Abstract

This paper presents the design, development and testing of a paste/clay extrusion device intended to be used as a drop-in replacement for the conventional thermoplastic extruder of a desktop filament-based 3D printer. A plastic cylinder loaded with gel, paste or clay material is placed into the device. Feedstock is pressed through an extrusion nozzle by a piston driven by an electrically actuated drive-screw and nut mechanism. The device allows the build material to heat up to 80 °C. Forced air cooling is used to assist the cooling or hardening process of the freshly-printed material during fabrication. The feedstock container, nozzle, and material-loading process are all suitable for use in a sterile environment. The device is designed for seamless integration with existing 3D printing firmware and slicing software. After designing the device, a prototype was produced and installed on a 3D printer. Silicone and acrylic polymers, as well as dental gel, were used to fabricate 3D printed sample objects.

1. Introduction

Additive manufacturing (AM) is a continuously developing industry. The manufacturing technology, which consists in fabricating objects layer-by-layer (i.e., in an additive manner), has seen big progress in terms of developing new processes and consolidating existing ones, improving equipment performances, and enlarging the range of build materials [1]. Previously used mostly for building prototypes and visual models, the AM technology that uses plastic polymers and metal powders today has matured, and is also used for manufacturing functional parts [2]. As 3D printing has gained a foothold in several fields such as aerospace and automotive, more and more industries are now searching for ways to exploit the advantages of AM processes. These ways include developing new materials for use with ‘traditional’ AM processes, as well as developing technology and devices that use existing materials such as the paste-like materials of interest in our research, in an AM process. In regards to the latter, advances have been made in 3D printing materials that had been previously restricted to conventional manufacturing processes, such as scaffolds for tissue engineering [3], cell cultures [4], live tissue [5], food [6], medical implants [7], ceramics [8], cements [9], and composites [10] with the use of specially designed paste extruders. It is therefore important that AM equipment keeps up with these new developments.

After reviewing the existing devices available, the authors have identified two main constructive designs for paste and clay extrusion devices. The first constructive design is a piston-type extruder, similar to a syringe, electrically or pneumatically actuated [11]. For the type of this device that uses an electric motor, the rotation is transformed into linear translation using a drive-screw and nut mechanism, or a pinion-rack mechanism. Open source devices made with 3D printed parts are also available. The Universal Paste Extruder by RichRap [12] uses a drive belt mechanism to drive the piston that presses feedstock through a nozzle. The limitations of this design relate to several aspects. Due to the reduced amount of feedstock the extruder tube can hold, and because of the inability to feed more material during fabrication, the productivity of this extruder is limited to fabricating small-volume objects. The use of linear motion to drive the piston often leads to design choices involving linear guides, which add weight, raise the center of gravity of the extrusion device, and affect the dynamic capabilities of the 3D printer. Also, in case of using pneumatically actuated pistons or other mechanisms such as the belt drive integrated in the Universal Paste Extruder, the feedstock retraction function cannot be used during fabrication. This function is specific to the material extrusion process, and improves the quality of 3D printed objects by allowing the extruder to retract a small volume of feedstock before repositioning the extruder head, which insures that no material will leak onto the part during fabrication.

The second constructive design uses an electrically actuated auger screw to push material through the nozzle [13]. Pressurized feedstock is stored in a separate container and fed to the extruder. While this design allows for the feeding of material during the fabrication process, and thus enables the fabrication of large objects, this feature also requires additional drive and control elements (electrical motors, pressure sensors, compressors, pneumatic valves, etc.). Consequently, it increases the complexity of the AM machine, and makes it difficult for the paste extruder to be provided as a system that can be a drop-in replacement for a typical thermoplastic extruder used in material extrusion applications.

Another aspect identified during literature analysis is that the existing solutions are either lacking, or require a difficult process for implementing features that allow the fine-tuning of various extrusion parameters, such as the speed of extrusion, and control of the volume of deposited material. For certain materials, such as air-drying clays, it is important that the drying process happens at a specific pace.

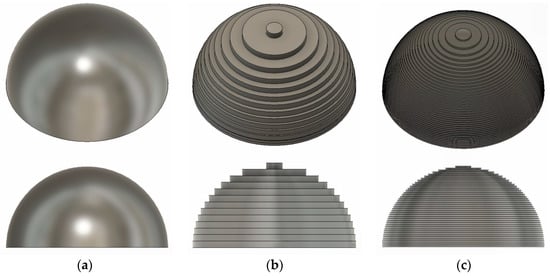

Syringe-based paste extruders typically use large nozzle diameters and layer heights to fabricate objects. This can have a negative impact on the level of detail that can be fabricated, as well as on surface finish. Figure 1 shows three-dimensional representations of differences produced by slicing a 20 mm diameter sphere (Figure 1a) at 0.8 mm (Figure 1b) and 0.25 mm layer heights (Figure 1c).

Figure 1.

The influence of layer height on additive manufacturing (AM) surface finish (a) Ideal sphere (b) Sphere sliced at 0.8 mm layer height, typical of commercial paste extruders (c) Sphere sliced at 0.25 mm layer height.

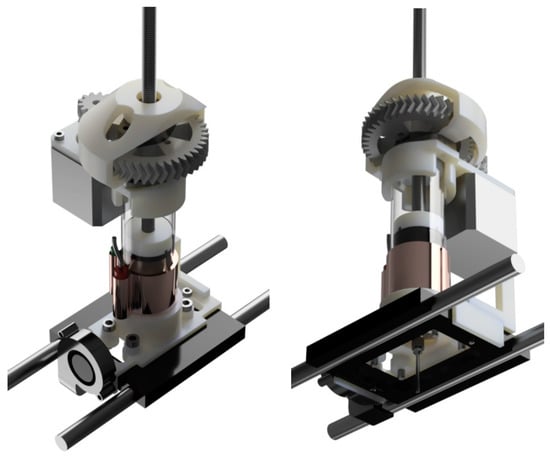

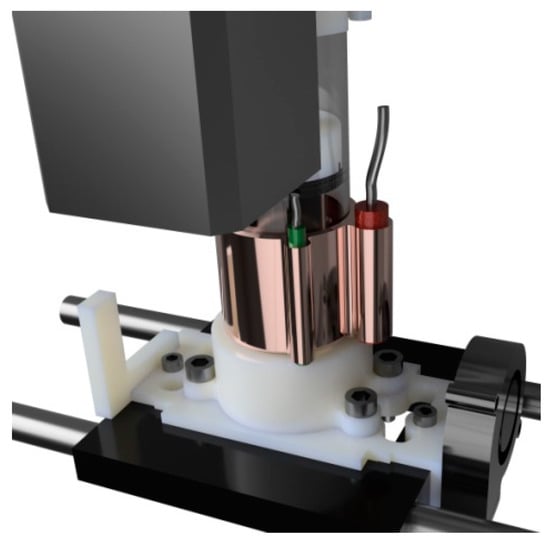

In this context, the authors designed and developed a paste extrusion device (Figure 2) that can eliminate some of the limitations of the aforementioned solutions and can be used with various paste-like materials. With such an add-ons to the existing material extrusion printers, one can control the flow (speed, volume) of material to accommodate certain needs for the extruded feedstock.

Figure 2.

Isometric views of the developed paste extruder for material extrusion 3D printers.

2. Towards an Improved 3D Printer Extruder Design

2.1. Design Considerations

In order to develop a device that can replace the thermoplastic material extruder on a typical desktop material extrusion 3D printer, there are several design aspects that must be taken into consideration.

The first aspect relates to the electromechanical components of a thermoplastic filament extruder. Most desktop material extrusion printers use stepper motors to grab and push feedstock into a heated nozzle [14]. The nozzle is heated using a ceramic heating cartridge, and the temperature is controlled using a thermistor, thermocouple or a temperature sensor. This means that the printer has the required electronics to control all these components, which include the stepper motor drivers, Analog-to-Digital Converters (ADCs) for temperature control, voltage regulators, and relays for switching the heating elements on and off.

Another aspect is the size of the 3D printer. The dimensions of the extruder carriage, and the mass allowed on the axis that holds the extruder, constrain the maximum dimensions of the paste extruder.

Another important fact is that the biggest 3D printer manufacturers develop their own proprietary software, which does not allow for the set-up of the parameters needed for a different type of extruder than the one specific to the machine. Therefore, the only possibility to circumvent this problem is to use open-source firmware and software.

The material extrusion desktop 3D printer on which the paste extruder was added-on is a Cartesian-style printer, equipped with a dual extruder (Figure 3). The printer has a closed build chamber and a build platform that can heat up to 110 °C. As for electronics, the printer comprises all the components that the paste extruder requires in order to function. These include two low-current stepper motor drivers, and two ADCs, which allow temperature control using thermistors. The 3D printer runs on open-source firmware Sailfish 3.4 (www.sailfishfirmware.com), during tests.

Figure 3.

QidiTech Avatar IV dual extrusion system.

Certain applications for paste-like materials, especially in the medical and food industries, require the use of sterile instruments. In order to fulfill this demand, the paste extruder design uses standard single-use 60 mL syringe tubes to hold the feedstock, and can be easily adapted to accommodate different tube sizes.

Material extrusion AM is an “additive manufacturing process in which material is selectively dispensed through a nozzle or orifice” [15]. For increased adaptability and ease of use, a Luer lock system [16] and blunt tip needles were used for the nozzle. Several dimensional variants are available for the blunt tip needle diameter (Figure 4).

Figure 4.

Various nozzle dimensions, from 0.15 mm to 1.54 mm.

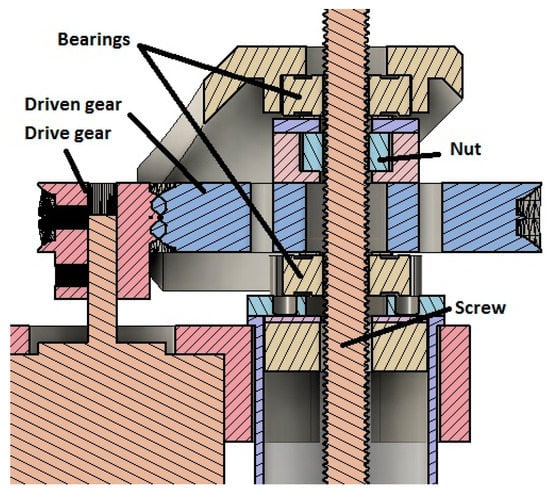

The feedstock is pushed through the nozzle using a piston actuated by a drive-screw and nut mechanism. The stepper motor is fixed in position, and no linear guides are needed, as the nut was pre-tensioned against the drive screw (Figure 5), and the inner rubber seal prevents the drive screw from spinning. The pitch of the drive screw is 1.25 mm.

Figure 5.

Section view of a virtual model of the paste extruder.

The paste extruder was designed to make use of one of the stepper motors that comes with the thermoplastic material extruders, in order to not modify the 3D printer too much. The stepper motor is a NEMA17-sized motor, which is typically used in desktop 3D printer extruders. The stepper motor is used in 200 micro steps per turn setting. The shaft of the stepper motor is connected to the drive screw through a set of double helical gears with a torque multiplier of 3.3 (Figure 6).

Figure 6.

Herringbone gears transmission.

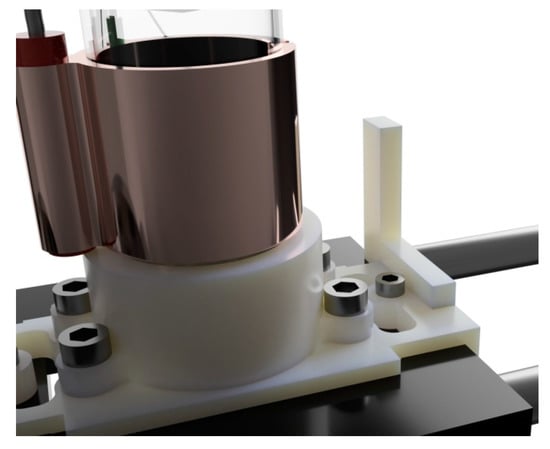

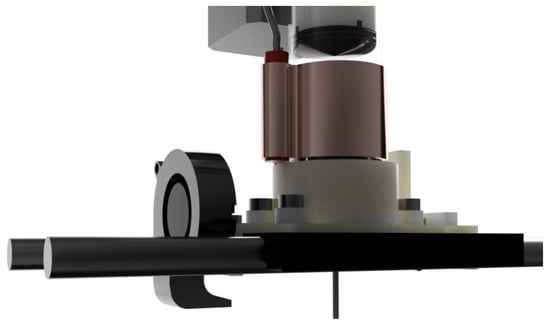

The extruder offers the possibility of heating the feedstock up to 80 °C if the fabrication process requires it. This temperature is achieved using a 30 W ceramic heater and controlled using an NTC 3950 thermistor. The heater and the thermistor are mounted on a copper sleeve attached to the extruder tube (Figure 7).

Figure 7.

Copper sleeve for heater and temperature sensor.

The 3D printer used in testing the device uses the stepper motor bodies mounted on the extruder to trigger the mechanical switch of the end stop for the x axis. Since the motor position was changed for the paste extruder, a new solution to trigger the end-stop was designed (Figure 8).

Figure 8.

End-stop trigger.

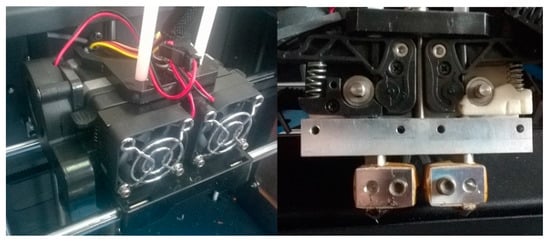

A fan mount was included on the side of the extruder carriage. It can be used to blow air onto the built part in order to cool or harden it (Figure 9).

Figure 9.

Fan design for forced cooling of printed part.

2.2. Materials

Various materials have been used to build the prototype device (see Table 1). The tube that holds the feedstock is made out of polypropylene, a plastic with a slippery surface that is resistant to many chemical solvents, bases and acids [17]. The tip of the plunger uses a polyisoprene seal. Other parts for the paste extruder have been 3D printed from acrylonitrile-butadiene-styrene (ABS) filament supplied by 3D Prima. For the set of double helical gears, polyethylene terephthalate glycol-modified (PETG) was used because of its superior mechanical properties.

Table 1.

3D printed materials used for prototype fabrication.

Using 3D printed parts has allowed for the efficient distribution of weight. The resulting extruder has a center of mass just 60 mm higher than the standard equipment, and a total mass when filled with 50 cm3 of clay of 640 g, which is roughly the same as the weight of the machine’s standard dual extruder.

2.3. 3D Printing Parameter Settings for Paste Extruder

As previously mentioned, the Cartesian 3D printer uses a version of Sailfish open-source firmware.

The firmware defines and enables the set-up of several important parameters of the AM process. For the thermoplastic filament extruder, the volume of extruded material is set up by specifying the diameter of the filament df, the diameter of the nozzle dn, an over/under extrusion parameter e, and a constant that reflects the specifications of the driving mechanism, m. Thus, the volume of extruded filament Ve is:

and the length of the extruded filament Le is:

These formulas were used to determine the parameters needed for the extrusion process while using the paste extruder prototype. The filament diameter is replaced by the inner diameter of the tube that holds the feedstock. The driving mechanism is also modified. The m variable for the thermoplastic material extruder is:

where s is the number of motor steps, and b is the radius of the toothed wheel that grabs and drives the filament.

This formula changes for the paste extruder, where m becomes:

where z1, z2 are the number of teeth in the double helical gears, and p is the pitch of the drive screw.

While these settings can be changed directly in the printer’s firmware, the same result can also be achieved by using a slicing software program that allows the user to access and modify these parameters.

The slicer program used to set the process parameters and split the test models into layers is Makerware from Makerbot. The source code of this software program was initially developed by Makerbot for use on its own products, and eventually made available to the public. The program uses text files that contain references to various parameters, and allow an end-user to easily load and unload fabrication process settings without modifying the printer firmware. Several test parts with basic geometry have been modeled, sliced, and 3D printed using various materials.

The settings used for testing the paste extruder prototype can be seen in Table 2.

Table 2.

Printing settings.

3. Discussion

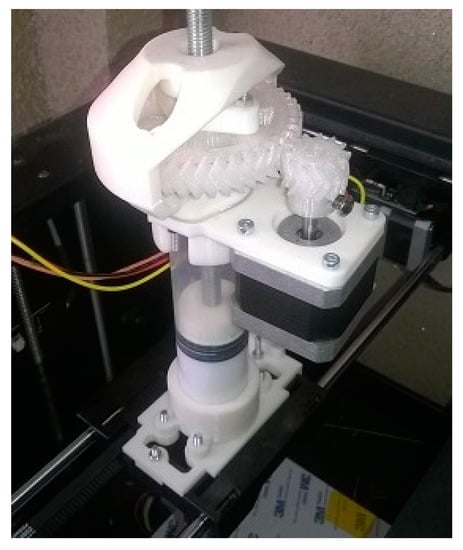

The paste extruder prototype (Figure 10) was integrated seamlessly with the desktop 3D printer. The stepper motor, ceramic heating cartridge, thermistor, and DC fan were successfully exported and incorporated into the new extruder.

Figure 10.

Paste extruder prototype.

Certain potential applications for material extrusion 3D printing, such as the fabrication of molds used in the dental industry, require high part detail and smooth surfaces. By removing the guide rail system found in other paste extruders, and lowering device mass through using lightweight 3D-printed parts, the proposed extruder is able to match typical desktop thermoplastic material extrusion accuracy, layer heights, and printing speeds.

Printing speed becomes increasingly important when printing with paste-like materials rather than thermoplastic filament. Most paste-like materials have different curing times, which means that the printer a limited timeframe to fabricate a part before the material starts to cure or harden, and it becomes difficult or even impossible to process. As build time in additive manufacturing is inversely proportional to the layer height, higher printing speeds enable the fabrication of highly detailed, smooth surfaces with a wider range of materials.

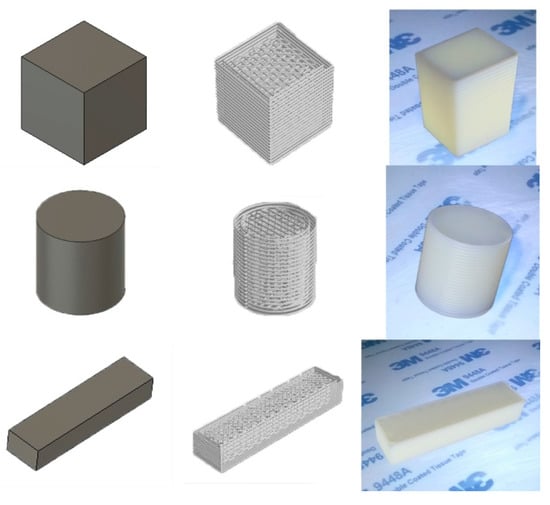

Subsequently, the prototype was used to fabricate a series of test parts: a 20 × 20 × 20 mm cube, a 20 × 20 mm cylinder and a 15 × 60 × 10 bar (Figure 11).

Figure 11.

Test samples (Left column) virtual models (Middle column) slicer paths (Right column) fabricated parts using silicone polymers.

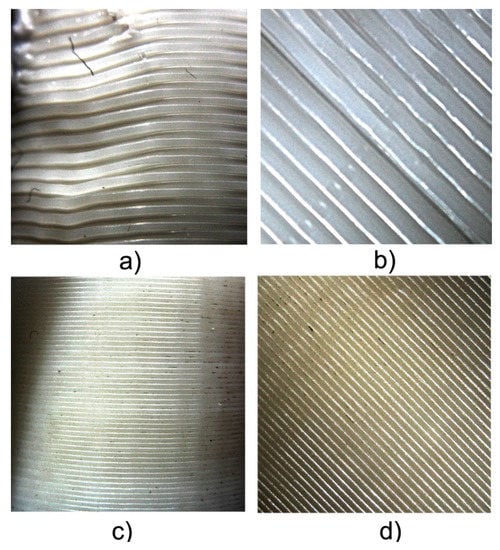

The fabricated parts show a good first layer adhesion on the polycarbonate print surface used during the test. Some noticeable drooping occurs due to the viscosity of the material. Figure 12 shows the differences in surface finish between a part made from silicone with the paste extruder prototype using a 1.5 mm needle and 1 mm layer height, and one made with ABS using the standard extruder with a 0.4 mm nozzle and 0.2 mm layer height. All configurations have been 3D printed on the same machine.

Figure 12.

Test sample surface quality (a) Cylindrical surface, silicone (b) Top surface, silicone (c) Cylindrical surface, acrylonitrile-butadiene-styrene (ABS) (d) Top surface, ABS.

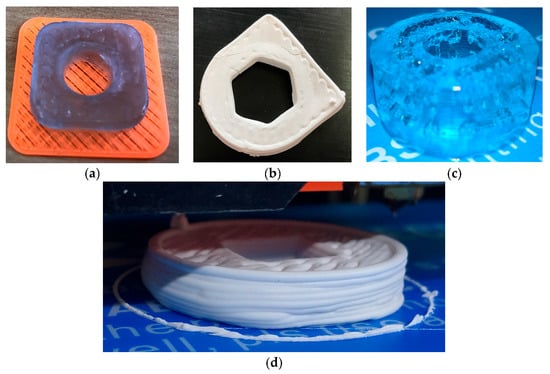

Figure 13 depicts the use of the proposed extruder when using various paste-like materials such as silicone, white cement mixture, and commercial dental gel (using the same parameters as above for the printing process, see Table 3 for materials characteristics). Figure 14 shows the same part fabricated using dental gel and two different nozzle sizes and layer heights, which illustrate the improvements in surface finish.

Figure 13.

Fabricated parts using the proposed solution (a) Part fabricated using silicone (b) Part fabricated using white cement mixture (c) Part fabricated using commercial dental gel (d) Part fabricated using white cement mixture.

Table 3.

Materials used during testing and process parameters.

Figure 14.

Same part fabricated out of dental gel using two different nozzles and layer heights (Left) 1.2 mm nozzle with 0.8 mm layer height (Right) 0.4 mm nozzle with 0.25 mm layer height.

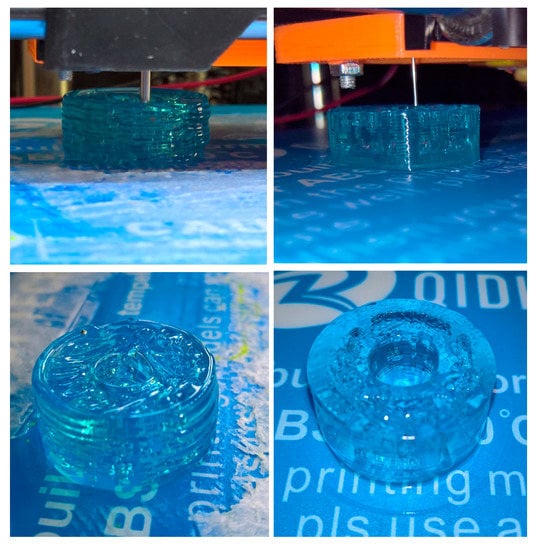

Figure 15 shows two images during the printing process of an ABS part and a silicone part manufactured using the same machine, as proof of the versatility added by our extruder solution to a desktop 3D printer.

Figure 15.

Parts 3D printed by the same machine (a) Extruder prototype component printed with ABS (b) Silicone sample part printed by paste extruder prototype.

4. Conclusions

In the last few years, the range of materials used in 3D printing has seen an extension towards paste-like materials. Applications have been developed for various industries, such as using cement-like materials in the construction industry, or chocolate material in the food industry. In the arts, clay 3D printed models are starting to be used, not only because of the possibility of exploiting the building capacity of objects with complex geometry, but also due to the advantage of reusing the paste-like material and the possibility of re-shaping the 3D printed model by hand to suit the needs of the artist or client. In other words, if the 3D part printed with paste-like materials does not correspond to various quality or design criteria, it can be immediately reworked as raw material and re-used to create another object. This process can reduce waste and have an important impact on the implementation of circular economy concepts [18].

The proof-of-concept device developed in this research has clearly indicated that a paste-like material extruder can open the way for new applications, especially in the creative fields, where remodeling due to frequent changes is one of the most important necessities of the design process. This is where the importance of our study lies.

From this point of view, our research brings us closer towards enabling 3D printing with recyclable, environmentally-friendly materials. Obviously, the idea is not to replace plastic materials with paste-like materials, but rather to enlarge the material range in order to offer more choice to designers, and more possibilities to adapt to particular applications.

The current paper has been focused on developing and testing a paste extruder designed to be an add-on for a desktop 3D printer. The development process consisted of analyzing the constructive variants of extruders available on the market and observing their advantages and disadvantages, industry outlook, and opportunities. A paste extruder was designed and a prototype was manufactured. Several of its parts were manufactured from different materials using a material extrusion 3D printing process. The resulting prototype was mounted on a desktop 3D printer, and replaced its standard thermoplastic filament extruder. After setting process parameters using slicing software, several sample parts were printed using silicone and acrylic polymers. A comparison with existing solutions is provided in Table 4.

Table 4.

Comparison of proposed solution with existing syringe-based paste extruders.

This research proved that a paste-like material extruder could be easily adapted to low-cost 3D printers, which extends the access of this technology to a larger number of designers. At this stage, the proposed solution allows for the creation of different, simple geometrical shapes. Further research will be focused on generating objects that are more complex and require the build of support structures using the second extruder of the 3D printer.

Further work will be focused on optimizing 3D printing process parameters for different types of paste/clay materials in order to obtain accurate and good quality objects. Future work will also investigate the possibility of combining the new extruder to a classic 3D printing extruder within the same deposition head, which would enable the building of paste/clay objects using support structures made of thermoplastic material.

Acknowledgments

This work has been funded by University Politehnica of Bucharest, through the “Excellence Research Grants” Program, UPB-GEX. Identifier: UPB-EXCELENȚĂ-2016 3D Printing system and method using paste-like materials (P3DM) Contract number 33/26.09.2016.

Author Contributions

Catalin Gheorghe Amza conceived the experiments; Aurelian Zapciu designed the extruder; Aurelian Zapciu and Diana Popescu performed the experiments; Aurelian Zapciu analyses the data obtained from the 3D prints; all three authors contributed in writing up the paper. All authors have read and approved the final manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wohlers Associates. Wohlers Report 2016—3D Printing and Additive Manufacturing State of the Industry Annual Worldwide Progress Report; Wohlers Associates: Fort Collins, CO, USA, 2016. [Google Scholar]

- Srivatsan, T.S.; Sudarshan, T.S. Additive Manufacturing: Innovations, Advances, and Applications; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- An, J.; Teoh, V.; Suntornnond, V.; Chua, C.K. Design and 3D printing of scaffolds and tissues. Engineering 2015, 1, 261–268. [Google Scholar] [CrossRef]

- Billiet, T.; Gevaert, E.; Schryver, T.D.; Cornelissen, M. The 3D printing of gelatin methacrylamide cell-laden tissue-engineered constructs with high cell viability. Biomaterials 2014, 35, 49–62. [Google Scholar] [CrossRef] [PubMed]

- Murphy, S.V.; Atala, A. 3D bioprinting of tissues and organs. Nat. Biotechnol. 2014, 32, 773–785. [Google Scholar] [CrossRef] [PubMed]

- Tran, J.L. 3D-printed food. Minn. J. Law Sci. Technol. 2016, 17, 855–880. [Google Scholar]

- Bertol, L.S.; Schabbach, R.; Dos Santos, L.A. Dimensional evaluation of patient-specific 3D printing using calcium phosphate cement for craniofacial bone resconstruction. J. Biomater. Appl. 2016, 31, 799–806. [Google Scholar] [CrossRef] [PubMed]

- Huson, D.; Hoskins, S. 3D printed ceramics for tableware, artists/designers and specialist applications. Key Eng. Mater. 2014, 608, 351–357. [Google Scholar] [CrossRef]

- Gibbons, G.J.; Williams, R.; Purnell, P.; Farahi, E. 3D printing of cement composites. Adv. Appl. Ceram. 2010, 109, 287–290. [Google Scholar] [CrossRef]

- Quan, Z.; Wu, A.; Keefe, M.; Qin, X.; Yu, J.; Suhr, J.; Byun, J.H.; Kim, B.S.; Chou, T.W. Additive manufacturing of multi-directional preforms for composites: Opportunities and challenges. Mater. Today 2015, 18, 503–512. [Google Scholar] [CrossRef]

- Bemm, R.A. Automatic Confection Decorating System. U.S. Patent 3,921,858 A, 5 November 1973. [Google Scholar]

- Horne, R. Reprap Development and Further Adventures in DIY 3D Printing: Universal Paste Extruder. 6 April 2012. Available online: http://richrap.blogspot.com/2012/04/universal-paste-extruder-ceramic-food.html (accessed on 10 January 2017).

- World’s Advanced Saving Project (WASP). WASP Launches the New Professional Clay Extruder. 22 May 2016. Available online: http://www.wasproject.it/w/en/wasp-launches-the-new-professional-clay-extruder/ (accessed on 3 February 2017).

- Crump, S.S. Apparatus and Method for Creating Three-Dimensional Objects. U.S. Patent 5,121,329 A, 30 October 1989. [Google Scholar]

- ISO 17296-1:2015. Additive Manufacturing—General Principles—Part 1. Teminology; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Werschmidt, G.S.; Feith, R.P.; Kipp, D.R. Luer Lock System. U.S. Patent 5,626,427 A, 27 April 1995. [Google Scholar]

- Maddah, H.A. Polypropylene as a promising plastic: A review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar]

- European Circular Economy Platform. Available online: http://ec.europa.eu/environment/circular-economy/index_en.htm (accessed on 24 July 2017).

- Seraph Robotics, Inc. Fab@Home M4 Product Spec Sheet. Available online: http://docs.wixstatic.com/ugd/5e1aea_7555527a4451412b8d95ad3b15106273.pdf (accessed on 20 July 2017).

- Structur3D Printing. Discov3ry Complete—Structur3D Printing|Go Beyond Plastic. Available online: https://www.structur3d.io/discov3ry-complete (accessed on 20 July 2017).

- Printrbot. Installing the Paste Extruder—Printrbot Support. Available online: https://printrbot.zendesk.com/hc/en-us/articles/115001240606-Installing-the-Paste-Extruder (accessed on 20 July 2017).

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).