Abstract

The high-performance piston has a great impact on the performance parameters of the engine. The rapid design of a high-performance piston can shorten the research and development cycle and lower the experimental cost. At present, the piston design is mostly considered from a single factor, but it has not been comprehensively designed from multiple factors. Starting from the concept of structural efficiency, this paper defines the restrictive factors affecting engine performance parameters in piston design, puts forward an evaluation method of quantifying the benefit of piston design on engine performance parameters, and deduces the calculation model. The piston is designed and iterated many times to obtain the best two schemes. The two schemes are quantitatively compared through the above calculation model and verified by experiments. The results show that the structural efficiency of the piston in scheme 2 is 4.6% higher than that in scheme 1. The calculation method is applicable to the design of key engine components, which can shorten the research and development cycle, save the test costs, and greatly improve the R&D efficiency.

1. Introduction

The piston is the core component of an internal combustion engine. For an aviation piston engine pursuing a high power to weight ratio and high reliability, piston performance is particularly important [1,2]. The ability of the piston to resist burst pressure and high temperature directly affects the power and time between overhauls (TBO) of the engine, the combustion chamber at the top of the piston affects the combustion efficiency and emission, the weight of the piston affects the power to weight ratio of the engine, and the high power to weight ratio and high reliability are the core evaluation indexes of an aviation kerosene engine, so the research on the piston is particularly important [3,4]. The aluminum alloy piston is favored by the aviation kerosene piston engine because of its light weight and small reciprocating inertia force. The design of the piston has a lot of influence on the engine performance, but at present, there is no method to effectively connect various restrictive factors in the process of piston design with engine performance, especially how to determine the influencing factors related to engine performance in the process of design. At present, there is little information published on the aviation kerosene engine, only a few articles on the performance simulation of the aviation kerosene piston engine [5,6,7,8,9,10] published by Wilksch company in the UK. There is less content on its piston. Most of the piston research is mainly aimed at vehicle diesel engines. Wang studied the effect of the combustion chamber surface anodizing on piston heat transfer for a combined piston [11]. Khan studied the effects of the piston combustion chamber and injection angle on emission performance [12]. Yang studied the thermal deformation behavior of a reinforced Al-12Si engine combination piston and a control piston and revealed the dynamic recovery and dynamic recrystallization of Al-12Si/Fe-based amorphous composites during thermal compression [13]. Singh studied the relationship between the piston ring profile design and braking thermal efficiency, the fuel consumption rate, and the thermal expansion coefficient [14]. Wu conducted an in-depth analysis on the thermal engine coupling of a marine diesel engine and showed that the stress concentration of the piston crown was mainly caused by thermal load. The destructive effect of thermal load was reduced by strengthening cooling and improving the structural design [15]. Hong proposed a structural efficiency evaluation method of quantitative analysis, obtained the structural efficiency coefficient by synthesizing various parameters, quantitatively evaluated the structural design level of the aeroengine, and realized the parametric method of evaluating the quality of the structural design [16]. Jegley used the structural efficiency evaluation method to analyze the pillar structure of the aircraft to obtain better optimization [17]. Some other scholars conducted finite element analysis on the piston with a steel crown and aluminum skirt, predicted the failure form of the piston, and confirmed the correctness of the finite element analysis [18,19,20,21,22,23,24,25]. Qualitative analysis of the constraints in the process of component structure design, and the correlation between these constraints and the performance of the engine, were performed to design the components that meet the engine performance, which has been complicating the development of aeroengine components. Structural efficiency is an evaluation method to quantify the benefits of various structural improvement designs on the overall performance of parts. However, according to different objects, the contents (evaluation indicators) of structural efficiency are completely different. It is necessary to conduct in-depth analysis, excavate the connotation of structural efficiency, and effectively connect the multi-dimensional evaluation indicators affecting the performance of parts with structural design, which has great significance in practical engineering. In 1989, GE company put forward the concept of structural efficiency, weighed the influence of various constraints on the whole machine, and applied this in the turbine engine [26], and it was also widely used in the aviation industry and building structure [27,28]. Zhang and his teams [29,30] put forward the connotation of structural efficiency for the whole machine and components according to the structural characteristics of the research object, the aero-rotor engine. The connotation involved was deeply analyzed, the quantitative evaluation method of the whole machine and component structure was put forward, and good research results were obtained. Due to different research objects and great differences in structural efficiency, so far there is no introduction to the application of structural efficiency in the piston. In many scholars’ studies, the research on the piston is relatively simple. To improve the performance of the piston, the effects of single factors on the piston performance are analyzed, mainly from the aspects of piston materials, thermal–mechanical coupling, combustion chamber injection angle, etc. Few researchers began to study the mechanical properties of aeroengine parts from multiple perspectives with structural efficiency, but the application of structural efficiency is very complex, which needs to be defined according to the unique use occasion and evaluation factors of each research object. There is no authoritative report on the piston of aeroengines at present. Focusing on the role of the piston in aviation engines, this paper scientifically analyzes several main factors affecting piston performance, proposes the specific connotation and calculation method of piston structure efficiency, establishes an evaluation method that can quantify the relationship between piston structure design and various performance objectives, provides a theoretical reference for piston improvement, and improves the overall performance. The current calculation and analysis methods are compared to comprehensively consider the problems encountered in the use of the piston from the original design, and quickly evaluate the quality of the piston structure design. The traditional analysis method can solve the problem from one factor but cannot comprehensively consider other problems. The structural efficiency proposed in this paper can avoid this problem, shorten the piston design iteration time, and reduce the experimental cost.

2. Connotation of Structural Efficiency

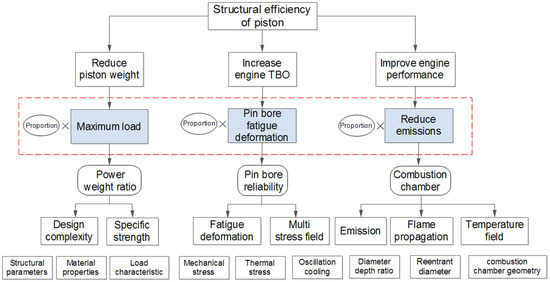

Analyzing the technical route of piston development, combined with the original definition of structural efficiency, and according to the use characteristics and development experience of the aviation kerosene piston engine, the piston should meet the fatigue resistance under lightweight conditions, the piston pin bore will not deform during the durability test, and the piston design should improve the engine combustion efficiency and reduce emissions. According to the above design requirements, the multi-dimensional objectives of structural efficiency of the aviation kerosene engine piston are put forward, that is, the maximum load of the piston under thermal–mechanical coupling, the deformation of piston pin bore, and the emission performance index caused by the piston’s top combustion chamber. The mathematical relationship between each target and piston structure is studied, the mathematical model of the piston structural efficiency is established, and the benefit between structural change and a multi-dimensional target is quantitatively evaluated, as shown in Figure 1. According to the technical obstacles of various objectives in development, each item was given the appropriate proportion.

Figure 1.

Piston structural efficiency analysis.

2.1. Maximum Load of Piston under Thermal–Mechanical Coupling

The maximum bearing capacity of the piston determines the maximum explosion pressure and combustion temperature that can be borne under thermal and mechanical stress, which directly affect the performance and service life of the engine and the power–weight ratio. Under the condition that the fatigue safety factor meets the design requirements, the lightweight piston should bear the load as much as possible to improve the power of the engine. Under the conditions of the in-cylinder burst pressure and temperature meeting the power requirements, the more the fatigue safety factor of key parts of the piston exceeds the design value, the stronger the maximum bearing capacity of the piston. The heat transfer coefficient, thermal expansion coefficient, mechanical performance parameters under different temperatures, and piston load boundary conditions were analyzed under different working conditions of the engine. The temperature curve and cylinder pressure curve were obtained under bad working conditions according to the engine simulation model. With the more rigorous Goodman mean stress correction method, the fatigue safety factors of different piston structural design schemes under explosive pressure and temperature that meet the power demand were studied, and the effects between the distribution of mechanical stress and thermal stress and the structural scheme were comprehensively considered. The design scheme that exceeds the set value of the fatigue safety factor was selected, which showed that the piston has a high bearing capacity and service life under thermal–mechanical coupling. In the subsequent engine performance improvement, within the specified range of the fatigue safety factor threshold, the maximum load borne by the piston was appropriately increased by adjusting the fuel injection and boost matching, to improve the engine power–weight ratio.

2.2. Fatigue Deformation of Piston Pin Bore under Multiple Fields

Piston fatigue includes many forms, such as piston mechanical fatigue damage, piston pin hole cracking, deformation, etc. These fatigue deformations directly affect the engine time between overhauls (TBO). According to the development experience, pin bore deformation is the main form of fatigue of the aeroengine piston, which is mainly due to the limitation of the aluminum alloy piston material and the high cylinder firing pressure. According to the engine simulation model and some experimental parameters, the thermal stress, gas explosion pressure, primary and secondary thrust, oscillation cooling, and other boundary conditions of the piston under bad working conditions were obtained. Considering the lubrication friction coefficient between the pin bore and the pin, the mechanical properties of the piston and the piston pin under a high-temperature environment were provided. The deformation of the piston pin bore under thermal–mechanical coupling and fluid–solid coupling of different structural schemes was calculated, and the elliptic regression curves on both sides of the pin hole were analyzed. According to the design value, the deformation of the pin hole under the specified impact was judged and analyzed, and the relationship between the fatigue deformation value of the piston pin bore and the structural design was discussed.

2.3. Emission Performance

Due to environmental protection, the emissions of aviation piston engines have been considered by countries all over the world. Emission is closely related to combustion, and the shape of the combustion chamber is an important feature of the piston crown. Its shape directly affects the internal turbulent movement and flame propagation and has a direct impact on the fuel economy and emission of the engine. The evaporation, fragmentation, collision, and turbulent diffusion models of kerosene droplets were studied, and the dynamic model of the combustion chamber under different crankshaft angles was established. By changing the geometric shape of the combustion chamber, the mixing quality of fuel and air was improved, the combustion speed was accelerated, and the duration of swirl was prolonged. The generation laws of full state parameters such as velocity field, temperature field, oxygen concentration, and NOx in the combustion chamber under different diameter–depth ratios and reentrant diameter–maximum diameter ratios were analyzed. The influence of the diameter–depth ratio on improving the squeeze and turbulence of the intake swirl in the combustion chamber was studied. The influence of the distance between the fuel injection nozzle and the combustion chamber wall on the turbulence intensity near the combustion chamber wall was studied. The relationship between the combustion chamber structure and parameters such as root and NOx were comprehensively analyzed, and the coordination and unification of multiple variables was considered.

According to the above analysis, the formula for defining the structural efficiency of the piston is shown in Equation (1):

where are the proportion factors, as shown in Equation (2):

: Maximum load of piston under thermal–mechanical coupling.

: Fatigue deformation of piston pin bore under multiple fields.

: Emission performance.

To compare between different structural schemes, it is necessary to perform a normalization process, . During the normalization process, the parameters of the prototype engine can be used as the basis, or the optimal design target can also be used as the basis. Since the connotation of structural efficiency is known according to the characteristics of components, the proportion coefficient can be appropriately adjusted. In the connotation definition of structural efficiency, the proportion coefficient is calculated as [31].

3. Structural Efficiency Calculation of the Piston

The piston is used in a certain type of aviation kerosene piston engine. The engine has a horizontal opposed layout, high power to weight ratio, fuel economy, and good adaptability to general aviation aircraft. The engine parameters are shown in Table 1.

Table 1.

Engine specifications.

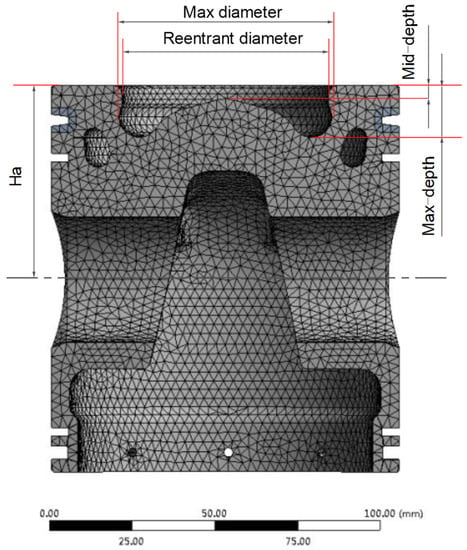

According to the analysis of the connotation of piston structural efficiency, three important components of the connotation were determined. The three connotations were calculated and analyzed and the numerical value was obtained. By comprehensively analyzing the operating conditions of the engine, the multiple design iteration of the piston was carried out, and two ideal piston design schemes were completed. According to the above three connotations, the design scheme optimizes the parameters that affect the above connotations. It mainly lies in the change of the distance from the center line of the piston pin to the piston crown and the size of the combustion chamber. Ha represents the distance between the center line of the piston pin and the piston crown, which affects the weight and stiffness of the piston. The smaller the value of Ha, the closer the piston pin approaches the piston crown, the larger the bearing area of the piston pin, and the lower the probability of deformation of the piston pin bore. The piston crown’s thickness was reduced, the piston mass was reduced, and the specific mass of the engine was improved. However, the stiffness decreased, which affected the maximum bearing capacity of the piston, and the connecting rod needed to be lengthened. The larger the value of Ha, the greater the piston stiffness and the higher the bearing capacity of the piston. However, the piston weight increased, the specific mass of the engine decreased, the stroke decreased, and the working volume of the engine decreased. The size of the combustion chamber has a great influence on the combustion efficiency and emissions of the engine. The three dimensional model of piston was meshed, as shown in Figure 2. According to the design manual [32], the key dimensions of the two piston design schemes obtained through multiple iterations are shown in Table 2.

Figure 2.

FE model.

Table 2.

Basic size of the piston.

The mesh convergence was analyzed, and the size of the mesh was reduced by half. Under the same conditions, it was found that the change of stress difference was within 3%, and the displacement was almost unchanged, so the current mesh convergence could be determined.

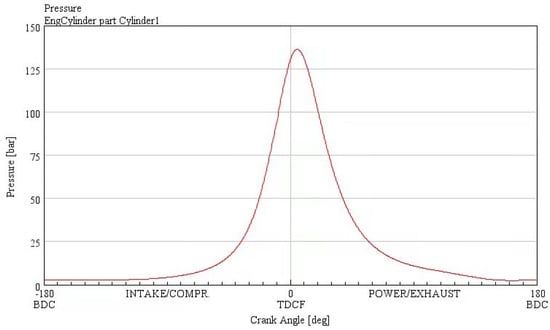

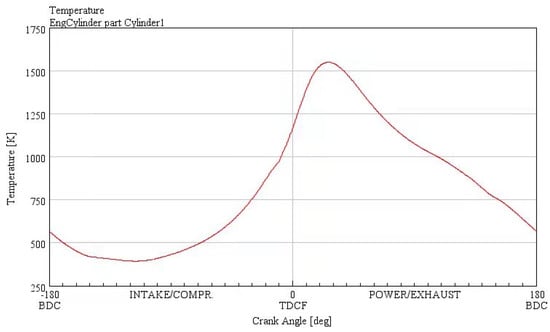

3.1. Maximum Bearing Capacity of the Piston

To calculate the bearing capacity of the piston, it is necessary to understand the boundary conditions of the piston. The combustion analyzer and the engine numerical model were used to obtain the explosion pressure curve and temperature field curve in the engine cylinder under adverse conditions, as shown in Figure 3 and Figure 4. The maximum explosion pressure in the cylinder was 139 bar, which appeared at 7 CA after the top dead center (TDC). The maximum temperature was 1590 K, which occurred at 20 CA after TDC, which was caused by the combustion characteristics of kerosene. The above two schemes were analyzed, applying the same temperature field and stress field, and the side stress of the primary and secondary thrust surfaces of the piston was considered, as well as the heat transfer coefficient and ambient temperature at different positions of the piston under the third kind of thermal boundary conditions. The analysis results are shown in Figure 5 and Figure 6.

Figure 3.

Explosion pressure curve in cylinder.

Figure 4.

Temperature curve in cylinder.

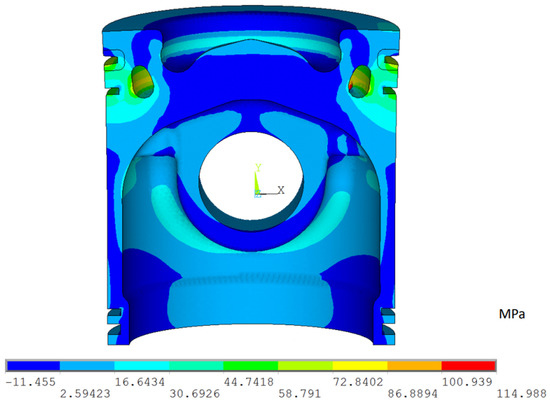

Figure 5.

Piston stress analysis under thermal–mechanical coupling in scheme 1.

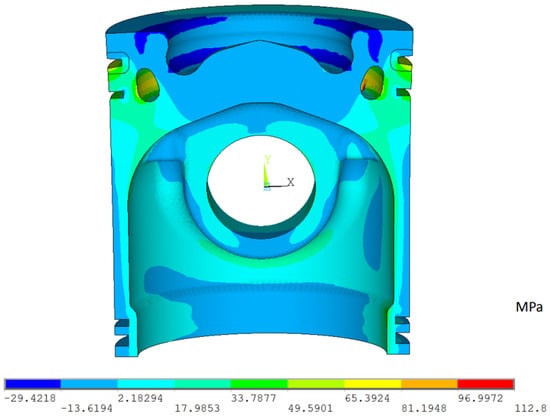

Figure 6.

Piston stress analysis under thermal–mechanical coupling in scheme 2.

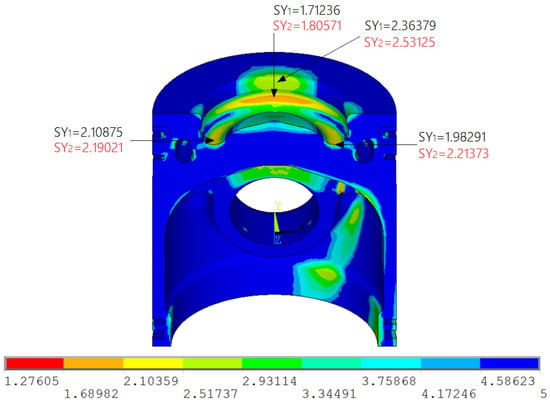

After analysis, the maximum stress of the piston was 114.98 MPa in scheme 1, which appeared in the internal lubricating oil passage. The stress of scheme 2 improved, and the maximum stress was 112.8 MPa, which is 2.1 MPa lower than that of scheme 1. At the same time, the temperature distribution of the piston was more uniform, the stress on the piston crown was smaller, and the stress on the skirt also improved. The maximum stress occurred in the lubricating oil passage inside the piston crown, which had no effect on the strength of the piston. During fatigue analysis, the calculation should be carried out according to the worst working condition. According to the operating parameters of the engine, the frequency was 180 Hz, the load and temperature curves in Figure 5 and Figure 6 were applied, and constraints were imposed according to the actual working state. The fatigue analysis of the key parts of the piston under the two schemes showed that the fatigue safety factor was the weakest at the bottom of the combustion chamber: the fatigue safety factor of scheme 1 was 1.71, and the fatigue safety factor of scheme 2 was 1.80, as is shown in Figure 7. The fatigue safety factor of other areas was high.

Figure 7.

Fatigue safety factor of key parts for the piston under the two schemes.

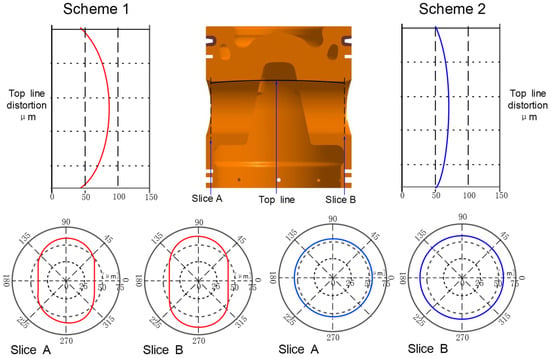

3.2. Deformation of Piston Pin Bore

According to the design objective of the engine, after the test and simulation calculation, the cylinder pressure of each cylinder reached 138 bar when reaching the rated power. For the same thermal–mechanical coupling analysis of the piston under the two schemes, the deformation calculation results of the piston pin hole are shown in Figure 8. According to the data in Figure 8, the pin bore deformation of scheme 1 reached 85 μm, and the pin bore deformation of scheme 2 was about 60 μm. This is because the distance between the piston pin bore and the piston crown in scheme 1 was greater than that in scheme 2, the force area of the piston pin decreased, the specific pressure on the upper surface of the piston pin hole increased, and the deformation under the same conditions will also increase. With the increase of the deformation of the piston pin bore, the cross-sections at both ends of the piston pin bore were also deformed. In scheme 1, the two ends are elliptical, while in scheme 2, the two ends are circular. The shape of the cross-sections at both ends also affected the lubrication between the piston pin and the pin bore. When the cross-sections at both ends were elliptical, it indicated that the pin hole was deformed greatly at this time, and extrusion occurred between the pin bore and the pin at the elliptical short half-axis. The lubrication conditions were poor, which aggravated the wear between the piston and the piston pin and reduced the service life of the piston components. When the cross-sections at both ends were circular, it indicated that the deformation in the piston pin bore tended to be uniform at this time. Within a reasonable control range, the lubrication between the piston and the piston pin was good, and the service life of the piston components was improved.

Figure 8.

Pin bore deformation under the two schemes.

3.3. Emission Performance

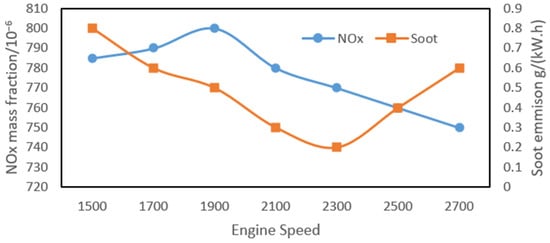

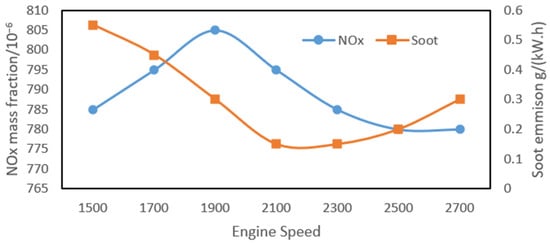

Emission is an inevitable problem of piston engines. The piston combustion chamber was studied under two schemes, mainly from the emissions generated by the combustion chamber, for comparative analysis. The engine uses aviation kerosene as fuel, and the main emissions are NOx and soot. The engine emissions under the two piston combustion chamber schemes are shown in Figure 9 and Figure 10.

Figure 9.

Emissions of scheme 1 at different speeds.

Figure 10.

Emissions of scheme 2 at different speeds.

From the data analysis results, it can be seen that the shape of the engine combustion chamber had a great impact on the engine emissions. Both the necking size and the ratio of diameter to depth affected the turbulent motion in the combustion chamber. From the above two groups of schemes, when GT-POWER was used to conduct simulation analysis, the temperature in the cylinder of scheme 2 was slightly higher than that of scheme 1, so the NOx mass fraction generated by scheme 2 was slightly higher than that of scheme 1. Soot production has a great relationship with the mixture concentration in the cylinder, and the mixture and temperature in the cylinder of scheme 1 easily caused the generation of soot. In the selection of emission data, the long-term operating conditions of the engine should be fully considered, and the emissions under the 2500 rpm parameter should be taken as the calculation data in combination with the long-term operating conditions of the engine in cruise status.

4. Calculation of Piston Structure Efficiency

Before calculating the structural efficiency of the piston, the calculation rule of the structural efficiency was first defined. The parameters of structural efficiency include multiple levels. The structural efficiency coefficient is a top-level parameter, called a coefficient item, which covers the maximum bearing capacity of the piston under thermal–mechanical coupling, the deformation of the piston pin hole, and the emission performance. These three items are called parameter items. Each parameter may contain several specific evaluation parameters, and the calculation standard is based on the numerical item of the best response selected for this item. The purpose of establishing the algorithm was to complete the calculation of the structural efficiency coefficient by integrating multi-level parameters with a unified operation method. In the calculation of the structural efficiency coefficient, the sub-parameters involved in the calculation should be normalized first to ensure that the parameter values of each level obtained are of comparative significance. The calculation method of the structural efficiency coefficient is as follows.

- (1)

- Each single-state sub-parameter was calculated and normalized to obtain the normalized value.

- (2)

- Using multiplication operation, the normalized values of single-state sub-parameters were synthesized to obtain full-state sub-parameters.

- (3)

- The multiplication operation was used to synthesize the full-state sub-parameters to obtain the corresponding parameter terms.

- (4)

- The structural efficiency of the piston can be obtained by adding and integrating all parameter items.

According to the above conditions, the above three connotations were normalized, and the calculation formula is:

where, is the calculated value of the simulation analysis, is the set target value, and the use of ±depends on the and numerical comparison [33]. For example, the maximum bearing capacity of the piston under thermal–mechanical coupling exceeded the set value, indicating that the piston has strong load resistance, and therefore the plus sign was used, and the normalized value showed an upward trend. On the other hand, when the deformation of the piston pin bore was higher than the set value, it indicated that the piston’s resistance to deformation was reduced, so the minus sign was used, and the normalized value showed a downward trend. When calculating if was much more than , then D = 0, and was the limit value in each example.

Maximum bearing capacity: The maximum bearing capacity of the piston is reflected in the fatigue safety factor. Under the same conditions, the higher the fatigue safety factor, the greater the bearing capacity of the piston. According to design experience, the piston combustion chamber requires the highest fatigue safety factor, at least 1.2, while other areas can reach 1.0. Therefore, for this piston, was 1.2. The normalized calculation of the two schemes is shown in Equation (4):

Deformation of piston pin bore: According to the conventional design criteria of the piston pin bore, the deformation of piston pin bore shall not exceed 80 μm during at least a 150 h durability test by FAA [34,35]. was 80, and the normalized calculation results of the two schemes are shown in Equation (5):

Emission performance: At present, emission standards are listed for aircraft for turbine engines [36], and there are no clear emission indicators for aircraft piston engines, but the European Union has determined that the indicators will be made clear in the near future. For this engine, it was proposed that the mass fraction of Nox under cruise condition is 760 × 10−6, and the soot emission design index is 0.18 g/(kW∙h). In the actual simulation analysis, both indicators exceeded the set value, indicating that the emissions of the two-stroke engine are unsatisfactory, and the emission still needs further improvements. The normalized calculation is shown in Equation (6):

According to the normalized calculation results of the above three parameters, the structural efficiency of the piston was calculated. The calculation results are shown in Table 3.

Table 3.

Comparison of piston structure efficiency under the two schemes.

According to the analysis of the above calculation results, the efficiency of the piston in scheme 2 was better than that in scheme 1, and it was determined that the structural efficiency of the piston in scheme 2 was 4.6% higher than in scheme 1. Although the emission performance index of scheme 1 was better than that of scheme 2, the overall index was still declining.

5. Experiment

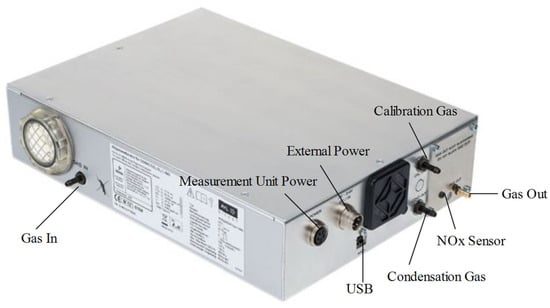

The piston of scheme 2 was used to assemble the engine, the engine performance and emission indicators were tested, and the propeller was used for testing according to the durability test requirements of FAA. On the engine universal characteristic test bench, the AVL combustion analyzer was connected. Through experimental verification, the cylinder pressure curve was basically consistent with the design simulation curve. The AVL di-test gas 1000 analyzer was used to monitor the combustion emissions of the engine, as shown in Figure 11.

Figure 11.

The measurement unit of the AVL di-test gas 1000 analyzer.

The AVL was connected to the computer to collect emissions at 2500 rpm. The experimental steps were as follows:

- It was installed on the engine test bench according to the AVL analyzer and smoke meter instructions.

- The engine was started, the oil temperature was allowed to reach 80 °C, and then emissions data were measured under different RPM.

- The sampling tube of the AVL di-test gas 1000 analyzer was inserted into the engine exhaust pipe and the data were read.

- After the measurement, the air pump should keep working for 10 min to clean the internal pipeline of the AVL di-test gas 1000 analyzer.

The emission value was recorded at 2500 rpm. The mass fraction of NOx was 772 × 10−6, and soot emission was 0.20 g/(kW∙h). The combustion emissions of the engine were tested, and the error between the test results and the simulation data of scheme 2 was within 3%, which verifies the accuracy of the simulation data in Figure 9 and Figure 10, and specific test results are shown in Table 4. After the durability test, as is shown in Figure 12 and Figure 13, the engine was disassembled, and it was checked that the deformation of the piston pin hole was within the allowable range, and that the piston had not suffered fatigue damage, which proves that the structural efficiency optimization design method was feasible.

Table 4.

Emission data under different operating conditions.

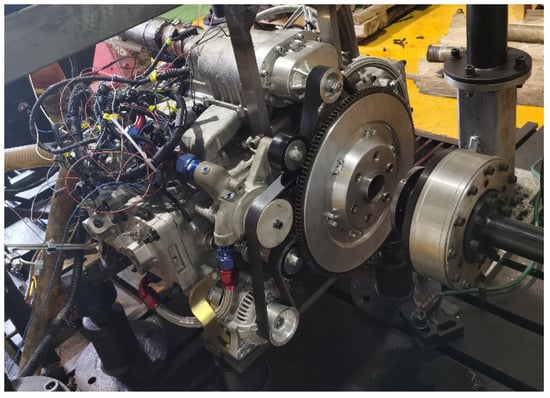

Figure 12.

Bench test.

Figure 13.

The piston of scheme 2.

6. Conclusions

The piston design schemes of aviation piston engines were compared by using the analysis method of structural efficiency, and the following conclusions were drawn:

- (1)

- Based on the role of the piston in engine performance, the connotation of piston structure efficiency was deeply analyzed. The parameter system of piston structure efficiency evaluation was established based on the maximum load of the piston under thermal–mechanical coupling, fatigue deformation of the piston pin bore under multiple fields, and the emission performance index. The direction of piston structure optimization was pointed out through the quantitative calculation and analysis of the evaluation parameters.

- (2)

- Based on the normalized formula of the evaluation parameters and the corresponding algorithm, the calculation method of the piston structure efficiency coefficient was established. This method makes the evaluation process clearer, and finally quantifies the evaluation results into a numerical value, which directly reflects the performance parameters affected by the piston and provides a reference for different structural design schemes from an overall perspective.

- (3)

- Through the calculation and analysis of the piston structure efficiency, the structural efficiency of the two schemes was compared. The results showed that the maximum bearing capacity index of the piston in scheme 1 was 2.3% lower than that in scheme 2, the piston pin hole deformation in scheme 1 was 33.2% lower than that in scheme 2, and the emission performance index in scheme 1 was 54% higher than that in scheme 2. After comprehensive consideration, the calculation results of scheme 2 was better compared to scheme 1. Subsequent tests have proven that the rationality of the scheme 2 design verifies that the proposed structural efficiency evaluation method has high applicability in piston design.

Author Contributions

Conceptualization, Z.P. and Q.H.; methodology, Z.P.; software, Z.P.; validation, Z.P., Q.H. and X.P.; formal analysis, X.P.; investigation, X.P.; resources, X.P.; data curation, X.P.; writing—original draft preparation, Z.P.; writing—review and editing, Q.H.; visualization, Z.P.; supervision, Q.H.; project administration, Q.H.; funding acquisition, Z.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by The Science and Technology Innovation Program of Hunan Province, grant number 2021wk2007, The Scientific Research Project of Hunan Provincial Education Department, grant number 21B0766, Talent Introduction Project of Changsha University, grant number SF1804.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing does not apply to this article.

Acknowledgments

Particular thanks to the Sunward Intelligent Equipment Co., Ltd. has provided a high-precision testing equipment. Thank Guo Yujia for assisting in the translation of a large number of references.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhao, Z.F.; Cui, H.S. Numerical investigation on combustion processes of an aircraft piston engine fueled with aviation kerosene and gasoline. Energy 2022, 239, 122264. [Google Scholar] [CrossRef]

- Pan, Z.; He, Q.; Zhang, X.; Zhang, D. Numerical simulation of 2-stroke diesel engine for light aircraft. IEEE Aerosp. Electron. Syst. Mag. 2015, 30, 4–10. [Google Scholar] [CrossRef]

- Kikuhara, K.; Koeser, P.S.; Tian, T. Effects of a cylinder liner microstructure on lubrication condition of a twin-land oil control ring and a piston skirt of an internal combustion engine. Tribol. Lett. 2022, 70, 6. [Google Scholar] [CrossRef]

- Zhongjian, P.; Yi, Z. Numerical investigation into high cycle fatigue of aero kerosene piston engine connecting rod. Eng. Fail. Anal. 2022, 120, 105028. [Google Scholar]

- Antonio, P.C.; Antonio, F.; Gianluca, T. Performance optimization of a two-stroke supercharged diesel engine for aircraft propulsion. Energy Convers. Manag. 2016, 122, 279–289. [Google Scholar]

- Enrico, M.; Giuseppe, C.; Carlo, A.R. Combustion system development of an opposed piston 2-stroke diesel engine. Energy Procedia 2017, 126, 1003–1010. [Google Scholar]

- Alberto, R.C.; Mattarelli, E.; Golovitchev, V. CFD analyses on 2-stroke high speed diesel engines. SAE Int. J. Engines 2011, 4, 2240. [Google Scholar]

- Mattarelli, E.; Paltrinieri, F.; Perini, F.; Rinaldini, C.A.; Wilksch, M. 2-Stroke Diesel Engine for Light Aircraft: IDI vs. DI Combustion Systems; SAE Technical Paper; SAE: Warrendale, PA, USA, 2010. [Google Scholar]

- Mattarelli, E.; Rinaldini, C.A.; Cantore, G.; Baldini, P. 2-Stroke Externally Scavenged Engines for Range Extender Applications; SAE Technical Paper; SAE: Warrendale, PA, USA, 2012. [Google Scholar]

- Carlucci, A.P.; Ficarella, A.; Laforgia, D.; Renna, A. Supercharging system behavior for high altitude operation of an aircraft 2-stroke Diesel engine. Energy Convers. Manag. 2015, 101, 470–480. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.T.; Yang, J.; Feng, R.H. Effects of anodic oxidation for combustion chamber on heat transfer of the piston in an aero-engine. Exp. Heat Transf. 2017, 30, 46–65. [Google Scholar] [CrossRef]

- Khan, S.; Panua, R.; Bose, P.K. Combined effects of piston bowl geometry and spray pattern on mixing, combustion and emissions of a diesel engine: A numerical approach. Fuel 2018, 225, 203–217. [Google Scholar] [CrossRef]

- Yang, H.; Wang, Y.; Wang, X.C.; Cen, Q.H.; Yu, X.H. Strengthening mechanism and thermal deformation behavior of Al-12Si/Fe piston composite. Mater. Res. Express 2020, 7, 016596. [Google Scholar] [CrossRef]

- Singh, R.C.; Chaudhary, R.; Pandey, R.K. Experimental studies for the role of piston rings’ face profiles on performance of a diesel engine fueled with diesel and jatropha based biodiesel. J. Sci. Ind. Res. 2012, 71, 57–62. [Google Scholar]

- Wu, J.; Duan, S.L.; Wei, L.D.; Yan, J. Strength analysis in piston crown of the marine diesel engine. J. Eng. Res. 2013, 1, 251–269. [Google Scholar]

- Hong, J.; Li, T.R.; Zheng, H.Q.; Ma, Y.H. Applications of structural efficiency assessment method on structural-mechanical characteristics integrated design in aero-engines. Chin. J. Aeronaut. 2020, 33, 1260–1271. [Google Scholar] [CrossRef]

- Jegley, D.C.; Wu, K.C.; Phelps, J.E.; McKenney, M.J.; Oremont, L. Structural efficiency of composite struts for aerospace applications. J. Spacecr. Rockets 2012, 49, 915–924. [Google Scholar] [CrossRef]

- Rao, X.; Sheng, C.X.; Guo, Z.W. A review of online condition monitoring and maintenance strategy for cylinder liner-piston rings of diesel engines. Mech. Syst. Signal Process. 2022, 165, 108385. [Google Scholar] [CrossRef]

- Wang, W.R.; Lu, Y.; Li, Z.Y. Simulations of engine knock flow field and wave-induced fatigue of a downsized gasoline engine. Int. J. Engine Res. 2021, 22, 554–568. [Google Scholar] [CrossRef]

- Deulgaonkar, V.R.; Ingolikar, N.; Borkar, A.; Ghute, S. Failure analysis of diesel engine piston in transport utility vehicles. Eng. Fail. Anal. 2021, 120, 105008. [Google Scholar] [CrossRef]

- Mechalikh, M.; Benhammou, A.; Zidane, I.; Bettahar, A. Study of piston thermo-elastic behavior under thermomechanical solicitations. Int. J. Automot. Mech. Eng. 2019, 16, 7287–7298. [Google Scholar] [CrossRef]

- Caldera, M.; Massone, J.M.; Martinez, R.A. Failure Analysis of a Damaged Direct Injection Diesel Engine Piston. J. Fail. Anal. Prev. 2017, 17, 979–988. [Google Scholar] [CrossRef]

- Karagoz, Z.B.A.; Demirtas, S.; Kaleli, H. Review of tribological behavior of graphene coatings on piston rings in engines. Ind. Lubr. Tribol. 2020, 72, 243–254. [Google Scholar] [CrossRef]

- Pan, Z.J.; He, Q.H. High cycle fatigue analysis for oil pan of piston aviation kerosene engine. Eng. Fail. Anal. 2015, 49, 104–112. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Liu, Y.Y.; Yu, S.W. Experimental study of piston ring-liner lubrication performance considering particles. J. Harbin Eng. Univ. 2021, 42, 833–838. (In Chinese) [Google Scholar]

- Storace, A.F. Turbine engine structural efficiency determination. In Proceedings of the 25th Joint Propulsion Conference, Monterey, CA, USA, 12–16 July 1989; AIAA: Reston, VA, USA, 1989. [Google Scholar]

- Svante, Y. Industry performance and structural efficiency measures: Solutions to problems in firm models. Eur. J. Oper. Res. 2000, 121, 164–174. [Google Scholar]

- Kumar, A.; Kumar, R.; Das, V. Assessing the structural efficiency and durability of burnt clay bricks incorporating fly ash and silica fume as additives. Constr. Build. Mater. 2021, 310, 125233. [Google Scholar] [CrossRef]

- Yu, P.C.; Zhang, D.Y.; Ma, Y.H. Dynamic modeling and vibration characteristics analysis of the aero-engine dual-rotor system with Fan blade out. Mech. Syst. Signal Process. 2018, 106, 158–175. [Google Scholar] [CrossRef]

- Hong, J.; Li, T.; Liang, Z.; Zhang, D.; Ma, Y. Research on Blade-Casing Rub-Impact Mechanism by Experiment and Simulation in Aeroengines. Shock. Vib. 2019, 2019, 3237960. [Google Scholar]

- Peng, G.; Li, C.; Zheng, H.Q.; Ma, Y.; Hong, J. Quantitative Analysis Method of Whole Aero-Engine Structural Design Based on Structural Efficiency. In Proceedings of the 10th International Conference on Rotor Dynamics, Rio de Janeiro, Brazil, 23–27 September 2018. [Google Scholar]

- John, B. Heywood. Internal Combustion Engine Fundamentals, 2nd ed.; McGraw-Hill: New York, NT, USA, 2018; pp. 868–932. [Google Scholar]

- Pan, Z.; He, Q.; Yang, J. Structural efficiency of block for aviation piston heavy fuel engine. Aircr. Eng. Aerosp. Technol. 2022, 94, 1327–1335. [Google Scholar]

- Pan, Z.; Guo, L. Failure analysis of the pin bore of the combined piston for the aero engine. Int. J. Aerosp. Eng. 2019, 2019, 7693403. [Google Scholar]

- Pan, z.; Deng, Y.; Cheng, L. Regular analysis of aero-diesel piston engine between combustion chamber size and emission. Int. J. Aerosp. Eng. 2019, 2019, 8690906. [Google Scholar]

- Perpignan, A.A.V.; Tomasello, S.G.; Rao, A.G. Evolution of Emission Species in an Aero-Engine Turbine Stator. Aerospace 2021, 8, 11. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).