1. Introduction

Renewable energies, particularly solar photovoltaics (PV), are key to mitigating climate change and advancing sustainable production [

1,

2]. Declining costs have made PV highly competitive [

3]; however, implementation faces challenges such as biodiversity loss and disposal of panels at the end of their lifespan. Additionally, climate change could impact renewable energy generation, with potential reductions of up to 40% in wind and hydroelectric power in certain regions [

4]. Nevertheless, PV has the potential to decarbonize 90% of the electricity sector and reduce greenhouse gas emissions by 4.9 Gt by 2050, covering up to 25% of global electricity demand [

5]. As prices of photovoltaic (PV) modules and related electronics have dropped significantly, the structural mounting system now accounts for an important share of the total system.

The most common problems in photovoltaic mounting system structures include several factors affecting their performance and durability. Limited access to proper panel cleaning can accelerate degradation, as moisture and pollutants negatively impact performance [

6]. In floating photovoltaic installations, wave action and wind can cause structural deformation, revealing insufficient robustness in specific designs under harsh environments [

7]. The use of low-quality components and absence of preventive maintenance increase the likelihood of early failures, particularly in critical elements such as inverters and batteries. Additionally, inadequate lightning protection can seriously damage the system [

8]. Environmental factors such as lightning storms and high temperatures can compromise system performance, reducing efficiency and causing component failures [

9].

Photovoltaic mounting structures are essential for solar energy systems and crucial in determining PV installations’ efficiency and environmental impact [

10]. These structures support the PV modules and optimize their orientation while also influencing thermal regulation, shading, and overall system performance [

11,

12]. The aim of this review is to evaluate and optimize PV mounting structures in terms of their mechanical performance, durability, and cost-effectiveness, emphasizing improvements in structural integrity under diverse environmental conditions and minimization of balance-of-system (BOS) costs. This area remains a significant challenge, leaving numerous areas open for further research.

Shademan et al. [

13] conducted an in-depth analysis of the relationship between the coefficients and the spacing between modules in solar panel structures, observing that an increase in this spacing leads to a reduction in the pressure difference between the windward and leeward sides. Similarly, Waqas et al. [

14] applied the finite element method (FEM) to assess the structural strength and reliability of photovoltaic systems, finding that the joints located at the center and base of the structure experienced greater deformations under various horizontal wind loads. Previous research has focused exclusively on the effects of aerodynamic forces on the structural behavior of ground-mounted photovoltaic systems with different solar array configurations.

Polymer-based alternatives have gained significant attention in exploring innovative materials for structural applications in solar energy systems. Shweta et al. [

15] studied structures made with polymeric materials, highlighting their potential as a strong alternative to traditional solar mounting designs due to their lightweight nature, high strength, and corrosion resistance. This paradigm shift leverages benefits of polymers such as their ease of manufacturing, low environmental impact, and design flexibility. This design approach supports the overarching goal of sustainable power generation by incorporating recyclable and eco-friendly components into systems alongside renewable solar energy. Zhiyu et al. [

16] introduced an innovative concept for floating photovoltaic (FPV) systems that can withstand harsh environmental conditions, including extreme wave heights exceeding 10 m. The design employs lightweight and standardized semi-submersible floaters configured as individual modules made from circular sustainable materials. This concept demonstrates outstanding performance in terms of modular motion and offers promising potential for further research and development.

Resch et al. [

17] reviewed various methods to prevent overheating of solar collection systems using polymer-based compounds. Kessentini et al. [

18] conducted simulations and experimental studies on technologies for mitigating collector overheating by attaching a transparent insulation material (TIM) to the rear side of the glass in a flat-plate collector. Yue Wu et al. [

19] studied flexible support structures for PV modules, highlighting advantages such as extensive span capability, rapid construction, speed and adaptability to complex environments. The authors proposed a novel support system based on a cable–truss structure, demonstrating excellent wind resistance performance. In summary, research on photovoltaic module structures has covered aspects ranging from aerodynamic design and structural resistance to using innovative materials and solutions tailored to complex environments and extreme conditions.

Recent developments in photovoltaic solar technology have focused on improving energy efficiency and optimizing the mechanical design and material selection for support structures. These decisions are increasingly influenced by the structural and climatic conditions of the installation sites, which can pose challenges such as high winds, heavy snow, corrosion, or seismic activity. Based on this, the following hypothesis is proposed: Environmental and structural conditions significantly determine the mechanical design strategies and material choices for photovoltaic support systems. From this hypothesis, three research questions emerge:

How do specific climatic factors such as wind load, temperature variation, and humidity affect the performance and longevity of different support structures in photovoltaic installations?

What recent innovations in mechanical design and materials have been most effective in enhancing the structural resilience of solar support systems across various environmental contexts?

How can photovoltaic support structures be systematically adapted to different geographic regions in order to mitigate risks related to local environmental stressors (e.g., corrosion, seismic activity, and extreme weather)?

To answer these questions, in this research we aim to develop a systematic review following the PRISMA methodology that identifies, classifies, and analyzes the main advances in structural design and the selection of materials used in photovoltaic mounting systems. Technical, regulatory, and environmental variables are considered to establish a comprehensive analytical framework for understanding how design decisions affect these systems’ efficiency, durability, and adaptability. This approach seeks to guide the development and implementation of sustainable and technically viable solutions in varying geographical and architectural contexts.

The rest of this paper is structured as follows.

Section 1 introduces the PRISMA methodology and reviews related work on mechanical design and material selection for support structures in photovoltaic systems. It also defines the research problem, emphasizing the need for a comprehensive understanding of how structural and climatic conditions influence the performance and reliability of solar systems. As this study addresses existing gaps by systematically analyzing the interaction between design strategies, material properties, and environmental demands,

Section 1 additionally outlines the specific contributions of this work.

Section 2 describes the PRISMA methodology and its application to engineering research, including the step-by-step procedure, inclusion and exclusion criteria, and rationale behind selecting relevant studies.

Section 3 presents the research process, results, and a critical analysis of the key patterns and trends identified in the literature.

Section 4 discusses the implications of the findings, proposes a classification framework for structural solutions based on environmental context, and compares this work with previous research. Finally,

Section 5 concludes the article by summarizing the main findings and suggesting opportunities for future research on photovoltaic support systems.

2. Materials and Methods

A systematic review is a form of scientific research in which the object of analysis consists of original primary studies that address the same topic. In this case, the review focuses on identifying the main factors influencing the design of solar panel mounts and analyzing the relevant variables and their percentage ranges under different conditions. This review aims to provide a clear and precise answer to the previously posed research questions. The PRISMA review method allows us to obtain a comprehensive and reliable view of the subject while minimizing possible biases in the research [

20,

21].

The PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) methodology offers a set of standardized guidelines to improve clarity, quality, and transparency when preparing systematic reviews and meta-analyses. Its primary purpose is to support researchers in conducting and presenting these types of studies in a more structured and complete manner, particularly in health contexts. The PRISMA methodology includes a checklist of 27 key elements to consider when writing a review along with a flowchart describing the process followed at each analysis stage. Implementing this methodology helps to increase scientific rigor, facilitate understanding of the results, and promote more transparent research practices [

22,

23].

2.1. Information Search

The most representative keywords related to the design and feasibility of support structures for solar photovoltaic systems were identified for this search. The Scopus database was used as the main source due to its extensive repository of scientific literature exceeding 75 million records and its advanced filtering functions that allows results to be refined according to different parameters. In addition, Scopus offers bibliometric indicators such as the h-index and CiteScore, which help to assess the relevance and impact of selected articles. The Scopus platform is continuously updated, which guarantees access to recent research in various areas of knowledge. The following set of key terms was used for the search: TITLE-ABS-KEY ((“solar photovoltaic system”) AND (“supports” OR “structures”)).

2.1.1. Selection of the Structure Type

The structural system anchors the photovoltaic panels to the rooftops or the ground. Its design depends on installation conditions, and can be classified as follows:

Coplanar structures are installed directly on sloped roofs; they optimize available space and minimize visual impact, offering a discreet aesthetic.

Triangular supports are used when the roof’s tilt or orientation is suboptimal. They adjust the panel angle to enhance solar exposure and improve energy yield.

Tracking systems are equipped with one or two axes; these dynamic structures follow the Sun’s movement to maximize irradiance capture, boosting energy production by up to 30% in high-radiation zones. Common types include:

- –

Dual-axis: Maintain panels perpendicular to sunlight throughout the day.

- –

Polar axis: Align rotation with the Earth’s meridian containing the Sun.

- –

Azimuthal axis: Rotate to track the Sun’s position on the local meridian.

- –

Horizontal axis: Oriented north–south to follow the Sun across the sky.

Fixed (static) structures contain panels arranged in a single optimized position. This is the most widely arrangement used due to its simplicity and its compatibility with rooftops and architectural settings.

East–west gable structures feature panels facing both directions to extend daily solar utilization, which is especially useful in locations with variable sun paths.

2.1.2. Selecting the Module’s Angle of Inclination Concerning the Installation Surface

In photovoltaic installations, the generator should ideally face south in the northern hemisphere and north in the southern hemisphere. The tilt angle must balance optimal production during summer and winter. A common guideline is to set the tilt at about 10° less than the site’s latitude. Regardless of method, the inclination should not fall below 10° in order to ensure that rainwater can effectively clean dust and debris from the panels. For greater accuracy, Equation (

1) can be applied using the tilt and latitude (in degrees) [

24,

25,

26]:

where:

= the optimum angle of inclination.

= the latitude of the installation site.

2.1.3. Determining the Azimuth of the Solar Modules

The azimuthal angle indicates the orientation of the modules. For locations in the northern hemisphere this is defined as the measured distance between the projection on the horizontal plane of the direction normal to the tilted surface and the south direction (in the southern hemisphere, the direction is due north) [

27]. To determine the optimal azimuthal angle for solar panels, it is necessary to consider the latitude of the location, the orientation that receives the most sunlight, and the purpose of the solar installation.

Positive values of azimuthal angles tend to be oriented towards the west, while negative values tend to the east. Good results are obtained when the modules are oriented southeast or southwest with a deviation of up to 45 degrees from the south direction. A slight elongation of the module surface can compensate for larger deviations.

2.1.4. Structural Support Calculation

In addition to considering seismic activity, the structural design of photovoltaic support systems must account for several key factors: [

28]:

Structural self-weight.

Panel weight.

Beam loading.

Wind-induced loads.

Joint strength analysis.

Engineers employ specialized simulation tools to assess these loads and ensure structural integrity. Software such as Autodesk Inventor, SAP2000, STAAD.Pro, ANSYS Mechanical, and SolidWorks Simulation are frequently used to model static and dynamic effects, including the performance of joints, anchorage systems, and counterweights. These tools offer reliable 3D analysis capabilities and have been widely validated in renewable energy applications.

2.1.5. Weight of the Structure

The support system is critical in securing photovoltaic panels and ensuring long-term stability. A well-optimized structure improves operational safety and helps to reduce overall system costs. Current research in PV engineering focuses on achieving a balance between structural efficiency and cost-effectiveness. Common support designs suited to specific environmental and operational conditions include fixed, adjustable, and floating systems [

29].

2.1.6. Weight of the Panels

The weight of photovoltaic panels varies depending on their type, size, and material. There are three types of material: monocrystalline, polycrystalline, and thin-film. Equation (

2) computes the weight of the panels [

30]:

where:

P = specified weight.

A = area.

= solar panel weight.

2.1.7. Load on the Beams

Equation (

3) computes the load on the beams:

where:

N = load on the beam.

= weight of the panel plus accessories.

= the total number of panels on the beam.

= length of the beams.

= linear weight of the conductor gauge.

2.1.8. Load Due to Wind Action

The wind speed acting on the front surface of the panels is determined by Equation (

4):

where:

V = wind speed.

= angle between the wind direction and the panel.

2.1.9. Wind Force on the Panels

Equation (

5) uses the fluid–elastic model to determine the force exerted by the wind on the panels. In this equation, the air’s mass density and pressure coefficients remain unchanged. Calculating the wind force is necessary because the stress applied to the support structures increases as the wind increases [

31]:

where:

= air density at sea level.

= drag coefficient of flat surfaces.

A = projected area of the panel.

= frontal wind speed.

2.1.10. Calculation Method

Equations (

6) and (

7) provide the wind pressure on the panels and mounting structures:

where:

= basic characteristic wind pressure for a 25-year recurrence period.

= wind speed in the region.

= recurrence coefficient for 25 years.

= site coefficient considering an exposed site.

= height coefficient.

= gust coefficient.

= area reduction coefficient.

= shape coefficient.

2.1.11. Calculation of Joint Strength

The methodology from Dobrovolski’s machine elements textbook calculates threaded joints in the panel support structure. The method applies to threaded joints without preloading during assembly.

In this case, the main failure mode is the bolt’s tensile failure. Equation (

8) provides the strength condition:

where:

= bolt diameter up to the outer edge of the thread (nominal diameter).

P = axial load applied to the joint.

= allowable tensile stress.

In addition to tensile failure, it is evident that other failure modes may occur, such as shearing of the bolt head, bolt thread, or nut thread as well as bending or crushing of the thread flanks.

Equations (

9) and (

10) provide the shear calculation of the bolt head to avoid failure along the cylindrical surface:

where:

= shear stress.

= bolt diameter at the base of the thread.

h = height of the bolt head.

= allowable shear stress.

The shear stress is determined by the following equation:

where:

H = thread height.

= thread height filling coefficient ( = 1 for triangular threads).

The thread flanks are assumed to act as cantilever beams for this computation. The distributed load on the thread surface is replaced by a concentrated force

, where z represents the number of thread turns applied at the midpoint of the thread’s working height (

), as seen in Equation (

11):

where:

= bending stress.

= half of the working height of the thread.

b = theoretical distance between thread flanks.

= allowable bending stress.

2.2. Criteria for Selection and Exclusion of Research

A systematic review must follow well-defined strategies and conditions to guarantee the reliability and precision of the findings. This type of study requires objectivity and methodological rigor both in qualitative and quantitative approaches as well as the application of specific tools that support data integration and the evaluation of study quality.

Despite their apparent simplicity, systematic reviews have gained popularity, especially among novice researchers, leading to inconsistencies in their quality. Although they have the potential to generate high-impact results, many such reviews are conducted without the necessary methodological rigor. The lack of universally accepted guidelines often compromises their reliability. Therefore, developing a clear and robust protocol is essential to ensure the transparency and credibility of the review process.

This research applied the following exclusion criteria:

Keyword Selection: The main keywords were selected to identify studies focusing on solar photovoltaic structural supports and mounting systems (PSS).

Timeframe Limitation: Only articles published from 2018 to 2025 were considered.

Scope Restriction: Studies from unrelated disciplines, such as neuroscience, dentistry, agriculture and biochemistry, were excluded in order to maintain a focus on engineering and energy-related topics.

Document Type: The selection process included only peer-reviewed research articles, excluding reviews and other publications such as conference review papers.

Technical Relevance: The selection process excluded articles primarily focused on MPPT, DC–DC converters, electric vehicles, fuzzy logic, or energy storage systems, as these topics fall outside the specific scope of support structures for PSS.

Energy System Focus: Studies centering on electric power distribution, transmission, inverters, battery systems, or microgrids were removed, as their focus diverges from the structural and mechanical design of photovoltaic support systems.

Non-Relevant Keywords: Studies on fossil fuels, greenhouse gas emissions, or subjects unrelated to physical infrastructure (such as software control or electrical system protection) were excluded.

Final Search Code: TITLE-ABS-KEY ((“solar photovoltaic system”) AND (“supports” OR “structures”)) AND PUBYEAR > 2018 AND (EXCLUDE (SUBJAREA,“NEUR”) OR EXCLUDE (SUBJAREA,“DENT”) OR EXCLUDE (SUBJAREA,“BIOC”) OR EXCLUDE (SUBJAREA,“AGRI”)) AND (EXCLUDE (DOCTYPE,“re”)) AND (EXCLUDE (EXACTKEYWORD,“MPPT”) OR EXCLUDE (EXACTKEYWORD,“DC-DC Converter”) OR EXCLUDE (EXACTKEYWORD,“Electric Vehicle”) OR EXCLUDE (EXACTKEYWORD,“Fuzzy Logic”) OR EXCLUDE (EXACTKEYWORD,“Vehicle-to-grid”) OR EXCLUDE (EXACTKEYWORD,“Maximum Power Point Tracking (MPPT)”) OR EXCLUDE (EXACTKEYWORD,“Electric Load Flow”) OR EXCLUDE (EXACTKEYWORD,“Gas Emissions”) OR EXCLUDE (EXACTKEYWORD,“Maximum Power Point”) OR EXCLUDE (EXACTKEYWORD,“Battery Storage”) OR EXCLUDE (EXACTKEYWORD,“Battery Energy Storage Systems”) OR EXCLUDE (EXACTKEYWORD,“Electric Power Distribution”) OR EXCLUDE (EXACTKEYWORD,“Electric Power Generation”) OR EXCLUDE (EXACTKEYWORD,“Secondary Batteries”) OR EXCLUDE (EXACTKEYWORD,“Electric Loads”) OR EXCLUDE (EXACTKEYWORD,“Electric Vehicles”) OR EXCLUDE (EXACTKEYWORD,“Microgrids”) OR EXCLUDE (EXACTKEYWORD,“Greenhouse Gases”) OR EXCLUDE (EXACTKEYWORD, “DC-DC Converters”) OR EXCLUDE (EXACTKEYWORD,“Electric Power System Control”) OR EXCLUDE (EXACTKEYWORD,“Electric Inverters”) OR EXCLUDE (EXACTKEYWORD,“Electric Power Transmission Networks”) OR EXCLUDE (EXACTKEYWORD,“Photovoltaic Cells”) OR EXCLUDE (EXACTKEYWORD,“Maximum Power Point Tracking”) OR EXCLUDE (EXACTKEYWORD,“Fossil Fuels”) OR EXCLUDE (EXACTKEYWORD,“Electricity Generation”) OR EXCLUDE (EXACTKEYWORD,“Carbon”) OR EXCLUDE (EXACTKEYWORD,“Electric Batteries”) OR EXCLUDE (EXACTKEYWORD,“Electric Power System Protection”) OR EXCLUDE (EXACTKEYWORD,“Microgrid”) OR EXCLUDE (EXACTKEYWORD,“Fossil Fuel Power Plants”))

2.3. Analysis Guide for Systematic Reviews

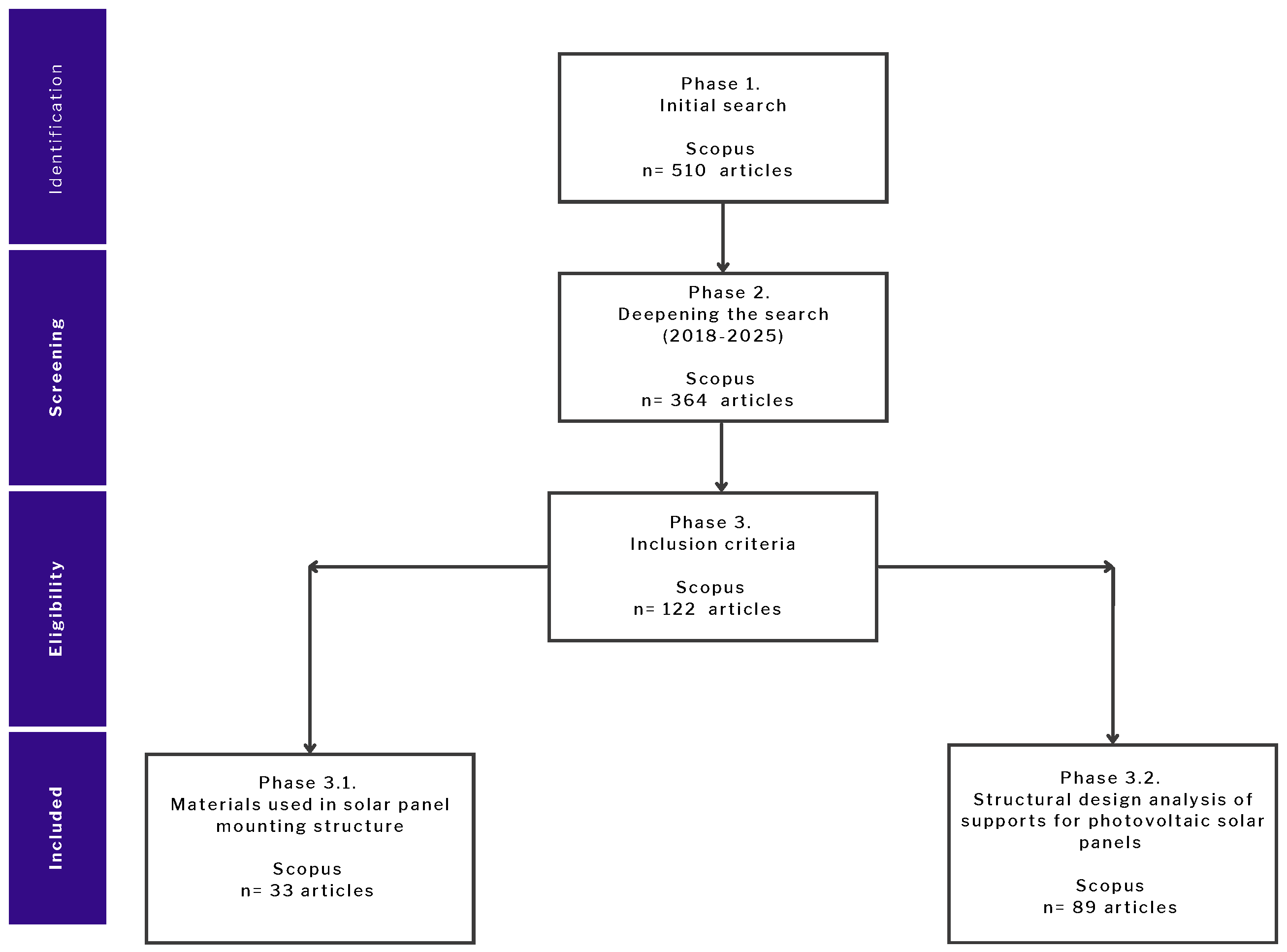

This study followed the structured multi-phase methodology illustrated in

Figure 1. It began with an initial search in the Scopus database, which identified 510 articles. The refinement process adjusted the search to focus on the 2018–2025 period, reducing the selection to 354 articles. After applying the inclusion criteria, 122 relevant articles were identified and classified into two main analytical categories, designated Phase 3.1 and Phase 3.2.

2.3.1. Phase 3.1: Materials Used in Solar Panel Mounting Structures

In this phase (n = 33 articles), the focus was on materials used for mounting systems in photovoltaic solar panels. Key aspects included:

Use of lightweight metals (e.g., aluminum, galvanized steel)

Anti-corrosive coatings

Innovations in composite materials

Comparative evaluations of structural strength and durability

Environmental factors influencing material selection (climate, humidity, solar exposure).

2.3.2. Phase 3.2: Structural Design Analysis of Photovoltaic Solar Panel Supports

This phase (n = 89 articles) analyzed the structural design criteria for support systems. The analysis identified key factors influencing the performance and efficiency of photovoltaic systems.

Structural design: Panel orientation, tilt angle, support geometry

Electrical configuration: Series/parallel connection, inverter placement

Dynamic factors: Wind loads, seismic forces, thermal expansion

Installation strategies: Use of solar tracking systems (single-axis, dual-axis)

Compliance with structural design standards for solar energy systems.

2.3.3. Synthesis of the Analytical Framework

Both phases highlight how various interrelated factors (technological, design-related, and operational) influence the performance of photovoltaic solar systems. Material selection, appropriate structural design, and preventive maintenance all contribute to a system’s efficiency, durability, and sustainability. Additionally, emerging trends such as energy storage solutions, smart grid integration, and advanced processes for manufacturing and recycling reinforce the role of photovoltaic solar systems as a sustainable energy solution.

4. Discussion

This section discusses the findings of the study and their relevance in different contexts, including residential and industrial applications. It also addresses the limitations of previous studies, pointing out possible biases or gaps in current knowledge. Finally, it discusses the practical implications of the findings and proposes future lines of research that may enrich the understanding and application of the studied factors in various scenarios.

4.1. New Perspectives in the Design of Supports for Solar Photovoltaic Systems

The present article analyzes publications from 2019 onward, focusing on the designs and materials used in solar panels. Our review identifies the main trends in the scientific literature during this period. As shown in

Figure 7, there has been a significant increase in interest in panel structures since 2023, with a notable rise in research related to both design and materials. However, the trend suggests that the most significant innovations are centered on searching for more efficient materials, accounting for 57.6% of the total publications, with 32.2% concentrated between 2023 and 2024.

Although the overall increase in the number of studies between 2023 and 2024 was 4.6%, the development of new technologies in both materials and design continues to grow. In fact, 26.8% of the total number of publications recorded in 2024 have already been reported in the first three months of 2025 alone, representing a 1.6% increase. These results indicate a sustained growth trend.

One particularly noteworthy aspect is the increasing use of computational science and mathematics tools to optimize solar panel structures (see

Figure 8). While the fields of engineering and energy still lead in terms of publication volume, the integration of these tools has been growing steadily since 2021. In 2022, their usage doubled compared to the previous year, and by 2023 their impact reached a level comparable to that of technological advancements in engineering and energy. This evolution aligns with global trends toward applying advanced algorithms and artificial intelligence in the energy sector.

4.2. Trends in the Design and Projection of Supports for Solar Photovoltaic Systems

Material selection considers essential aspects such as performance, cost, availability, and environmental impact. In addition, mechanical and physical properties such as strength, conductivity, manufacturability, and long-term reliability all play critical roles in determining suitability. ASTM International is widely recognized for developing technical standards to ensure the quality and safety of various materials, products, and industry processes. For this study, material selection was primarily guided by compliance with the following standards:

- -

ASTM A36: Standard that specifies a carbon structural steel.

- -

ASTM B209: Standard establishing requirements for sheets and plates of aluminum and its alloys used in structural applications.

- -

ASTM D638: Test method used to determine the tensile properties of plastics.

The design of mounting structures for solar panels involves a comprehensive process that begins with the project definition phase, where key parameters such as installation type, panel specifications, and site location are established to guide subsequent decisions. The environmental and structural evaluation phase adapts the design to local conditions, including wind, snow, seismic activity, and corrosion risks, ensuring the structure’s safety and durability. During the materials and mechanical design phase, durable and recyclable materials such as galvanized steel and anodized aluminum are selected to prioritize modularity and ease of assembly. Additionally, these materials are chosen for their ability to accommodate thermal expansion, ensure proper drainage, and facilitate adequate ventilation. The electrical integration phase ensures efficient and safe cable routing, easy access for maintenance, scalability for future expansions, and compliance with relevant technical standards.

The compliance with norms and standards phase ensures that the design adheres to local and international codes such as NEC, CFE, IEC, and UL, preventing legal issues and ensuring safe system operation. Finally, the sustainability analysis and cost evaluation phase considers the long-term environmental impact and economic feasibility of the project by analyzing material choices, installation methods, maintenance needs, and return on investment (ROI). All of these stages are closely interrelated, and proper planning is essential for achieving an efficient, safe, cost-effective, and sustainable photovoltaic system.

Figure 9 shows the recommended process to be followed for the design of structures for solar photovoltaic systems.

4.3. Comparative Table of Review Articles on Structures for Solar Photovoltaic Systems

Unlike other review articles focused on support structures for photovoltaic systems, the present work offers five key contributions that distinguish it from the current state of the art. First, previous studies have focused exclusively on energy efficiency or advances in materials; this article systematically integrates environmental and structural factors as critical variables in the design of support systems. This perspective enables a more comprehensive understanding of photovoltaic installations’ fundamental challenges under diverse geographic and climatic conditions.

Second, we employ the PRISMA methodology, which remains uncommon in applied engineering research. This approach reflects the methodological rigor and transparency of the literature selection and analysis process.

Third, in addition to reporting recent innovations, this study proposes a structured classification of technical solutions based on environmental context, facilitating their adaptation to various regions and extreme conditions.

Fourth, we conduct an integrated analysis of the interaction between mechanical design and material properties, which has generally been addressed in a fragmented or superficial manner by prior reviews. Finally, this study explicitly incorporates geographic adaptation criteria, considering environment-related risks such as corrosion, seismic activity, and extreme weather events that have often been excluded in other reviews on photovoltaic support systems.

These distinguishing elements are summarized in

Table 10, highlighting the topics addressed in this review that have gone uncovered in previous reviews. This table provides concrete evidence of the added value of this contribution in offering a more comprehensive, applied, and context-sensitive framework for the analysis and development of support structures in photovoltaic systems.

In contrast to previous reviews that have primarily focused on specific photovoltaic integration technologies such as building applications or flexible envelope systems, this study adopts a broader and more structured approach; rather than limiting our analysis to a single type of application or material, in this review we have systematically incorporated criteria for material selection, structural design variables, and environmental conditions that influence the performance of photovoltaic mounting systems across various contexts. By applying the PRISMA methodology, this review ensures a transparent, rigorous, and reproducible selection process that remains uncommon in applied engineering research. Furthermore, it introduces an analytical framework that categorizes technical solutions according to installation type, climatic conditions, and regulatory requirements, thereby offering a decision-making tool grounded in evidence. In addition to synthesizing existing knowledge, this work provides a practical reference for the design and implementation of photovoltaic systems, whether integrated into buildings or deployed in other configurations. As such, it provides a multidisciplinary and globally applicable guide for designing efficient, sustainable, and resilient structural solutions tailored to real-world project demands.

5. Conclusions

This review article systematically analyzes the key aspects involved in the design of mounting structures for photovoltaic solar systems, considering mechanical, environmental and regulatory criteria. The review emphasizes the importance of integrating early-stage elements such as project definition, environmental and structural evaluation, mechanical design and material selection, electrical integration, regulatory compliance, sustainability, and cost assessment. These stages are closely interrelated, and each is essential to ensuring an efficient, safe, and long-lasting solar installation.

Mechanical design plays a fundamental role, not only determining the structure’s resistance and stability against environmental loads such as wind, snow, or seismic activity but also guiding the selection of materials based on the installation type (ground-mounted, flat roof, or sloped roof) and ease of assembly. The criteria for selecting the materials must be carefully and precisely determined according to environmental conditions and structural demands.

For instance, mild steel is suitable for lightweight structures or rooftops with limited load capacity thanks to its flexibility and ease of machining. Due to its excellent corrosion resistance, galvanized steel is widely used in outdoor or industrial settings that are exposed to harsh climates. On the other hand, aluminum is advantageous in large-scale solar plants where the design must optimize both weight and ease of installation thanks to its exceptionally light weight. Proper integration between structural design and material selection is key to ensuring system durability, efficiency, and sustainability.

Current solar mounting system design trends are moving toward lighter, more modular, and more sustainable solutions that enable faster installation, lower environmental impact, and greater adaptability to diverse geographic and climatic conditions. There is also increasing interest in incorporating lifecycle analysis and return-on-investment considerations from the early design stages as well as ensuring adherence to international standards that support scalability in the global market. In this context, the present review provides a solid foundation that can guide future research and technological development towards addressing energy efficiency, climate resilience, and economic sustainability demands in photovoltaic projects.