Experimental Study on the Adhesion Strength of the Frozen Ice for Aircraft Moving Parts

Abstract

1. Introduction

2. Test Design of the Adhesion Strength of the Frozen Ice

2.1. Experiment Design

2.2. Test Equipment

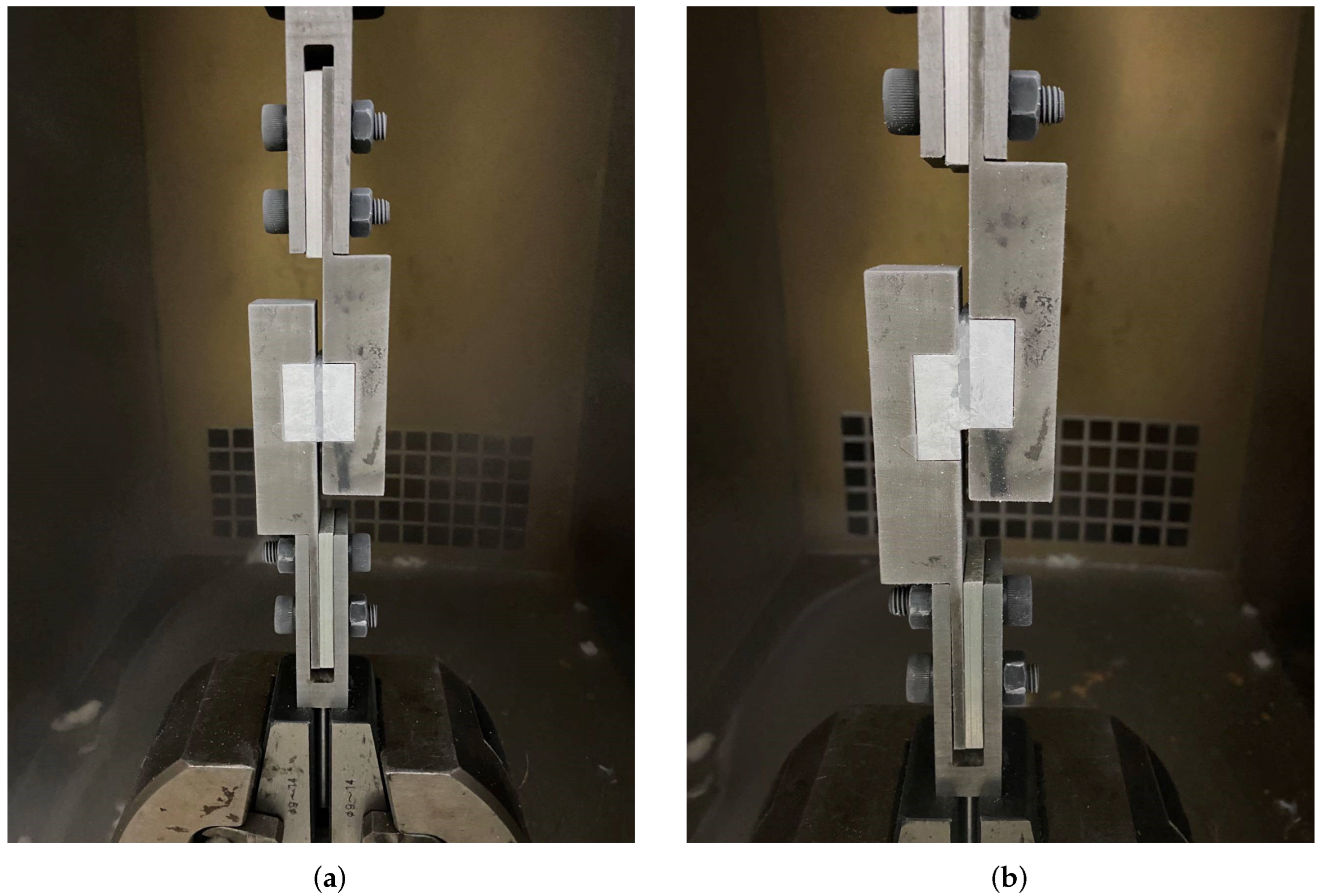

2.3. Implementation Method of the Test

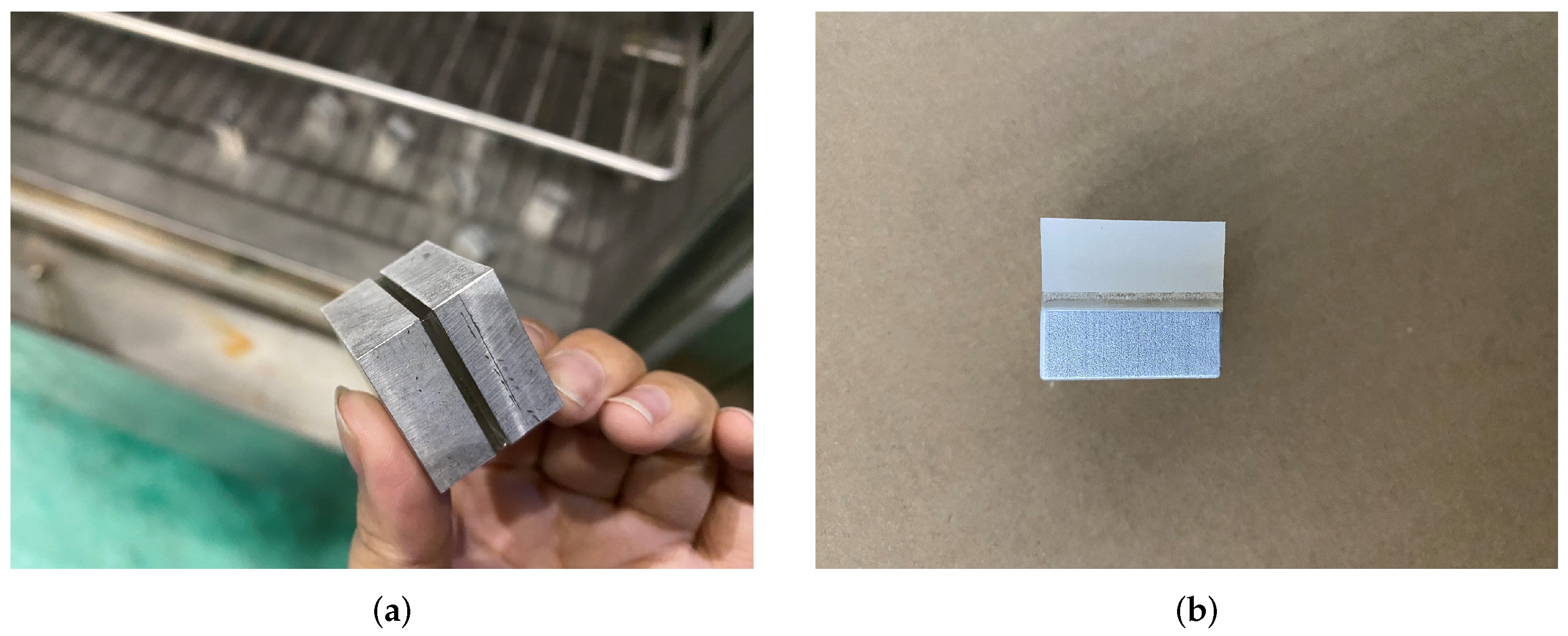

2.3.1. Test Piece Design and Production Principle

2.3.2. Method of Specimen Icing and Thermal Insulation

2.4. Process of the Test Operation

3. Key Technique for the Adhesion Strength Test of Frozen Ice

4. Results and Analysis of the Adhesion Strength Test of Frozen Ice

4.1. The Result of the Shear Destruction of Frozen Ice

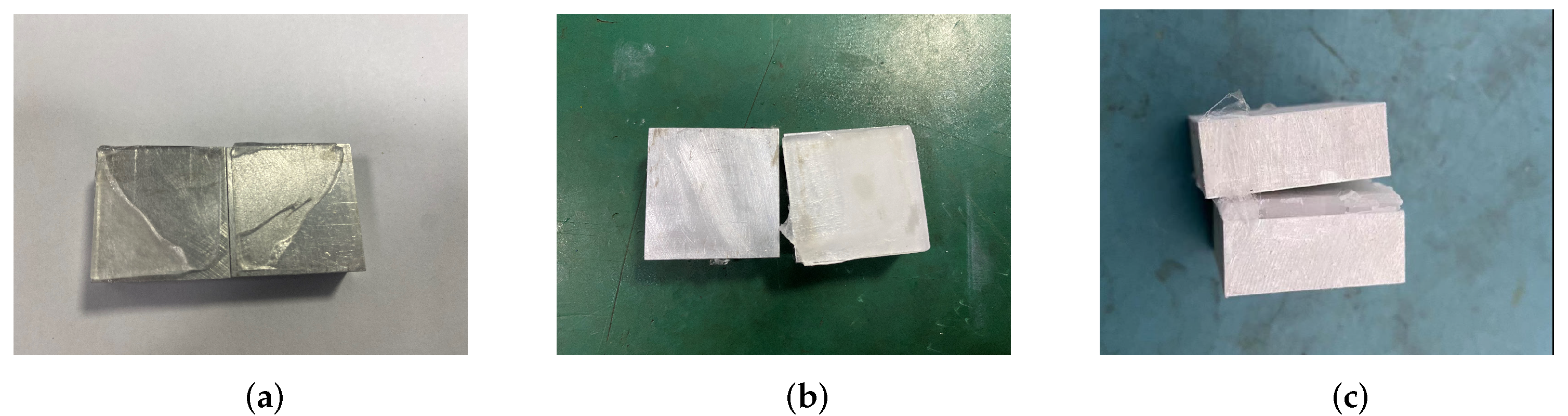

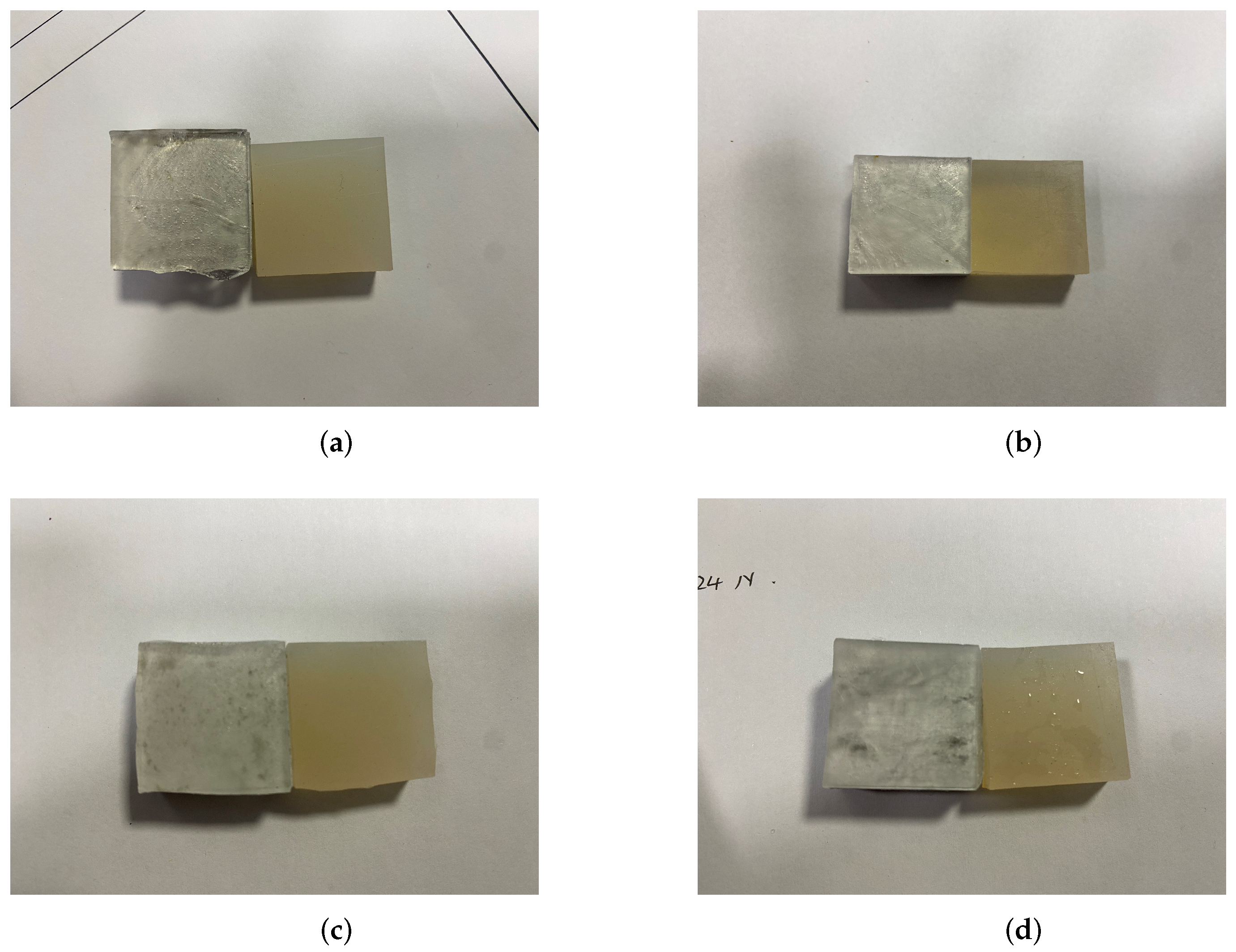

4.1.1. Shear-Section Situation of the Ice Layer

4.1.2. Ice-Breaking Load of Frozen Ice of Aviation Material

4.2. Analysis of the Shear Adhesion Strength of Frozen Ice

4.3. Significance Analysis of the Influencing Factors

4.4. Analysis of Systematic Errors of the Test

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Douglass, R.G.; Palacios, J.L. Effects of strain rate variation on the shear adhesion strength of impact ice. Cold Reg. Sci. Technol. 2021, 181, 103168. [Google Scholar] [CrossRef]

- Work, A.H. A statistical analysis of impact ice adhesion strength data acquired with a modified lap joint test. In Proceedings of the AIAA AVIATION 2020 FORUM, Online, 15–19 June 2020. [Google Scholar]

- Zou, M.; Beckford, S.; Wei, R.; Ellis, C.; Hatton, G.; Miller, M.A. Effects of surface roughness and energy on ice adhesion strength. Appl. Surf. Sci. 2011, 257, 3786–3792. [Google Scholar] [CrossRef]

- Gagnon, R.; Bugden, A.; Garvin, M.; Teigen, S.; Elliott, B. Ice Adhesion Shear Tests on Ice-Phobic Surfaces; Lulea University of Technology: Lulea, Sweden, 2021; Volume 6. [Google Scholar]

- Rnneberg, S.; Laforte, C.; Volat, C.; He, J.; Zhang, Z. The effect of ice type on ice adhesion. AIP Adv. 2019, 9, 055304. [Google Scholar] [CrossRef]

- Rebekah, G.D.; Jose, L.P.; Grant, M.S. Design, Fabrication, Calibration, and Testing of a Centrifugal Ice Adhesion Test Rig with Strain Rate Control Capability. In Proceedings of the 2018 Atmospheric and Space Environments Conference, Atlanta, GA, USA, 25–29 June 2018; Volume 6, p. 3342. [Google Scholar]

- Pervier, M.; Lerma, B.G.; Moncholi, E.P.; Hammond, D.W. A new test apparatus to measure the adhesive shear strength of impact ice on titanium 6Al-4V alloy. Eng. Fract. Mech. 2019, 214, 212–222. [Google Scholar] [CrossRef]

- Matsushita, H. A Study on the Shearing Strength and Adhesive Strength of Sea Ice. Mar. Dev. Proc. 1997, 13, 765–770. [Google Scholar] [CrossRef]

- Chu, M.C.; Scavuzzo, R.J. Adhesive shear strength of impact ice. AIAA J. 1991, 29, 1921–1926. [Google Scholar] [CrossRef]

- Chen, T.; Cong, Q.; Sun, C.; Jin, J.; Choy, K.L. Influence of substrate initial temperature on adhesion strength of ice on aluminum alloy. Cold Reg. Sci. Technol. 2018, 148, 142–147. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Guo, R.Z.; Zhang, Y.H.; Liang, K. Adhesion shear strength test method for freshwater/seawater ice on carbon ceramicbrake pads of amphibious aircraft. Aircr. Eng. Aerosp. Technol. 2022, 5, 781–791. [Google Scholar] [CrossRef]

- Jin, J.F.; Li, Y.; Chen, T.K. The effect of coating elastic modulus on icing adhesion strength. J. Jilin Univ. 2017, 47, 5. [Google Scholar]

- Dawood, B.; Yavas, D.; Bastawros, A.F. Characterization of Ice Adhesion: Approaches and Modes of Loading. In Proceedings of the 2020 AIAA Aviation Forum, Virtual Event, 15–19 June 2020; Volume 6, p. 2802. [Google Scholar]

- Prashanth, B.; Rye, W.; Hui, H. Ice Adhesion Measurements of Ice Mitigation Coatings Pertinent to Aircraft Icing. In Proceedings of the 9th AIAA Atmospheric and Space Environments Conference, Denver, CO, USA, 5–9 June 2017; Volume 6, p. 3928. [Google Scholar]

- Pan, H. Modeling and Simulation of Aircraft Frozen Ice Form Prediction. J. Syst. Simul. 2014, 1, 221–229. [Google Scholar]

- Zhang, Y.J.; Zhang, Y.H.; Guo, R.Z. Summary of the Test Methods for Icing Strength of Freshwater and Seawater. J. Phys. Conf. Ser. 2021, 1786, 012044. [Google Scholar] [CrossRef]

- Dong, Y.Q. An application of Deep Neural Networks to the in-flight parameter identification for detection and characterization of aircraft icing. Aerosp. Sci. Technol. 2018, 77, 34–49. [Google Scholar] [CrossRef]

- Susan Frankenstein, P.E.; Andrew, M.; Tuthill, P.E. Ice Adhesion to Locks and Dams: Past Work; Future Directions? J. Cold Reg. Eng. 2002, 16, 83–96. [Google Scholar] [CrossRef]

- Aly, M.; Taylor, R.S.; Bailey, E.; Turnbull, I. Scale Effect in Ice Flexural Strength. J. Offshore Mech. Arct. Eng. 2019, 141, 051501. [Google Scholar] [CrossRef]

- Janjua, Z.A. The influence of freezing and ambient temperature on the adhesion strength of ice. Cold Reg. Sci. Technol. 2017, 140, 14–19. [Google Scholar] [CrossRef]

- Xiao, Z. Reliability Study of the Brazilian Test Method for the Determination of Mechanical Properties of Ice; Dalian University of Technology: Dalian, China, 2017. [Google Scholar]

- Ding, L. Research on aircraft icing adhesion strength test. In Proceedings of the Eleventh National Academic Conference on Fluid Mechanics, Shenzhen, China, 3–7 December 2020. [Google Scholar]

- Han, D.T.; Deborah, L.S.; Howard, L.S. An anisotropic elastic-decohesive constitutive relation for sea ice. Int. J. Numer. Anal. Methods Geomech. 2015, 39, 988–1013. [Google Scholar]

| Number | Project | Content |

|---|---|---|

| 1 | Test objective | Measure the shear adhesion strength of the aviation material to the ice layer |

| 2 | Trial basis | Outline of Mechanical Property of Civil Machine; GB/T 13936-2014 Methods for Determination of Tensile Shear Strength of Rubber Rubber and Metal |

| 3 | Test item | The ice adhesion strength test of aluminum alloy-ice-aluminum alloy (AL-Ice-AL); The ice adhesion strength test of aluminum alloy-ice-silicone rubber (AL-Ice-SR) |

| 4 | Laboratory environment | Temperature: 23 C ± 3 C; Humidity: 50% RH 10% RH |

| 5 | Proving time | December 2021–March 2022 |

| Project | AL-Ice-AL Static Test Piece | AL-Ice-SR Static Test Piece |

|---|---|---|

| Sample composition | Two aluminum alloy plates | An aluminum alloy plate and an silicone rubber board |

| Material of test piece | 7050-T7451 | 7050-T7451/TX-FROL 50 |

| Size of test piece | 25 × 25 × 10 | 25 × 25 × 10 |

| Use of test piece | Test the ice adhesion strength on the aluminum alloy surface | Test the ice adhesion strength on the silicone rubber surface |

| Test Item | Sub-Items of the Experiment | Freeze for 2 h | Freeze for 4 h | Freeze for 6 h |

|---|---|---|---|---|

| Distilled water at −15 C | 2 | 2 | 2 | |

| Distilled water at −25 C | 3 | 3 | 3 | |

| Lake water at −25 C | 3 | 3 | 3 | |

| Static test of AL-Ice-AL | Sea water at −25 C | 3 | 3 | 3 |

| Distilled water at −35 C | 3 | 3 | 3 | |

| Distilled water at −45 C | 3 | 3 | 3 | |

| Distilled water at −55 C | 2 | 2 | 2 | |

| Distilled water at −15 C | 2 | 2 | 2 | |

| Distilled water at −25 C | 3 | 3 | 3 | |

| Lake water at −25 C | 3 | 3 | 3 | |

| Static test of AL-Ice-SR | Sea water at −25 C | 3 | 3 | 3 |

| Distilled water at −35 C | 3 | 3 | 3 | |

| Distilled water at −45 C | 3 | 3 | 3 | |

| Distilled water at −55 C | 2 | 2 | 2 |

| Number | Device | Unit Type | Use |

|---|---|---|---|

| 1 | Temperature and humidity meter | HTC-1 | Measure ambient humidity |

| 2 | Number of vernier calipers | 0∼150 mm | Measure the ice specification |

| 3 | Damand heat test box for high and low temperature alternating | GDJS-1000 | Make frozen ice specimens |

| 4 | Electronic universal test machine | UTM5205HB | Apply the load |

| 5 | Type S sensor | BSS-200 kg | Measure the ice-breaking load |

| 6 | Test machine environment box | TS-160 | Provide the test temperature environment for the specimen |

| 7 | Camera | - | Take a picture |

| Ambient Temperature (C) | Freeze Time (h) | The Form of Destruction | Average Value of the Ice-Breaking Load (N) | Maximum Value of the Ice-Breaking Load (N) | Frozen Area (mm) |

|---|---|---|---|---|---|

| 2 | Shear destruction inside the ice layer | 235.0 | 267.0 | 620.38 | |

| −15 | 4 | Shear destruction inside the ice layer | 124.0 | 138.0 | 624.38 |

| 6 | Shear destruction inside the ice layer | 177.1 | 222.0 | 620.01 | |

| 2 | The adhesion surface falls off | 110.2 | 150.0 | 622.25 | |

| −25 | 4 | The adhesion surface falls off | 189.1 | 369.1 | 620.92 |

| 6 | The adhesion surface falls off | 352.3 | 417.0 | 620.76 | |

| −25 (lake water) | 2 | The adhesion surface falls off | 105.9 | 150.0 | 622.50 |

| −25 (sea water) | 2 | The adhesion surface falls off | 5.7 | 6.1 | 621.75 |

| 2 | The adhesion surface falls off | 82.0 | 110.0 | 622.25 | |

| −35 | 4 | The adhesion surface falls off | 30.7 | 62.8 | 620.92 |

| 6 | The adhesion surface falls off | 35.9 | 42.1 | 620.76 | |

| 2 | The adhesion surface falls off | 46.6 | 89.2 | 622.25 | |

| −45 | 4 | The adhesion surface falls off | 28.7 | 39.7 | 620.92 |

| 6 | The adhesion surface falls off | 21.2 | 23.6 | 620.76 | |

| 2 | The adhesion surface falls off | 5.8 | 6.0 | 620.38 | |

| −55 | 4 | The adhesion surface falls off | 37.4 | 38.4 | 624.38 |

| 6 | The adhesion surface falls off | 16.7 | 19.7 | 620.01 |

| Ambient Temperature (C) | Freeze Time (h) | The Form of Destruction | Average Value of the Ice-Breaking Load (N) | Maximum Value of the Ice-Breaking Load (N) | Frozen Area (mm) |

|---|---|---|---|---|---|

| 2 | The adhesion surface falls off | 18.7 | 19.6 | 623.13 | |

| −15 | 4 | The adhesion surface falls off | 18.1 | 20.6 | 623.50 |

| 6 | The adhesion surface falls off | 53.4 | 54.3 | 624.62 | |

| 2 | The adhesion surface falls off | 88.2 | 99.8 | 623.25 | |

| −25 | 4 | The adhesion surface falls off | 51.3 | 78.1 | 624.25 |

| 6 | The adhesion surface falls off | 91.6 | 103.0 | 624.67 | |

| −25 (lake water) | 2 | The adhesion surface falls off | 35.3 | 53.4 | 624.75 |

| −25 (sea water) | 2 | The adhesion surface falls off | 3.2 | 4.2 | 624.75 |

| 2 | The adhesion surface falls off | 32.1 | 45.0 | 623.25 | |

| −35 | 4 | The adhesion surface falls off | 46.3 | 72.2 | 624.25 |

| 6 | The adhesion surface falls off | 62.4 | 68.9 | 624.67 | |

| 2 | The adhesion surface falls off | 51.8 | 80.0 | 623.25 | |

| −45 | 4 | The adhesion surface falls off | 56.5 | 63.5 | 624.25 |

| 6 | The adhesion surface falls off | 41.4 | 44.5 | 624.67 | |

| −50 | 2 | The adhesion surface falls off | 36.2 | 41.9 | 623.13 |

| 4 | The adhesion surface falls off | 37.4 | 38.4 | 624.38 | |

| −55 | 2 | The adhesion surface falls off | 16.7 | 19.7 | 620.01 |

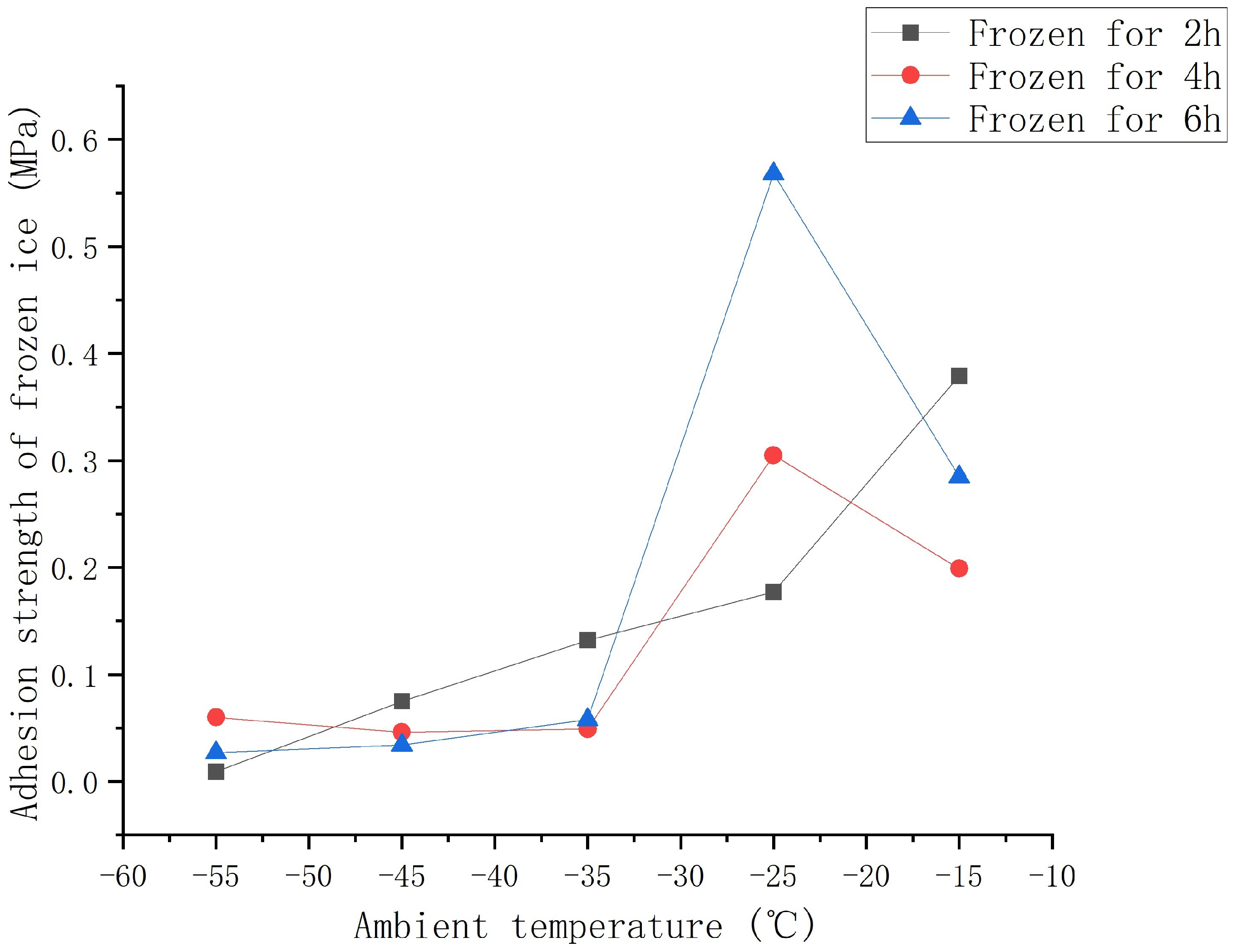

| Ambient Temperature (C) | Freeze Time (h) | Mean Adhesion Strength of Frozen Ice (MPa) | Maximum Value of Adhesion Strength for Frozen Ice (MPa) |

|---|---|---|---|

| 2 | 0.379 | 0.477 | |

| −15 | 4 | 0.199 | 0.221 |

| 6 | 0.285 | 0.358 | |

| 2 | 0.177 | 0.243 | |

| −25 | 4 | 0.305 | 0.594 |

| 6 | 0.568 | 0.672 | |

| −25 (lake water) | 2 | 0.170 | 0.241 |

| −25 (sea water) | 2 | 0.009 | 0.011 |

| 2 | 0.132 | 0.177 | |

| −35 | 4 | 0.049 | 0.101 |

| 6 | 0.058 | 0.068 | |

| 2 | 0.075 | 0.143 | |

| −45 | 4 | 0.046 | 0.064 |

| 6 | 0.034 | 0.038 | |

| 2 | 0.009 | 0.010 | |

| −55 | 4 | 0.060 | 0.062 |

| 2 | 0.027 | 0.032 |

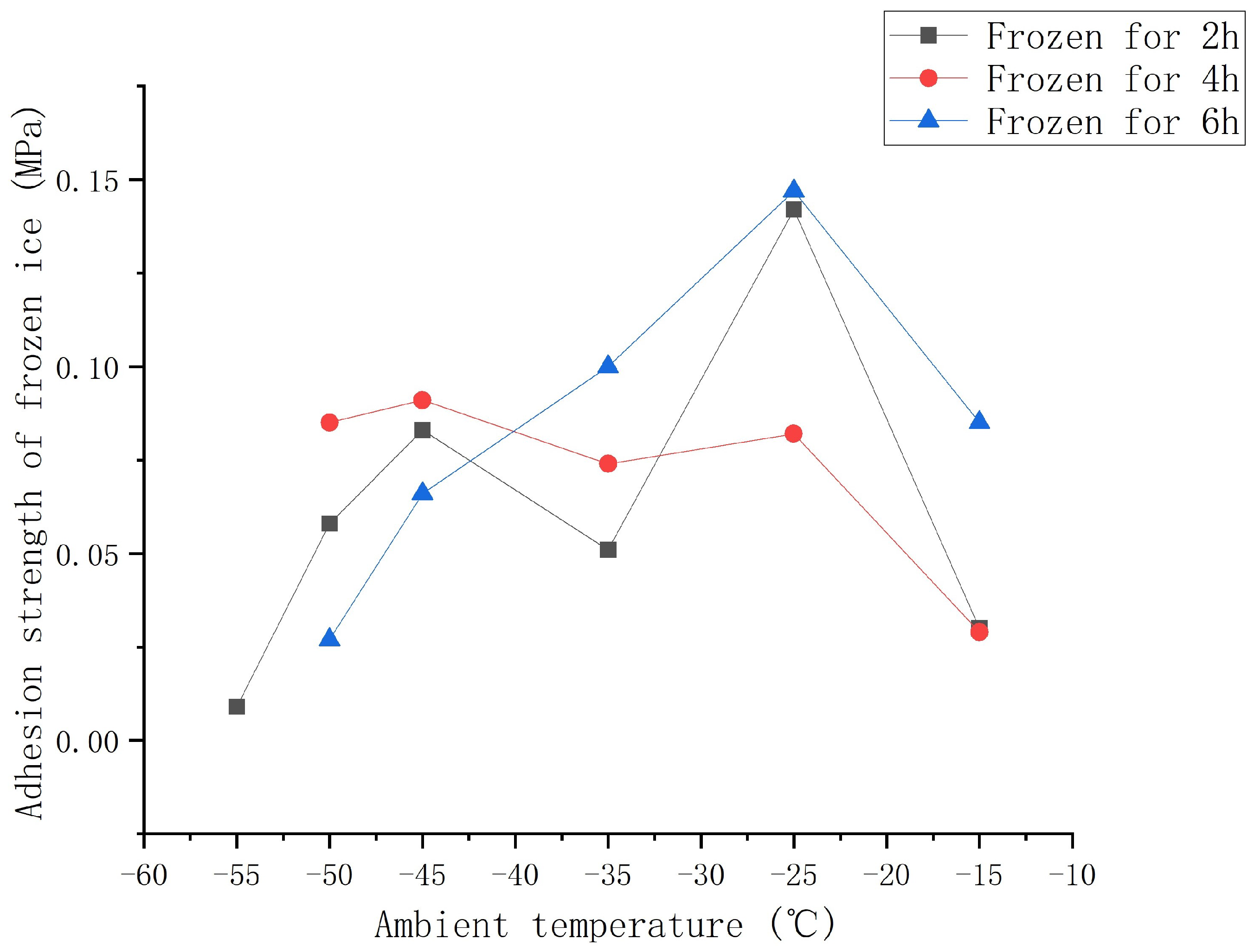

| Ambient Temperature (C) | Freeze Time (h) | Mean Adhesion Strength of Frozen Ice (MPa) | Maximum Value of Adhesion Strength for Frozen Ice (MPa) |

|---|---|---|---|

| 2 | 0.030 | 0.031 | |

| −15 | 4 | 0.029 | 0.033 |

| 6 | 0.085 | 0.087 | |

| 2 | 0.142 | 0.160 | |

| −25 | 4 | 0.082 | 0.125 |

| 6 | 0.147 | 0.165 | |

| −25 (lake water) | 2 | 0.057 | 0.085 |

| −25 (sea water) | 2 | 0.005 | 0.007 |

| 2 | 0.051 | 0.072 | |

| −35 | 4 | 0.074 | 0.116 |

| 6 | 0.100 | 0.110 | |

| 2 | 0.083 | 0.128 | |

| −45 | 4 | 0.091 | 0.102 |

| 6 | 0.066 | 0.071 | |

| −50 | 2 | 0.058 | 0.067 |

| 4 | 0.085 | 0.103 | |

| −55 | 2 | 0.009 | 0.010 |

| Project | Freezing 2 h () | Freezing 4 h () | Freezing 6 h () |

|---|---|---|---|

| −25 C () | 0.175, 0.243, 0.113 | 0.148, 0.592, 0.172 | 0.592, 0.439, 0.639 |

| −35 C () | 0.122, 0.177, 0.096 | 0.017, 0.030, 0.102 | 0.057, 0.049, 0.068 |

| −45 C () | 0.143, 0.029, 0.052 | 0.064, 0.047, 0.028 | 0.032, 0.038, 0.032 |

| Project | Freezing 2 h () | Freezing 4 h () | Freezing 6 h () |

|---|---|---|---|

| −25 C () | 0.135 0.130, 0.160 | 0.011, 0.125, 0.111 | 0.116, 0.164, 0.159 |

| −35 C () | 0.039, 0.043, 0.072 | 0.042, 0.116, 0.065 | 0.110, 0.090, 0.099 |

| −45 C () | 0.057, 0.064, 0.128 | 0.077, 0.102, 0.093 | 0.007, 0.071, 0.057 |

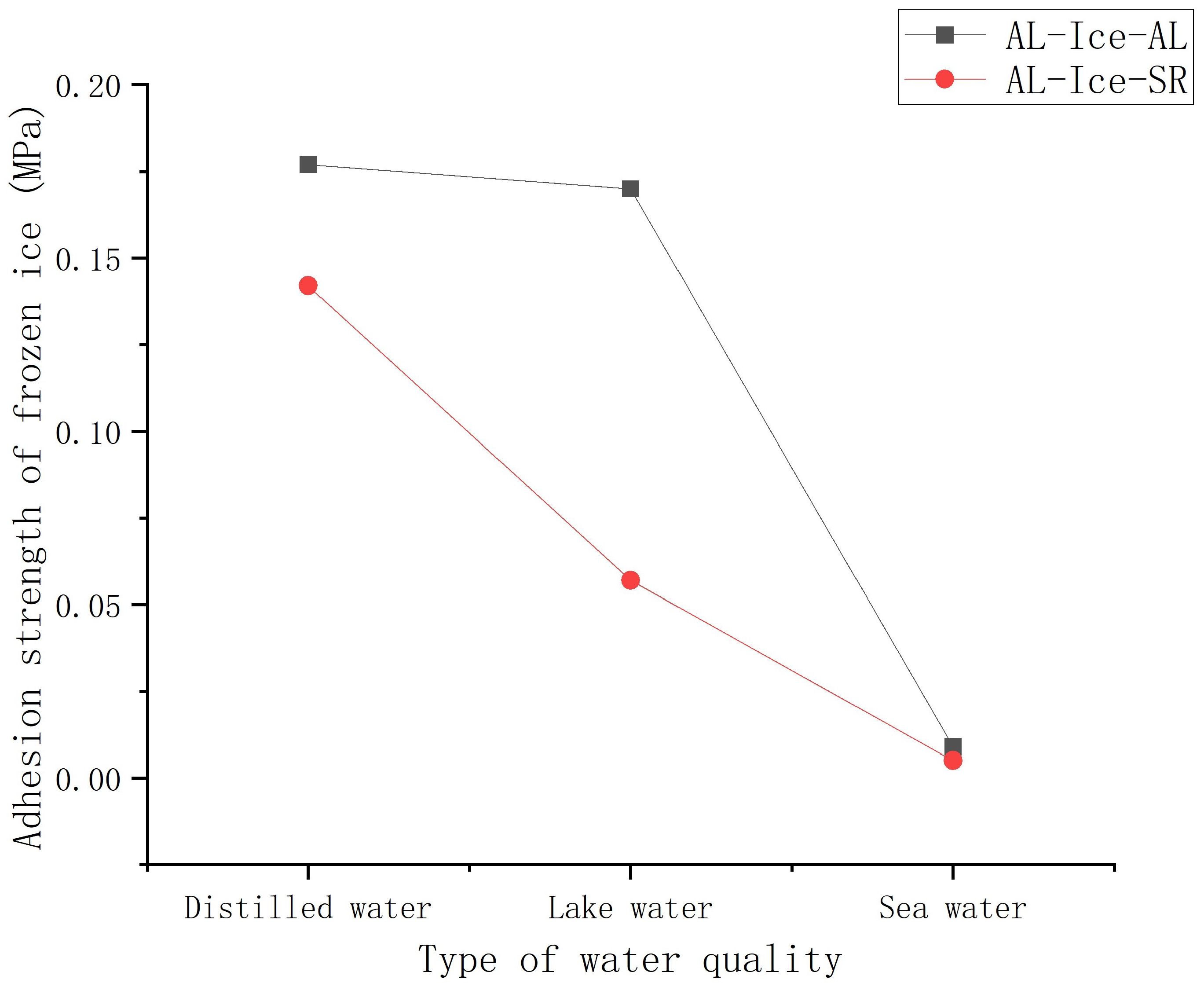

| Project | AL-Ice-AL () | AL-Ice-SR () |

|---|---|---|

| Distilled water () | 0.175, 0.243, 0.113 | 0.135, 0.130, 0.160 |

| Lake water () | 0.243, 0.100, 0.168 | 0.529, 0.031, 0.085 |

| Sea water () | 0.009, 0.008, 0.011 | 0.007, 0.005, 0.003 |

| Source of Variance | The Sum Of Squares of Deviations | Degree of Freedom | Mean of the Sum of Squares of Deviations | The Value of F | Significance Level |

|---|---|---|---|---|---|

| Factor A | 0.4873 | 2 | 0.2437 | 24.71 | Yes |

| Factor B | 0.0480 | 2 | 0.0240 | 2.43 | No |

| Interactions of A and B | 0.2050 | 4 | 0.0513 | 5.20 | Yes |

| Error | 0.1775 | 18 | 0.0099 | ||

| Total sum value | 0.9178 | 26 |

| Source of Variance | The Sum of Squares of Deviations | Degree of Freedom | Mean of the Sum of Squares of Deviations | The Value of F | Significance Level |

|---|---|---|---|---|---|

| Factor A | 0.0127 | 2 | 0.0064 | 6.79 | Yes |

| Factor B | 0.0021 | 2 | 0.0011 | 1.12 | No |

| Interactions of A and B | 0.0100 | 4 | 0.0025 | 2.66 | No |

| Error | 0.0169 | 18 | 0.0009 | ||

| Total sum value | 0.0417 | 26 |

| Source of Variance | The Sum of Squares of Deviations | Degree of Freedom | Mean of the Sum of Squares of Deviations | The Value of F | Significance Level |

|---|---|---|---|---|---|

| Factor C | 0.0732 | 2 | 0.0366 | 21.22 | Yes |

| Factor D | 0.0117 | 1 | 0.0117 | 6.81 | Yes |

| Interactions of C and D | 0.0096 | 2 | 0.0048 | 2.79 | No |

| Error | 0.0207 | 12 | 0.0017 | ||

| Total sum value | 0.1152 | 17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, X.; Qiang, G.; Feng, Y.; Luo, T. Experimental Study on the Adhesion Strength of the Frozen Ice for Aircraft Moving Parts. Aerospace 2022, 9, 589. https://doi.org/10.3390/aerospace9100589

Xue X, Qiang G, Feng Y, Luo T. Experimental Study on the Adhesion Strength of the Frozen Ice for Aircraft Moving Parts. Aerospace. 2022; 9(10):589. https://doi.org/10.3390/aerospace9100589

Chicago/Turabian StyleXue, Xiaofeng, Guoyan Qiang, Yunwen Feng, and Tiansu Luo. 2022. "Experimental Study on the Adhesion Strength of the Frozen Ice for Aircraft Moving Parts" Aerospace 9, no. 10: 589. https://doi.org/10.3390/aerospace9100589

APA StyleXue, X., Qiang, G., Feng, Y., & Luo, T. (2022). Experimental Study on the Adhesion Strength of the Frozen Ice for Aircraft Moving Parts. Aerospace, 9(10), 589. https://doi.org/10.3390/aerospace9100589