A Cyber–Physical System Based on Digital Twin and 3D SCADA for Real-Time Monitoring of Olive Oil Mills

Abstract

1. Introduction

2. Literature Review

2.1. Digital Twin (DT)

2.2. Related Work

2.3. Research Gap

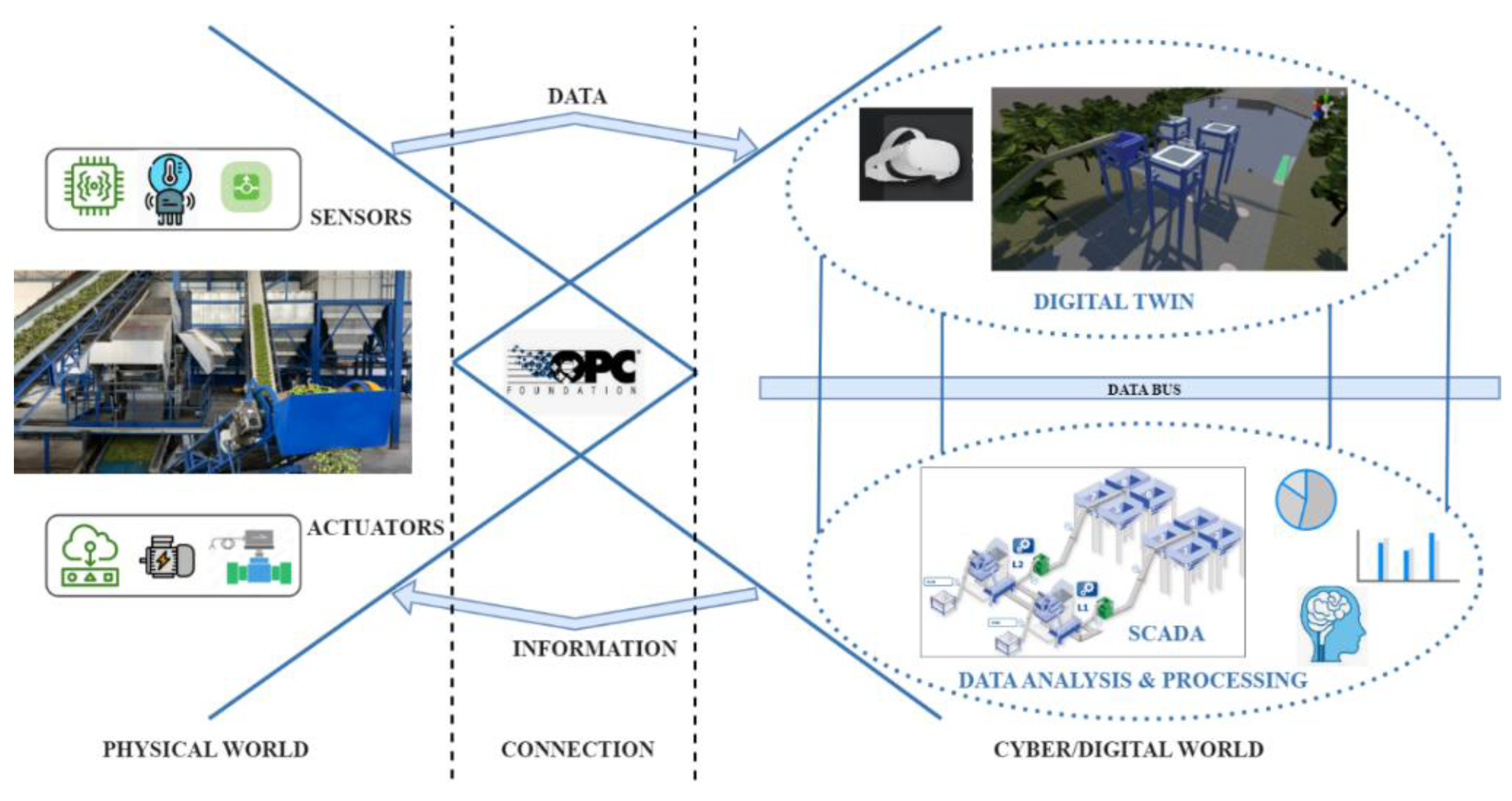

3. Proposed Approach

3.1. Experimental Environment

3.2. Design of Architecture and Framework Description

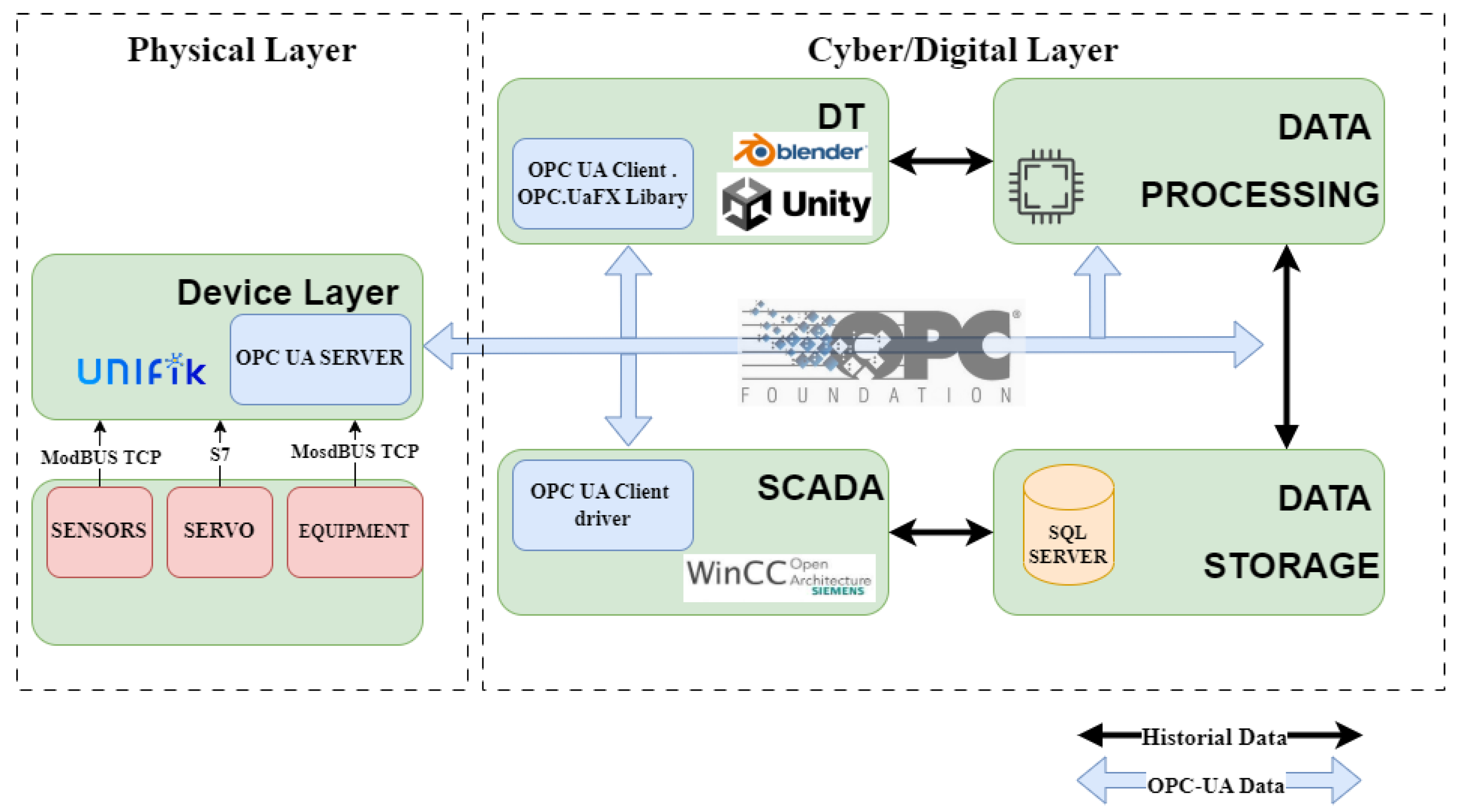

3.2.1. General Architecture

3.2.2. Protocols and Framework

4. Implementation and Results

4.1. Cyber/Digital Layer

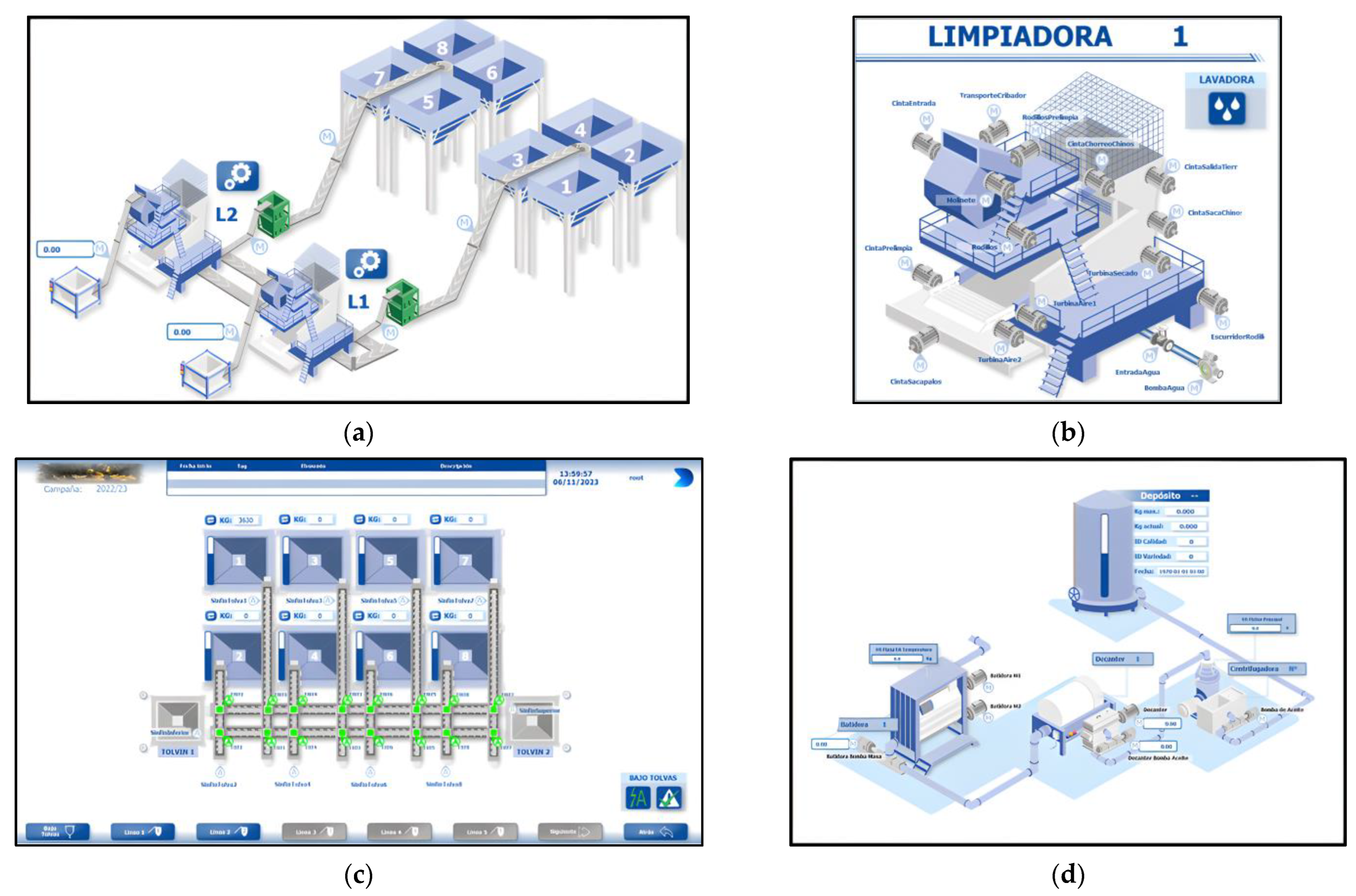

4.1.1. 3D SCADA

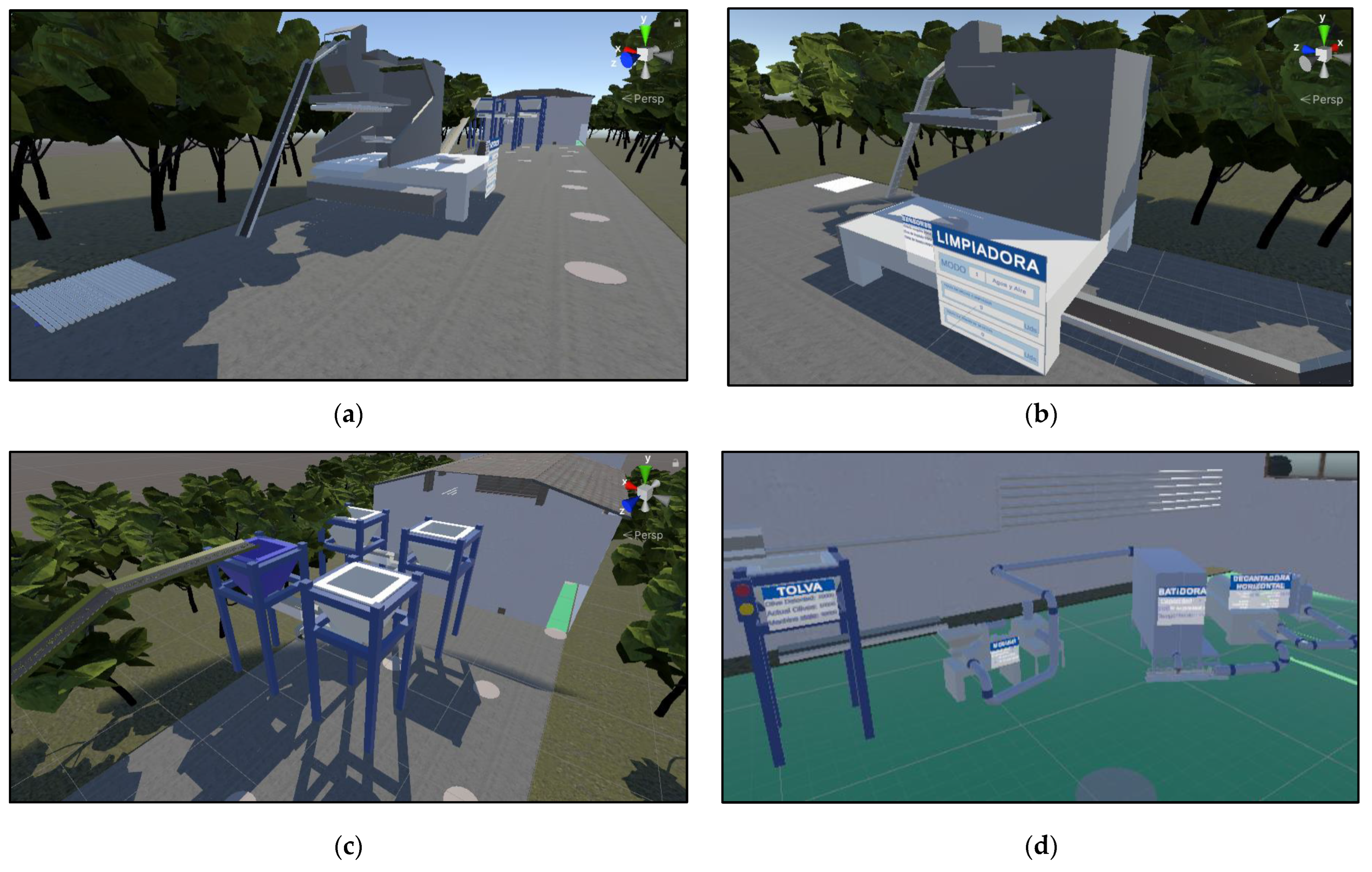

4.1.2. Digital Twin

4.2. Communication Layer

4.3. Case Use

5. Discussion

- Immersive and Intuitive Monitoring: It enables real-time monitoring from a more immersive and intuitive environment, as documented in studies [42].

- Enhanced Maintenance Practices: By facilitating preventive maintenance strategies, it contributes to the enhancement of maintenance tasks, thus bolstering operational efficiency [8].

- Digital Model Generation and Validation: The system permits the generation and validation of digital process models. The SCADA system can execute these models on the DT, allowing for rigorous validation before implementing them in the real-world environment [28]. This approach effectively circumvents production disruptions.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q. New IT Driven Service-Oriented Smart Manufacturing: Framework and Characteristics. SYSTEMS 2019, 49, 81–91. [Google Scholar] [CrossRef]

- Suler, P.; Palmer, L.; Bilan, S. Internet of Things Sensing Networks, Digitized Mass Production, and Sustainable Organizational Performance in Cyber-Physical System-Based Smart Factories. J. Self-Gov. Manag. Econ. 2021, 9, 42–51. [Google Scholar] [CrossRef]

- Uhlemann, T.H.J.; Lehmann, C.; Steinhilper, R. The Digital Twin: Realizing the Cyber-Physical Production System for Industry 4.0. Procedia CIRP 2017, 61, 335–340. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, X.; Liang, W.; Zeng, Z.; Shimizu, S.; Yang, L.T.; Jin, Q. Intelligent Small Object Detection for Digital Twin in Smart Manufacturing with Industrial Cyber-Physical Systems. IEEE Trans Ind. Inf. 2022, 18, 1377–1386. [Google Scholar] [CrossRef]

- Josifovska, K.; Yigitbas, E.; Engels, G. Reference Framework for Digital Twins within Cyber-Physical Systems. In Proceedings of the 2019 IEEE/ACM 5th International Workshop on Software Engineering for Smart Cyber-Physical Systems, SEsCPS 2019, Montreal, QC, Canada, 28 May 2019; pp. 25–31. [Google Scholar] [CrossRef]

- Zhou, J.; Li, P.; Zhou, Y.; Wang, B.; Zang, J.; Meng, L. Toward New-Generation Intelligent Manufacturing. Engineering 2018, 4, 11–20. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Digital Twin for Smart Manufacturing, A Review. Sustain. Manuf. Serv. Econ. 2023, 2, 100017. [Google Scholar] [CrossRef]

- Ebni, M.; Hosseini Bamakan, S.M.; Qu, Q. Digital Twin Based Smart Manufacturing; From Design to Simulation and Optimization Schema. Procedia Comput. Sci. 2023, 221, 1216–1225. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Bucchiarone, A. Gamification and Virtual Reality for Digital Twins Learning and Training: Architecture and Challenges. Virtual Real. Intell. Hardw. 2022, 4, 471–486. [Google Scholar] [CrossRef]

- Martínez-Gutiérrez, A.; Díez-González, J.; Verde, P.; Perez, H. Convergence of Virtual Reality and Digital Twin Technologies to Enhance Digital Operators’ Training in Industry 4.0. Int. J. Hum. Comput. Stud. 2023, 180, 103136. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Reddy, G.S.R.; Saluja, K.P.S.; Ghosh, S.; Peña-Rios, A.; Gopal, G.; Biswas, P. Virtual-Reality-Based Digital Twin of Office Spaces with Social Distance Measurement Feature. Virtual Real. Intell. Hardw. 2022, 4, 55–75. [Google Scholar] [CrossRef]

- Qiu, C.; Zhou, S.; Liu, Z.; Gao, Q.; Tan, J. Digital Assembly Technology Based on Augmented Reality and Digital Twins: A Review. Virtual Real. Intell. Hardw. 2019, 1, 597–610. [Google Scholar] [CrossRef]

- Pérez, L.; Rodríguez-Jiménez, S.; Rodríguez, N.; Usamentiaga, R.; García, D.F. Digital Twin and Virtual Reality Based Methodology for Multi-Robot Manufacturing Cell Commissioning. Appl. Sci. 2020, 10, 3633. [Google Scholar] [CrossRef]

- da Rocha, H.; Pereira, J.; Abrishambaf, R.; Espirito Santo, A. An Interoperable Digital Twin with the IEEE 1451 Standards. Sensors 2022, 22, 7590. [Google Scholar] [CrossRef] [PubMed]

- Definition of a Digital Twin—Digital Twin Consortium. Available online: https://www.digitaltwinconsortium.org/initiatives/the-definition-of-a-digital-twin/ (accessed on 4 September 2023).

- Grieves, M. Digital twin: Manufacturing excellence through virtual factory replication. White Pap. 2014, 1, 1–7. [Google Scholar]

- Qi, Q.; Tao, F.; Zuo, Y.; Zhao, D. ScienceDirect 51st CIRP Conference on Manufacturing Systems Digital Twin Service towards Smart Manufacturing-Review under Responsibility of the Scientific Committee of the 51st CIRP Conference on Manufacturing Systems. Procedia CIRP 2018, 72, 237–242. [Google Scholar] [CrossRef]

- Assawaarayakul, C.; Srisawat, W.; Ayuthaya, S.D.N.; Wattanasirichaigoon, S. Integrate Digital Twin to Exist Production System for Industry 4.0. In Proceedings of the TIMES-iCON 2019—2019 4th Technology Innovation Management and Engineering Science International Conference, Bangkok, Thailand, 11–13 December 2019. [Google Scholar] [CrossRef]

- Rolle, R.; Martucci, V.; Godoy, E. Architecture for Digital Twin Implementation Focusing on Industry 4.0. IEEE Lat. Am. Trans. 2020, 18, 889–898. [Google Scholar] [CrossRef]

- Qin, H.; Wang, H.; Zhang, Y.; Lin, L. Constructing Digital Twin for Smart Manufacturing. In Proceedings of the 2021 IEEE 24th International Conference on Computer Supported Cooperative Work in Design, CSCWD 2021, Dalian, China, 5 May 2021; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA; pp. 638–642. [Google Scholar]

- Wu, P.; Qi, M.; Gao, L.; Zou, W.; Miao, Q.; Liu, L.L. Research on the Virtual Reality Synchronization of Workshop Digital Twin. In Proceedings of the 2019 IEEE 8th Joint International Information Technology and Artificial Intelligence Conference, ITAIC 2019, Chongqing, China, 24–26 May 2019; pp. 875–879. [Google Scholar] [CrossRef]

- Yin, Y.; Zheng, P.; Li, C.; Wang, L. A State-of-the-Art Survey on Augmented Reality-Assisted Digital Twin for Futuristic Human-Centric Industry Transformation. Robot. Comput.-Integr. Manuf. 2022, 81, 102515. [Google Scholar] [CrossRef]

- Kerin, M.; Hartono, N.; Pham, D.T. Optimising Remanufacturing Decision-Making Using the Bees Algorithm in Product Digital Twins. Sci. Rep. 2023, 13, 701. [Google Scholar] [CrossRef]

- Zhu, Y.; Cheng, J.; Liu, Z.; Cheng, Q.; Zou, X.; Xu, H.; Wang, Y.; Tao, F. Production Logistics Digital Twins: Research Profiling, Application, Challenges and Opportunities. Robot Comput. Integr. Manuf. 2023, 84, 102592. [Google Scholar] [CrossRef]

- Bottani, E.; Vignali, G.; Carlo Tancredi, G.P. A Digital Twin Model of a Pasteurization System for Food Beverages: Tools and Architecture. In Proceedings of the 2020 IEEE International Conference on Engineering, Technology and Innovation, ICE/ITMC 2020, Cardiff, UK, 15–17 June 2020. [Google Scholar] [CrossRef]

- Jeon, S.M.; Schuesslbauer, S. Digital Twin Application for Production Optimization. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 14 December 2020; IEEE Computer Society; Volume 2020, pp. 542–545. [Google Scholar]

- Padovano, A.; Longo, F.; Nicoletti, L.; Mirabelli, G. A Digital Twin Based Service Oriented Application for a 4.0 Knowledge Navigation in the Smart Factory. IFAC-Pap. 2018, 51, 631–636. [Google Scholar] [CrossRef]

- Caiza, G.; Sanz, R. Digital Twin to Control and Monitor an Industrial Cyber-Physical Environment Supported by Augmented Reality. Appl. Sci. 2023, 13, 7503. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Wang, K.I.K.; Huang, H.; Xu, X. Digital Twin-Driven Smart Manufacturing: Connotation, Reference Model, Applications and Research Issues. Robot Comput. Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Alam, K.M.; El Saddik, A. C2PS: A Digital Twin Architecture Reference Model for the Cloud-Based Cyber-Physical Systems. IEEE Access 2017, 5, 2050–2062. [Google Scholar] [CrossRef]

- Morgan, Y.L. Managing DSRC and WAVE Standards Operations in a V2V Scenario. Int. J. Veh. Technol. 2010, 2010, 797405. [Google Scholar] [CrossRef]

- Zhou, Y.; Fu, Z.; Zhang, J.; Li, W.; Gao, C. A Digital Twin-Based Operation Status Monitoring System for Port Cranes. Sensors 2022, 22, 3216. [Google Scholar] [CrossRef] [PubMed]

- Alves, R.G.; Maia, R.F.; Lima, F. Development of a Digital Twin for Smart Farming: Irrigation Management System for Water Saving. J. Clean Prod. 2023, 388, 135920. [Google Scholar] [CrossRef]

- Martínez-Ruedas, C.; Adame-Rodríguez, F.J.; Díaz-Cabrera, J.M. Integrating and Interconnecting of Older SINUMERIK CNC Machines with Industry 4.0 Using a Plug-and-Play System. J. Ind. Inf. Integr. 2024, 38, 100583. [Google Scholar] [CrossRef]

- Unifik|Unified Communications. Available online: https://unifik.net/ (accessed on 6 September 2023).

- About Shader Graph|Shader Graph|10.10.1. Available online: https://docs.unity3d.com/Packages/com.unity.shadergraph@10.10/manual/index.html (accessed on 6 September 2023).

- Download—Blender.Org. Available online: https://www.blender.org/download/ (accessed on 6 September 2023).

- Paquetes de MRTK—MRTK 2|Microsoft Learn. Available online: https://learn.microsoft.com/es-es/windows/mixed-reality/mrtk-unity/mrtk2/packages/mrtk-packages?view=mrtkunity-2022-05 (accessed on 6 September 2023).

- NuGet Gallery|Opc.UaFx.Client 2.32.0. Available online: https://www.nuget.org/packages/Opc.UaFx.Client (accessed on 6 September 2023).

- Meta Quest 2: Immersive All-In-One VR Headset|Meta Store|Meta Store. Available online: https://www.meta.com/es/en/quest/products/quest-2/ (accessed on 6 September 2023).

- Delivery Release—WinCC Open Architecture V3.18—ID: 109796197—Industry Support Siemens. Available online: https://support.industry.siemens.com/cs/document/109796197/delivery-release-%E2%80%93-wincc-open-architecture-v3-18?dti=0&lc=en-ES (accessed on 6 September 2023).

| Devices | Characteristics | |

|---|---|---|

| MSI GE63 RAIDER 8RF LAPTOP | CPU | Intel i7 8750H |

| MEMORIA RAM | 16 GB 3200 MHZ | |

| DISPLAY | 1920X1080 120 HZ | |

| GPU | NVIDIA GEFORCE 1070 | |

| DELL INSPIRON LAPTOP | CPU | Intel i7 11800H |

| MEMORIA RAM | 16 GB 3200 MHZ | |

| DISPLAY | 1920X1080 60 HZ | |

| GPU | NVIDIA GEFORCE 3050 Ti | |

| NVIDIA GEFORCE 3050 Ti | ||

| META QUEST 2 VÍA AIRLINK | ||

| Reception | ||

|---|---|---|

| Communes | Line 1 | Line 2 |

| March/stop of the zone | March/stop of the zone | March/stop of the zone |

| Rotary position | Rotary position | |

| Status of drives | Status of drives | |

| Washing machine on/off | Washing machine on/off | |

| Ton/toff pulses vibro | Ton/toff pulses vibro | |

| Hopper gate open/closed | Hopper gate open/closed | |

| Weighing |

|---|

| Hopper info (status, kg, max. kg, quality, variety, start and emptying dates) |

| Info scales (weighed state, empty hopper, total kilos, partial kilos, weighing time, card number, quality, variety, number of weighed, hopper, supplier, farm, vehicle, party) |

| Milling | ||

|---|---|---|

| Under Hoppers | Line 1 | Line 2 |

| March/stop of the zone | Start/stop of the zones (grinder, mixer and decanter, centrifuge) | Start/stop of the zones (Grinder, Mixer and Decanter, Centrifuge) |

| Status of drives | Status of drives | Status of drives |

| Max. and min. hopper level | State of milling | State of milling |

| Mill intensity | Mill intensity | |

| Decanter main motor intensity | Decanter main motor intensity | |

| Decanter main engine torque | Decanter main engine torque | |

| Decanter load cell | Decanter load cell | |

| Blender temperature | Blender temperature | |

| Oil temperature | Oil temperature | |

| Mass flow meter | Mass flow meter | |

| Oil flow meter | Oil flow meter | |

| Decanter speed | Decanter speed | |

| Pomace mass pump speed | Pomace mass pump speed | |

| Tank info (kg mass, kg oil, start date, end date, condition, quality, and variety) | Tank info (kg mass, kg oil, start date, end date, condition, quality, and variety) | |

| Configuration way (hopper, auger, mill, centrifuge, and tank) | Configuration way (hopper, auger, mill, centrifuge, and tank) | |

| De-Stoning | ||

|---|---|---|

| Communes | Line 1 | Line 2 |

| March/stop of the zone | March/stop of the zone | March/stop of the zone |

| Level hopper pomace | De-stoner hopper level | De-stoner hopper level |

| Hopper level | Deboning intensity | Deboning intensity |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martinez-Ruedas, C.; Flores-Arias, J.-M.; Moreno-Garcia, I.M.; Linan-Reyes, M.; Bellido-Outeiriño, F.J. A Cyber–Physical System Based on Digital Twin and 3D SCADA for Real-Time Monitoring of Olive Oil Mills. Technologies 2024, 12, 60. https://doi.org/10.3390/technologies12050060

Martinez-Ruedas C, Flores-Arias J-M, Moreno-Garcia IM, Linan-Reyes M, Bellido-Outeiriño FJ. A Cyber–Physical System Based on Digital Twin and 3D SCADA for Real-Time Monitoring of Olive Oil Mills. Technologies. 2024; 12(5):60. https://doi.org/10.3390/technologies12050060

Chicago/Turabian StyleMartinez-Ruedas, Cristina, Jose-Maria Flores-Arias, Isabel M. Moreno-Garcia, Matias Linan-Reyes, and Francisco Jose Bellido-Outeiriño. 2024. "A Cyber–Physical System Based on Digital Twin and 3D SCADA for Real-Time Monitoring of Olive Oil Mills" Technologies 12, no. 5: 60. https://doi.org/10.3390/technologies12050060

APA StyleMartinez-Ruedas, C., Flores-Arias, J.-M., Moreno-Garcia, I. M., Linan-Reyes, M., & Bellido-Outeiriño, F. J. (2024). A Cyber–Physical System Based on Digital Twin and 3D SCADA for Real-Time Monitoring of Olive Oil Mills. Technologies, 12(5), 60. https://doi.org/10.3390/technologies12050060