Abstract

Nylon filament is a widely used thermoplastic material in extrusion-based 3D printing, favored for its strength, durability, and excellent printability. It enables the fabrication of parts with complex geometries, high design flexibility, and cost-effective production, making it ideal for both prototyping and functional components. However, one significant drawback of nylon is its hygroscopic nature—it readily absorbs moisture from the surrounding environment, often at a rapid rate. This moisture uptake can negatively impact the filament’s performance during printing, leading to poor surface finish, reduced mechanical strength, and altered thermal behavior in the final printed parts. To better understand the effects of moisture absorption, this study investigates the mechanical and thermal properties of nylon parts printed using filaments with varying levels of moisture content. The nylon filament was conditioned in a controlled humidity chamber for different durations to simulate moisture exposure over time. Specimens were then printed using these conditioned filaments, and a series of tests were performed to assess their mechanical integrity and thermal stability. By analyzing the test results, the study aims to establish a correlation between filament moisture content and part quality, offering valuable insights into the degradation mechanisms and guiding best practices for filament handling and storage in nylon 3D printing applications.

1. Introduction

Nylon is a family of synthetic polymers composed of polyamides of high molecular weight. Nylon polymers are tough, strong, and outstanding for their high resistance to heat, chemicals, and impact, which are of great interest for industrial and commercial applications as a thermoplastic material. With the introduction of additive manufacturing (AM) or 3D printing to the market, nylon has become a popular feedstock material in the form of powder and filament [1]. In particular, 3D printing nylon filament affords great convenience for making parts of low-volume production or complex structures, using a material extrusion (MEX) 3D printing process such as fused deposition modeling (FDM) or fused filament fabrication (FFF). Also, nylon filaments are low-cost and easily acquired through various vendors or suppliers, making MEX 3D printing for nylon parts very accessible to end users, in comparison with other AM processes such as powder bed fusion (PBF) [2].

The influence of moisture and environmental humidity on 3D printing attracts more attention in a wide range of areas [3,4,5,6,7]. Many commonly used 3D printing filaments, such as polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), polycarbonate, or related composites, were studied to reveal the material property degradation and the guidelines for minimizing the negative effects of filament moisture. PLA plastic is significantly influenced by moisture [8,9,10]. Menezes et al. [11] examined the long-term effects of seawater on PLA by submerging samples in artificial seawater at 22–60 °C for up to ten weeks. Mechanical tests, including tensile, nanoindentation, and Hopkinson bar impact tests, assessed aging effects. Diffusion data were collected, and an accelerated aging model was developed using Arrhenius relationships. The results showed significant aging, with PLA losing 0.5% ductility at 5166 h and 10 MPa in yield strength at 2084 h when submerged in 17 °C seawater. Kakanuru et al. [12] compared moisture penetration and aging effects on FFF parts made from PLA, SiC-filled PLA composites, and ABS. Samples were aged in distilled water at 50 °C and 70 °C for up to 140 days. PLA and 20 wt.% SiC/PLA degraded in 58 days at 50 °C, while higher SiC loadings lasted 140 days. Moisture diffusivity decreased with increased SiC content. While 20 wt.% SiC improved PLA strength, higher loadings reduced performance. ABS retained tensile strength but softened. Digital image correlation revealed significant microstructural variability, affecting strain distribution and part properties during aging. Fang et al. [13] studied how environmental temperature and humidity affect the quality of FFF-printed parts using bisphenol A polycarbonate. Infrared imaging revealed a thermal gradient of up to 5.4 °C/mm when printing with an open-chamber printer and a heated build plate. X-ray micro-CT scans showed porosity reaching 11.7% due to moisture absorption. Tensile tests confirmed mechanical degradation, though transverse ductility increased with higher porosity. Analytical and parametric studies established quantitative relations between environmental conditions and print quality. Based on these findings, guidelines were developed to help users predict and control printing outcomes under varying environmental conditions. Wichniarek et al. [14] explored how adjusting process parameters can compensate for the negative effects of filament humidity on the mechanical properties of FDM-printed parts. Key parameters studied include layer thickness, deposition speed, deposition temperature, and chamber temperature. Experimental results identified the relationship between these factors and product performance. Among them, layer thickness was found to be the most effective in mitigating moisture-related degradation. The study provides guidelines for optimizing printing parameters to counteract humidity effects, improving the overall quality and mechanical strength of FDM-printed components. High-performance plastic materials, such as ULTEM, are also influenced by moisture. Zaldivar et al. [15] evaluated the moisture absorption characteristics of ULTEM® 9085 filament and its impact on FDM parts. Filaments were exposed to varying humidity levels (0–0.8 wt.%), and tensile tests assessed mechanical performance in different building orientations. Moisture uptake followed Fickian diffusion, significantly reducing tensile strength (>60%) and failure strain (>50%), with vertical prints most affected. Moisture-induced porosity and pseudo-crosslinking contributed to degradation. Optical microscopy revealed increased roughness and voids at 0.16% moisture or higher. Rheological analysis showed plasticization effects, lowering the glass transition temperature Tg. The results highlight the need for careful moisture control to ensure high-quality material extrusion manufacturing. The effects of moisture on 3D printing PMMA [16] and Onyx [17] were also reported.

Some 3D printing filaments for pharmaceutical applications have been investigated for stability challenges of varied storage conditions, including temperature and relative humidity [18]. It was reported that the increased relative humidity had a significant effect on the physical properties of pharmaceutical filaments, such as shape, dimensions, and flexibility. Due to their hygroscopic nature, cellulose- and polyvinyl pyrrolidone-based filaments demonstrated a reduction in Tg upon storage, leading to increased flexibility and incompatibility with the FDM 3D printer. Shrinkage behavior of building materials for 3D printing was also studied regarding the different drying or moistening conditions [19]. Monson et al. [20] reported the dimensional changes associated with the moisture absorption of various polyamides. Banjo et al. [21] used 3D-printed nylon specimens and immersed them in deionized water at different temperatures and concluded that nylon-based materials absorb much more water than 3D-printed PLA specimens. A direct relationship between moisture absorption and reduction in flexural properties was also observed for the nylon specimens. As a hygroscopic material, nylon plastic can absorb moisture from the surrounding humidity [22,23,24]. The degradation of nylon material can be attributed to the amount of filament moisture, which acts as a plasticizer, reducing the molecular entanglements and bonding between the molecules [25]. It has been found that water sorption (immersion into a liquid water bath) has very different transport mechanisms at the surface compared to moisture sorption (moisture in air) [26]. Thus, this project conducts a preliminary study of the effects of environmental (air) humidity on the feedstock filament of nylon materials used for the 3D printing process. The mechanical and thermal properties of 3D-printed nylon were evaluated when the nylon filaments were treated using different moistening times (moisture contents).

2. Experiment

The feedstock material OVERTURE Easy Nylon filament (Nylon 6, dia. 1.75 mm) was acquired for this study. The virgin filament was placed in a MEMMERT humidity chamber (HCP 50, Memmert USA) for absorbing moisture. The humidity chamber was set with a constant temperature (40 °C) and humidity (80% rh) to mimic a stable humid environment (expediting moisture absorption of the filament). After a certain amount of time (0 h, 24 h, 48 h, and 72 h), the moisture content of the nylon filament was measured using a Torbal moisture analyzer (model no. BTS110, moisture measurement accuracy 0.1% and repeatability ±0.4%). Time = 0 h represents the virgin filament without any moistening. The moisture content is calculated using Equation (1).

Here, m0 is the mass of the moistened filament; m is the mass of the dried filament.

The moistened nylon filament was fed into a FFF 3D printer (CreatBot F430, nozzle dia. 0.4 mm) for printing specimens. The nozzle temperature was 245 °C. The print bed temperature was 100 °C. The print speed was 70 mm/s, with a layer thickness of 0.1 mm and an infill rate of 100%. Three types of nylon artifacts were created for comparison of varied moisture content: extruded material, thin-wall samples, and mechanical and thermal testing specimens. The extruded material was a continuous nylon fiber that was squeezed out of the nozzle. The thin-wall sample had a hollow cubical shape with a wall of stacked nylon strands. The extruded materials and thin-wall samples were observed using an Olympus optical microscope (BX53M) and a Keyence 3D Measurement Macroscope (VR-3200). Mechanical tests included tensile testing and Izod impact testing. The size of the tensile specimens and impact specimens is in compliance with the ASTM D638 [27] and ASTM D256 [28] standards. The tensile specimens were printed with a YX orientation, and the Izod specimens were printed with an XY orientation, as per the ISO 17295 [29] standard. The specimens were tested using the MTS CriterionTM Model 43 tensile tester (force accuracy ± 1.0% and displacement accuracy ± 0.008 mm) and CEAST 9050 pendulum impact tester at room temperature, respectively. Thermal testing was performed using the TA SDT 650 DSC/TGA system for thermogravimetric analysis.

3. Results and Discussion

3.1. Moisture Measurement

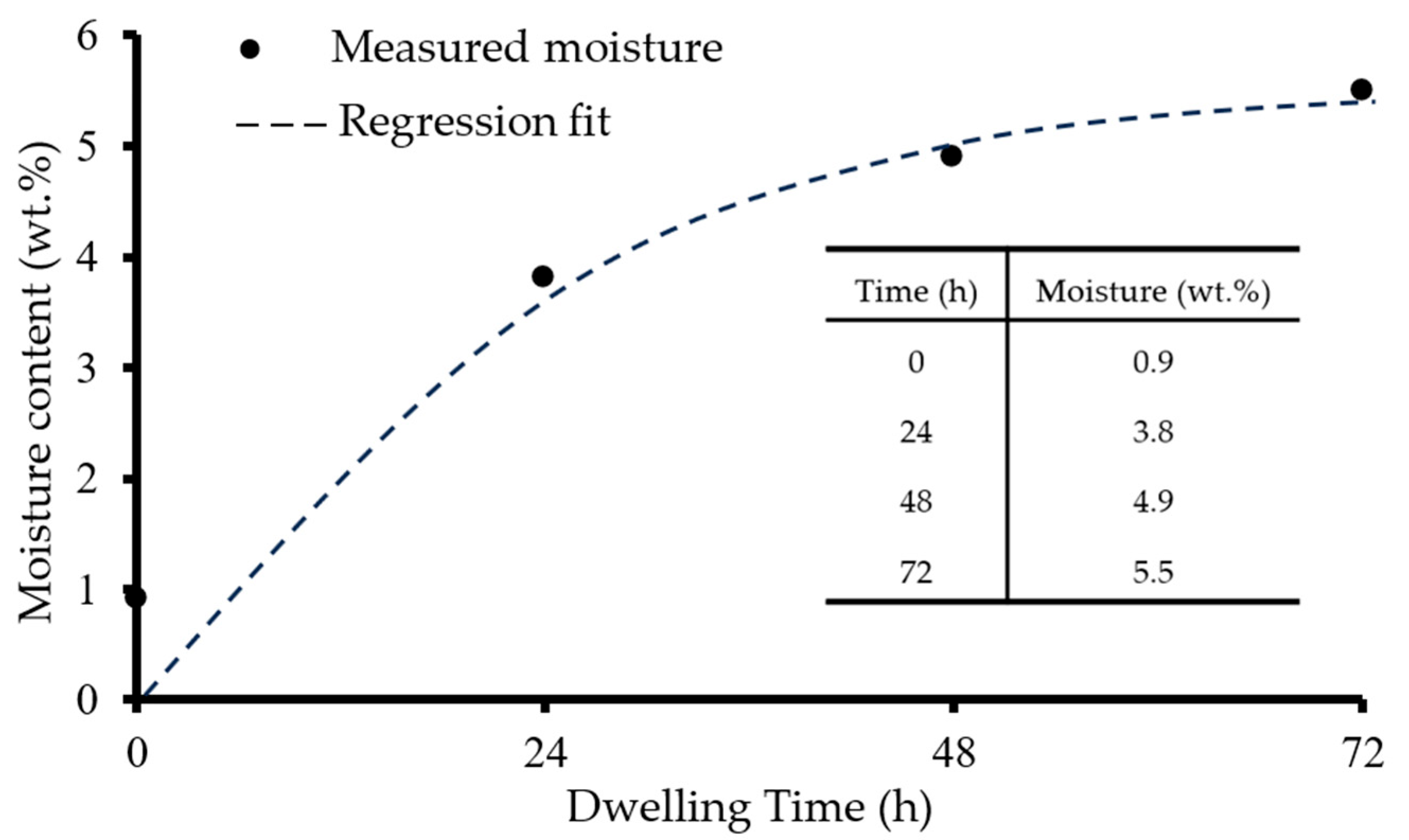

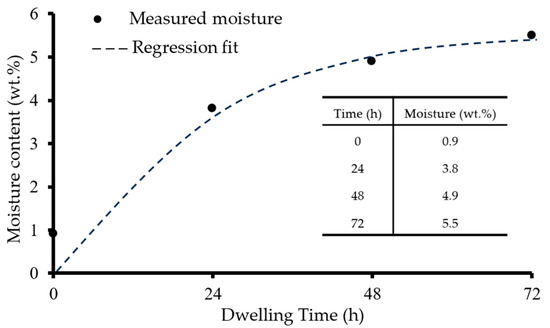

In this study, nylon filament samples were placed in the humidity chamber at various dwelling times (four levels) to absorb moisture. As a hygroscopic material, nylon filament was moistened at a fast rate, as shown in Figure 1.

Figure 1.

Moisture content of nylon filament versus dwelling time in the humidity chamber: temperature (40 °C) and humidity (80% rh).

The nylon filament exhibits a dramatic increase in moisture content with the extended dwelling time in the humidity chamber. It is noted that even the virgin nylon filament (0 h, no moistening) contains about 1 wt.% water, which can be ascribed to moisture absorption during the filament production. The regression fit of the measured moisture versus dwelling time (excluding 0 h) can be expressed using Equation (2).

Here, M denotes the moisture content (wt.%), and t is the filament dwelling time in a humidity chamber in hours. The hygroscopicity of nylon material causes inevitable moisture absorption in a humid environment if a new spool of nylon filament is installed for 3D printing without the full enclosure or a drying device. When the environmental temperature and humidity reach a high level (namely, 40 °C and 80% rh in this study), the nylon filament continuously absorbs the moisture in the surrounding air. The measured nylon filament moisture is around 5.5 wt.% after three days (72 h) in the humidity chamber, showing no sign of saturation. Equation (2) suggests that moisture increases rapidly at first and then levels off near a saturation point of approximately 5.65 wt.%, as demonstrated in Figure 1. The nylon filament exhibits a comparable absorption rate to the nylon samples immersed in deionized water [21].

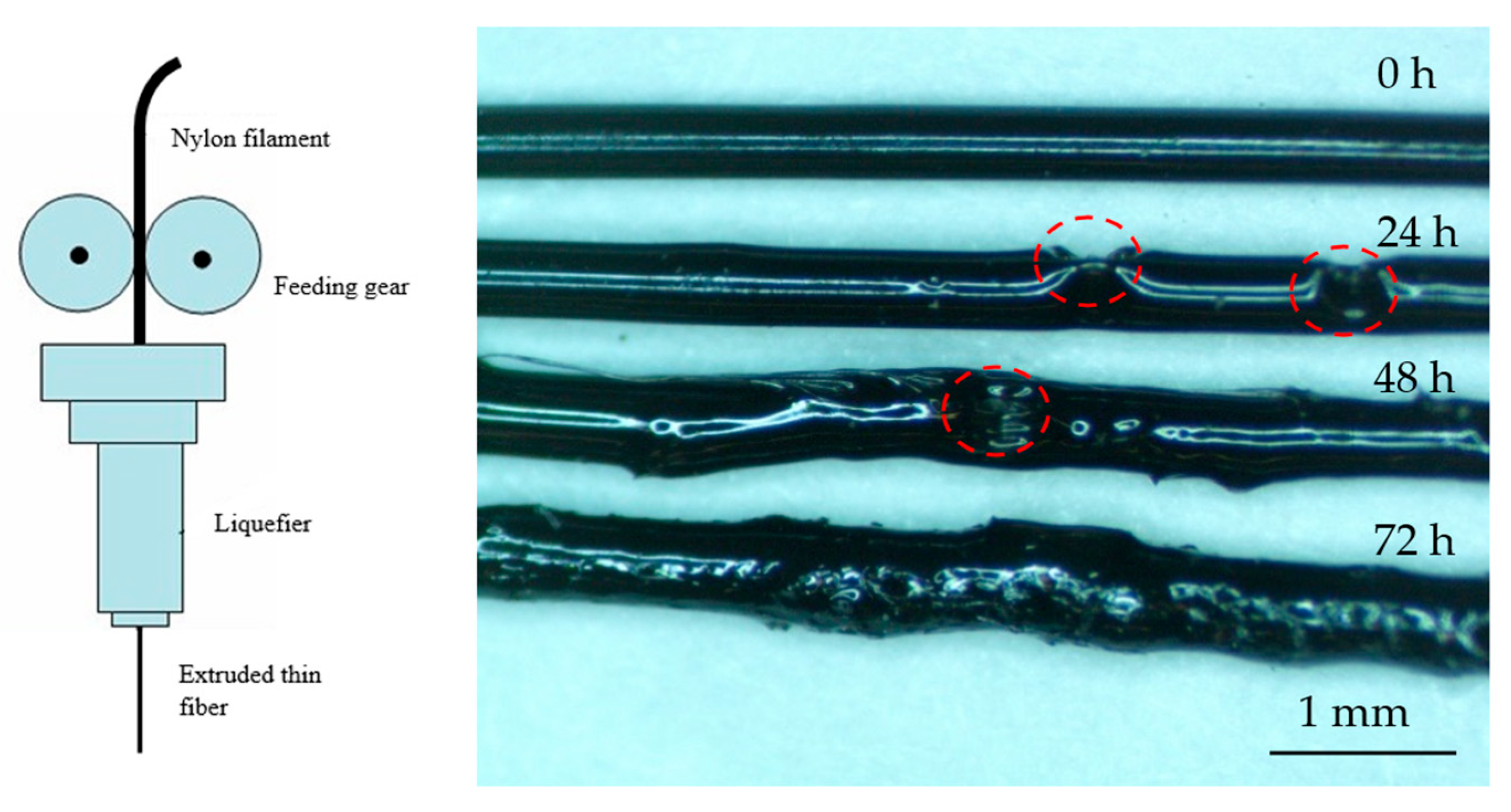

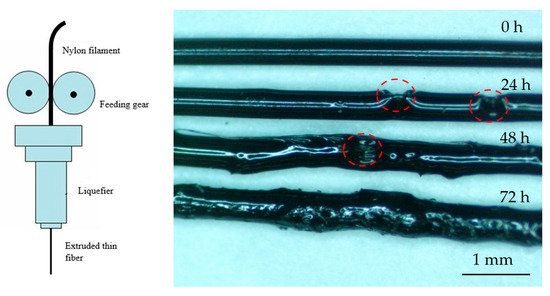

3.2. Extruded Material

The extruded material samples were collected after nylon filaments were directly fed into the liquefier and forced out through the nozzle, bypassing the printing process. As depicted in Figure 2, the morphology and consistency of the extruded nylon strands are strongly affected by the moisture content in the feedstock filament. The strands produced from 0 h and 24 h nylon exhibit a uniform diameter corresponding to the nozzle tip size. However, small surface defects, caused by the bursting of moisture evaporation bubbles during heating, are visible on the 24 h nylon strand. In contrast, nylon filaments with higher moisture content (48 h and 72 h) show significant deterioration in fiber morphology. This degradation occurs due to the expansion of internal bubbles and the bursting of external bubbles, resulting from moisture evaporation. Increased moisture uptake reduces the viscosity of the molten nylon, which accelerates void formation and foaming. Additionally, the interaction between water molecules and the polymer’s carbonyl and ether groups forms hydrogen bonds, leading to a “pseudo-crosslinking” effect [15] and causing material degradation.

Figure 2.

Schematic of the extrusion-based 3D printing process and the extruded nylon strand.

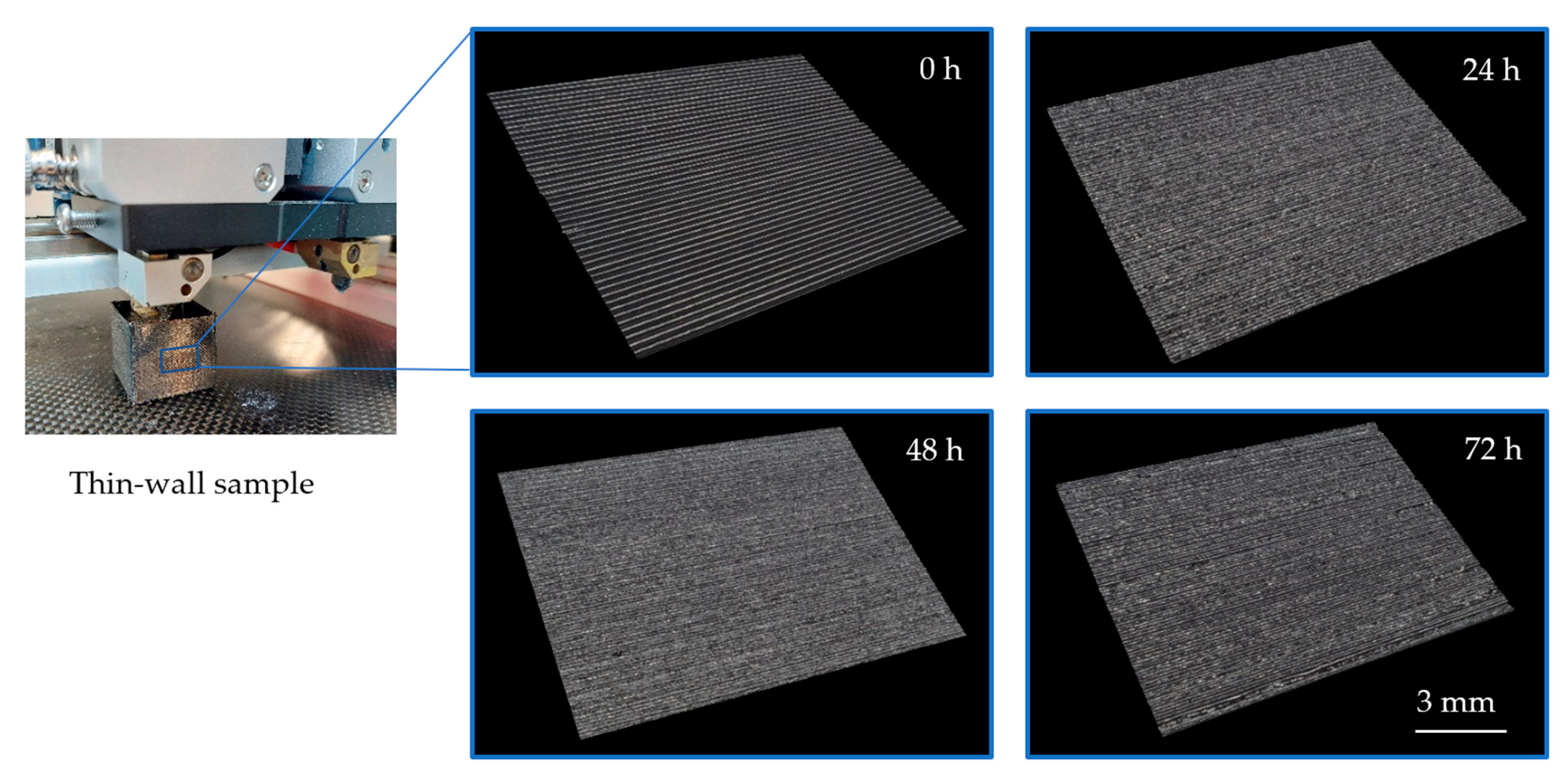

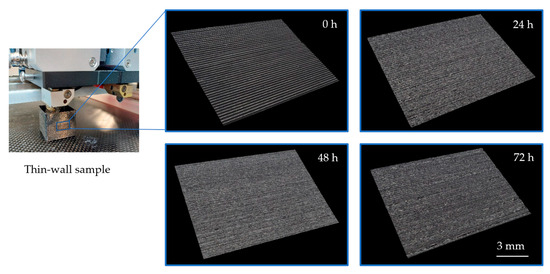

3.3. Surface Finish

Four thin-wall samples were printed using moistened filaments to investigate the effect of moisture on the surface finish of 3D-printed nylon parts. The lateral walls were analyzed using a Keyence automatic 3D measuring macroscope (height measurement accuracy ±3 µm). The results revealed a significant decline in surface quality, attributed to the deterioration of nylon strands with increased moisture content. Figure 3 illustrates the changes in surface finish corresponding to specific moistening times (or elevated moisture levels) of the nylon filaments.

Figure 3.

Lateral surface profile of thin-wall nylon samples.

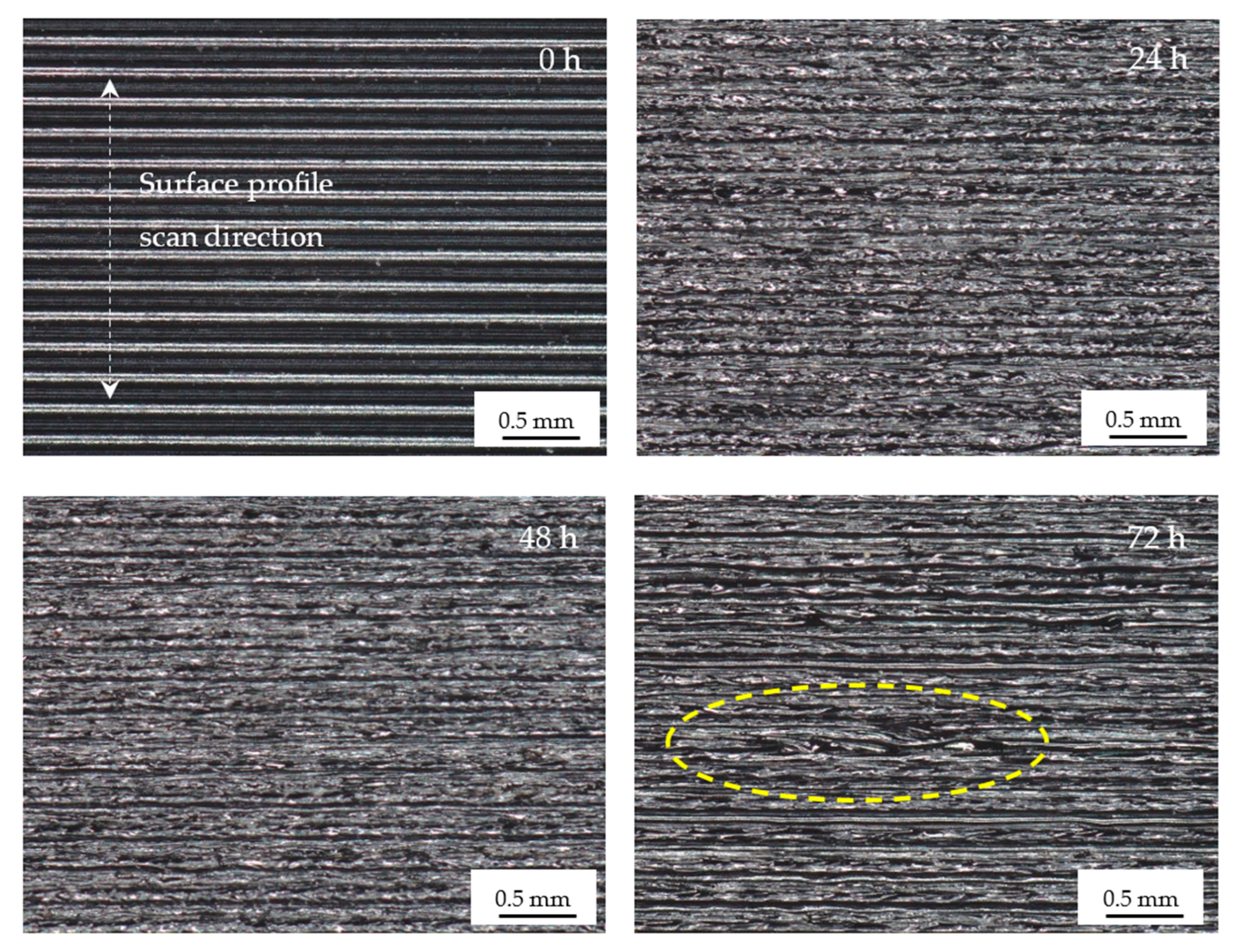

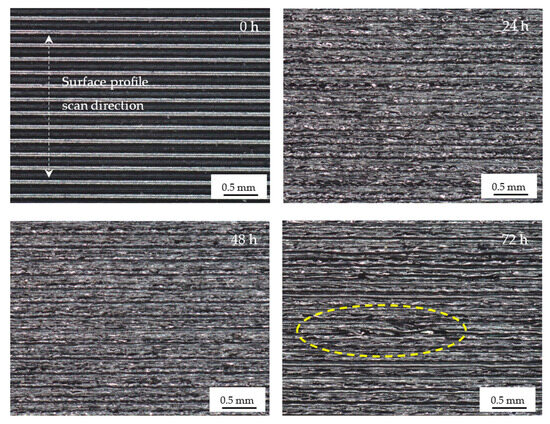

The magnified surface profiles (0~72 h) highlight the contrast of the surface quality of nylon samples at low and high moisture levels, as shown in Figure 4. It can be seen that the extruded nylon strand of the 72 h sample can hardly maintain a smooth morphological bonding with adjacent layers. The layer building consistency is occasionally interrupted by the insufficient or excessive strand extrusion of the prior layer, as highlighted in the 72 h surface profile of Figure 4. A clear layer bonding boundary is hard to recognize, in contrast to the 0 h sample. The inconsistent bonding might cause an increased difficulty in predicting the material properties of nylon parts, making the 3D printing parts’ anisotropy problem prominent.

Figure 4.

Magnified surface profile of 0 h, 24 h, 48 h, and 72 h nylon samples.

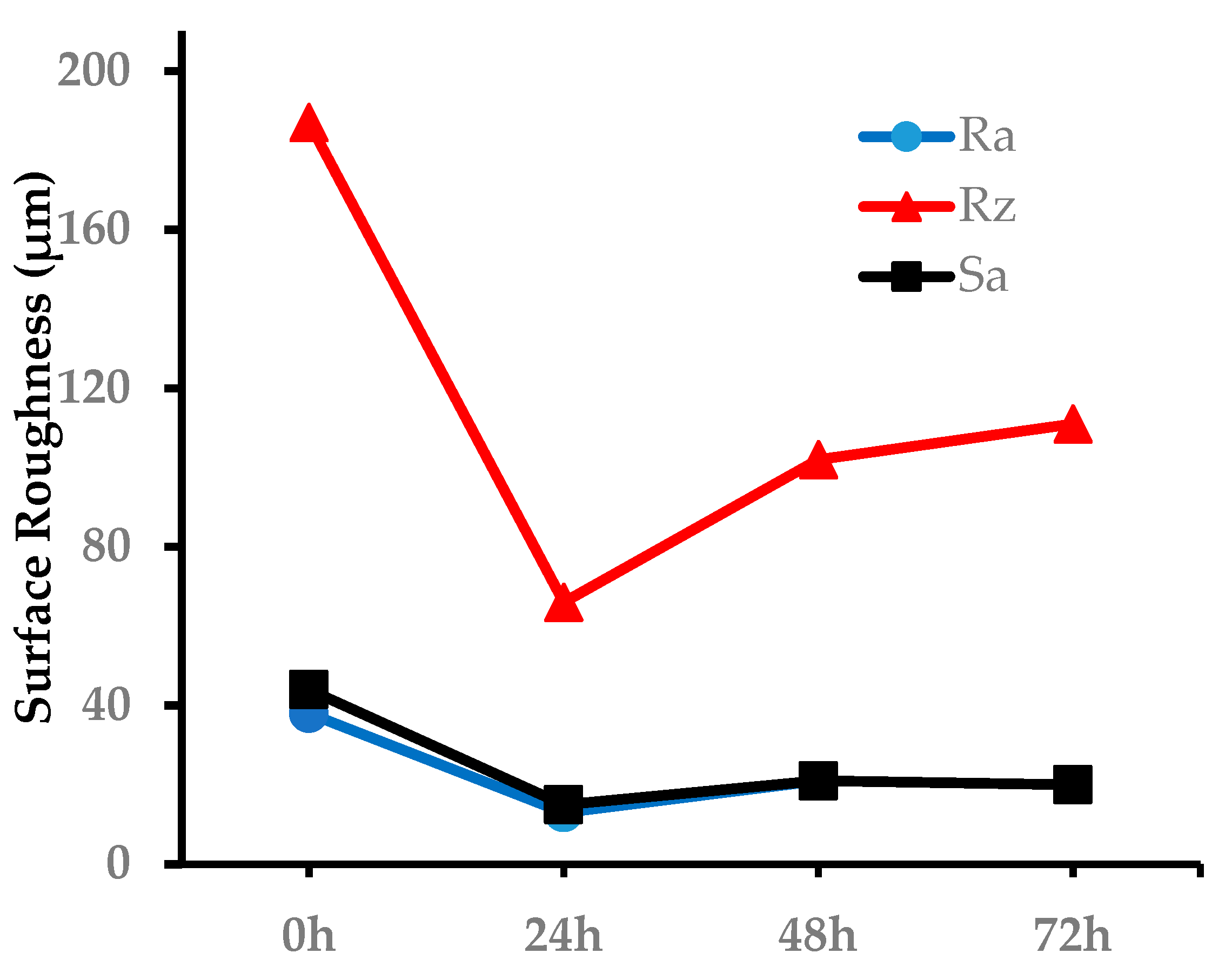

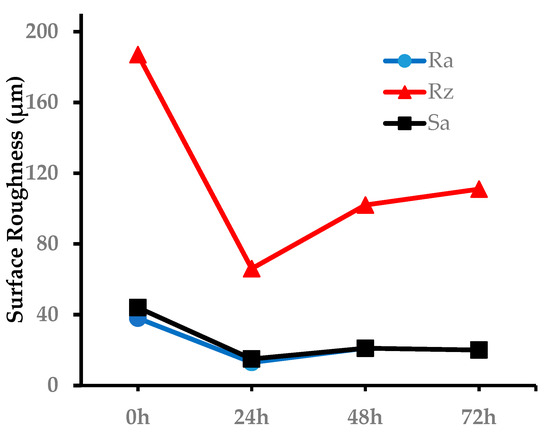

In addition to the optical microscopy, the surface quality was also assessed using the scanned surface profile. The Ra and Rz evaluations were conducted with an orientation along the building direction (perpendicular to the layers as shown in Figure 4). The areal average roughness (Sa) was evaluated over the entire region. Periodic peaks and valleys were observed in the roughness profile, using the Keyence macroscope. The Ra, Rz, and Sa values were automatically averaged based on the profile heights across the evaluation region, as shown in Figure 5. Notably, the Ra value exhibited minimal variation despite visible differences in surface finish, even for the roughness profiles of the 48 h and 72 h samples (Ra 21 µm for the 48 h sample and 20 µm for the 72 h sample), which displayed significant irregularities. Sa value has a similar trend compared to the Ra value. The Rz value for the 24 h, 48 h, or 72 h specimens was even lower than that of the 0 h specimen. The measured surface roughness value hardly reflects the surface irregularities of 3D-printed nylon specimens. This suggests that reliance solely on Ra, Rz, or Sa measurements may underestimate the impact of moisture on the surface quality of 3D-printed nylon parts. Visual differentiation of surface finishes corresponding to varying moisture contents is often challenging if the nylon filament has already absorbed moisture. Therefore, it is recommended to use multiple metrological methods for a comprehensive evaluation of the surface quality of 3D-printed components.

Figure 5.

Surface roughness of 3D-printed nylon samples.

3.4. Mechanical Testing

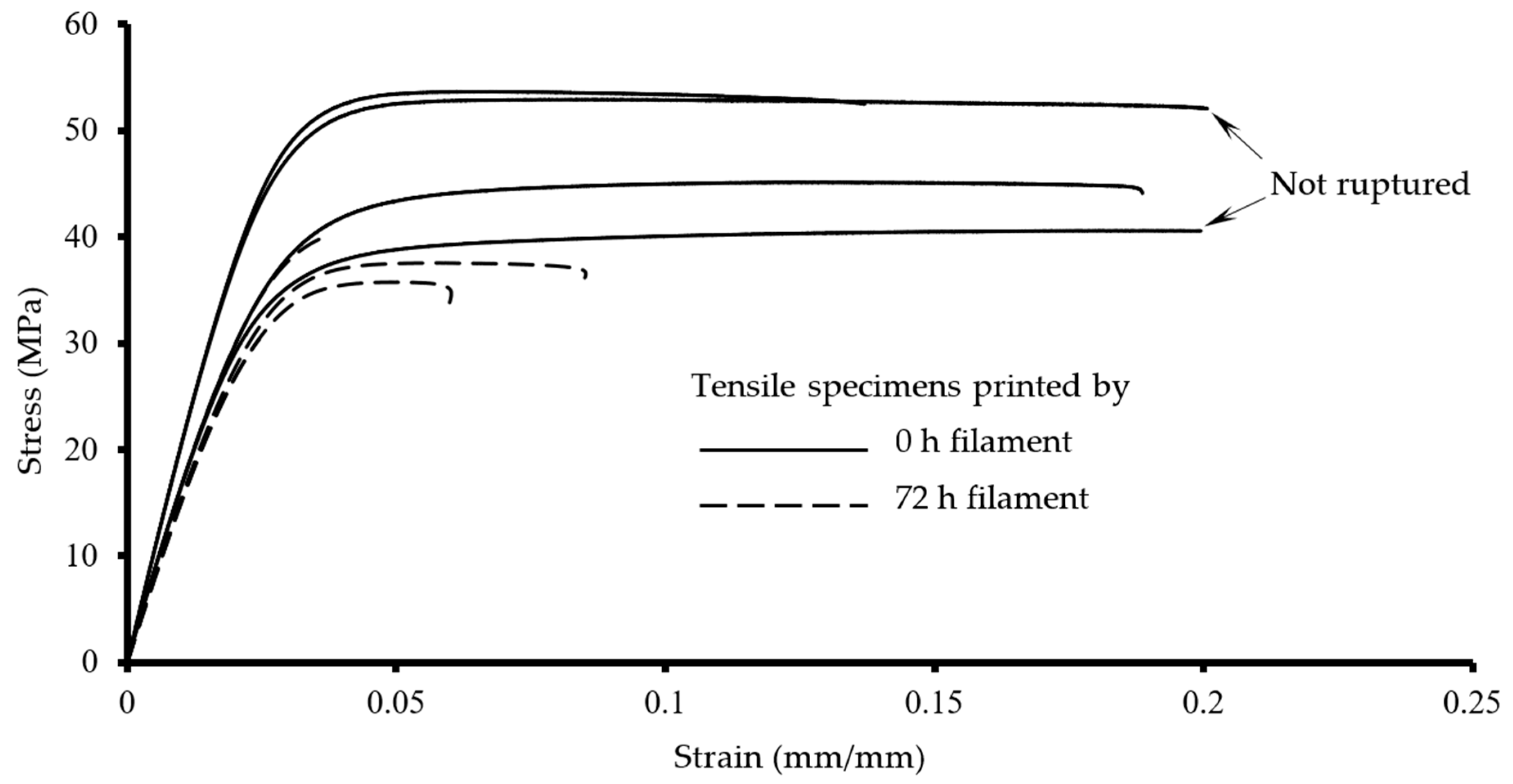

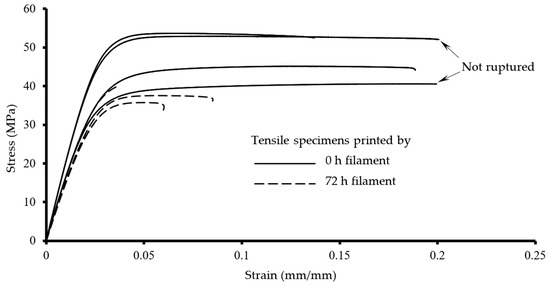

A tensile test was conducted at room temperature on specimens 3D-printed using virgin nylon filament (0 h) and moistened nylon filament (72 h). The purpose of the test was to investigate the impact of moisture content on the tensile strength of nylon materials. To achieve this, two filaments with distinctly different moisture levels (0.9% for virgin filament and 5.5% for moistened filament) were utilized. The tensile specimens were designed to conform to the ASTM D638 Type I standard, with a thickness of 4 mm, and four specimens were tested for each filament type. The resulting stress–strain curves are presented in Figure 6. As is common with 3D-printed plastic materials, some variation in mechanical properties was observed. For instance, slight differences in elastic modulus (ranging from 1.50 to 1.81 GPa) were noted among the 0 h specimens. The ultimate tensile strength varied within the range of 40–54 MPa. The elongation (at break) of 0 h specimens was more than 12%. Two 0 h specimens did not rupture during the test due to the strain limitation of the extensometer (20%). A great ductility was expected when the nylon specimens were printed using a virgin filament. The testing results of 0 h specimens are comparable or superior to the published literature of FDM or FFF nylon 6 material. For example, Lay et al. [30] compared the mechanical properties of nylon 6 fabricated by FDM and injection molding and concluded that the FDM nylon 6’s tensile strength, Young’s modulus, and elongation at break were approximately 49 MPa, 1.45 GPa, and 14%, respectively. Ramesh et al. [31] optimized the parameters for FDM nylon 6 material and observed the highest tensile strength at 43.5 MPa. Shashikumar et al. [32] also investigated the influence of parameters of FDM on the tensile properties of nylon 6 and obtained a slightly inferior tensile strength. In this study, the nylon specimens printed using the virgin filament presented tensile properties as anticipated. In contrast, the stress–strain curves for the 72 h specimens showed inferior tensile properties compared to the 0 h specimens. Those printed with 72 h moistened filament exhibited reduced Young’s modulus and ultimate tensile strength. In particular, regarding ductility, the maximum strain value for the 72 h specimens was only 8%, markedly lower than that of the 0 h specimens. Some specimens ruptured immediately after the yield point, as shown in Figure 6. Overall, the nylon specimens printed with the virgin filament (0 h) demonstrated excellent elasticity and ductility. However, both the yield strength and ultimate tensile strength were diminished due to the higher moisture content. The inferior tensile properties of the 72 h nylon specimens can be attributed to moisture-induced degradation of the filament material. Moisture acts as a plasticizer, reducing the strength and stiffness of nylon by diffusing into the material and bonding to polymer chains in the amorphous regions. This bonding forces the polymer chains apart, weakening interlayer adhesion during layer building. Furthermore, moisture-related void formation and the “pseudo-crosslinking” effect contribute to the degradation of the extruded nylon material. These combined factors result in the decreased ductility and overall mechanical performance of the 72 h specimens.

Figure 6.

Stress–strain curve of tensile testing specimens of nylon.

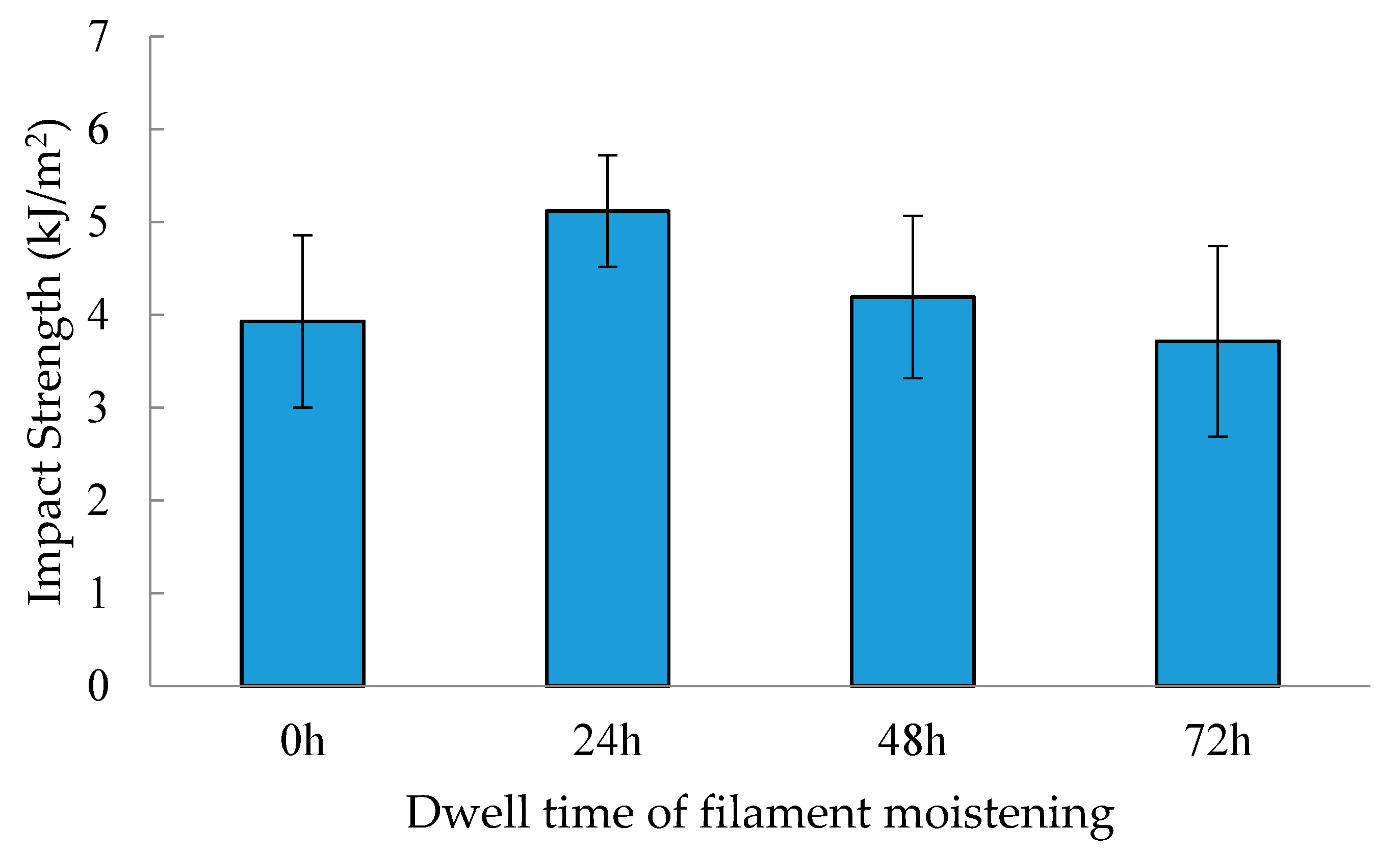

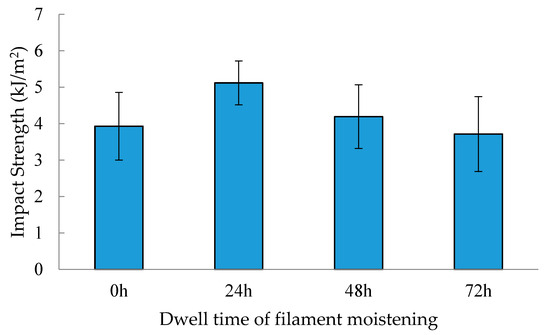

The Izod impact test was performed on nylon specimens prepared in accordance with the ASTM D256 standard. For each moisture condition, four specimens were 3D-printed. A standard notching device was used to create the notches on each sample to ensure consistency in testing. The average impact strength values are shown in Figure 7. Overall, the results indicate minimal variation in impact strength among most of the tested specimens. Notably, the specimens conditioned for 24 h displayed a slightly higher average impact strength compared to the others. However, the difference was relatively small. Given the limited number of specimens tested for each condition, it was not possible to confirm whether the observed differences were statistically significant. Therefore, no definitive conclusions could be drawn regarding the effect of moisture content on the impact strength of 3D-printed nylon parts based on these data alone. Further testing with a larger sample size is necessary to establish any meaningful trends or correlations.

Figure 7.

Izod impact strength of 3D-printed nylon parts.

3.5. Thermal Testing

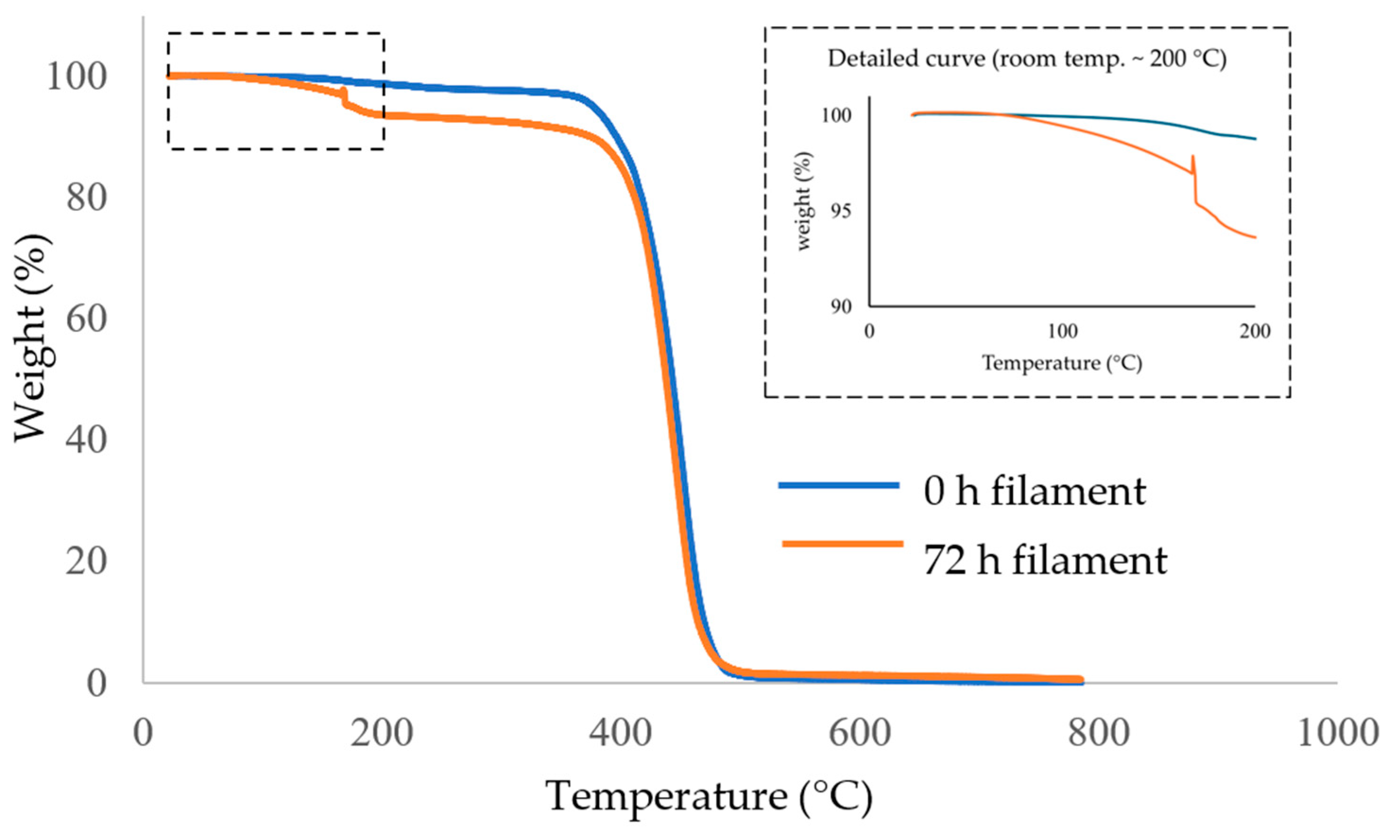

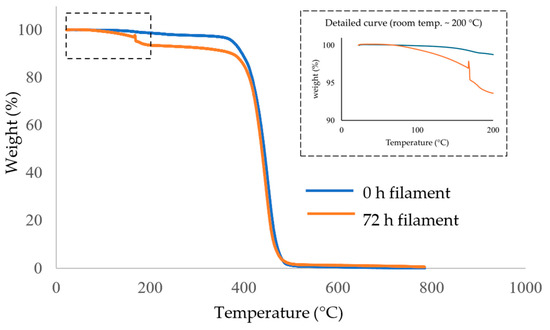

Thermogravimetric analysis (TGA) was conducted to evaluate the thermal behavior of nylon filaments in both dry (0 h) and moisture-conditioned (72 h) states. Samples were prepared by cutting small segments of nylon filament and placing them on the microbalance of a TA SDT 650 DSC/TGA instrument (dynamic temperature precision ± 0.5 °C and weighing accuracy ± 0.5%). Each sample was subjected to a controlled heating program at a rate of 20 °C per minute, starting from room temperature and increasing up to 800 °C, under a continuous nitrogen purge to maintain an inert environment. The resulting TGA curves, presented in Figure 8, reveal distinct thermal responses between the virgin and moistened nylon filaments. For the dry (0 h) nylon, thermal degradation began at approximately 417 °C, with the material exhibiting a total mass loss of around 99%, indicating complete decomposition of the polymer matrix. In contrast, the filament exposed to moisture for 72 h showed additional behavior in the lower temperature range of the TGA curve. Specifically, a small but noticeable weight loss occurred around 167 °C, suggesting that absorbed moisture within the polymer structure was evaporated at this stage. This minor mass loss is likely responsible for the fluctuations observed in the early portion of the TGA curve. Moreover, the onset degradation temperature for the moistened filament was slightly reduced compared to that of the dry sample. This shift implies a potential alteration in the thermal stability of the nylon due to moisture absorption. One plausible explanation is that the presence of moisture induces hydrolysis, leading to partial cleavage of the polymer chains. This degradation mechanism can reduce molecular weight and subsequently lower the temperature at which thermal breakdown begins. These findings highlight the sensitivity of nylon’s thermal properties to moisture exposure and underscore the importance of moisture control for applications requiring precise thermal and mechanical performance.

Figure 8.

TGA curves of 0 h and 72 h moistened nylon filaments.

The impact of moisture on 3D printing with nylon filament, as demonstrated in this study, is a critical factor that demands close attention for ensuring consistent part quality. Nylon is a hygroscopic material, meaning it readily absorbs moisture from the environment. This moisture absorption significantly affects the filament’s behavior during the extrusion process, leading to issues such as poor surface finish, irregular material flow, and compromised mechanical properties in the final printed parts. Furthermore, thermal properties are also influenced, as evidenced by the slight changes observed in thermogravimetric analysis (TGA) results. To achieve high-quality and reliable 3D-printed nylon components, stringent moisture control measures must be implemented throughout the printing workflow. First and foremost, nylon filament should be stored in vacuum-sealed packaging or within a dry box equipped with desiccant materials when not in use. This prevents prolonged exposure to ambient humidity, which can quickly degrade filament quality. When preparing for printing, the use of an enclosed and heated chamber is highly recommended to minimize environmental moisture uptake during the build process. If the filament has been left exposed to open-air conditions or stored improperly for any duration, it is advisable to conduct a moisture content analysis before printing. Should the moisture level be elevated, the filament must undergo a controlled drying process, typically in a filament dryer or a low-temperature oven, to restore optimal printability. Additionally, establishing standardized operating procedures—including environmental humidity monitoring, material conditioning protocols, and moisture level thresholds—will help ensure the repeatability and mechanical reliability of nylon’s 3D-printed parts. By adopting these preventive practices, users can significantly reduce variability in part performance and maintain the structural and functional integrity of components across different production runs, such as 3D printing lightweight structures of polymers [33]. Ultimately, effective moisture management is essential for unlocking the full potential of nylon as a high-performance 3D printing material.

4. Conclusions

This study examines the relationship between the moisture content of 3D printing nylon filament and its exposure time in a constant humid environment. Moisture measurements confirm the hygroscopic nature of nylon filament. The adverse effects of moisture on nylon filament are evident through the analysis of extruded materials, surface finish, and tensile properties of nylon specimens. The results indicate that a highly moistened filament led to significant degradation of extruded nylon material, resulting in an irregular surface finish. Additionally, the tensile properties, particularly ductility, were markedly reduced due to the combined effects of water molecules interacting with the nylon filament. The TGA results exhibit the influence of moisture on the nylon degradation with elevated temperature. To ensure consistent quality in 3D-printed parts, the development of operational guidelines or standards for handling and storing nylon filaments is strongly recommended. These measures are essential to mitigate moisture-related issues and maintain reliable part performance.

Author Contributions

Conceptualization, H.G.; Validation, L.W.; Formal analysis, L.W. and Y.Z.; Investigation, M.R., Z.W. and Y.Z.; Data curation, H.G.; Writing—original draft, H.G.; Project administration, H.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Michael Runzi was employed by the company Outpost Technologies. Author Zezheng Wang was employed by the company Double Medical Technology Inc. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Klenam, D.E.P.; McBagonluri, F.; Asumadu, T.K.; Osafo, S.A.; Bodunrin, M.O.; Agyepong, L.; Osei, E.D.; Mornah, D.; Soboyejo, W.O. Additive manufacturing: Shaping the future of the manufacturing industry—Overview of trends, challenges and opportunities. Appl. Eng. Sci. 2025, 22, 100224. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies, 3rd ed.; Springer: Cham, Switzerland, 2020; pp. 188–191. [Google Scholar]

- Kleba-Ehrhardt, R.; Jastram, B.; Heinze, C.; Gordei, A.; Gurlo, A.; Karl, D. Effect of relative humidity on powder flowability and powder bed formation in additive manufacturing. Addit. Manuf. 2025, 109, 104862. [Google Scholar] [CrossRef]

- Mattingly, F.; Kumar, V.; Chawla, K.; Bras, W.; Kunc, V.; Duty, C. Vacuum-assisted extrusion to reduce internal porosity in large-format additive manufacturing. Addit. Manuf. 2025, 97, 104612. [Google Scholar]

- Al-Mazrouei, N.; Al-Marzouqi, A.H.; Ahmed, W. Characterization and sustainability potential of recycling 3D-printed nylon composite wastes. Sustainability 2022, 14, 10458. [Google Scholar] [CrossRef]

- Agrawal, K.; Bhat, A.R. Advances in 3D printing with eco-friendly materials: A sustainable approach to manufacturing. RSC Sustain. 2025, 3, 2582–2604. [Google Scholar] [CrossRef]

- Tuli, N.T.; Khatun, S.; Rashid, A.B. Unlocking the future of precision manufacturing: A comprehensive exploration of 3D printing with fiber-reinforced composites in aerospace, automotive, medical, and consumer industries. Heliyon 2024, 10, e27328. [Google Scholar] [CrossRef]

- Lee, S.; Wee, J.W. Effect of temperature and relative humidity on hydrolytic degradation of additively manufactured PLA: Characterization and artificial neural network modeling. Polym. Degrad. Stab. 2024, 230, 111055. [Google Scholar] [CrossRef]

- Lendvai, L.; Fekete, I.; Jakab, S.K.; Szarka, G.; Verebélyi, K.; Iván, B. Influence of environmental humidity during filament storage on the structural and mechanical properties of material extrusion 3D-printed poly (lactic acid) parts. Results Eng. 2024, 24, 103013. [Google Scholar] [CrossRef]

- Palaniappan, M.; Tirlangi, S.; Mohamed, M.J.S.; Sathiya Moorthy, R.M.; Valet, S.V.; Boopathi, S. Fused deposition modelling of polylactic acid (PLA)-based polymer composites: A case study, development, properties, and industrial applications of 3D printed polymer composites. In Development, Properties, and Industrial Applications of 3D Printed Polymer Composites; Keshavamurthy, R., Tambrallimath, V., Davim, J.P., Eds.; IGI Global: Hershey, PA, USA, 2023; pp. 66–85. [Google Scholar]

- Menezes, O.; Roberts, T.; Motta, G.; Patrenos, M.; McCurdy, W.; Alotaibi, A.; Vanderpool, M.; Vaseghi, M.; Beheshti, A.; Davami, K. Performance of additively manufactured polylactic acid (PLA) in prolonged marine environments. Polym. Degrad. Stab. 2022, 199, 109903. [Google Scholar] [CrossRef]

- Kakanuru, P.; Pochiraju, K. Moisture ingress and degradation of additively manufactured PLA, ABS and PLA/SiC composite parts. Addit. Manuf. 2020, 36, 101529. [Google Scholar]

- Fang, L.; Yan, Y.; Agarwal, O.; Yao, S.; Seppala, J.E.; Kang, S.H. Effects of environmental temperature and humidity on the geometry and strength of polycarbonate specimens prepared by fused filament fabrication. Materials 2020, 13, 4414. [Google Scholar] [CrossRef] [PubMed]

- Wichniarek, R.; Hamrol, A.; Kuczko, W.; Górski, F.; Rogalewicz, M. ABS filament moisture compensation possibilities in the FDM process. CIRP J. Manuf. Sci. Technol. 2021, 35, 550–559. [Google Scholar] [CrossRef]

- Zaldivar, R.J.; Mclouth, T.D.; Ferrelli, G.L.; Patel, D.N.; Hopkins, A.R.; Witkin, D. Effect of initial filament moisture content on the microstructure and mechanical performance of ULTEM® 9085 3D printed parts. Addit. Manuf. 2018, 24, 457–466. [Google Scholar]

- Vidakis, N.; Petousis, M.; Michailidis, N.; Papadakis, V.; Mountakis, N.; Argyros, A.; Spiridaki, M.; Valsamos, J. Cyclic economy driven additive manufacturing: Valorization of mechanically recycled poly(methyl methacrylate) scrap in material extrusion 3D printing. J. Clean. Prod. 2025, 486, 144639. [Google Scholar]

- Nikiema, D.; Balland, P.; Sergent, A. Study of the mechanical properties of 3D-printed Onyx parts: Investigation on printing parameters and effect of humidity. Chin. J. Mech. Eng. Addit. Manuf. Front. 2023, 2, 100075. [Google Scholar] [CrossRef]

- Okwuosa, T.C.; Sadia, M.; Isreb, A.; Habashy, R.; Peak, M.; Alhnan, M.A. Can filaments be stored as a shelf-item for on-demand manufacturing of oral 3D printed tablets? An initial stability assessment. Int. J. Pharm. 2021, 600, 120442. [Google Scholar]

- Shahmirzadi, M.R.; Gholampour, A.; Kashani, A.; Ngo, T.D. Shrinkage behavior of cementitious 3D printing materials: Effect of temperature and relative humidity. Cem. Concr. Compos. 2021, 124, 104238. [Google Scholar] [CrossRef]

- Monson, L.; Braunwarth, M.; Extrand, C.W. Moisture absorption by various polyamides and their associated dimensional changes. J. Appl. Polym. Sci. 2008, 107, 355–363. [Google Scholar]

- Banjo, A.D.; Agrawal, V.; Auad, M.L.; Celestine, A.N. Moisture-induced changes in the mechanical behavior of 3D printed polymers. Compos. Part C Open Access 2022, 7, 100243. [Google Scholar]

- Pillay, S.; Vaidya, U.K.; Janowski, G.M. Effects of moisture and UV exposure on liquid molded carbon fabric reinforced nylon 6 composite laminates. Compos. Sci. Technol. 2009, 69, 839–846. [Google Scholar] [CrossRef]

- Hou, Y.; Panesar, A. The moisture absorption of additively manufactured short carbon fibre reinforced polyamide. Compos. Part A 2025, 188, 108528. [Google Scholar]

- Hadi, A.; Kadauw, A.; Zeidler, H. The effect of printing temperature and moisture on tensile properties of 3D printed glass fiber reinforced nylon 6. Mater. Today Proc. 2023, 91, 48–55. [Google Scholar]

- Achhammer, B.G.; Reinhart, F.W.; Kline, G.M. Mechanism of the degradation of polyamides. J. Res. Natl. Bur. Stand. 1951, 46, 391–421. [Google Scholar] [CrossRef]

- Fan, X. Mechanics of moisture for polymers: Fundamental concepts and model study. In Proceedings of the EuroSimE 2008—International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Micro-Systems, Freiburg im Breisgau, Germany, 20–23 April 2008; IEEE: Piscataway, NJ, USA, 2008. [Google Scholar]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D256; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2024.

- ISO 17295; Additive Manufacturing—General Principles: Part Positioning, Coordinates and Orientation. International Organization for Standardization: Geneva, Switzerland, 2023.

- Lay, M.; Thajudin, N.L.N.; Hamid, Z.A.A.; Rusli, A.; Abdullah, M.K.; Shuib, R.K. Comparison of physical and mechanical properties of PLA, ABS and nylon 6 fabricated using fused deposition modeling and injection molding. Compos. Part B 2019, 176, 107341. [Google Scholar]

- Ramesh, M.; Panneerselvam, K. Mechanical investigation and optimization of parameter selection for Nylon material processed by FDM. Mater. Today Proc. 2021, 46, 9303–9307. [Google Scholar]

- Shashikumar, S.; Sreekanth, M.S. The effect of printing parameters on tensile properties of thermoplastics prepared by fused deposition modeling (FDM) based additive manufacturing technique. Mater. Today Proc. 2023, 90, 256–261. [Google Scholar]

- Ngo, C.; Nguyen, Q.A.; Le, N.; Le, N.L.L.; Nguyen, Q.H. Fabrication of airy, lightweight polymer below-elbow cast by a combination of 3D scanning and 3D printing. In Proceedings of the IFToMM Asian Conference on Mechanism and Machine Science, Hanoi, Vietnam, 15–18 December 2021; Springer International Publishing: Cham, Switzerland, 2021; pp. 628–637. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).