Abstract

This work presents the development and characterization of alumina–carbon black (ACB) composite membranes for enhanced hydrogen separation performance. A series of membranes containing 0–3.0 wt.% carbon black was fabricated via high-temperature sintering and systematically investigated with respect to their structural, morphological, mechanical, and gas separation properties. The addition of carbon black significantly influenced membrane microstructure, promoting pore network formation, increasing specific surface area, and enhancing gas transport. Gas permeation tests using H2 and N2 revealed that all ACB membranes exhibited higher hydrogen permeance than the pure Al2O3 membrane. Notably, the ACB3.0 specimen demonstrated the highest H2 permeance of 508 × 10−6 mol m−2 s−1 Pa−1 at 303 K, which is nearly four times greater than the unmodified membrane. At an elevated temperature (773 K), H2/N2 selectivity improved with increasing carbon black content, with ACB3.0 achieving a maximum selectivity of 3.82, exceeding the theoretical Knudsen value, suggesting a synergistic contribution of Knudsen diffusion and surface diffusion. These results demonstrate that carbon black is a cost-effective and versatile additive for modifying ceramic membranes, offering a promising route for advancing hydrogen purification technologies in industrial applications.

1. Introduction

The growing global demand for efficient and environmentally sustainable energy has accelerated the transition toward a hydrogen-based economy [1,2,3]. For a promising long-term solution to the growing energy crisis, hydrogen (H2) offers several advantages that make it an attractive energy carrier. It possesses high energy efficiency and a substantial heating value, making it a viable alternative to conventional fossil fuels. Additionally, the combustion of hydrogen generates only heat and water vapor as by-products, leading to a significant reduction in pollutant emissions [4,5,6,7]. Due to its versatility, hydrogen can be derived from various resources, including membrane desalination, coal gasification, and natural gas, as well as renewable alternatives such as biomass [8,9,10,11,12,13,14,15]. However, hydrogen is derived from biomass, typically contains several gases, including nitrogen (N2), carbon dioxide (CO2), and unreacted methane (CH4), which must be removed before the hydrogen can be utilized effectively [16].

To obtain high-purity hydrogen, an essential step in the hydrogen production process is purification, which involves separating hydrogen from other gaseous components. Several technologies are employed for this purpose, including cryogenic distillation, pressure swing adsorption (PSA), and membrane-based separation [17,18,19]. While cryogenic distillation and PSA are widely used, they have notable challenges such as high equipment costs and substantial energy consumption [19,20]. In contrast, membrane-based processes have gained attention as a promising alternative due to their compact design, lightweight structure, high hydrogen flux, and cost-effective fabrication. Additionally, membrane separation system offers low operational costs and excellent flexibility, enabling hydrogen purification in both high- and low-pressure applications [21]. Consequently, significant research efforts have been directed toward developing advanced membrane materials with enhanced hydrogen permeability and selectivity to improve the overall efficiency of the purification process.

Carbon-based materials have emerged as promising candidates for hydrogen separation membranes due to their advantageous structural and chemical properties. These membranes can be prepared using a variety of carbon forms, including activated carbon, graphite, graphene oxide, carbon nanotube, carbon black, and carbon derived from polymeric precursors [22,23,24,25,26,27]. The advantages of carbon materials for gas separation applications include the following: (i) The porous structure of carbon materials, particularly activated carbon, offers a large surface area that enhances gas adsorption, improving separation performance. (ii) Carbon materials can be engineered to exhibit specific pore sizes and distributions, allowing for molecular sieving based on size exclusion and selective gas interactions. This tunability enhances both selectivity and permeability. (iii) Carbon materials exhibit high resistance to chemical degradation and can operate under corrosive and high-temperature environments, making them suitable for long-term use. (iv) Carbon-based materials provide a more economical alternative without compromising functional performance, making them competitive with conventional materials such as zeolites, metal–organic frameworks, and Pd-alloys [7,28,29]. Additionally, Pd-based membranes are well known for their excellent hydrogen selectivity through the solution-diffusion mechanism [30], which can be several orders of magnitude higher than that of ceramic and carbon-based membranes. However, their high fabrication cost and susceptibility to poisoning significantly limit large-scale applications. In contrast, carbon-based materials represent a compelling alternative to zeolites or palladium alloys for cost-efficient production. Therefore, carbon-based materials represent a compelling alternative to zeolites or palladium alloys for cost-efficient production. Therefore, carbon materials are attractive candidates for gas separation technologies, especially in hydrogen purification applications, due to their large surface area, tunable porosity, chemical durability, and economic viability.

Lee et al. [31] fabricated three types of hydrogen separation membranes: ACG/Al (Al2O3-CeO2-Graphene oxide/Al), ACZ (Al2O3/CuO2/ZnO2)-10wt.% Co, and ACZ (Al2O3/CuO2/ZnO2)-10wt.% Ni. These composite membranes were prepared in pellet shape using the hot pressure sintering method. The hydrogen permeation rates of the membrane were reported as 2.62 × 10−7 mol/m s Pa1/2 for ACG/Al, 4.9 × 10−8 mol/ m s Pa1/2 for ACZ-10wt.% Co, and 1.47 × 10−8 mol/ m s Pa1/2 for ACZ-10wt.% Ni. These results indicate that the incorporation of graphene oxide and cerium oxide significantly enhances hydrogen permeation performance compared to traditional metal oxide systems such as CuO and ZnO. The improved performance is attributed to the effects of the high surface area of graphene oxide and the catalytic role of CeO2 in promoting hydrogen transport. Terra et al. [32] utilized carbon materials, specifically graphite derived from a commercial 2B pencil, to fabricate an interlayer between alumina hollow fibers and the palladium (Pd) layer. The inclusion of this graphite interlayer resulted in a 25% reduction in the thickness of the Pd layer. Moreover, the modified membrane exhibited a hydrogen permeance of 1 × 10−6 mol m−2 s−1 Pa−1 (at 723 K) and achieved complete H2/N2 (infinity) selectivity. Zhang et al. [33] fabricated a nonporous carbon membrane derived from resorcinol-formaldehyde resin. The membrane demonstrated gas permeances of 8.74, 0.78, 0.56, and 0.12 × 10−9 mol m−2 s−1 Pa−1 for H2, CO2, O2, and N2, respectively. It also exhibited ideal selectivity values of 46.4 for H2/N2, 4.7 for CO2/N2, and 3.3 for O2/N2. These results suggest that the membrane separates gases primarily via a molecular sieving mechanism, favoring smaller gas molecules such as hydrogen. Nie et al. [34] reported the use of wood tar as a coating material for the carbon molecular sieve membrane via a solution-coating technique. This resulting membrane exhibited high hydrogen selectivity with for H2/N2 and H2/CH4 selectivity values of 155 and 340, respectively, along with an H2 permeance of 2.87 × 10−8 mol m−2 s−1 Pa−1.

In addition to ceramic-based approaches, carbon materials have also been integrated with polymeric membranes to enhance gas separation performance through improved permeability and selectivity. Yousef et al. [35] developed composite membranes comprising polyether sulfone (PES) incorporated with carbon nanotubes (CNTs) at concentrations ranging from 0.01 to 0.03 wt.%. At a CNT loading of 0.01 wt.%, the membrane exhibited permeabilities of 2.96 × 10−6 mol m−2 s−1 Pa−1 for H2, 1.19 × 10−6 mol m−2 s−1 Pa−1 for CH4, 7.83 × 10−7 mol m−2 s−1 Pa−1 for N2, and 6.98 × 10−7 mol m−2 s−1 Pa−1 for CO2. Moreover, the CNT/PES membrane also demonstrated enhanced ideal selectivity, with values of 29 for O2/N2, 396 for CH4/N2, and 426 for H2/N2. These results underscore the effectiveness of CNT incorporation in improving both gas permeability and selectivity compared to the pristine PES membrane.

The previous literature offers various carbon-based materials such as graphene oxide, graphite, carbon nanotubes (CNTs), and pyrolytically derived carbon for hydrogen separation membrane applications. The type of carbon material and the method of membrane fabrication are critical factors influencing membrane performance. Among carbon-based materials, carbon black (CB) is recognized for its versatility and widespread use in diverse fields, including bioimaging [36], photothermal antibacterial [37], solar energy [38], gas sensors [39,40], batteries [41,42], polymer reinforcement [43], and methane adsorption [44]. These applications arise from the unique properties of CB, such as high electrical conductivity, excellent chemical stability, and tunable particle morphology and size distributions [45]. Carbon black is a versatile material with applications in a wide range of industries. However, the use of carbon black in the fabrication of hydrogen gas separation membranes remains unexplored. This gap poses a challenge and an opportunity to broaden the utilization of carbon black in gas separation technologies.

In this research, we report the fabrication of alumina–carbon black (ACB) composite membrane via high-temperature sintering at 1500 °C. Comprehensive characterization, including phase identification, morphology observation, and evaluation of physical and mechanical properties, was conducted. Furthermore, single gas permeation experiments using hydrogen (H2) and nitrogen (N2) were conducted to examine the influence of carbon black content on separation performance. This work provides insights into the feasibility of utilizing carbon black as a functional additive in ceramic membrane systems and proposes a cost-effective strategy for advancing hydrogen purification technologies.

2. Materials and Methods

2.1. Materials

The raw materials used in this presented study included commercially available reagents. Alumina oxide (α-Al2O3) powder with 99.9% purity and an average particle size of 1–2 mm was obtained from Nippon Light Metal, Tokyo, Japan. Magnesium oxide (MgO) with 99.9% purity and an average particle size of 0.2 mm was supplied by Fujifilm Wako Chemical, Tokyo, Japan. Carbon black powder with an average particle size of 100–140 nm was acquired from Cabot Corporation, Boston, MA, USA. Ethanol (95% purity, laboratory reagent grade) was purchased from RCI Labscan Limited, Thailand

2.2. Powder Mixture and Green Compact Preparation

In this study, six ceramic matrix composite membranes were fabricated by the high-temperature sintering method. Carbon black was added to the Al2O3 matrix at concentrations of 0.5, 1.0, 1.5, 2.0, 2.5, and 3.0 wt.%, and the corresponding samples were designated as ACB0.5, ACB1.0, ACB1.5, ACB2.0, ACB2.5, and ACB3.0. A carbon black-free Al2O3 sample (pure Al2O3) was prepared as a reference. For all specimens, 1 wt.% MgO was incorporated as a sintering additive.

To ensure homogeneous mixing, Al2O3, MgO, and CB powders were combined and milled in ethanol using 3 mm alumina balls as grinding media. The powder mixture was placed in a sealed polypropylene bottle and processed in a ball mill at approximately 300 rpm for 24 h. After milling, the slurry was dried at 393 K for 24 h in an electric oven. The dried powders were then sieved through a 200-mesh screen and uniaxially pressed into disk-shaped green compacts using a stainless-steel mold (13 mm diameter × 3 mm thickness) under a pressure of 24 MPa. Sintering was carried out in a tube furnace under an argon atmosphere. Each sample was placed in an alumina crucible and embedded in carbon black powder to prevent oxidation during the sintering process. The temperature increased from room temperature to 1227 K at a heating rate of 5 K/min, followed by soaking for 2 h at the peak temperature. The samples were then allowed to cool naturally to room temperature within the furnace.

2.3. Characteristic

X-ray diffraction (XRD; Miniflex600, Rigaku, Tokyo, Japan) was employed to identify the crystalline phases of specimens using Cu Kα radiation at 40 kV and 15 mA. The scan parameters were set as follows: a 2θ range from 10° to 80°, a scanning step of 0.02°, and a scanning speed of 10°/min. The microstructures of the sintered samples were examined using field-emission scanning electron microscopy (FESEM; Apreo 2, Thermo Fisher Scientific, Waltham, MA, USA). Average grain size was determined using the mean linear intercept method via ImageJ image analysis software (version 1.54p).

The bulk density and apparent porosity of the sintered compacts were measured using the Archimedes principle, with deionized water as the immersion medium. Theoretical densities were calculated based on the rule of mixtures, using densities of 3.98 g/cm3 for Al2O3, 3.57 g/cm3 for MgO, and 2.1 g/cm3 for carbon black [46,47]. The relative density of each specimen was obtained by dividing the measured bulk density by its corresponding theoretical density.

To determine the pore size distribution of the specimens, mercury porosimetry was performed using a MicroActive AutoPore V 9600 instrument (ATS Scientific Inc., Burlington, ON, Canada). The mechanical properties of specimens were evaluated in terms of hardness using Vickers’s indentation technique (Zwick Roell, Ulm, Germany), applying a load of 98 N with a dwell time of 15 s. For each specimen, the average hardness was calculated from ten indentations performed on different areas of the surface. Vickers’s hardness was calculated using the following equation [48]:

where F is the applied load (N) and d is the value of the average indentation diagonal (mm).

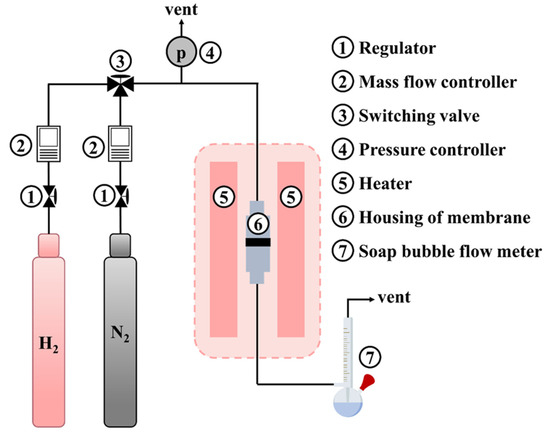

Gas permeation experiments were conducted to evaluate the separation performance using single gases consisting of nitrogen gas (N2, 99.99% purity) and hydrogen gas (H2, 99.99% purity). The experiments were carried out at operating temperatures of room temperature, 373 K, 473 K, 573 K, 673 K, and 773 K. The transmembrane pressure (ΔP) ranged from 25 to 150 KPa for N2 gas and from 25 to 125 KPa for H2 gas. The effective permeation area of each membrane was 0.77 cm2. The gas permeation setup consisted of gas supply cylinders, regulators, pressure controllers, a membrane housing cell, an electric furnace with a temperature controller, and a soap bubble flow meter. A schematic diagram of the permeation system is shown in Figure 1. The gas permeance (P; unit: mol m−2 s−1 Pa−1) through the membranes was calculated using the following equation [49].

where F is the molar flow rate (mol s−1), A is the effective membrane area (m2), and ΔP is the pressure difference between the feed and permeate side of the membrane (Pa), respectively. The ideal selectivity of the membranes was calculated from the ratio of the H2 permeance ( to that of N2 () under identical operating conditions, as follows.

Figure 1.

A scheme of the single gas permeation setup.

3. Results

3.1. Phase Composition

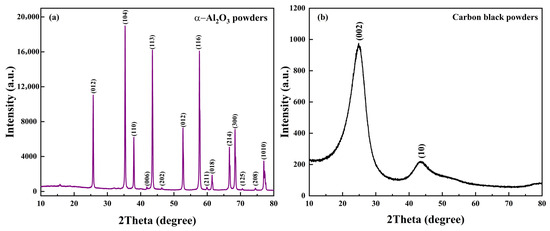

Figure 2 illustrates X-ray diffraction patterns (XRD) of the starting materials of α-Al2O3 and carbon black powder. The XRD patterns of α-Al2O3 powder in Figure 2a shows the characteristic peaks at 25.57°, 35.14°, 37.76°, 41.67°, 43.34°, 46.16°, 52.53°, 57.48°, 59.72°, 61.29°, 66.50°, 68.18°, 70.39°, 74.28°, and 76.86°, corresponding to the crystal planes of (012), (104), (110), (006), (113), (202), (012), (116), (211), (018), (214), (300), (125), (208), and (1010), respectively. These peaks confirm the hexagonal crystal structure of α-Al2O3, in accordance with JCPDS card No. 01-073-1123. The XRD pattern of carbon black powder in Figure 2b exhibits a broad peak centered at approximately 24.84°, corresponding to the (002) plane of graphitic carbon. This observation is consistent with the findings reported by Singh et al. [50] and Ostyn et al. [51]. Although the (002) reflection is commonly associated with graphite (typically located near 26.5°), the lower peak position and broader profile in carbon black suggest a difference in microcrystalline structure. Additionally, a weak diffraction peak was observed at approximately 43.83°, corresponding to the (10) plane. This reflection is typically associated with the overlapping of the (100) and (101) planes, which were not distinctly resolved in the carbon black pattern. The absence of clear peak separation suggests a lack of long-range order in the stacking of carbon layers. This behavior is characteristic of a turbostratic carbon structure, in which individual graphene layers are misaligned or randomly oriented [52,53]. These results confirm the disordered microstructure of carbon black as opposed to the well-ordered lattice of crystalline graphite.

Figure 2.

XRD patterns of the precursor materials (a) Al2O3 and (b) carbon black powders.

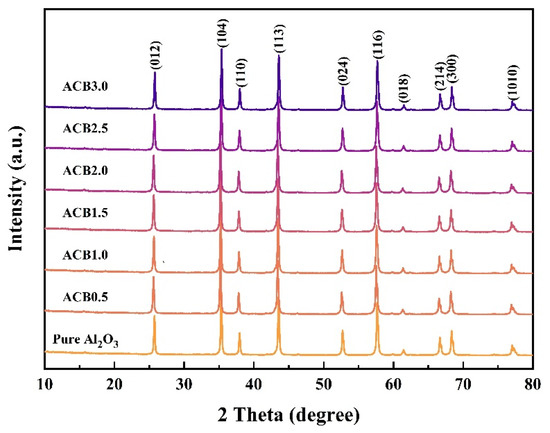

Figure 3 shows XRD patterns of the reference Al2O3 sample and the alumina–carbon black (ACB) composite specimens after sintering. All samples exhibit diffraction peaks corresponding solely to the α-Al2O3 phase, with no detectable carbon-related phases. This suggests that no significant chemical reaction occurred between carbon black and alumina during the sintering process. Additionally, the high-intensity diffraction peaks of α-Al2O3 may have obscured any weak reflections from carbon black, which could explain the absence of observable carbon peaks in the composite specimens. This is consistent with the low intensity of carbon peaks observed in the XRD profile of the starting material.

Figure 3.

The XRD patterns of reference Al2O3 sample and ACB composite membranes.

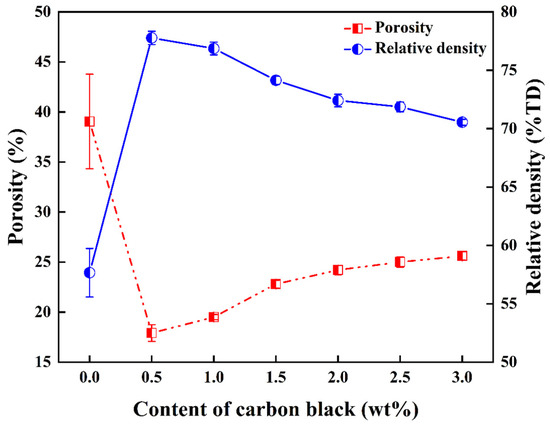

3.2. Densification Properties

Figure 4 shows the porosity and relative density of the pure Al2O3 sample and ACB composite membranes as a function of carbon black content. Initially, the porosity of the samples significantly reduced, decreasing from 41.0% (at 0 wt.% CB) to 17.2% (at 0.5 wt.% CB). On the other hand, the relative density increased; the pure Al2O3 sample exhibited a low relative density of 57.6%, while the ACB composite containing 0.5 wt.% CB achieved the highest relative density of 77.8%. The minimum porosity (and correspondingly the highest density) observed at 0.5 w.t% carbon black can be attributed to the enhanced densification mechanism at this composition. With a small amount of carbon black addition, the particles are more effectively rearranged during sintering, resulting in a reduction in pore volume and formation of a more compact microstructure. Above this point, increasing the carbon black content leads to a decrease in relative density, reaching 70.8% at 3.0 wt.% CB. This reduction in relative density is attributed to the distribution of carbon black at grain boundaries, which hindered the densification process during sintering [54]. This indicates that 0.5 wt.% carbon black provides an optimal condition for sintering improvement before excessive carbon black content leads to pore formation due to agglomeration during the mixed stage. Based on the experimental results, the porosity of ACB composite membranes was lower than that of the pure Al2O3 specimen. In contrast, the relative densities of the ACB membranes were higher than those of Al2O3. These findings suggest that the addition of carbon black, particularly at low concentrations, can enhance the physical properties of Al2O3-based composites.

Figure 4.

Effect of carbon black addition on porosity and relative density.

3.3. Surface Morphology

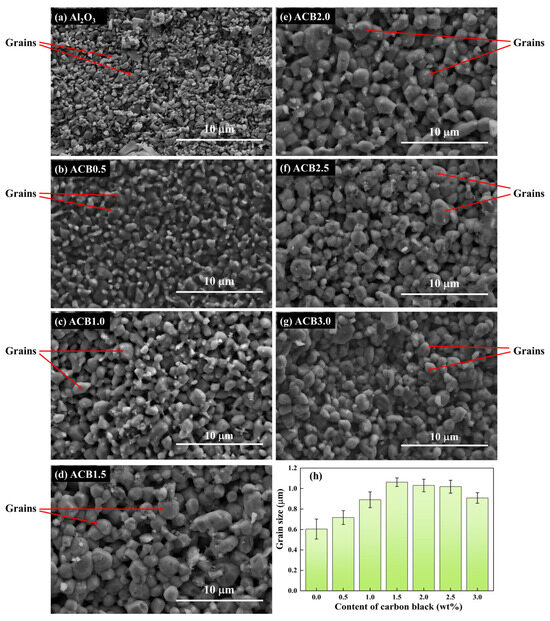

The surface morphologies of sintered Al2O3 and ACB composite membranes are shown in Figure 5a–g. The red arrows indicate representative grains in the specimens. The pure Al2O3 membrane shown in Figure 5a displays irregularly shaped grains with non-uniform particle distribution and indistinct grain boundaries. The absence of evident grain necking suggests an incomplete sintering process, likely due to the relatively low densification efficiency. This observation is consistent with the findings reported by Xu et al. [55]. At a sintering temperature of 1227 K, the surface morphology clearly exhibits a heterogeneous distribution of particles with varying shapes and sizes.

Figure 5.

Surface morphology of (a) Al2O3, (b) ACB0.5, (c) ACB1.0, (d) ACB1.5, (e) ACB2.0, (f) ACB2.5, (g) ACB3.0, and (h) grain size of the ACB composite membranes. The red solid arrows indicate representative grains in the specimens.

In contrast, the ACB composite membranes Figure 5b–g exhibit more well-defined, equiaxed grains with improved grain boundary connectivity, indicative of enhanced sintering behavior. The addition of carbon black promotes microstructural refinement by facilitating local rearrangement and pore generation during sintering, which enhances mass transport and grain growth. Notably, at 0.5–1.5 wt.% CB Figure 5b–d, the grain morphology becomes progressively more uniform and rounded, suggesting that moderate carbon black content effectively promotes densification and grain coarsening.

The grain size evolution with increasing carbon black content is quantitatively illustrated in Figure 5h. The average grain size of the composite membranes increases from approximately 0.60 μm in the pure Al2O3 sample to a peak value of around 1.06 μm at 1.5 wt.% CB. This increase can be attributed to enhanced sintering kinetics induced by the partial burnout of carbon black, which generates porosity that facilitates grain boundary diffusion and coalescence. However, further addition beyond 1.5 wt.% (i.e., ACB2.0–ACB3.0) results in a slight reduction in grain size, maintaining at ~0.91 μm. This trend suggests that excessive carbon black may introduce excessive porosity or microstructural instability, limiting further grain growth. The phenomenon of increasing–decreasing in grain size of alumina–carbon composites has been reported before within other categories of carbon, such as graphene [56]. These observations indicate that carbon black plays a dual role as both a pore-forming agent and microstructure modifier, contributing to the improved grain morphology and size distribution in the ACB membranes.

3.4. Pore Distributions and Specific Surface Area

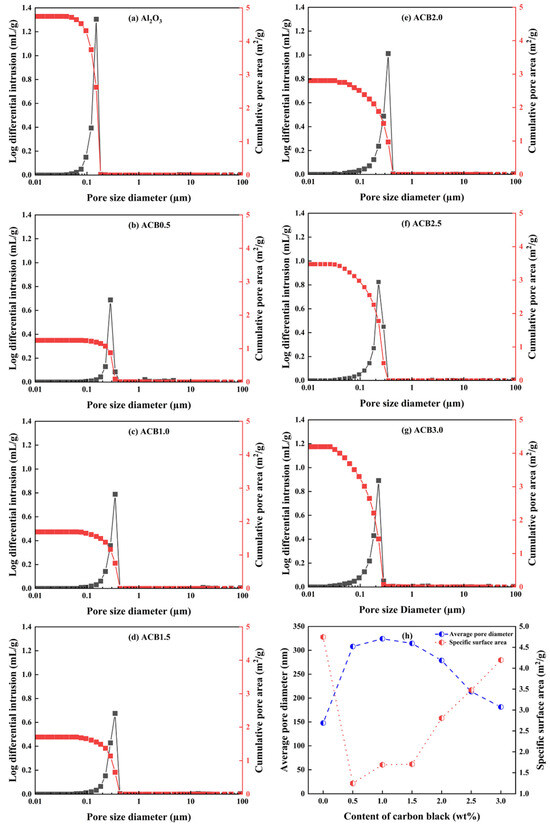

Figure 6 shows the log differential intrusion profiles as a function of pore size for composite membranes with varying carbon black contents. As shown in Figure 6a, the pore size distribution of the pure Al2O3 membrane predominantly falls within the range of 60–180 nm, with the majority of pores centered around approximately 150 nm. This unimodal distribution reflects the intrinsic porosity of the sintered Al2O3 structure in the absence of carbon black. For the ACB0.5 specimen shown in Figure 6b, the pore size distribution ranges from 148 to 445 nm, with a dominant peak centered around 282 nm. This indicates a noticeable increase in pore size compared to the pure Al2O3 membrane. As the carbon black content increases, a trend of pore enlargement is observed. The ACB1.0 and ACB1.5 specimens shown in Figure 6c,d exhibit pore size distributions of 110–445 nm and 107–436 nm, respectively, with peak values centered at approximately 343 nm and 349 nm. Notably, the ACB2.0 sample demonstrates the broadest pore size range, from 61 to 428 nm, with the highest peak centered near 428 nm, suggesting significant pore development at this concentration. However, further increases in carbon black content to 2.5 and 3.0 wt.% result in a reduction in peak pore size values, with ACB2.5 and ACB3.0 showing maxima at approximately 228 nm and 226 nm, respectively. This reduction may be attributed to excessive carbon black agglomeration during sintering, which could limit further pore expansion. These results indicate that pore size distribution in the ACB composite membranes is strongly influenced by carbon black content, exhibiting an initial increase followed by a decline at higher concentrations.

Figure 6.

Mercury intrusion porosimetry (MIP) results of the log differential intrusion as the function of pore size diameter of (a) Al2O3, (b) ACB0.5, (c) ACB1.0, (d) ACB1.5, (e) ACB2.0, (f) ACB2.5, and (g) ACB3.0, and (h) summary of the average pore diameter and specific surface area of the ACB composite membranes as a function of carbon black content.

Furthermore, the average pore diameter and specific surface area of the ACB composite membranes are presented in Figure 6h. The average pore diameter shows an increasing trend with rising carbon black content up to 1.0 wt.% (ACB1.0), reaching a maximum value of 324 nm. Beyond this concentration, further addition of carbon black results in a gradual decrease in average pore size. Specifically, the measured average pore diameters for Al2O3, ACB0.5, ACB1.0, ACB1.5, ACB2.0, ACB2.5, and ACB3.0 were 147, 307, 324, 314, 278, 213, and 181 nm, respectively. In contrast, the specific surface area exhibited an inverse relationship with average pore diameter. While a slight increase was observed from Al2O3 (4.74 m2/g) to ACB0.5 (1.24 m2/g), further increases in carbon black content beyond 0.5 wt.% led to a progressive rise in specific surface area, with values of 1.69, 1.70, 2.80, 3.47, and 4.19 m2/g for ACB1.0 to ACB3.0, respectively. This opposing behavior between pore diameter and specific surface area is consistent with observations reported by Lee and Choi [57], suggesting that the formation of smaller, more numerous pores at higher carbon black concentrations contributes to the increase in surface area despite the reduction in average pore size. According to the IUPAC classification, all ACB composite membranes examined in this study exhibit average pore diameters in the range of 147–324 nm, which categorizes them as macroporous materials (pore diameter > 50 nm) [58]. These results indicate the significant role of carbon black in modulating the microstructural features of the membranes, with direct implications for their gas transport and separation performance.

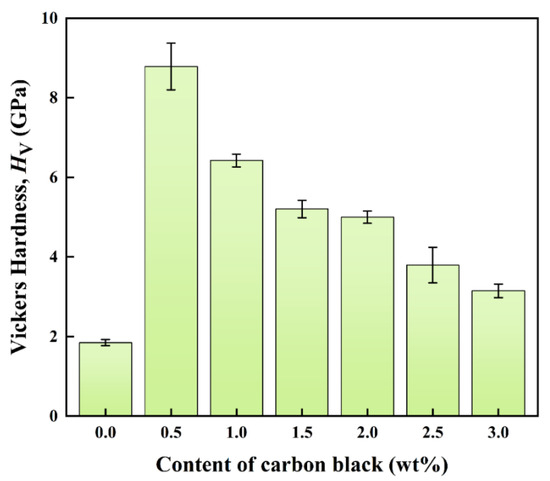

3.5. Mechanical Properties

The incorporation of carbon black into the ACB composite membranes significantly influences their mechanical performance, particularly in terms of hardness. Figure 7 presents the Vickers hardness values of both pure Al2O3 and ACB composite membranes. The pure Al2O3 sample exhibited a relatively low hardness of 1.84 ± 0.07 GPa, whereas the ACB0.5 specimen, containing 0.5 wt.% carbon black, achieved the highest hardness value of 8.78 ± 0.58 GPa. This represents a substantial improvement of approximately 73.9% compared to the carbon black-free membrane, indicating the beneficial effect of a small amount of carbon black as a reinforcing agent within the ceramic matrix. However, further increases in carbon black content beyond 0.5 wt.% resulted in a decline in hardness. The ACB3.0 specimen, with the highest carbon black loading (3.0 wt.%), exhibited a hardness of 3.15 ± 0.17 GPa, still notably higher than that of pure Al2O3 but significantly reduced relative to the ACB0.5 sample. This declining trend is consistent with the predictions of the rule of mixtures [59], wherein the addition of a softer phase (carbon black) into a harder matrix (Al2O3) decreases the overall hardness of the composite. Additionally, the reduction in hardness may be influenced by increased porosity and microstructural heterogeneity introduced at higher carbon black concentrations. In the context of membrane applications, mechanical hardness is a critical parameter. Membranes used in high-temperature gas separation systems, such as those designed for hydrogen purification, must possess sufficient mechanical strength to endure thermal cycling, applied pressure differentials, and physical handling during installation and operation. The enhanced hardness of the ACB composite membranes demonstrates their mechanical resiliency and suggests good structural stability under pressurized conditions. Notably, no cracking or fracture was observed during the setup of hydrogen permeation tests, confirming the mechanical reliability of the fabricated membranes for use in high-pressure membrane cell assemblies.

Figure 7.

Vickers hardness as a function of carbon black content of ACB composite membranes.

3.6. Gas Permeation

The gas separation performance of the ACB composite membranes was evaluated based on two key parameters: gas permeance and selectivity. Gas permeance, typically expressed in units of mol m−2 s−1 Pa−1, quantifies the rate at which a specific gas permeates through the membrane under a given pressure gradient. Selectivity, defined as the ratio of the permeabilities of two gases (SA/B = PA/PB), indicates the membrane preferential transport of one gas over another, where PA represents the permeability of hydrogen (H2), and PB represents that of nitrogen (N2). These two parameters are critical in determining the viability of ACB composite membranes for gas separation applications, particularly in hydrogen purification processes [60].

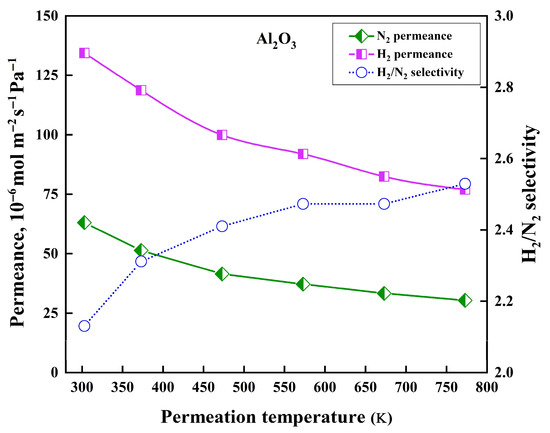

Figure 8 illustrates the gas permeation behavior of the carbon black-free Al2O3 membrane. At room temperature, the membrane exhibited high permeance values of 134 × 10−6 mol m−2 s−1 Pa−1 for hydrogen (H2) and 63 × 10−6 mol m−2 s−1 Pa−1 for nitrogen (N2), consistent with its macroporous structure. However, a gradual decline in permeance was observed with increasing temperature. At 773 K, the permeance values decreased to 76 × 10−6 mol m−2 s−1 Pa−1 for H2 and 30 × 10−6 mol m−2 s−1 Pa−1 for N2. This inverse relationship between temperature and gas permeance may be attributed to reduced surface adsorption and increased gas-phase diffusivity, a behavior previously reported in other macroporous Al2O3 and zeolite membranes [61,62,63,64]. The H2/N2 selectivity of the pure Al2O3 membrane ranged from 2.13 to 2.52 over the tested temperature range, which is lower than the theoretical Knudsen diffusion value of 3.74. This deviation is in agreement with prior studies on macroporous ceramic membranes, where non-ideal pore structures and gas–membrane interactions often result in reduced selectivity [63,65]. While the pure Al2O3 membrane exhibits reasonably high gas permeance, its limited selectivity underscores the need for structural modification. Therefore, the incorporation of carbon black into the Al2O3 matrix (ACB composites) is explored in the following section as a strategy to enhance both permeance and selectivity in H2/N2 gas separation.

Figure 8.

Effect of temperature on the hydrogen and nitrogen permeance and H2/N2 selectivity of the pure Al2O3 membrane.

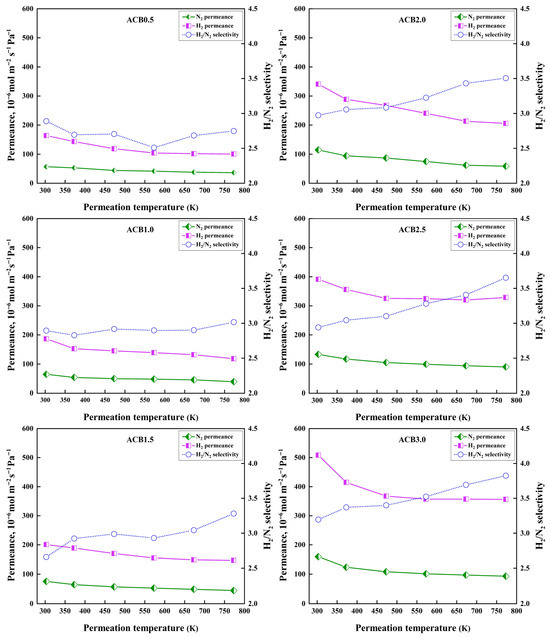

To evaluate the effect of carbon black incorporation on the gas separation performance of Al2O3 membranes, single-gas permeation tests were conducted using H2 and N2 gases. The results for the ACB composite membranes are presented in Figure 9. As shown, all ACB membranes exhibited a decreasing trend in gas permeance with increasing temperature, which is a characteristic behavior of macroporous membranes. This is consistent with the pore size distribution results, which confirmed that the ACB membranes fall within the macroporous range, similar to the pure Al2O3 membrane. A closer examination of each composition reveals distinct differences in permeation performance. The ACB0.5 membrane exhibited H2 and N2 permeance values ranging from 100 to 163 × 10−6 mol m−2 s−1 and 36 to 56 × 10−6 mol m−2 s−1 Pa−1, respectively, with H2/N2 selectivity values between 2.51 and 2.88. Increasing the carbon black content to 1.0 wt.% (ACB1.0) enhanced both H2 and N2 permeance, reaching 118–186 × 10−6 mol m−2 s−1 Pa−1 for H2 and 39–64 × 10−6 mol m−2 s−1 Pa−1 for N2, with a slightly improved H2/N2 selectivity ranging from 2.89 to 3.01. The ACB1.5 membrane exhibited further increases in permeance, with H2 values between 146 and 200 × 10−6 mol m−2 s−1 Pa−1 and N2 between 44 and 75 × 10−6 mol m−2 s−1 Pa−1. The corresponding H2/N2 selectivity ranged from 2.65 to 3.28.

Figure 9.

Effect of temperature on the hydrogen and nitrogen permeance and H2/N2 selectivity of the ACB membranes.

A substantial enhancement in hydrogen transport was observed in ACB2.0 and ACB2.5 membranes. For ACB2.0, H2 and N2 permeance ranged from 205–340 × 10−6 mol m−2 s−1 Pa−1 to 58–114 × 10−6 mol m−2 s−1 Pa−1, respectively, with H2/N2 selectivity values between 2.97 and 3.50. Similarly, ACB2.5 demonstrated H2 permeance of 328–391 × 10−6 mol m−2 s−1 Pa−1 and N2 permeance of 90–133 × 10−6 mol m−2 s−1 Pa−1, resulting in H2/N2 selectivity ranging from 2.94 to 3.65. The ACB3.0 membrane exhibited the highest gas permeation performance among all samples. Hydrogen permeance ranged from 356 to 508 × 10−6 mol m−2 s−1 Pa−1, while nitrogen permeance ranged from 93 to 159 × 10−6 mol m−2 s−1 Pa−1. The H2/N2 selectivity for ACB3.0 varied between 3.19 and 3.82, approaching the theoretical Knudsen selectivity value of 3.74. These results demonstrate that increasing carbon black content enhances both gas permeance and selectivity, particularly at higher loadings.

The incorporation of carbon black into the Al2O3 matrix significantly enhances gas permeation performance, as evidenced by the increased hydrogen permeance and H2/N2 selectivity across all ACB composite membranes compared to the pure Al2O3 sample. This improvement can be attributed to the role of carbon black in modifying the microstructure of the membrane. During the sintering process, carbon black acts as a structural modifier, creating additional pathways and promoting the development of interconnected porous networks within the ceramic matrix. These modified pore architectures facilitate easier transport of gas molecules by reducing mass transfer resistance and increasing accessible permeation channels.

Furthermore, the impact of carbon black on pore characteristics is corroborated by the pore distributions and specific surface area results. The introduction of carbon black up to 1.0 wt.% led to an increase in average pore diameter from 147 nm in pure Al2O3 to 324 nm in ACB1.0, enhancing gas flow through the membrane. However, beyond 1.0 wt.%, the average pore diameter gradually decreased, while the specific surface area increased notably, particularly for ACB2.5 and ACB3.0. This shift suggests a transition from larger, fewer pores to smaller, more numerous pores, resulting in a denser and more complex pore network. Despite the reduction in average pore size, the increased specific surface area contributes to higher gas-membrane interaction sites, therefore enhancing surface diffusion and adsorption transport mechanisms, particularly for small gas molecules like hydrogen [57,66].

Additionally, carbon black possesses a high surface energy and an intrinsic affinity for gas adsorption [67,68]. Its ability to interact with gas molecules through physisorption or surface diffusion depends on the molecular size and kinetic properties of the permeating species. Since hydrogen has a smaller kinetic diameter (2.89 Å) compared to nitrogen (3.64 Å) [69], it experiences less steric hindrance and is more readily adsorbed and transported through the membrane. This explains the observed trend of increasing H2/N2 selectivity with higher carbon black content, particularly in the ACB3.0 membrane, where selectivity values approached the theoretical Knudsen diffusion limit.

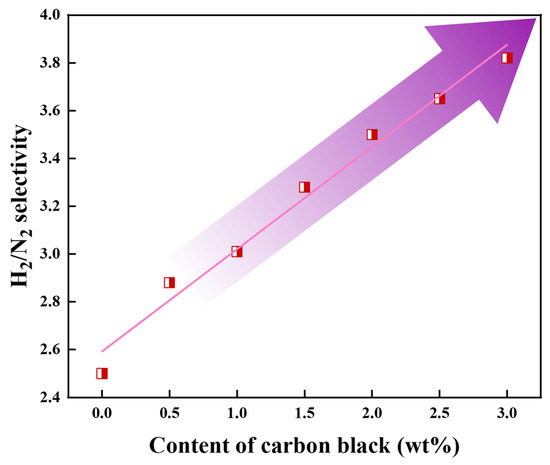

The results from the above experiments clearly demonstrate that increasing the carbon black content in ACB composite membranes systematically enhances their gas separation performance, particularly in terms of H2/N2 selectivity. The selectivity shows a linear relationship with increasing carbon black content. This trend is consistent across different temperatures. Figure 10 focuses specifically on selectivity behavior at an elevated operational temperature of 773 K, which represents the industrial gas separation conditions. As shown, the H2/N2 selectivity increased from 2.53 in the carbon black-free Al2O3 membrane to 3.82 in the ACB3.0 sample, corresponding to an approximate 51% enhancement. This progressive improvement in selectivity with increasing carbon black content suggests a more favorable pore architecture for kinetic-based separation. At higher temperatures, Knudsen diffusion becomes a dominant transport mechanism. In this mechanism, gas transport is governed by differences in molecular weight, favoring smaller and lighter molecules like hydrogen. Theoretical Knudsen selectivity for H2 over N2 is based on the square root of the inverse molecular weight ratio. Given the molecular weights of 2 g/mol for H2 and 28 g/mol for N2, the expected selectivity is approximately 3.74 [63,70]. The ACB3.0 membrane, with an observed selectivity of 3.82, slightly exceeds this theoretical value, which is likely due to additional contributions from surface diffusion and adsorption effects facilitated by the high specific surface area introduced by carbon black. This combination effect of mechanisms enhances the functional advantage of carbon black in modifying pore environments to promote selective transport, particularly for hydrogen. Although higher carbon black contents could potentially enhance H2 selectivity, the concentration was restricted to 0–3.0 wt.%. Preliminary tests showed that loadings above 3.0 wt.% caused membrane cracking and structural failure during cell assembly; thus, this range was chosen to ensure mechanical stability and reliable permeation measurements.

Figure 10.

Effect of carbon black content on H2/N2 selectivity of ACB composite membranes at 773 K. The red square symbols represent the experimental data points, while the pink line indicates the linear fitting trend between carbon black content and H2/N2 selectivity. The purple arrow highlights the overall increasing trend in selectivity with higher carbon black content.

Furthermore, a comparative summary of H2 permeance and H2/N2 selectivity from previously reported membranes incorporating various carbon-based materials is presented in Table 1. These include membranes fabricated using materials such as graphene oxide, carbon nanotubes, graphite, and pyrolytic carbon. When compared to these reported systems, the ACB composite membranes developed in this study exhibit competitive, and in some cases superior, gas separation performance. Specifically, the ACB3.0 membrane achieved a high hydrogen permeance of 356 × 10−6 mol m−2 s−1 Pa−1 and a corresponding H2/N2 selectivity of 3.82, which closely approaches the theoretical Knudsen selectivity limit and matches or exceeds values reported in other carbon-based membranes [65,71,72,73].

Table 1.

Comparison of H2 permeance and H2/N2 selectivity with other carbon membranes.

Notably, despite the widespread application of carbon black in areas such as energy storage, polymer reinforcement, and catalysis, its use in gas separation membrane fabrication, particularly for hydrogen purification, remains largely unexplored. There are very limited studies specifically addressing the role of carbon black in ceramic-based membranes for H2/N2 separation. Therefore, the present work introduces a novel and cost-effective strategy for enhancing membrane performance by incorporating carbon black as a functional additive. This method utilizes the beneficial characteristics of carbon black, including adjustable particle morphology, chemical stability, and increased surface area, while also extending its application to high-temperature gas separation technologies. The results indicate an advantageous possibility for the advancement of carbon black-based composite membranes in sustainable hydrogen production and purification systems. Nevertheless, the relatively large pore size remains a limiting factor for achieving high selectivity, as the molecular sieving effect is less dominant. For future work, the fabrication of additional selective layers will be explored to enhance gas selectivity, even though a moderate reduction in permeability may occur. Such optimization is expected to achieve a more balanced trade-off between permeability and selectivity, advancing the potential of ACB membranes for practical gas separation applications.

4. Conclusions

This study successfully demonstrates that the gas separation performance of Al2O3-based ceramic membranes can be significantly enhanced through the incorporation of carbon black. By systematically varying the carbon black content from 0 to 3.0 wt.%, a series of alumina–carbon black (ACB) composite membranes was fabricated and evaluated for their structural, morphological, and gas permeation properties. Gas permeation testing revealed a consistent increase in hydrogen permeability with higher carbon black content. At an ambient temperature, hydrogen permeance improved from 134 × 10−6 mol m−2 s−1 Pa−1 in the pure Al2O3 membrane to 508 × 10−6 mol m−2 s−1 Pa−1 in the ACB3.0 composite. This enhancement is attributed to the formation of interconnected pore networks and increased the adsorption capacity associated with the presence of carbon black. Pore structure analysis confirmed that carbon black effectively modified the membrane morphology, initially increasing the average pore diameter (up to ACB1.0) and subsequently promoting a rise in specific surface area at higher loadings, thereby facilitating gas transport. In addition to permeability, carbon black incorporation also improved gas selectivity, particularly at elevated temperatures. At 773 K, the ACB3.0 membrane exhibited H2 and N2 permeance values of 245 × 10−6 mol m−2 s−1 Pa−1 and 93 × 10−6 mol m−2 s−1 Pa−1, respectively, and achieved the highest H2/N2 selectivity of 3.89. This value exceeds the theoretical Knudsen selectivity limit (3.74), indicating the combined influence of Knudsen diffusion and enhanced surface interactions induced by carbon black. The ACB3.0 composite offers a unique combination of high hydrogen permeance and favorable selectivity, achieved through a simple, cost-effective fabrication process. The Al2O3/carbon black composite membranes developed in this work present a promising and scalable solution for hydrogen separation and purification, particularly under high-temperature industrial conditions.

Author Contributions

Conceptualization, S.V., D.A., J.Z., M.K. and P.T.; methodology, M.H., M.K., and P.T.; validation, S.V., D.A., J.Z. and P.T.; formal analysis, M.H.; investigation, M.H. and M.R.; resources, S.V., D.A., M.K. and P.T.; data curation, M.H. and P.T.; writing—original draft preparation, M.H.; writing—review and editing, M.K.; visualization, M.H.; supervision, M.K.; project administration, M.K.; funding acquisition, M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research (grant number RE-KRIS/FF68/08) by King Mongkut’s Institute of Technology Ladkrabang (KMITL) has received funding support from the NSRF. M. Hankoy would like to thank the Thailand Graduate Institute of Science and Technology (TGIST) for his Ph.D. scholarship, Grant Number SCA-CO-2563-12077-TH.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data of this research are available upon request to the corresponding author. The data are not publicly available due to privacy concerns.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, W.; Olguin, G.; Hotza, D.; Seelro, M.A.; Fu, W.; Gao, Y.; Ji, G. Inorganic membranes for in-situ separation of hydrogen and enhancement of hydrogen production from thermochemical reactions. Renew. Sust. Energy Rev. 2022, 160, 112124. [Google Scholar] [CrossRef]

- Moliner, R.; Lázaro, M.J.; Suelves, I. Analysis of the strategies for bridging the gap towards the hydrogen economy. Int. J. Hydrogen Energy 2016, 41, 19500–19508. [Google Scholar] [CrossRef]

- Ball, M.; Weeda, M. The hydrogen economy—Vision or reality? Int. J. Hydrogen Energy 2015, 40, 7903–7919. [Google Scholar] [CrossRef]

- Assareh, E.; Delpisheh, M.; Baldinelli, A.; Cinti, G.; Emami, H.; Lee, M. Integration of geothermal-driven organic rankine cycle with a proton exchange membrane electrolyzer for the production of green hydrogen and electricity. Environ. Sci. Pollut. Res. 2023, 30, 54723–54741. [Google Scholar] [CrossRef] [PubMed]

- Cardoso, S.P.; Azenha, I.S.; Lin, Z.; Portugal, I.; Rodrigues, A.E.; Silva, C.M. Inorganic membranes for hydrogen separation. Sep. Purif. Rev. 2018, 47, 229–266. [Google Scholar] [CrossRef]

- Megia, P.J.; Vizcaino, A.J.; Calles, J.A.; Carrero, A. Hydrogen production technologies: From fossil fuels toward renewable sources. A mini review. Energy Fuels 2021, 35, 16403–16415. [Google Scholar] [CrossRef]

- Karousos, D.S.; Qadir, D.; Sapalidis, A.A.; Ahmad, F.; Favvas, E.P. Polymeric, Metallic and carbon membranes for hydrogen separation: A review. Gas Sci. Eng. 2023, 120, 205167. [Google Scholar] [CrossRef]

- Chehade, G.; Lytle, S.; Ishaq, H.; Dincer, I. hydrogen production by microwave based plasma dissociation of water. Fuel 2020, 264, 11683. [Google Scholar] [CrossRef]

- Antonini, C.; Treyer, K.; Streb, A.; van der Spek, M.; Bauer, C.; Mazzotti, M. Hydrogen production from natural gas and biomethane with carbon capture and storage—A techno-environmental analysis. Sustain. Energy Fuels 2020, 4, 2967–2986. [Google Scholar] [CrossRef]

- Koumi Ngoh, S.; Njomo, D. An overview of hydrogen gas production from solar energy. Renew. Sust. Energy Rev. 2012, 16, 6782–6792. [Google Scholar] [CrossRef]

- Soja, R.J.; Gusau, M.B.; Ismaila, U.; Garba, N.N. Comparative analysis of associated cost of nuclear hydrogen production using iaea hydrogen cost estimation program. Int. J. Hydrogen Energy 2023, 48, 23373–23386. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, X.; Wen, H.; Pei, A. Hydrogen production from offshore wind power in South China. Int. J. Hydrogy Energy 2022, 47, 24558–24568. [Google Scholar] [CrossRef]

- Lepage, T.; Kammoun, M.; Schmetz, Q.; Richel, A. Biomass-to-hydrogen: A review of main routes production, processes evaluation and techno-economical assessment. Biomass Bioenergy 2021, 144, 105920. [Google Scholar] [CrossRef]

- Gnanapragasam, N.V.; Reddy, B.V.; Rosen, M.A. Hydrogen production from coal gasification for effective downstream CO2 capture. Int. J. Hydrogen Energy 2010, 35, 4933–4943. [Google Scholar] [CrossRef]

- Liang, Y.Y.; Shahabuddin, M. Production of green hydrogen from desalinated water using membranes: A review. Desalination 2025, 614, 119200. [Google Scholar] [CrossRef]

- Qian, J.X.; Chen, T.W.; Enakonda, L.R.; Liu, D.B.; Basset, J.M.; Zhou, L. Methane decomposition to pure hydrogen and carbon nano materials: State-of-the-art and future perspectives. Int. J. Hydrogen Energy 2020, 45, 15721–15743. [Google Scholar] [CrossRef]

- Wu, X.; Wu, S. Production of High-purity hydrogen by sorption-enhanced steam reforming process of methanol. J. Energy Chem. 2015, 24, 315–321. [Google Scholar] [CrossRef]

- Liu, Y.; Xiao, S.; Bai, P.; Hu, H.; Jin, L. Adsorption separation performance of H2/CH4 on ETS-4 by concentration pulse chromatography. J. Energy Chem. 2014, 23, 213–220. [Google Scholar] [CrossRef]

- Adhikari, S.; Fernando, S. Hydrogen membrane separation techniques. Ind. Eng. Chem. Res. 2006, 45, 875–881. [Google Scholar] [CrossRef]

- Sircar, S.; Golden, T.C. Purification of hydrogen by pressure swing adsorption. Sep. Sci. Technol. 2000, 35, 667–687. [Google Scholar] [CrossRef]

- Salim, W.; Ho, W.S.W. Hydrogen purification with CO2-selective facilitated transport membranes. Curr. Opin. Chem. Eng. 2018, 21, 96–102. [Google Scholar] [CrossRef]

- Yan, S.; Zhang, F.; Kong, J.; Wang, B.; Li, H.; Yang, Y.; Xing, P. Mechanical properties of geopolymer composite foams reinforced with carbon nanofibers via modified hydrogen peroxide method. Mater. Chem. Phys. 2020, 253, 123258. [Google Scholar] [CrossRef]

- De Araújo, M.J.G.; Villarroel-Rocha, J.; De Souza, V.C.; Sapag, K.; Pergher, S.B.C. Carbon foams from sucrose employing different metallic nitrates as blowing agents: Application in CO2 capture. J. Anal. Appl. Pyrolysis 2019, 141, 104627. [Google Scholar] [CrossRef]

- Kusdhany, M.I.M.; Ma, Z.; Mufundirwa, A.; Li, H.W.; Sasaki, K.; Hayashi, A.; Lyth, S.M. Hydrogen and carbon dioxide uptake on scalable and inexpensive microporous carbon foams. Microporous Mesoporous Mater. 2022, 343, 112141. [Google Scholar] [CrossRef]

- Shim, D.H.; Jung, S.S.; Kim, H.S.; Cho, H.; Kim, J.K.; Kim, T.G.; Yoon, S.J. Effect of carbon nanotubes on the properties of spark plasma sintered ZrO2/CNT composites. Arch. Metall. Mater. 2015, 60, 1315–1318. [Google Scholar] [CrossRef][Green Version]

- He, J.; Wu, H.; Zhong, L.; Zhong, Q.; Yang, Q.; Ye, X.; Liu, Z.; Kang, Y. Mechanical properties and thermal conductivity of lightweight and high-strength carbon-graphite thermal insulation materials. J. Mater. Sci. 2022, 57, 4166–4179. [Google Scholar] [CrossRef]

- Pal, N.; Agarwal, M. Advances in materials process and separation mechanism of the membrane towards hydrogen separation. Int. J. Hydrogen Energy 2021, 46, 27062–27087. [Google Scholar] [CrossRef]

- Hasan, I.U.; Othmen, A.B.; Onaizi, S.A. CO2 separation from gas mixtures using metal organic frameworks-based mixed matrix membranes: A comprehensive review. Gas. Sci. Eng. 2025, 138, 205604. [Google Scholar] [CrossRef]

- Silva, A.M.A.; Britto de Faria, A.C.; de Lima Ribeiro, C.; Athayde, D.D.; Paulo da Silva, E.; Magalhães dos Santos, G.; Fernando de Sousa Lima, L.; Nunes de Souza, R.; Pereira da Silva, S.L.; Mohallem, N.D.S. Review of zeolite membranes for natural gas processing and treatment: State of the art and future perspectives. Gas. Sci. Eng. 2023, 117, 205056. [Google Scholar] [CrossRef]

- Karim, S.S.; Ahsan, M.; Farrukh, S.; Fan, X.; Yu, Z. Multi-layer composite (MLC) membranes gas transport models and separation mechanisms. In Multi-Layer Composite (MLC) Membranes for Gas Separation; Lecture Notes in Energy; Springer: Cham, Switzerland, 2025; Volume 102, pp. 159–185. [Google Scholar] [CrossRef]

- Lee, N.R.; Lee, S.S.; Kim, K.I.; Kim, W.G.; Ju, H.; Kim, D.M.; Hong, T.W. Fabrications and evaluations of hydrogen permeation on Al2O3/CeO2/Graphene (ACG) composites membrane by Hot Press Sintering (HPS). Int. J. Hydrogen Energy 2013, 38, 7654–7658. [Google Scholar] [CrossRef]

- Terra, N.M.; Bessa, L.P.; Cardoso, V.L.; Reis, M.H.M. Graphite coating on alumina substrate for the fabrication of hydrogen selective membranes. Int. J. Hydrogen Energy 2018, 43, 1534–1544. [Google Scholar] [CrossRef]

- Zhang, B.; Shi, Y.; Wu, Y.; Wang, T.; Qiu, J. Preparation and Characterization of Supported Ordered Nanoporous Carbon Membranes for Gas Separation. J. Appl. Polym. Sci. 2014, 131, 39925. [Google Scholar] [CrossRef]

- Nie, J.; Okada, F.; Kita, H.; Tanaka, K.; Mihara, T.; Kondo, D.; Yamashita, Y.; Yahagi, N. Fabrication of carbon molecular sieve membranes supported on a novel porous carbon fiber. Energy Fuels 2022, 36, 7147–7157. [Google Scholar] [CrossRef]

- Yousef, S.; Tuckute, S.; Tonkonogovas, A.; Stankevičius, A.; Mohamed, A. Ultra-permeable cnts/pes membranes with a very low cnts content and high H2/N2 and CH4/N2 selectivity for clean energy extraction applications. J. Mater. Res. Technol 2021, 15, 5114–5127. [Google Scholar] [CrossRef]

- Molaei, M.J. Synthesis and application of carbon quantum dots derived from carbon black in bioimaging. J. Fluoresc. 2023, 34, 213–226. [Google Scholar] [CrossRef]

- Yang, Y.; Sun, J.; Wen, J.; Mo, S.; Wang, J.; Zhang, Z.; Wang, G.; Liu, M.; Liu, H. Single-atom doping in carbon black nanomaterials for photothermal antibacterial applications. Cell. Rep. Phys. Sci. 2021, 2, 100535. [Google Scholar] [CrossRef]

- Kosinska, A.; Balakin, B.V.; Kosinski, P. Use of biodegradable colloids and carbon black nanofluids for solar energy applications. AIP Adv. 2021, 11, 055214. [Google Scholar] [CrossRef]

- Tsubokawa, N.; Shirai, Y.; Okazaki, M.; Maruyama, K. A novel gas sensor from crystalline polymer-grafted carbon black: Responsibility of electric resistance of composite from crystalline polymer-grafted carbon black against solvent vapo. Polym. Bull. 1999, 42, 425–431. [Google Scholar] [CrossRef]

- Xie, H.; Yang, Q.; Sun, X.; Yang, J.; Huang, Y. Gas sensor arrays based on polymer-carbon black to detect organic vapors at low concentration. Sens. Actuators B Chem. 2006, 113, 887–891. [Google Scholar] [CrossRef]

- Grießl, D.; Huber, K.; Scherbauer, R.; Kwade, A. Dispersion kinetics of carbon black for the application in lithium-ion batteries. Adv. Powder Technol. 2021, 32, 2280–2288. [Google Scholar] [CrossRef]

- Gauthier, N.; Agrawal, A.; Dubrunfaut, O.; Franger, S.; Lestriez, B.; Badot, J.C.; Assaud, L. Carbon black/electrolyte interface study by electromagnetic and electrochemical techniques in γAl2O3/poly(vinylidene fluoride)/carbon black composite materials: Application for lithium-ion batteries. Electrochim. Acta 2023, 437, 141495. [Google Scholar] [CrossRef]

- Robertson, C.G.; Hardman, N.J. Nature of carbon black reinforcement of rubber: Perspective on the original polymer nanocomposite. Polymers 2021, 13, 538. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.W.; Zheng, Q.R. Methane adsorption on the graphene sheets, activated carbon and carbon black. Appl. Therm. Eng. 2016, 108, 605–613. [Google Scholar] [CrossRef]

- Youssry, M.; Madec, L.; Soudan, P.; Cerbelaud, M.; Guyomard, D.; Lestriez, B. Non-Aqueous carbon black suspensions for lithium-based redox flow batteries: Rheology and simultaneous rheo-electrical behavior. Phys. Chem. Chem. Phys. 2013, 15, 14476–14486. [Google Scholar] [CrossRef]

- Çelik, A.; Çağlar, G.; Çelik, Y. Fabrication of porous Al2O3 ceramics using carbon black as a pore forming agent by spark plasma sintering. Ceram. Int. 2022, 48, 28181–28190. [Google Scholar] [CrossRef]

- Manisa, V.K.; Porter, M.; Whiting, M.J.; Dorey, R.A. Effect of processing on the stability and electrical properties of pressureless sintered graphene oxide–alumina composites. Ceram. Int. 2022, 48, 15839–15847. [Google Scholar] [CrossRef]

- Li, Q.; Chen, Y.; Xu, Q.; Yang, M.; Zhang, S.; Goto, T.; Tu, R. Effect of TZP nanoparticles synthesized by RCVD on mechanical properties of ZTA composites sintered by SPS. J. Eur. Ceram. Soc. 2022, 42, 3550–3558. [Google Scholar] [CrossRef]

- Kageyama, N.; Takagaki, A.; Sugawara, T.; Kikuchi, R.; Oyama, S.T. Synthesis and Characterization of a silica-alumina composite membrane and its application in a membrane reactor. Sep. Purif. Technol. 2018, 195, 437–445. [Google Scholar] [CrossRef]

- Singh, M.; Vander Wal, R. Nanostructure quantification of carbon blacks. C-J. Carbon Res. 2018, 5, 2. [Google Scholar] [CrossRef]

- Ostyn, N.R.; Steele, J.A.; De Prins, M.; Sree, S.P.; Chandran, C.V.; Wangermez, W.; Vanbutsele, G.; Seo, J.W.; Roeffaers, M.B.J.; Breynaert, E.; et al. Low-temperature activation of carbon black by selective photocatalytic oxidation. Nanoscale Adv. 2019, 1, 2873–2880. [Google Scholar] [CrossRef]

- Pawlyta, M.; Rouzaud, J.N.; Duber, S. Raman microspectroscopy characterization of carbon blacks: Spectral analysis and structural information. Carbon 2015, 84, 479–490. [Google Scholar] [CrossRef]

- Lee, S.M.; Lee, S.H.; Roh, J.S. Analysis of activation process of carbon black based on structural parameters obtained by XRD analysis. Crystals 2021, 11, 153. [Google Scholar] [CrossRef]

- Mohammed, A.S.; Alahmari, T.S.; Laoui, T.; Hakeem, A.S.; Patel, F. Mechanical and thermal evaluation of aluminum hybrid nanocomposite reinforced with alumina and graphene oxide. Nanomaterials 2021, 11, 1225. [Google Scholar] [CrossRef]

- Xu, H.; Li, S.; Liu, R.; Bao, C.; Mu, M.; Wang, K. Fabrication of alumina ceramics with high flexural strength using stereolithography. Int. J. Adv. Manuf. Technol. 2023, 128, 2983–2994. [Google Scholar] [CrossRef]

- Rivero-Antúnez, P.; Zamora-Ledezma, C.; Sánchez-Bajo, F.; Moreno-López, J.C.; Anglaret, E.; Morales-Flórez, V. Sol–gel method and reactive SPS for novel alumina–graphene ceramic composites. J. Eur. Ceram. Soc. 2023, 43, 1064–1077. [Google Scholar] [CrossRef]

- Lei, L.; Pan, F.; Lindbråthen, A.; Zhang, X.; Hillestad, M.; Nie, Y.; Bai, L.; He, X.; Guiver, M.D. Carbon hollow fiber membranes for a molecular sieve with precise-cutoff ultramicropores for superior hydrogen separation. Nat. Commun. 2021, 12, 268. [Google Scholar] [CrossRef]

- White, R.J.; Budarin, V.; Luque, R.; Clark, J.H.; Macquarrie, D.J. Tuneable Porous carbonaceous materials from renewable resources. Chem. Soc. Rev. 2009, 38, 3401–3418. [Google Scholar] [CrossRef]

- Wu, C.C.; Rice, R.W. Porosity dependence of wear and other mechanical properties on fine-grain Al2O3 and B4C. Ceram. Eng. Sci. Proc. 1985, 6, 977. [Google Scholar] [CrossRef]

- Freeman, B.D. Basis of permeability/selectivity tradeoff relations in polymeric gas separation membranes. Macromolecules 1999, 32, 375–380. [Google Scholar] [CrossRef]

- Qin, Y.; Xu, L.; Liu, L.; Ding, Z. Zeolitic imidazolate framework membranes with a high h2 permeance fabricated on a macroporous support with novel spherical porous hybrid materials. Ind. Eng. Chem. Res. 2021, 60, 1387–1395. [Google Scholar] [CrossRef]

- Nian, P.; Cao, Y.; Li, Y.; Zhang, X.; Wang, Y.; Liu, H.; Zhang, X. Preparation of a pure zif-67 membrane by self-conversion of cobalt carbonate hydroxide nanowires for H2 separation. CrystEngComm 2018, 20, 2440–2448. [Google Scholar] [CrossRef]

- Yu, C.Y.; Sea, B.K.; Lee, D.W.; Park, S.J.; Lee, K.Y.; Lee, K.H. effect of nickel deposition on hydrogen permeation behavior of mesoporous γ-alumina composite membranes. J. Colloid Interface Sci. 2008, 319, 470–476. [Google Scholar] [CrossRef]

- Lee, H.K.; Suda, H.; Haraya, K. Gas permeation properties in a composite mesoporous alumina ceramic membrane. Kor. J. Chem. Eng. 2005, 22, 721–728. [Google Scholar] [CrossRef]

- Briceño, K.; Iulianelli, A.; Montané, D.; Garcia-Valls, R.; Basile, A. Carbon molecular sieve membranes supported on non-modified ceramic tubes for hydrogen separation in membrane reactors. Int. J. Hydrogen Energy 2012, 37, 13536–13544. [Google Scholar] [CrossRef]

- Ordoñez, M.J.C.; Balkus, K.J.; Ferraris, J.P.; Musselman, I.H. Molecular sieving realized with ZIF-8/matrimid® mixed-matrix membranes. J. Memb. Sci. 2010, 361, 28–37. [Google Scholar] [CrossRef]

- Hynek, S.; Fuller, W.; Bentley, J. Hydrogen storage by carbon sorption. Int. J. Hydrogen Energy 1997, 22, 601–610. [Google Scholar] [CrossRef]

- Kaneko, T.; Toyama, T.; Kojima, Y.; Nishimiya, N. temperature dependence of hydrogen adsorption on Pd-modified carbon blacks and their enthalpy-entropy changes. C-J. Carbon Res. 2022, 8, 16. [Google Scholar] [CrossRef]

- Panella, B.; Hirscher, M.; Roth, S. Hydrogen adsorption in different carbon nanostructures. Carbon 2005, 43, 2209–2214. [Google Scholar] [CrossRef]

- Cheng, Z.L.; Liu, Z.; Wan, H.L. Microwave-heating synthesis and gas separation performance of NaA zeolite membrane. Chin. J. Chem. 2005, 23, 28–31. [Google Scholar] [CrossRef]

- Zeynali, R.; Ghasemzadeh, K.; Iulianelli, A.; Basile, A. Experimental evaluation of graphene oxide/TiO2-alumina nanocomposite membranes performance for hydrogen separation. Int. J. Hydrogen Energy 2020, 45, 7479–7487. [Google Scholar] [CrossRef]

- Kumar, R.; Kamakshi; Kumar, M.; Awasthi, K. Functionalized Pd-decorated and aligned MWCNTs in polycarbonate as a selective membrane for hydrogen separation. Int. J. Hydrogen Energy 2016, 41, 23057–23066. [Google Scholar] [CrossRef]

- Ribeiro, S.R.F.L.; Bessa, L.P.; Cardoso, V.L.; Reis, M.H.M. Enhanced hydrogen permeance through graphene oxide membrane deposited on asymmetric spinel hollow fiber substrate. Int. J. Hydrogen Energy 2022, 47, 9616–9626. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).