Mechanical Design, Analysis, and Dynamics Simulation of a Cable-Driven Wearable Flexible Exoskeleton System

Abstract

1. Introduction

- Existing wearable robotic arms are often rigid, excessively heavy, and lack the necessary flexibility for effective rehabilitation. Ideally, a robotic arm should be lightweight, agile, smooth, and closely conform to the patient’s arm.

- The robotic arm should have appropriate degrees of freedom and a simple structural design. This ensures effective rehabilitation while minimizing the burden on patients during use.

- The robotic arm should exhibit extremely high stability and safety.

2. Mechanical Design

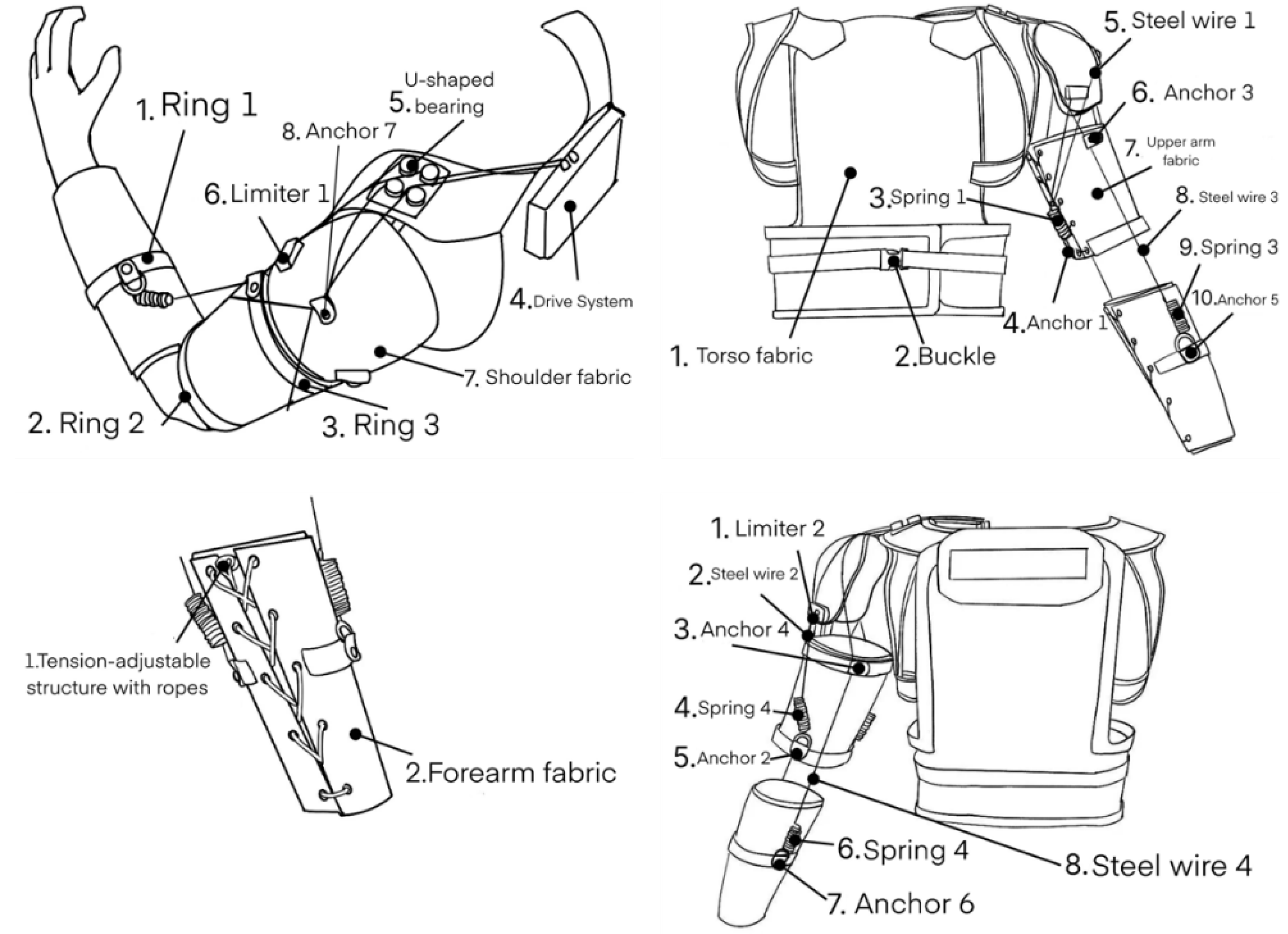

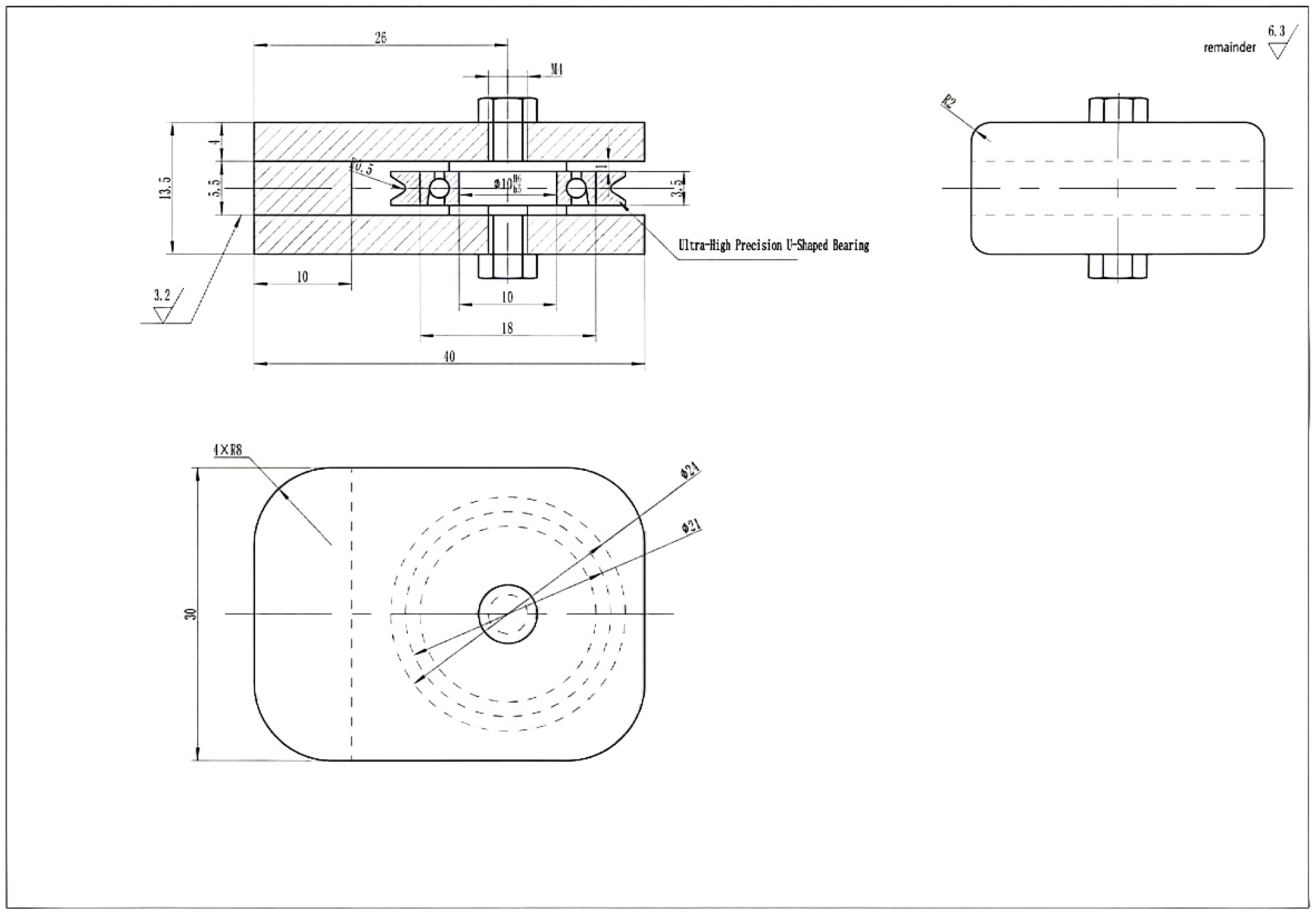

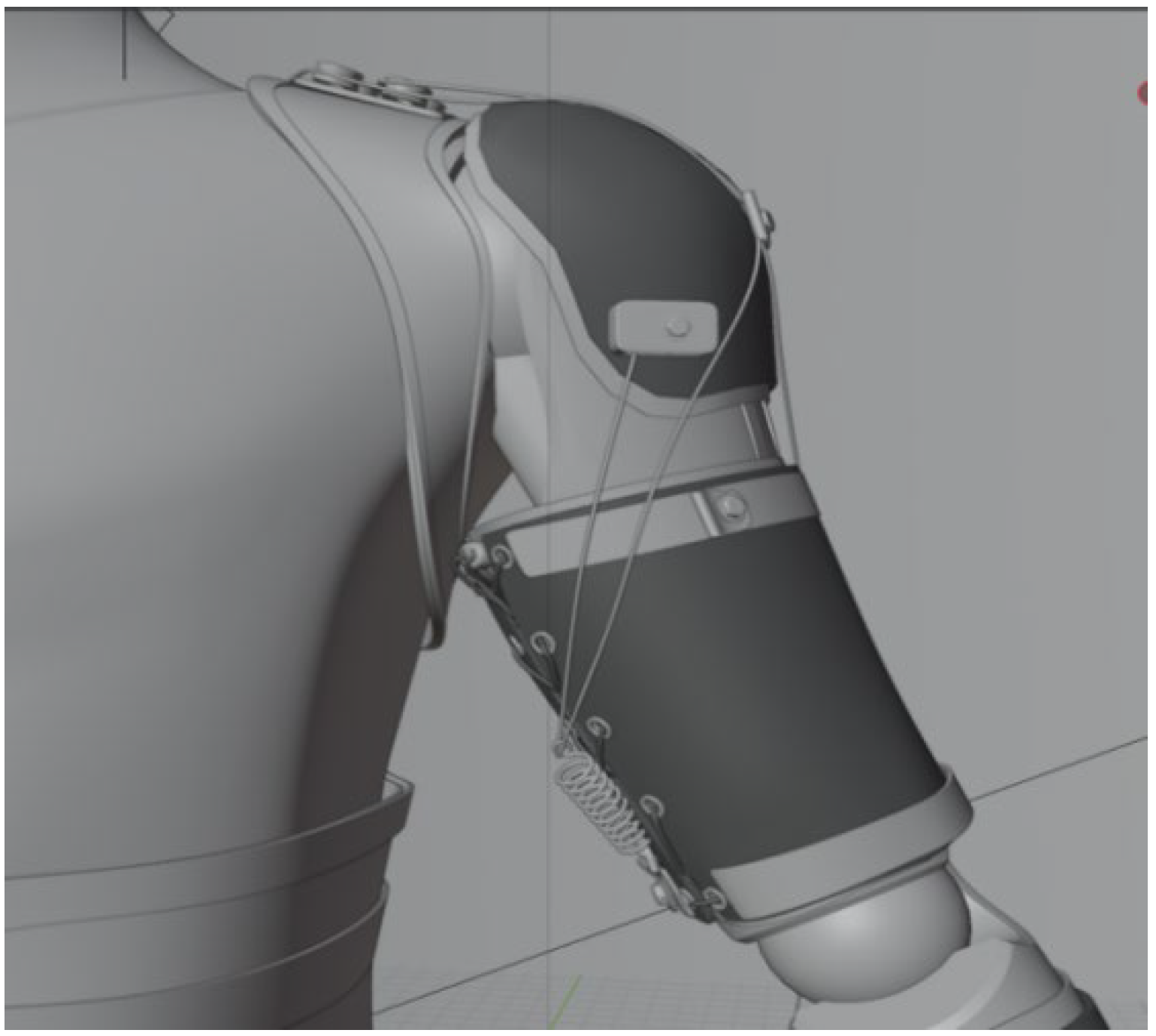

2.1. Structural Design

2.2. Dimensional Determination

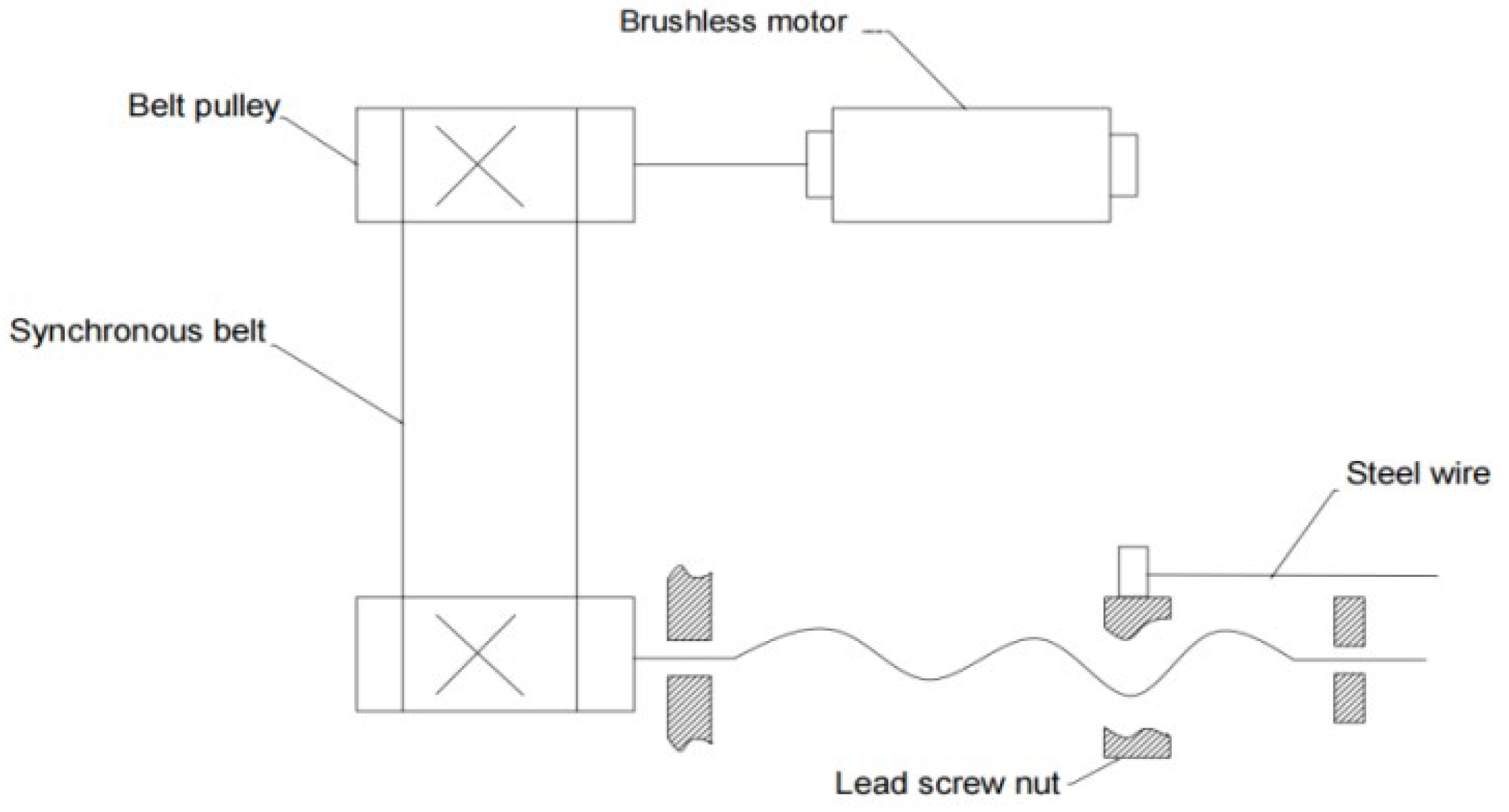

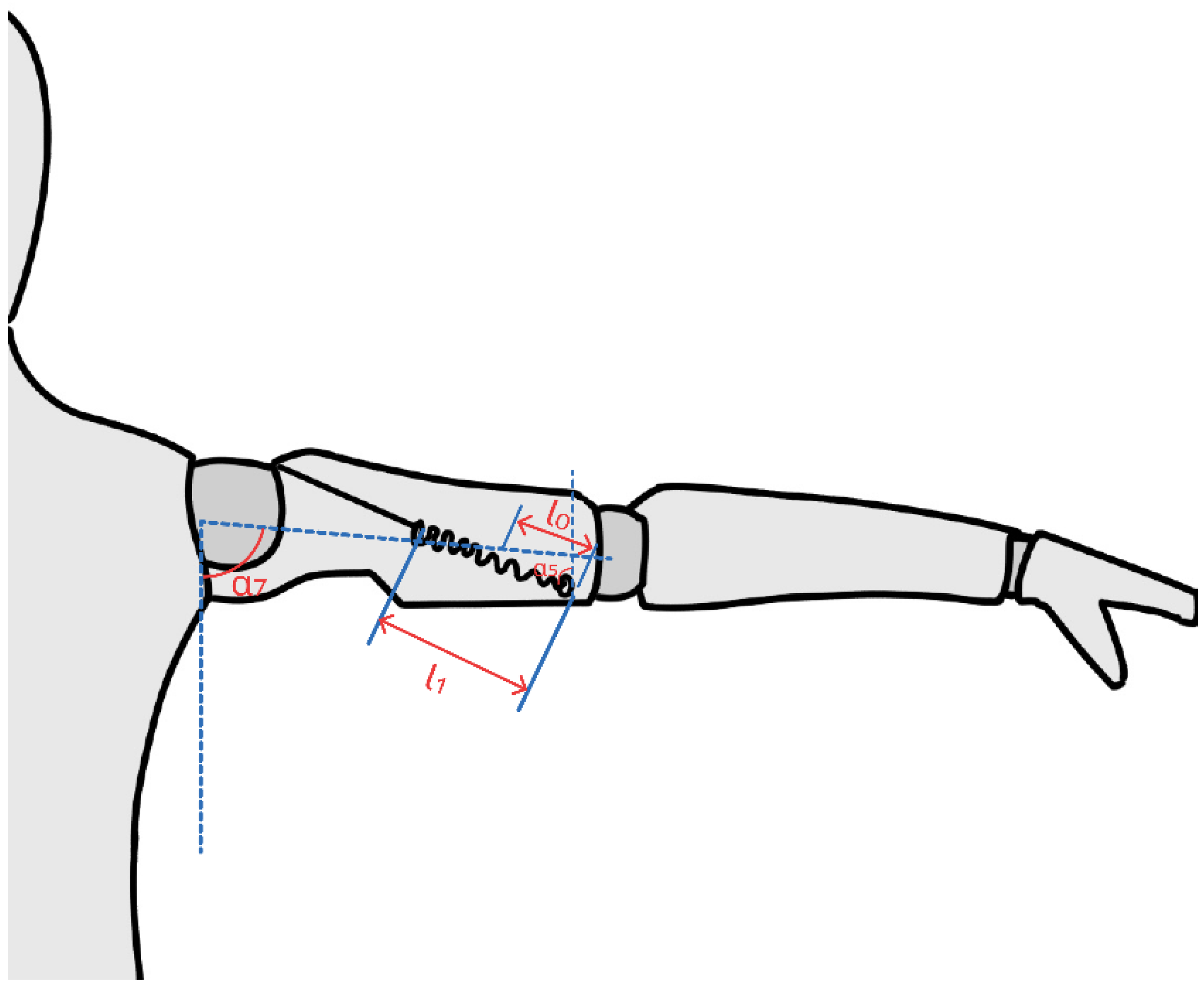

2.3. Driving System Design

2.4. Weight Estimation

3. Kinematic and Static Analysis

3.1. Kinematic Analysis

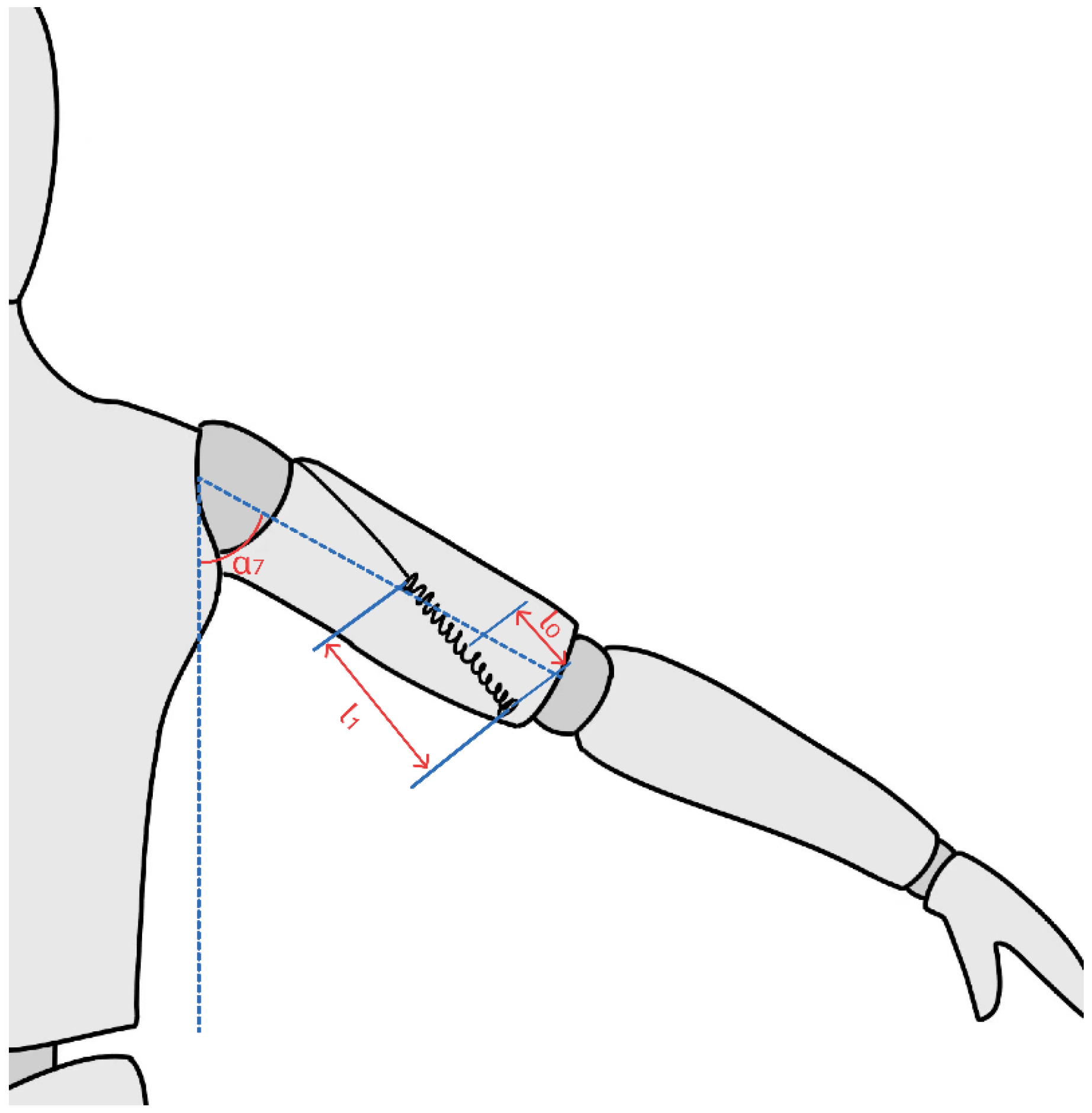

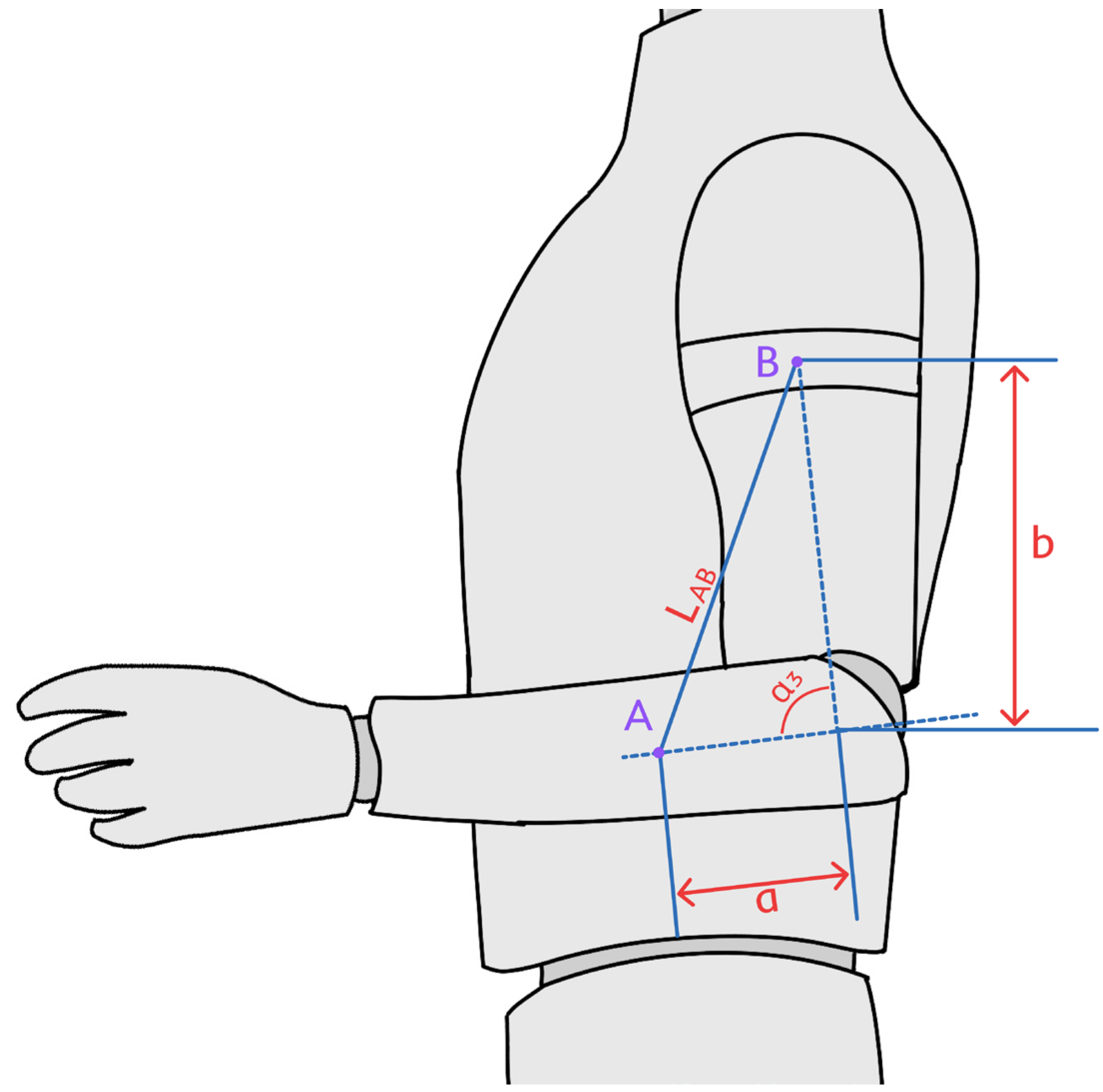

3.1.1. Kinematic Analysis of the Upper Arm

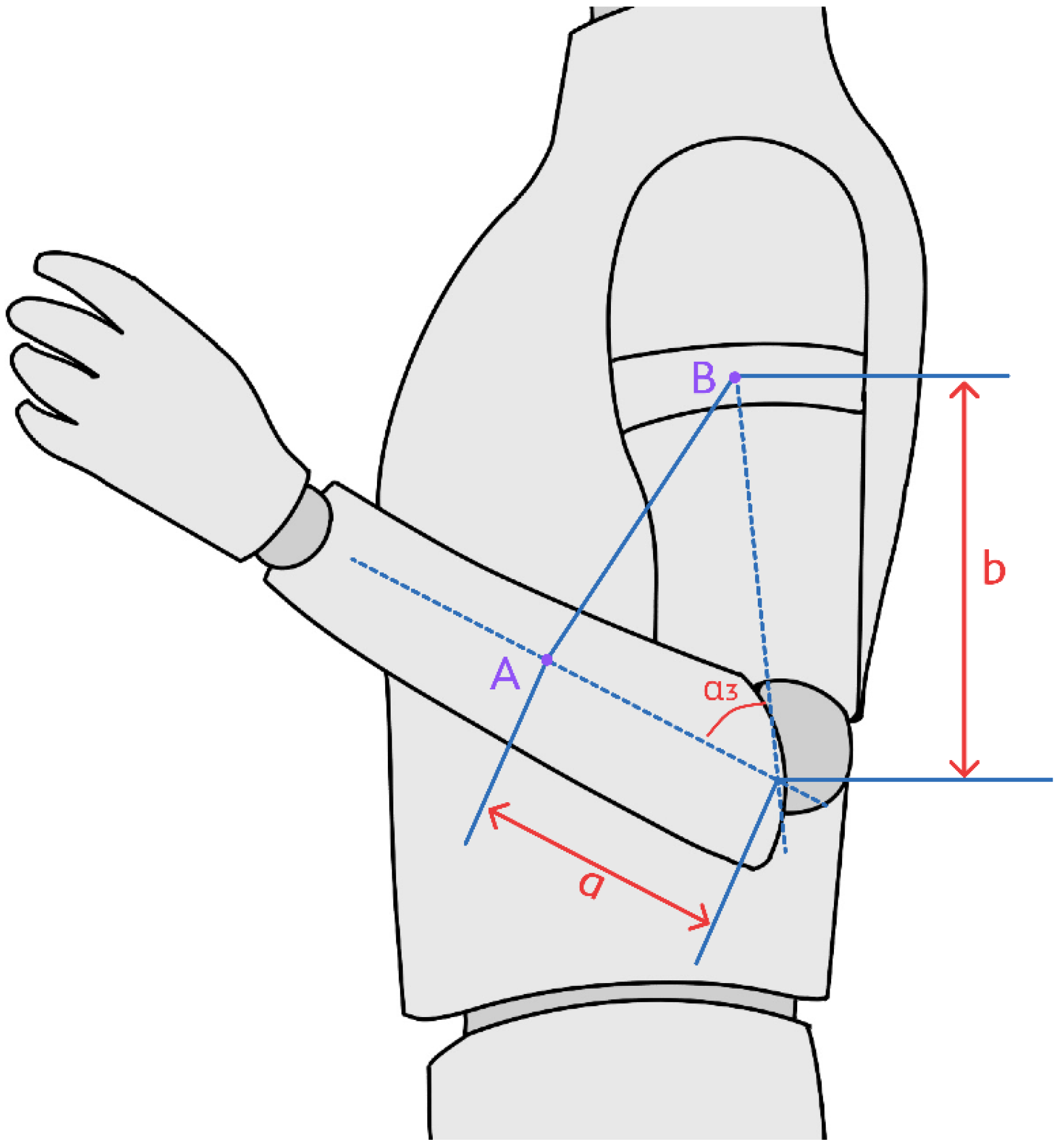

3.1.2. Kinematic Analysis of the Forearm

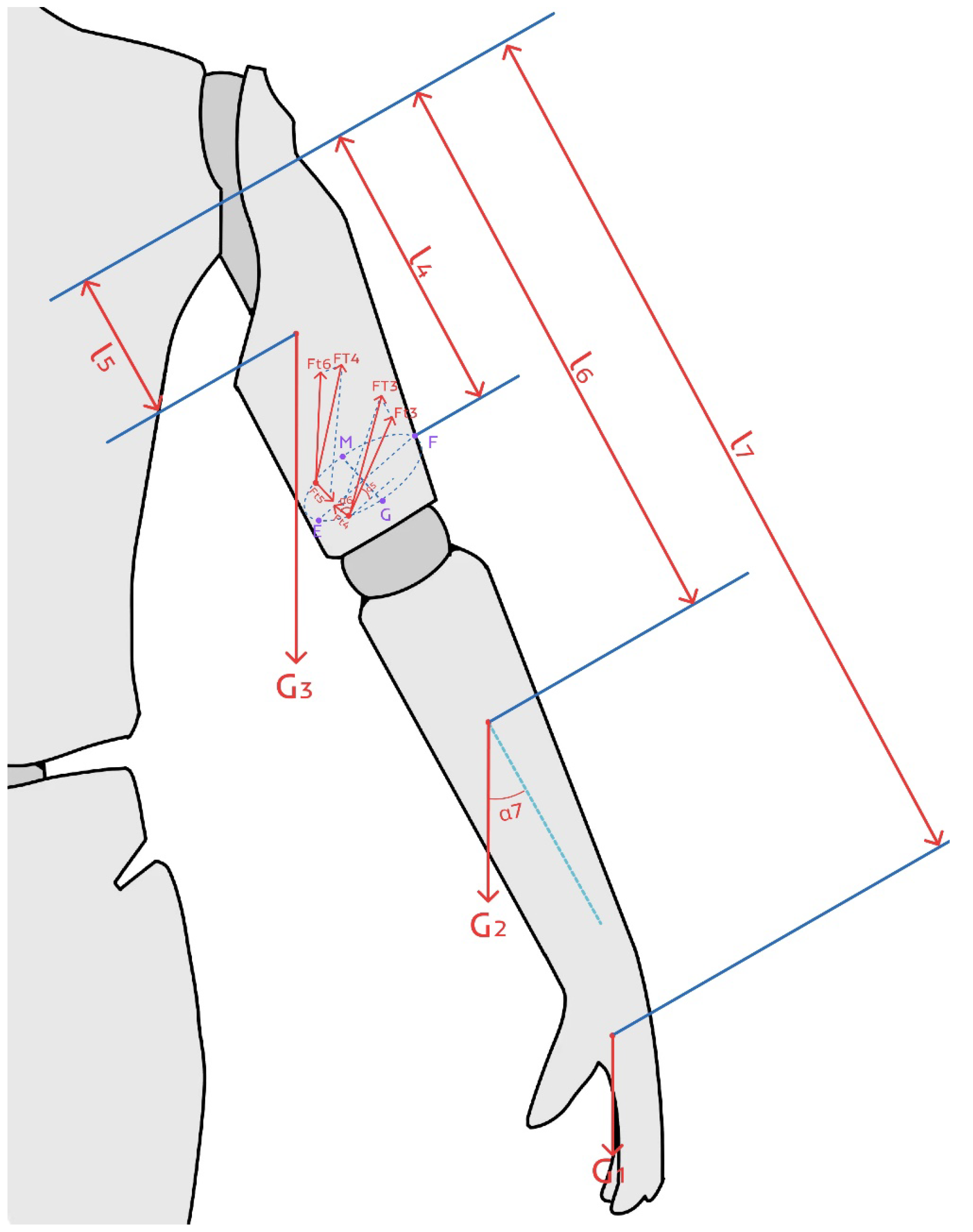

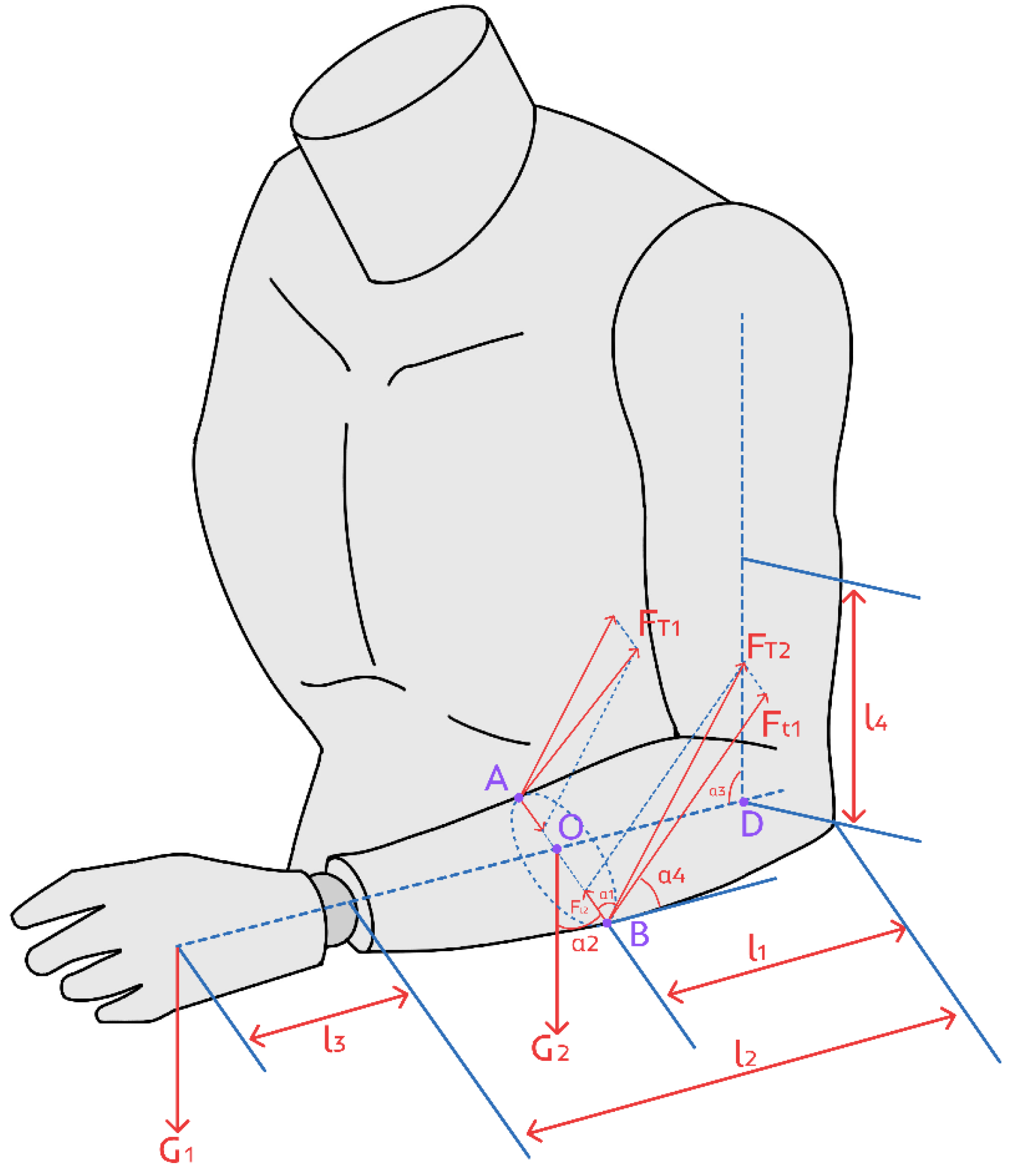

3.2. Static Analysis

3.2.1. Static Analysis of the Upper Arm

3.2.2. Static Analysis of the Forearm

4. Spring and Limiter Analysis

4.1. Spring Analysis

4.1.1. Spring Analysis for the Upper Arm Section

4.1.2. Spring Analysis for the Forearm Section

4.2. Feature Matching

5. Dynamics Simulation

5.1. Parameter Setting

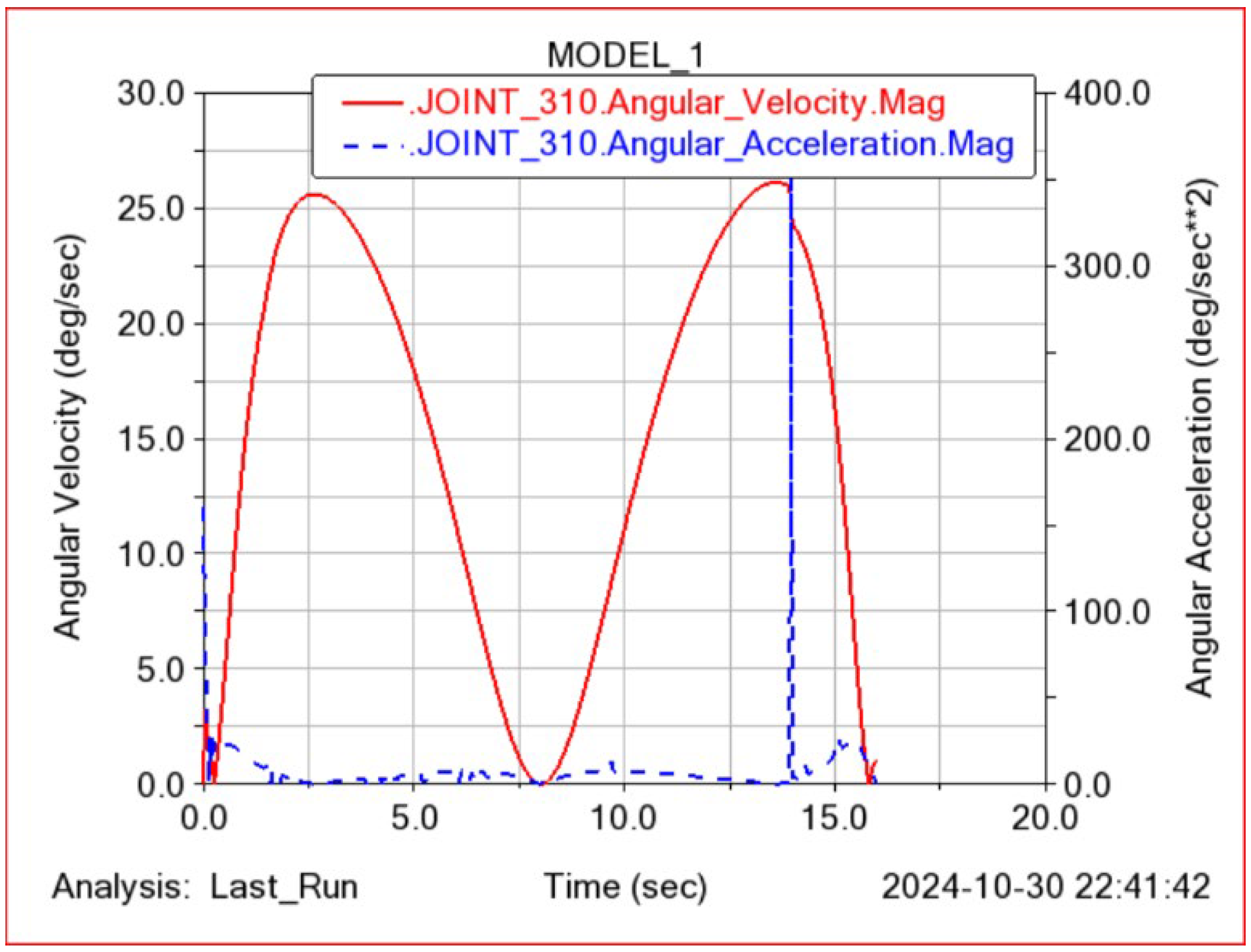

5.2. Simulation of Shoulder Joint Internal/External Rotation Movements

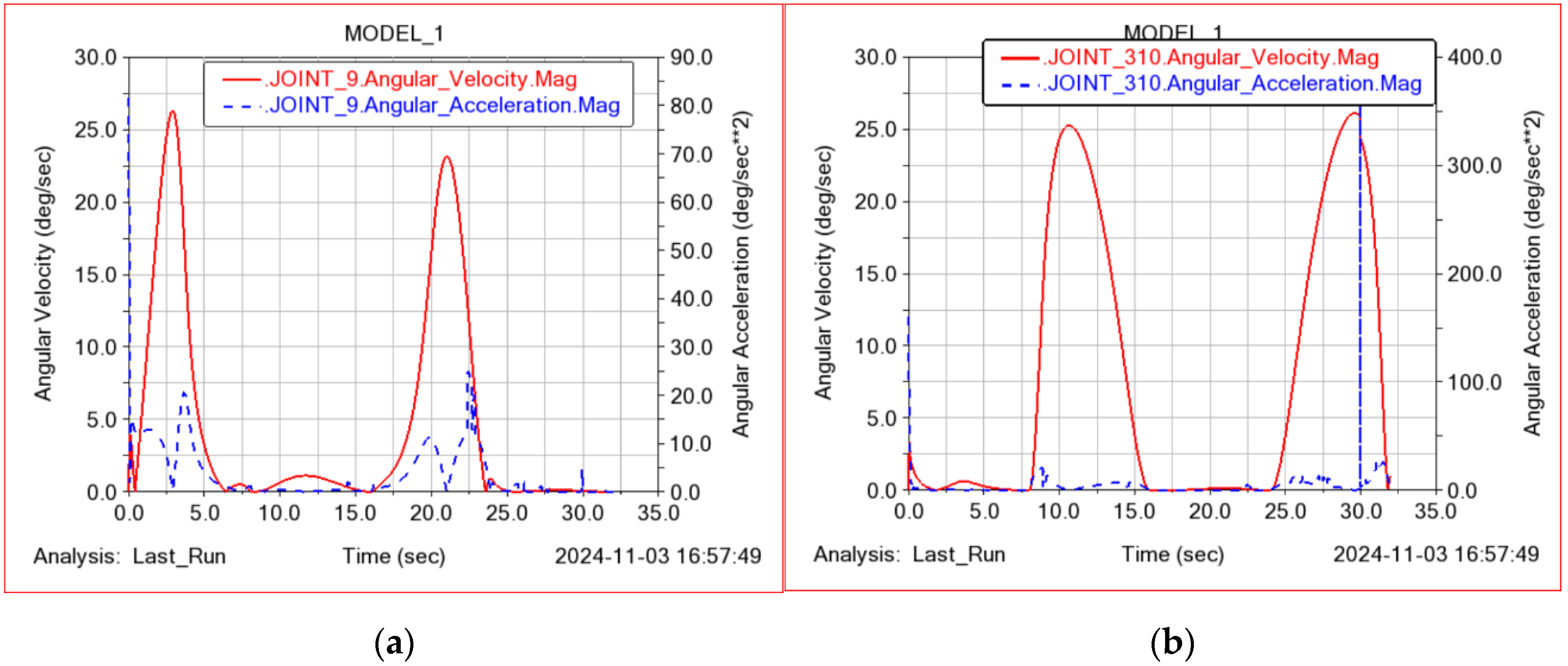

5.3. Simulation of Elbow Joint Flexion/Extension Movements

5.4. Simulation of Combined Rehabilitation Movements of the Shoulder and Elbow Joints

6. Discussion

- (1)

- Using flexible materials and motor-driven steel wires ensures that the exoskeleton system is lighter in weight, thereby reducing the burden on patients during rehabilitation.

- (2)

- It significantly reduces the production cost of the exoskeleton.

- (3)

- The limiter designed in this paper improves the safety of the exoskeleton system.

- (4)

- This portable exoskeleton system allows patients to perform rehabilitation training in any scenario.

- (5)

- The human-body-conforming structural design ensures the rehabilitation effect for patients of different body types.

- (1)

- The arrangement of steel wires on the arm may lead to unpredictable nonlinear changes, resulting in a significant difference between the actual rehabilitation effect and theoretical analysis.

- (2)

- The lifespan of the soft exoskeleton is relatively short.

7. Conclusions

- (1)

- The flexible wearable robot utilizes elastic fiber fabric as its main structure. The exoskeleton system significantly reduces its overall weight compared to rigid exoskeletons.

- (2)

- Designed for patients with upper limb movement disorders, the robot features three degrees of freedom: elbow flexion/extension, shoulder flexion/extension, and shoulder internal/external rotation.

- (3)

- In both the upper arm and forearm fabric, there are sewn on three alloy rings that serve as fixed anchor points for connecting the driving wires. One ring is sewn onto the middle section of the forearm fabric, while the other two are positioned at the upper and lower edges of the upper arm fabric. The alloy rings at the upper edges of the forearm and upper arm fabric are used to secure the wires driving forearm movements, while the alloy ring at the lower edge of the upper arm fabric is used to secure the wires driving upper arm movements.

- (4)

- The drive unit is mounted on the back and controlled by a motor to stretch the wires, simulating human upper limb movements.

- (5)

- By integrating the trunk–shoulder–upper arm fabric into one unit and keeping the forearm fabric separate, this flexible upper limb rehabilitation robot isolates the rehabilitation movements of each joint. Steel wires connect the drive unit to various components of the robot, transmitting the driving force and enabling rehabilitation movements across the arm joints, resulting in consistent human–robot motion. Rehabilitation exercises can be tailored to individual patients based on their specific needs and joint conditions, leading to effective rehabilitation outcomes.

- (6)

- The special elastic cord tension structure used in both the upper arm and forearm fabric ensures secure and adjustable attachment to different body sizes.

- (7)

- Springs connect the driving wires to the fabric, providing greater flexibility and cushioning for patient rehabilitation.

- (8)

- A layer of silicone material is sewn onto the inner side of the upper arm and lower arm fabric. Using silicone as the inner layer structure increases the friction between the exoskeleton device and the user’s arm. This effectively prevents the occurrence of sliding of the fabric up and down during the driving process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reshetnyak, E.; Ntamatungiro, M.; Pinheiro, L.C.; Howard, V.J.; Carson, A.P.; Martin, K.D.; Safford, M.M. Impact of multiple social determinants of health on incident stroke. Stroke 2020, 51, 2445–2453. [Google Scholar] [CrossRef] [PubMed]

- Yu, C. Orthopedic Rehabilitation; People’s Medical Publishing House: Beijing, China, 2010; pp. 152–187. [Google Scholar]

- Liu, G.; Ji, X. Human Factors Engineering; Peking University Press: Beijing, China, 2012; pp. 101–114. [Google Scholar]

- Schwarz, A.; Bhagubai, M.M.; Wolterink, G.; Held, J.P.; Luft, A.R.; Veltink, P.H. Assessment of upper limb movement impairments after stroke using wearable inertial sensing. Sensors 2020, 20, 4770. [Google Scholar] [CrossRef] [PubMed]

- Borschmann, K.N.; Hayward, K.S. Recovery of upper limb function is greatest early after stroke but does continue to improve during the chronic phase: A two-year, observational study. Physiotherapy 2020, 107, 216–223. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Xu, Z.; Shi, J.; Zhang, F. Development of Upper-Limb Wearable Exoskeleton Robot. In Proceedings of the 2nd International Conference on Artificial Intelligence and Advanced Manufacture, Manchester, UK, 15–17 October 2020; ACM: New York, NY, USA, 2020; pp. 434–439. [Google Scholar]

- Li, N.; Yu, P.; Yang, T.; Zhao, L.; Liu, Z.; Xi, N.; Liu, L. Bio-inspired wearable soft upper-limb exoskeleton robot for stroke survivors. In Proceedings of the 2017 IEEE International Conference on Robotics and Biomimetics (ROBIO), Macau, Macao, 5–8 December 2017; IEEE: New York, NY, USA, 2017; pp. 2693–2698. [Google Scholar]

- Ponomarenko, Y.; Aubakir, B.; Hussain, S.; Shintemirov, A. An end-effector based upper-limb rehabilitation robot: Preliminary mechanism design. In Proceedings of the 2014 10th France-Japan/8th Europe-Asia Congress on Mecatronics (MECATRONICS2014-Tokyo), Tokyo, Japan, 27–29 November 2014; pp. 168–172. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, S.; Hirata, H.; Ishihara, H.; Tamiya, T. Development of a powered variable-stiffness exoskeleton device for elbow rehabilitation. Biomed. Microdevices 2018, 20, 64. [Google Scholar] [CrossRef] [PubMed]

- Velez-Guerrero, M.A.; Callejas-Cuervo, M.; Mazzoleni, S. Design, development, and testing of an intelligent wearable robotic exoskeleton prototype for upper limb rehabilitation. Sensors 2021, 21, 5411. [Google Scholar] [CrossRef] [PubMed]

- Grasgruber, P.; Hrazdíra, E. Nutritional and socio-economic predictors of adult height in 152 world populations. Econ. Hum. Biol. 2020, 37, 100848. [Google Scholar] [CrossRef] [PubMed]

- Cao, K. Design and Performance Testing of a Flexible Wearable Upper Limb Power Suit. Master’s Thesis, Yanshan University, Qinhuangdao, China, 2019. [Google Scholar] [CrossRef]

- Sun, X. Research on a Soft Wearable Exoskeleton System for Upper Limb Rehabilitation. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2019. [Google Scholar] [CrossRef]

- Nef, T.; Guidali, M.; Klamroth-Marganska, V.; Riener, R. ARMin-exoskeleton robot for stroke rehabilitation. In Proceedings of the World Congress on Medical Physics and Biomedical Engineering, Munich, Germany, 7–12 September 2009; Volume 25/9 Neuroengineering, Neural Systems, Rehabilitation and Prosthetics. Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Balasubramanian, S.; Wei, R.; Perez, M.; Shepard, B.; Koeneman, E.; Koeneman, J.; He, J. RUPERT: An exoskeleton robot for assisting rehabilitation of arm functions. In Proceedings of the 2008 Virtual Rehabilitation, Vancouver, BC, Canada, 25–27 August 2008; IEEE: New York, NY, USA, 2008. [Google Scholar]

- Kim, H.; Rosen, J. Predicting redundancy of a 7 dof upper limb exoskeleton toward improved transparency between human and robot. J. Intell. Robot. Syst. 2015, 80, 99–119. [Google Scholar] [CrossRef]

- Wen, C.; Fan, C.; An, L.; Chen, H.; Wang, Y.; Tang, J. Real-time quantitative ultrasound elastography for detecting differences in the elastic modulus of the biceps brachii muscle under relaxed and tense states. Chin. J. Med. Ultrasound (Electron. Ed.) 2011, 8, 129–134. [Google Scholar]

- Gull, M.A.; Bak, T.; Bai, S. Dynamic modeling of an upper limb hybrid exoskeleton for simulations of load-lifting assistance. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 2147–2160. [Google Scholar] [CrossRef]

- Mekruksavanich, S.; Jitpattanakul, A. Exercise Activity Recognition with Surface Electromyography Sensor using Machine Learning Approach. In Proceedings of the 2020 Joint International Conference on Digital Arts, Media and Technology with ECTI Northern Section Conference on Electrical, Electronics, Computer and Telecommunications Engineering (ECTI DAMT & NCON), Pattaya, Thailand, 11–14 March 2020; pp. 75–78. [Google Scholar] [CrossRef]

- Jin, X.; Ding, W.; Li, Q.; Yang, W.; Wei, Y. Mechanical Design and Analysis of a Cable-Driven Wearable Flexible Exoskeleton System. In Proceedings of the 2024 2nd International Conference on Precision Engineering and Mechanical Manufacturing (PEMM 2024), Inha University, Incheon, Republic of Korea, 7–9 August 2024. [Google Scholar]

| Joint | Action | Maximum Range of Motion (°) | Functional Range (°) |

|---|---|---|---|

| shoulder joint | external/internal rotation | 0~90 | 0~80 |

| elbow joint | flexion/extension | 0~150 | 0~120 |

| Parameter Estimation | Standard Parameter | |

|---|---|---|

| Upper arm length (mm) | 336 | ---- |

| Upper arm circumference (mm) | 58/40 | ---- |

| Upper arm quality (kg) | 2.68 | 1.89 |

| Forearm length (mm) | 260 | ---- |

| Forearm circumference (mm) | 45/27 | ---- |

| Forearm quality (kg) | 1.35 | 1.12 |

| Palm quality (kg) | 0.5 | 0.4 |

| Palm center | 50 | 50 |

| Upper Arm | Forearm | ||

|---|---|---|---|

| Parameter | Value | Parameter | Value |

| L1 | 28 cm | L4 | 18 cm |

| h1 | 20 cm | h3 | 20 cm |

| d1 | 1 cm | d3 | 1 cm |

| L2 | 26 cm | L5 | 16 cm |

| h2 | 2 cm | h4 | 2 cm |

| d2 | 0.5 cm | d4 | 0.5 cm |

| b | 20 cm | L6 | 3 cm |

| L3 | 10 cm | k2 | 4 |

| k1 | 5.2 | a | 12 cm |

| R1 | 0.25 cm | R2 | 0.25 |

| x1 | 4.75 cm | x3 | 4.75 cm |

| x2 | 0.5 cm | x4 | 0.5 cm |

| Lightweight | Driving Mechanism | |

|---|---|---|

| The exoskeleton designed in this paper | 2.5–3 kg | motor drive |

| ARMin IV | 14 kg | motor drive |

| RUPERT | 10 kg | pneumatic muscle drive |

| UL-EXO7 | 12 kg | motor drive |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, X.; Ding, W.; Baumert, M.; Wei, Y.; Li, Q.; Yang, W.; Yan, Y. Mechanical Design, Analysis, and Dynamics Simulation of a Cable-Driven Wearable Flexible Exoskeleton System. Technologies 2024, 12, 238. https://doi.org/10.3390/technologies12120238

Jin X, Ding W, Baumert M, Wei Y, Li Q, Yang W, Yan Y. Mechanical Design, Analysis, and Dynamics Simulation of a Cable-Driven Wearable Flexible Exoskeleton System. Technologies. 2024; 12(12):238. https://doi.org/10.3390/technologies12120238

Chicago/Turabian StyleJin, Xuetong, Wenqian Ding, Mathias Baumert, Yan Wei, Qinglin Li, Wei Yang, and Yuqiao Yan. 2024. "Mechanical Design, Analysis, and Dynamics Simulation of a Cable-Driven Wearable Flexible Exoskeleton System" Technologies 12, no. 12: 238. https://doi.org/10.3390/technologies12120238

APA StyleJin, X., Ding, W., Baumert, M., Wei, Y., Li, Q., Yang, W., & Yan, Y. (2024). Mechanical Design, Analysis, and Dynamics Simulation of a Cable-Driven Wearable Flexible Exoskeleton System. Technologies, 12(12), 238. https://doi.org/10.3390/technologies12120238