Parameter Sensitivity Study on Inflow Distortion of Boundary Layer Ingested Turbofans

Abstract

:1. Introduction

2. Methodology

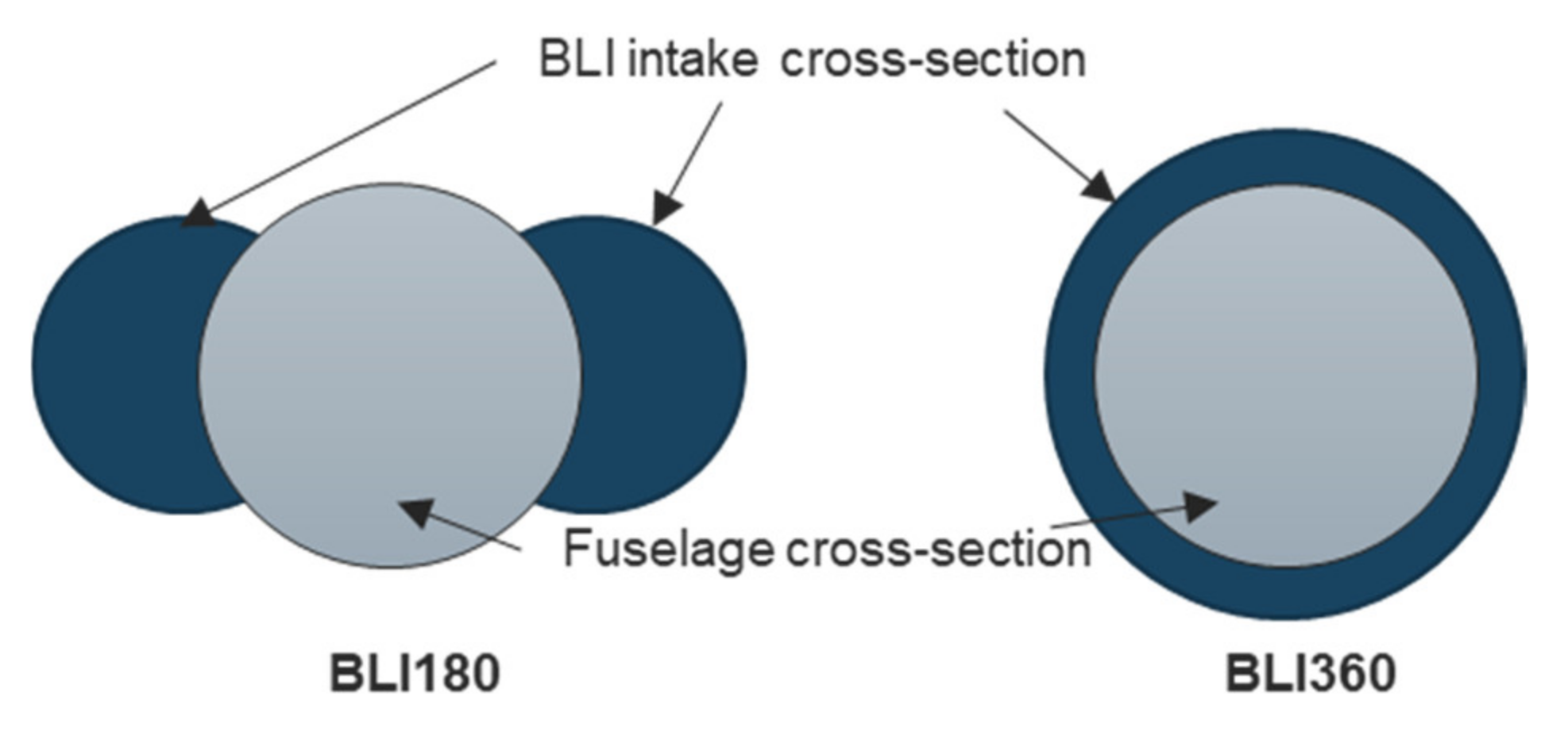

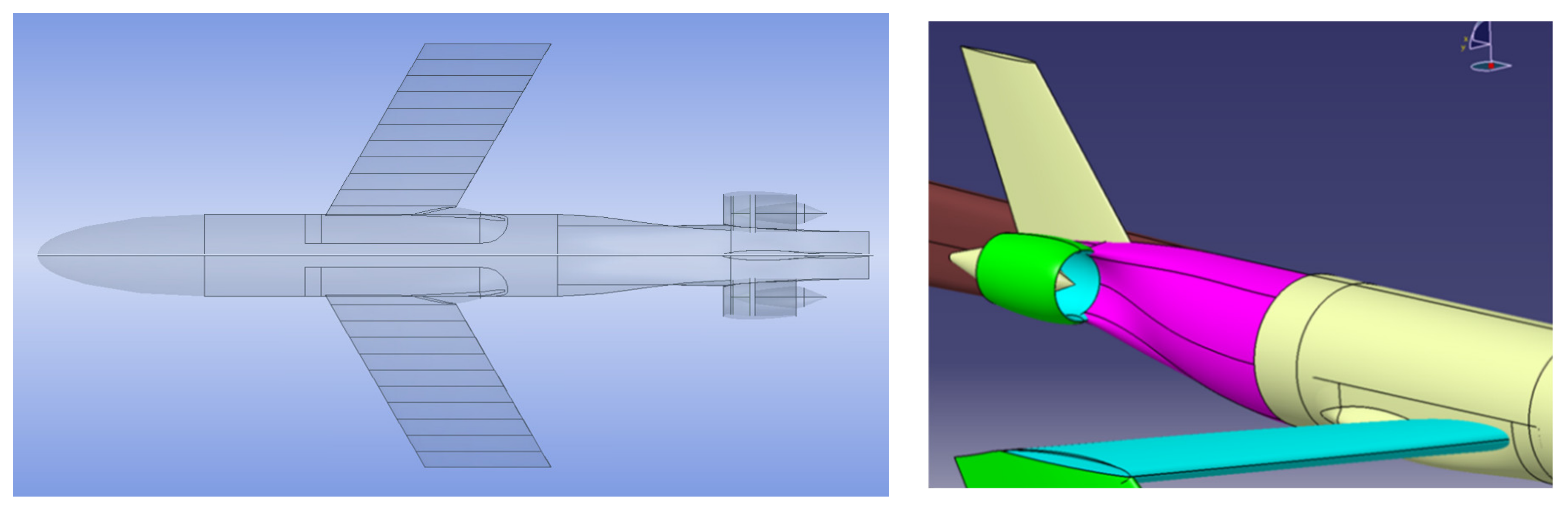

2.1. Aircraft Geomoetry

2.2. Selection of Design Parameters

2.3. Numerical Simulations Setup

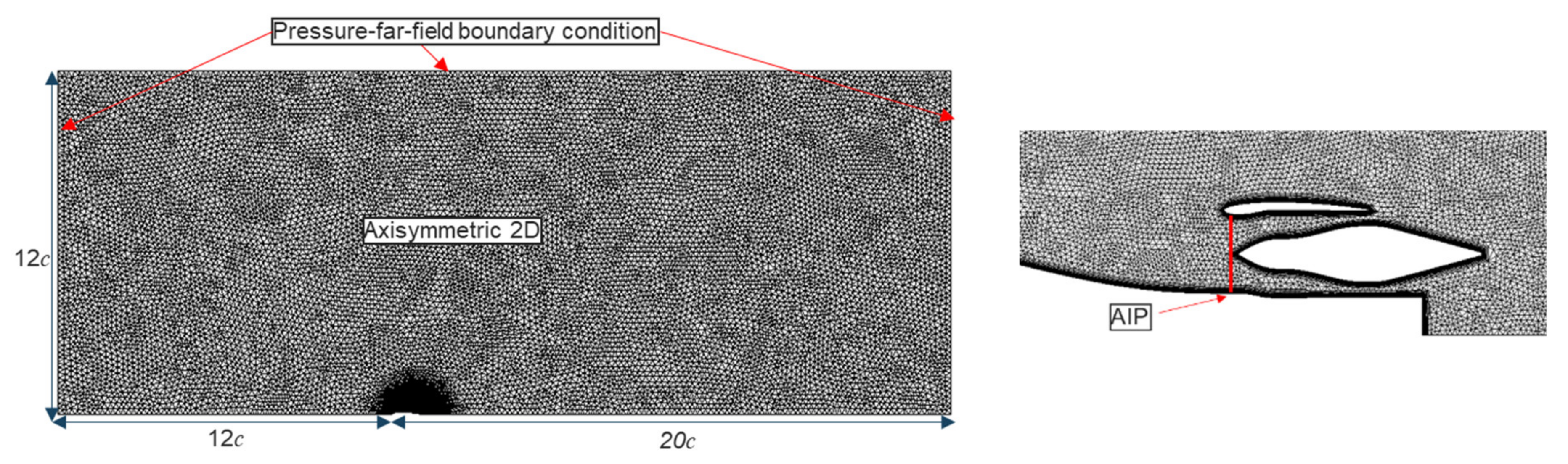

2.3.1. CFD Setup—2D

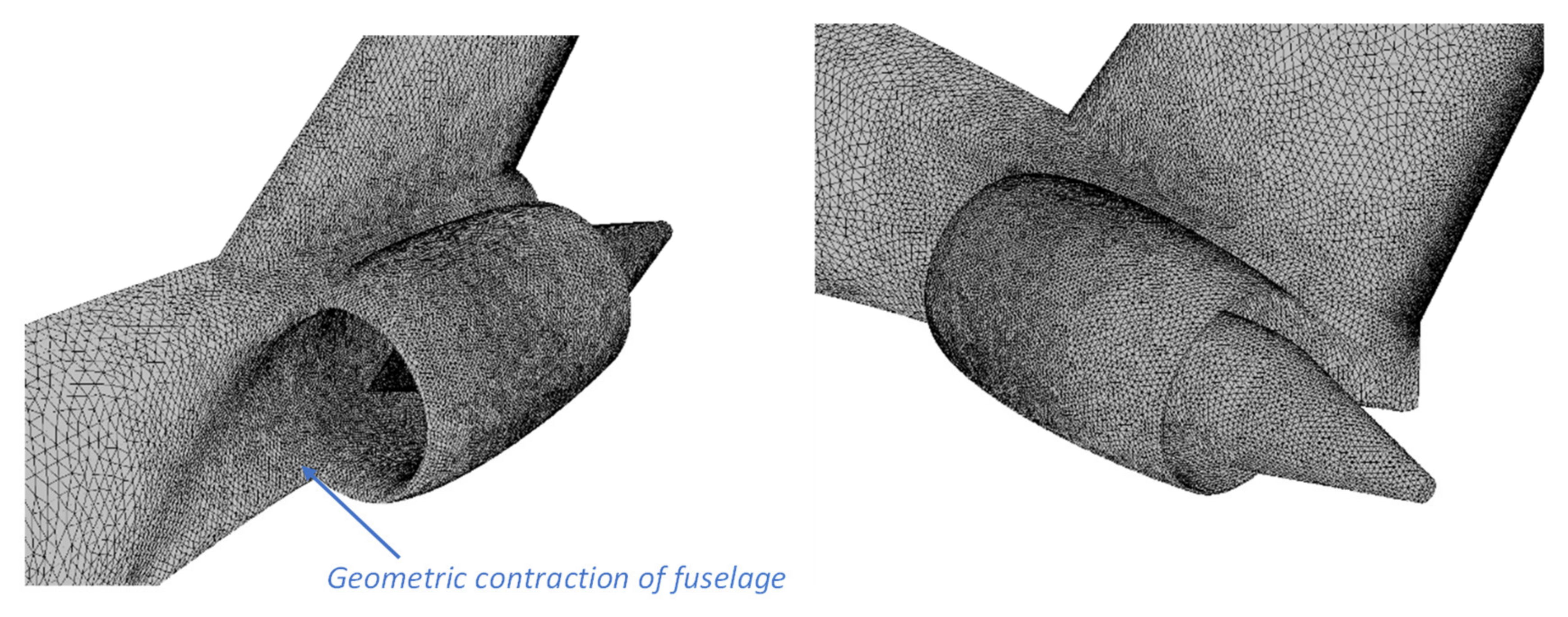

2.3.2. CFD Setup—3D

2.4. Metrics for Benchmarking BLI Effects

2.4.1. Pressure Recovery Coefficient

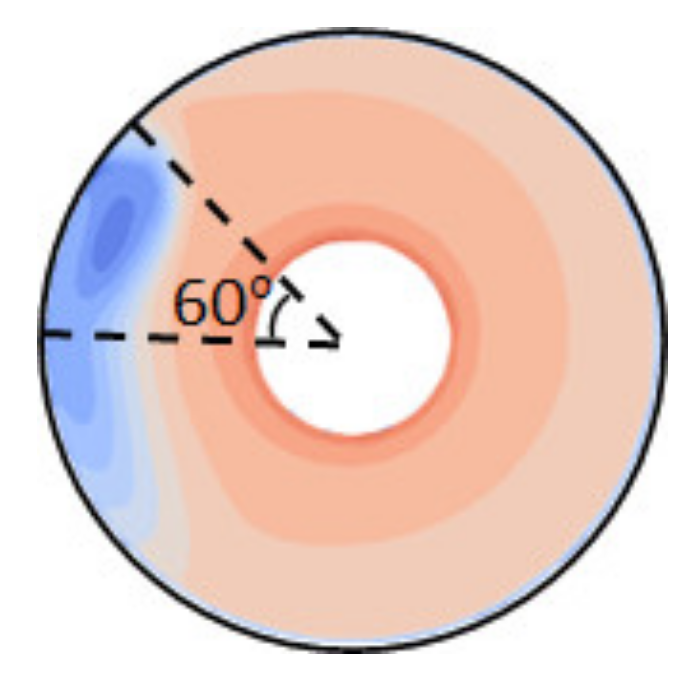

2.4.2. Flow Distortion Severity Index

3. Results and Discussion

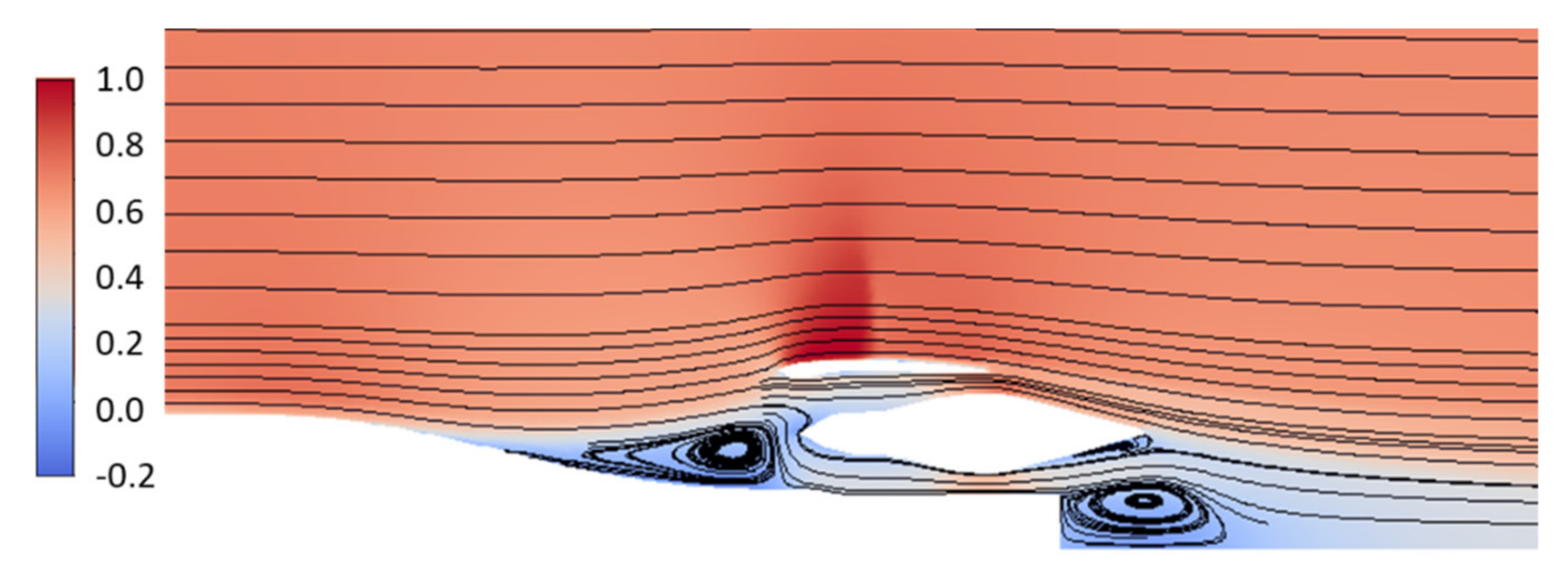

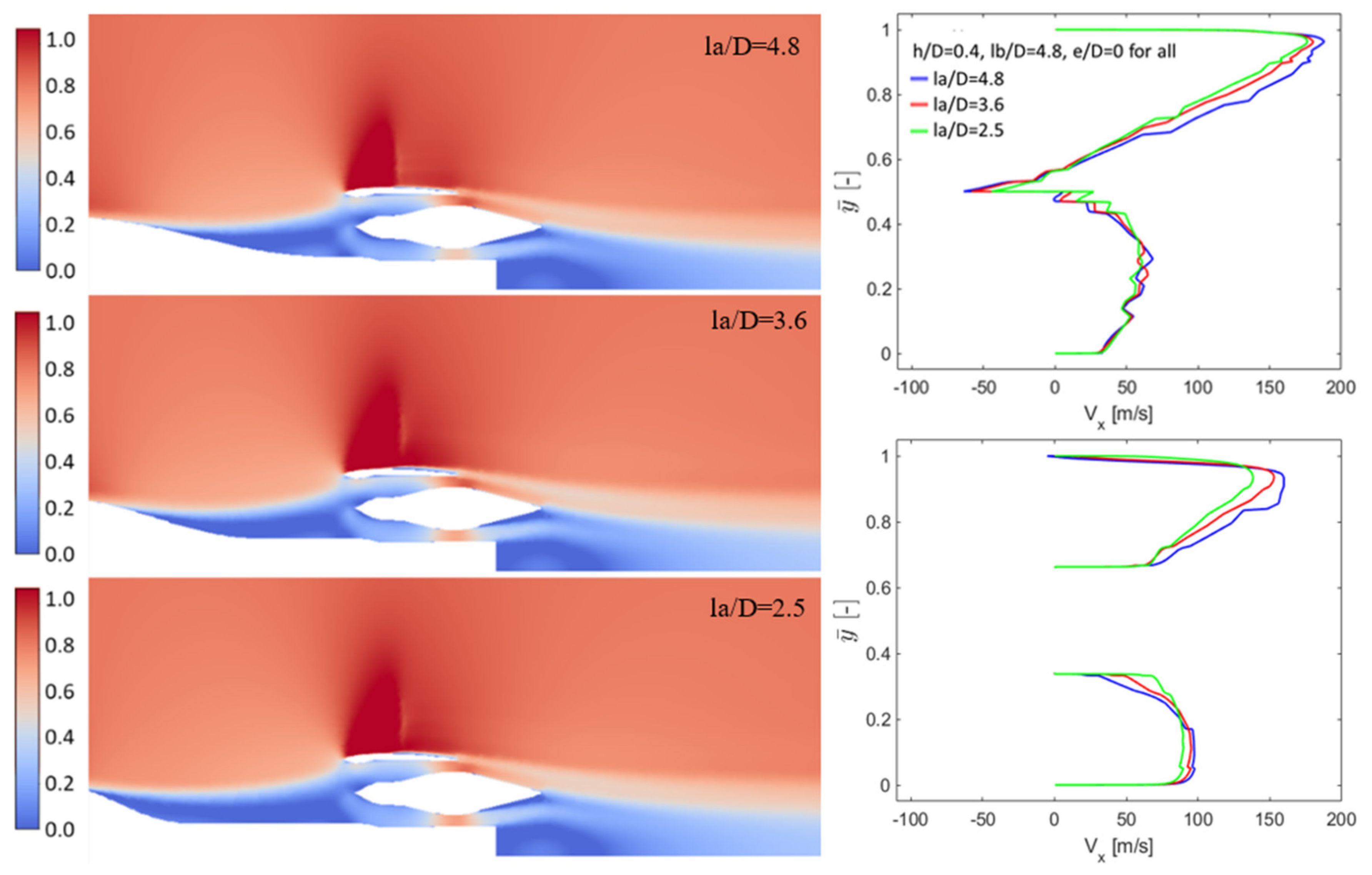

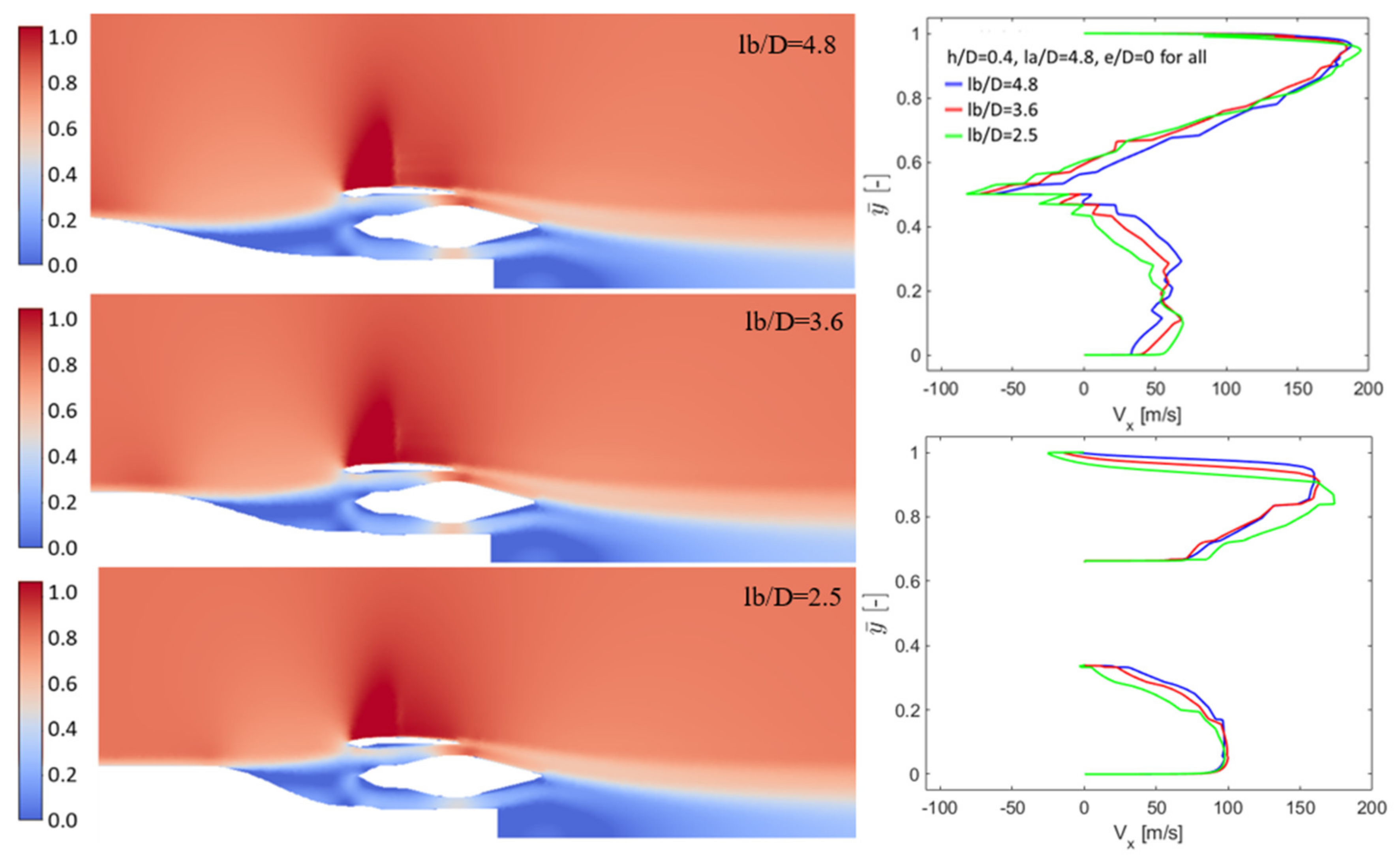

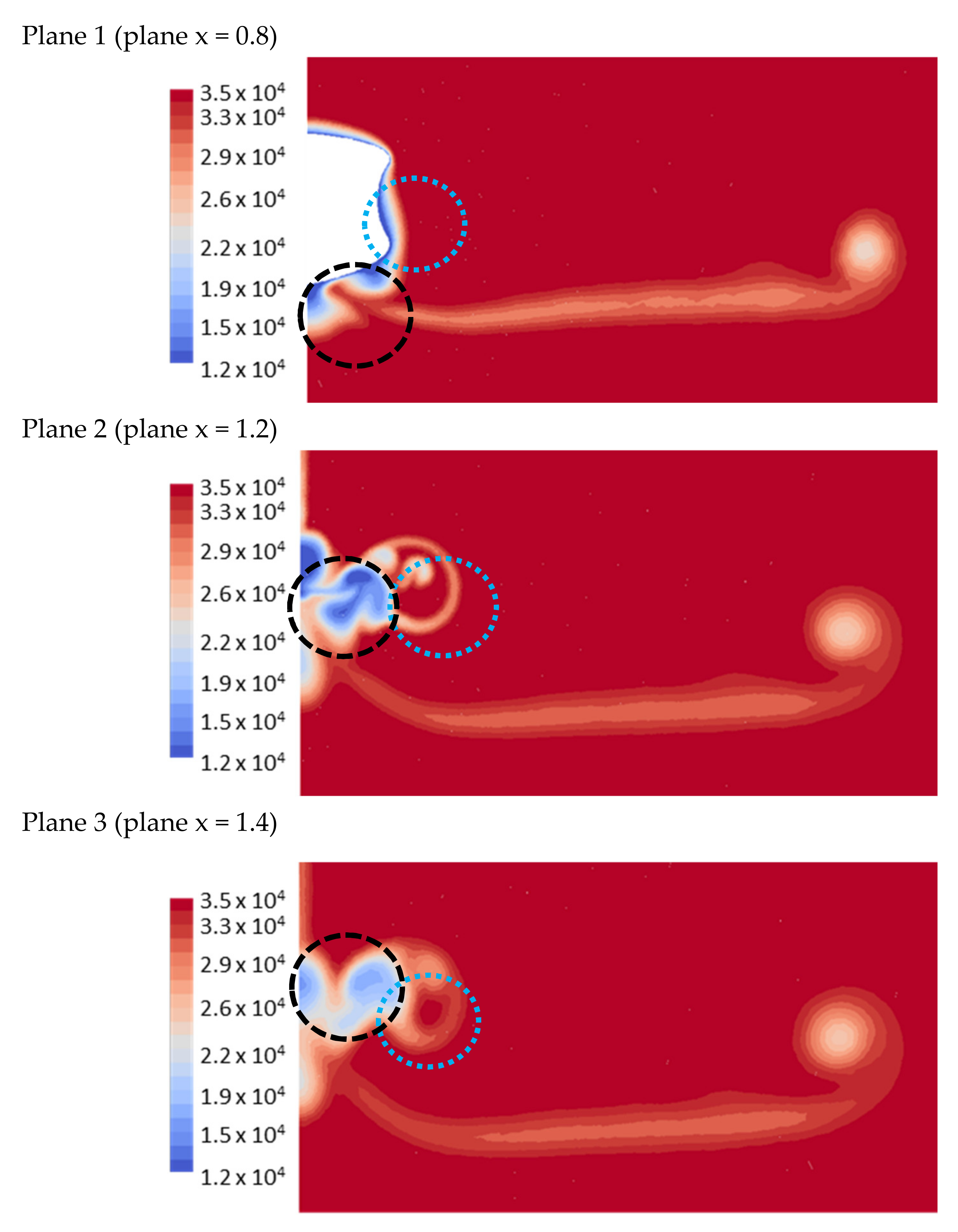

3.1. Simulation Results—2D

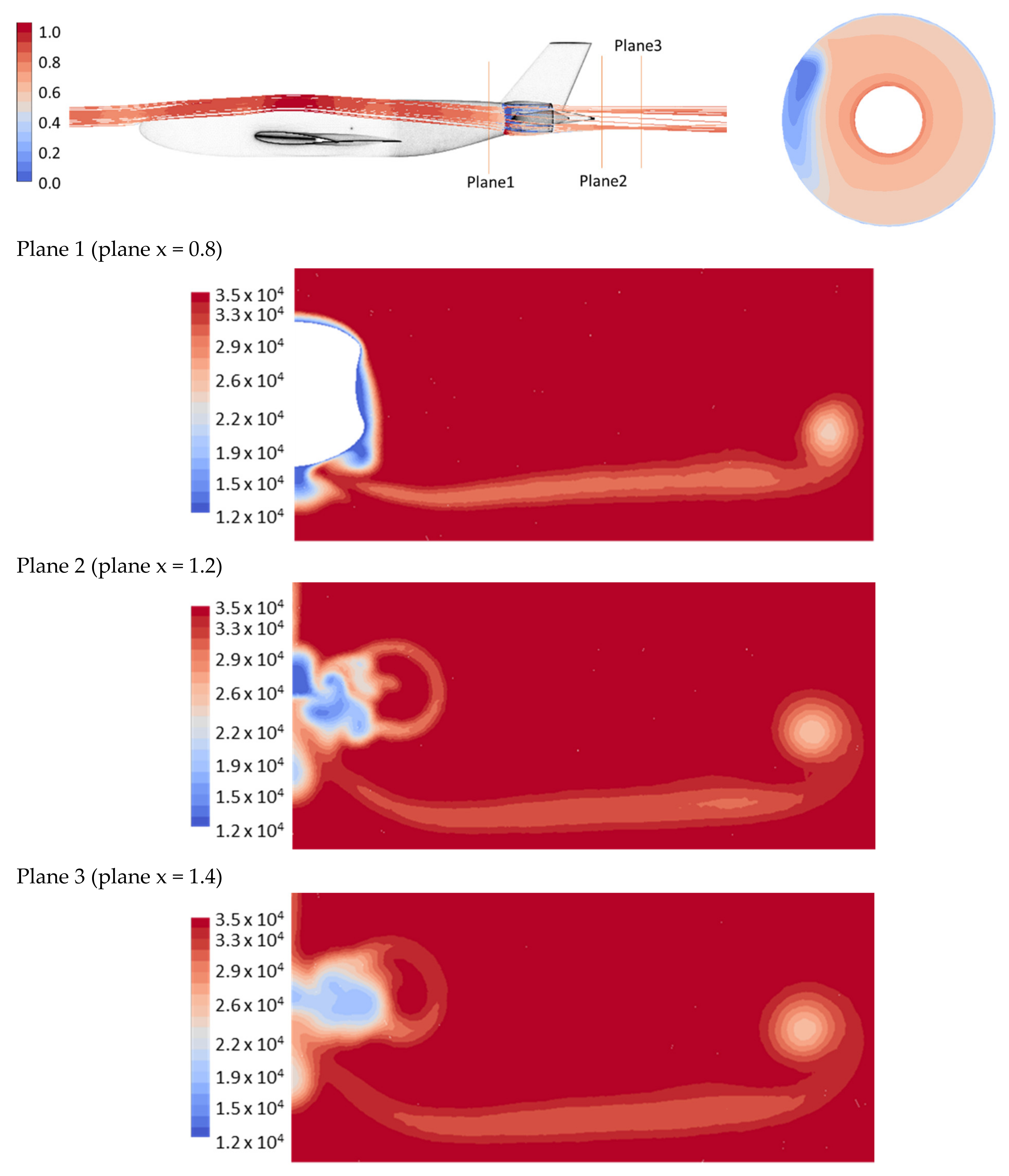

3.2. Simulation Results—3D

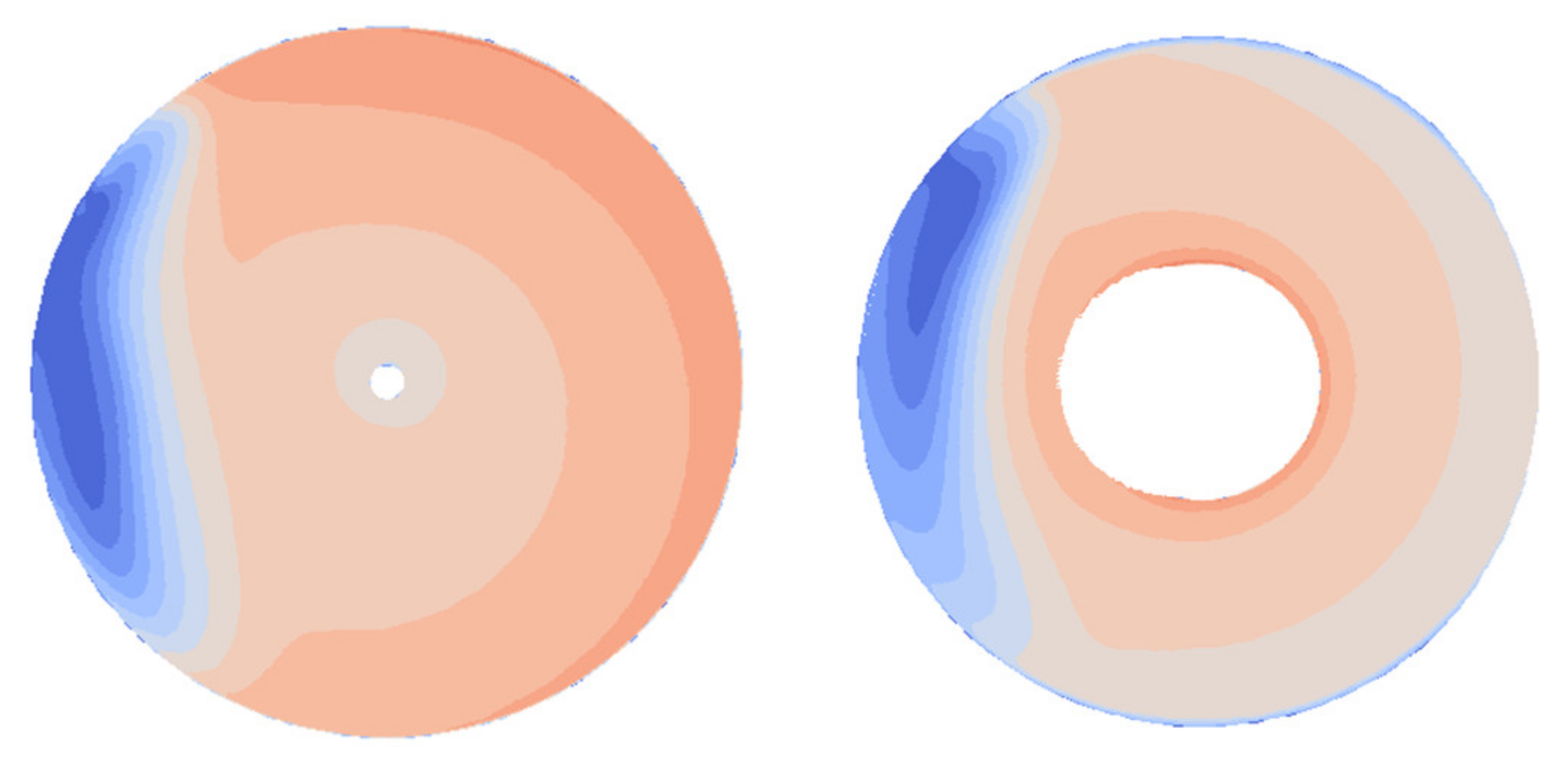

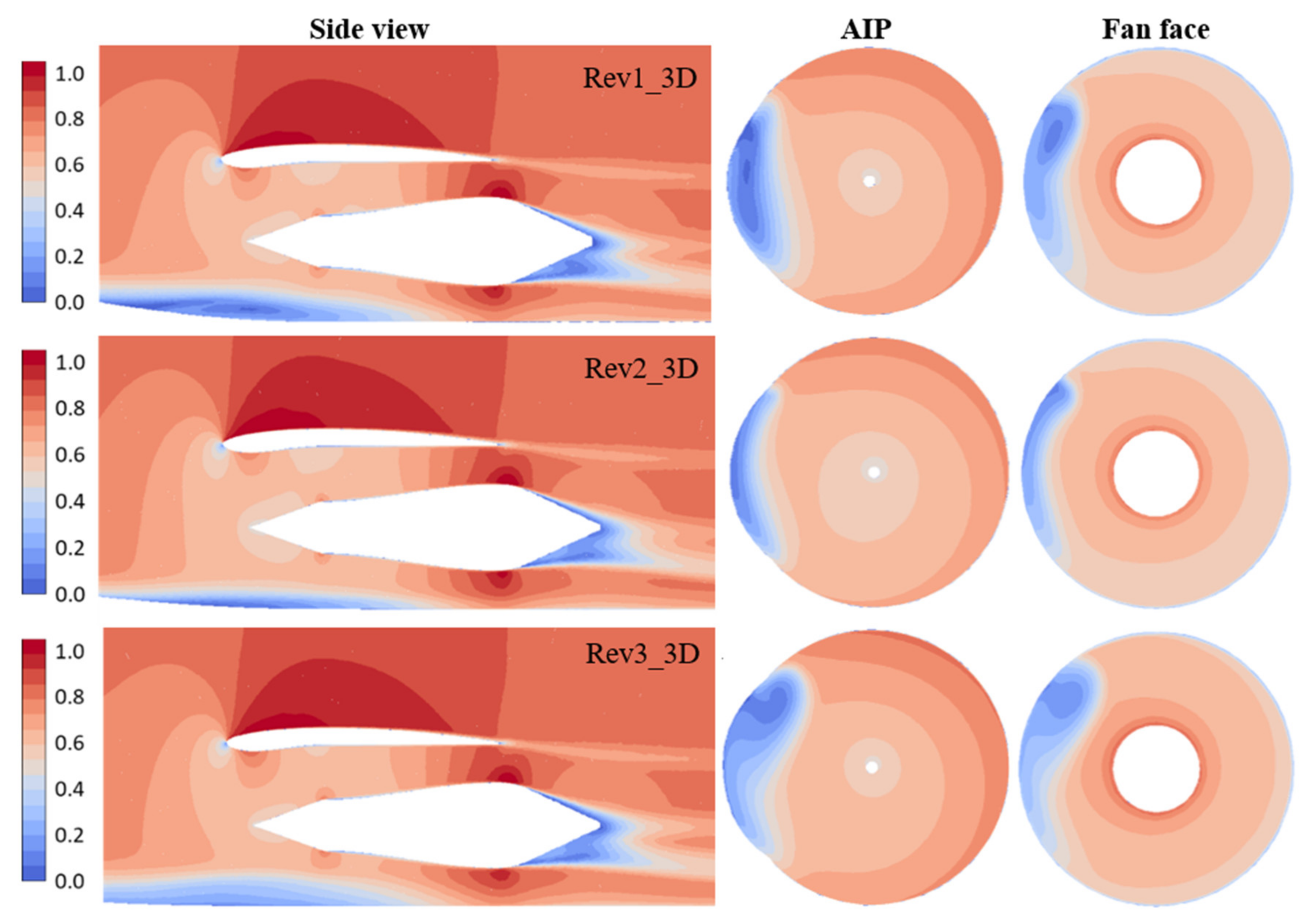

3.2.1. Comparison between 2D and 3D Simulations

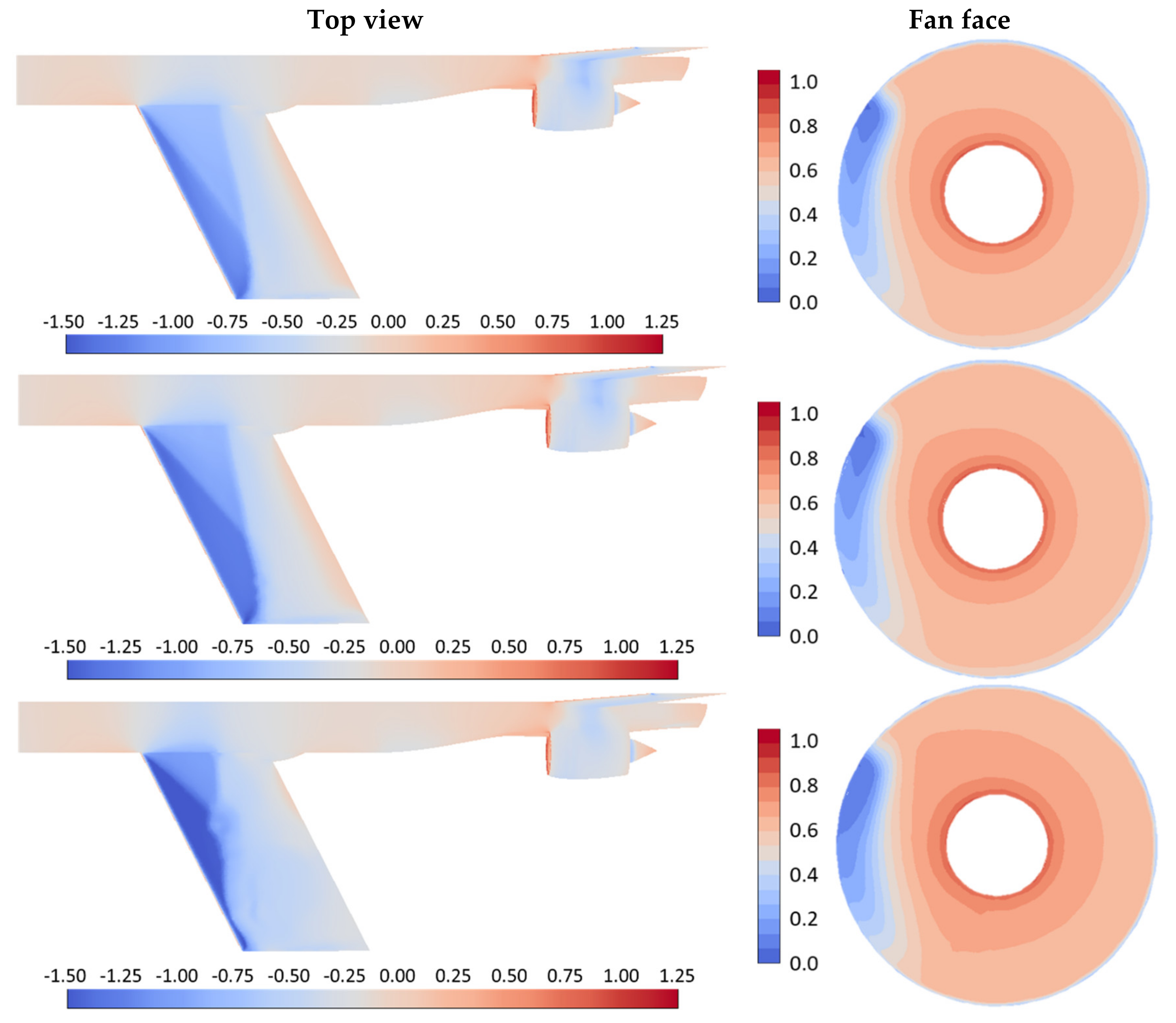

3.2.2. Design Parameters Sensitivities—3D

- No. A—Rev1_3D had the same design parameters as the case h/D = 0.6, e/D = 0, la/D = lb/D = 4.8. Revisions included the removal of the bump on the diffusion slope formed by the nacelle lip shape as can be seen in the lower figure of Figure 13 and the resize of the nozzle for a desired mass flow rate.

- No. B—Rev2_3D had a higher highlight position with h/D = 0.8 compared to Rev1_3D.

- No. C—Rev3_3D had a more aggressive diffusion slope with la/D = 3.6 compared to Rev1_3D.

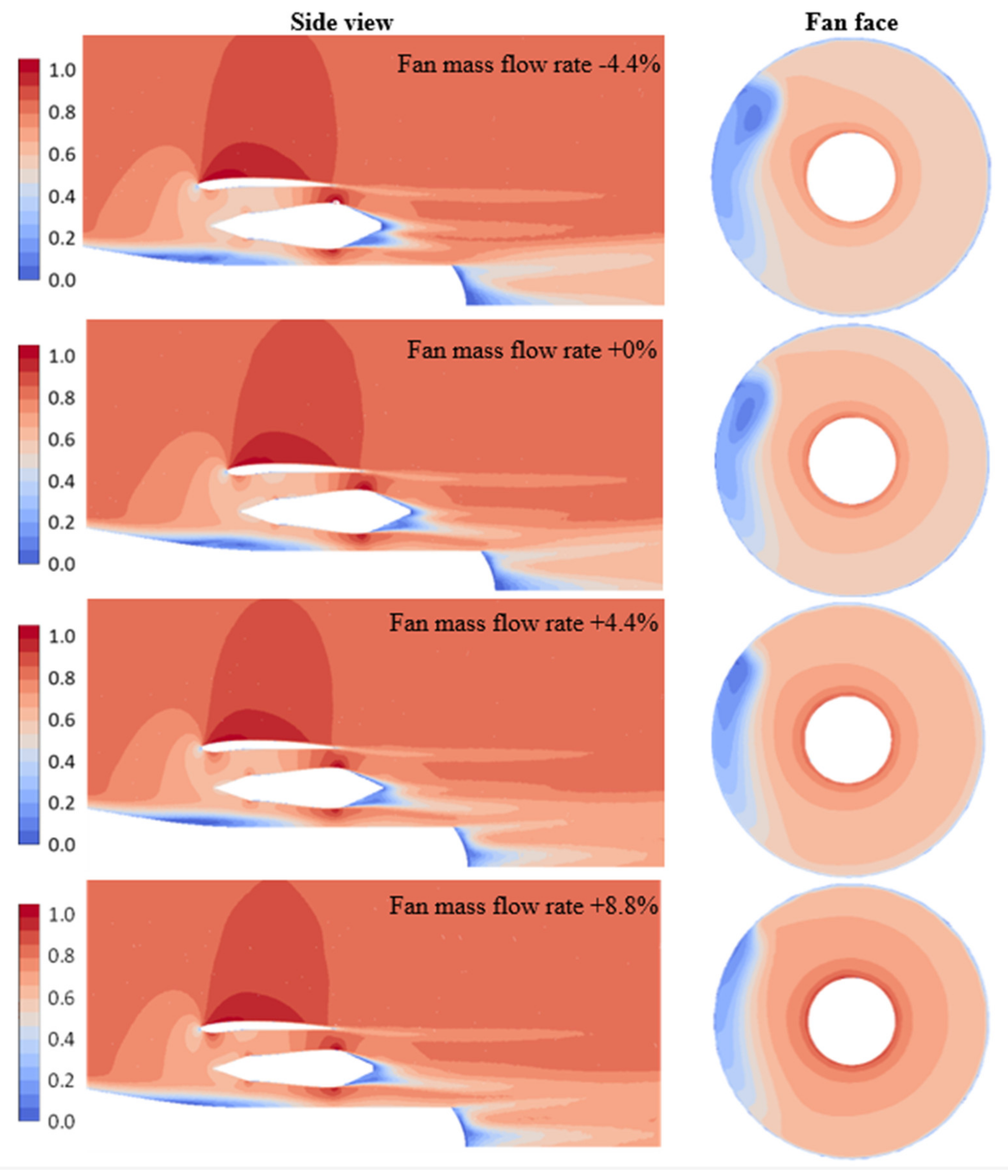

3.2.3. Mass Flow Sensitivity

3.2.4. Angle of Attack Sensitivities

3.2.5. Wing Position Parametric Study

3.2.6. Fuselage Length Parametric Study

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature and Performance Metrics Definition

| AOA | Angle of attack |

| AIP | Aerodynamic interface plane |

| BLI | Boundary layer ingestion |

| BWB | Blended wing body |

| CFD | Computational fluid dynamics |

| DC60 | Distortion coefficient |

| EPNdB | Effective perceived noise in decibels |

| MFCR | Mass flow capture ratio |

| TWB | Tube-and-wing body |

| c | Length scale of aircraft fuselage |

| D | Engine fan diameter |

| e | Nacelle length extension |

| h | Engine installation highlight |

| la | Intake diffusion |

| lb | Intake diffusion |

| p0 | Total pressure |

| ηPR | Pressure recovery coefficient |

References

- Smith, A.M.O.; Roberts, H.E. The Jet Airplane Utilizing Boundary Layer Air for Propulsion. J. Aeronaut. Sci. 1947, 14, 97–109. [Google Scholar] [CrossRef]

- IATA. Aircraft Technology Roadmap to 2050; International Air Transport Association: Montreal, QC, USA, 2020. [Google Scholar]

- IATA. Technology Roadmap for Environmental Improvement Fact Sheet; International Air Transport Association: Montreal, QC, USA, 2020. [Google Scholar]

- Sahoo, S.; Zhao, X.; Kyprianidis, K. A Review of Concepts, Benefits, and Challenges for Future Electrical Propulsion-Based Aircraft. Aerospace 2020, 7, 44. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.D.; Felder, J.; Tong, M.T.; Berton, J.; Haller, W. Turboelectric Distributed Propulsion Benefits on the N3-X Vehicle. Aircr. Eng. Aerosp. Technol. Int. J. 2014, 86, 558–561. [Google Scholar] [CrossRef]

- Liou, M.-F.; Gronstal, D.; Kim, H.; Liou, M. Aerodynamic design of the hybrid wing body with nacelle: N3-X propulsion-airframe configuration. In Proceedings of the 34th AIAA Applied Aerodynamics Conference, Washington, DC, USA, 13–17 June 2016. [Google Scholar]

- Kawai, R.T.; Friedman, D.M.; Serrano, L. Blended Wing Body (BWB) Boundary Layer Ingestion (BLI) Inlet Configuration and System Studies; NASA: Washington, DC, USA, 2006. [Google Scholar]

- Stückl, S.; van Toor, J.; Lobentanzer, H. VOLTAIR—The All Electric Propulsion Concept Platform—A Vision for Atmospheric Friendly Flight. In Proceedings of the 28th International Congress of the Aeronautical Sciences (ICAS), Brisbane, Australia, 23–28 September 2012. [Google Scholar]

- Steiner, H.-J.; Vratny, P.C.; Gologan, C.; Wieczorek, K.; Isikveren, A.T.; Hornung, M. Optimum number of engines for transport aircraft employing electrically powered distributed propulsion. CEAS Aeronaut. J. 2014, 5, 157–170. [Google Scholar] [CrossRef]

- Kruger, M.; Uranga, A. The Feasibility of Electric Propulsion for Commuter Aircraft. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 1499. [Google Scholar]

- Welstead, J.; Felder, J.; Guynn, M.; Haller, B.; Tong, M.; Jones, S.; Ordaz, I.; Quinlan, J.; Mason, B. Overview of the NASA STARC-ABL (rev. B) Advanced Concept; NASA: Washington, DC, USA, 2017. [Google Scholar]

- Seitz, A.; Habermann, A.L.; Peter, F.; Troeltsch, F.; Castillo Pardo, A.; Della Corte, B.; Van Sluis, M.; Goraj, Z.; Kowalski, M.; Zhao, X.; et al. Proof of Concept Study for Fuselage Boundary Layer Ingesting Propulsion. Aerospace 2021, 8, 16. [Google Scholar] [CrossRef]

- Bradley, M.K.; Droney, C.K. Subsonic Ultra Green Aircraft Research Phase II: N+ 4 Advanced Concept Development; NASA: Washington, DC, USA, 2012. [Google Scholar]

- Schnell, R.; Zhao, X.; Rallis, E.; Kavvalos, M.; Sahoo, S.; Schnoes, M.; Kyprianidis, K. Assessment of a Turbo-Electric Aircraft Configuration with Aft-Propulsion Using Boundary Layer Ingestion. Aerospace 2019, 6, 134. [Google Scholar] [CrossRef] [Green Version]

- Steiner, H.-J.; Seitz, A.; Wieczorek, K.; Plotner, K.; Isikveren, A.T.; Hornung, M.; Luftfahrt, B. Multi-disciplinary design and feasibility study of distributed propulsion systems. In Proceedings of the 28th International Congress of the Aeronautical Sciences, Brisbane, Australia, 23–28 September 2012. [Google Scholar]

- Samuelsson, S.; Grönstedt, T. Performance analysis of turbo-electric propulsion system with fuselage boundary layer ingestion. Aerosp. Sci. Technol. 2021, 109, 106412. [Google Scholar] [CrossRef]

- Uranga, A.; Drela, M.; Greitzer, E.M.; Titchener, N.A.; Lieu, M.K.; Siu, N.M.; Huang, A.C.; Gatlin, G.M.; Hannon, J. Preliminary Experimental Assessment of the Boundary Layer Ingestion Benefit for the D8 Aircraft. In Proceedings of the 52nd Aerospace Sciences Meeting, Hannon, National Harbor, MD, USA, 13–17 January 2014. [Google Scholar]

- Yutko, B.; Titchener, N.; Courtin, C.; Lieu, M.; Wirsing, L.; Hall, D.; Tylko, J.; Chambers, J.; Roberts, T.; Church, C. Design and development of the D8 commercial transport concept. In Proceedings of the 31st Congress of the International Council of the Aeronautical Sciences, ICAS 2018, Belo Horizonte, Brazil, 9–14 September 2018. [Google Scholar]

- Marien, T.; Welstead, J.R.; Jones, S.M. Vehicle level system impact of boundary layer ingestion for the NASA D8 concept aircraft. In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018. [Google Scholar]

- Yutko, B.; Titchener, N.; Courtin, C.; Lieu, M.; Wirsing, L.; Hall, D.; Tylko, J.; Chambers, J.; Roberts, T.; Church, C. Conceptual design of a D8 commercial aircraft. In Proceedings of the 17th AIAA Aviation Technology, Integration, and Operations Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar]

- Wiart, L.; Atinault, O.; Hue, D.; Grenon, R. Development of NOVA Aircraft Configurations for Large Engine Integration Studies. In Proceedings of the 5th SCAD, Naples, Italy, 12 October 2015. [Google Scholar]

- Wiart, L.; Atinault, O.; Boniface, J.C.; Barrier, R. Aeropropulsive performance analysis of the NOVA configurations. In Proceedings of the 30th Congress of the International Council of the Aeronautical Sciences, Daejeon, Korea, 25–30 September 2016. [Google Scholar]

- Romani, G.; Ye, Q.; Avallone, F.; Ragni, D.; Casalino, D. Fan Noise Boundary-Layer Ingestion Installation Effects for NOVA Aircraft Configuration. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Deft, The Netherlands, 20–23 May 2019. [Google Scholar]

- Romani, G.; Ye, Q.; Avallone, F.; Ragni, D.; Casalino, D. Numerical analysis of fan noise for the NOVA boundary-layer ingestion configuration. Aerosp. Sci. Technol. 2019, 96, 105532. [Google Scholar] [CrossRef]

- Wiart, L.; Negulescu, C. Exploration of the airbus “Nautilius” engine integration concept. In Proceedings of the 31st Congress of the International Council of the Aeronautical Sciences, Belo Horizonte, Brazil, 9–14 September 2018. [Google Scholar]

- Godard, B.; Negulescu, C. Fan Design Investigation on the Airbus Nautilius Engine Integration Concept. In Proceedings of the Turbomachinery Technical Conference and Exposition 2020, Turbo Expo: Power for Land, Sea, and Air, American Society of Mechanical Engineers, Virtual, 21–25 September 2020. [Google Scholar]

- Ahuja, J.; Mavris, D.N. Sensitivity of boundary layer ingestion effects to tube and wing airframe design features. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar]

- Arend, D.; Tillman, G.; O‘Brien, W. Generation after next propulsor research: Robust design for embedded engine systems. In Proceedings of the 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Atlanta, GA, USA, 30 July–1 August 2012. [Google Scholar]

- Florea, R.V.; Matalanis, C.; Hardin, L.W.; Stucky, M.; Shabbir, A. Parametric Analysis and Design for Embedded Engine Inlets. J. Propuls. Power 2015, 31, 843–850. [Google Scholar] [CrossRef]

- Cousins, W.T.; Voytovych, D.; Tillman, G.; Gray, E. Design of a distortion-tolerant fan for a boundary-layer ingesting embedded engine application. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10–12 July 2017. [Google Scholar]

- Pardo, A.C.; Hall, C.A. Design of a Transonic Boundary Layer Ingesting Fuselage Fan. In Proceedings of the Global Power and Propulsion Society, Chania, Greece, 7–8 September 2020. [Google Scholar]

- Brown, K.A.; Fleming, J.L.; Langford, M.; Ng, W.; Schwartz, K.; Combs, C. Development of a Ducted Propulsor for BLI Electric Regional Aircraft-Part I: Aerodynamic Design and Analysis. In Proceedings of the AIAA Propulsion and Energy 2019 Forum, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar]

- Celestina, M.L.; Long-Davis, M.J. Large-scale boundary layer ingesting propulsor research. In Proceedings of the ISABE Conference 2019, Canberra, Australia, 22–27 September 2019. [Google Scholar]

- Clark, I.; Thomas, R.H.; Guo, Y. Aircraft system noise assessment of the NASA D8 subsonic transport concept. In Proceedings of the 2018 AIAA/CEAS Aeroacoustics Conference, Atlanta, GA, USA, 25–29 June 2018. [Google Scholar]

- Clark, I.; Thomas, R.H.; Guo, Y. Far Term Noise Reduction Roadmap for the NASA D8 and Single-Aisle Tube-and-Wing Aircraft Concepts. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Deft, The Netherlands, 20–23 May 2019. [Google Scholar]

- Gray, J.S.; Mader, C.; Kenway, G.; Martins, J.R.R.A. Approach to modeling boundary layer ingestion using a fully coupled propulsion-RANS model. In Proceedings of the 58th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar]

- Gray, J.S.; Martins, J.R.R.A. Coupled aeropropulsive design optimisation of a boundary-layer ingestion propulsor. Aeronaut. J. 2018, 123, 121–137. [Google Scholar] [CrossRef] [Green Version]

- Fernández, A.M.; Smith, H. Effect of a fuselage boundary layer ingesting propulsor on airframe forces and moments. Aerosp. Sci. Technol. 2020, 100, 105808. [Google Scholar] [CrossRef]

- Kenway, G.K.; Kiris, C.C. Aerodynamic shape optimization of the STARC-ABL concept for minimal inlet distortion. In Proceedings of the 2018 AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 8–12 January 2018. [Google Scholar]

- Gray, J.S.; Mader, C.A.; Kenway, G.K.W.; Martins, J.R.R.A. Modeling Boundary Layer Ingestion Using a Coupled Aeropropulsive Analysis. J. Aircr. 2018, 55, 1191–1199. [Google Scholar] [CrossRef]

- Battiston, A.; Ponza, R.; Benini, E. Design Exploration for an Axisymmetric Rear BLI Propulsor. In Proceedings of the AIAA Propulsion and Energy 2021 Forum, Virtual, 9–11 August 2021. [Google Scholar]

- Brodersen, O. Drag Prediction of Engine-Airframe Interference Effects Using Unstructured Navier-Stokes Calculations. J. Aircr. 2002, 39, 927–935. [Google Scholar] [CrossRef]

- SAFRAN. Leap-1A Technical Characteristics Table. Available online: https://www.safran-aircraft-engines.com/commercial-engines/single-aisle-commercial-jets/leap/leap-1a (accessed on 24 May 2021).

- Langley, M. The Design of Axisymmetric Cowls for Podded Nacelles for High By-Pass Turbofan Engines; Aeronautical Research Council: London, UK, 1979. [Google Scholar]

- Frink, N.T. 3rd AIAA CFD Drag Prediction Workshop Gridding Guidelines; NASA Langley: Hampton, VA, USA, 2007. [Google Scholar]

- Du, P.; Agarwal, R.K. Numerical drag prediction of NASA Common Research Models using different turbulence models. Comput. Fluids 2019, 191, 104238. [Google Scholar] [CrossRef] [Green Version]

- Togiti, V.; Eisfeld, B.; Brodersen, O. Turbulence Model Study for the Flow Around the NASA Common Research Model. J. Aircr. 2014, 51, 1331–1343. [Google Scholar] [CrossRef]

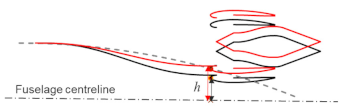

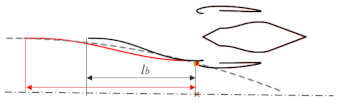

| Illustrative Diagram | Design Parameter Description | Cases |

|---|---|---|

| Distance h between fuselage centreline and the nacelle highlight | h/D = [0.2, 0.4, 0.6, 0.8] |

| Intake diffusion length la (Fixing the start point of the fuselage side profile) | la/D = [4.8, 3.6, 2.5] |

| Intake diffusion length lb (Fixing the end point of the fuselage side profile) | lb/D = [4.8, 3.6, 2.5] |

| Outer nacelle extension e | e/D = [0, 0.6, 1.2] |

| 2D Setup | 3D Setup | ||

|---|---|---|---|

| Steady State, Ideal Gas | Steady State, Ideal Gas | ||

| Turbulence Model | k-ω SST | ✓ Viscous Heating | ✓ Viscous Heating |

| ✓ Production Limiter | ✓ Curvature Correction | ||

| ✓ Production Limiter | |||

| Freestream Conditions | Pressure Far Field | Static Pressure: 66,471 [Pa] | Static Pressure: 66,471 [Pa] |

| Static Temperature: 277 [K] | Static Temperature: 277 [K] | ||

| Mach: 0.8 | Mach: 0.8 | ||

| Turbulent Intensity: 0.1% | Turbulent Intensity: 0.1% | ||

| Turbulent Viscosity Ratio: 1 | Turbulent Viscosity Ratio: 1 | ||

| Solution Methods | Pressure-Velocity Scheme | Coupled | Coupled |

| Spatial Discretization | Gradient: LSCB Pressure: Second Order Density, Momentum, k, ω, Energy: Second Order | Gradient: LSCB Pressure: Second Order Density, Momentum, k, ω, Energy: Second Order | |

| Mesh | Number of Elements | ~0.38 million | ~40 million |

| Wall inflation layers | 46 | 41 | |

| First layer height | 0.0004 mm | 0.0004 mm | |

| Layer growth rate | <1.25 | <1.25 | |

| Maximum y plus | <1.0 | <1.0 |

| No. | Case | AOA | Fan Mass Flow | ||

|---|---|---|---|---|---|

| A | Rev1_3D | 1 deg | 1.02 kg/s | 0.987 | 0.290 |

| B | Rev2_3D | 1 deg | 1.07 kg/s | 0.995 | 0.112 |

| C | Rev3_3D | 1 deg | 1.04 kg/s | 0.980 | 0.300 |

| D | Rev1_3D −4.4% mass flow rate | 1 deg | 0.98 kg/s | 0.989 | 0.280 |

| E | Rev1_3D +4.4% mass flow rate | 1 deg | 1.07 kg/s | 0.986 | 0.287 |

| F | Rev1_3D +8.8% mass flow rate | 1 deg | 1.11 kg/s | 0.985 | 0.259 |

| G | Rev1_3D +4.4% mass flow rate | 2 deg | 1.06 kg/s | 0.985 | 0.306 |

| H | Rev1_3D +4.4% mass flow rate | 4 deg | 1.12 kg/s | 0.993 | 0.346 |

| I | Rev1_3D +4.4% mass flow rate, High wing | 1 deg | 0.99 kg/s | 0.968 | 0.410 |

| J | Rev1_3D +4.4% mass flow rate, Short fuselage | 1 deg | 1.03 kg/s | 0.995 | 0.290 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Van Hoorn, P.; Yao, H.-D.; Alderman, J. Parameter Sensitivity Study on Inflow Distortion of Boundary Layer Ingested Turbofans. Aerospace 2022, 9, 426. https://doi.org/10.3390/aerospace9080426

Zhao X, Van Hoorn P, Yao H-D, Alderman J. Parameter Sensitivity Study on Inflow Distortion of Boundary Layer Ingested Turbofans. Aerospace. 2022; 9(8):426. https://doi.org/10.3390/aerospace9080426

Chicago/Turabian StyleZhao, Xin, Philip Van Hoorn, Hua-Dong Yao, and James Alderman. 2022. "Parameter Sensitivity Study on Inflow Distortion of Boundary Layer Ingested Turbofans" Aerospace 9, no. 8: 426. https://doi.org/10.3390/aerospace9080426

APA StyleZhao, X., Van Hoorn, P., Yao, H.-D., & Alderman, J. (2022). Parameter Sensitivity Study on Inflow Distortion of Boundary Layer Ingested Turbofans. Aerospace, 9(8), 426. https://doi.org/10.3390/aerospace9080426