1. Introduction

Distributed electric propulsion systems (DEP) represent a promising branch of aircraft development. Nowadays, much attention is given to the DEP, which is represented by electrical engines used to power the propellers or fans. Electrical motors are very convenient for this application because of the relatively small dimensions and ease of installation in various positions.

The first knowledge regarding aerodynamic causalities dates back to the roots of aviation, i.e., to the end of the 19th century [

1]. Otto Lilienthal was probably the first to discover a relation between the value of airspeed squared and aerodynamic forces. It can be deduced that a required lift force can be produced either by movement of an airplane creating sufficient relative freestream velocity, or the airplane can be stationary while the freestream is generated by the propellers. The combination of both ways is a principle that seeks to be beneficial in distributed propeller systems.

The basic idea of DEP divides the aircraft design into two separate modes: take-off/landing and cruise regime. Take-off and landing require high lift, while the cruise regime is typically optimized for low aerodynamic drag (in terms of maximum lift to drag ratio). The classical approach to aircraft design usually means that the wing area is deter-mined by a take-off or landing condition. High lift devices, such as slats and flaps, are used for the increase in the lift coefficient during the take-off and landing, and the size of the wing surface is determined by speed requirements in these regimes (e.g., regulation requirements or runway length). This results in a wing that is not preferably optimized for a cruise regime in which the airplane is travelling for most of the flight time. Distributed propulsion systems, discussed here as DEP, bring a completely different design approach. The shape of the wing is designed directly for the cruise regime. Lift force required for take-off and landing is assured by increased dynamic pressure generated by propellers positioned along the wing leading edge. High lift devices can be used for a further increase in the lift force. It is assumed that propellers used to increase dynamic pressure are folded during the cruise regime and do not create additional drag. This approach allows the use of wings with a high aspect ratio and low drag, in other terms a high lift to drag ratio. Optimization tools should be used in the design process in order to fully exploit the DEP potential.

The main motivation of this study was to use fast computational methods to determine the impact of the DEP system on fuel consumption, which has an effect on direct operational costs. In addition, by reducing fuel consumption it reduces greenhouse gas emissions which is an essential requirement in many aviation projects. At present, efforts are being made to create a new type of aircraft using DEP. One of the main motivations in the EU for these efforts is to meet the requirements of the European Green Deal and the FlightPath 2050 specifications [

2]. These challenges determine the necessary changes to be achieved in the EU in the aviation sector. The key objectives include reducing fuel consumption and emissions of the greenhouse gases CO

2 and NOx. Another objective is to allow travel within 4 h door–door within the EU. This directly predetermines the use of the commuter category on shorter distances of transport, allowing the use of airports with shorter runways, currently rarely or not used at all. Reducing fuel consumption and CO

2 emissions can contribute to a greater expansion of the commuter category for regular traffic.

High accuracy methods such as CFD are used for computations and optimization during the detailed design phase. However, there is still a need for a simple and fast computation procedure for the preliminary study. This paper presents such a method which can be used for the fast computation of the wing with DEP. It can be used for a basic aircraft and wing optimization. It should provide input data for the first iteration with more precise methods.

Recently, an electrical airplane was supposed to be a new addition to the traffic system [

3]. Use of electrical engines provides large benefits and offers a different kind of airplane design [

4]. The DEP concept has been developed over a long period of time by various countries and organizations. Among the more advanced projects is undoubtedly the Maxwell X-57, a follow-up to the previous NASA-led LEAP project. The main goal of the Maxwell X-57 project was to create a demonstrator based on the Tecnam P2006T to validate the DEP system technology of a fully electric two-seat aircraft with a range of 160 km at a design cruising speed of 280 km/h. The increase in cruise mode efficiency is expected to be 3.5–5 times due to the DEP. There are several EU projects that aim to solve the DEP system implementation. The ELICA project focuses on the MDO design of 19 passenger airplanes [

5], the project FutPrint50 solves individual systems of 50 passenger hybrid-electric aircraft such as thermal management, energy storage and aeroacoustics [

6], and the project IMOTHEP is aimed at the development of a hybrid–electric engine. Another effort to meet Flightpath 2050 requirements through the DEP system is the design of a 70-passenger regional airliner [

7], where the main focus is on optimizing the DEP electrical system for different flight configurations. The DEP system can also be used for the super STOL aircraft solution, where propellers located on the leading edge are used to maximize the dynamic pressure on the wing. Studies have indicated that the runway length for an initially twin-engine aircraft can be reduced using the DEP system by up to 80% [

8], by reaching the extreme values of the lift coefficient [

9].

The presented work is divided into three parts. The first part contains an analytical description of the use of the DEP system, the calculation of the induced velocity from the propellers, a description of the sizing of the DEP system, and an estimation of the masses of its individual parts. The second part contains both aerodynamic and strength calculations. Aerodynamic calculations were used to determine the total drag of the aircraft and fuel consumption, and strength calculations allow the weight of the calculated wing to be estimated. A flight envelope, composite for gust and maneuver envelopes, was used to determine aerodynamic loads and velocities for structural design under CS-23 regulation. After that a geometry of spars, ribs, and skin was designed with consideration of the buckling effect of the full aluminum material. The last part of work focuses on flight performance and a cost efficiency analysis of the calculated geometries.

This paper presents a study that analyses the potential benefits of introducing a DEP system into an existing aircraft. Replacement of the wing of the existing aircraft with a wing with the DEP system is considered and flight performance is compared, with fuselage and tail surfaces unchanged. Although this is a study, or rather a preliminary proposal, the impact of the DEP system is assessed in a complex way through flight performance. The calculations of aerodynamic characteristics are solved using a modified lifting line theory, the effect of the wing configuration on the sizing of the DEP system is assessed, and the weight of the wing structural elements is estimated. The aircraft selected for this study was a Pilatus PC-12 for nine passengers with an MTOW of 4740 kg and a cruise speed of 528 km/h.

3. Aerodynamic and Structural Aspects of the Wing

This chapter presents the computational procedures for determining the aerodynamic characteristics and mass of the wing. Considering that the work concerned a conceptual study, fast computational methods were used which provided results with adequate accuracy in a relatively short time.

3.1. Aerodynamic Characteristics—Lifting Line Theory

To calculate the aerodynamic characteristics of the wings, the lifting line theory was chosen. Its modified form allows the use of nonlinear profile characteristics to estimate relatively accurately the total resistance of the wing, which is composed of induced, frictional, and pressure parts [

26]. The basic idea of the equation describing the flow around a wing with a finite span is based on the Biot–Savart law. Ludwig Prandtl described the vortex scheme around the wing by means of horseshoe-shaped vortices [

27] and then defined the calculation of the induced velocity by these vortices by the following relation:

where

is the local increment in circulation,

is the local downwash velocity, and

is the spanwise position. For the purpose of determining the downwash velocity, the equation calculating the local lift force based on the local total angle of attack was used. Then the Kutta–Joukowski law was applied to calculate the local circulation:

The point is that the local lift coefficient in this form can be interpolated from the profile characteristics and thus the downwash velocity or lift distribution can be accurately calculated. In addition, once the lift distribution calculation is converged, it is possible to calculate both the induced wing drag, which is a function of lift and downwash velocity, and to interpolate the profile drag, which contains both friction and pressure components. Thus, the wing aerodynamic polar can be calculated relatively accurately [

26].

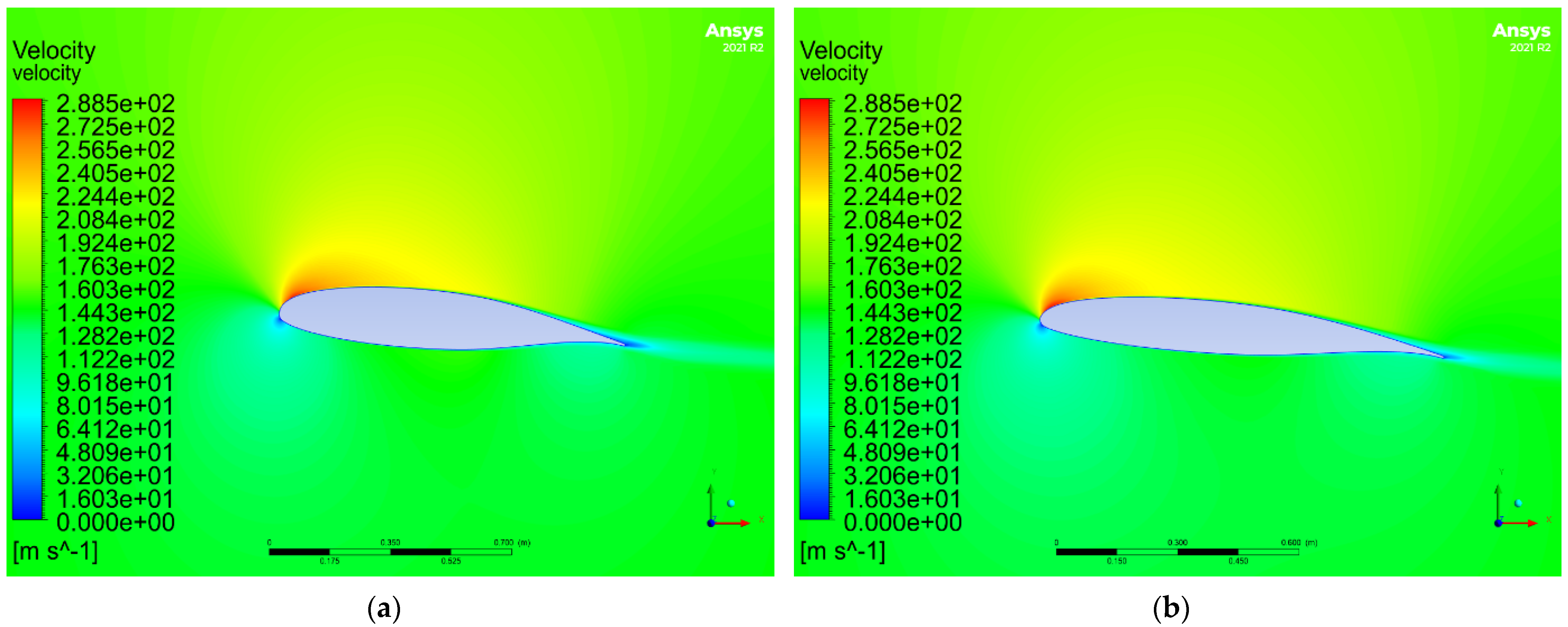

In this work, the software ANSYS Fluent was used and the drag polar and pitching moment coefficient curves were obtained for GA(W)-1 and GA(W)-2 airfoils. Two-dimensional airfoil bodies were imported into an Ansys DesignModeller and were used for a 2D CFD analysis. The domain used was rectangular with an overall height of 30c and width of 35c, where c is the airfoil chord. Mesh was refined in the vicinity of the profile and also in the wake behind the airfoil. Prismatic elements (inflation layer) were used to cover the boundary layer, with first cell thickness 𝑡 = 2.5 × 10−4 determined by the target 𝑦+ ≈ 30–40. All state variables used a 2nd order discretization, and the SST k-ω model of turbulence was chosen. Mesh size was globally refined to about 66% of the original calculation for the base AOA and it was shown that the result was mesh-independent. Angle of attack was varied as a parameter and the coefficients of the lift, drag, and pitching moment were gathered up to stall angle. These were then used as profile characteristic inputs to the lifting-line theory method.

The profile characteristics were calculated for the Reynolds number corresponding to the cruise regime of the original geometry. The GA(W)-1 and GA(W)-2 profiles were used to maintain the relative thickness of the original wing profiles. As the wing area decreased at a constant span, the root and tip chords changed, and hence, the Reynolds number. A change in the Reynolds number in this regime does not imply a significant change in drag or lift coefficient; therefore, a profile polar corresponding to the cruise regime of the original geometry was used in this study. The effect of the change in Reynolds number on the aerodynamic characteristics was validated using the lifting line theory and CFD calculations for significantly tapered wings, for example with an elliptical planform [

26].

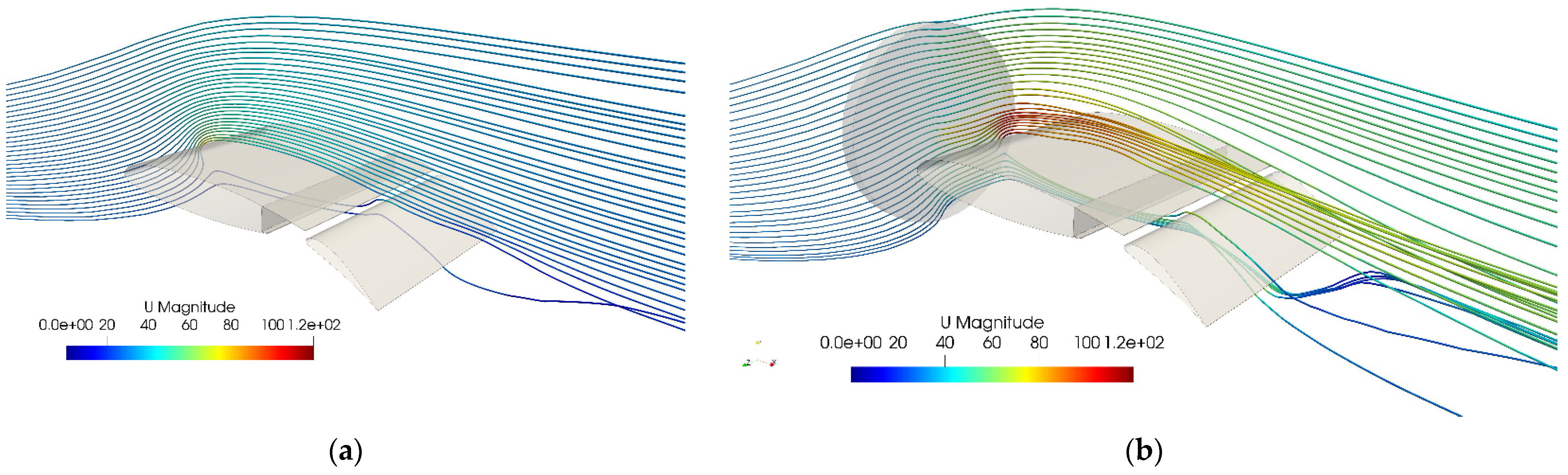

Figure 7 shows the velocity field solution for 5° angle of attack for the two profiles investigated.

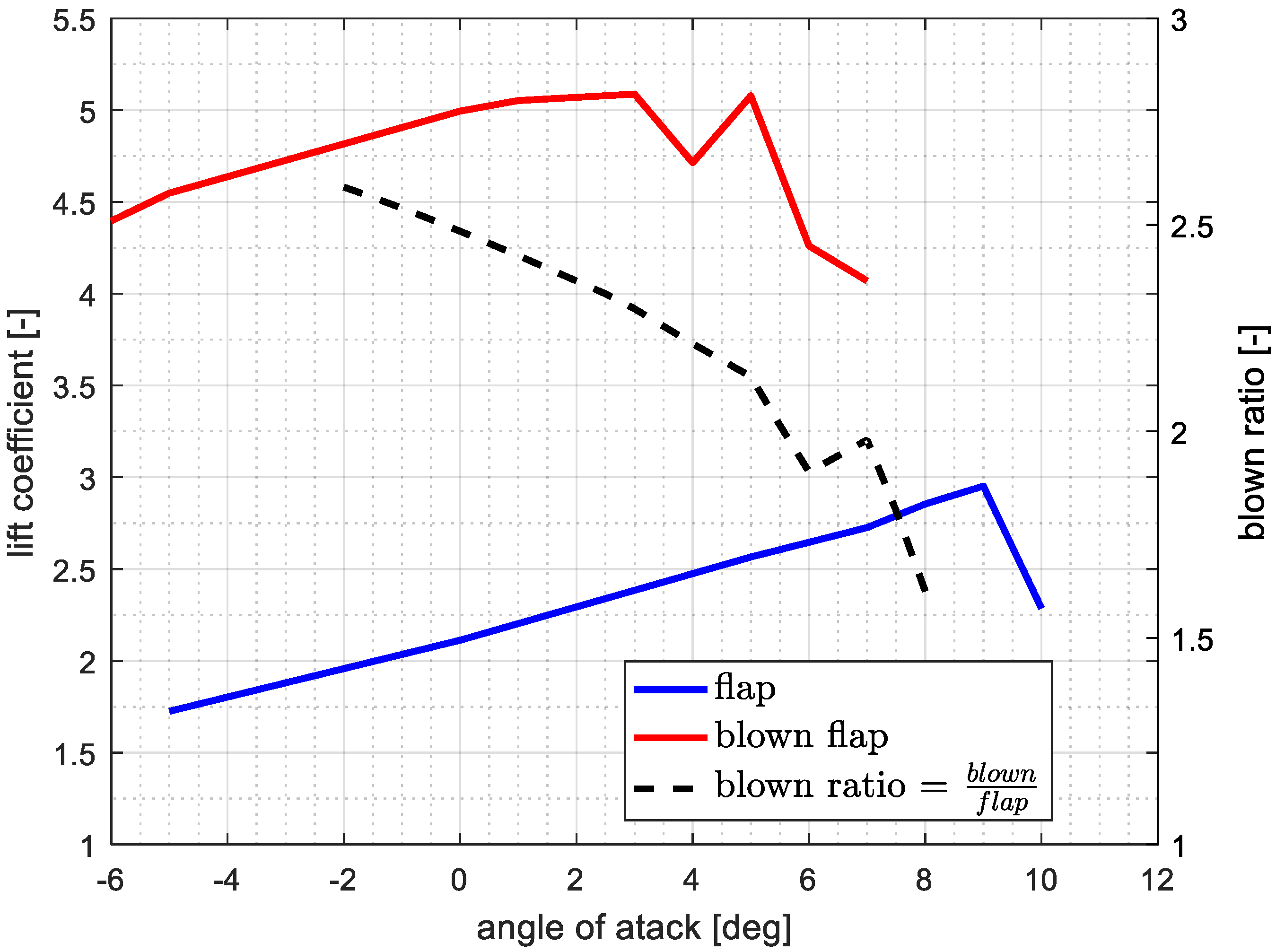

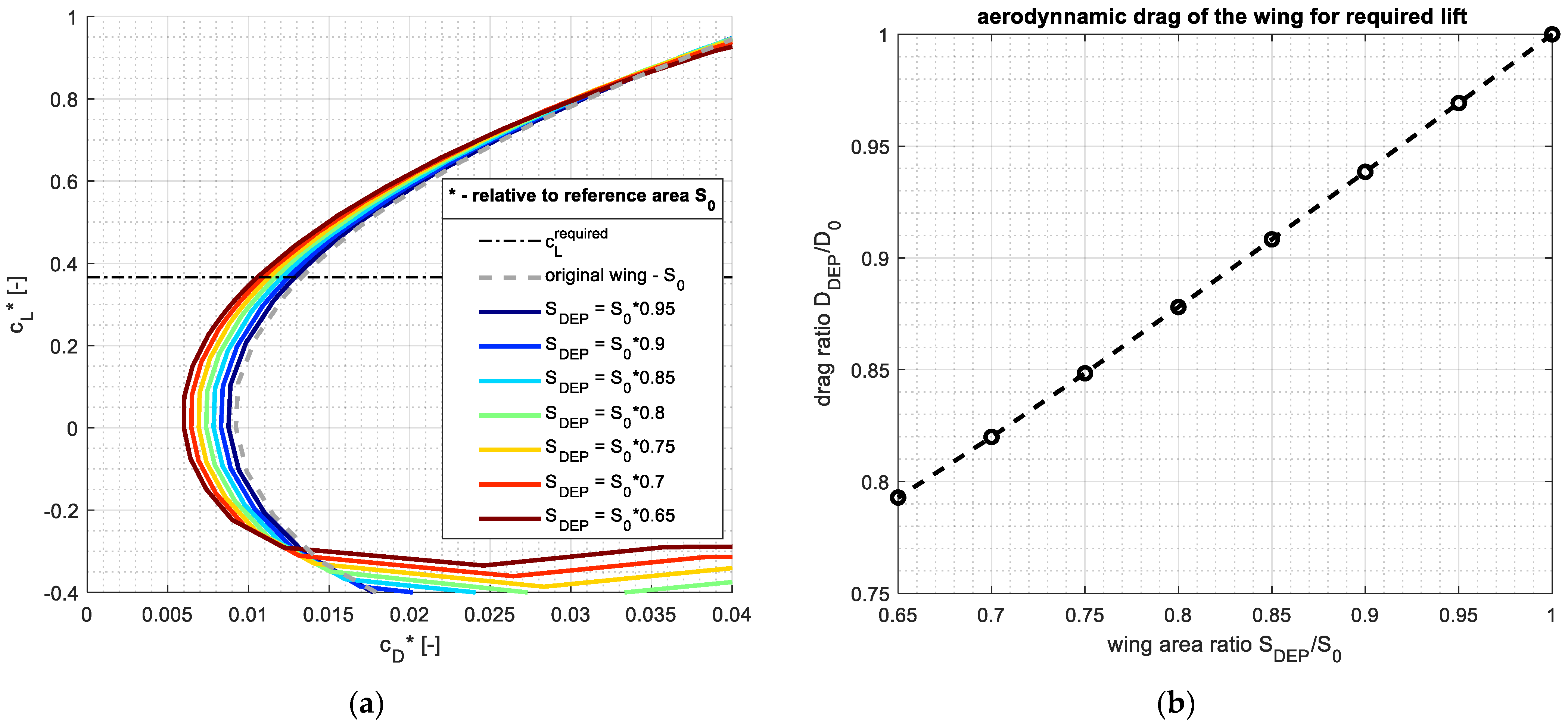

The results of the wing aerodynamic performance calculations using the lifting line theory are shown in

Figure 8. The investigated wing geometries had the same span as the original wing; they differed from each other by having reduced chords in defined proportions. This reduced the total area of the wing.

Figure 8a shows that the aerodynamic drag coefficient decreased with decreasing the wing area. The lift and drag coefficients are shown here relative to the area of the original wing. The dash dotted line shows the amount of lift required for cruise mode. The values of aerodynamic drag interpolated for the required lift as a function of wing area are shown in

Figure 8b. From the results it can be deduced that the drag of a wing with 65% of the area of the original wing had approximately 20% less drag.

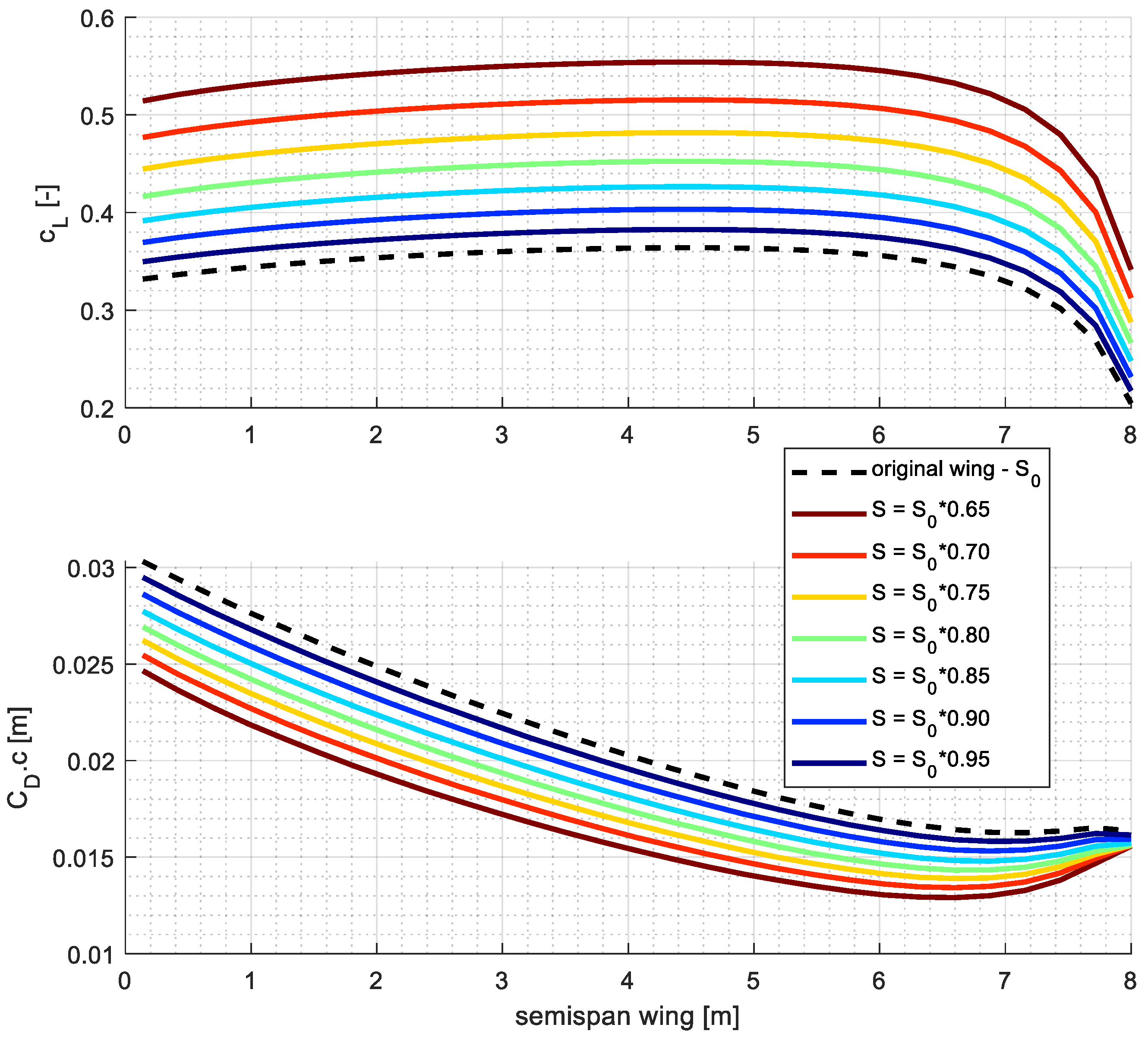

Figure 9 shows the distribution of the lift coefficient and drag force both for the desired lift in cruise mode. Compared to the previous figure, where the coefficients were relative to the original area, it can be seen here that the wing needed higher values of lift coefficients as the area decreased to achieve the required force. The distribution of the drag force shows that this was achieved with a higher aerodynamic efficiency, i.e., a lower drag.

3.2. Wing Structural Design

Based on the calculation of the aerodynamic characteristics of the wings, the design of the wing structure according to the requirements of CS-23 was performed [

28]. The result of the wing design was its weight, which is the last piece for comparing flight performance.

The wing design according to the requirements can be divided into two parts. In the first part, the envelope in which the wing must transfer aerodynamic and mass loads is determined. In the second part, the dimensions of the individual control parts are calculated to meet the required loads [

29].

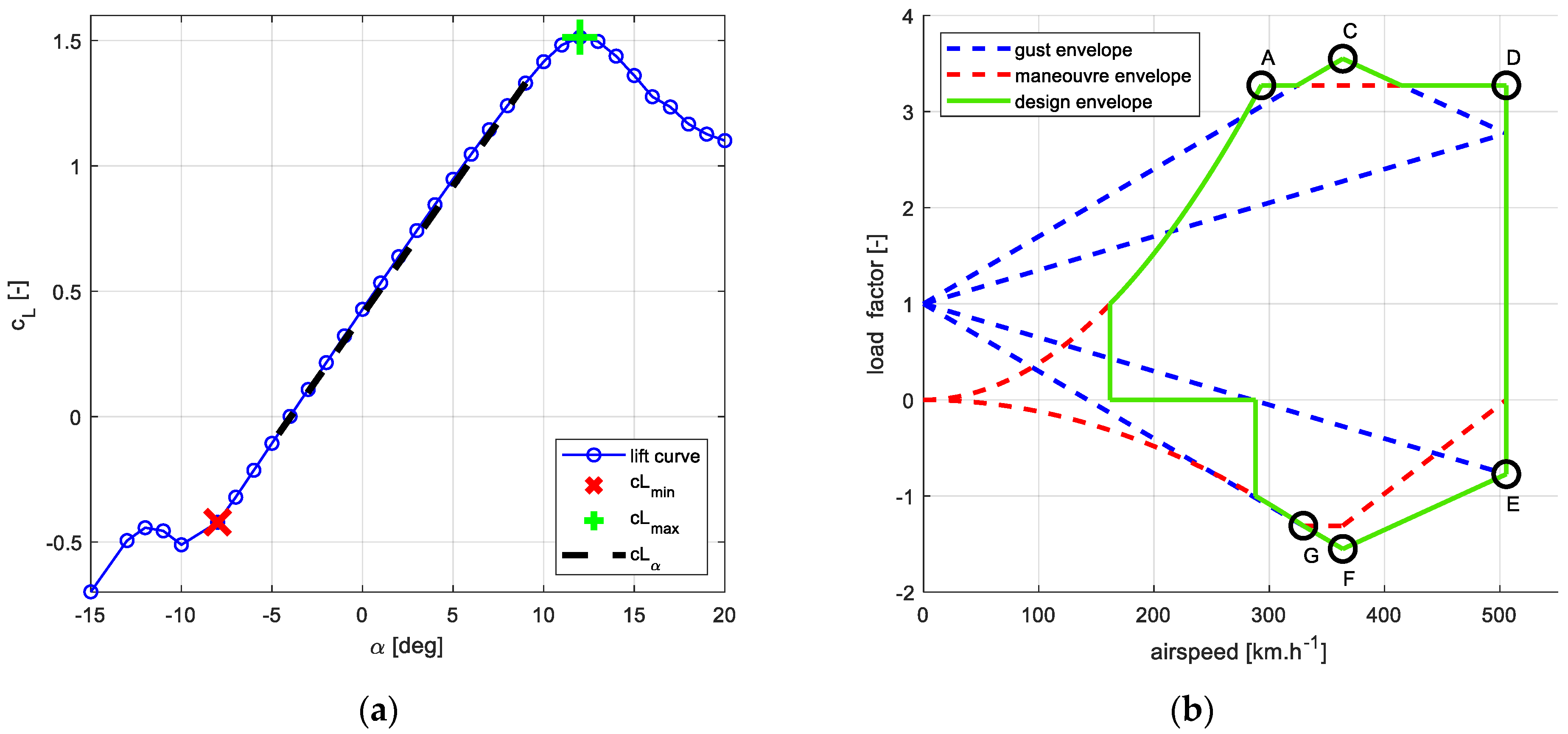

The flight envelope was created in accordance with CS 23 regulations, specifically CS 23.333. The design flight envelope was created from the limits of the maneuvering and gust envelope. For the purpose of strength calculations, the values of velocities and loads at each point of the envelope (A–F) were determined. These were mainly design cruising speed, design dive speed, design maneuvering speed, design speed for maximum gust intensity, maneuvering load factors, and gust load factors. The determination of the flight envelope parameters was made from the lifting line method results.

Figure 10a shows the wing lift curve from which the lift curve pitch (dashed line) and stall speeds based on the maximum and minimum lift coefficients were determined. The final shape of the design envelope is shown in

Figure 10b.

In the second part of the wing weight calculation, the structural design was performed to cover the entire design envelope. The first step was to determine the loads from the forces and moments on the wing for the specified envelope points. From the distribution of aerodynamic forces and moments calculated using the lifting line theory, the shear forces, the bending, and the torque moment were calculated at selected points of the envelope. The effect of inertial loads was considered. From the calculated operational loads, those with the highest value were selected and multiplied by a safety factor of 1.5 to determine the numerical load (CS 23.303 criteria).

The last step is the dimensioning of the individual structural elements of the wing. In this case, the identical structural arrangement was used for all the wings, a double spar wing with two cells where the general geometry and equation for shear flow calculation was considered [

26]. The thickness of the structural elements was not designed to the strength limit of the chosen material, but its stability according to the direction of stress was considered. Specifically, the flanges were checked for compressive stability [

30] and the spars with plates were checked for shear stability of the plates [

31,

32].

The structural design of the wing procedure can be divided into three basic points:

The distribution of ribs along the span;

Design of the flanges transmitting the bending moment and calculation of the elastic axis;

The design of the spar and cover that transmit the combination of the torque and the shear force, where the torque is equal to the sum of the fluxes of the individual cells multiplied by their area and the shear force of the individual spar is divided according to the ratios of the bending stiffnesses.

The total weight was calculated by summing the volumes of all designed parts and multiplying this by the density of the selected material. This was aluminium alloy AW-2024 with a density of 2770 [kg.m−3].

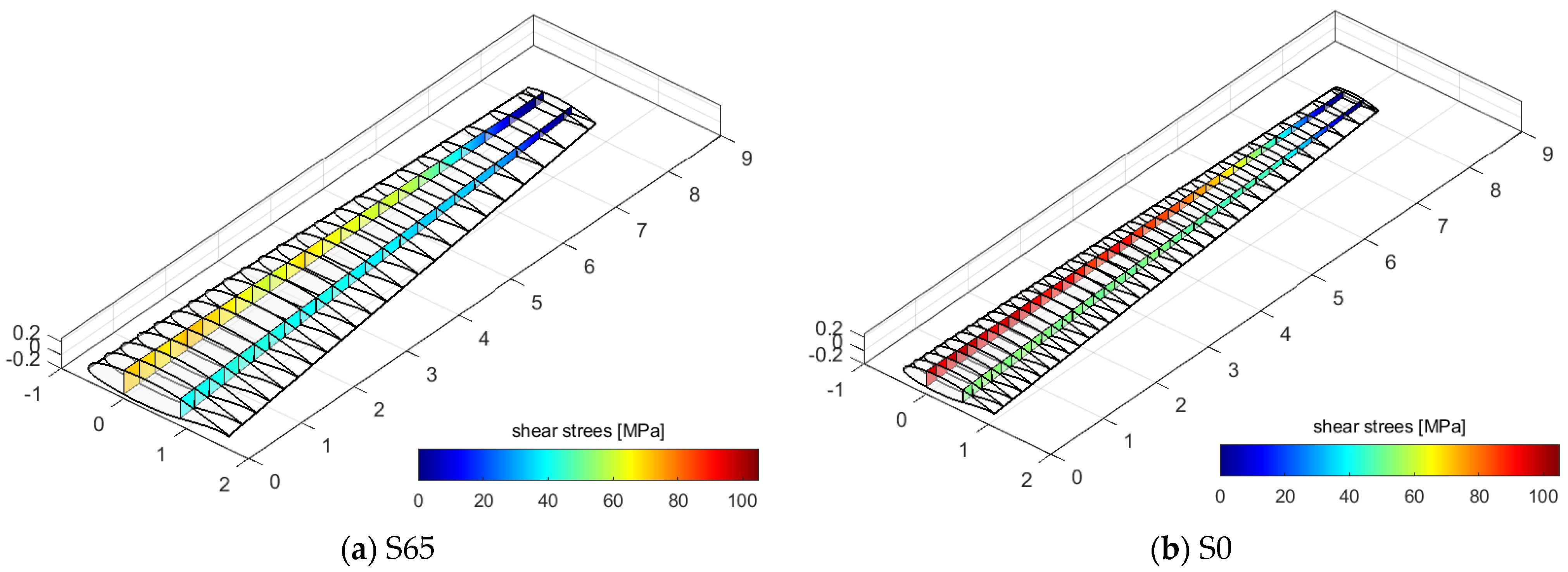

Figure 11 shows the shear force distribution for the two calculated wings, (a) is the original wing and (b) is the wing reduced to 65% of the original area. It can be seen that when the area of the wing, or its construction height, was reduced, there was an increase in the shear force that the spar must carry.

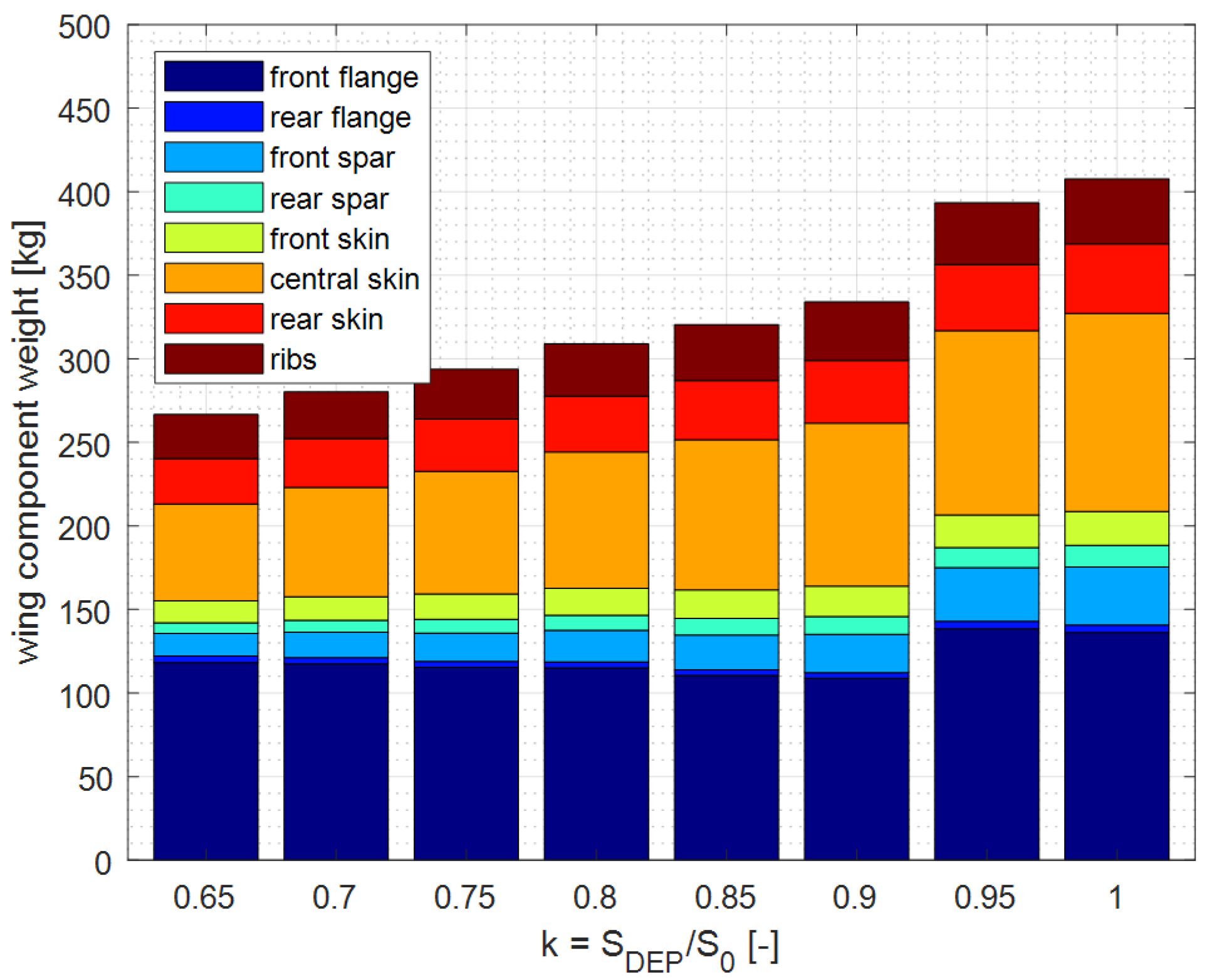

Figure 12 then shows a comparison of the weights of the wing parts for the calculated wing area ratios. There was a noticeable decrease in the weight of the entire wing cover while the spars and flanges had an almost constant weight. It follows that the change in weight is directly related to the wing area.

This completes the preliminary calculation of the mass of the basic structural parts of the wing. It did not take into account the high-lift devices, fuel tank, or landing gear. The calculation also did not consider the effect of the weight of the DEP system such as engines, propellers, controllers, and cables. However, this was on the safe side of the calculation because the wing was aerodynamically stressed for lift and the weight of the wing reduced this load. In addition, the sum of the masses of the calculated parts, the fuel mass, the wing mass, and the DEP system, was almost equal to the original solution.

4. Flight Performance

The main objective of this work was to investigate how an aircraft with a distributed propulsion wing can reduce fuel consumption compared to an aircraft with a conventionally designed wing. For this purpose, the flight performance of the aircraft was calculated for all wings under investigation.

A simulated typical flight mission consists of three parts: climb, cruise mode, and descent. The climb was calculated for a defined climb rate

and cruise speed

. In the cruise regime, the fuel consumption was determined by calculating the required lift for a given mass and dynamic pressure, and then interpolating the wing drag to calculate the required power for the entire aircraft. Here, the parasitic drag coefficient

of the fuselage and tail surfaces was considered as discussed in the previous section. In addition, for distributed propeller wings, the drag of the pylons and nacelles

for distributed engine was considered, which, similar to the fuselage drag, was calculated in the openVSP program. The descent mode was considered such that the aircraft was gliding at a maximum glide ratio and the engine was at an idle mode, i.e., zero fuel consumption. The whole calculation was iterative and took into account the fuel loss on the total weight of the aircraft [

26]. The required thrust of the aircraft in climb and cruise regime was further increased by the propeller efficiency and then the required power was calculated. For a steady flight, fuel consumption was determined from the specific fuel consumption of the turbine engine

. The flight performance variables are listed in

Table 4.

Moreover, a study was carried out on the effect of range of the flight on the change of fuel consumption and its possible percentage savings. Simulations of flight over shorter distances were carried out. The cruise speed, flight altitude, and climb rate were considered the same for all missions. The only parameter that varied for different ranges was the initial weight. For the maximum range, i.e., 3417 km, a fuel consumption of approximately 1000 kg was calculated. If we consider a range of 2000 km, the consumption will be approximately half of the consumption at original range and the initial weight of the aircraft is reduced by this difference, thus simulating the real case of a flight mission. Alternate fuel was not considered in this study.

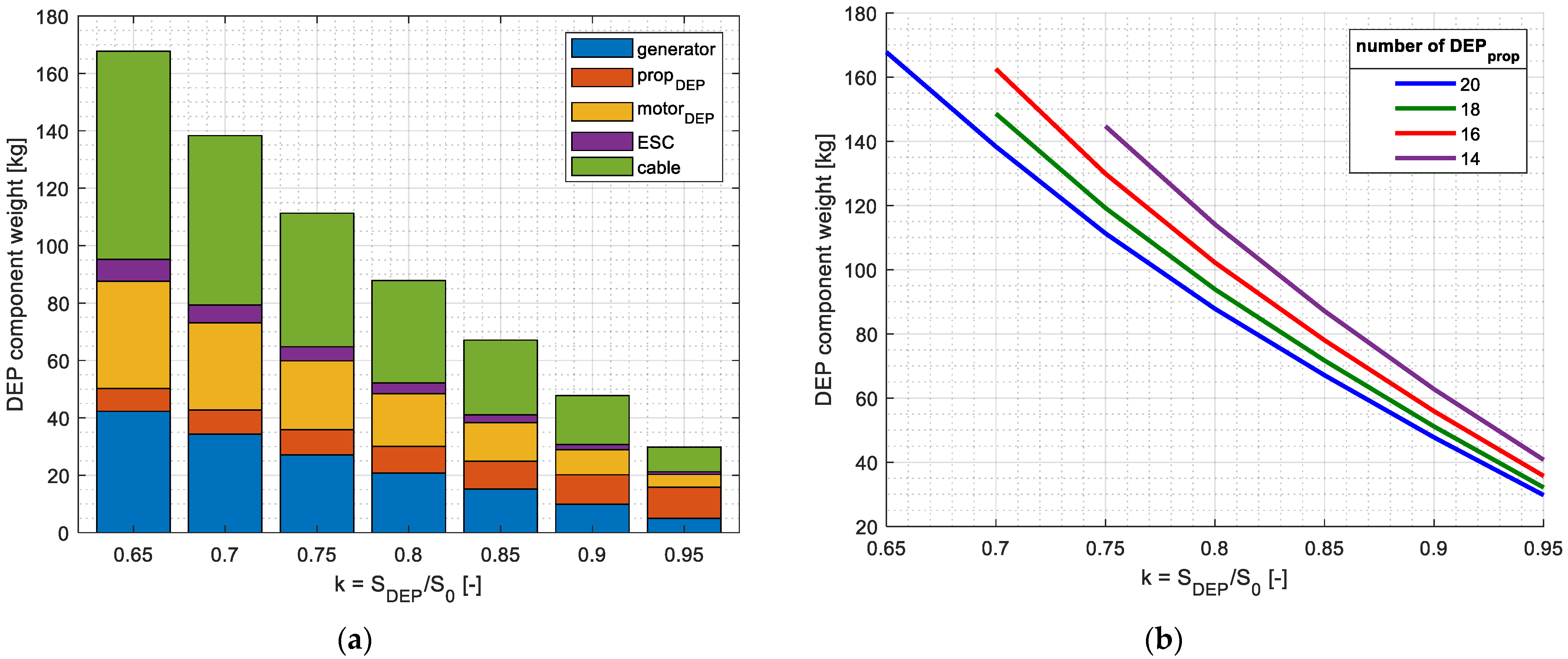

The results of the aircraft mission simulation for the above declared conditions, including the calculated key parameters of all wing variants, are presented in

Table 5. The items listed are the wing area ratio relative to the original wing

k, the wing area

S, the wing root

croot and tip

ctip chord, the aerodynamic drag of the aircraft

D, the wing weight

mWing, the weight of the DEP system

mDEP, and the weight of fuel consumed

mFuel.

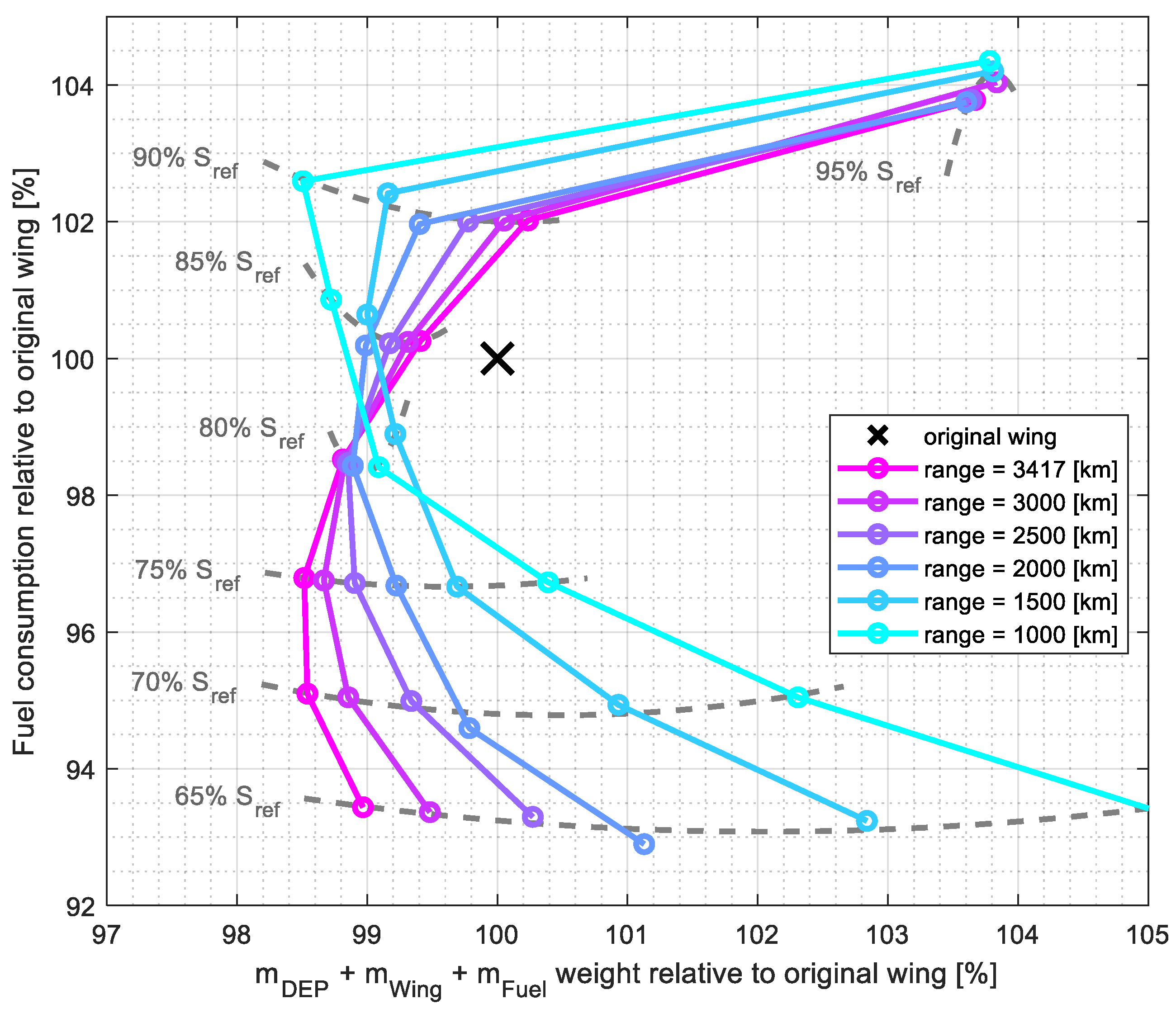

The results of such simulations are shown in

Figure 13. On the horizontal axis are plotted the values of the sum of the weights that are calculated in the simulation, i.e., the weight of the DEP system, the weight of the wing, and the weight of the fuel consumed. This sum of weights was relative to the original solution, to the aircraft with the original wing size without the DEP system. The vertical axis shows the percentage difference in fuel consumption between the aircraft with DEP and the original aircraft. The individual-colored curves correspond to a specific flight range, the black cross with the value 100/100 corresponds to the reference aircraft without DEP, and the dashed curves connect the solutions for the selected wing area. From the chart the fuel economy can be read directly together with total weight for a given wing size and range.

Note that all solutions with no less than 85% wing area achieved no fuel savings compared to the reference aircraft. This is due to the fact that in these wings the benefit of lower wing drag is not outweighed by the increase in drag due to the DEP system’s nacelles . On the other hand, the wing with the smallest area had the lowest fuel consumption, but at shorter ranges the weight of the calculated parts increased compared to the reference aircraft. This is due to the fact that the small wing has a large weight of the DEP system and at short ranges the fuel economy is not as great which implies that the weight of the DEP system becomes the more dominant part. Therefore, the percentage increase in weight relative to the reference aircraft is the fastest with shorter range for the smallest wing.

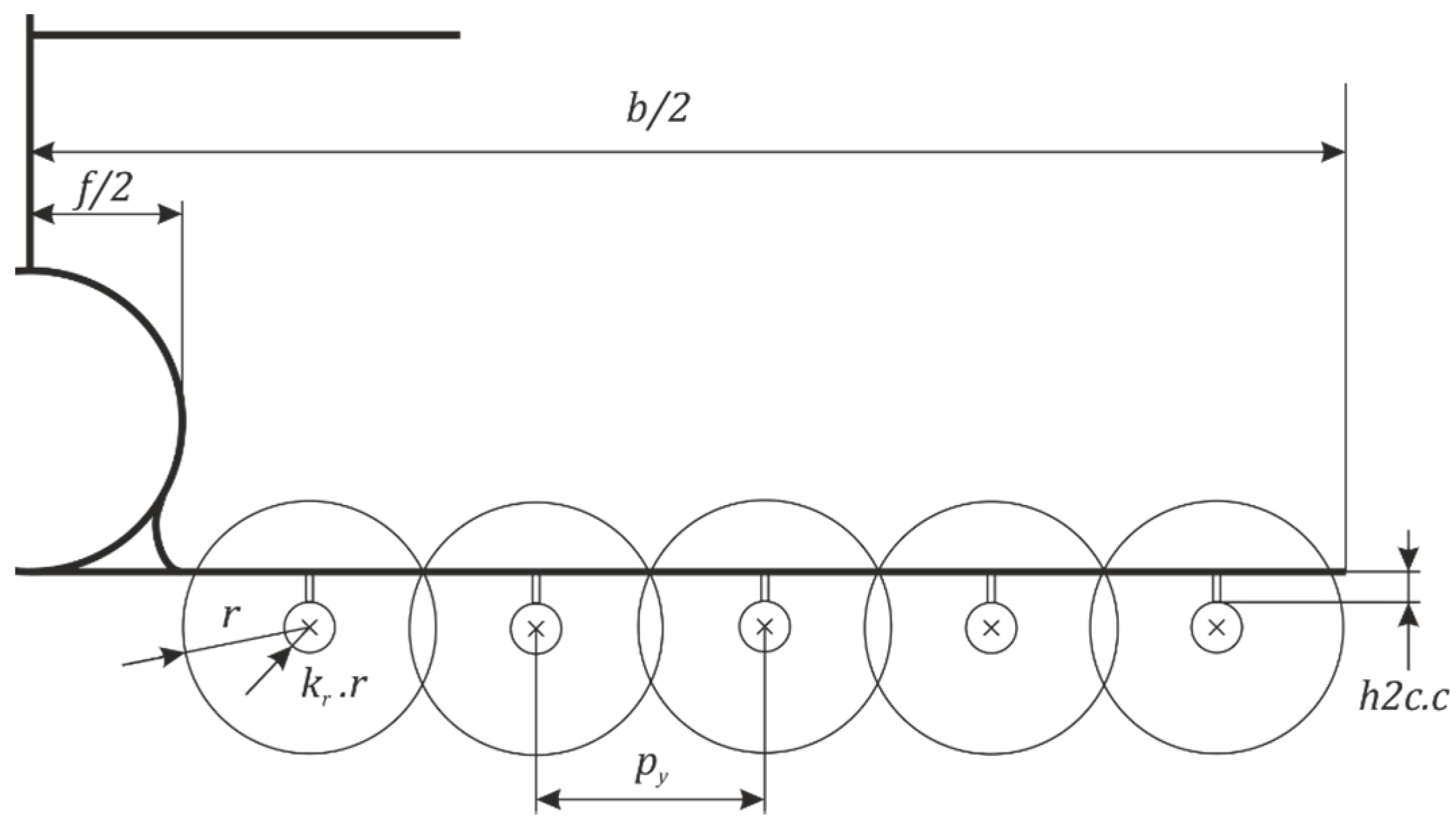

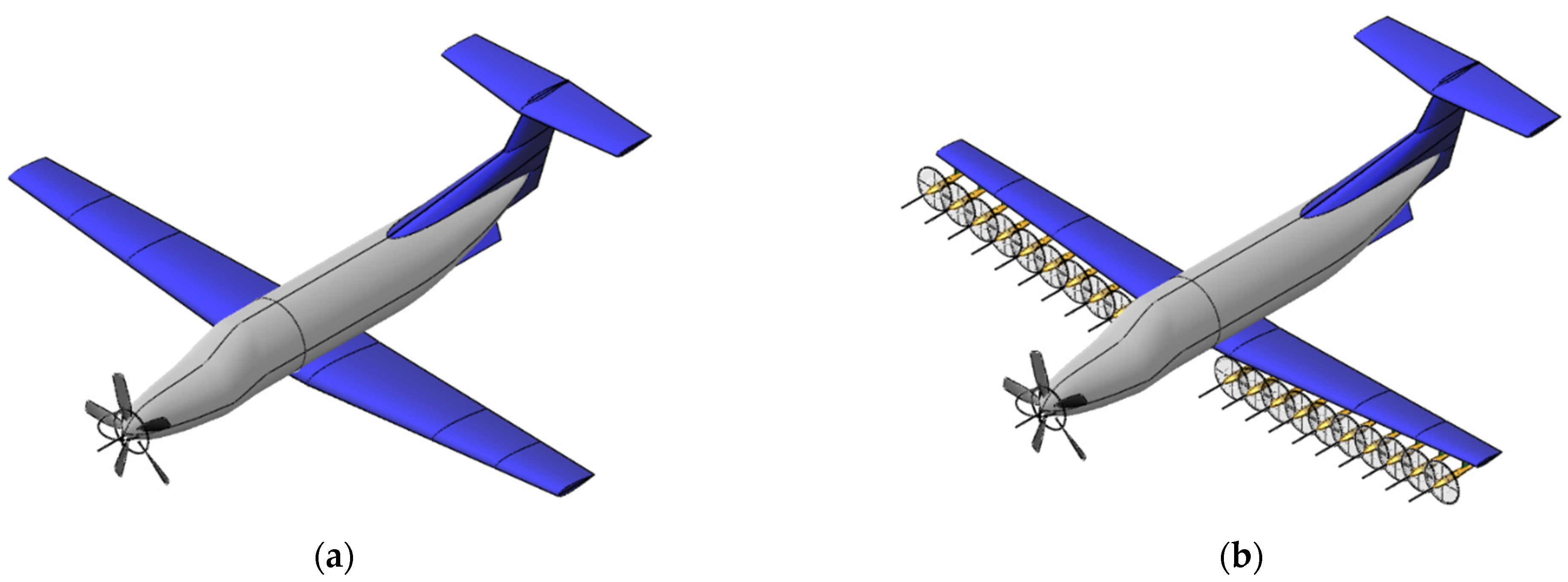

Figure 14 shows the geometry of the reference airplane with the existing wing area and the airplane with the wing area reduced to 65% of the original area. Distributed propellers with overlap were placed so that the leading edge of the wing was completely covered.

5. Conclusions

Current trends in aerospace research and development are primarily motivated by reducing fuel consumption and thus greenhouse gas emissions. This study demonstrated how distributed propulsion can help these efforts. This is a preliminary design that took into account the effect of wing size on the aerodynamic characteristics and structural design of the wing, and also considered the weight calculation of the electrical parts of the DEP system. From the flight performance calculation, it can be observed that an aircraft with DEP and a wing area reduced to 65% relative to the reference wing can reduce fuel consumption by about 6%. Note that this is a relatively quick design method with low fidelity and for further steps it would be necessary to perform calculations using more accurate methods.

One other option to increase aerodynamic efficiency and thus reduce fuel consumption is to use a wing-tip propeller to reduce the effect of induced drag. The calculation of total fuel consumption is also significantly affected by the drag of the engine nacelles. These are calculated using an empirical method and it would be advisable to perform at least a more accurate CFD calculation, ideally optimizing the shape and position of the nacelles. Further improvements in flight performance could be achieved by using high-lift propellers for the DEP system, thus reducing the required power while maintaining the required propeller induced velocity. The voltage value of the electrical system is another factor that significantly affects the overall weight of the DEP system. Appropriate selection of motors or inclusion of DC/DC converters could lead to a noticeable reduction in cable weight. On the other hand, the DEP system does not include the cooling of power losses dissipated as heat. This is because the use of DEP is assumed to be on the order of units of minutes. A detailed study of the electrical parts could identify the need for a thermal management system and thus increase the predicted mass. In spite of all these problems, it can be concluded that DEP is a promising direction of development in aeronautics that will make it possible, using available technologies, to reduce fuel consumption.