On Electrical Discharge Machining of Non-Conductive Ceramics: A Review

Abstract

1. Introduction

2. Scientific Problem

- -

- The creation of a new class of nanocomposite ceramics with the inclusion of the conductive phase allowing the machining of blanks in order to obtain the finished product with the use of minimal technological effort and the absence of direct contact between the material and tool, i.e., using the electric discharging methods of machining [33,34,35,36,37,38,39];

- -

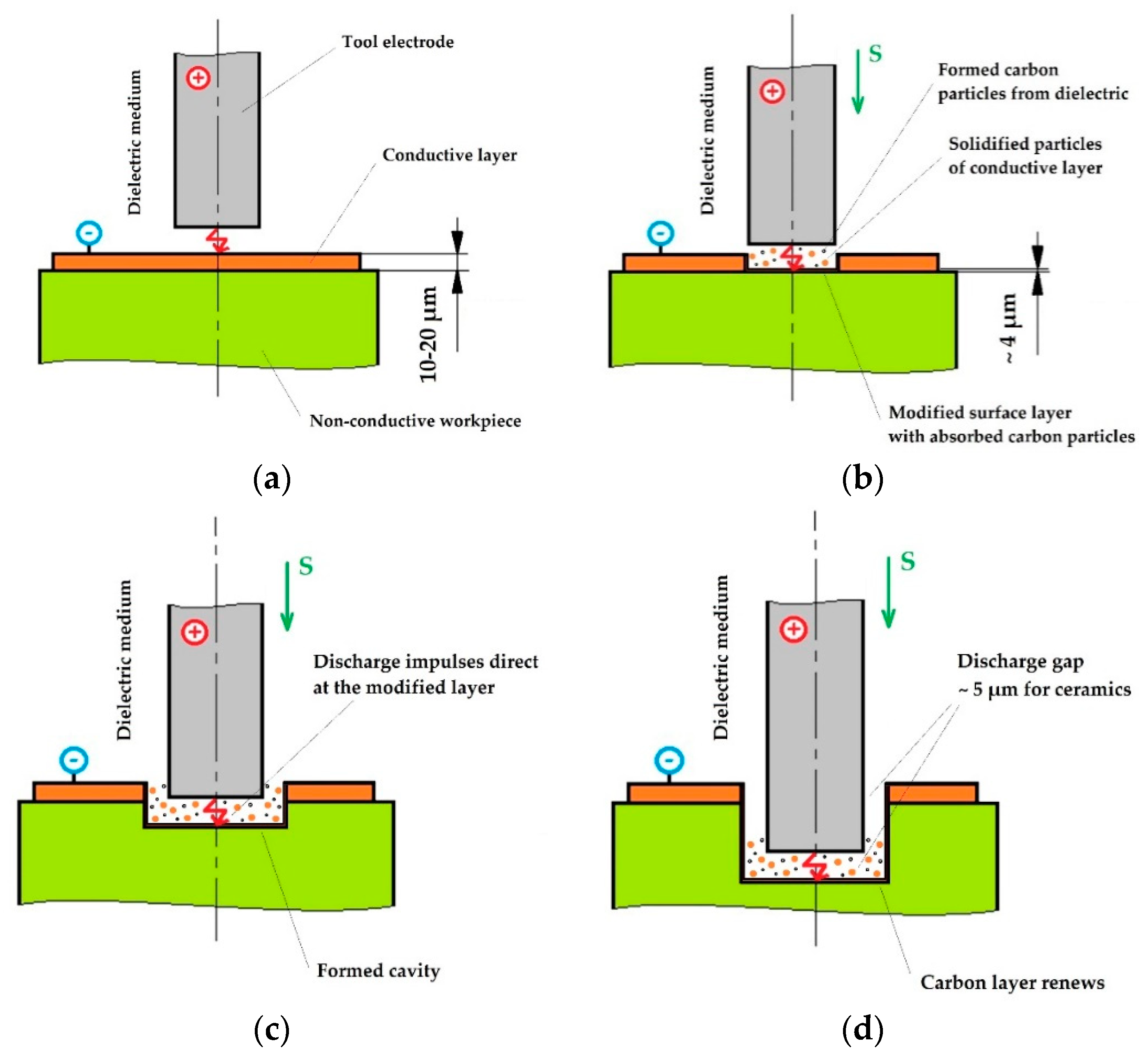

- The modification of the surface layer of the nonconducting workpiece, the geometric shape of which is already close to the geometry of the final product, by applying a conductive coating (auxiliary electrode) with a thickness of ~20 μm, which could become an intensifier of electrical discharge machining of non-conductive ceramics [40,41,42,43,44].

3. Current State of Research

3.1. The Main Scientific Competitors

3.2. Production of Nanoceramics by Advanced SPS

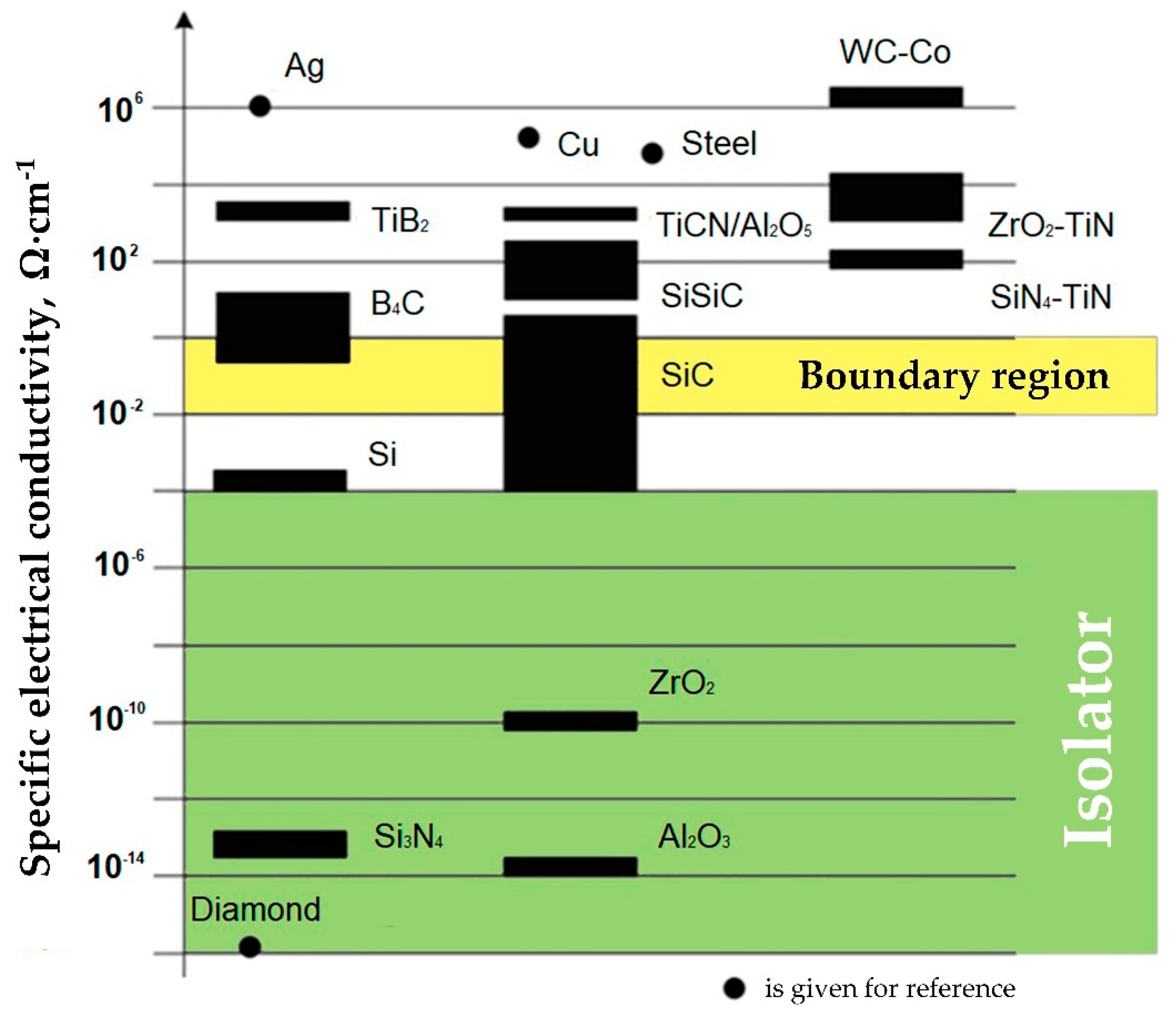

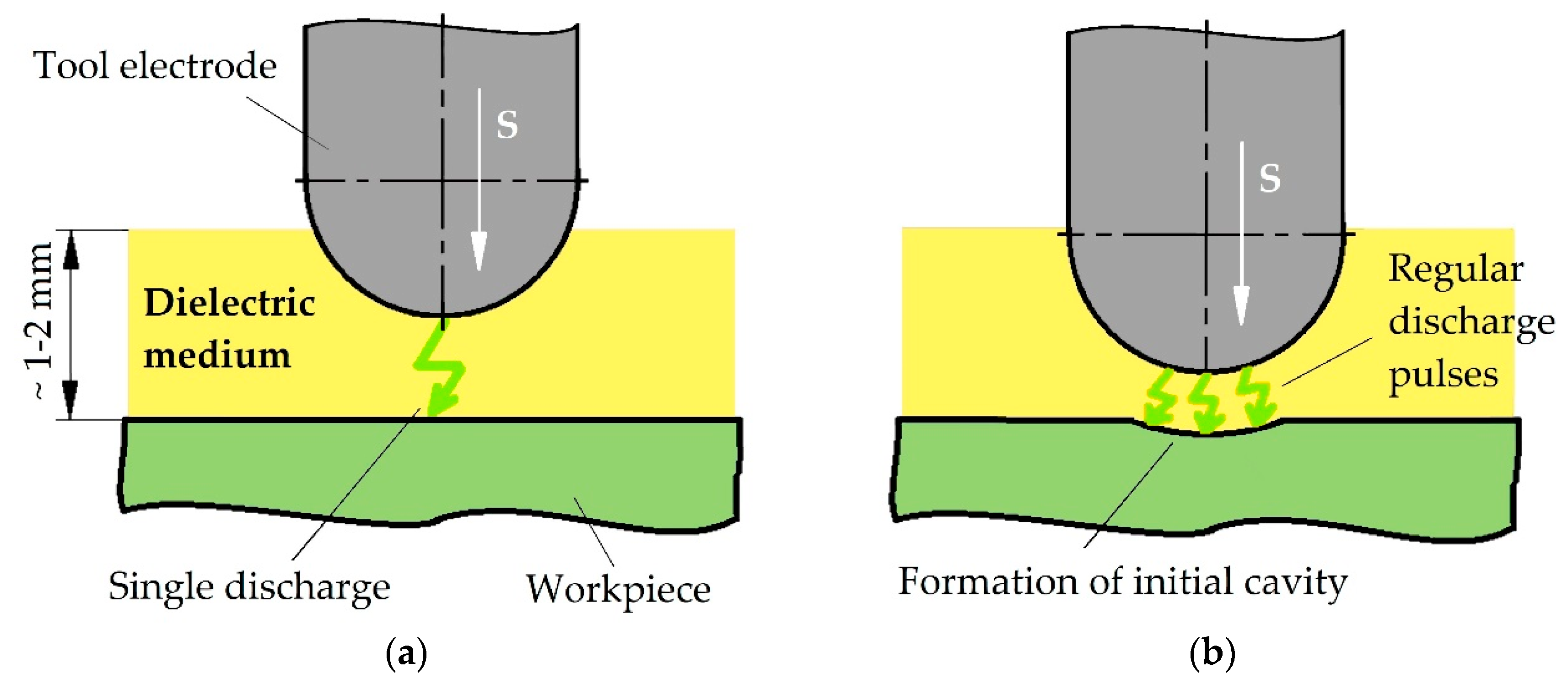

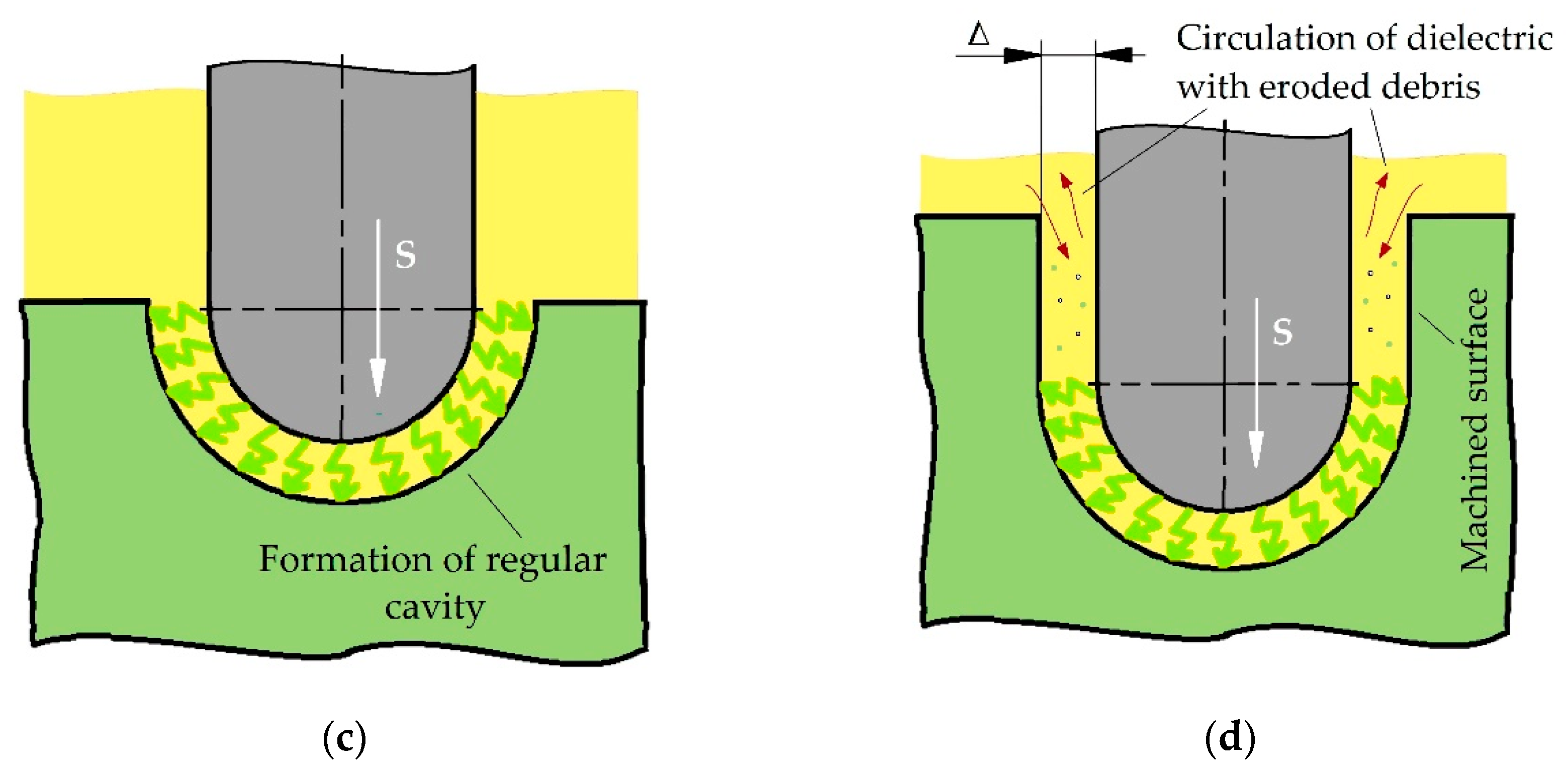

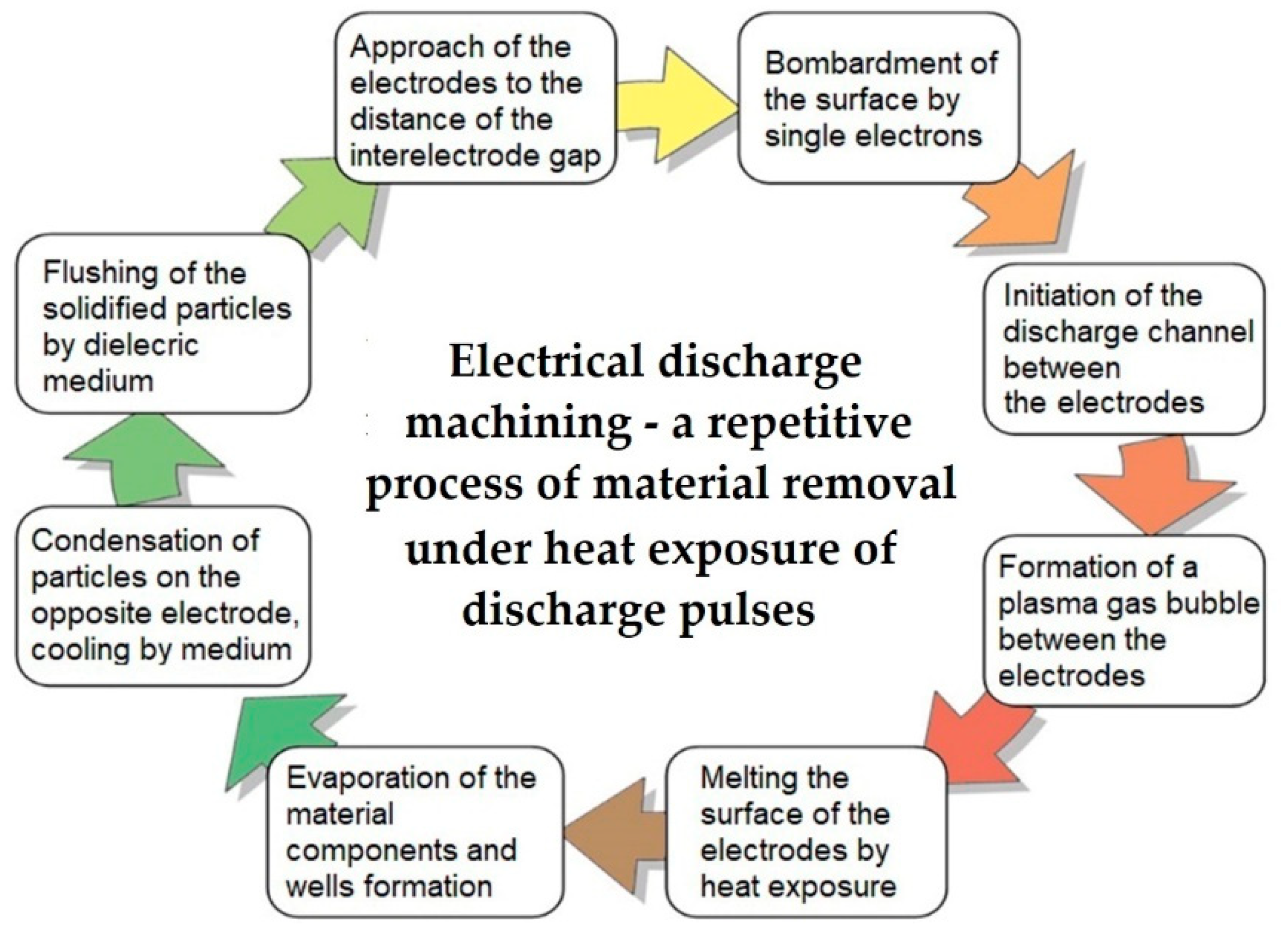

3.3. Classification of Technical Ceramics and Its Workability by EDM

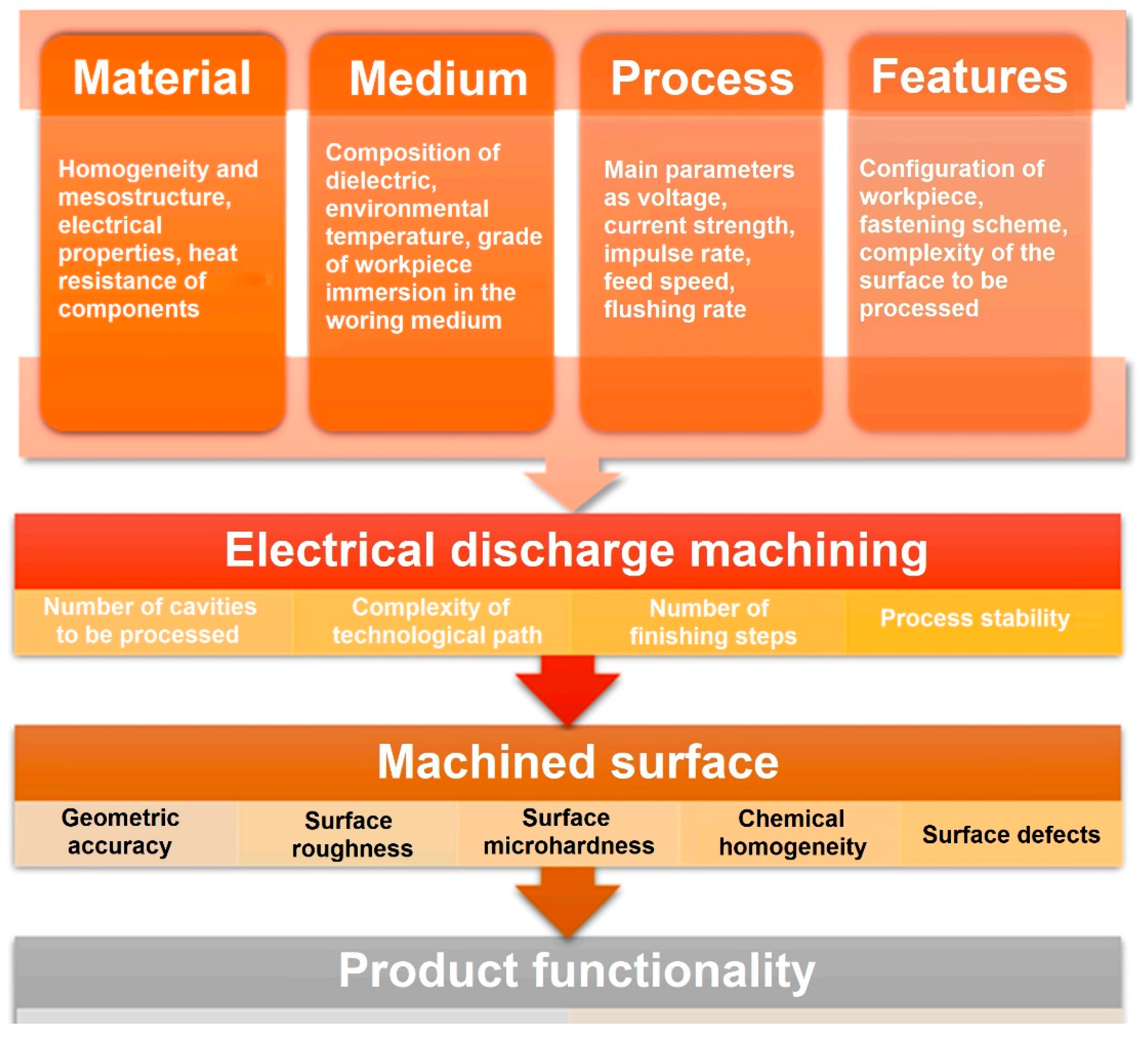

- factors related to the material of electrodes (e.g., homogeneity, conductivity for a tool and a workpiece, heat resistance of the material components);

- factors related to the environment (e.g., temperature, dielectric composition, a grade of workpiece immersion into the fluid);

- factors related to machining process and controlled by CNC-system (e.g., operation voltage, strength of the operational current, auxiliary voltage, strength of the auxiliary current, operational and auxiliary impulses rate, electrode feed, the dielectric pressure in nozzles);

- factors related to technological features of processing (e.g., scheme and system of workpiece fastening, configuration of the workpiece, complexity of surface to be processed).

- 1)

- Doping ceramics with an additional electrically conductive phase;

- 2)

- Deposition of an electrically conductive coating on the surface of the non-conductive ceramics, initiating the start of interaction and initiation of the first sparks. The authors propose to use the second approach in the research and development of a method for processing non-conductive ceramics and composites as it can help to introduce available up-to-date solutions for the machining of ceramics without the additional costs of a second conductive phase of ceramics, which can reduce the exploitation properties of ceramics (Figure 5).

4. Discussion

5. Conclusions

5.1. Research Work

5.2. Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Grigoriev, S.N.; Kozochkin, M.P.; Sabirov, F.S.; Kutin, A.A. Diagnostic Systems as Basis for Technological Improvement. Procedia CIRP 2012, 1, 599–604. [Google Scholar] [CrossRef]

- Grigoriev, S.; Metel, A. Plasma- and beam-assisted deposition methods. NATO Sci. Ser. 2004, 155, 147–154. [Google Scholar]

- Kozochkin, M.P.; Porvatov, A.N.; Sabirov, F.S.; Kozochkin, M. The fitting of technological equipment with data-measuring systems. Meas. Tech. 2012, 55, 530–534. [Google Scholar] [CrossRef]

- Hameed, S.; Rojas, H.A.G.; Benavides, J.I.P.; Alberro, A.N.; Egea, A.J.S. Influence of the Regime of Electropulsing-Assisted Machining on the Plastic Deformation of the Layer Being Cut. Materials 2018, 11, 886. [Google Scholar] [CrossRef]

- Volosova, M.; Grigoriev, S.; Metel, A.; Shein, A. The Role of Thin-Film Vacuum-Plasma Coatings and Their Influence on the Efficiency of Ceramic Cutting Inserts. Coatings 2018, 8, 287. [Google Scholar] [CrossRef]

- Gallo, L.S.; Boas, M.O.V.; Rodrigues, A.C.; Melo, F.C.; Zanotto, E.D. Transparent glass–ceramics for ballistic protection: materials and challenges. J. Mater. Res. Technol. 2019, 8, 3357–3372. [Google Scholar] [CrossRef]

- Naveau, A.; Rignon-Bret, C.; Wulfman, C. Zirconia abutments in the anterior region: A systematic review of mechanical and esthetic outcomes. J. Prosthet. Dent. 2019, 121, 775. [Google Scholar] [CrossRef]

- Panzani, A. Globalisation Scenarios in the World Ceramic Tile Market Extract of the speach given by Alfonso Panzani at QUALICER CFI Ceram. Forum Int. 2014, 91, E20. [Google Scholar]

- Pascariu, P.; Homocianu, M. ZnO-based ceramic nanofibers: Preparation, properties and applications. Ceram. Int. 2019, 45, 11158–11173. [Google Scholar] [CrossRef]

- Roata, I.C.; Croitoru, C.; Pascu, A.; Stanciu, E.M. Photocatalytic coatings via thermal spraying: A mini-review. AIMS Mater. Sci. 2019, 6, 335–353. [Google Scholar] [CrossRef]

- Xie, S.; Xu, J.; Chen, Y.; Tan, Z.; Nie, R.; Wang, Q.; Zhu, J. Indentation Behavior and Mechanical Properties of Tungsten/Chromium co-Doped Bismuth Titanate Ceramics Sintered at Different Temperatures. Materials 2018, 11, 503. [Google Scholar] [CrossRef]

- Killinger, A.; Gadow, R.; Kern, F. Manufacturing of nanocomposite structural ceramic materials and coatings. Int. J. Mater. Prod. Technol. 2009, 35, 334–345. [Google Scholar]

- Volosova, M.A.; Grigor’ev, S.N.; Kuzin, V.V. Effect of Titanium Nitride Coating on Stress Structural Inhomogeneity in Oxide-Carbide Ceramic. Part Action of Heat Flow. Refract. Ind. Ceram. 2015, 56, 91–96. [Google Scholar] [CrossRef]

- Guo, D.; Song, S.; Luo, R.; Goddard, W.A.; Chen, M.; Reddy, K.M.; An, Q. Grain Boundary Sliding and Amorphization are Responsible for the Reverse Hall-Petch Relation in Superhard Nanocrystalline Boron Carbide. Phys. Rev. Lett. 2018, 121, 145504. [Google Scholar] [CrossRef]

- Balokhonov, R.R.; Zinoviev, A.V.; Romanova, V.A.; Batukhtina, E.E. A Mesomechanical Analysis of the Deformation and Fracture in Polycrystalline Materials with Ceramic Porous Coatings. AIP Conf. Proc. 2015, 1683, 20020. [Google Scholar]

- Murzin, S.P.; Balyakin, V.B. Microstructuring the surface of silicon carbide ceramic by laser action for reducing friction losses in rolling bearings. Opt. Laser Technol. 2017, 88, 96–98. [Google Scholar] [CrossRef]

- Kuzin, V.V.; Seleznev, A.E.; Fedorov, S.Y. Effect of conditions of diamond grinding on tribological behavior of alumina-based ceramics. J. Frict. Wear 2016, 37, 371–376. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Gurin, V.D.; Volosova, M.A.; Cherkasova, N.Y.; Volosova, M. Development of residual cutting tool life prediction algorithm by processing on CNC machine tool. Materialwissenschaft und Werkstofftechnik 2013, 44, 790–796. [Google Scholar] [CrossRef]

- Boswell, B.; Islam, M.N.; Davies, I.J. A review of micro-mechanical cutting. Int. J. Adv. Manuf. Technol. 2018, 94, 789–806. [Google Scholar] [CrossRef]

- Pratap, A.; Patra, K.; Dyakonov, A.A. On-machine texturing of PCD micro-tools for dry micro-slot grinding of BK7 glass. Precis. Eng. 2019, 55, 491–502. [Google Scholar] [CrossRef]

- Isaev, A.V.; Kozochkin, M.P.; Kozochkin, M. Use of a Measurement Information System to Increase the Precision with which Thin-Walled Parts are Machined on Numerically Controlled Milling Machines. Meas. Tech. 2014, 56, 1155–1161. [Google Scholar] [CrossRef]

- Razeghiyadaki, A.; Molardi, C.; Talamona, D.; Perveen, A. Modeling of Material Removal Rate and Surface Roughness Generated during Electro-Discharge Machining. Machines 2019, 7, 47. [Google Scholar] [CrossRef]

- Schubert, A.; Zeidler, H.; Hackert-Oschaetzchen, M.; Schneider, J.; Hahm, M. Enhancing Micro-EDM using Ultrasonic Vibration and Approaches for Machining of Nonconducting Ceramics. Strojniski Vestnik J. Mech. Eng. 2013, 59, 156–164. [Google Scholar] [CrossRef]

- Okunkova, A.A.; Povolotskiy, D.E.; Podrabinnik, P.A. Study of electrical discharge machining for the parts of nuclear industry usage. Mech. Ind. 2015, 16, 706. [Google Scholar]

- Grigor’ev, S.N.; Kozochkin, M.P.; Fedorov, S.V.; Porvatov, A.N.; Okun’kova, A.A.; Kozochkin, M. Study of Electroerosion Processing by Vibroacoustic Diagnostic Methods. Meas. Tech. 2015, 58, 878–884. [Google Scholar] [CrossRef]

- Glaziev, S.Y. The Discovery of Regularities of Change of Technological Orders in the Central Economics and Mathematics Institute of the Soviet Academy of Sciences. Ekonomika i Matematiceskie Metody. Econ. Math. Methods 2018, 54, 17–30. [Google Scholar] [CrossRef]

- Chen, H. Sustainable Consumption and Production in China. In Handbook on Sustainability Transition and Sustainable Peace. Hexagon Series on Human and Environmental Security and Peace; Brauch, H., Oswald Spring, U., Grin, J., Scheffran, J., Eds.; Springer: Cham, Switzerland, 2016; Volume 10, pp. 571–591. [Google Scholar]

- Korotayev, A.V.; Tsirel, S.V. A Spectral Analysis of World GDP Dynamics: Kondratiev Waves, Kuznets Swings, Juglar and Kitchin Cycles in Global Economic Development, and the 2008–2009 Economic Crisis. Struct. Dyn. 2010, 4, 3–57. [Google Scholar]

- Schumpeter, J.; Becker, M.C.; Knudsen, T. The fundamental phenomenon of economic development. Am. J. Econ. Sociol. 2002, 61, 405–437. [Google Scholar] [CrossRef]

- Perez, C. Technological revolutions and techno-economic paradigms. Camb. J. Econ. 2010, 34, 185–202. [Google Scholar] [CrossRef]

- Bobovich, B.B. Glass-Fiber Reinforced Plastics—Construction Materials of the Sixth Technological Paradigm? Glas. Ceram. 2019, 76, 38–41. [Google Scholar] [CrossRef]

- Wonglimpiyarat, J. Towards the Sixth Kondratieff Cycle of Nano Revolution. Nanotechnol. Microelectron. 2010, 87–100. [Google Scholar] [CrossRef]

- Hou, J.; Feng, Y.; Liao, J.; Ding, W.; Shui, L.; Li, H.; Wang, Y.; Tang, B.; Umar, A.; Zhou, G. Multiscale Interface Effect on Homogeneous Dielectric Structure of ZrO2/Teflon Nanocomposite for Electrowetting Application. Polymers 2018, 10, 1119. [Google Scholar] [CrossRef]

- Sun, S.; Xu, Q. Fabricating a Novel Intragranular Microstructure for Al2O3/GdAlO3 Ceramic Composites. Materials 2018, 11, 1879. [Google Scholar] [CrossRef]

- Hanzel, O.; Singh, M.A.; Marla, D.; Sedlák, R.; Šajgalík, P. Wire electrical discharge machinable SiC with GNPs and GO as the electrically conducting filler. J. Eur. Ceram. Soc. 2019, 39, 2626–2633. [Google Scholar] [CrossRef]

- Gordeev, Y.I.; Abkaryan, A.K.; Surovtsev, A.V.; Lepeshev, A.A. Investigation into the Peculiarities of Structure Formation and Properties of Copper-Based Powder Pseudoalloys Modified by ZnO and TiN Nanoparticle Additives. Russ. J. Non Ferrous Met. 2019, 60, 68–75. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Peretyagin, P.Y.; Seleznev, A.E.; Okunkova, A.A.; Smirnov, A. The Effect of TiC Additive on Mechanical and Electrical Properties of Al2O3 Ceramic. Appl. Sci. 2018, 8, 2385. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Melnik, Y.A.; Metel, A.S.; Panin, V.V.; Prudnikov, V.V. A compact vapor source of conductive target material sputtered by 3-keV ions at 0.05-Pa pressure. Instruments Exp. Tech. 2009, 52, 731–737. [Google Scholar] [CrossRef]

- Díaz, L.A.; Montes-Morán, M.A.; Peretyagin, P.Y.; Vladimirov, Y.G.; Okunkova, A.; Moya, J.S.; Torrecillas, R. Zirconia–alumina–nanodiamond composites with gemological properties. J. Nanoparticle Res. 2014, 16, 2257. [Google Scholar] [CrossRef]

- Lei, J.; Wu, X.; Wang, Z.; Xu, B.; Zhu, L.; Wu, W. Electrical discharge machining of micro grooves using laminated disc electrodes made of Cu and Sn foils. J. Mater. Process. Technol. 2019, 271, 455–462. [Google Scholar] [CrossRef]

- Arab, J.; Mishra, D.K.; Kannojia, H.K.; Adhale, P.; Dixit, P. Fabrication of multiple through-holes in non-conductive materials by Electrochemical Discharge Machining for RF MEMS Packaging. J. Mater. Process. Technol. 2019, 271, 542–553. [Google Scholar] [CrossRef]

- Urazov, M.N.; Efimov, A.A.; Lizunova, A.A.; Ivanov, V.V.; Mylnikov, D.A. Investigation of electric erosion of silicon electrodes in aerosol nanoparticles synthesis. AIP Conf. Proc. 2017, 1858, 040007. [Google Scholar]

- Metel, A.; Bolbukov, V.; Volosova, M.; Grigoriev, S.; Melnik, Y. Equipment for deposition of thin metallic films bombarded by fast argon atoms. Instrum. Exp. Tech. 2014, 57, 345–351. [Google Scholar] [CrossRef]

- Kuzin, V.V.; Grigor’ev, S.N.; Volosova, M.A. Effect of a TiC Coating on the Stress-Strain State of a Plate of a High-Density Nitride Ceramic Under Nonsteady Thermoelastic Conditions. Refract. Ind. Ceram. 2014, 54, 376–380. [Google Scholar] [CrossRef]

- Wysocka, I.; Hupka, J.; Rogala, A. Catalytic Activity of Nickel and Ruthenium–Nickel Catalysts Supported on SiO2, ZrO2, Al2O3, and MgAl2O4 in a Dry Reforming Process. Catalysts 2019, 9, 540. [Google Scholar] [CrossRef]

- Promakhov, V.; Zhukov, A.; Dubkova, Y.; Zhukov, I.; Kovalchuk, S.; Zhukova, T.; Olisov, A.; Klimenko, V.; Savkina, N. Structure and Properties of ZrO2–20%Al2O3 Ceramic Composites Obtained Using Additive Technologies. Materials 2018, 11, 2361. [Google Scholar] [CrossRef]

- Di, J.; Liu, W.; Xue, L.; Zhou, Q.; Yan, Y. A Dense Cr2O3/Al2O3 Composite Ceramic Coating Prepared by Electrodeposition and Sealing with Al2O3. Coatings 2019, 9, 14. [Google Scholar] [CrossRef]

- Koltsov, I.; Smalc-Koziorowska, J.; Prześniak-Welenc, M.; Małysa, M.; Kimmel, G.; McGlynn, J.; Ganin, A.; Stelmakh, S. Mechanism of Reduced Sintering Temperature of Al2O3–ZrO2 Nanocomposites Obtained by Microwave Hydrothermal Synthesis. Materials 2018, 11, 829. [Google Scholar] [CrossRef]

- Gommeringer, A.; Kern, F.; Gadow, R. Enhanced Mechanical Properties in ED-Machinable Zirconia-Tungsten Carbide Composites with Yttria-Neodymia Co-Stabilized Zirconia Matrix. Ceramics 2018, 1, 26–37. [Google Scholar] [CrossRef]

- Nayebzadeh, H.; Saghatoleslami, N.; Tabasizadeh, M. Application of microwave irradiation for fabrication of sulfated ZrO2–Al2O3 nanocomposite via combustion method for esterification reaction: process condition evaluation. J. Nanostructure Chem. 2019, 9, 141–152. [Google Scholar] [CrossRef]

- Podzorova, L.I.; Il’Icheva, A.A.; Pen’Kova, O.I.; Antonova, O.S.; Baikin, A.S.; Konovalov, A.A. Al2O3-Based Ceramic Composites with a High Brittle Fracture Resistance. Inorg. Mater. 2019, 55, 628–633. [Google Scholar] [CrossRef]

- Deirmina, F.; Almangour, B.; Grzesiak, D.; Pellizzari, M. H13–partially stabilized zirconia nanocomposites fabricated by high-energy mechanical milling and selective laser melting. Mater. Des. 2018, 146, 86–297. [Google Scholar] [CrossRef]

- Bin Mansoor, M.; Köble, S.; Wong, T.W.; Woias, P.; Goldschmidtböing, F. Design, Characterization and Sensitivity Analysis of a Piezoelectric Ceramic/Metal Composite Transducer. Micromachines 2017, 8, 271. [Google Scholar] [CrossRef] [PubMed]

- Jurczyk, K.; Adamek, G.; Kubicka, M.M.; Jakubowicz, J.; Jurczyk, M. Nanostructured Titanium-10 wt% 45S5 Bioglass-Ag Composite Foams for Medical Applications. Materials 2015, 8, 1398–1412. [Google Scholar] [CrossRef] [PubMed]

- Todorova, T.; Gaier, M.; Zwanziger, J.; Plucknett, K. Understanding the elastic and thermal response in TiC-based ceramic-metal composite systems: First-principles and mechanical studies. J. Alloy. Compd. 2019, 789, 712–719. [Google Scholar] [CrossRef]

- Beitollahi, H.; Garkani-Nejad, F.; Tajik, S.; Ganjali, M.R. Voltammetric Determination of Acetaminophen and Tryptophan Using a Graphite Screen Printed Electrode Modified with Functionalized Graphene Oxide Nanosheets Within a Fe3O4@SiO2 Nanocomposite. Iran. J. Pharm. Res. 2019, 18, 80–90. [Google Scholar] [PubMed]

- Ming, K.; Su, Q.; Gu, C.; Xie, D.; Wang, Y.; Nastasi, M.; Wang, J. Influence of Metal Additives on Microstructure and Properties of Amorphous Metal–SiOC Composites. JOM 2019, 71, 2445–2451. [Google Scholar] [CrossRef]

- Balokhonov, R.; Romanova, V.; Schmauder, S.; Emelianova, E. A numerical study of plastic strain localization and fracture across multiple spatial scales in materials with metal-matrix composite coatings. Theor. Appl. Fract. Mech. 2019, 101, 342–355. [Google Scholar] [CrossRef]

- Smolin, A.; Shilko, E.; Astafurov, S.; Konovalenko, I.; Buyakova, S.; Psakhie, S.; Smolin, A. Modeling mechanical behaviors of composites with various ratios of matrix–inclusion properties using movable cellular automaton method. Def. Technol. 2015, 11, 18–34. [Google Scholar] [CrossRef]

- Ojha, N.; Hoesel, T.; Mueller, C.; Reinecke, H. Characterization of The Conductive Layer Formed During Mu - Electric Discharge Machining Of Non-Conductive Ceramics. Ceram. Trans. 2013, 240, 105–110. [Google Scholar]

- Gotoh, H.; Tani, T.; Mohri, N. EDM of Insulating Ceramics by Electrical Conductive Surface Layer Control. Procedia CIRP 2016, 42, 201–205. [Google Scholar] [CrossRef]

- Ali, M.Y.; Moudood, M.A.; Maleque, M.A.; Hazza, M.; Adesta, E.Y.T. Electro-discharge machining of alumina: Investigation of material removal rate and surface roughness. J. Mech. Eng. Sci. 2017, 11, 3015–3026. [Google Scholar] [CrossRef]

- Zhang, G.; Guo, Y.; Wang, L. Experimental Study on the Machining of Inclined Holes for Thermal Barrier-Coated Nickel Superalloys by EDM. J. Mater. Eng. Perform. 2016, 25, 4574–4580. [Google Scholar] [CrossRef]

- Bilal, A.; Jahan, M.P.; Talamona, D.; Perveen, A. Electro-Discharge Machining of Ceramics: A Review. Micromachines 2019, 10, 10. [Google Scholar] [CrossRef] [PubMed]

- Hanaoka, D.; Fukuzawa, Y.; Yamashita, K. Research of Large-Area Electrical Discharge Machining for Insulating Si3N4 Ceramics with the Assisting Electrode Method. Adv. Mater. Res. 2014, 939, 76–83. [Google Scholar] [CrossRef]

- Kaneko, K.; Fukuzawa, Y. Characteristics of Micro EDM for Insulating Aluminum Nitride Ceramics. Adv. Mater. Res. 2012, 579, 86–91. [Google Scholar] [CrossRef]

- Furutani, K.; Tomoto, M. Performance of Wire-Sawing of Glass Assisted by Electro-Chemical Discharge. Key Eng. Mater. 2012, 523, 299–304. [Google Scholar] [CrossRef]

- Hanaoka, D.; Ito, R.; Fukuzawa, Y. Electrical Discharge Machined Surface of the Insulating ZrO2 Ceramics. J. Adv. Mech. Des. Syst. Manuf. 2011, 5, 372–384. [Google Scholar] [CrossRef]

- Schubert, A.; Berger, T.; Martin, A.; Hackert-Oschätzchen, M.; Treffkorn, N.; Kuhn, R. Surface structuring of boron doped CVD diamond by micro electrical discharge machining. AIP Conf. Proc. 2018, 1960, 080003. [Google Scholar]

- Zeller, F.; Hoesel, T.; Mueller, C. Microstructuring of non-conductive silicon carbide by electrical discharge machining. Microsyst. Technol. 2014, 20, 1875–1880. [Google Scholar] [CrossRef]

- Mohri, N. EDM of advanced ceramics—From finish machining to machining insulating ceramics. CIRP Ann. Manuf. Technol. 1996, 45, 289–296. [Google Scholar]

- Takayuki, T.; Tsujita, Y.; Gotoh, H.; Okada, M.; Mohri, N. Observation of Material Removal Process by Single Discharge in Air Gap. Procedia CIRP 2018, 68, 276–279. [Google Scholar] [CrossRef]

- Rona, N.; Yenisey, M.; Kucukturk, G.; Gürün, H.; Cogun, C.; Esen, Z. Effect of electrical discharge machining on dental Y-TZP ceramic-resin bonding. J. Prosthodont. Res. 2017, 61, 158–167. [Google Scholar] [CrossRef] [PubMed]

- Esen, Z.; Genc, A.; Akturk, N.; Cogun, C.; Cogun, F. Effect of powder metallurgy Cu-B 4 C electrodes on workpiece surface characteristics and machining performance of electric discharge machining. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 2190–2203. [Google Scholar]

- Erdem, O.; Cogun, C.; Urtekin, L. The effect of powder mixed and heated dielectric on drilling performance of electric discharge machining (EDM). J. Fac. Eng. Archit. Gazi Univ. 2007, 31, 531–544. [Google Scholar]

- Khan, M.A.R.; Rahman, M.M.; Noor, M.; Kadirgama, K.; Maleque, M. Current Research Trends on Dry, Near-Dry and Powder Mixed Electrical Discharge Machining. Adv. Mater. Res. 2011, 264, 956–961. [Google Scholar] [CrossRef]

- Hosni, N.; Lajis, M. Multi-response optimization of the machining characteristics in electrical discharge machining (EDM) using span-20 surfactant and chromium (Cr) powder mixed. Materialwissenschaft Und Werkstofftechnik 2019, 50, 329–335. [Google Scholar] [CrossRef]

- Lajis, M.; Hosni, N. The influences of various mixed dielectric fluids on the performance electrical discharge machining of AISI D2 hardened steel. Materialwissenschaft Und Werkstofftechnik 2018, 49, 413–419. [Google Scholar] [CrossRef]

- Ablyaz, T.R.; Simonov, M.Y.; Shlykov, E.S. Analysis of the Surface of Deposited Copper After Electroerosion Treatment. Met. Sci. Heat Treat. 2018, 59, 779–785. [Google Scholar] [CrossRef]

- Bains, P.S.; Singh, S.; Sidhu, S.S.; Kaur, S.; Ablyaz, T.R. Investigation of Surface Properties of Al–SiC Composites in Hybrid Electrical Discharge Machining. In Materials Horizons: From Nature to Nanomaterials; Springer Singapore: Singapore, 2018; pp. 181–196. [Google Scholar]

- Ogleznev, N.; Oglezneva, S.; Ablyaz, T. Perspective Composition Materials for Electrode-Tools Production. In Materials Horizons: From Nature to Nanomaterials; Springer Singapore: Singapore, 2018; pp. 319–344. [Google Scholar]

- Yang, L.; Ditta, A.; Feng, B.; Zhang, Y.; Xie, Z. Study of the Comparative Effect of Sintering Methods and Sintering Additives on the Microstructure and Performance of Si3N4 Ceramic. Materials 2019, 12, 2142. [Google Scholar] [CrossRef]

- Jia, D.; Ma, J.; Gan, X.; Tao, J.; Xie, M.; Yi, J.; Liu, Y. A Comparison Study of Ag Composites Prepared by Spark Plasma Sintering and Hot Pressing with Silver-Coated CNTs as the Reinforcements. Materials 2019, 12, 1949. [Google Scholar] [CrossRef]

- Lun, H.; Zeng, Y.; Xiong, X.; Zhao, L.; Li, D.; Ye, Z.; Qian, T. The Effect of SiC Content on Microstructure and Microwave Heating Rate of h-BN/SiC Ceramics Fabricated by Spark Plasma Sintering. Materials 2019, 12, 1909. [Google Scholar] [CrossRef] [PubMed]

- Hsieh, C.; Tuan, W. Thermal expansion behavior of a model ceramic–metal composite. Mater. Sci. Eng. A 2007, 460, 453–458. [Google Scholar] [CrossRef]

- Hsieh, C.; Tuan, W. Elastic properties of ceramic–metal particulate composites. Mater. Sci. Eng. A 2005, 393, 133–139. [Google Scholar] [CrossRef]

- Pędzich, Z.; Wajler, C. Slow crack propagation in Y-TZP/metal composites. J. Eur. Ceram. Soc. 2006, 26, 679–682. [Google Scholar] [CrossRef]

- Oraei, M.; Mostaan, H.; Rafiei, M.; Abbasian, A.R.; Zarezadeh, M. Investigation into microstructural evolutions, mechanical properties and thermal analysis of Al(Zn)/Al2O3 nano-composite fabricated by mechanical milling and SPS method. Mater. Res. Express 2019, 6, 0865g9. [Google Scholar] [CrossRef]

- Moriceau, J.; Houizot, P.; Pasturel, M.; Guizouarn, T.; Rouxel, T. A magnetic glass matrix (ZnO-BaO-B2O3) particulate (Fe3O4) nanocomposite obtained by SPS. J. Non Crystalline Solids 2019, 514, 116–121. [Google Scholar] [CrossRef]

- Tukmakova, A.; Novotelnova, A.; Samusevich, K.; Usenko, A.; Moskovskikh, D.; Smirnov, A.; Mirofyanchenko, E.; Takagi, T.; Miki, H.; Khovaylo, V. Simulation of Field Assisted Sintering of Silicon Germanium Alloys. Materials 2019, 12, 570. [Google Scholar] [CrossRef]

- Moskovskikh, D.; Song, Y.; Rouvimov, S.; Rogachev, A.; Mukasyan, A. Silicon carbide ceramics: Mechanical activation, combustion and spark plasma sintering. Ceram. Int. 2016, 42, 12686–12693. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Melnik, Y.A.; Metel, A.S.; Panin, V.V. Broad beam source of fast atoms produced as a result of charge exchange collisions of ions accelerated between two plasmas. Instruments Exp. Tech. 2009, 52, 602–608. [Google Scholar] [CrossRef]

- Galatanu, M.; Enculescu, M.; Galatanu, A. High temperature thermo-physical properties of SPS-ed W–Cu functional gradient materials. Mater. Res. Express 2018, 5, 026502. [Google Scholar] [CrossRef]

- Kotoban, D.; Grigoriev, S.; Okunkova, A.; Sova, A. Influence of a shape of single track on deposition efficiency of 316L stainless steel powder in cold spray. Surf. Coatings Technol. 2017, 309, 951–958. [Google Scholar] [CrossRef]

- Grigoriev, S.; Fominski, V.Y.; Romanov, R.; Gnedovets, A.; Volosova, M.; Gnedovets, A.; Volosova, M. Shadow masked pulsed laser deposition of WSex films: Experiment and modeling. Appl. Surf. Sci. 2013, 282, 607–614. [Google Scholar] [CrossRef]

- Fook, P.; Berger, D.; Riemer, O.; Karpuschewski, B. Structuring of Bioceramics by Micro-Grinding for Dental Implant Applications. Micromachines 2019, 10, 312. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Sanchez, A.M.; Machado-Moreira, B.; Freire, M.; Santos, R.; Monteiro, S.; Dias, D.; Neves, O.; Dionísio, A.; Miller, A.Z. Characterization of Microbial Communities Associated with Ceramic Raw Materials as Potential Contributors for the Improvement of Ceramic Rheological Properties. Minerals 2019, 9, 316. [Google Scholar] [CrossRef]

- Pramanik, A.; Islam, M.N.; Basak, A.K.; Dong, Y.; Littlefair, G.; Prakash, C. Optimizing dimensional accuracy of titanium alloy features produced by wire electrical discharge machining. Mater. Manuf. Process. 2019, 34, 1083–1090. [Google Scholar] [CrossRef]

- Fedorov, S.V.; Pavlov, M.D.; Okunkova, A.A. Effect of structural and phase transformations in alloyed subsurface layer of hard-alloy tools on their wear resistance during cutting of high-temperature alloys. J. Frict. Wear 2013, 34, 190–198. [Google Scholar] [CrossRef]

- Liu, K.; Lauwers, B.; Reynaerts, D. Crossing barriers in structuring ceramics. Mikroniek 2010, 50, 28–34. [Google Scholar]

- Zhang, H.; Jayaseelan, D.; Bogomol, I.; Reece, M.; Hu, C.; Grasso, S.; Lee, W. A novel microstructural design to improve the oxidation resistance of ZrB2-SiC ultra-high temperature ceramics (UHTCs). J. Alloy. Compd. 2019, 785, 958–964. [Google Scholar] [CrossRef]

- Ghelich, R.; Aghdam, R.M.; Jahannama, M.R. Elevated temperature resistance of SiC-carbon/phenolic nanocomposites reinforced with zirconium diboride nanofibers. J. Compos. Mater. 2018, 52, 1239–1251. [Google Scholar] [CrossRef]

- Chiang, K.-T. Modeling and analysis of the effects of machining parameters on the performance characteristics in the EDM process of Al2O3+TiC mixed ceramic. Int. J. Adv. Manuf. Technol. 2008, 3, 523–533. [Google Scholar] [CrossRef]

- Egea, A.S.; Peiró, J.J.; Signorelli, J.W.; Rojas, H.G.; Celentano, D.J. On the microstructure effects when using electropulsing versus furnace treatments while drawing inox 308L. J. Mater. Res. Technol. 2019, 8, 2269–2279. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Volosova, M.; Okunkova, A.; Peretyagin, P.; Melnik, Y.A.; Kapustina, N. On Electrical Discharge Machining of Non-Conductive Ceramics: A Review. Technologies 2019, 7, 55. https://doi.org/10.3390/technologies7030055

Volosova M, Okunkova A, Peretyagin P, Melnik YA, Kapustina N. On Electrical Discharge Machining of Non-Conductive Ceramics: A Review. Technologies. 2019; 7(3):55. https://doi.org/10.3390/technologies7030055

Chicago/Turabian StyleVolosova, Marina, Anna Okunkova, Pavel Peretyagin, Yury A. Melnik, and Natalya Kapustina. 2019. "On Electrical Discharge Machining of Non-Conductive Ceramics: A Review" Technologies 7, no. 3: 55. https://doi.org/10.3390/technologies7030055

APA StyleVolosova, M., Okunkova, A., Peretyagin, P., Melnik, Y. A., & Kapustina, N. (2019). On Electrical Discharge Machining of Non-Conductive Ceramics: A Review. Technologies, 7(3), 55. https://doi.org/10.3390/technologies7030055