving Billets in Solid-Liquid Conditions; RU 133441, 05.04.2013.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Grigoriev, S.N.; Sinopalnikov, V.A.; Tereshin, M.V.; Gurin, V.D. Control of parameters of the cutting process on the basis of diagnostics of the machine tool and workpiece. Meas. Tech. 2012, 55, 555–558. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Fominski, V.Y.; Romanov, R.I.; Gnedovets, A.G.; Volosova, M.A. Shadow masked pulsed laser deposition of WSex films: Experiment and modeling. Appl. Surf. Sci. 2013, 282, 607–614. [Google Scholar] [CrossRef]

- Grigoriev, S.; Metel, A. Plasma-and beam-Assisted deposition methods. NATO Sci. Ser. 2004, 155, 147–154. [Google Scholar]

- Floren, H.; Frishammar, J.; Lof, A.; Ericsson, M. Raw materials management in iron and steelmaking firms. Miner. Econ. 2019, 32, 39–47. [Google Scholar] [CrossRef]

- Sista, K.S.; Dwarapudi, S. Iron Powders from Steel Industry by-Products. ISIJ Int. 2018, 58, 999–1006. [Google Scholar] [CrossRef]

- Gallardo, J.M.; Agote, I.; Astacio, R.; Schubert, T.; Cintas, J.; Montes, J.M.; Torres, Y.; Cuevas, F.G. Hard Metal Production by ERS: Processing Parameter Roles in Final Properties. Metals 2019, 9, 172. [Google Scholar] [CrossRef]

- Agrawal, A.; Dube, R.K. Methods of fabricating Cu-Al-Ni shape memory alloys. J. Alloys Compd. 2018, 750, 235–247. [Google Scholar] [CrossRef]

- Herraiz Lalanaa, E. Permanent magnets and its production by powder metallurgy. Rev. Metal. 2018, 54, e121. [Google Scholar]

- Palmero, P. Structural Ceramic Nanocomposites: A Review of Properties and Powders’ Synthesis Methods. Nanomaterials 2015, 5, 656–696. [Google Scholar] [CrossRef]

- Letenneur, M.; Brailovski, V.; Kreitcberg, A.; Paserin, V.; Bailon-Poujol, I. Laser Powder Bed Fusion of Water-Atomized Iron-Based Powders: Process Optimization. J. Manuf. Mater. Process. 2017, 1, 23. [Google Scholar] [CrossRef]

- Qin, Q.; Yang, F.; Shi, T.; Guo, Z.; Sun, H.X.; Li, P.; Lu, X.; Chen, C.G.; Hao, J.J.; Cao, P. Spheroidization of tantalum powder by radio frequency inductively coupled plasma processing. Adv. Powder Technol. 2019, 30, 1709–1714. [Google Scholar] [CrossRef]

- Petrov, G.V.; Shneerson, Y.M.; Andreev, Y.V. Extraction of Platinum Metals During Procssing of Chromium Ores from Dunnite Deposits. J. Min. Inst. 2018, 231, 281–286. [Google Scholar]

- Balog, M.; Ibrahim, A.M.H.; Krizik, P.; Bajana, O.; Klimova, A.; Catic, A.; Schauperl, Z. Bioactive Ti plus Mg composites fabricated by powder metallurgy: The relation between the microstructure and mechanical properties. J. Mech. Behav. Biomed. Mater. 2019, 90, 45–53. [Google Scholar] [CrossRef] [PubMed]

- Nicoara, M.; Buzdugan, D.; Locovei, C.; Bena, T.; Stoica, M. About thermostability of biocompatible Ti-Zr-Ag-Pd-Sn amorphous alloys. J. Therm. Anal. Calorim. 2018, 133, 189–197. [Google Scholar] [CrossRef]

- Metel, A.; Bolbukov, V.; Volosova, M.; Grigoriev, S.; Melnik, Y. Equipment for Deposition of Thin Metallic Films Bombarded by Fast Argon Atoms. Instrum. Exp. Tech. 2014, 57, 345–351. [Google Scholar] [CrossRef]

- Sezer, N.; Evis, Z.; Kayhan, S.M.; Tahmasebifar, A.; Koc, M. Review of magnesium-Based biomaterials and their applications. J. Magnes. Alloys 2018, 6, 23–43. [Google Scholar] [CrossRef]

- McDevitt, E.; Minisandram, R.; Garcia-Avila, M. The Case for Physical Experiments in a Digital Age. Miner. Metals Mater. Ser. 2018, 941–956. [Google Scholar] [CrossRef]

- Volykhov, A.A.; Sanchez-Barriga, J.; Sirotina, A.P.; Neudachina, V.S.; Frolov, A.S.; Gerber, E.A.; Kataev, E.Y.; Senkovsky, B.; Khmelevsky, N.O.; Aksenenko, A.Y.; et al. Rapid Surface Oxidation of Sb2Te3 as Indication for a Universal Trend in the Chemical Reactivity of Tetradymite Topological Insulators. Chem. Mater. 2016, 28, 8916–8923. [Google Scholar] [CrossRef]

- Kotoban, D.; Grigoriev, S.; Okunkova, A.; Sova, A. Influence of a shape of single track on deposition efficiency of 316L stainless steel powder in cold spray. Surf. Coat. Technol. 2017, 309, 951–958. [Google Scholar] [CrossRef]

- Dmitriev, A.M.; Korobova, N.V.; Badalyan, A.Z. Development and Research of Formation Technologies on Specialized Presses With Subsequent Sintering of High-Density Details From Iron-Based Powders. J. Min. Inst. 2019, 236, 216–228. [Google Scholar] [CrossRef]

- Ferreira, S.C.; Conde, A.; Arenas, M.A.; Rocha, L.A.; Velhinho, A. Anodization Mechanism on SiC Nanoparticle Reinforced Al Matrix Composites Produced by Power Metallurgy. Materials 2014, 7, 8151–8167. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Liu, F.; Huang, L.; Jiang, L. Dependence of Creep Performance and Microstructure Evolution on Solution Cooling Rate in a Polycrystalline Superalloy. Metals 2018, 8, 4. [Google Scholar] [CrossRef]

- Chauhan, S.; Verma, V.; Prakash, U.; Tewari, P.C.; Khanduja, D. Studies on induction hardening of powder-Metallurgy-Processed Fe-Cr/Mo alloys. Int. J. Miner. Metall. Mater. 2017, 24, 918–925. [Google Scholar] [CrossRef]

- Rezaei, A.; Hosseini, H.R.M. Evolution of microstructure and mechanical properties of A1-5 wt% Ti composite fabricated by P/M and hot extrusion: Effect of heat treatment. Mater. Sci. Eng. A 2017, 689, 166–175. [Google Scholar] [CrossRef]

- Colombini, E.; Bocchini, G.F.; Parigi, G.; Sola, R.; Veronesi, P.; Poli, G. Laser hardening of homogeneous and inhomogeneous p/m steels. Metall. Ital. 2015, 10, 15–24. [Google Scholar]

- Rivolta, B.; Gerosa, R.; Silva, G.; Tavasci, A.; Engstrom, U. Wear performances of surface hardened PM steel from pre-Alloyed powder. Wear 2012, 289, 160–167. [Google Scholar] [CrossRef]

- Nosewicz, S.; Rojek, J.; Chmielewski, M.; Pietrzak, K. Discrete Element Modeling of Intermetallic Matrix Composite Manufacturing by Powder Metallurgy. Materials 2019, 12, 281. [Google Scholar] [CrossRef] [PubMed]

- Khodaee, A.; Melander, A. Numerical and Experimental Analysis of the Gear Size Influence on Density Variations and Distortions during the Manufacturing of PM Gears with an Innovative Powder Processing Route Incorporating HIP. J. Manuf. Mater. Process. 2018, 2, 49. [Google Scholar] [CrossRef]

- Coman, E. Physical, Chemical and Structural Characteristics of Sintered Hard Alloys Obtained by Means of Powder Metallurgy. Metal. Int. 2012, 17, 39–42. [Google Scholar]

- Niada, R.F.; Bittencourt, S.D.; de Martins, R.M.; de Aquim, P.M.; Dias, M.M.; Schaeffer, L. Development of a motor with permanent magnets and rotor core obtained from powder metallurgy to be used in model airplanes. Cienc. Tecnol. Dos Mater. 2015, 27, 53–62. [Google Scholar]

- Grigoriev, S.N.; Dmitriev, A.M.; Korobova, N.V. Uprating the Uniformity of the Hardness Distribution within the Powder Billets Moulded with the Shifts of Layers. Metallofiz. Noveishie Tekhnol. 2013, 35, 1527–1538. [Google Scholar]

- Dmitriev, A.M.; Korobova, N.V. A Study of Advanced Processes for Large-Scale Production of Parts from Powder Steels. Metal Sci. Heat Treat. 2018, 60, 457–463. [Google Scholar] [CrossRef]

- Iankov, R. Finite element simulation of powder metal compaction processes in container with several punches. Nato Sci. Ser. 2001, 176, 169–180. [Google Scholar]

- Dmitriev, A.M.; Grigoriev, S.N.; Korobova, N.V.; Stupnikov, V.P. A study of the quality of preforms from iron-Base powders produced by forming combined with sintering by electric current pulses. Metal Sci. Heat Treat. 2012, 54, 17–21. [Google Scholar] [CrossRef]

- GOST—Interstate Standard 9849-86 “Iron Powder. Specifications.”; Ministerstvo chernoy metallurgii SSSR (USSR Ministry of Ferrous Metallurgy): Moscow, USSR, 1986.

- Xu, W.; Liu, Z.; Lu, X.; Tian, J.; Chen, G.; Liu, B.; Li, Z.; Qu, X.; Wen, C. Porous Ti-10Mo alloy fabricated by powder metallurgy for promoting bone regeneration. Sci. China 2019, 62, 1053–1064. [Google Scholar] [CrossRef]

- Ramirez, A.M.M.; Vintila, R.R.; Drew, R.A.L. Morphology of Aluminum Alloy Foams Produced with Dolomite via Partial Sintering of Precursors. Materials 2019, 12, 1691. [Google Scholar] [CrossRef] [PubMed]

- Romero, C.; Yang, F.; Bolzoni, L. Fatigue and fracture properties of Ti alloys from powder-Based processes —A review. Int. J. Fatigue 2018, 117, 407–419. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Szlancsik, A. On the Mechanical Properties of Aluminum Matrix Syntactic Foams. Adv. Eng. Mater. 2018, 20, 1700980. [Google Scholar] [CrossRef]

- Xiao, J.; Qiu, G. Research Progress in Preparation Methods of Titanium Foams or Porous Titanium. Rare Metal Mater. Eng. 2017, 46, 1734–1748. [Google Scholar]

- Arifvianto, B.; Zhou, J. Fabrication of Metallic Biomedical Scaffolds with the Space Holder Method: A Review. Materials 2014, 7, 3588–3622. [Google Scholar] [CrossRef]

- Torralba, J.M.; Campos, M. Toward high performance in Powder Metallurgy. Rev. Metal. 2014, 50. [Google Scholar] [CrossRef]

- Dmitriev, A.M.; Korobova, N.V. Expanding of Application of Cold Die Forging by Inducing Active Contact Friction Forces. J. Frict. Wear 2013, 34, 232–237. [Google Scholar] [CrossRef]

- Gnedovets, A.G.; Zelenskii, V.A.; Ankudinov, B.; Alymov, M.I. Hierarchically Structured, Highly Porous Nickel Synthesized in Sintering-Evaporation Process from a Metal Nanopowder and a Space Holder. Dokl. Chem. 2019, 484, 64–67. [Google Scholar] [CrossRef]

- Yu, C.; Cao, P.; Jones, M.I. Microstructural Evolution during Pressureless Sintering of Blended Elemental Ti-Al-V-Fe Titanium Alloys from Fine Hydrogenated-Dehydrogenated Titanium Powder. Metals 2017, 7, 285. [Google Scholar] [CrossRef]

- Ma, Y.; Bao, C.; Han, L.; Chen, J. Study on Microstructures and Properties of Porous TiC Ceramics Fabricated by Powder Metallurgy. J. Mater. Eng. Perform. 2017, 26, 636–643. [Google Scholar] [CrossRef]

- Leparoux, M.; Kollo, L.; Kwon, H.; Kallip, K.; Babu, N.K.; AlOgab, K.; Talari, M.K. Solid State Processing of Aluminum Matrix Composites Reinforced with Nanoparticulate Materials. Adv. Eng. Mater. 2018, 20, 1800401. [Google Scholar] [CrossRef]

- Jones, W.P. Forming process of Powder Metallurgy. Int. J. Powder Met. Powder Technol. 1984, 20, 103–105. [Google Scholar]

- Jones, W.P. Fundamental Principles of Powder Metallurgy; Edward Arnold: London, UK, 1960; pp. 342–346. [Google Scholar]

- Budiansky, B.E.; Dow, N.F.; Peters, R.W.; Shepherd, R.P. Experimental Studies of Polyaxial Stress—Strain Laws of Plasticity, 1st ed.; ASME-AMER Soc Mechanical Eng: New York, NY, USA, 1952. [Google Scholar]

- Batdorf, S.B.; Budiansky, B.A. Mathematical theory of plasticity based on the concept of slip. NACA Tech. Note 1949, 1847, 331–350. [Google Scholar]

- Zhu, W.; Montesi, L.G.; Wong, T.F. Shear-Enhanced compaction and permeability reduction: Triaxial extension tests on porous sandstone. Mech. Mater. 1997, 25, 199–214. [Google Scholar] [CrossRef]

- Le Coff, P.; Leclerc, D.; Dodds, S. The structure of packet beds: Continuity of research in Nancy and some new results. Powder Technol. 1985, 42, 47–53. [Google Scholar] [CrossRef]

- Peronius, N.; Sweeting, T.S. On the correlation of minimum porosity with particle size distribution. Powder Technol. 1985, 42, 118–121. [Google Scholar] [CrossRef]

- Saxl, H.; Pelican, K.; Bestersi, N. On the parameters distribing spatidl distribution of particles in dispersion strengthened materials. Powder Metall. 1987, 19, 27–32. [Google Scholar]

- Itoh, T.; Wanibe, Y.; Sakao, H. Simulation of random packing processes of the powder with forsfields size distribution and analysis of the packing configuration. J. Jpn. Inst. Metals 1986, 50, 423–429. [Google Scholar] [CrossRef][Green Version]

- Itoh, T.; Wanibe, Y.; Sakao, H. Analysis of packing density by randomly packed models of binary powders. J. Jpn. Inst. Metals 1986, 50, 475–479. [Google Scholar] [CrossRef]

- Hirschvogel, M. Beitrag zur Plasizitatstheorie Poroser, Kompressible Materialien Mit Anwendung in der Pulvermetallurgie (Contribution to the Plasticity Theory of Porous, Compressible Materials with Application in the Powder Metallurgy). Ph.D. Thesis, Universitat Stutgart, Stuttgart, Germany, 1975. [Google Scholar]

- Honess, H. Uber des plastische Verhalten von Sintermetallen bei Rauntemperatur. In Berichte aus dem Institut fur Umformtechnik Universitat Stutgart; W. Girandet: Essen, Germany, 1976; p. 152. [Google Scholar]

- Oyane, M.; Shima, S.; Kono, Y. Theory of plasticity for porous metals. Bull. JSME 1973, 16, 1254–1262. [Google Scholar] [CrossRef]

- Dmitriev, A.M.; Korobova, N.V. Analysis of a Method of Intense Plastic Deformation and Its Application to Molding of Iron Powder Billets. Metal Sci. Heat Treat. 2016, 57, 570–575. [Google Scholar] [CrossRef]

- Kulagin, R.; Zhao, Y.; Beygelzimer, Y.; Toth, L.S.; Shtern, M. Modeling strain and density distributions during high-Pressure torsion of pre-Compacted powder materials. Mater. Res. Lett. 2017, 5, 179–186. [Google Scholar] [CrossRef]

- Rajeshkannan, A.; Narayan, S.; Jeevanantham, A.K. Modelling and analysis of strain hardening characteristics of sintered steel preforms under cold forging. AIMS Mater. Sci. 2019, 6, 63–79. [Google Scholar] [CrossRef]

- Dorofeyev, V.Y.; Sviridova, A.N.; Berezhnoy, Y.M.; Bessarabov, E.N.; Kochkarova, K.S.; Tamadaev, V.G. Rolling contact fatigue of hot-Deformed powder steels with calcium microadditives. IOP Conf. Ser. 2019, 537, 022046. [Google Scholar] [CrossRef]

- Montes, J.M.; Cuevas, F.G.; Cintas, J.; Torres, Y. Powder compaction law for cold die pressing. Granul. Matter 2010, 12, 617. [Google Scholar] [CrossRef]

- Wendel, J.; Shvab, R.; Cao, Y.; Hryha, E.; Nyborg, L. Surface analysis of fine water-Atomized iron powder and sintered material. Surf. Interface Anal. 2018, 50, 1065–1071. [Google Scholar] [CrossRef]

- Montes, J.M.; Cuevas, F.G.; Ternero, F.; Astacio, R.; Caballero, E.S.; Cintas, J. A Method to Determine the Electrical Resistance of a Metallic Powder Mass under Compression. Metals 2017, 7, 479. [Google Scholar] [CrossRef]

- Negari, A.N.M.; Mamoory, R.S.; Simchi, A.; Ehsani, N. Determination of the physical and mechanical properties of iron-Based powder materials produced by microwave sintering. Powder Metall. Metal Ceram. 2007, 46, 423–428. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Andreev, A.G.; Tyurin, V.B.; Korobova, N.V.; Dmitriev, A.M.; Petrov, M.D.; Aksyonenko, A.Yu.; Tolmachev, N.S. Hydraulic Press of Triple Action. RU 128861, 5 October 2012. [Google Scholar]

- Kuzin, V.V.; Grigor’ev, S.N.; Volosova, M.A. Effect of a TiC Coating on the Stress-Strain State of a Plate of a High-Density Nitride Ceramic Under Nonsteady Thermoelastic Conditions. Refract. Ind. Ceram. 2014, 54, 376–380. [Google Scholar] [CrossRef]

- Volosova, M.A.; Grigor’ev, S.N.; Kuzin, V.V. Effect of Titanium Nitride Coating on Stress Structural Inhomogeneity in Oxide-Carbide Ceramic. Part 4. Action of Heat Flow. Refract. Ind. Ceram. 2015, 56, 91–96. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Gurin, V.D.; Volosova, M.A.; Cherkasova, N.Y. Development of residual cutting tool life prediction algorithm by processing on CNC machine tool. Materialwissenschaft Und Werkstofftechnik 2013, 44, 790–796. [Google Scholar] [CrossRef]

- Grigoriev, S.; Melnik, Y.; Metel, A. Broad fast neutral molecule beam sources for industrial-Scale beam-Assisted deposition. Surf. Coat. Technol. 2002, 156, 44–49. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Dmitriev, A.M.; Korobova, N.V.; Tolmachev, N.S. Stamping of pots by enclosed broaching. Russ. Eng. Res. 2013, 33, 463–467. [Google Scholar] [CrossRef]

- Montes, J.M.; Cuevas, F.G.; Cintas, J.; Sepúlveda, R. Modelling of three powder compaction laws for cold die pressing. Int. J. Mater. Res. 2012, 103, 1444–1454. [Google Scholar] [CrossRef]

- Narayan, S.; Rajeshkannan, A. Workability studies of sintered aluminium composites during hot deformation. Proc. Inst. Mech. Eng. Part B 2016, 230, 494–504. [Google Scholar] [CrossRef]

- Prabu, S.S.; Prathiba, S.; Venkatesan, N.; Sharma, A.; Ahmed, S.; Shah, Y.A. Influence of Titanium on dry sliding wear behaviour of sintered P/M low alloy steel (Fe-C-W). Procedia Eng. 2014, 97, 2110–2118. [Google Scholar] [CrossRef]

- Fominski, V. Yu.; Grigoriev, S.N.; Celis, J.P.; Romanov, R.I.; Oshurko, V.B. Structure and mechanical properties of W-Se-C/diamond-like carbon and W-Se/diamond-Like carbon bi-Layer coatings prepared by pulsed laser deposition. Thin Solid Films 2012, 520, 6476–6483. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Melnik, Y.A.; Metel, A.S.; Panin, V.V.; Prudnikov, V.V. A Compact Vapor Source of Conductive Target Material Sputtered by 3-keV Ions at 0.05-Pa Pressure. Inst. Exp. Tech. 2009, 52, 731–737. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Metel, A.S.; Volosova, M.A.; Melnik, Y.A. Deposition of wear-resistant coatings using a combined source of metal atoms and fast gas molecules. Mech. Ind. 2015, 16, 705. [Google Scholar] [CrossRef]

- Fominski, V.Y.; Grigoriev, S.N.; Gnedovets, A.G.; Romanov, R.I. Pulsed laser deposition of composite Mo-Se-Ni-C coatings using standard and shadow mask configuration. Surf. Coat. Technol. 2012, 206, 5046–5054. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, L.; Dong, G.; Liu, Z.W.; Qin, M.L.; Qu, X.H.; Lu, Y.Z. Effects of annealing on high velocity compaction behavior and mechanical properties of iron-Base PM alloy. Powder Technol. 2016, 288, 435–440. [Google Scholar] [CrossRef]

- Ludwik, P. Elemente der Technologischen Mechanik; Springer: Berlin, Germany, 1909; p. 32. [Google Scholar]

- Khasanov, O.L.; Dvilis, E.S.; Sokolov, V.M. Compressibility of the structural and functional ceramic nanopowders. J. Eur. Ceram. Soc. 2007, 27, 749–752. [Google Scholar] [CrossRef]

- Amigo, A.; Vicente, A.; Afonso, C.R.M.; Amigo, V. Mechanical Properties and the Microstructure of beta Ti-35Nb-10Ta-xFe Alloys Obtained by Powder Metallurgy for Biomedical Applications. Metals 2019, 9, 76. [Google Scholar] [CrossRef]

- Velasco, B.; Gordo, E.; Hu, L.; Radovic, M.; Tsipas, S.A. Influence of porosity on elastic properties of Ti2AlC and Ti3SiC2 MAX phase foams. J. Alloys Compd. 2018, 764, 24–35. [Google Scholar] [CrossRef]

- Zeng, X.; Liu, W.; Xu, B.; Shu, G.G.; Li, Q.L. Microstructure and Mechanical Properties of Al-SiC Nanocomposites Synthesized by Surface-Modified Aluminium Powder. Metals 2018, 8, 253. [Google Scholar] [CrossRef]

- Saboori, A.; Padovano, E.; Pavese, M.; Badini, C. Novel Magnesium Elektron21-AlN Nanocomposites Produced by Ultrasound-Assisted Casting; Microstructure, Thermal and Electrical Conductivity. Materials 2018, 11, 27. [Google Scholar] [CrossRef] [PubMed]

- Grigor’ev, S.N.; Fedorov, S.V.; Pavlov, M.D.; Okun’kova, A.A.; So, Y.M. Complex surface modification of carbide tool by Nb plus Hf plus Ti alloying followed by hardfacing (Ti plus Al) N. J. Frict. Wear 2013, 34, 14–18. [Google Scholar] [CrossRef]

- Fedorov, S.V.; Pavlov, M.D.; Okunkova, A.A. Effect of structural and phase transformations in alloyed subsurface layer of hard-Alloy tools on their wear resistance during cutting of high-temperature alloys. J. Frict. Wear 2013, 34, 190–198. [Google Scholar] [CrossRef]

- Nakayama, H.; Kobayashi, K.; Ozaki, K.; Kikuchi, K. Carbon-Dispersed WC-FeAl Hard Material Fabricated by Mechanical Milling and Subsequent Pulsed Current Sintering. Mater. Trans. 2014, 55, 947–951. [Google Scholar] [CrossRef]

- Park, H.Y.; Kilicaslan, M.F.; Hong, S.J. Densification behaviour analysis of ZrO2 nanopowders for dental applications compacted by magnetic pulsed compaction. Mater. Chem. Phys. 2013, 141, 208–215. [Google Scholar] [CrossRef]

- Bhuiyan, M.H.; Isoda, Y.; Kim, T.S.; Hong, S.J. Thermoelectric properties of n-Type 95%Bi2Te3-5%Bi2Se3 materials fabricated by magnetic pulsed compaction (MPC). Intermetallics 2013, 34, 49–55. [Google Scholar] [CrossRef]

| Grade | Chemical Composition (wt. %) | Tap Porosity of the Powder | Mean Radius, µm | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mn | Si | Cr | P | S | O | C | Fe | |||

| WPL200 | 6 | 0.36 | 0.13 | 0.01 | 0.02 | 0.33 | 0.03 | bal. | 0.63 | 39.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grigoriev, S.N.; Dmitriev, A.M.; Korobova, N.V.; Fedorov, S.V. A Cold-Pressing Method Combining Axial and Shear Flow of Powder Compaction to Produce High-Density Iron Parts. Technologies 2019, 7, 70. https://doi.org/10.3390/technologies7040070

Grigoriev SN, Dmitriev AM, Korobova NV, Fedorov SV. A Cold-Pressing Method Combining Axial and Shear Flow of Powder Compaction to Produce High-Density Iron Parts. Technologies. 2019; 7(4):70. https://doi.org/10.3390/technologies7040070

Chicago/Turabian StyleGrigoriev, Sergey N., Alexandr M. Dmitriev, Natalya V. Korobova, and Sergey V. Fedorov. 2019. "A Cold-Pressing Method Combining Axial and Shear Flow of Powder Compaction to Produce High-Density Iron Parts" Technologies 7, no. 4: 70. https://doi.org/10.3390/technologies7040070

APA StyleGrigoriev, S. N., Dmitriev, A. M., Korobova, N. V., & Fedorov, S. V. (2019). A Cold-Pressing Method Combining Axial and Shear Flow of Powder Compaction to Produce High-Density Iron Parts. Technologies, 7(4), 70. https://doi.org/10.3390/technologies7040070