Design and Fabrication of a Compact Evaporator–Absorber Unit with Mechanical Enhancement for LiBr–H2O Vertical Falling-Film Absorption, Part I: Experimental Validation

Abstract

1. Introduction

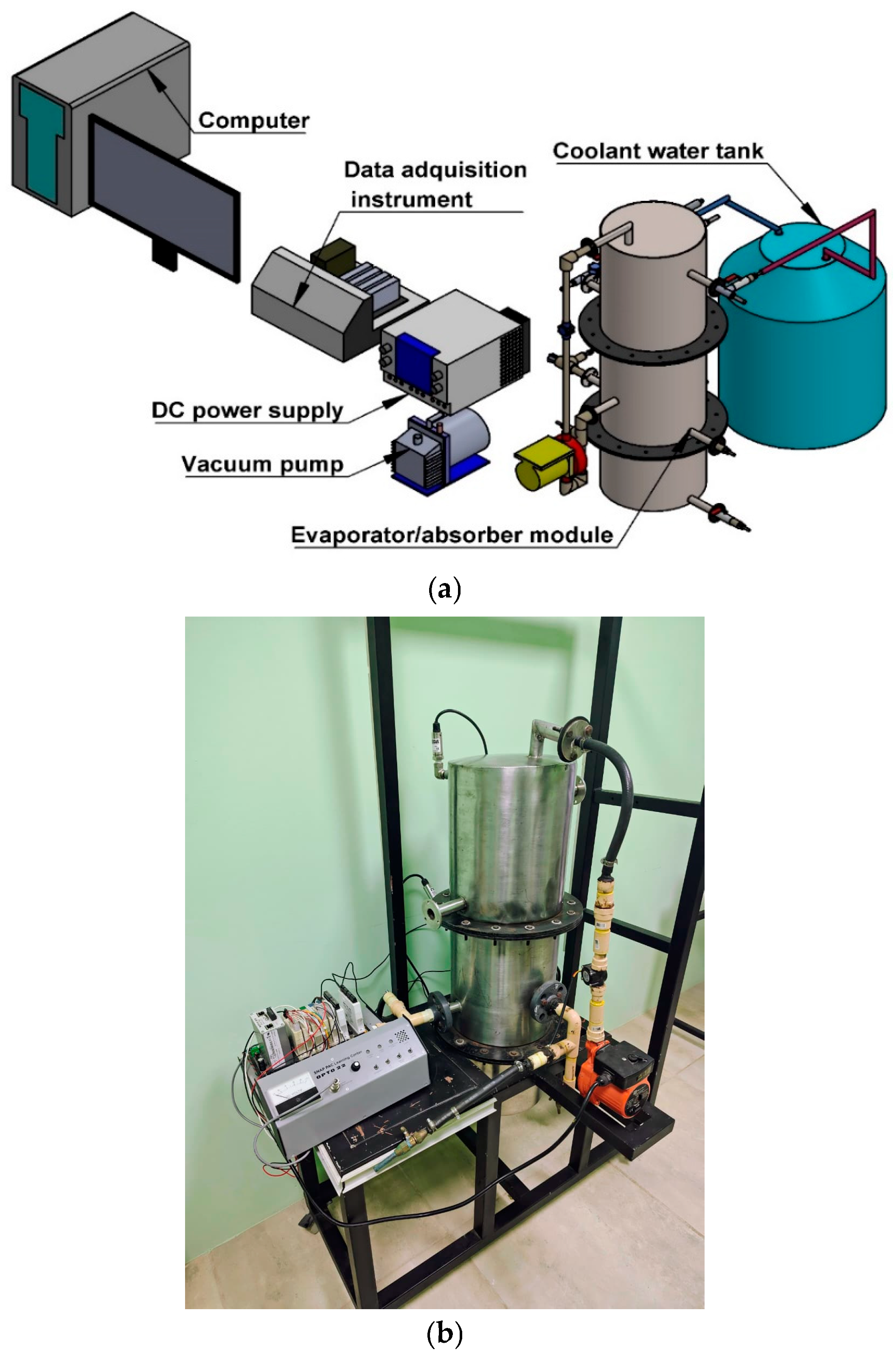

2. Materials and Methods

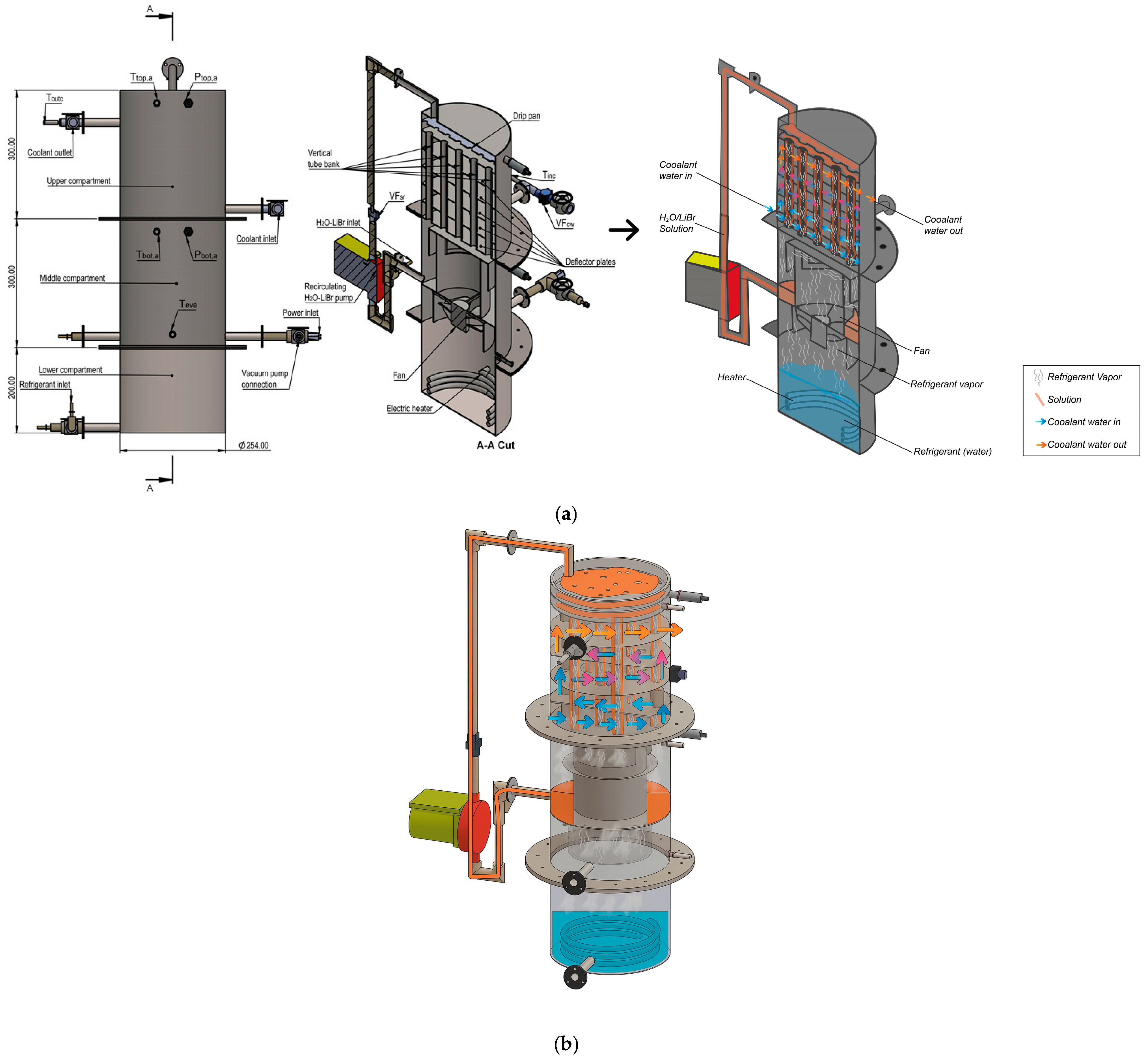

2.1. Design of the Evaporator–Absorber Unit and Experimental Setup

- The lower compartment (height: 200 mm) acts as a reservoir for the refrigerant (H2O), where the evaporation process occurs. It includes an H2O inlet and two internal electric heaters used to simulate thermal load by generating refrigerant vapor.

- The middle compartment (height: 300 mm) acts as a vapor transport chamber and temporary brine reservoir. It contains a 20 W fan, two temperature sensors (Teva and Tbot,a), one pressure sensor (Pbot,a), and a volumetric flow meter (VFsr). It also includes connections for the vacuum pump, brine recirculation loop, and initial loading of the LiBr solution. The middle section facilitates upward vapor movement from the evaporator and prevents cross-contamination between vapor and solution phases.An inner cylindrical shell surrounding the fan defines a vertical flow duct so that the refrigerant vapor generated in the lower compartment is drawn upward through this inner shell and discharged toward the upper absorber region.The integrated conveyance element is a compact 4-inch inline axial fan (≈100–110 mm outer diameter) housed inside the middle compartment. Fans of this size and rating typically operate at ≈2800 rpm under low static pressure and deliver nominal airflows of the order of 200 CFM (≈350 m3 h−1), consistent with the component in-stalled in the present bench. In this study, the fan was operated at its nominal fixed speed during all OFF/ON transitions, without external modulation.

- The upper compartment (height: 300 mm) serves as a cross-flow tubular absorber. Internally, it features:

- A perforated drip pan (2 mm holes) for uniform distribution of the falling film of LiBr solution.

- A vertical tube bank consisting of 43 stainless steel tubes (12.7 mm OD, 1.25 mm wall thickness, 250 mm height), where refrigerant vapor absorption takes place.

- On the shell side, coolant water flows across the tubes, directed by deflector plates spaced at 50 mm intervals, covering approximately three-quarters of the compartment’s cross-sectional area.

- Additional components include a pressure sensor (Ptop,a), temperature sensor (Ttop,a), and connections for coolant water inlet/outlet, where two temperature sensors (Tinc and Toutc) and a flow meter (VFcw) are installed.

2.2. Operating Cycle and Thermal Load Strategy

2.3. Data Reduction and Derived Metrics ()

- Tabs is the temperature in the absorber section;

- Tev is the evaporator temperature;

- , are the number of samples for fan-on and fan-off conditions, respectively.

2.4. Measurement System and Sensor Accuracies

2.5. Uncertainty and Error Propagation for ΔT, ΔP, and n

2.5.1. Temperatures and ΔT

2.5.2. Inferred Evaporator Pressure, Pev

2.5.3. Absorber Pressure and ΔP

2.5.4. Dimensionless Index, n

2.5.5. Reporting

3. Results

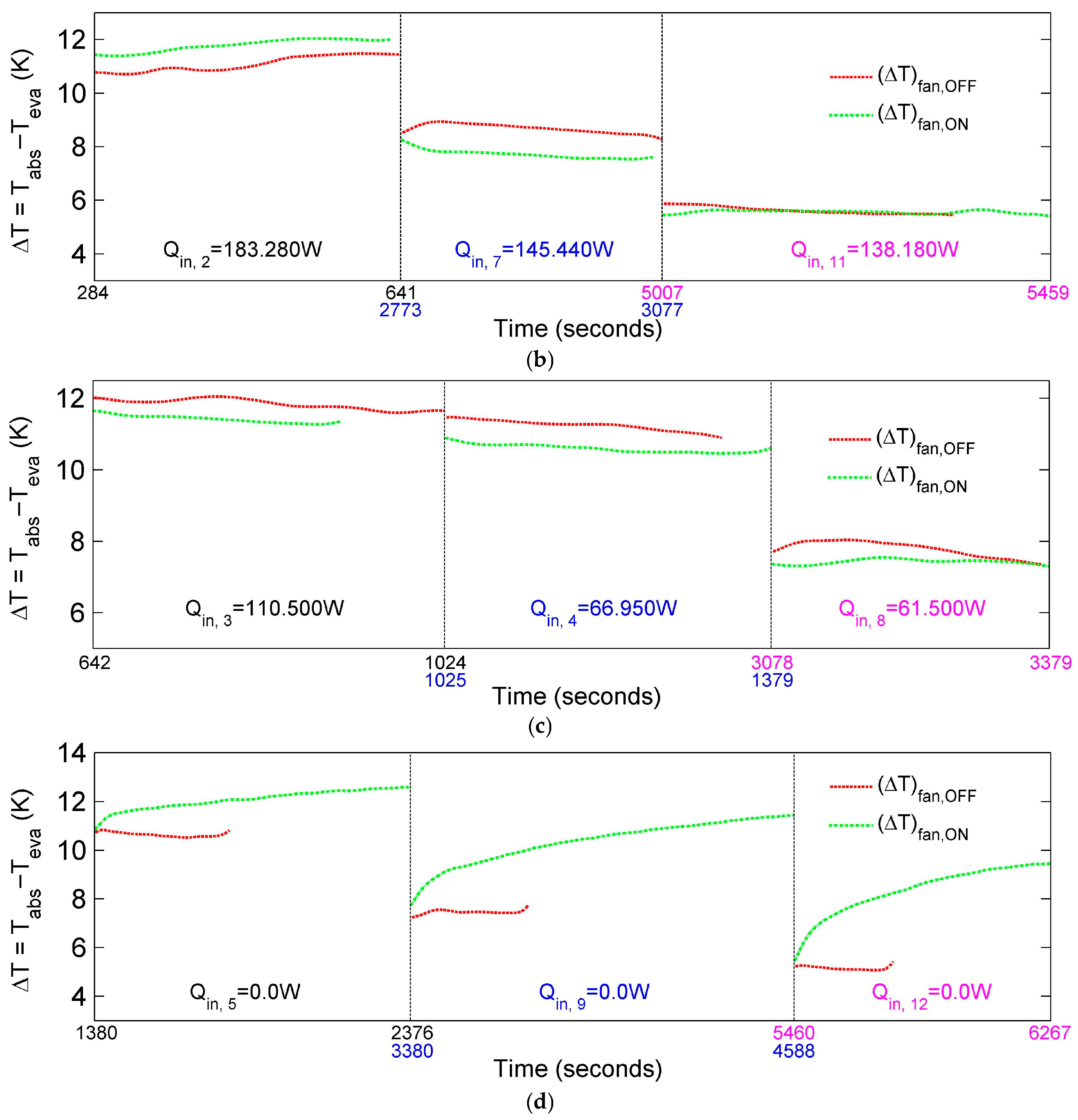

- Group 2 includes Qin,2, Qin,7, and Qin,11;

- Group 3 consists of Qin,3, Qin,4, and Qin,8;

- Group 4 is formed by Qin,5, Qin,9, and Qin,12.

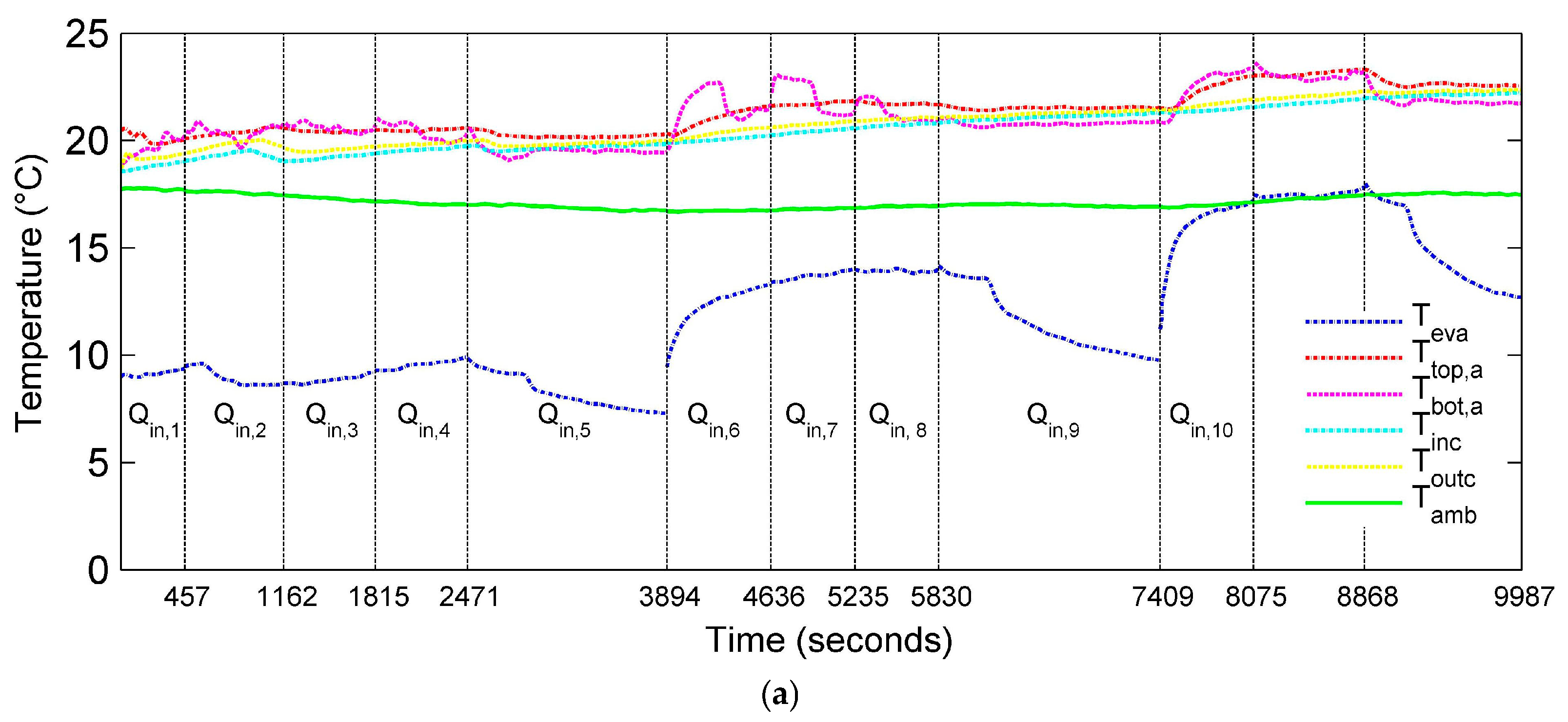

3.1. Experimental Results and Monitored Variables

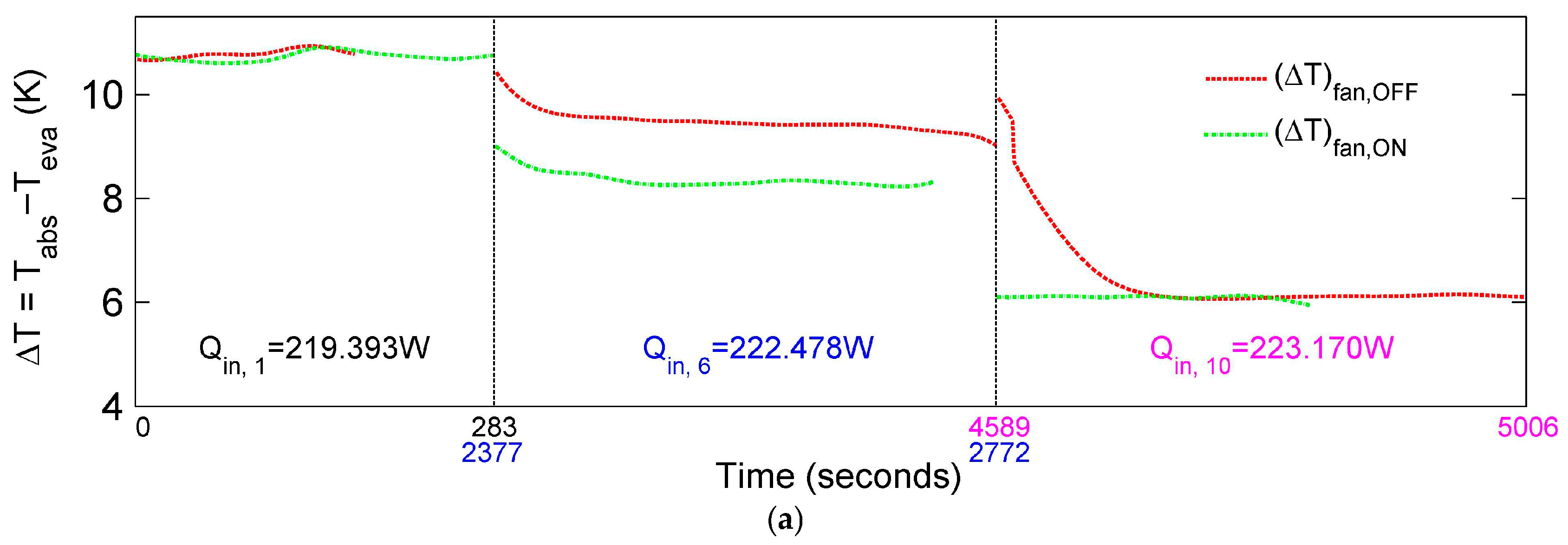

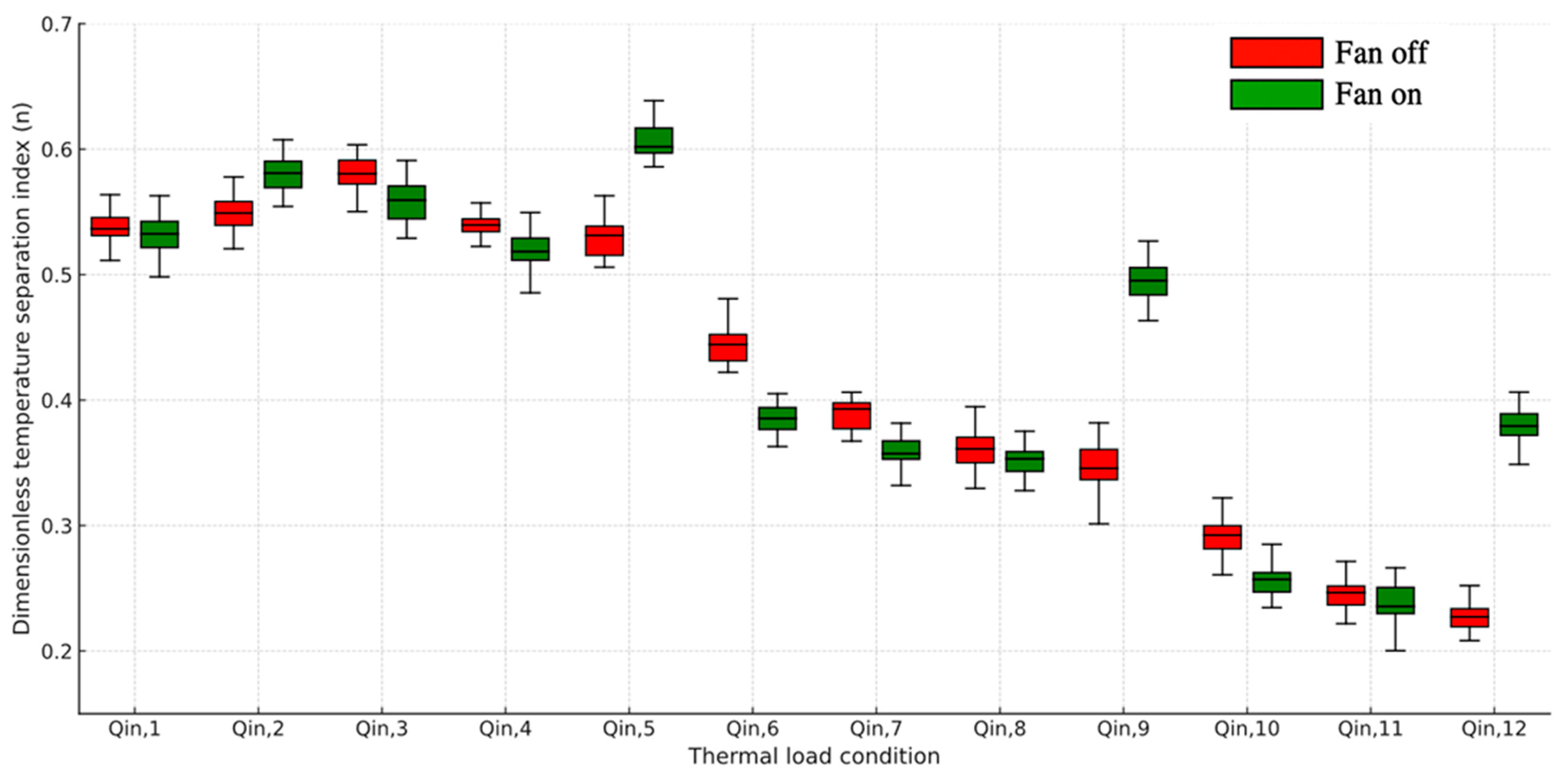

3.2. Dimensionless Temperature Separation Index (n)

- Under high thermal loads (Qin,1 to Qin,5), remains relatively high (>0.50), and the influence of the fan is marginal. Natural convection appears sufficient to maintain robust thermal gradients.

- In medium-to-low thermal loads (Qin,6 to Qin,11), gradually decreases, indicating reduced thermal separation due to lower energy input. The fan has a stabilizing role, though the improvement is limited.

- In zero thermal load conditions (Qin,5, Qin,9, Qin,12), the fan contributes significantly to enhancing . For example, in Qin,12, the index rises from 0.23 to 0.38, a 65% increase, evidencing that forced convection can partially restore thermal stratification in the absence of active heating.

4. Discussion

5. Conclusions

6. Patents

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

| Phase Qin,k | Fan | N | U (n) | ||||

|---|---|---|---|---|---|---|---|

| 1 | Off | 174 | 0.367423 | 0.023749 | 0.731431 | 0.731816 | 0.001238 |

| 1 | On | 284 | 0.367423 | 0.024016 | 0.731431 | 0.731825 | 0.001238 |

| 2 | Off | 358 | 0.367423 | 0.024194 | 0.731431 | 0.731831 | 0.001236 |

| 2 | On | 347 | 0.367423 | 0.023187 | 0.731431 | 0.731798 | 0.001234 |

| 3 | Off | 383 | 0.367423 | 0.023301 | 0.731431 | 0.731802 | 0.001234 |

| 3 | On | 270 | 0.367423 | 0.023666 | 0.731431 | 0.731814 | 0.001235 |

| 4 | Off | 301 | 0.367423 | 0.024159 | 0.731431 | 0.731830 | 0.001234 |

| 4 | On | 355 | 0.367423 | 0.024719 | 0.731431 | 0.731848 | 0.001237 |

| 5 | Off | 426 | 0.367423 | 0.024158 | 0.731431 | 0.731801 | 0.001238 |

| 5 | On | 997 | 0.367423 | 0.024719 | 0.731431 | 0.731848 | 0.001237 |

| 6 | Off | 396 | 0.367423 | 0.023990 | 0.731431 | 0.731798 | 0.001236 |

| 6 | On | 346 | 0.367423 | 0.023187 | 0.731431 | 0.731799 | 0.001234 |

| 7 | Off | 305 | 0.367423 | 0.022867 | 0.731431 | 0.731796 | 0.001232 |

| 7 | On | 294 | 0.367423 | 0.023525 | 0.731431 | 0.731798 | 0.001231 |

| 8 | Off | 293 | 0.367423 | 0.024013 | 0.731431 | 0.731799 | 0.001230 |

| 8 | On | 302 | 0.367423 | 0.024405 | 0.731431 | 0.731800 | 0.001229 |

| 9 | Off | 370 | 0.367423 | 0.023892 | 0.731431 | 0.731798 | 0.001228 |

| 9 | On | 1209 | 0.367423 | 0.024153 | 0.731431 | 0.731799 | 0.001226 |

| 10 | Off | 418 | 0.367423 | 0.024487 | 0.731431 | 0.731799 | 0.001224 |

| 10 | On | 248 | 0.367423 | 0.024931 | 0.731431 | 0.731800 | 0.001222 |

| 11 | Off | 340 | 0.367423 | 0.023711 | 0.731431 | 0.731798 | 0.001221 |

| 11 | On | 453 | 0.367423 | 0.024005 | 0.731431 | 0.731799 | 0.001220 |

| 12 | Off | 311 | 0.367423 | 0.024381 | 0.731431 | 0.731799 | 0.001218 |

| 12 | On | 808 | 0.367423 | 0.024812 | 0.731431 | 0.731800 | 0.001216 |

References

- Florides, G.A.; Tassou, S.A.; Kalogirou, S.A.; Wrobel, L.C. Review of solar and low energy cooling technologies for buildings. Renew. Sustain. Energy Rev. 2002, 6, 557–572. [Google Scholar] [CrossRef]

- Ochoa, A.A.V.; Dutra, J.C.C.; Henríquez, J.R.G.; Dos Santos, C.A.C. Dynamic study of a single-effect absorption chiller using neural LiBr/H2O. Energy Convers. Manag. 2016, 108, 30–42. [Google Scholar] [CrossRef]

- Manohar, H.J.; Saravanan, R.; Renganarayanan, S. Modelling of steam fired double-effect vapour absorption Energy. Energy Convers. Manag. 2006, 47, 2202–2210. [Google Scholar] [CrossRef]

- Martínez, J.C.; Martínez, P.J.; Bujerdo, L.A. Development and experimental validation of a simulation model to reproduce the performance of a 17.6 kW LiBr—Water absorption chiller. Renew. Energy 2016, 86, 473–482. [Google Scholar] [CrossRef]

- Beausoleil-Morrison, I.; Johnson, G.; Kemery, B.P. The experimental characterization of a lithium bromide–water absorption chiller and the development of a calibrated model. Sol. Energy 2015, 122, 368–381. [Google Scholar] [CrossRef]

- Stanciu, C.; Stanciu, D.; Gheorghian, A.T.; Tănase, E.B.; Dobre, C.; Spiroiu, M. Maximum exergetic efficiency operation of a solar powered H2O-LiBr absorption cooling system. Entropy 2017, 19, 676. [Google Scholar] [CrossRef]

- Aguilar-Jiménez, J.A.; Velázquez, N.; López-Zavala, R.; González-Uribe, L.A.; Beltrán, R. Simulation of a Solar-Assisted Air-Conditioning System Applied to a Remote School. Appl. Sci. 2019, 9, 3398. [Google Scholar] [CrossRef]

- Wang, J.; Yan, R.; Wang, Z.; Zhang, X.; Shi, Z. Thermal performance analysis of an absorption cooling system based on parabolic trough solar collectors. Energies 2018, 11, 2679. [Google Scholar] [CrossRef]

- Lin, P.; Wang, R.Z.; Xia, Z.Z. Numerical investigation of a two-stage air-cooled absorption refrigeration system for solar cooling. Renew. Energy 2011, 36, 1401–1412. [Google Scholar] [CrossRef]

- Yaxiu, G.; Yuyuan, W.; Xin, K. Experimental research on a new solar pump-free LiBr absorption system with second generator. Sol. Energy 2008, 82, 33–42. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Wang, R.Z.; Wang, H.B. Experimental evaluation of a variable effect LiBr—Water absorption chiller designed for high-efficiente solar cooling system. Int. J. Refrig. 2015, 59, 135–143. [Google Scholar] [CrossRef]

- Hernández-Magallanes, J.A.; Ibarra-Bahena, J.; Rivera, W.J.; Romero, R.; Gómez-Arias, E.; Dehesa-Carrasco, U.; Espinoza-Ojeda, O.M.; Kozhiparambil Chandran, S. Thermodynamic analysis of a half-effect absorption cooling system powered by low-enthalpy geothermal source. Appl. Sci. 2019, 9, 1220. [Google Scholar] [CrossRef]

- Wang, J.J.; Yang, K.; Xu, Z.-L.; Fu, C. Energy and exergy analyses of an integrated CCHP system with biomass air gasification. Appl. Energy 2015, 142, 317–327. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Y. Energy, exergy and environmental analysis of a hybrid combined cooling heating and power system utilizing biomass and solar energy. Energy Convers. Manag. 2016, 124, 566–577. [Google Scholar] [CrossRef]

- Kalinowski, P.; Hwang, Y.; Radermacher, R.; Al Hashimi, S.; Rodgers, P. Application of waste heat powered absorption refrigeration system to the LNG recovery process. Int. J. Refrig. 2009, 32, 687–694. [Google Scholar] [CrossRef]

- Popli, S.; Rodgers, P.; Eveloy, V. Gas turbine efficiency enhancement using waste heat powered absorption chillers in the oil and gas industry. Appl. Therm. Eng. 2013, 50, 918–931. [Google Scholar] [CrossRef]

- Sun, J.; Fu, L.; Zhang, S.; Hou, W. A mathematical model with experiments of single effect absorption heat pump using LiBr–H2O. Appl. Therm. Eng. 2010, 30, 2753–2762. [Google Scholar] [CrossRef]

- Chua, K.J.; Chou, S.K.; Yang, W.M. Advances in heat pump systems: A review. Appl. Energy 2010, 87, 3611–3624. [Google Scholar] [CrossRef]

- Yin, Y.L.; Song, Z.P.; Wang, R.Z.; Zhai, X.Q. Experimental investigation of a mini-type solar absorption cooling system under different cooling modes. Energy Build. 2012, 47, 131–138. [Google Scholar] [CrossRef]

- Ibarra-Bahena, J.; Romero, R.J. Performance of Different Experimental Absorber Designs in Absorption Heat Pump Cycle Technologies: A Review. Energies 2014, 7, 751–766. [Google Scholar] [CrossRef]

- Álvarez, M.E.; Hernández, J.A.; Bourouis, M. Modelling the performance parameters of a horizontal falling film absorber with aqueous (lithium, potassium, sodium) nitrate solution using artificial neural networks. Energy 2016, 102, 313–323. [Google Scholar] [CrossRef]

- Medrano, M.; Bourouis, M.; Coronas, A. Absorption of water vapour in the falling film of water–lithium bromide inside a vertical tube at air-cooling thermal conditions. Int. J. Therm. Sci. 2002, 41, 891–898. [Google Scholar] [CrossRef]

- Kiyota, M.; Morioka, I.; Matsuyama, T. Steam absorption into aqueous lithium bromide solution films falling inside vertical pipes. Heat Transf. Asian Res. 2003, 32, 740–752. [Google Scholar] [CrossRef]

- Allouhi, A.; Kousksou, T.; Jamil, A.; Bruel, P.; Mourad, Y.; Zeraouli, Y. Solar driven cooling systems: An updated review. Renew. Sustain. Energy Rev. 2015, 44, 159–181. [Google Scholar] [CrossRef]

- Ghafoor, A.; Munir, A. Worldwide overview of solar thermal cooling technologies. Renew. Sustain. Energy Rev. 2015, 43, 763–774. [Google Scholar] [CrossRef]

- Hassan, M.; El-Sharkawy, I.I.; Harby, K. Study of an innovative combined absorption-adsorption cooling system employing the same evaporator and condenser. Case Stud. Therm. Eng. 2023, 42, 102690. [Google Scholar] [CrossRef]

- Zhai, C.; Xu, M.; Liu, Z.; Han, H.; Wu, W. An efficient and compact integrated microchannel membrane-based absorption refrigeration system. Appl. Therm. Eng. 2024, 243, 122574. [Google Scholar] [CrossRef]

- Chen, Y.M.; Sun, C.Y. Experimental study on the heat and mass transfer of a combined absorber-evaporator exchanger. Int. J. Heat Mass Transf. 1997, 40, 961–971. [Google Scholar] [CrossRef]

- Inoue, S.; Dang, C.; Hihara, E. Development of a compact absorption chiller using hydrophobic flat sheet membrane. In Proceedings of the 17th International Refrigeration and Air Conditioning Conference at Purdue, West Lafayette, IN, USA, 9–12 July 2018. [Google Scholar]

- Olvera Olvera, C.A.; Díaz Flórez, G.; Morales Oviedo, E.D.; Gómez Meléndez, D.J.; Araiza Esquivel, M.A.; Espinoza García, G. Módulo Evaporador/Absorbedor para Sistemas de Refrigeración por Absorción. Mexican Utility-Model. Application No. MX/u/2018/000306, 25 January 2021. [Google Scholar]

- Choong, Y.H.; Krishnan, M.; Gupta, M. Recent Advances in the 3D Printing of Pure Copper Functional Structures for Thermal Management Devices. Technologies 2023, 11, 141. [Google Scholar] [CrossRef]

- LaRocco, J.; Tahmina, Q.; Simonis, J.; Vedati, V. Comparing Elastocaloric Cooling and Desiccant Wheel Dehumidifiers for Atmospheric Water Harvesting. Technologies 2024, 12, 178. [Google Scholar] [CrossRef]

- Liu, Y.; Han, X.; Shen, C.; Yao, F.; Zhang, M. Experimental study on the evaporation and condensation heat transfer characteristics of a vapor chamber. Energies 2019, 12, 11. [Google Scholar] [CrossRef]

- ASHRAE. Psychrometrics. In ASHRAE Handbook—Fundamentals, SI ed.; Owen, M.S., Ed.; ASHRAE: Atlanta, GA, USA, 2017; pp. 1.1–1.40. [Google Scholar]

- Park, C.W.; Cho, H.C.; Kang, Y.T. The effect of heat transfer additive and surface roughness of micro-scale hatched tubes on absorption performance. Int. J. Refrig. 2004, 27, 264–270. [Google Scholar] [CrossRef]

- Mortazavi, M.; Nasr Isfahani, R.; Bigham, S.; Moghaddam, S. Absorption characteristics of falling film LiBr solution over a finned structure. Energy 2015, 87, 270–278. [Google Scholar] [CrossRef]

- Kim, J.k.; Park, C.W.; Kang, Y.T. The effect of micro-scale surface treatment on heat and mass transfer performance for a falling film H2O/LiBr absorber. Int. J. Refrig. 2003, 26, 575–585. [Google Scholar] [CrossRef]

- Zhang, H.; Yin, D.; You, S.; Zheng, W.; Wei, S. Experimental investigation of heat and mass transfer in a LiBr-H2O solution falling film absorber on horizontal tubes: Comprehensive effects of tube types and surfactants. Appl. Therm. Eng. 2019, 146, 203–211. [Google Scholar] [CrossRef]

- Goel, N.; Goswami, D.Y. Analysis of a counter-current vapor flow absorber. Int. J. Heat Mass Transf. 2005, 48, 1283–1292. [Google Scholar] [CrossRef]

- Hafsia, N.B.; Chaouachi, B.; Gabsi, S. A study of the coupled heat and mass transfer during absorption process in a spiral tubular absorber. Appl. Therm. Eng. 2015, 76, 37–46. [Google Scholar] [CrossRef]

- Hafsia, N.B.; Chaouachi, B.; Gabsi, S. Global modeling of heat and mass transfers in spiral tubular absorber of a water–lithium bromide absorption chiller. Appl. Therm. Eng. 2014, 38, 323–332. [Google Scholar]

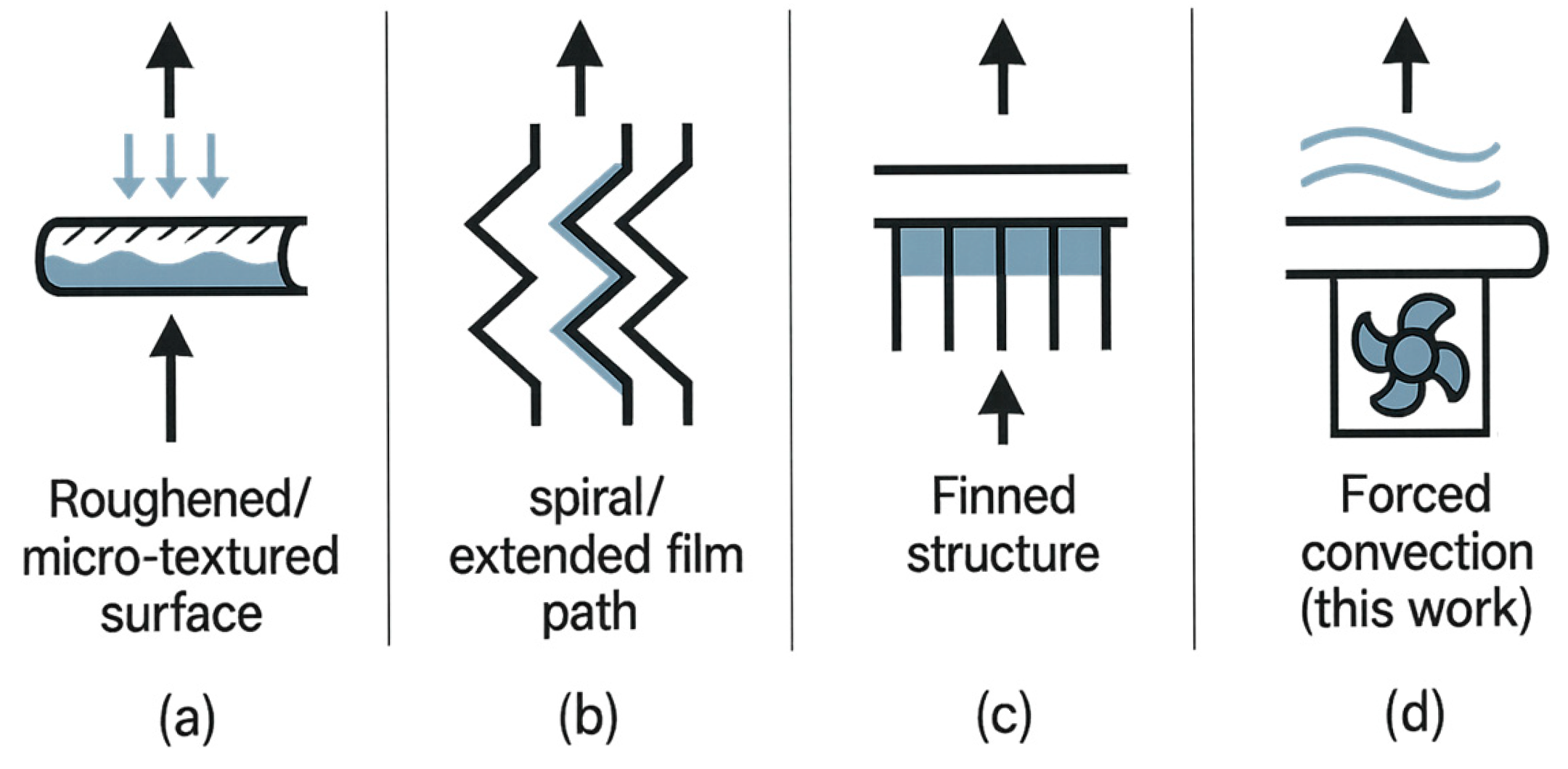

- Amaris, C.; Valles, M.; Bourouis, M. Vapour absorption enhancement using passive techniques for absorption cooling/heating technologies: A review. Appl. Energy 2018, 231, 826–853. [Google Scholar] [CrossRef]

- Sehgal, S.; Alvarado, J.L.; Hassan, I.G.; Kadam, S.T. A comprehensive review of recent developments in falling-film, spray, bubble and microchannel absorbers for absorption systems. Renew. Sustain. Energy Rev. 2021, 142, 110807. [Google Scholar] [CrossRef]

- Zheng, J.; Castro, J.; Papakokkinos, G.; Assensi, O. Sensitivity study to an absorption system performance considering heat and mass transfer enhancements. In Proceedings of the 19th International Refrigeration and Air Conditioning Conference at Purdue, West Lafayette, IN, USA, 10–14 July 2022. [Google Scholar]

| Parameter | Value |

|---|---|

| Inlet concentration of solution (wt % of LiBr–H2O) | 59.76 |

| Inlet mass of the refrigerant (g) | 1553 |

| Inlet mass of the solution (g) | 3208 |

| Qin | Value (W) | ||

|---|---|---|---|

| Fan OFF | Fan ON | ||

| Qin,1 | 219.393 | 174 | 284 |

| Qin,2 | 183.280 | 358 | 347 |

| Qin,3 | 110.500 | 383 | 270 |

| Qin,4 | 66.950 | 301 | 355 |

| Qin,5 | 0 | 426 | 997 |

| Qin,6 | 222.478 | 396 | 346 |

| Qin,7 | 145.440 | 305 | 294 |

| Qin,8 | 61.500 | 293 | 302 |

| Qin,9 | 0 | 370 | 1209 |

| Qin,10 | 223.170 | 418 | 248 |

| Qin,11 | 138.180 | 340 | 453 |

| Qin,12 | 0 | 311 | 808 |

| Measured Variable | Range | Accuracy (±) | Unit |

|---|---|---|---|

| Temperature (T) | Test operating range | 0.3 | °C |

| Pressure (P) | 0–103.44 | 1% of FS | kPa |

| Flow rate (coolant water) | 0.0167–0.5 | 10% | |

| Voltage/current (heaters) | Per device | 0.5% |

| Qin | Fan Off | Fan On | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (IQR) | (IQR) | |||||||||||

| Qin,1 | 10.94 | 10.67 | 10.79 (0.12) | 0.10 | 0.09 | 0.10 | 10.91 | 10.61 | 10.71 (0.12) | 0.10 | 0.08 | 0.09 |

| Qin,2 | 11.48 | 10.71 | 10.98 (0.56) | 0.09 | 0.08 | 0.08 | 12.04 | 11.39 | 11.84 (0.40) | 0.09 | 0.08 | 0.08 |

| Qin,3 | 12.05 | 11.59 | 11.89 (0.24) | 0.09 | 0.08 | 0.09 | 11.65 | 11.28 | 11.42 (0.17) | 0.1 | 0.09 | 0.09 |

| Qin,4 | 11.47 | 10.89 | 11.29 (0.26) | 0.09 | 0.09 | 0.09 | 10.89 | 10.46 | 10.57 (0.21) | 0.09 | 0.08 | 0.08 |

| Qin,5 | 10.83 | 10.52 | 10.63 (0.14) | 0.09 | 0.08 | 0.08 | 12.58 | 10.83 | 12.10 (0.58) | 0.08 | 0.02 | 0.04 |

| Qin,6 | 10.46 | 9.02 | 9.46 (0.15) | 0.08 | 0.06 | 0.07 | 9.00 | 8.23 | 8.31 (0.14) | 0.07 | 0.06 | 0.06 |

| Qin,7 | 8.94 | 8.27 | 8.69 (0.29) | 0.08 | 0.06 | 0.07 | 8.26 | 7.54 | 7.72 (0.34) | 0.07 | 0.07 | 0.07 |

| Qin,8 | 8.04 | 7.36 | 7.86 (0.40) | 0.08 | 0.07 | 0.07 | 7.54 | 7.29 | 7.44 (0.10) | 0.08 | 0.06 | 0.07 |

| Qin,9 | 7.73 | 7.24 | 7.46 (0.05) | 0.08 | 0.06 | 0.08 | 11.44 | 7.74 | 10.58 (1.23) | 0.07 | −0.05 | −0.01 |

| Qin,10 | 9.96 | 6.07 | 6.13 (0.14) | 0.08 | 0.01 | 0.07 | 6.13 | 5.94 | 6.11 (0.03) | 0.08 | 0.07 | 0.07 |

| Qin,11 | 5.87 | 5.46 | 5.58 (0.23) | 0.09 | 0.08 | 0.08 | 5.65 | 5.40 | 5.59 (0.10) | 0.09 | 0.07 | 0.07 |

| Qin,12 | 5.44 | 5.07 | 5.13 (0.11) | 0.10 | 0.08 | 0.09 | 9.44 | 5.46 | 8.63 (1.39) | 0.08 | −0.04 | −0.01 |

| Thermal Load | * Relative Improvement (%) | ||

|---|---|---|---|

| Qin,1 | 0.54 | 0.53 | −1.9 |

| Qin,2 | 0.55 | 0.58 | 5.5 |

| Qin,3 | 0.58 | 0.56 | −3.4 |

| Qin,4 | 0.54 | 0.52 | −3.7 |

| Qin,5 | 0.53 | 0.61 | 15.1 |

| Qin,6 | 0.44 | 0.39 | −11.4 |

| Qin,7 | 0.39 | 0.36 | −7.7 |

| Qin,8 | 0.36 | 0.35 | −2.8 |

| Qin,9 | 0.35 | 0.49 | 40.0 |

| Qin,10 | 0.29 | 0.26 | −10.3 |

| Qin,11 | 0.24 | 0.24 | 0.0 |

| Qin,12 | 0.23 | 0.38 | 65.2 |

| Study/Source | Enhancement Mechanism | Description/Reported Effect * |

|---|---|---|

| Kim & Kang [37] | Wavy/structured films | Wavy-laminar falling films enhance contact and promote higher mass-transfer coefficients compared with flat films. |

| Park et al. [35] | Roughened/hatched tubes | Micro-structured tube surfaces and additives increase wetting and interfacial area, improving local absorption rates versus smooth tubes. |

| Mortazavi et al. [36] | Finned structure | Finned surfaces on vertical tubes increase effective area and external gradient, yielding higher absorption and heat-transfer coefficients than plain tubes |

| Goel & Goswami [39] | Compact counterflow designs | Compact falling-film absorber and counter-current configurations to intensify absorption in small footprints |

| Hafsia et al. [41] | Spiral/extended paths | Spiral tubular absorber providing extended Flow path and compact configuration; model predicts improved utilization of driving potentials |

| Zheng et al. [44] | Hybrid enhancement | Sensitivity analysis showing that combining enhanced surfaces and improved flow distribution can lead to significant performance gains, depending on configuration |

| This study | Internal forced convection | Small integrated fan promoting vapor conveyance and stabilizing hot–cold separation; under near zero load, n increases from 0.23 to 0.38 (≈+65%) between fan-OFF and fan-ON |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Díaz-Flórez, G.; Olvera-Olvera, C.A.; Villagrana-Barraza, S.; Solís-Sánchez, L.O.; Guerrero-Osuna, H.A.; Ibarra-Pérez, T.; Jaramillo-Martínez, R.; Correa-Aguado, H.C.; Díaz-Flórez, G. Design and Fabrication of a Compact Evaporator–Absorber Unit with Mechanical Enhancement for LiBr–H2O Vertical Falling-Film Absorption, Part I: Experimental Validation. Technologies 2025, 13, 538. https://doi.org/10.3390/technologies13110538

Díaz-Flórez G, Olvera-Olvera CA, Villagrana-Barraza S, Solís-Sánchez LO, Guerrero-Osuna HA, Ibarra-Pérez T, Jaramillo-Martínez R, Correa-Aguado HC, Díaz-Flórez G. Design and Fabrication of a Compact Evaporator–Absorber Unit with Mechanical Enhancement for LiBr–H2O Vertical Falling-Film Absorption, Part I: Experimental Validation. Technologies. 2025; 13(11):538. https://doi.org/10.3390/technologies13110538

Chicago/Turabian StyleDíaz-Flórez, Genis, Carlos Alberto Olvera-Olvera, Santiago Villagrana-Barraza, Luis Octavio Solís-Sánchez, Héctor A. Guerrero-Osuna, Teodoro Ibarra-Pérez, Ramón Jaramillo-Martínez, Hans C. Correa-Aguado, and Germán Díaz-Flórez. 2025. "Design and Fabrication of a Compact Evaporator–Absorber Unit with Mechanical Enhancement for LiBr–H2O Vertical Falling-Film Absorption, Part I: Experimental Validation" Technologies 13, no. 11: 538. https://doi.org/10.3390/technologies13110538

APA StyleDíaz-Flórez, G., Olvera-Olvera, C. A., Villagrana-Barraza, S., Solís-Sánchez, L. O., Guerrero-Osuna, H. A., Ibarra-Pérez, T., Jaramillo-Martínez, R., Correa-Aguado, H. C., & Díaz-Flórez, G. (2025). Design and Fabrication of a Compact Evaporator–Absorber Unit with Mechanical Enhancement for LiBr–H2O Vertical Falling-Film Absorption, Part I: Experimental Validation. Technologies, 13(11), 538. https://doi.org/10.3390/technologies13110538