Climate Impact Mitigation Potential of Novel Aircraft Features

Abstract

:1. Introduction

2. Novel Design Features

2.1. Open-Rotor Engines

2.2. Synthetic Aviation Fuels

2.3. Natural Laminar Flow Airfoils

2.4. Riblets

3. Methodology

3.1. Preliminary Sizing Process

3.2. Direct Operating Cost Evaluation

3.3. Open-Rotor Engine Model

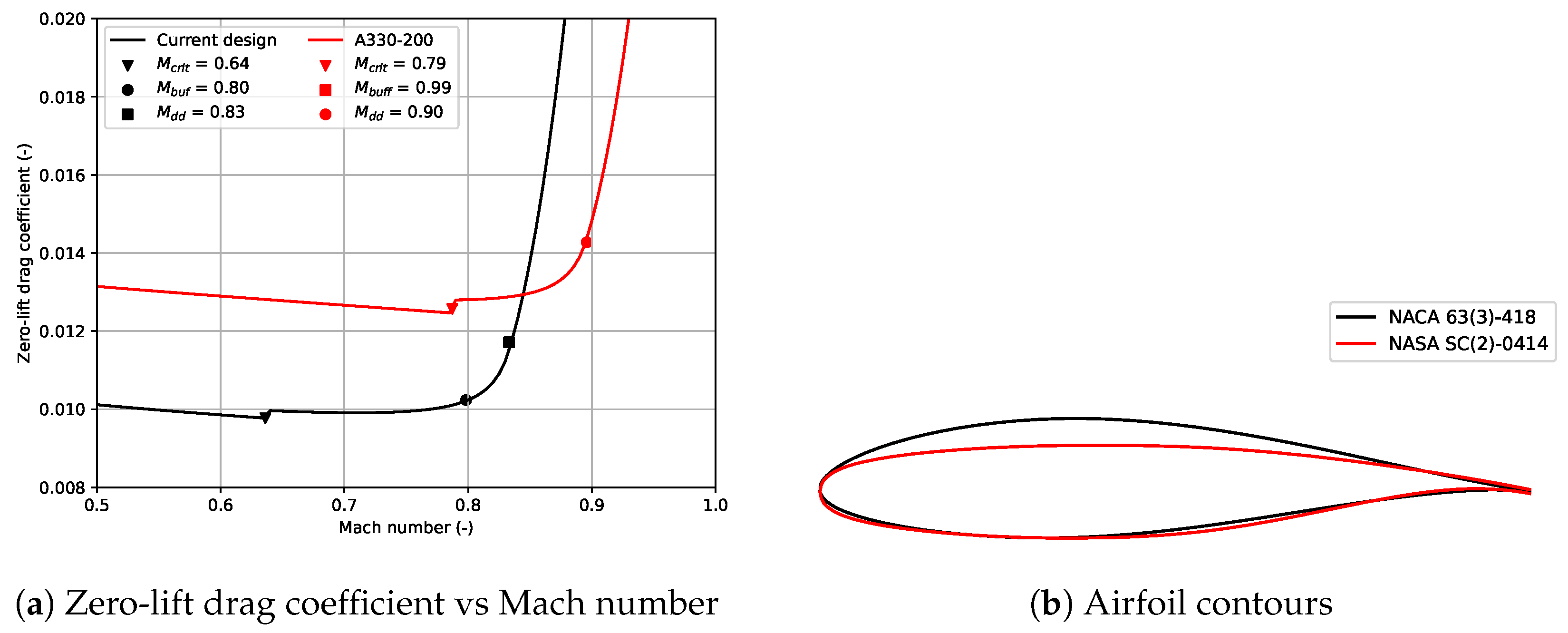

3.4. Aerodynamic Model

3.4.1. Modifications for Riblets

3.4.2. Modifications for Open-Rotor Engines

3.4.3. Modifications for NLF Airfoils

3.5. Aircraft Climate Impact Evaluation

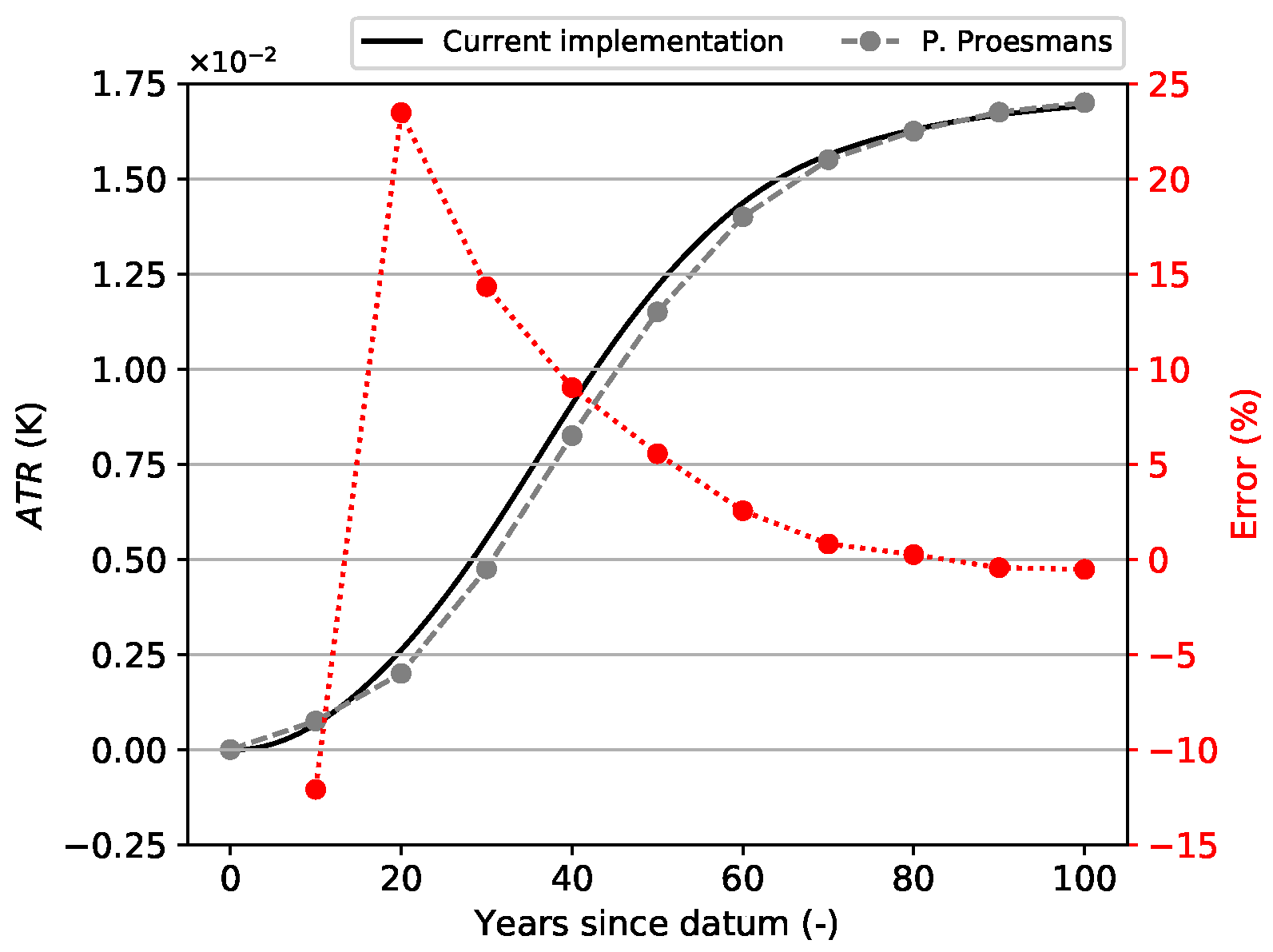

3.5.1. Evaluation for a Specific Design

3.5.2. Limitations of the Climate Impact Model

4. Results and Discussion

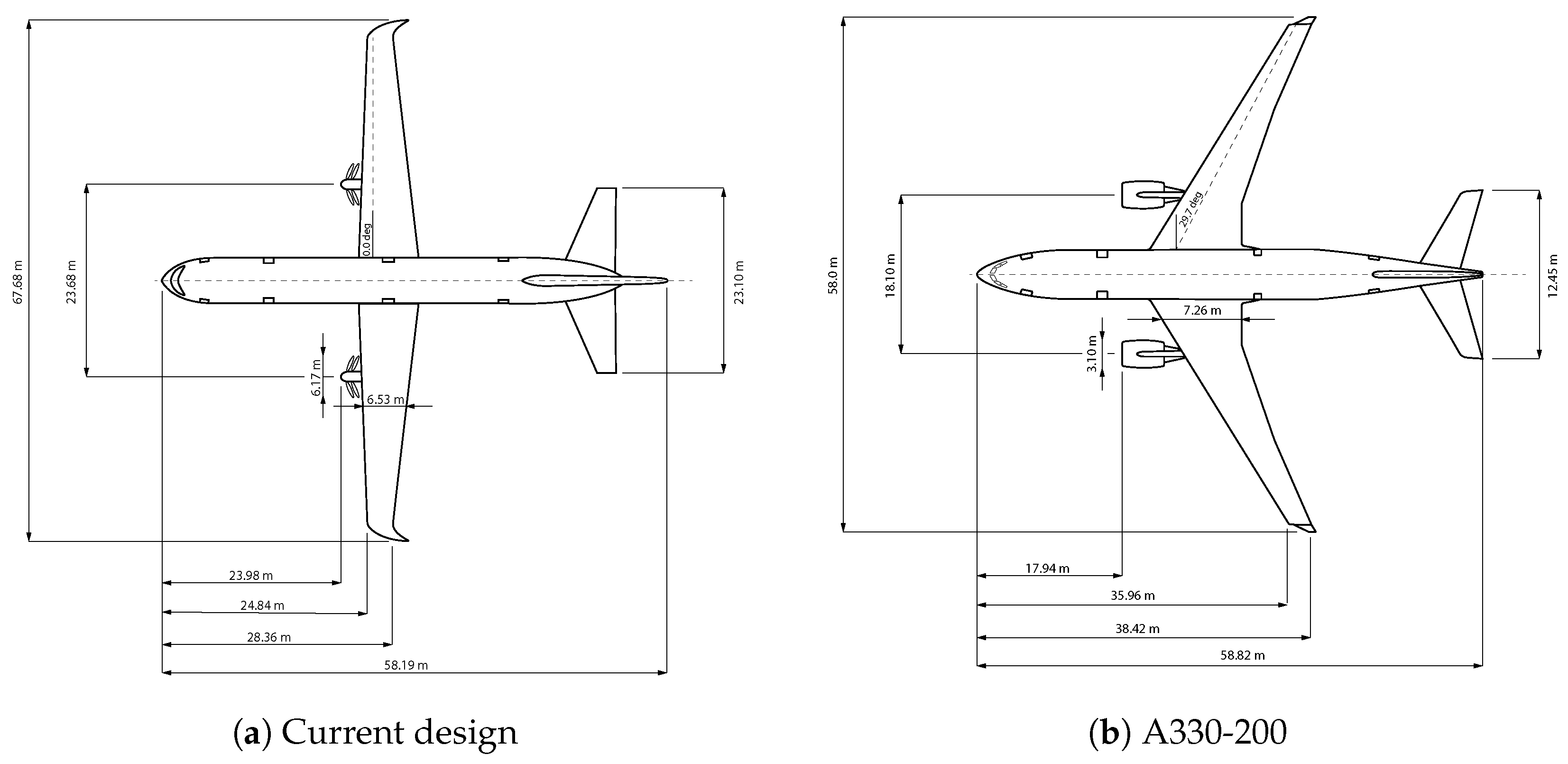

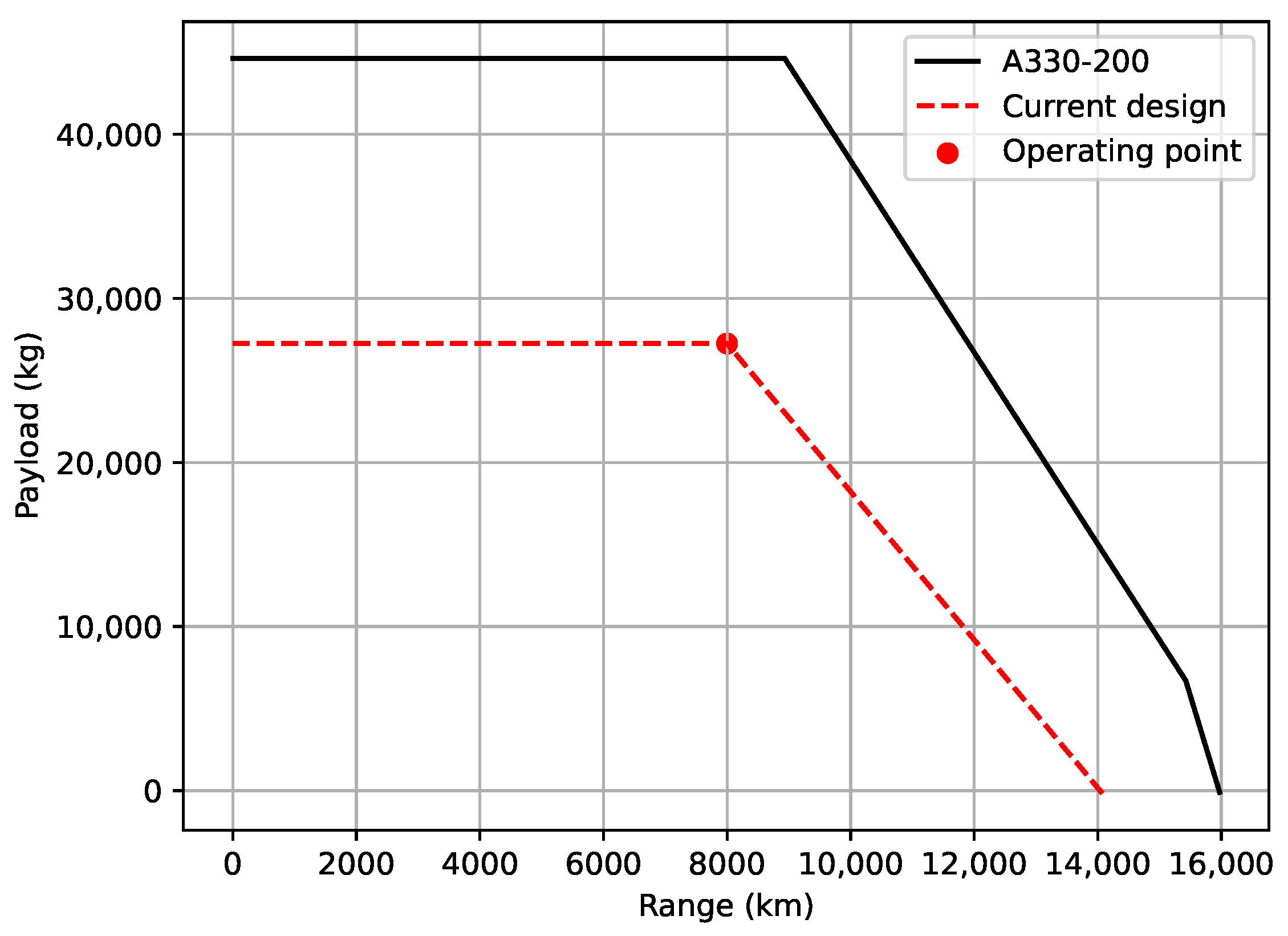

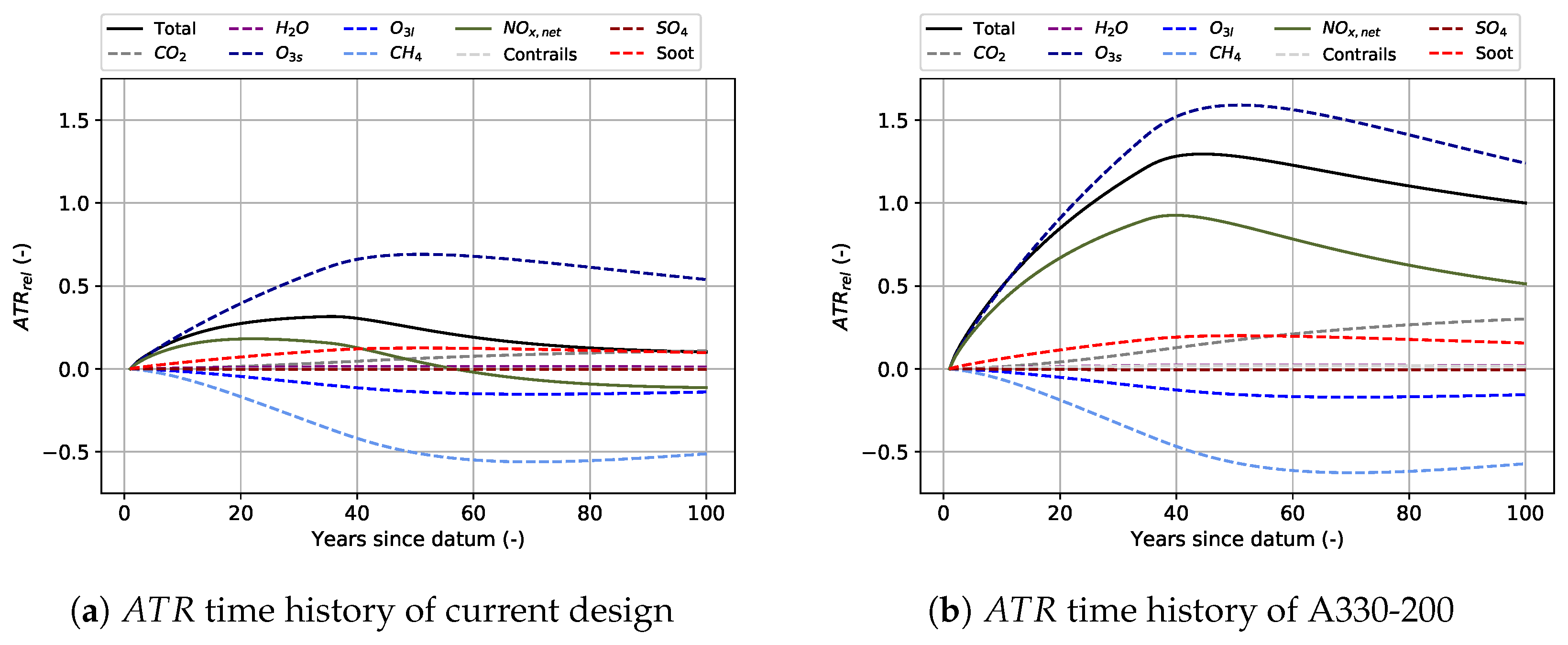

4.1. Comparison of Aircraft Configurations

4.2. Comparison of Mission Profiles

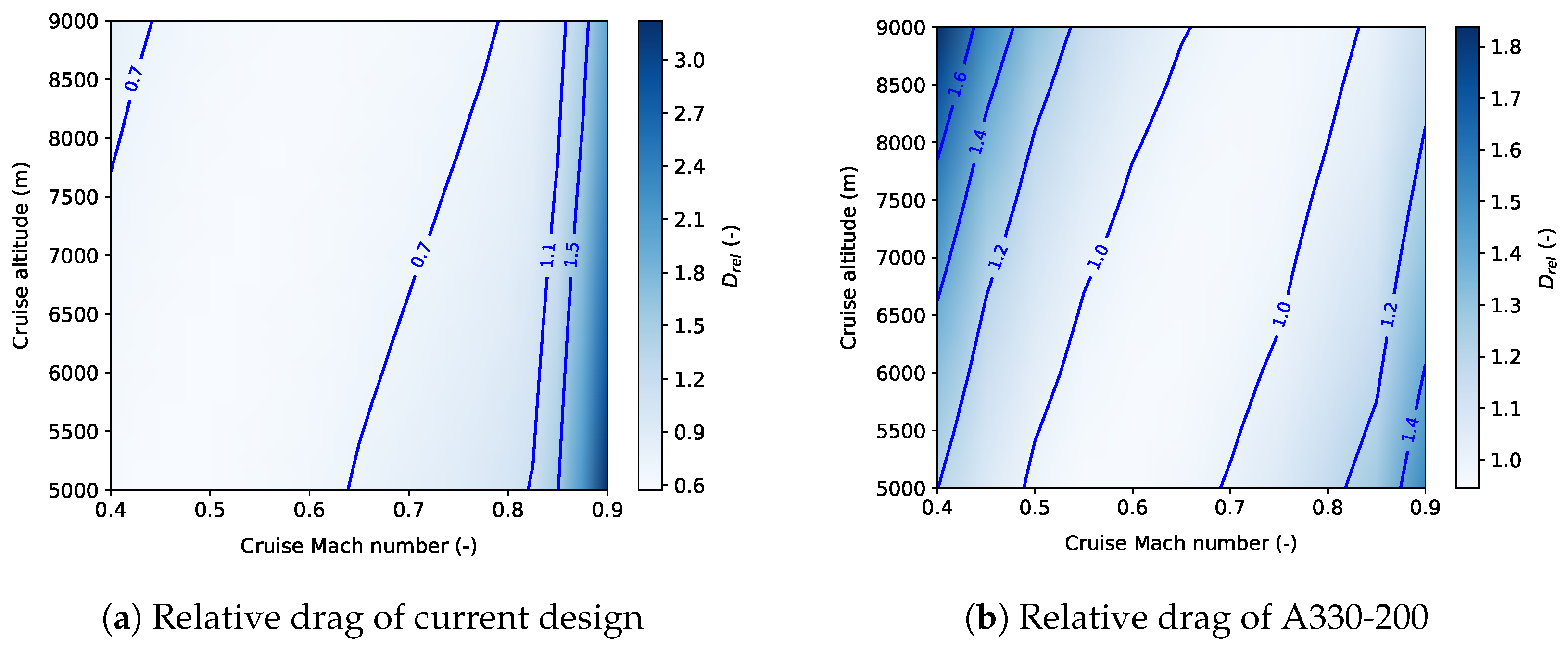

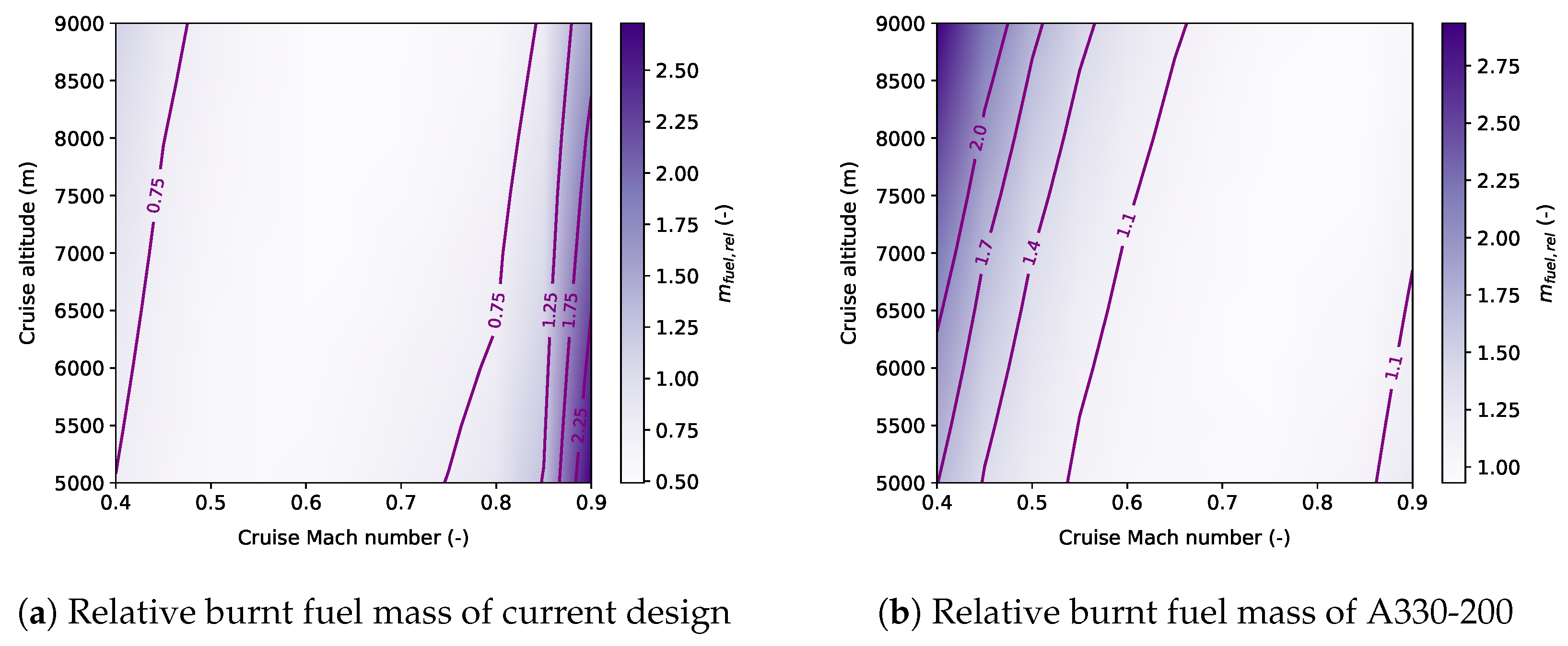

4.3. Comparison of Spectra

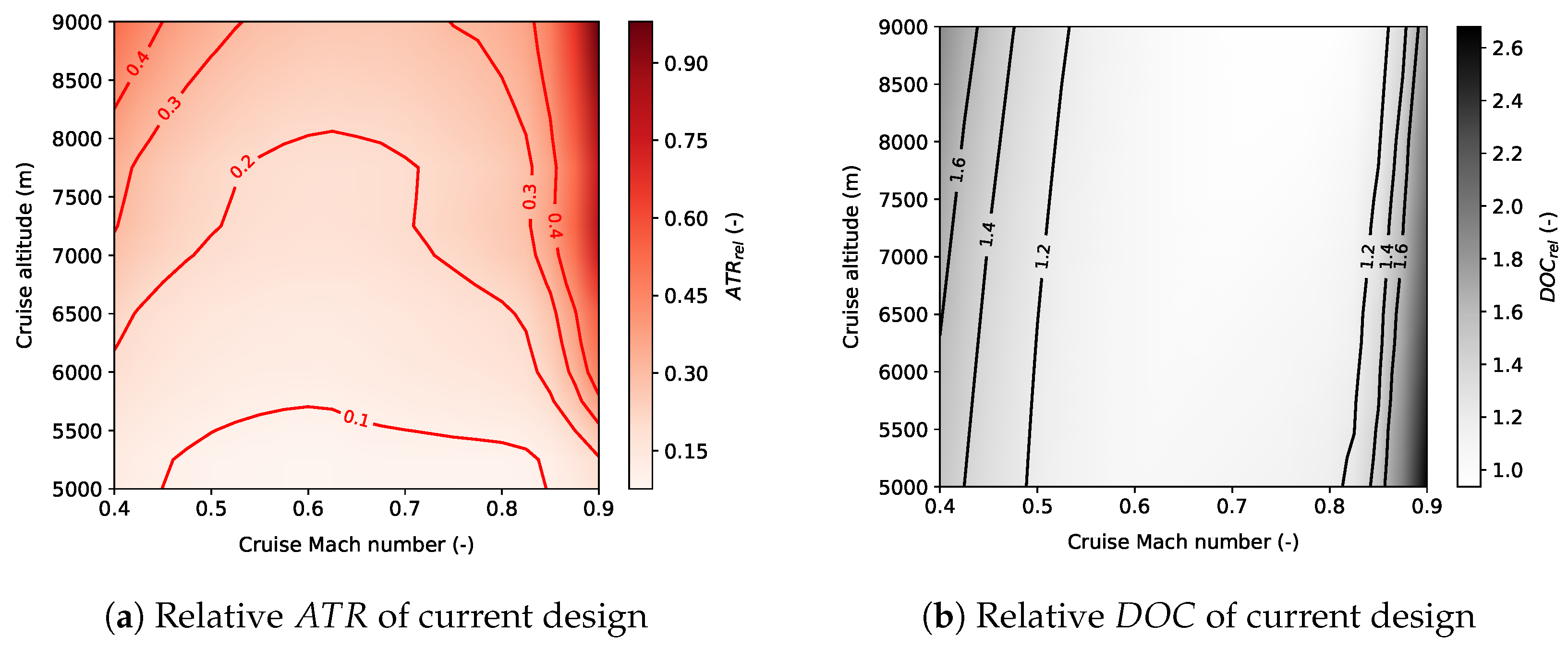

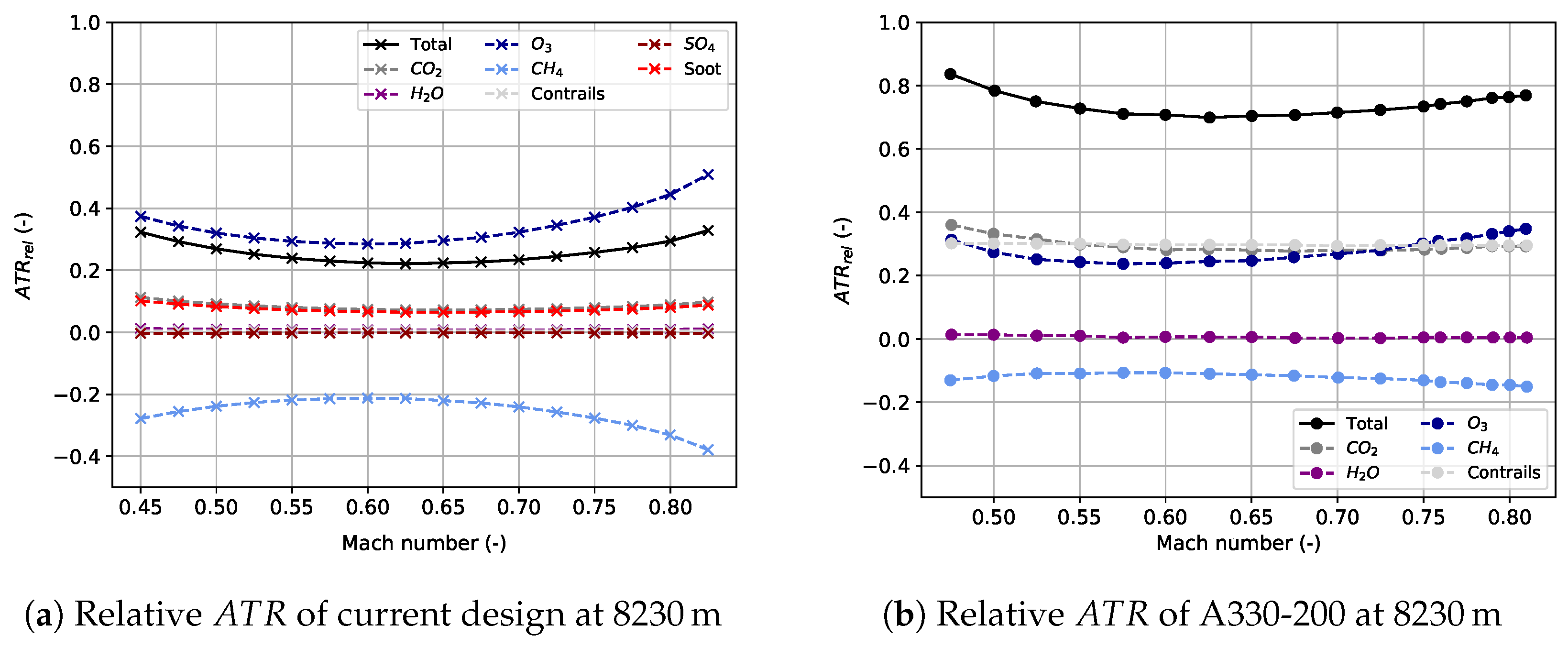

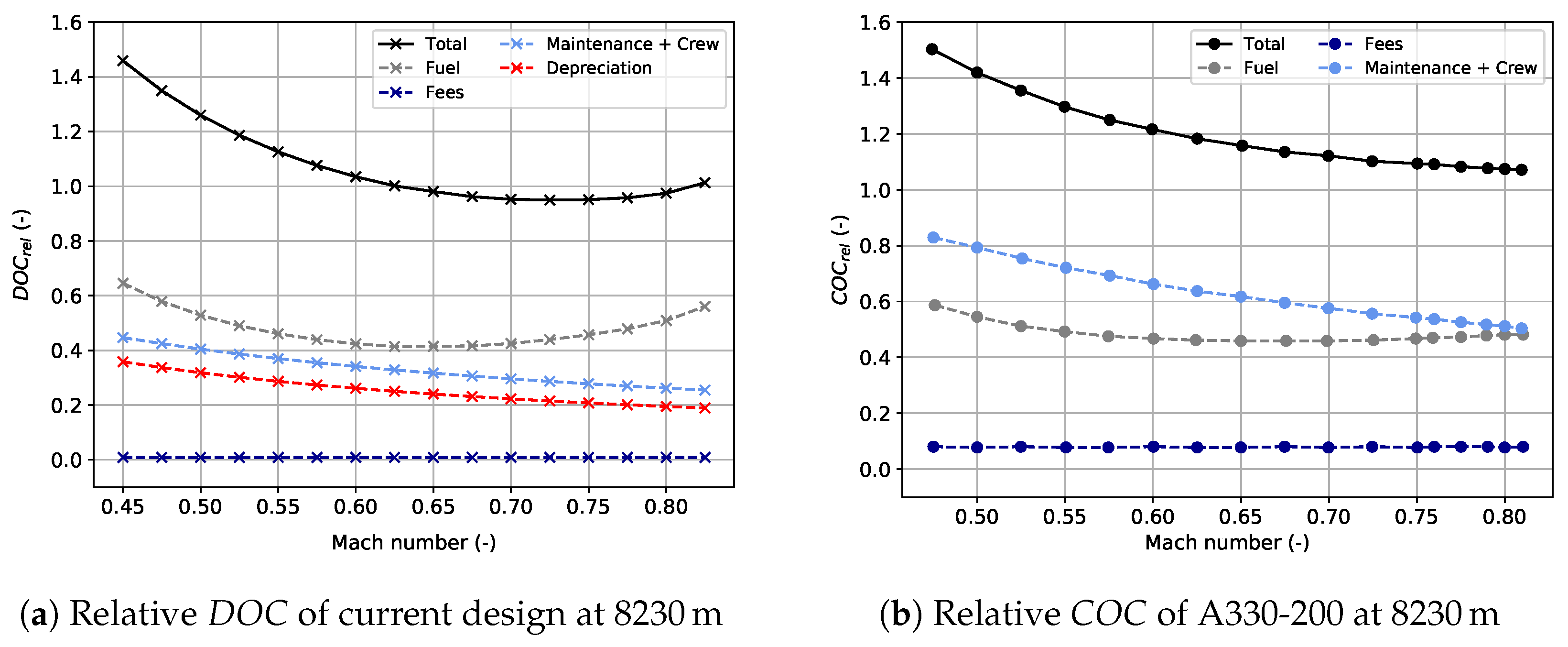

4.4. Performance Sensitivity to Mission Parameters

4.5. Life-Cycle Climate Impact

4.6. Performance Breakdown per Novel Design Feature

4.7. Implications of Revised Operating Conditions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Friction coefficient | |

| Drag, drag coefficient | |

| f | Laminar-to-turbulent fraction |

| h | Altitude |

| Lift, lift coefficient | |

| M | Mach number |

| Mass, mass flow | |

| P | Power |

| Pressure, pressure coefficient | |

| Reynolds number | |

| S | Surface area |

| T | Temperature, thrust |

| t | Time |

| V | Velocity |

| Ratio of specific heats | |

| Efficiency |

Appendix A

- 1.

- The aircraft shall have a maximum operating range of 8000

- 2.

- The maximum flight time for the distance in 1. shall not exceed 16 h

- 3.

- The aircraft shall accommodate 250 passengers

- 4.

- The aircraft shall operate from runways of 2500 in length

- 5.

- The aircraft shall operate in crosswinds of 25 kts

- 6.

- The aircraft shall operate in all weather conditions, including at least CAT II landings, with diversion capabilities

- 7.

- In addition to standard CS-25 certification requirements, the safety and reliability of the passive flow control devices shall be assessed

- 8.

- The aircraft shall make use of laminar flow control to delay laminar-to-turbulent transition

- 9.

- The aircraft shall employ riblets to reduce turbulent skin-friction drag

- 10.

- The aircraft shall utilise appropriate materials in manufacturing

- 11.

- The aircraft design shall include an end-of-life plan for all system components

- 12.

- The aircraft shall minimise with no more than a 15% increase in relative to an A330-200

References

- Hyde, D.; Barker, B.; Hodgson, P.; Miller, R.; Rapeanu, M. Target True Zero-Unlocking Sustainable Battery and Hydrogen-Powered Flight; Insight Report; World Economic Forum: Geneva, Switzerland, 2022. [Google Scholar]

- Koch, A. Climate Impact Mitigation Potential given by Flight Profile and Aircraft Optimization. Ph.D. Thesis, Technische Universität Hamburg-Harburg, Hamburg, Germany, 2013. [Google Scholar]

- Proesmans, P.; Vos, R. Airplane Design Optimization for Minimal Global Warming Impact. In Proceedings of the 2021 AIAA Scitech 2021 Forum, Virtual, 11–21 January 2021; pp. 1–25. [Google Scholar]

- Dallara, E.S.; Kroo, I.; Waitz, I. Metric for Comparing Lifetime Average Climate Impact of Aircraft. AIAA J. 2011, 49, 1600–1613. [Google Scholar] [CrossRef]

- Franz, K.; Risse, K.; Stumpf, E. Framework for Sustainability-Driven Aircraft Design. In Proceedings of the 2013 Aviation Technology, Integration, and Operations Conference, Los Angeles, CA, USA, 12–14 August 2013; pp. 1–20. [Google Scholar]

- Proesmans, P.J.; Vos, R. Comparison of Future Aviation Fuels to Minimize the Climate Impact of Commercial Aircraft. In Proceedings of the AIAA AVIATION 2022 Forum, Chicago, IL, USA, 27 June–1 July 2022; pp. 1–25. [Google Scholar]

- Marks, T.; Dahlmann, K.; Grewe, V.; Gollnick, V.; Linke, F.; Matthes, S.; Stumpf, E.; Swaid, M.; Unterstrasser, S.; Yamashita, H.; et al. Climate Impact Mitigation Potential of Formation Flight. Aerospace 2021, 8, 14. [Google Scholar] [CrossRef]

- Hendricks, E.; Tong, M. Performance and Weight Estimates for an Advanced Open Rotor Engine. In Proceedings of the 48th Joint Propulsion Conference and Exhibit, Atlanta, GA, USA, 30 July–1 August 2012; pp. 1–12. [Google Scholar]

- Gamah, I.; Self, R. Advanced Open Rotors-Balancing Noise Costs Against Reduced Carbon Emissions for Future Aircraft; Omega Project 36—Final Report; University of Southampton: Southampton, UK, 2009. [Google Scholar]

- Hall, C.; Zachariadis, A.; Brandvik, T.; Sohoni, N. How to Improve Open Rotor Aerodynamics at Cruise and Take-off. Aeronaut. J. 2014, 118, 1103–1123. [Google Scholar] [CrossRef] [Green Version]

- Rolls-Royce Ultrafan. Available online: https://www.rolls-royce.com/media/our-stories/innovation/2016/advance-and-ultrafan.aspx (accessed on 5 February 2022).

- CFM Aero Engines. Available online: https://www.cfmaeroengines.com/sustainability/ (accessed on 5 February 2022).

- Cabrera, E.; de Sousa, J.M.M. Use of Sustainable Fuels in Aviation—A Review. Energies 2022, 15, 2440. [Google Scholar] [CrossRef]

- Braun-Unkhoff, M.; Riedel, U.; Wahl, C. About the Emissions of Alternative Jet Fuels. CEAS Aeronaut. J. 2016, 8, 167–180. [Google Scholar] [CrossRef] [Green Version]

- Blakey, S.; Rye, L.; Wilson, C. Aviation Gas Turbine Alternative Fuels: A Review. Proc. Combust. Inst. 2011, 33, 2863–2885. [Google Scholar] [CrossRef]

- Hileman, J.; Ortiz, D.S.; Bartis, J.T.; Wong, H.M.; Donohoo, P.E.; Weiss, M.A.; Waitz, I.A. Near-Term Feasibility of Alternative Jet Fuels; Technical Report; RAND Corporation: Santa Monica, CA, USA, 2009. [Google Scholar]

- Zschocke, A.; Scheuermann, S. High Biofuel Blends in Aviation (HBBA); Technical Report; Deutsche Lufthansa AG: Cologne, Germany, 2012. [Google Scholar]

- Novelli, P. Sustainable Way for Alternative Fuels and Energy in Aviation; Technical Report; ONERA-Fundamental and Applied Energetic Department: Palaiseau, France, 2012. [Google Scholar]

- Zang, G.; Sun, P.; Yoo, E.; Elgowainy, A.; Lee, A.B.U.; Wang, M.; Supekar, S. Synthetic Methanol/Fischer-Tropsch Fuel Production Capacity, Cost, and Carbon Intensity Utilizing CO2 from Industrial and Power Plants in the United States. Environ. Sci. Technol. 2021, 55, 7595–7604. [Google Scholar] [CrossRef] [PubMed]

- Dallara, E.S. Aircraft Design for Reduced Climate Impact. Ph.D. Thesis, Stanford University, Stanford, CA, USA, 2011. [Google Scholar]

- Wicke, K.; Kruse, M.; Linke, F.; Gollnick, V. Impact of Insect Contamination on Operational and Economic Effectiveness of Aircraft with Natural Laminar Flow Technology. In Proceedings of the 29th Congress of the International Council of the Aeronautical Sciences (ICAS), St. Petersburg, Russia, 7–12 September 2014; pp. 1–17. [Google Scholar]

- Spalart, P.; McLean, J. Drag Reduction: Enticing Turbulence, and then an Industry. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2011, 369, 1556–1569. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Quinn, M.; McGrath, D.; Bell, D.C.; Bilinsky, H.C.; Builth-Williams, J.; Feichtinger, C.; Leitl, P.A.; Flanschger, A.; Shahjahan, S. Advancements in Drag-Reducing Riblet Film Production for Aviation and Other Applications. In Proceedings of the AIAA SCITECH 2022 Forum, San Diego, CA, USA, 3–7 January 2021; pp. 1–10. [Google Scholar]

- Leitl, P.A.; Feichtinger, C.; Bilinsky, H.C.; Flanschger, A.; Quinn, M.; de Vinaspre, I.O.; Forster, B. Riblet design, manufacturing, and measurements—A new rapid iteration process. In Proceedings of the AIAA Scitech 2021 Forum, Virtual, 11–15 & 19–21 January 2021; pp. 1–11. [Google Scholar]

- Bilinsky, H.C. Microfabrication of Riblets for Drag Reduction. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017; pp. 1–11. [Google Scholar]

- Lufthansa Technik. Available online: https://www.lufthansa-technik.com/aeroshark (accessed on 30 January 2022).

- Roskam, J. Airplane Design Part I: Preliminary Sizing of Airplanes; DARcorporation: Lawrence, KS, USA, 2002; pp. 1–85. [Google Scholar]

- Torenbeek, E. Synthesis of Subsonic Aircraft Design; Kluwer Academic Publishers: Delft, The Netherlands, 1982; pp. 50–53. [Google Scholar]

- Roskam, J. Airplane Design: Part VIII: Airplane Cost Estimation: Design, Development, Manufacturing and Operating; DARcorporation: Lawrence, KS, USA, 1990. [Google Scholar]

- Pearce, B. State of the Airline Industry. Available online: https://www.iata.org/en/iata-repository/publications/economic-reports/state-of-the-airline-industry/ (accessed on 18 June 2021).

- Hemmings, B.; Eckhard, P.; Forsyth, P.; Strand, J.; Mundaca, G.; Kageson, P. Taxing Aviation Fuel in Europe. Back to the Future? Technical Report; European Federation for Transport and Environment: Brussels, Belgium, 2020. [Google Scholar]

- Brons, M.; Pels, E.; Nijkamp, P.; Rietveld, P. Price Elasticities of Demand for Passenger Air Travel: A Meta-Analysis. J. Air Transp. Manag. 2002, 8, 165–175. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Lukachko, S.; Waitz, I.; Schafer, A. Historical and Future Trends in Aircraft Performance, Cost and Emissions. Annu. Rev. Energy Environ. 2001, 26, 167–200. [Google Scholar] [CrossRef] [Green Version]

- Saravanamuttoo, H.; Rogers, G.; Cohen, H. Gas Turbine Theory, 5th ed.; Pearson: London, UK, 2001. [Google Scholar]

- Durand, W. Aerodynamic Theory, 2nd ed.; Julius Springer: Berlin, Germany, 1935. [Google Scholar]

- Raymer, D. Aircraft Design: A Conceptual Approach, 6th ed.; American Institute of Aeronautics and Astronautics, Inc.: Reston, VA, USA, 2018. [Google Scholar]

- Modesti, D.; Endrikat, S.; Hutchins, N.; Chung, D. Dispersive Stresses in Turbulent Flow over Riblets. J. Fluid Mech. 2021, 917, 1–36. [Google Scholar] [CrossRef]

- Dorsey, A.; Uranga, A. Design Space Exploration of Future Open Rotor Configurations. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Virtual, 24–28 August 2020; pp. 1–30. [Google Scholar]

- Bowers, A. Laminar Flow and the Holy Grail (blog). 11 February 2011. Available online: https://blogs.nasa.gov/Dryden/2011/02/11/post_1296777084480/ (accessed on 8 June 2021).

- Solomon, S.; Qin, D.; Manning, M.; Chen, Z.; Marquis, M.; Averyt, K.B.; Tignor, M.; Miller, H.L. (Eds.) Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2007. [Google Scholar]

- Sausen, R.; Schumann, U. Estimates of the Climate Response to Aircraft CO2 and NOx Emissions Scenarios. Clim. Chang. 1998, 44, 27–58. [Google Scholar] [CrossRef] [Green Version]

- Lee, D.S.; Pitari, G.; Grewe, V.; Gierens, K.; Penner, J.E.; Petzold, A.; Prather, M.J.; Schumann, U.; Bais, A.; Berntsen, T.; et al. Transport Impacts on Atmosphere and Climate: Aviation. Atmos. Environ. 2010, 44, 4678–4734. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vos, R.; Farokhi, S. Introduction to Transonic Aerodynamics; Springer: Dordrecht, The Netherlands, 2015; Volume 110. [Google Scholar]

- Mason, W. Configuration Aerodynamics: Transonic Aerodynamics of Airfoils and Wings; Virginia Tech: Blacksburg, VA, USA, 2006; pp. 12–13. [Google Scholar]

- Airbus A330-200. Available online: https://aircraft.airbus.com/en/aircraft/a330/a330-200 (accessed on 28 July 2022).

- Airbus A330 Aircraft Characteristics—Airport and Maintenance Planning Manual. Available online: https://www.airbus.com/sites/g/files/jlcbta136/files/2021-11/Airbus-Commercial-Aircraft-AC-A330.pdf (accessed on 28 July 2022).

- EASA Type-Certificate Data Sheet for CF6-80E1 Series Engines. Available online: https://www.easa.europa.eu/downloads/7789/en (accessed on 24 January 2022).

- Lukaczyk, T.W.; Wendorff, A.D.; Colonno, M.; Economon, T.D.; Alonso, J.J.; Orra, T.H.; Ilario, C. SUAVE: An Open-Source Environment for Multi-Fidelity Conceptual Vehicle Design. In Proceedings of the 16th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Dallas, TX, USA, 22–26 June 2015; pp. 1–56. [Google Scholar]

- Köhler, M.O.; Rädel, G.; Dessens, O.; Shine, K.P.; Rogers, H.L.; Wild, O.; Pyle, J.A. Impact of Perturbations to Nitrogen Oxide Emissions from Global Aviation. J. Geophys. Res. 2008, 113, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Ashby, M.; Shercliff, H.; Cebon, D. Materials: Engineering, Science, Processing and Designs, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar]

- IATA, 20 Year Passenger Forecast. Available online: https://www.iata.org/en/publications/store/20-year-passenger-forecast/ (accessed on 4 February 2022).

- Met Office, What Is the Jet Stream. Available online: https://www.metoffice.gov.uk/weather/learn-about/weather/types-of-weather/wind/what-is-the-jet-stream (accessed on 4 February 2022).

- Smith, W.L., Jr.; Minnis, P.; Fleeger, C.; Spangenberg, D.; Palikonda, R.; Nguyen, L. Determining the Flight Icing Threat to Aircraft with Single-Layer Cloud Parameters Derived from Operational Satellite Data. J. Appl. Meteorol. Climatol. 2020, 51, 1794–1810. [Google Scholar] [CrossRef]

| Aircraft | (N) | (N) | (-) | (-) | (deg) |

|---|---|---|---|---|---|

| Current design | 250 | 11 | 0 | ||

| A330-200 | 253 | 9.26 | 29.7 |

| Engine | (-) | (-) | (N) | (m) | (m) | (kg) |

|---|---|---|---|---|---|---|

| Open rotor | 30 | 30 | 5.3 | 3.79 | 5334 | |

| CF6-80E1 | 5.3 | 32.6 | 2.9 | 4.17 | 5091.62 |

| Parameter | (hours) | (-) | (m) | (kg) | () | (%) |

|---|---|---|---|---|---|---|

| Current design | 11.41 | 0.61 | 4667 | 37,403 | 11.85 | 39.2 |

| A330-200 | 9.73 | 0.77 | 9946 | 59,117 | 17.27 | 32.3 |

| Relative change | +17.3% | −20.8% | −53.1% | −36.7% | −31.4% | +21.4% |

| Life-Cycle Phase | Current Design | A330-200 | Relative Gain (%) |

|---|---|---|---|

| Manufacturing (%) | 0.32 | 0.18 | −35.24 |

| Operations (%) | 99.69 | 99.85 | −63.90 |

| End-of-life (%) | −0.01 | −0.03 | −85.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barner, N.M.; Ghafourpour, L.; Güverte, M.S.; Modesti, D.; Hulshoff, S.J. Climate Impact Mitigation Potential of Novel Aircraft Features. Aerospace 2022, 9, 436. https://doi.org/10.3390/aerospace9080436

Barner NM, Ghafourpour L, Güverte MS, Modesti D, Hulshoff SJ. Climate Impact Mitigation Potential of Novel Aircraft Features. Aerospace. 2022; 9(8):436. https://doi.org/10.3390/aerospace9080436

Chicago/Turabian StyleBarner, Nils M., Luca Ghafourpour, Mustafa S. Güverte, Davide Modesti, and Steven J. Hulshoff. 2022. "Climate Impact Mitigation Potential of Novel Aircraft Features" Aerospace 9, no. 8: 436. https://doi.org/10.3390/aerospace9080436

APA StyleBarner, N. M., Ghafourpour, L., Güverte, M. S., Modesti, D., & Hulshoff, S. J. (2022). Climate Impact Mitigation Potential of Novel Aircraft Features. Aerospace, 9(8), 436. https://doi.org/10.3390/aerospace9080436