1. Introduction

The mine ventilation system is critical for maintaining a safe underground environment and ensuring mine production safety. Developing smart mine ventilation systems is vital for enhancing underground safety and driving the mining industry’s intelligent transformation. By integrating technologies such as smart sensing, automated control, data analysis, and simulation modeling, intelligent ventilation systems can provide mines with a comprehensive, multi-layered safety framework operating at multiple levels [

1,

2].

An intelligent mine ventilation system uses information-based technologies and adaptive regulation for real-time, dynamic airflow regulation. Through interconnected subsystems—encompassing data acquisition, decision support, adaptive control, and dynamic feedback—it fulfills two core functions: (1) on-demand air supply and optimized regulation during normal operations, and (2) dynamic early warning and real-time disaster scenario management during emergencies. Ensuring safe, efficient, and cost-effective ventilation operation is a key goal of smart mining, supported by extensive research [

3,

4,

5,

6].

The development of intelligent mine ventilation systems has exhibited distinct iterative characteristics. The first-generation online monitoring ventilation system, based on sensing networks, achieved real-time collection of environmental parameters and threshold alerts. However, it lacked closed-loop control, limiting its ability to act on monitored data [

7]. The second-generation remote-controlled ventilation system used IoT for remote centralized control of ventilation equipment. Nevertheless, unidirectional communication delays and human-dependent control caused delayed responses [

8]. Currently, the third-generation intelligent ventilation system integrates ventilation network calculation and regulation methods on the foundation of monitoring and control systems. It enables auxiliary decision-making and regulation simulation for remote control, shifting ventilation management from passive to proactive optimization. Ventilation network calculation technology builds models to compute air resistance, airflow volume, and critical node pressures in real-time. This provides a basis for precise airflow regulation decisions. Regulation optimization methods, based on network calculation results, combine targets (such as airflow demand and energy consumption constraints) with advanced algorithms (e.g., mixed-integer linear programming [

9], dynamic CFD-based methods [

10,

11], solution optimization algorithms [

12,

13,

14,

15]) to automatically generate optimal airflow distribution plans and execution instructions (e.g., adjusting air doors, fan speeds). However, current systems still face significant challenges, including limited environmental perception accuracy (e.g., air velocity measurement errors exceeding ±20% in dusty environments), slow network calculation speeds often resulting in minute-level delays, insufficient real-time performance, low automation in on-demand regulation, and inadequate system robustness under dynamic conditions. In the future, a fourth-generation smart ventilation system should integrate intelligent algorithms and big data technology to achieve comprehensive autonomous management of ventilation in mines. It should provide more reliable technical support for mine safety production through a closed-loop management process of sensing–warning–decision–control–feedback.

Currently, research on smart mine ventilation primarily focuses on utilizing advanced sensing technologies and data communication to enable real-time monitoring of ventilation systems. For instance, Wang Kai et al. [

16] developed a monitoring system for ventilation network parameters based on a typical ventilation network model, aimed at achieving on-demand ventilation in coal mines. Jo Byung Wan et al. [

17] created an IoT system for autonomous gas detection and information sharing underground, leveraging sensors, IoT, and cloud computing. This system provides a more synchronized and cost-effective way to facilitate the near-real-time monitoring of mine environments, ventilation control, emergency communication, and information sharing, significantly enhancing underground mine safety. Liu Hui et al. [

18] designed a prototype Web system named 3D VentCloud, successfully applying it to real coal mine ventilation solutions, thereby demonstrating the model’s rationality and practicality. Additionally, researchers have employed intelligent algorithms such as fuzzy control and neural networks to adaptively adjust the operational parameters of ventilators, meeting ventilation demands under complex conditions. Lawal AI et al. [

19] proposed an intuitionistic fuzzy TOPSIS (IFT) method to select booster fans, improving methane emission and overall ventilation efficiency in underground mines. Arnab Chatterjee et al. [

20] optimized mine ventilation fan speeds based on ventilation needs and real-time electricity prices to minimize total power consumption. Yu Baocai and Shao Liangshan [

21] introduced a smart control-based system for seamless switching of the main mine fans, effectively mitigating fluctuations in underground airflow during the switching process. In terms of intelligent ventilation system development, Zhou Fubao and others [

22] proposed the concept of smart sensing and interaction control of integrated information flows involving humans, machines, and the environment underground, guided by the “normal-emergency integration” principle, providing theoretical support for smart ventilation system design. Yang Jie et al. [

23] explored research methodologies for intelligent ventilation systems based on Industry 4.0 concepts, designing an intelligent ventilation system scheme based on fieldbus technology. To address the critical issue of delayed regulation in metal mine ventilation systems, Li Hongwei et al. [

24] developed an operation control software platform for smart ventilation systems, grounded in autonomous regulation methods and system architecture. Lu Xinming and Yin Hong [

25] designed a four-layer architecture for intelligent ventilation systems, centered on computer software technology, offering insights for the development of fully intelligent mine ventilation systems.

Traditional digital mine ventilation software is limited by static modeling, delayed response, and non-real-time network computation. This prevents timely hazard warnings and diagnostics and limits efficient decision-making support for airflow regulation and disaster rescue. As both mine digitalization and intelligentization advance, smart ventilation systems have become a key focus for smart mine development [

26]. New-generation information technologies have improved real-time data acquisition and remote control of equipment, providing safer, more economical, and efficient ventilation solutions for underground mines.

2. Overall Framework of Intelligent Ventilation

2.1. Implementation Phases

The scope of the intelligent ventilation system covers the entire mine ventilation workflow, spanning from mining design through network optimization to production operations. Overall, the core functions of the smart ventilation system are primarily concentrated in three stages: the mining design stage, the network optimization stage, and the production operation stage.

In the mining design stage, key functions include constructing a 3D ventilation model, selecting main and auxiliary fans, analyzing critical airflow paths (maximum resistance), computing ventilation networks, and simulating disaster scenarios. Through ventilation network solving and disaster modeling, the system can simulate ventilation effectiveness during the most challenging periods, the easiest periods, and disaster conditions, providing critical data support for design decisions.

In the network optimization stage, key activities include detecting ventilation anomalies, renovating and optimizing networks, and selecting fan retrofits. Utilizing fault diagnosis techniques such as recirculation airflow detection, series airflow detection, and excessive air velocity detection, the system identifies potential issues within the ventilation network and implements targeted retrofit plans and optimized control strategies.

In the production stage, key functions focus on daily management and emergency management. Daily management includes on-demand ventilation, ventilation network statistical reporting, and equipment maintenance and management. The key function, on-demand ventilation, regulates airflow facilities by monitoring required airflow changes, optimizing distribution, and maintaining optimal system performance. Emergency management involves disaster scenario adaptive control, emergency plan management, and escape route planning. Furthermore, the intelligent ventilation system provides comprehensive visualization of the entire ventilation network. By displaying real-time airflow direction, air quantity distribution, and operational status of critical equipment, it enables management personnel to promptly identify abnormalities and make scientifically informed decisions.

2.2. Integrated Architecture

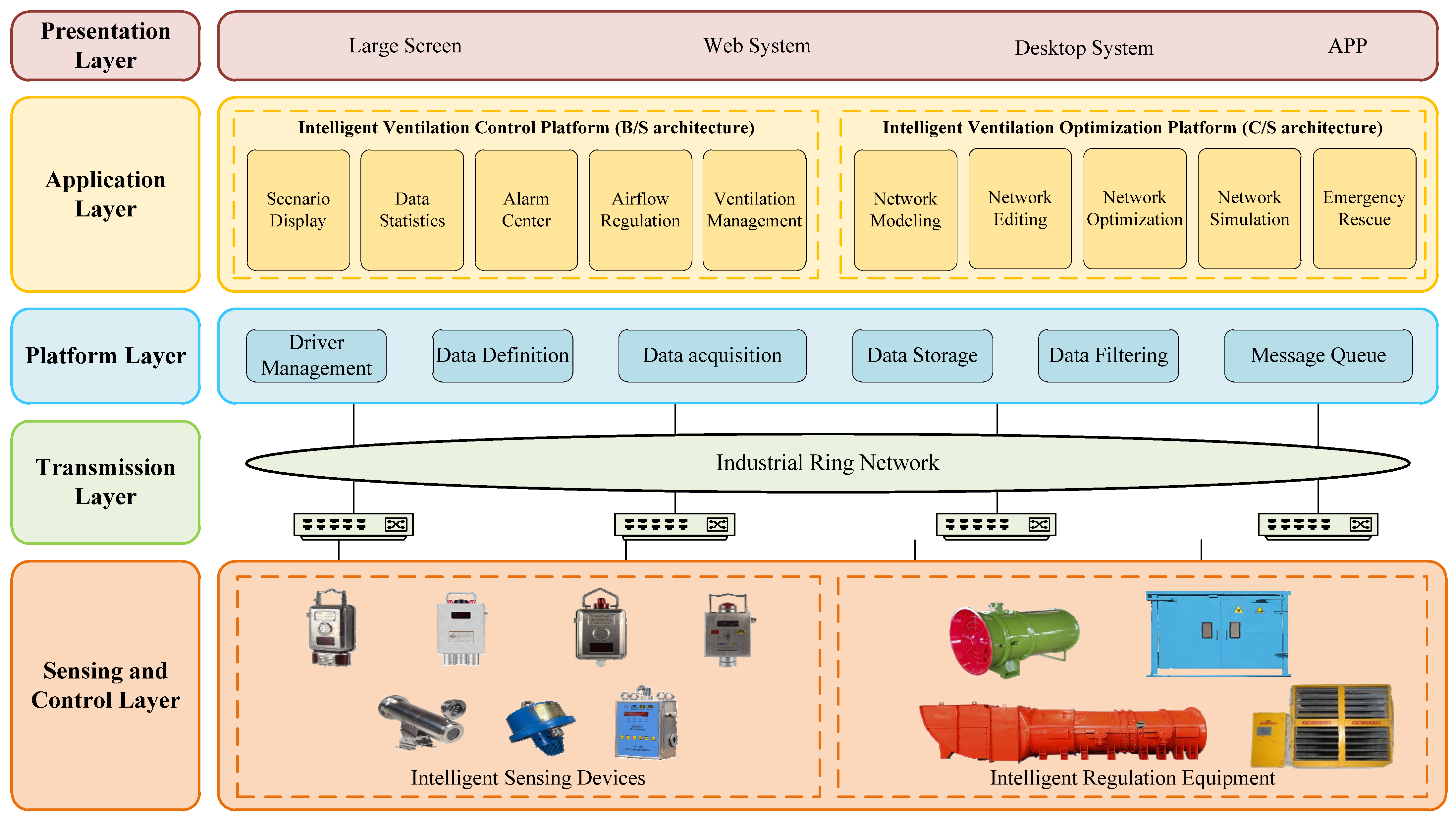

The intelligent mine ventilation system, built on information and automation technologies, enables real-time monitoring, smart analysis, and dynamic regulation of the ventilation network. Its core uses data-driven methods and intelligent algorithms for automated management, improving ventilation network regulation and safety. As illustrated in

Figure 1, the overall architecture of the intelligent mine ventilation system is composed of five layers: the Sensing and Control Layer, the Transmission Layer, the Platform Layer, the Application Layer, and the Presentation Layer.

2.2.1. Sensing and Control Layer

The Sensing and Control Layer serves as the physical foundation of the intelligent ventilation system. Through the automation of equipment such as sensors, ventilation power sources (fans), and ventilation structures (stoppings, doors, dampers), it achieves precise sensing of various underground environmental parameters and the operational status of ventilation equipment, along with accurate regulation of underground ventilation equipment. This layer provides reliable data support and execution assurance for the intelligent ventilation system.

2.2.2. Transmission Layer

The Transmission Layer is responsible for data communication tasks within the smart ventilation system. Constructed from highly reliable and high-throughput wired and wireless networks, it ensures the efficient and stable transmission of diverse sensor data and control commands between all hierarchical levels of the system.

2.2.3. Platform Layer

The Platform Layer functions as the data processing center of the intelligent ventilation system, comprising six modules: Driver Management, Data Definition, Scheduled Polling & Collection, Data Storage, Data Filtering, and Data Retrieval & Push. This layer processes and stores collected data in a standardized format, providing the essential data foundation for implementing the functionalities of the Application Layer.

2.2.4. Application Layer

The Application Layer constitutes the core functional layer of the intelligent ventilation system. It consists of two main platforms: the Intelligent Ventilation Control Platform and the Intelligent Ventilation Optimization Platform. The Intelligent Ventilation Control Platform provides secure, remote access to ventilation systems from any location and device through a standard web browser. The Intelligent Ventilation Optimization Platform facilitates complex data processing and optimization analysis through the C/S (Client/Server) architecture.

2.2.5. Presentation Layer

The Presentation Layer serves as the system’s information display and user interaction interface, enabling multi-scenario visualization via industrial-scale display monitors, PC clients, and mobile devices.

2.3. System Design

The smart mine ventilation system includes three key components: the Intelligent Sensing System, the Intelligent Decision-Making System, and the Intelligent Control System. The system utilizes various sensors to acquire real-time data on airflow states and mine production activities. This data facilitates the analysis and assessment of the ventilation system’s operating condition. Based on this analysis, the system develops regulation strategies and optimization solutions for various ventilation scenarios and anomalies. Finally, it controls ventilation facilities to execute regulation commands, thereby achieving precision regulation of the ventilation network. This process establishes a closed-loop smart management mode spanning the entire ventilation workflow, ensuring the mine ventilation system operates safely, cost-effectively, and with high efficiency.

2.3.1. Intelligent Sensing System

The primary function of the Intelligent Sensing System is to collect, transmit, and process environmental, equipment, personnel, and production information underground, providing data support for smart decision-making and regulation. The system deploys multiple environmental parameter sensors throughout the mine to acquire critical environmental data. It synchronously interfaces with operational status data from smart ventilation equipment. Combined with the data processing capabilities of the Platform Layer, it forms a comprehensive sensing network covering the environment, equipment, and personnel, establishing a reliable data foundation for the intelligent ventilation system.

Furthermore, to ensure the safety of underground personnel and production, the Intelligent Sensing System integrates personnel positioning and scene sensing capabilities. This enables the system to acquire real-time personnel location information and identify hazard sources such as fires, heat hazards, dust, and toxic/flammable gases. Particularly during emergencies, the rapid localization of personnel positions provides crucial data support for the Intelligent Decision-Making System to formulate optimal escape routes.

2.3.2. Intelligent Decision-Making System

The Intelligent Decision-Making System enables the smart mine ventilation system to perform functions ranging from data acquisition and status monitoring to intelligent decision support and command execution through the collaborative operation of the Intelligent Ventilation Control Platform (B/S architecture) and the Intelligent Ventilation Optimization Platform (C/S architecture). The Optimization Platform serves as a powerful backend engine, providing results such as network computational solving, on-demand regulation strategies, emergency response plans, and escape route planning. These results are fed back to the Control Platform for visualization.

The Intelligent Ventilation Control Platform adopts a B/S architecture to enhance system accessibility and usability. Its functionalities encompass all operational phase activities, featuring modules for network management, alarm center, scenario visualization, data statistics, and network regulation. The Control Platform visualizes the mine ventilation network and allows direct command dispatching to ventilation equipment via a graphical interface, effectively elevating smart management levels and operational efficiency.

The Intelligent Ventilation Optimization Platform employs a C/S architecture to enhance data processing and optimization capabilities. Its functionalities cover all design and optimization phase activities, featuring modules for network modeling, network computational solving & diagnostics, emergency rescue planning, and network simulation. During ventilation network optimization, the Optimization Platform simulates airflow distribution under various schemes and conducts an in-depth analysis of their impacts on energy consumption and safety. Additionally, simulating ventilation disaster scenarios provides a scientific basis for formulating emergency response plans.

2.3.3. Intelligent Control System

The Intelligent Control System acts as the “operational command center” of the smart mine ventilation system. It is tasked with precisely executing commands generated by the Intelligent Decision-Making System and ensuring effective ventilation underground. The system responds in real-time and executes regulation commands from the decision system. Based on actual underground conditions, it precisely adjusts ventilation equipment such as fans, air doors, and air dampers to achieve the goals of safe, economical, and highly efficient ventilation.

2.4. System Development

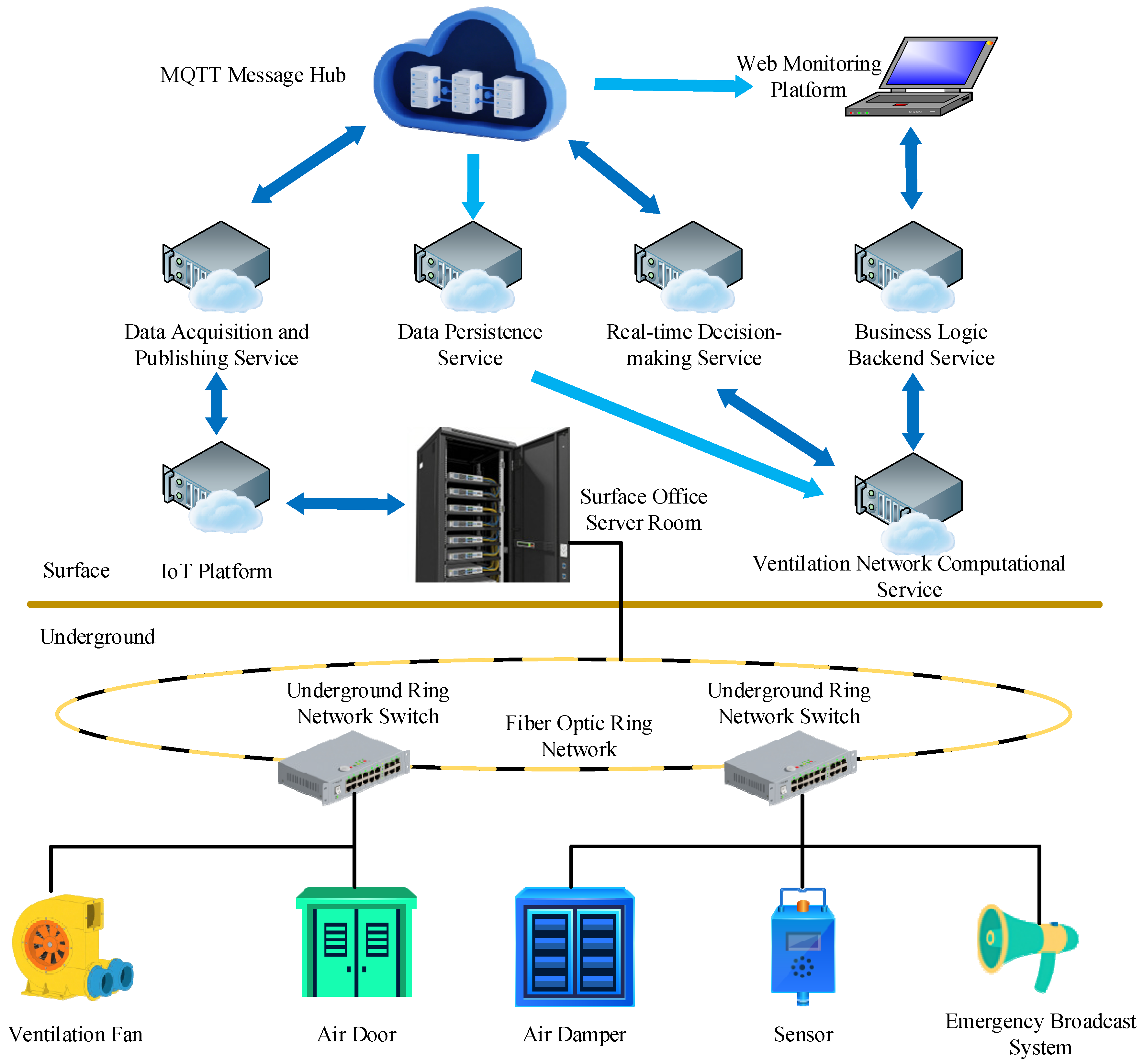

The networking architecture of the intelligent mine ventilation system is illustrated in

Figure 2. Numerous actuators, such as fans, air doors, and air dampers, along with various sensors and emergency broadcast systems, are deployed underground. These connect to the IoT platform via the industrial ring network. Through this IoT platform, real-time collection of equipment status and sensor data is achieved, and real-time control of equipment—either automated or through manual intervention—can be performed. The IoT platform transmits the data collected in real-time to the Data Acquisition Service via a Socket link. This service parses the data and publishes it to the MQTT Message Hub. The Data Persistence Service subscribes to relevant data topics, and the data is kept in long-term storage. The Real-time Decision-making Service retrieves all decision rules/policies from the Business Backend Service. It subscribes to relevant data streams and performs continuous monitoring and assessment. Upon detecting anomalous conditions, it promptly invokes the Ventilation Network Computational Service. The computational results are displayed, and notifications are sent via the MQTT Message Hub to the Web Monitoring Platform, enabling personnel to identify issues promptly. For certain predefined scenarios, the system supports automatic handling based on predetermined strategies, issuing relevant equipment control commands to the MQTT Message Hub. These commands are forwarded by the Data Acquisition and Publishing Service to the IoT platform for final delivery to the designated actuators.

3. Key Technologies of Intelligent Ventilation

3.1. Construction of Ventilation Networks

Building an accurate mine ventilation network is fundamental to intelligent ventilation systems. Its core lies in establishing a true 3D simulation model that replicates the physical underground ventilation system. This 3D mine ventilation network simulation model functions as a simplified digital twin, approximating real-world airflow dynamics and forming the digital foundation for real-time monitoring, early disaster warnings, and smart decision-making.

Ventilation network modeling technology requires abstracting the ventilation system into a fluid network by integrating automatic topology extraction and simplification algorithms. The standard workflow for an initial static ventilation network model involves extracting roadway floor centerlines from 3D surveyed models to define branches and establishing topological adjacency between nodes and branches. The Kd-Tree-based spatial indexing approach can be employed to enhance the efficiency of dynamic ventilation network topology construction. Another critical step is acquiring initial system parameters, such as aerodynamic data, roadway cross-sections, and ventilation equipment status. In practice, these branch-specific aerodynamic parameters are typically approximated through a combined approach that uses field measurements, theoretical estimations, CFD simulations, and parameter inversion techniques.

As mine operations advance—including development, extraction, roadway connections, and equipment modifications—the ventilation network model requires timely updates to maintain consistency with actual underground conditions. Building upon the initial static ventilation network model, updates were made to the ventilation network model and real-time adjustments were made to fundamental parameters. Ventilation network model updates are typically executed periodically based on actual mining progress and airflow regulation plans, such as sealing mined-out areas or adding ventilation control devices. Parameter updates operate continuously: fan parameters are dynamically refined by fitting characteristic curves via least squares regression using multiple monitored operating points; ventilation equipment statuses update instantly in response to control commands like fan speed adjustments, while updates to airway airflow volumes and resistance values present greater complexity due to their dynamic nature.

A critical challenge in current smart ventilation implementation involves the inherent inaccuracy of static equivalent resistance measurements derived from simplified network models, compounded by non-steady-state resistance fluctuations within underground ventilation systems. To address these dynamic airflow disturbances, intelligent ventilation monitoring systems must evolve into self-learning, self-correcting architectures featuring adaptive calibration and robust feedback mechanisms. By continuously integrating real-time data streams, such systems ensure reliable data acquisition and validate regulation outcomes, thereby establishing a closed-loop framework capable of autonomously reconciling model predictions with actual ventilation behavior under transient operational conditions.

3.2. Intelligent Sensing

The core technologies of the mine ventilation smart sensing system encompass real-time monitoring, parameter sensing, data mining analytics, and autonomous early warning. Anchored by a multi-source heterogeneous sensor network, the system constructs a mine-wide 3D dynamic sensing framework through continuous monitoring of critical parameters such as roadway air velocity, temperature, humidity, and gas concentrations. Leveraging big data analytics, it processes and fuses massive heterogeneous datasets, while machine learning algorithms establish ventilation efficiency evaluation models and abnormal condition identification mechanisms. Utilizing edge-cloud collaborative computing, the system achieves dynamic ventilation network optimization and triggers multi-tiered smart alerts (audible/visual alarms, ventilation equipment linkage, emergency route planning) based on risk prediction, significantly enhancing ventilation system safety and disaster resilience.

The real-time monitoring module deploys diverse environmental sensors across suitable locations using optimal algorithms, acquiring parameters including air velocity, temperature, humidity, CO, dust, and smoke. This enables comprehensive coverage at critical junctions with high-frequency data sampling (multi-readings per second), ensuring precise sensing of underground airflow states. Optimized sensor placement balances economic feasibility and measurement accuracy.

The parameter sensing module semi-automatically calibrates fundamental ventilation network parameters using real-time data, ensuring the construction of a relatively dynamic ventilation network model. Grounded in high-precision airflow measurement systems, it employs global airflow derivation and resistance parameter inversion techniques. By optimizing sensor placement at key roadway locations, it dynamically assists in calibrating network parameters. However, current limitations hinder the direct acquisition of critical airflow parameters, as existing technologies primarily focus on monitoring basic airflow states and issuing dynamic alerts.

The data mining analytics module performs 3D visualization of monitored data, integrating multi-sensor inputs with ventilation network topology for deep analysis. It conducts real-time hazard assessments for fires, toxic gases, and other threats through multi-sensor fusion anomaly detection. By incorporating personnel positioning data into the analytics framework, the system enhances underground worker safety via dynamic risk mapping, feeding into downstream decision modules for emergency response.

The intelligent early warning module detects both single-parameter anomalies and systemic risks through multi-sensor data fusion, historical data correlation, and real-time ventilation network solving. By leveraging big data analysis and machine learning techniques, the system can perform real-time analysis and processing of monitoring data and timely identify abnormal conditions in the ventilation system. The system supports the integration of multi-sensor data for optimized diagnostic analysis of ventilation networks, automatically identifying abnormal conditions such as circulating air, airflow short circuits, series connections, and unreasonable ventilation network structures. Integrated with 3D software platforms (iVent V1.1.0), it enables online ventilation warnings and 3D visualization of disaster simulations.

3.3. Real-Time Solution

Ventilation network computational solving constitutes the core theoretical foundation of mine ventilation systems. It enables rapid calculation of key parameters such as airflow volume and pressure based on real-time monitoring data, providing critical data support for fault diagnosis and smart airflow regulation decisions. This capability is essential for simulating airflow distribution and optimizing ventilation network control.

The essence of ventilation network calculation is to establish a system of nonlinear equations under the topology of the ventilation network based on the fluid mechanics continuity equation, energy conservation equation, and resistance law. This system can be formally expressed as (among them,

is the power source in circuit

(e.g., fan pressure or natural ventilation pressure))

where

is airflow volume in branch

connected to a node and

is the aerodynamic resistance of branch

in a circuit. The objective is to solve this equation system numerically to determine airflow and pressure distributions across all network branches.

Ventilation network solving has long been a focus of ventilation research, with dozens of methods developed to date. Among these, the circuit airflow method remains the most widely adopted in ventilation software. Traditional approaches, exemplified by the Scot-Hinsley circuit airflow method, employ iterative correction strategies to approximate solutions. Their strength lies in high algorithmic stability, making them suitable for static network analysis. However, for complex ventilation networks, these methods exhibit high sensitivity to initial values—convergence speed depends heavily on the rationality of initial airflow assumptions, often resulting in local optima and failing to meet smart ventilation’s real-time demands.

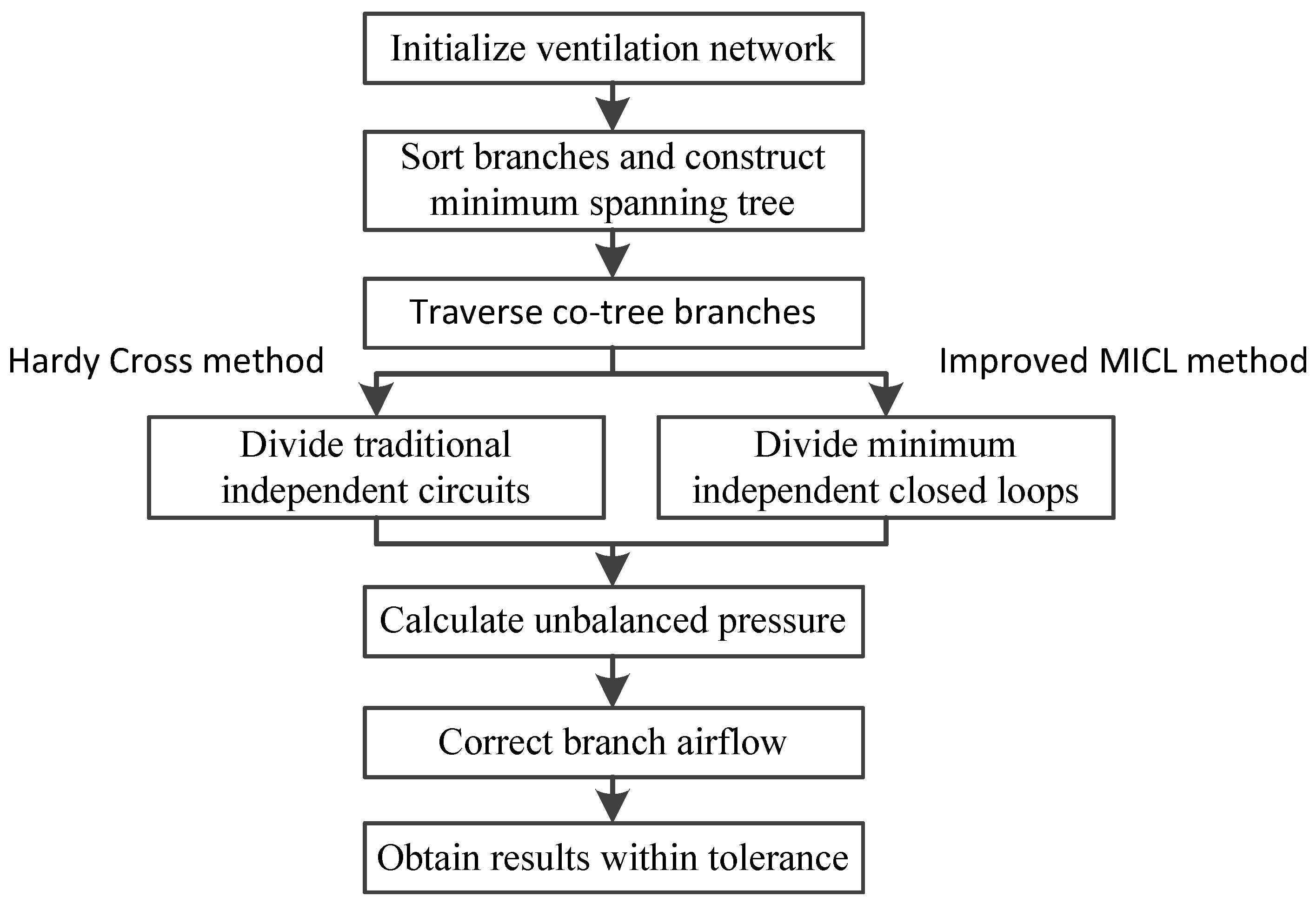

To address real-time solving requirements for smart ventilation, a mesh-based computational method is proposed in this paper, which is centered on minimum independent closed loops. This approach accelerates convergence while reducing computational load. Traditional independent circuits often form lengthy paths with numerous shared branches, causing slow or failed convergence during iterative airflow distribution. In contrast, the minimum-loop-based mesh method constructs near-optimal independent circuits. A dedicated network-solving solver is developed, which is capable of computing airflow distribution in large-scale, multi-fan ventilation networks. It supports simulating airflow effects under different control schemes and predicting airflow trend variations. The real-time solving process achieves second-level response times in airflow distribution calculations, enabling a critical transition from offline analysis to online computation. This breakthrough lays the groundwork for online real-time adaptive ventilation control simulation.

Figure 3 compares the traditional Hardy Cross method with the improved minimum independent closed loops (MICL) method [

13]. The Hardy Cross method proceeds by dividing the network into traditional independent circuits, where each loop typically contains a single co-tree branch. In contrast, the Improved MICL method employs a more sophisticated strategy to partition the network into minimum independent closed loops, which are optimized for a smaller number and reduced overlap of branches in each loop.

3.4. Ventilation Regulation

Airflow regulation stands as the core imperative for both energy efficiency and safety assurance in ventilation systems. Traditional trial-and-error regulation methods based on computational solving simulations fail to meet the requirements of smart ventilation development. Due to the high costs of precise regulation with current technologies and the lack of need for perfect real-time control in mines, this paper proposes a multi-tier airflow regulation framework designed to fulfill on-demand ventilation requirements across diverse operational scenarios at different stages.

The multi-tier airflow regulation framework comprises two distinct approaches.

(1) Optimal regulation for phase-specific airflow distribution is applicable during ventilation system retrofitting. This approach permits significant infrastructure modifications (e.g., adding/removing ventilation installations or updating network models) to compute optimal solutions satisfying on-demand ventilation requirements.

(2) On-demand regulation for dynamic airflow distribution is deployed during routine production operations. This method leverages existing ventilation installations and current network models to determine feasible solutions that maximally comply with on-demand ventilation demands.

3.4.1. Optimal Regulation

Building upon this conceptual framework, the regulation scheme derived from optimal regulation can be regarded as a phase-specific static solution for on-demand ventilation retrofitting. Conversely, the scheme obtained through on-demand regulation constitutes a dynamically computed solution based on real-time computational solving, which can be directly executed by integrating with remote equipment control systems.

The defining characteristic of optimal regulation is its capacity for offline optimization computation, allowing users to iteratively adjust constraints based on actual underground conditions to refine the optimal control strategy. Taking a typical hybrid airflow distribution network as an example, the fundamental mathematical model for nonlinear optimization regulation is formulated as:

where

is the number of ventilation network branches;

is the aerodynamic resistance of branch

;

is the airflow volume in branch

;

is the pressure regulation value for branch

;

is the natural ventilation pressure in branch

;

is the node-branch incidence coefficient;

is the branch-circuit incidence coefficient;

is the algebraic sum of pressure in branch

;

is the minimum/maximum allowable airflow in branch

; and

is the minimum/maximum adjustable pressure in branch

. The decision variables are the airflow volumes

for all unknown-flow branches and the pressure regulation values

for all branches.

Ventilation optimal regulation in intelligent systems requires developing technically sound, economically optimal, and operationally reliable solutions that satisfy dynamic on-demand airflow distribution across mining phases. This is achieved through fluid network-based optimization theory, which adjusts airflow allocation and pressure distribution to ensure safe, reliable, stable, and cost-effective mine ventilation system operations.

Current optimal regulation methods face two critical challenges: computational solving and constraint handling. The nonlinear terms in both the objective function and constraints render it a nonlinear programming (NLP) model, making optimal solution derivation exceptionally difficult. Moreover, the complexity of ventilation systems and multi-factor interactions causes conflicting constraints, requiring multi-objective formulations and flexible structures for feasible solutions.

To address the decades-old challenge of solving nonlinear airflow regulation, this paper proposes a linear optimization technique based on continuous variable discretization. This method transforms the NLP model into a mixed-integer linear programming (MILP) model. Combined with heuristic search strategies to accelerate the branch and bound method, it enables efficient solving of large-scale models, overcoming the computational bottlenecks of traditional approaches. Additionally, this paper develops a multi-objective MILP framework integrating ventilation energy use and constraints, ensuring feasible, practical solutions.

3.4.2. On-Demand Regulation

Optimal regulation computes phase-specific static retrofitting schemes for on-demand ventilation, specifying adjustment locations, control methods, and regulation magnitudes. In contrast, on-demand regulation generates dynamic on-demand ventilation strategies by prescribing operational adjustments for existing equipment, such as fan frequency modulation and damper angle settings.

The core characteristic of on-demand regulation lies in its online dynamic computation capability, which automatically derives feasible control schemes from existing equipment configurations without requiring precise real-time regulation. On-demand regulation can be divided into global on-demand regulation and local on-demand regulation. Local on-demand regulation adjusts the local fans based on the air demand requirements of the working face through interlinked control, which is already relatively mature. Global on-demand regulation, similar to optimal regulation, involves solving large-scale nonlinear programming problems and remains a key technical challenge in the development of intelligent ventilation systems.

To address global regulation’s nonlinear solving challenges, this paper realized the mixed-integer linear programming (MILP) method [

9] based on the linearization strategy of the nonlinear model, enabling the feasibility of demand-based control in large-scale ventilation networks. The core idea is to discretize the continuous airflow variable

for each airway

into a finite set of permissible values

, where

denotes the number of discrete airflow levels and

represents the

kth possible air quantity value for the

jth airway. A binary variable

is introduced to indicate whether the

-th airway adopts the

-th airflow value

where

is the airflow of the

jth airway,

.

These binary variables are constrained such that exactly one value is selected per airway:

The airflow variable

and its higher-order terms

and

, which appear in the ventilation resistance law, can then be expressed as linear combinations of the binary variables:

Based on the above transformation, the originally nonlinear objective function and constraints are reformulated into linear expressions involving binary and continuous variables, resulting in a MILP model that can be efficiently solved using off-the-shelf optimization solvers such as Gurobi. This discretization strategy not only enhances computational feasibility but also allows for the incorporation of practical constraints such as regulation positions, adjustment methods, and energy consumption objectives, thereby providing a flexible and robust framework for real-world ventilation system optimization.

The intelligent decision-making platform determines the overall air requirement plan for various areas based on the ventilation demands of mining production sites and dynamically generates airflow regulation schemes through optimization calculations to provide decision support for ventilation regulation. The overall process involves the following steps: Firstly, it quantifies airflow demands by identifying ventilation points and volumes based on mining activities, designating demand branches in the network model, and computing required airflow using safety protocols and environmental parameters. The smart ventilation system can connect to monitoring systems to dynamically obtain parameters, support custom airflow demand configurations, and feature automatic calculation and dynamic alarm functions. It achieves on-demand airflow distribution through automatic regulation, thereby saving energy and reducing consumption. Secondly, construct a mathematical model for on-demand regulation, using the feasible adjustment methods of ventilation facilities as a decision-making basis, while considering multiple objectives such as minimum fan power, to obtain the window opening degree and frequency modulation control methods for fans. The priority of ventilation facility adjustments can be adjusted according to the actual underground conditions, and a solver can be invoked to determine multiple alternative equipment control schemes. Finally, it simulates airflow effects for manager selection, remotely applies optimal solutions, and adjusts strategies based on outcomes for energy savings.

3.5. Remote Control

The remote-control system must possess local self-regulation and dynamic feedback capabilities, enabling ventilation system integrated control through a “sensing–prediction–decision–execution” processing chain. Building upon the regulation schemes determined by the airflow regulation decision support system, it should comprehensively analyze real-time monitoring data and control feedback data to identify optimal solutions. Fundamentally, the remote-control system for ventilation facilities should deliver four core functions: monitoring real-time operational statuses of remote-controlled equipment; receiving control signals via centralized control platforms; remotely adjusting ventilation equipment states based on received commands; and dynamically feeding back regulation effects according to equipment control states.

Regulation feedback should employ an adaptive mechanism integrated with monitoring systems. When data deviations exceed predefined tolerance thresholds, the system dynamically corrects measurements through a self-correcting process. Additionally, feedback mechanisms must account for factors like airflow fluctuations in ventilation systems. If feedback outcomes deviate beyond reasonable ranges for on-demand ventilation requirements, the system initiates secondary adjustments of the regulation scheme and re-validates effectiveness post-correction.

The intelligent mine airflow regulation system establishes a tripartite remote-control architecture integrating centralized control platforms, status monitoring modules, and closed-loop feedback mechanisms. Operating on an Industrial IoT framework, this system centralizes remote ventilation control through three functional modules:

(1) Centralized Control Module: Computes optimal regulation schemes via intelligent decision systems, enabling remote-assisted and automated control of main fan frequency modulation, adaptive air door operations, and resistance-adjusting damper opening degree.

(2) Equipment Status Feedback Module: Continuously monitors critical operational indicators, including fan vibration spectra, hydraulic actuator statuses of air doors, and displacement parameters of explosion-proof doors.

(3) Regulation Validation Module: Dynamically evaluates ventilation network performance by constructing computational solving models combined with real-time monitoring data (e.g., air velocity, gas concentration).

3.6. Disaster Regulation

Disaster-response ventilation control, essential for safeguarding mine ventilation systems during catastrophic events, aims to suppress hazard escalation, maintain operational continuity, and secure safe evacuation conditions. Its effective implementation relies on smart hazard sensing, multi-source disaster simulation across diverse locations, strategic regulation planning, and remote facility control.

Currently, the challenges in disaster ventilation control lie in the hazard sensing, the simulation of disasters’ impact on ventilation systems, and the formulation of ventilation control strategies. Achieving comprehensive hazard sensing requires fusing data from gas/temperature/pressure sensors with visible-light/infrared video feeds, enhanced by AI-driven image recognition for accurate hazard identification. Simulating disaster impacts can be enhanced through the integration of Computational Fluid Dynamics (CFD) for detailed hazard propagation analysis and tools like VentSim for system-wide ventilation response modeling; however, the core methodology presented in this study focuses on network-level modeling and intelligent control integration for emergency response. Developing effective control strategies demands coordinated equipment operations, including main/auxiliary fan activation/reversal sequences and critical air-reversal door closures, to rapidly contain threats while sustaining ventilation functionality and enabling safe progress.

The intelligent mine ventilation decision platform executes ventilation network regulation during disaster scenarios through three integrated processes: hazard definition, disaster simulation, and emergency equipment linkage control. Hazard definition designates location-specific disaster types within the system, configuring corresponding alarm sensors as triggering indicators when disasters occur. Disaster simulation conducts preemptive modeling using computational fluid dynamics (CFD), VentSim, and other fluid/ventilation simulation methods to analyze disaster progression patterns and impact ranges. It further simulates ventilation system responses to proposed control strategies, validating scheme reliability before implementation. Emergency linkage activation occurs upon disaster detection: The system’s platform instantly issues alerts, recommends tailored ventilation network regulation schemes based on triggered disaster models, and remotely executes control commands to underground ventilation equipment.

3.7. Emergence Rescue

Underground mine emergency rescue operations encompass both pre-disaster contingency planning and real-time disaster response. Before disasters, mining enterprises must conduct regular emergency drills and establish evacuation routes for scenarios like mine fires or water inrushes. During disasters, immediate hazard control measures should be activated, including ventilation system adjustments to maintain breathable atmospheres and utilization of six major life-saving systems to guide personnel along real-time evacuation paths to safe zones.

Real-time evacuation route planning requires multi-system integration: leveraging personnel positioning systems to track real-time locations, monitoring systems to assess hazard propagation, and 3D visualization platforms to synthesize mine-wide data, all coordinated through life-saving systems to enhance escape efficiency.

Throughout emergency evacuation operations, predetermined evacuation routes—equipped with optimal escape conditions and supplemental facilities such as refuge chambers and compressed-air self-rescue units—typically form the foundation for real-time evacuation path solutions during disasters. Real-time evacuation paths consistently direct personnel from their current locations to these predefined contingency routes. Concurrently, ventilation system regulation during disasters ensures passable atmospheric conditions in underground roadways, thereby guaranteeing the safety, stability, and usability of predetermined evacuation routes, preventing scenarios where real-time evacuation planning becomes unsolvable.

The evacuation route optimization problem incorporating life-saving facilities can be formalized as: Find the shortest path satisfying the following: travel time through smoke

self-rescuer rated protection time; minimized total equivalent path length; minimized smoke-exposure duration.

where

denotes the set of nodes in the network

represents the set of directed edges;

indicates the cardinality of nodes;

indicates the cardinality of edges;

denotes the destination; which is the safe location for evacuation (such as emergency exits; shelters; etc.);

and

denote arbitrary node indices;

signifies a directed edge from node

to node

;

denotes equivalent weight of edge

denotes traversal time across edge

denotes total equivalent length along any path

from origin to destination;

denotes total time spent traversing smoke-contaminated segments;

denotes binary state variable (

if edge

lies on the evacuation path from personnel location to target, otherwise

); and

denotes the binary state variable (

if edge

is smoke-contaminated, otherwise

).

4. Case Studies

This study found that the proposed key technologies for smart ventilation are suitable for complex ventilation networks, based on an evaluation using the developed 3D mine ventilation software platform (iVent V1.1.0). To validate the efficacy of the integrated intelligent ventilation system proposed in this research, several comprehensive field trials were conducted at real-world metal and coal mines.

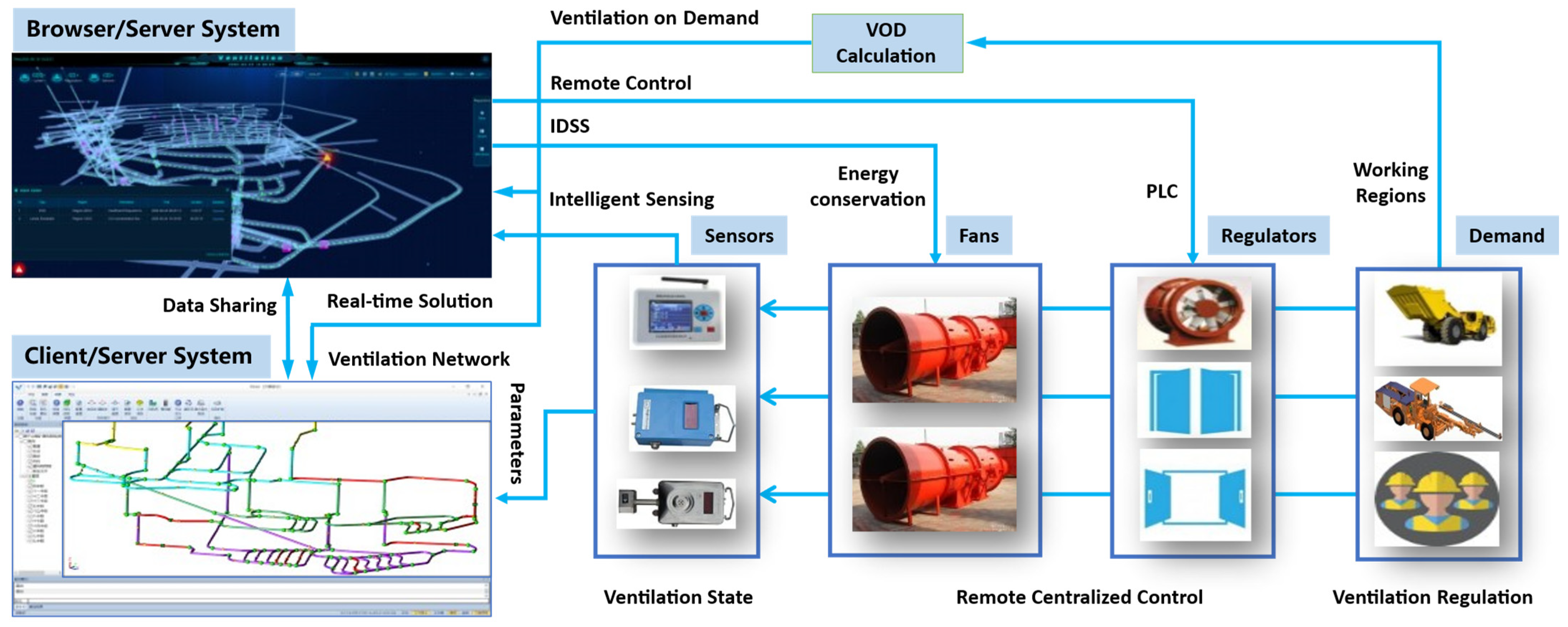

Figure 4 demonstrates the overall design of the intelligent ventilation system. The integrated system aims to achieve real-time monitoring, computational solving, and dynamic regulation of ventilation networks.

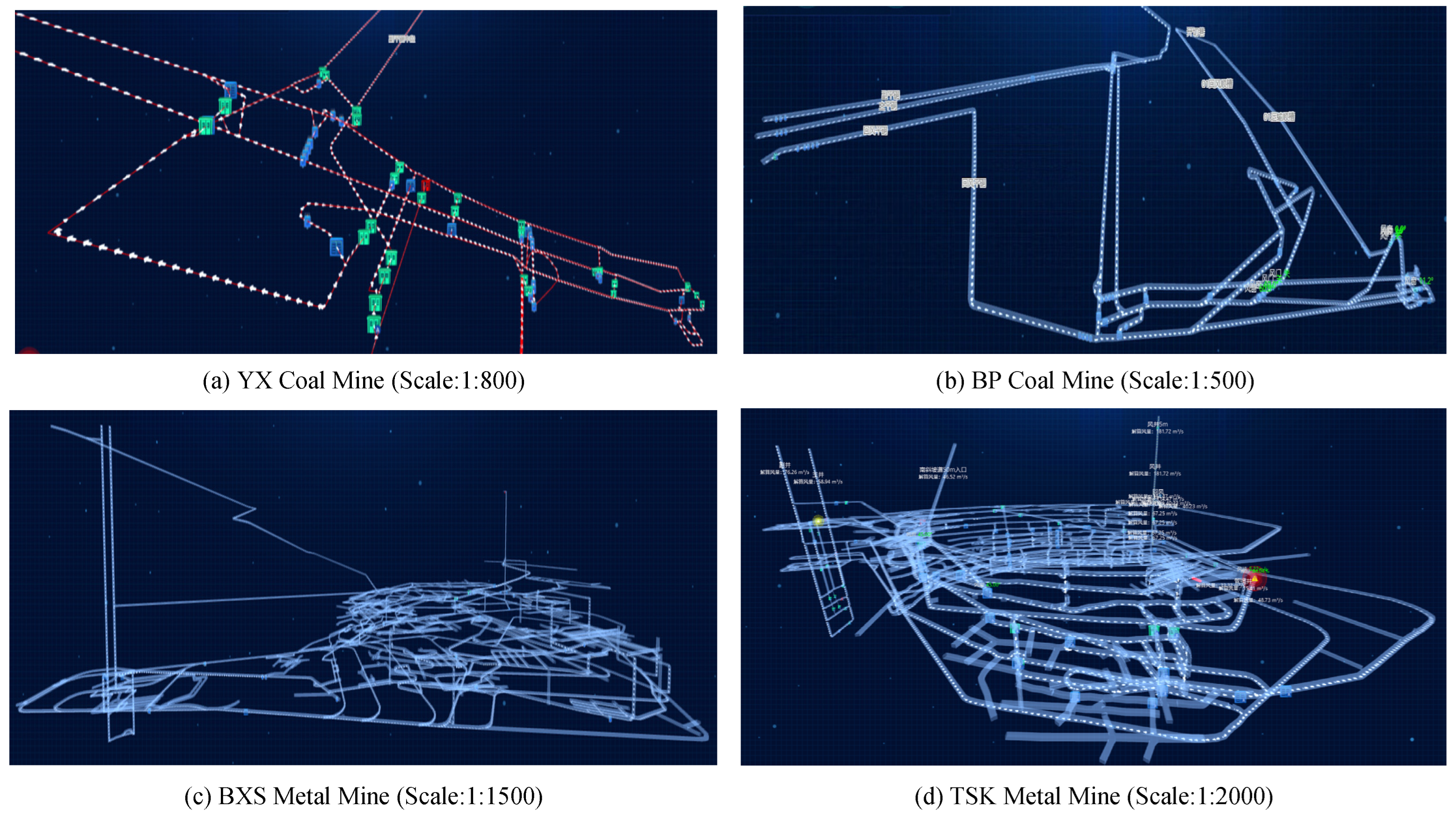

4.1. Construction of Ventilation Networks

The self-developed 3D mine ventilation software employs advanced 3D engine technology to achieve true-3D simulation of the spatial positions and stratigraphic relationships within the mine ventilation network. Equipped with a built-in dynamic topology construction and adjustment mechanism, it integrates functionalities including ventilation system design, ventilation network calculation/solving, ventilation network regulation, mine ventilation resistance measurement management, ventilation network diagnostics and early warning, and monitoring data integration. The ventilation network constructed based on this self-developed 3D mine ventilation software is illustrated in

Figure 5.

Figure 5 demonstrates a 3D visualization of ventilation network models for the case study mines, including YX Coal Mine, BP Coal Mine, BXS Metal Mine and TSK Metal Mine. The models depict the spatial topology of airways, key ventilation control devices (e.g., fans, regulators), and real-time monitoring sensor data (air velocity, CO concentration) integrated from the IoT platform. It utilizes a mesh-based calculation method centered on the minimum independent closed loop to compute airflow distribution, with the results presented in

Table 1. Computational performance is demonstrated as follows: for ventilation networks with multiple fans comprising up to 1000 branches, the iteration time is consistently maintained within 1 s.

4.2. Remote Centralized Control

The self-developed remote centralized control system enables remote monitoring and control of critical ventilation equipment, including main fans, auxiliary fans, air doors, air dampers, and various environmental sensors, as illustrated in

Figure 6.

Figure 6 demonstrates a 3D visualization of an intelligent mine ventilation platform (B/S). The main viewport (center) shows the real-time airflow distribution and direction (indicated by animated arrows) across the network. The top panel displays a hierarchical tree of network layers and ventilation facilities (fans, air doors, sensors). The right panel is used for issuing remote control instructions, such as adjusting fan frequencies, based on optimization results. The bottom command console provides real-time alarms for key environmental parameters (e.g., gas concentration, temperature, and on-demand quantity) and recommended regulation schemes. This system is built upon the IoT architecture. Utilizing a high-speed, redundant, and interference-resistant wired/wireless converged communication network, it interconnects smart terminal devices deployed at key underground nodes in real-time. At the surface dispatch center, a fully featured centralized control software platform has been developed. This platform integrates core functional modules such as Data Acquisition and Monitoring, 3D Visualization, Intelligent Analysis and Decision Support, Remote Operation, and Alarm Linkage.

4.3. Ventilation On-Demand

The self-developed airflow on-demand regulation system enables remote precision control of actuators—including main fan frequency adjustment, auxiliary fan start/stop operations, and air door/damper opening positioning—based on regulation algorithms, predefined strategies, or manual commands. This system operates through three sequential processes: required airflow configuration, required airflow calculation, and on-demand equipment control. First, underground locations requiring ventilation are designated as airflow demand roadways, with their specific airflow calculation methodologies configured. The system then automatically computes required airflow volumes using parameters such as personnel density, explosive quantities, hazardous gas concentrations, temperature, and humidity of the mining face, worksite dust removal requirements, and air velocity constraints. Finally, it selects the optimal regulation scheme—either derived from computational optimization results or user-defined control strategies—to best align with actual ventilation demands, thereby executing precise control actions.

Table 2 demonstrates an example of the airflow demand and recommended regulation scheme of TSK Metal Mine pushed by the platform. The optimization results are generated by the MILP model using the Gurobi solver. For example, the system identifies that the sealed mining area at Level -100 and the low-intensity mining area at Level -160 require increased resistance to optimize airflow distribution, achieved through adjusting regulation dampers. Conversely, the deep excavation faces at Levels -220 and -280, where airflow demand is increased, are prescribed decreased resistance to ensure sufficient ventilation.

4.4. Safety Monitoring and Rescue

The self-developed safety monitoring and emergency rescue system substantially enhances the automation and intelligence level of ventilation management, significantly strengthening the mine’s rapid response capabilities for disaster scenarios and daily airflow adjustments, thereby providing robust technical support for safe production. The system establishes a tiered alarm mechanism based on disaster types: threshold alarms (e.g., CO concentration exceeding 200 ppm), trend alarms (e.g., CO concentration rising by 50 ppm within a short period), and correlation alarms (e.g., sudden temperature spikes accompanied by CO surges). Upon disaster occurrence or alarm escalation, the system immediately activates emergency response protocols. On one hand, the decision support subsystem leverages disaster scenario simulations to autonomously calculate optimal escape routes. On the other hand, the system deeply integrates ventilation control functions, executing pre-defined or dynamically generated adaptive emergency ventilation strategies to coordinate remote control of ventilation equipment, maximizing containment of hazard propagation. This system achieves a smart paradigm shift in ventilation management under disaster conditions, transforming it from passive reaction to proactive intervention.

Figure 6 demonstrates a 3D visualization of an intelligent mine ventilation platform (B/S). The main viewport (center) shows the real-time airflow distribution and direction (indicated by animated arrows) across the network. The top panel displays a hierarchical tree of network layers and ventilation facilities (fans, air doors, sensors). The right panel is used for issuing remote control instructions, such as adjusting fan frequencies, based on optimization results. The bottom command console provides real-time alarms for key environmental parameters (e.g., gas concentration, temperature, and on-demand quantity) and recommended regulation schemes.

The constructed intelligent ventilation system achieves the objective of real-time, dynamic airflow regulation through information-based and intelligent technological approaches, utilizing smart monitoring and smart control methods. By integrating interconnected subsystems—including data acquisition, decision support, smart control, and dynamic feedback—it delivers two core operational capabilities: (1) dynamic on-demand air supply and optimized regulation during normal operations, and (2) real-time dynamic early warning and disaster scenario management during emergencies. This system maximizes the safety, reliability, stability, and cost-effectiveness of the mine ventilation system, establishing itself as an indispensable critical component for the ultimate realization of smart mining.

Through its on-demand airflow regulation functionality, the intelligent ventilation system adaptively regulates air volume and pressure based on underground requirements, achieving significant energy savings, reduced consumption, and enhanced operational efficiency, thereby generating substantial economic benefits. By enabling abnormal diagnosis of ventilation facilities, hazard early warning for underground gases, and disaster response control with escape route planning, it significantly elevates safety performance in underground mining operations. Furthermore, on-demand airflow regulation strengthens ventilation management for dust and blasting fumes, optimizing the underground working environment and consequently improving environmental sustainability. Collectively, these capabilities demonstrate the system’s notable practical engineering value.