1. Introduction

Production scheduling is a crucial problem that has been extensively explored in the literature. This problem refers to the assignment of production jobs (tasks) to be processed on machines (resources). The aim of machine scheduling problems in production (MSPP) is to find a sequence of jobs to be processed on machines in a way that optimizes a set of objectives [

1].

For manufacturers, it is crucial to optimize equipment utilization by ensuring efficient schedules at the operational level. Nonetheless, in MSPP theory, the majority of studies assume that resources are continuously available for processing tasks throughout the scheduling horizon. However, in realistic situations, machines may be unavailable during certain periods due to deterministic or stochastic reasons. In the deterministic case, the machine may not be available because of some planned machine stopping, such as inspections, repair, tool change, preventive maintenance (PM), etc., where the starting times and durations may be known or estimated in advance. Whereas in the stochastic case, the unavailability of machines may be due to unpredictable machine stopping or breakdowns, implying the inability to process the tasks until the restart of the machine. This work deals with the first category of scheduling, where the deterministic aspect implies that the factors influencing the schedule are not subject to randomness or uncertainty, providing a clear and predictable environment for scheduling decisions. In this area, preventive maintenance (PM) is the major reason for machine unavailability. PM tasks aim to avoid failures and production stopping by trading off between planned unproductive downtimes dedicated to performing maintenance interventions, and the risk of unscheduled downtimes due to machine breakdown.

Deterministic scheduling problems with unavailability intervals have received considerable attention since the beginning of the 1990s. Several comprehensive reviews of scheduling under availability constraints in different kinds of production systems are provided [

2,

3,

4,

5]. When unavailability constraints are due to PM, two different ways of modelling the unavailability intervals have been considered in different machine environments: (i) the intervals are fixed, and (ii) the intervals are flexible. The first type is the interrelated model, which considers maintenance as a constraint, not a decision. The second type is the integrated model, which corresponds to the situation where unavailability intervals due to maintenance interventions also have decision variables. Moreover, regarding the possibility for an operation to be interrupted by an unavailability period, jobs may be resumable, where the interrupted operation can be continued without any penalty after the end date of the unavailability period, or non-resumable, where the operation needs to be fully restarted [

6].

While much research has been done on the interrelated model, there are fundamental limitations in this approach. For instance, the machine availability constraints must be set ahead, which is challenging to know in practice and may affect the search space where optimal solutions exist. Hence, it is more advantageous to adopt the integrated model, which considers maintenance and production scheduling simultaneously [

7,

8,

9,

10,

11]. All these studies assume that the optimal PM intervals are regular, which means that after a constant period, the PM actions must take place to renew the machine. This strategy may lead to poor performance because it constrains the flexibility of the PM schedule, which does not coordinate the production scheduling and maintenance well. To address this issue, the non-periodic PM intervals are proposed [

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23].

Recently, predictive maintenance has emerged as an intelligent strategy based on the actual condition of the equipment. Unlike time-based PM, which attempts to predefined regular or flexible intervals based on reliability analysis or manufacturer recommendations, predictive maintenance is scheduled based on the prognostics and health management (PHM) process [

24]. PHM seeks to analyze the health status of equipment which allows us to define the optimal moment to schedule a maintenance intervention. This proactive approach enables early detection of potential failures, minimizing downtime, optimizing maintenance schedules, and extending the lifespan of equipment for improved operational efficiency. Concisely, the production system’s health state is continuously (or periodically) monitored by analyzing signals collected from embedded sensors (or inspection information). After that, the current state is inferred and the future progression of failure is predicted to estimate the time before failure, known as the remaining useful life (RUL). The development of effective PHM approaches is a significant research field. Indeed, PHM benefits are heavily reliant on decision-making based on prognosis information, a process known as post-prognostic decision (PPD) [

25]. PPD may occur as the integration of predictive maintenance planning and production schedule, to enhance safety, and minimize downtimes and inopportune maintenance spending.

Building upon the above advancement in the field of predictive maintenance and its superior advantages over traditional PM, this paper focuses on the optimization of integrated production scheduling and predictive maintenance planning in permutation flowshop, one of the most common types of manufacturing layouts. In such an organization, the goal of production scheduling is to determine the optimal order of jobs to be processed by the machines to minimize the overall completion time, referred to as Makespan or . When coupled with predictive maintenance decisions, this job sequence must take into account the integration of maintenance interventions for each machine. Concretely, each machine on the floor is run to process jobs in the form of several production batches (or processing periods). Upon completion of a production batch and reaching a high level of degradation, the machine is stopped and a maintenance period takes place, during which, a predictive maintenance activity is performed to renew the machine before it can resume processing the next production batch. The pivotal decision to conclude a processing period and initiate a maintenance period is based on the health state of the machine, provided by prognostics information. Machines are permitted to operate as long as possible to optimize their utilization. However, considering the objective of minimizing the Makespan, the starting dates of maintenance operations are not fixed, which leads to more flexibility in the schedule.

The PFSP with predictive maintenance is recognized as NP-hard as it extends the classical flowshop scheduling problem under availability constraints [

26]. Consequently, metaheuristic algorithms have emerged as the most practical approach for addressing this challenge. Hence, we propose tackling this issue by employing a population-based metaheuristic, specifically the artificial bees colony (ABC) algorithm [

27]. ABC is a promising metaheuristic algorithm that simulates the specific intelligent and collective behaviour of honey bee swarms. Since ABC was proposed, it has mainly been used to solve unconstraint and constraint continuous function optimization problems [

28,

29]. Compared with other metaheuristic algorithms, there are some remarkable characteristics of ABC such as its effective global exploration capability, excellent local exploitation ability, and fast convergence speed. Due to its simple structure and convenient implementation, ABC has demonstrated efficiency in handling combinatorial optimization problems [

30], and particularly scheduling problems [

31]. Its successful applications on scheduling prove that ABC possesses an excellent searchability and convergence rate. These factors motivated our idea to use ABC to solve the integrated PFSP and predictive maintenance planning. However, ABC cannot be directly used to solve this problem because it is completely different from other scheduling problems. The algorithm needs to be modified according to our problem features. Therefore, we are committed to making improvements on ABC for solving the integrated PFSP and predictive maintenance planning, in this paper.

The remaining part of the paper is organized as follows. Related works are summarized in

Section 2.

Section 3 describes the research problem.

Section 4 explains the proposed ABC algorithm.

Section 5 is depicted to present the experimental results and discussions.

Section 6 outlines the main conclusions and future research topics.

2. Related Works

In this research work, the production scheduling part deals with one of the most studied problems in the literature with extensive applications in real-life manufacturing, namely the permutation flowshop scheduling problem (PFSP). Several interesting papers reviewing the existing methods to solve the PFSP can be found in [

32,

33,

34,

35,

36,

37].

Whereas production scheduling is studied separately in the conventional PFSP, excluding maintenance considerations, the key contribution of this paper falls within the scope of embedding maintenance activities. As the importance of joint optimization of production and maintenance scheduling has been highlighted, this topic has attracted significant research interest for several decades. The latest research trends are directing their attention to the implementation and optimization of PHM approaches by establishing the most effective integrated scheduling of production and predictive maintenance to enhance the overall outcomes. Here, we will provide an overview of studies, focusing on flowshop scheduling problems with flexible unavailability periods due to predictive maintenance. In this area, it is noticed that relatively few works were proposed compared to conventional PM. The reader may refer to the extensive review in [

38].

The first approach to tackle with PFSP with predictive maintenance was introduced in [

39]. The authors proposed a new case study where machines can switch between two production modes: nominal and sub-nominal. In the second mode, the machine is slowed down to avoid early failures. As a consequence, the production tasks will be longer than expected but the RUL is increased. They developed a mixed integer linear model (MILP) that allows finding the best production and predictive maintenance scheduling optimizing the aggregated sum of makespan and maintenance delays. However, a single maintenance operation is considered per machine during the production horizon. Moreover, the defined MILP optimally solves small instances but it is not able to compute the optimal solution for instances with an important number of jobs and machines. To deal with large instances of the same problem, the study in [

40] proposes a local search method that is proven to be effective and scalable compared to the exact approach (MILP). Authors in [

41] designed an improved genetic algorithm (GA) to solve the PFSP with predictive maintenance, where several maintenance interventions are planned for each machine based on degradation information provided by PHM module. In a close context, we can refer to the works provided in [

42,

43], where authors studied the PFSP under maintenance constraints and proposed different metaheuristics to minimize the expected Makespan. However, it was assumed that the degradation value of a machine could be determined only through inspections in pre-specified intervals.

To address uncertainties of PHM information, [

44,

45] proposed fuzzy logic-based metaheuristics to solve the PFSP with predictive maintenance. In these studies, uncertain PHM outputs are modelled using fuzzy logic. A modified version of the PFSP with flexible maintenance is investigated in [

46] where processing times of jobs are assumed to be variable due to deterioration and learning effects. Considering the dynamic aspect of real-life scheduling, a novel approach is developed in [

47] to solve the PFSP with predictive maintenance. Sensor data are processed using machine learning algorithms and times to failure (RULs) are predictive. The proposed framework, combined with discrete event simulation, enables the integration of predictive maintenance constraints into the scheduling process, to minimize the Makespan.

Production scheduling is an arduous decision-making process and has been recognized as NP-hard for almost all machine configurations, constraints, and optimization criteria combinations [

48,

49]. Indeed, the simplest single-machine scheduling with total tardiness is NP-hard, so large-scale scheduling problems are often difficult to solve by the traditional methods and metaheuristics become the main path to solve these problems for their effectiveness in offering optimal/near-optimal results within a reasonable amount of time notably on large-scale optimization problems [

50,

51]. Metaheuristic algorithms mimic the processes of natural phenomena [

52,

53,

54,

55]. Evolutionary algorithms mimic the evolution behaviour of humans or animals (genetic algorithms [

56], biogeography-based optimization [

57], etc.), swarm intelligence algorithms imitate the activity of groups of animals (such as particle swarm optimization [

58], ant colony optimization [

59], fruit fly optimization [

60], bat algorithm [

61], grey wolf optimization [

62], migrating birds optimization [

63], etc.), and physics or chemical processes based algorithms emulate physics or chemical laws (such as chemical reaction optimization [

64], galaxy-based search algorithm [

65], black hole algorithm [

66], etc.). Due to the large number of problem variants and solution methods, several survey papers provide comprehensive insights into the literature addressing various types of scheduling problems. These surveys cover solution methods such as evolutionary algorithms [

67], automatically generated dispatching rules [

68], and multi-population-based metaheuristics [

31].

Among swarm intelligence algorithms for optimization problems, the artificial bee colony (ABC) algorithm was first proposed in 2005 to solve continuous (unconstrained) problems [

27] and it was later successfully extended to constrained optimization problems [

69]. Literature results show that the performance of ABC algorithm is comparable to other state-of-the-art algorithms for high dimensionality optimization [

70]. ABC has become a very active research area and many modifications [

28] and enhancements [

71] of the original algorithm were introduced. For PFSP, ABC was applied for different versions of the problem, as a standalone method [

72,

73,

74,

75,

76,

77], hybridized with other approaches [

46,

78], to optimize single or multiple objective functions [

79,

80].

3. Problem Statement

We tackle the joint scheduling of production and predictive maintenance within a specific manufacturing layout: the permutation flowshop. This integrated problem involves the simultaneous optimization of the production schedule and maintenance activities planning. Hence, the goal is to identify the most effective sequencing of jobs and the strategic timing of maintenance activities for each machine. The optimization objective is to minimize the total completion time (of production jobs and maintenance activities), referred to as Makespan or . For each machine on the shopfloor, the resulting joint schedule can be seen as a succession of production blocks, during which the machine executes the jobs included in the block, separated by unavailability periods, in which predictive maintenance interventions are planned.

In a permutation flowshop, a set of n production jobs move through a series of m machines, in a predetermined order without altering the order of the jobs from one machine to another, i.e., only permutation schedules are allowed. The processing time of job on machine is denoted . All jobs are assumed to be available at time zero and preemption of jobs is not allowed, i.e., once the execution of an operation is started, it cannot be interrupted neither by other operations nor by maintenance activities. Each machine processes only one action (production job or maintenance activity) at a time. Setup times are included in the processing times and are sequence-independent.

For the maintenance side, multiple unavailability periods are considered for each machine. Unavailability periods are due to predictive maintenance activities scheduled based on PHM outputs. For each machine , a degradation value is associated when processing each job . We consider the degradation value associated to job when being processed on machine , where and is the remaining useful life provided by PHM process.

At

, all machines are supposed to be “as good as new”; i.e., their initial degradation values are null. When processing each job

, the accumulated degradation of a machine

is updated according to the corresponding degradation value

. When the current accumulated degradation of a machine (i.e., the sum of degradation values of jobs that have been processed) reaches a maximal threshold

, a maintenance intervention must be performed. Flexible interventions are considered. The time intervals between each two consecutive maintenance activities as well as the number of maintenance activities are assumed to be decision variables and they are defined during the search process. Indeed, the maintenance planning strategy, described in

Section 4.1 allows to align with the production schedule by ensuring minimal disruption of the schedule. Maintenance intervention timing is not fixed but is adapted for each machine with respect to total completion time (

) minimization. We suppose that at least one maintenance intervention is performed on each machine and no maintenance intervention is performed after the processing of the last job. After each maintenance intervention, the machine is recovered to be “as good as new”.

The resulting integrated schedule is denoted

where

represents the corresponding integrated sequence of

n jobs and

(

) flexible maintenance on machine

. Then

can be seen as a succession of

blocks of jobs

(subsets of

) separated by predictive maintenance operations

:

4. Proposed ABC-Based Solving Approach

The ABC algorithm has demonstrated notable success in solving scheduling problems [

31]. For PFSP, ABC was applied for different versions of the problem, as a standalone method [

72,

73,

74,

75,

76,

77], hybridized with other approaches [

46,

78], to optimize single or multiple objective functions [

79,

80]. This success lies in its ability to leverage the principles of swarm intelligence to efficiently navigating solution spaces and finding near-optimal schedules. Indeed, bee colonies collect information from their surroundings and adapt their behavior accordingly. When applied in the context of scheduling problems, subject to multiple constraints, this intelligent and highly dynamic behavior seems to be very efficient. ABC capacity to strike a balance between exploration and exploitation makes it well-suited for such complex optimization problems. These two key mechanisms, i.e., exploration and exploitation, are inherently included within the ABC algorithm, as will be described in the next section. Moreover, its simplicity and ease of implementation contribute to its widespread applicability. Furthermore, since the performance of metaheuristic algorithms depends on parameters tuning, a notable advantage of the ABC algorithm is that it uses only 3 control parameters (colony size, maximum cycle number, and number of iteration to drop out a solution).

Concretely, ABC algorithm employs three distinct and collective classes of artificial bees: employed bees, onlookers, and scouts. Employed bee stays on a food source (i.e., candidate solution) and examines its neighborhood. Onlookers are allocated to a food source based on the information that they gain from employed bees. If a food source does not improve for a certain number of cycles, scouts replace that food source with a new random one.

The general scheme of the proposed ABC algorithm to solve the integrated production and flexible maintenance scheduling problem is shown in

Figure 1 and given in Algorithm 1. Two stopping criteria are used in the proposed ABC algorithm. The first one is the maximum cycle number

. Another option is to stop the search if the best solution found by the algorithm has not been improved for a given number of iterations

.

The detailed description of the main features of the proposed algorithm including the initialization procedure, employed bees phase, onlookers phase, and scouts phase, are detailed in the sections below.

| Algorithm 1 The proposed ABC algorithm |

- 1:

Parameters - 2:

: Colony size (number of food sources) - 3:

: Maximum number of iterations without improvement to drop out a food source - 4:

: Maximum cycle number of the algorithm - 5:

: Maximum number of iterations without improvement to stop the algorithm - 6:

Initialize population with food sources (solutions); - 7:

Associate a food source to each employed bee; - 8:

while and not reached do - 9:

EMPLOYED_BEES_PHASE(); - 10:

ONLOOKER_BEES_PHASE(); - 11:

SCOUT_BEES_PHASE(); - 12:

Return best solution; - 13:

end while

|

4.1. Solution Representation, Objective Function and Initialization Procedure

In ABC, food sources represent solutions in search space, and the nectar density corresponds to the fitness value of a feasible solution. In this paper, a two-field structure is used to represent a candidate solution, i.e., food source, which jointly specifies the production job sequence and the maintenance operations positions on each machine, as proposed in [

13]. The sequence of jobs to be processed by the permutation flowshop is coded using a permutation

, where

is the

jth job to be executed. For the maintenance side, to represent the maintenance intervention positions on each machine, a binary matrix

is used, where each line is dedicated to a machine of the shopfloor. To indicate the presence of maintenance activity on machine

after the

jth job of the sequence, we put

, otherwise

.

A single objective function is addressed in this work, which is the total completion time of the integrated schedule, after maintenance activities planning, referred to as Makespan or .

As for any evolutionary algorithm, population (colony) initialization is a critical step for ABC algorithm. Indeed, the convergence speed and the quality of the final solution are highly affected by the diversity of the initial population. In this work, random solutions as well as good quality solutions are generated and included in the initial population. Randomly generated solutions contribute to the exploration phase of the algorithm by helping in exploring distinct regions of the solution space, which increases the chances of discovering more promising areas and avoids getting trapped in local optima. On the other side, good candidate solutions enhance the exploitation phase by focusing on promising areas where optimal or near-optimal solutions may be located. Hence, in this study, we proposed a two-step initialization procedure to generate an initial population of food sources (integrated solutions) as follows:

- 1.

Generation of production sequences In this work, production sequences are generated as follows:

- 2.

Generation of maintenance activities planning

To build a feasible solution, i.e., an integrated production and maintenance schedule, a maintenance matrix

is associated with each production sequence

S, obtained from the previous step. The maintenance planning is achieved based on PHM data, in the form of degradation values. We use the heuristic proposed in [

41]. The main idea of this heuristic is to schedule maintenance operations in ascending order, i.e., starting from the first machine of the flowshop, by evaluating the total accumulated degradation of the machine when processing jobs. Jobs in the sequence

S are scanned one by one and maintenance tasks are inserted, on each machine, according to the current cumulative degradation

with respect to the threshold (

). Hence, for each machine

in the shopfloor, two cases could be observed as shown in the illustrative example in

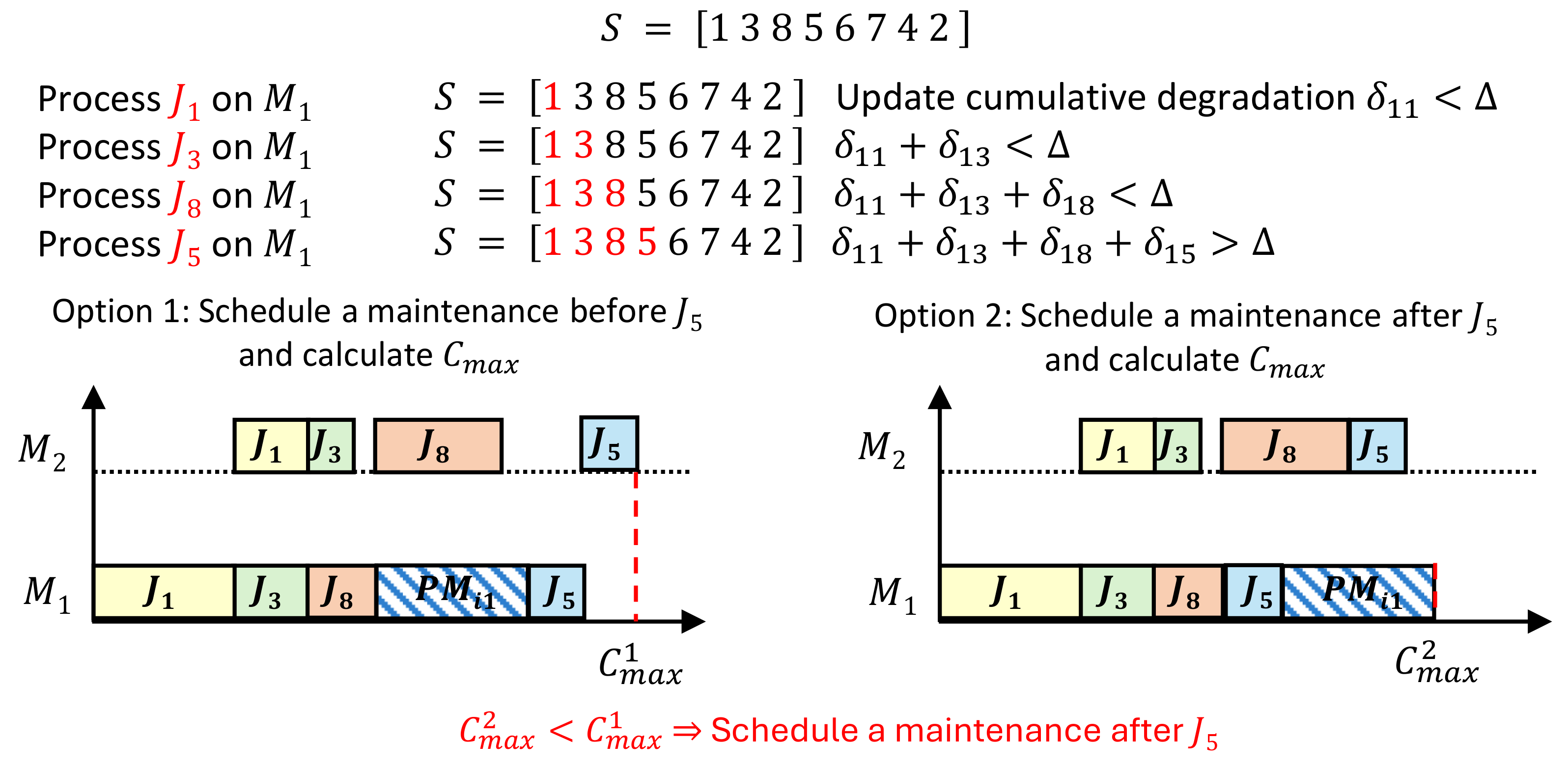

Figure 2:

If

, no predictive maintenance intervention has to be scheduled because the full degradation has not been achieved yet. So, we scan the next production job in the sequence. This is observed in example of

Figure 2, when performing jobs

, the cumulative degradation of machine

doesn’t reach the full degradation

, hence, no maintenance operation is scheduled;

If

. The machine reaches the total degradation threshold (

) and a high risk of machine failure is faced. Hence, we schedule a maintenance intervention either before or after the current job, according to the position that best optimizes the Makespan. This is shown in the example of

Figure 2 when processing job

:

so we evaluate the two options of scheduling a maintenance before or after current job

and we choose the one minimizing

.

This strategy seeks to use machines at their full potential by planning maintenance only when necessary. Moreover, this enhances schedule flexibility and minimizes production disturbance by considering various options for maintenance insertion for the Makespan optimization.

Once the initial population is created, the search process is launched. Each iteration consists of three stages: the employed bees phase, the onlooker bees phase, and the scout bees phase, which will be presented in the next sections.

4.2. Employed Bees Phase

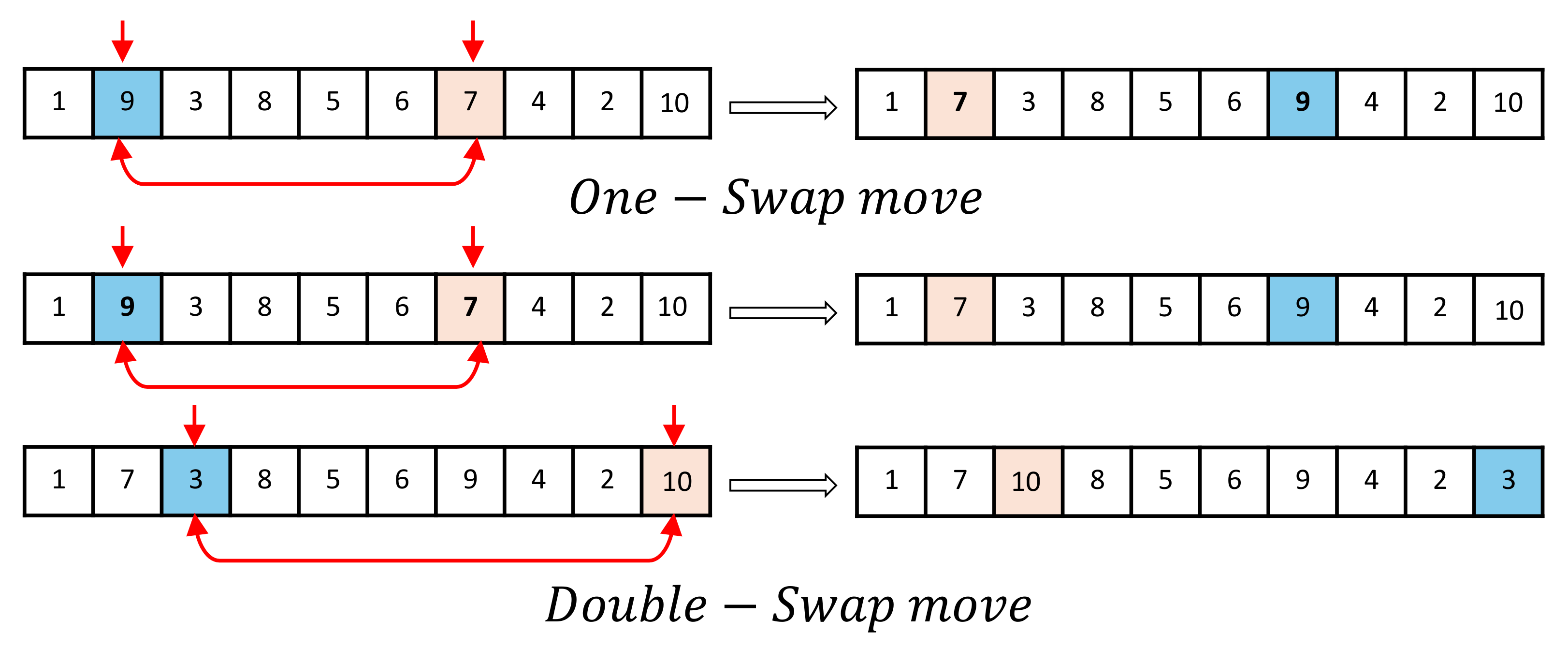

The employed bees phase is the first step in the search process of ABC algorithm. In this phase, a food source, i.e., an integrated schedule within the current population, is associated with each employed bee. Hence, the number of employed bees is equal to the number of food sources . The main role of employed bees is to move around the neighborhood of their assigned food sources to discover new and potentially better solutions. Hence, move strategies need to be defined to navigate in the search space. In this work, we use two complementary and efficient neighborhood structures from the existing literature, which have proven to be efficient in exploring solutions in PFSP. These structures allow exploration of production sequences neighborhood as follows:

One-swapping based neighborhood. To obtain a neighbor solution, a swap move is carried out by exchanging the positions of two production jobs, randomly selected from the production sequence of the current solution, as shown in

Figure 3.

Let

S be the production sequence of the current solution.

p and

q are two distinct positions, randomly selected from 1 to

n (size of

S). When applying one-swapping move, all jobs are maintained but jobs corresponding to positions

p and

q are interchanged to obtain the new sequence

:

Double-swapping based neighborhood. In this case, two swap moves are carried out successively on the production jobs sequence, as shown in

Figure 3.

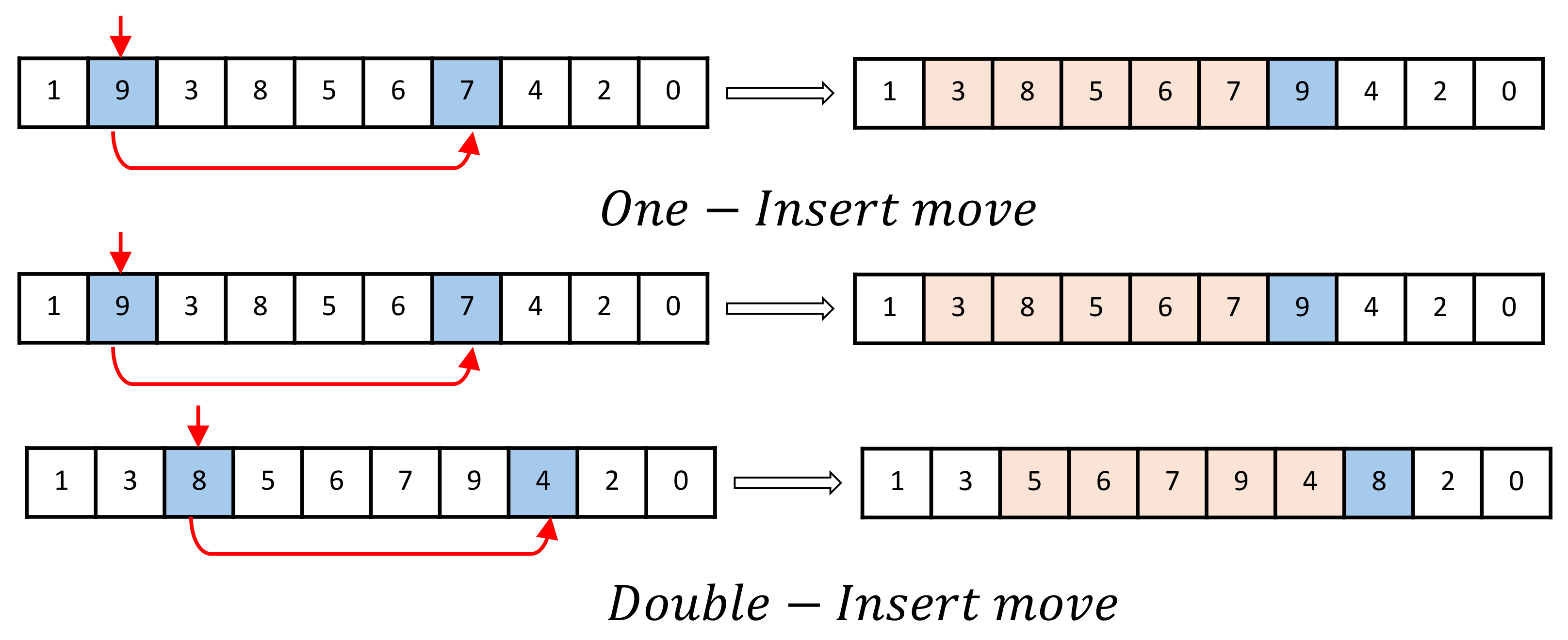

One-insertion-based neighborhood. A production job is randomly selected from the production sequence, deleted from its current position, and then inserted into a new randomly selected one, as shown in

Figure 4.

Let S be the production sequence of the current solution. p and q are two distinct positions, randomly selected from 1 to n (size of S). When applying one-insertion move, job corresponding to position p is deleted from the sequence S and then inserted in position q.

Double-insertion based neighborhood. It consists of two insert moves, carried out successively on the production jobs sequence, as shown in

Figure 4.

To explore solutions neighborhood based on maintenance planning, two other structures are used as shown in

Figure 5:

Right shift-based neighborhood. In this move, a maintenance operation planned on a selected machine is randomly chosen from the predictive maintenance matrix, and then shifted to the right, i.e., moved forward to be rescheduled after the next job.

Left shift-based neighborhood. A maintenance operation planned on a selected machine is randomly chosen and then shifted to the left, i.e., moved backward to be rescheduled before the current job.

Figure 5.

Illustrative examples of right and left shift moves.

Figure 5.

Illustrative examples of right and left shift moves.

Once the initial population is generated as explained before, each employed bee flies to a unique food source (candidate solution). Throughout the search process iteration, each employed bee seeks to find a new food source within its neighborhood. For this reason, the employed bee randomly selects one of the previous neighborhood structures and uses it to generate a new solution. Note that if maintenance operations are altered, they will be readjusted. A greedy selection mechanism is used to choose between the current and the new food sources. In other words, if the Makespan of the current solution is improved, then it is replaced by the new solution, which will be then assigned to the employed bee in subsequent iterations. Otherwise, the current solution is retained. To control the evolution of solutions manipulated by the employed bees and their eventual stagnation in local optima, a counter

is associated with each solution and incremented whenever its objective function (Makespan) doesn’t improve. Employed bees share their findings (solution information) with onlooker bees. The process of employed bees phase in given in Algorithm 2.

| Algorithm 2 Employed bees phase algorithm |

- 1:

procedure

Employed_bees_phase() - 2:

for all Employed bees do - 3:

Let be the food source associated to - 4:

Randomly select a neighborhood structure from (swap, double swap, insert, double insert, leftshift, rightshift) - 5:

Use to generate new solution from - 6:

Reschedule maintenance operations of - 7:

if then - 8:

Update food solution with - 9:

Reset of to 0 - 10:

else - 11:

Increment of ; - 12:

end if - 13:

end for - 14:

end procedure

|

4.3. Onlooker Bees Phase

The onlooker bees phase in the ABC algorithm deals with the exploitation of the search process. This phase involves the selection of promising food sources by onlooker bees based on the information shared by employed bees. Onlooker bees then generate new solutions through a local search method, and if the new solution is better in term of the Makespan, the corresponding food source is updated, as detailed in Algorithm 3. Similarly, if maintenance operations are modified, they are readjusted after the local search process.

| Algorithm 3 Onlooker bees phase algorithm |

- 1:

procedure

Onlooker_bees_phase() - 2:

: Number of onlooker bees - 3:

for all Onlooker bees do - 4:

Select a food source using roulette wheel scheme - 5:

- 6:

Reschedule maintenance activities of - 7:

if then - 8:

Update food solution with - 9:

Reset of to 0 - 10:

else - 11:

Increment of - 12:

end if - 13:

end for - 14:

Apply the same process on the best food source in the population - 15:

end procedure

|

The selection process is performed by onlooker bees using a roulette wheel approach, where each food source is associated with a selection probability determined by its fitness evaluation. This allows food sources with better fitness to have a higher chance of being selected. Note that for Makespan (

) minimization, the considered fitness function is

. The following formula is used to evaluate the selection probability

of a food source

:

Once each onlooker bee selects a food source, it starts generating a new solution through a local search method. Various local search algorithms are available in the literature. In this work, the proposed local search is inspired by the construction/destruction mechanism introduced in [

73]. This procedure consists of removing a predetermined number of jobs from the production sequence and then rescheduling them based on the well-known NEH heuristic [

81]. Since NEH heuristics allows finding the best emplacement of a job in a sequence to minimize

, this local search method enhances the quality of the solution found by the employed bees, promoting then the exploitation of the search process. Two distinct stopping criteria are considered for the local search:

first improve criterion, where the local search concludes upon achieving the first improved solution. This criterion is applied to all selected food sources at each iteration. The second criterion involves conducting an exhaustive search, by inserting the removed jobs into all possible positions. Given that this criterion is greedy in terms of computational time, it is applied only to the best solution in each iteration. Similarly to the employed bees phase, if a solution is not improved after the local search procedure, its respective counter (

) is incremented. The local search procedure integrated in onlooker bees phase is given Algorithm 4.

| Algorithm 4 Local search algorithm |

- 1:

procedure Local_Search() - 2:

: food source (solution) - 3:

d: number of jobs to be rescheduled - 4:

Let be the job sequence associated to solution - 5:

for to d do - 6:

Select a random job position j and delete corresponding job - 7:

for to do - 8:

Insert in position k and evaluate new Makespan - 9:

if < then - 10:

Update solution - 11:

end if - 12:

if is not the best solution in the population then - 13:

stop procedure (first improvement scheme) - 14:

end if - 15:

end for - 16:

end for - 17:

end procedure

|

4.4. Scout Bees Phase

The scout bees phase is the last stage of ABC algorithm iteration. During this phase, scout bees fly to candidate solutions with

exceeding the allowed maximum threshold, denoted

. These solutions are abandoned and replaced by new randomly generated ones in the subsequent iteration, as given in Algorithm 5.

| Algorithm 5 Scout bees phase algorithm |

- 1:

procedure

Scout_bees_phase() - 2:

for all Food sources do - 3:

if of > then - 4:

Generate new random solution ; - 5:

Update food solution with ; - 6:

Reset of to 0; - 7:

end if - 8:

end for - 9:

end procedure

|

5. Computational Results

This section is devoted to presenting the results of computational experiments conducted to calibrate and evaluate the newly proposed ABC algorithm for the integrated scheduling of production and predictive maintenance. All algorithms and tests were developed using Python and executed on Microsoft Azure cloud using the Standard virtual machine under the Ubuntu 18 operating system, equipped with 6 cores and 6 gigabytes of RAM.

We first describe the data benchmarks used in this study. Next, we outline the statistical analysis conducted for the configuration of ABC parameters. Finally, we analyze the performance of the proposed ABC algorithm when compared to a VNS (variable neighborhood search) method from the literature [

44].

5.1. Data Benchmarks for the Integrated Scheduling Problem

We apply a similar data generation approach as proposed in [

44]. For production data, we use the well-known Taillard’s instances [

83]. This benchmark consists of 120 instances of the PFSP, where 12 configurations of flowhsop

are considered:

and

. For each configuration, 10 instances are included. For predictive maintenance data, PHM information in form of degradation values

are generated for each job when being executed by each machine, according to its processing time

. This involves three cases: Low, Medium, and High degradation values as follows:

Jobs with processing times induce machine degradation uniformly distributed in ;

Jobs with processing times induce machine degradation uniformly distributed in distributed in ;

Jobs with processing times induce machine degradation uniformly distributed in .

For maintenance operations processing times, two variants are considered. In the first mode, medium maintenance durations are generated from the uniform distribution . In the second mode, long maintenance durations are generated from the uniform distribution . Hence, we obtain a set of 120 instances of the integrated scheduling problem for each maintenance mode, and then a total of 240 instances.

Three metrics are calculated to assess the performance of the proposed ABC algorithm:

(1) The relative percentage deviation (

) of the Makespan (

) obtained by the ABC algorithm, with respect to a theoretical lower bound

. The

is calculated as follows:

The proposed lower bound

is based on the lower bound suggested by Taillard in [

83], taking into account the maintenance operations. Let

be the minimum duration that machine

must wait before it can start processing (waiting for the previous machines in the flowshop),

the minimum duration the machine

remains inactive after completing processing all jobs (waiting for the next machines in the flowshop),

the total number of maintenance activities of duration

D and

be the total processing time of machine

including both production and maintenance operations. Then:

where

m is the number of machines in the flowshop,

n is the number of jobs, and

is the processing time of task

on machine

.

The sum

represents the time a machine should wait before it starts processing (

), added to the total time it needs to process all production and maintenance tasks (

), added to the minimum period it waits till the next machines of the flowshop finish their execution (

). Given that no waiting times are considered between tasks,

must exceeds the maximum of

. On the other hand,

also exceeds the maximum period required for jobs to pass through all machines of the flowshop. Hence, the lower bound

is obtained as follows:

(2) The average percentage of maintenance operations earliness/tardiness (

). It is calculated according to the machine’s accumulated degradation at the moment of predictive maintenance intervention scheduling. An ideal maintenance operation is scheduled when the machine is fully exploited, i.e., its accumulated degradation is equal to

. Otherwise, a maintenance operation is either early if the accumulated machine degradation is less than

or tardy if the accumulated machine degradation is greater than

. Hence, the

of maintenance operations on machine

is:

where

is the number of predictive maintenance operations scheduled on machine

and

is the value of the accumulated degradation of the machine when the

kth predictive maintenance is scheduled.

The average percentage of

of all maintenance operations of the schedule is calculated as follows:

(3) Computation time .

5.2. Statistical Analysis for ABC Parameters Tuning

The ABC algorithm has three parameters, namely, the number of food sources () which is equal to the number of employed bees, the number of iterations after which a non-improved solution is abandoned , and the maximum cycle number (). In most cases, the number of onlooker bees is equal to the number of employed bees. In this work, to limit the computation time and enhance the balance between exploration and exploitation for the specific needs of our optimization problem, the number of onlooker bees (denoted ) is also considered as a parameter.

Four parameters (, , , and ) are assessed in the calibration procedure. Various levels are considered for each parameter: , , , and of the total number of food sources . A full factorial design was conducted, in which all possible combinations of various parameters were tested. The results were then analyzed using analysis of variance method statistical method, with the least significant difference intervals at , to set each factor to its best level.

To allow fair parameter tuning, the algorithm calibration tests are executed on a new set of instances. Production data are generated following procedure outlined in [

83], including 20 combinations of

, where

and

. Two instances are generated for each combination, resulting in a total of 40 instances. The same approach described in

Section 5.1 is used for maintenance data generation (the first maintenance mode is adopted).

Applying a full factorial design, we have parameter combinations to test on 40 instances, with 5 runs per instance, resulting in executions. The response variable for analysis of variance is the Makespan deviation . Results show that the best combination of ABC parameters is: , , , and .

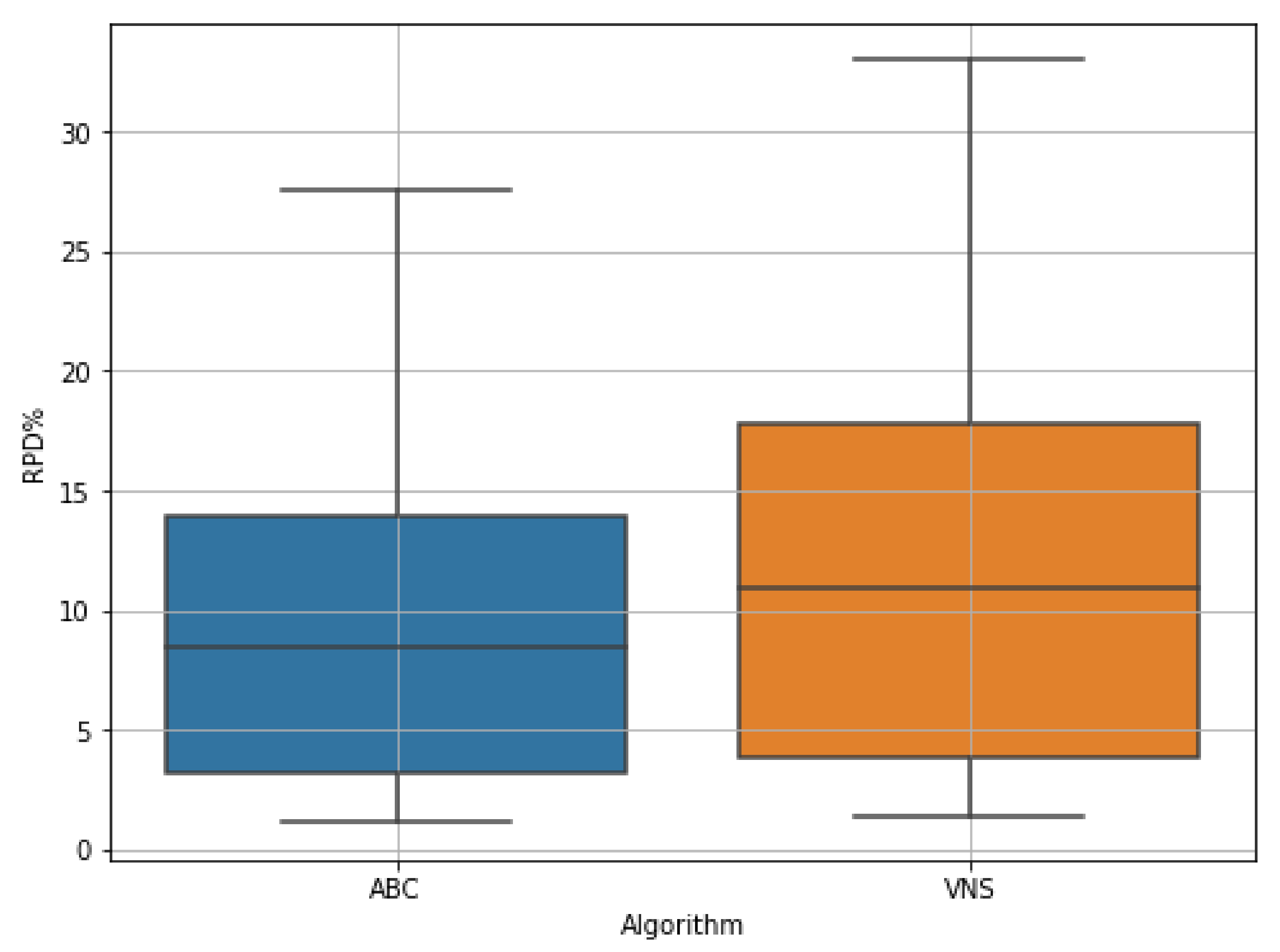

5.3. ABC Performance Analysis

In this section, we will provide insights into results obtained by the proposed ABC algorithm when applied to solve the 120 instances of the integrated scheduling problem in the two maintenance modes. To assess the performance of the ABC approach, it is compared to a variable neighborhood approach (VNS) from the literature [

44]. This work was selected as it tackles the same integrated scheduling problem of production and predictive maintenance. To make a fair comparison, the VNS algorithm was re-executed on the same instances and in the same environment (machine configuration). Results obtained by ABC and VNS in terms of

and

are depicted in

Table 1 and

Table 2, for maintenance modes 1 and 2, respectively.

For Makespan () minimization, the proposed ABC algorithm outperforms the VNS method for the majority of instances, in both maintenance modes. On average, ABC is the best, with an average of against for VNS in maintenance mode 1, and against in maintenance mode 2. Hence we could conclude that ABC is more efficient in minimization. It is important to note that we could not execute the VNS algorithm for instances due to excessively long execution times.

To statistically validate the significance of the difference in

values provided by the proposed ABC algorithm and VNS, Wilcoxon’s statistical analysis of variance was conducted. Results reject the null hypothesis, i.e., significant variance is validated between the two algorithms at a confidence interval of

(

p-

) was set to

).

Figure 6 shows the mean plots of both algorithms for

optimization.

On the other hand, when considering maintenance average minimization, the VNS method provides better results in most cases, with an average of against for the proposed ABC in maintenance mode 1, and against for maintenance mode 2. It is worth noting that the maintenance criterion (average ) was only calculated in this study, but single objective optimization, of , was considered. However, when jointly observing both criteria, we can confirm that ABC allows achieving a good trade-off between production completion time and maintenance while maintaining good results for .

When comparing maintenance modes, we notice that deviations increase in mode 2, while maintenance average remains steady. Indeed, deviations are influenced by the duration of maintenance interventions: greater disruptions occur when longer maintenance activities are scheduled. However, maintenance depends solely on the timing of maintenance interventions and remains unaffected by their duration.

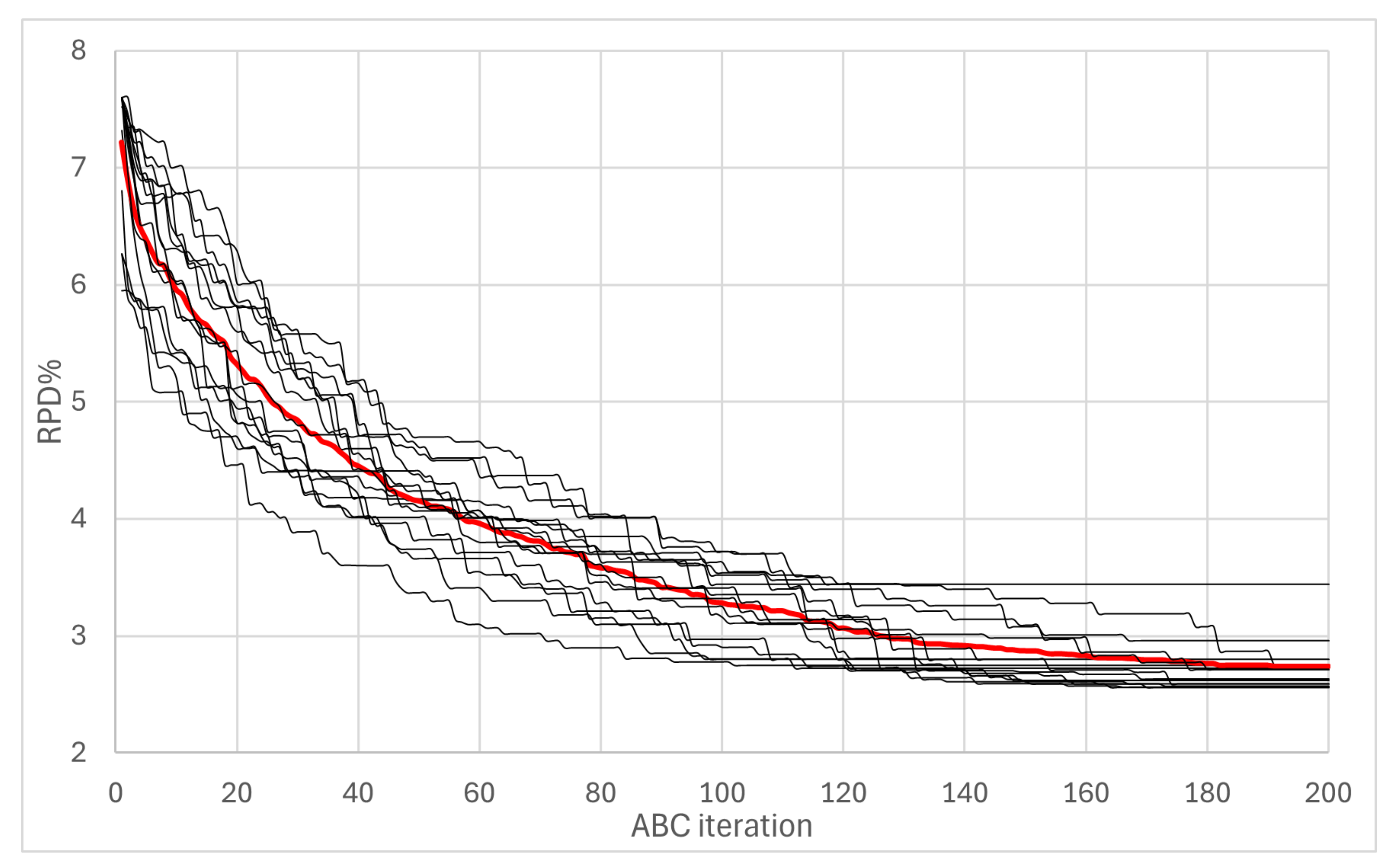

A critical feature of an optimization problem is the convergence phenomenon. To analyze the behaviour of the proposed ABC algorithm through the search iterations, we provide in

Figure 7 an illustrative example of several independent executions of the ABC algorithm on one given instance of the integrated problem of size

in maintenance mode 1. We can observe that the ABC algorithm is effectively progressing towards finding the near-optimal possible solution. We notice that the convergence rate is high at the first

iterations, after that, the search progress slows down. In most cases, the search process globally converges towards the same best solution (

). Some local convergences (in local optima) are also observed, but the ABC algorithm is most often able to boost the search process. Otherwise, based on the second termination criterion

iterations, the search process is stopped if the algorithm is stacked in local optimum for more than 40 iterations.

To assess the computational performance of both methods,

time is evaluated in

Table 3. This metric aids in identifying potential trade-offs between solution quality and computational speed. For small instances

, VNS is faster than ABC. When the instance size increases, ABC becomes faster with an average difference of 2915.51 s, which can go up to 5.07 h (for benchmark

. Moreover, for the set of instances

, we were enabled to run the VNS algorithm. For small instances, the CPU time difference can be explained by the fact that VNS applies its research process on a single solution at each iteration, while ABC manipulates a whole population, which makes it slower. For larger instances, exhaustive neighbourhood exploration during the VNS research process makes it slower, because the neighbourhood size explodes. As a consequence, when considering the scalability of both methods, we can confirm that the proposed ABC algorithm is more practical.

6. Conclusions

This work deals with the integrated scheduling problem of production and predictive maintenance in permutation flowshops. This problem is characterized by flexible maintenance activities scheduled based on PHM outputs. Metaheuristic approaches seem to be the best and most practical choice to solve such an NP-hard problem. Among a large number of swarm intelligence-inspired methods, artificial bee colony (ABC), simulating the foraging behaviour of honey bees, has been successfully applied to different variants of scheduling problems. Hence, in this study, we develop an ABC algorithm with an efficient search process, to minimize the total completion time (Makespan) of the schedule. The main idea is to design adapted search procedures with appropriate structures to balance the exploration and exploitation of the search. A statistical analysis was used to accurately calibrate the ABC parameters. Comprehensive experiments were carried out to assess the performance of the proposed ABC compared to a VNS algorithm from the literature, dealing with the same problem. Results analysis shows that the proposed ABC is more efficient, providing better solutions in terms of Makespan minimization, in a shorter computational time.

While the proposed ABC algorithm has demonstrated good results, some improvements can be considered. One potential enhancement axis involves the integration of a more robust selection scheme of the neighborhood structures by the employed bees. Moreover, the hybridization of ABC with other local search methods allows them to leverage their complementary strengths. Considering the average earliness/tardiness of maintenance interventions, the proposed ABC seems to be less performant. Indeed, this criterion was not tackled in this paper. Hence, a promising perspective would be to develop a multi-objective ABC algorithm where both production and maintenance criteria are simultaneously optimized.