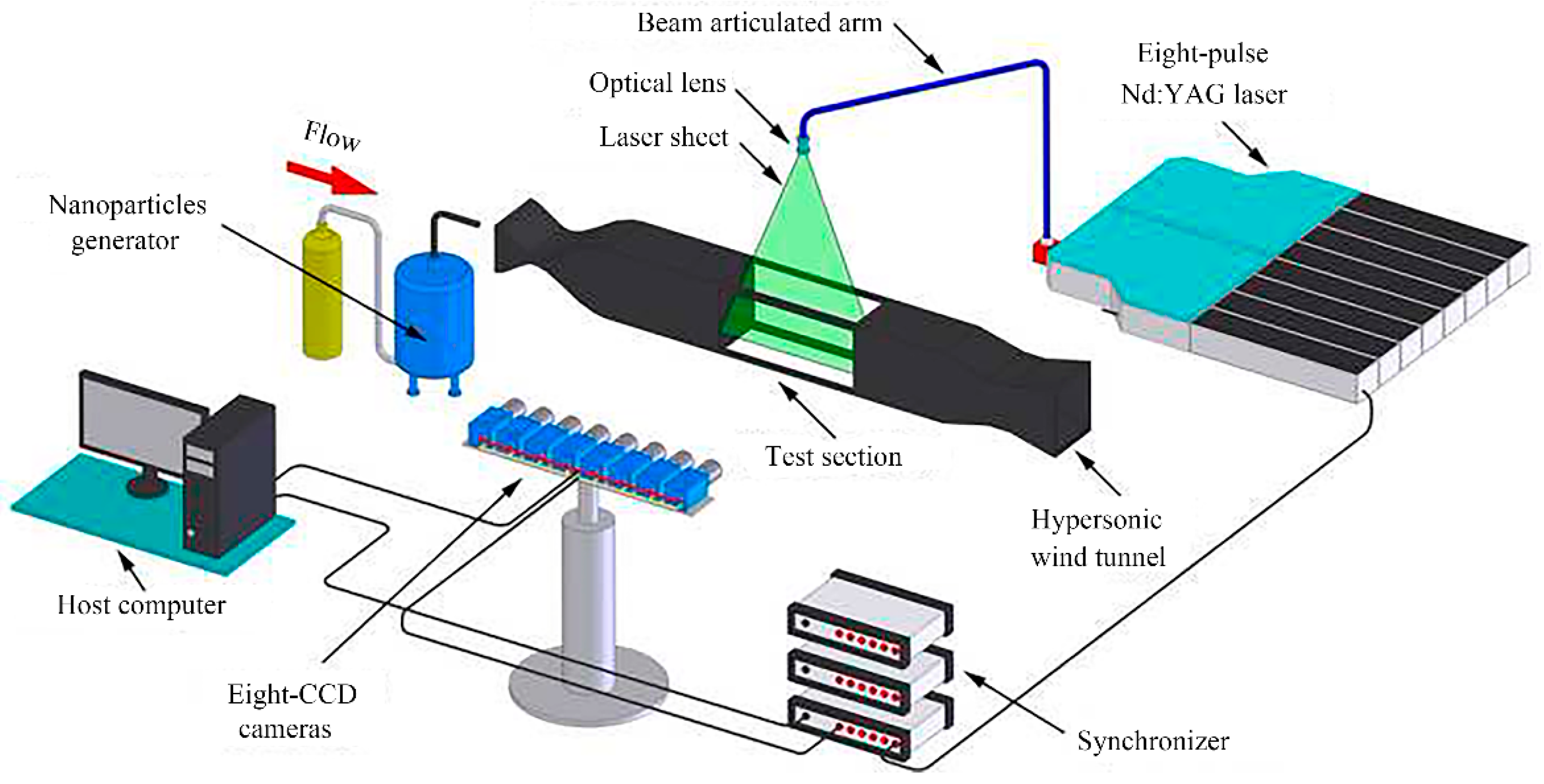

3.1. Boundary Layer Transient Flow Structure of the Smooth Plate in the xy-Plane

In order to compare the influence of the roughness element on the wake flow field, the flow structure without the roughness element was firstly analyzed and taken as the reference flow field. The transient flow field image of the boundary layer of a smooth flat plate in the

xy-plane is displayed in

Figure 7. The range of the flow field was specified by

x = 110 mm–310 mm,

y = 0 mm–15 mm, and the spatial resolution of the image was 103 μm/pixel. The flow direction was considered from left to right and the actual unit Reynolds number was 1.29 × 10

7 m

−1.

Since the thickness of the hypersonic laminar boundary layer was thin and the velocity gradient was large, it was difficult to perform accurate velocity distribution measurements to evaluate the boundary layer thickness. Therefore, the boundary layer thickness was determined based on the image structure. The tracer particles were uniformly scattered in the supersonic flow field. Due to the good following property of nanoparticles, in the region of the low-density flow field, the particle concentration was low, and the corresponding image brightness was low, as described by Tian et al. [

31]. As we know, the flow field density inside the boundary layer is lower than that of the external mainstream flow field. Therefore, in

Figure 7, the dark area at

y = 0–2 mm is pertinent to the interior of the boundary layer, and the relatively light area at

y = 2–15 mm is associated with the mainstream. In the present paper, the height of the dark area was exploited to define the boundary layer thickness. Actually, in the laminar boundary layer, due to the Magnus effect [

32] and the leading-edge lift effect [

33], some of the particles were thrown out of the boundary layer and eventually moved along the streamline. Other ones moved toward the wall due to the influence of the Suffman lift force [

33], leading to the light–dark step change in the boundary layer region of the NPLS image. This implies that there was a specific error between the boundary layer thickness based on the image structure and the real one. Furthermore, the former may increase with the growth of the real boundary layer thickness. Huntley [

34] found the same phenomenon by applying the filtered Rayleigh scattering technology to analyze the boundary layer transition on a Mach 8 elliptic cone, indicating that the boundary layer thickness based on the image structure was about 10% thinner than the real one. Therefore, the thickness of the dark area in

Figure 7 can qualitatively represent the boundary layer thickness, and it was thinner than the real one. The plotted results in

Figure 7 show that the flow field remained laminar and there was no instability in the boundary layer. The roughness elements were planned to be installed in the red rectangular region. According to the image approach, the boundary layer thickness

δ was approximately obtained as 2 mm, and this value was utilized as the reference for evaluating the dimensionless factor of the REH (i.e.,

).

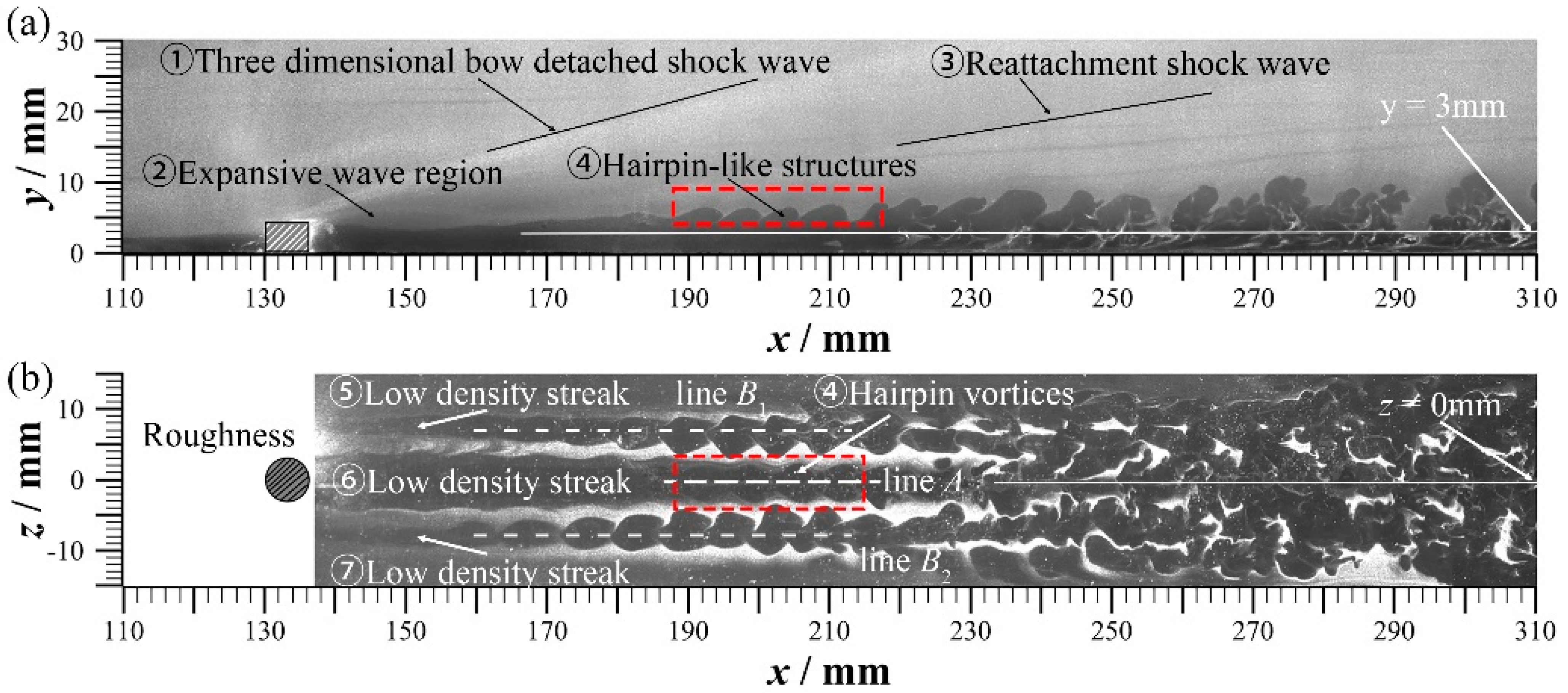

3.2. Transient Wake Flow Field of Various Plane Roughness Elements

The transient images of the wake flow field of the roughness element with

= 2 at various plane positions are demonstrated in

Figure 8. The

xy-plane flow field image at

z = 0 mm is displayed in

Figure 8a, and the range of the flow field is identified by

x = 110 mm–310 mm,

y = 0 mm–30 mm. The solid white line is associated with the position of

Figure 8b in the

xy-plane, where this figure presents the flow field image in the

xz-plane at

y = 3 mm. The range of the flow field is specified by

x = 137 mm–310 mm,

z = −15 mm–15 mm, and the central white solid line is pertinent to the position of

Figure 8a in the

xz-plane. The flow direction was from left to right, and the actual unit Reynolds number was 1.35 × 10

7 m

−1. For the convenience of comparison, the flow directions in

Figure 8a,b were adjusted to be consistent. It should be noticed that the plotted results in

Figure 8a and those of

Figure 8b were not taken simultaneously.

In

Figure 8a, a three-dimensional bow-shaped detached shock wave ① is detectable near the leading edge of the roughness element. After the airflow bypassed the roughness element, it expanded above and behind the roughness element, forming the expansion wave region ②, corresponding to the dark area in the upper mainstream behind the roughness element in

Figure 8a. The expanded airflow was compressed through the wall to form a reattachment shock wave ③. As the value of

x varied from 150 mm to 180 mm, the wake boundary layer was initially developed, and the thickness of the boundary layer grew rapidly. For the case of

x value in the range of 190 mm–215 mm, the wave-shaped structure can be detected from the rectangular region in

Figure 8a, indicating the head of the regularly arranged hairpin vortex structure. As the value of

x became higher than 215 mm, the hairpin vortex broke into a small-scale vortex structure.

In the spreading plane (see

Figure 8b), there were three low-density strip structures ⑤–⑦ extending along the flow direction downstream of the roughness element. The streaky structures ⑤ and ⑦ were generated by the roughness element and extended to the downstream horseshoe vortex region, and the streaky structure ⑥ is the wake region directly behind the roughness element. In the horseshoe vortex region, the plotted results in

Figure 8b show that the upper and lower symmetrical gourd-shaped hairpin vortex structure appeared in the interval of

x = 150 mm–186 mm, and the straight lines B

1 and B

2 represent the symmetry axes of the structures. As the value of

x changed from 186 mm to 210 mm, the scale of the hairpin vortex structure became larger and compared with the outer part of the symmetry axis, the structure scale of the inner part of the hairpin vortex grew more noticeably. Additionally, the hairpin vortex structure was closer to the wake region. Subbareddy et al. [

35] investigated the transition of a Mach 6 laminar boundary layer due to an isolated cylindrical roughness element using large-scale direct numerical simulations. The obtained results indicated that the hairpin vortex in the horseshoe vortex tilted to the inside. In the current paper, this phenomenon will be methodically examined in

Section 3.3.

For the wake region behind the roughness element, at

x = 180 mm, the boundary layer rolled up the first hairpin vortex, corresponding to the small vortex structure outside the red dotted rectangular region in

Figure 8a. In the range of

x = 190 mm–215 mm, the gourd-shaped hairpin vortex structure ④ can be detected in

Figure 8b, in which line A denotes the axis of symmetry, and the gourd-shaped structure corresponds to the wave-shaped structure of the rectangular region in

Figure 8a. As the flow developed downstream, the horseshoe vortex and hairpin vortex were broken up into the small-scale vortex structure. The hairpin vortex in the wake flow appeared later than that in the horseshoe vortex, which is consistent with the numerical simulation results of the wake flow field of a cylindrical roughness element by Wheaton et al. [

36] and Zhou et al. [

37].

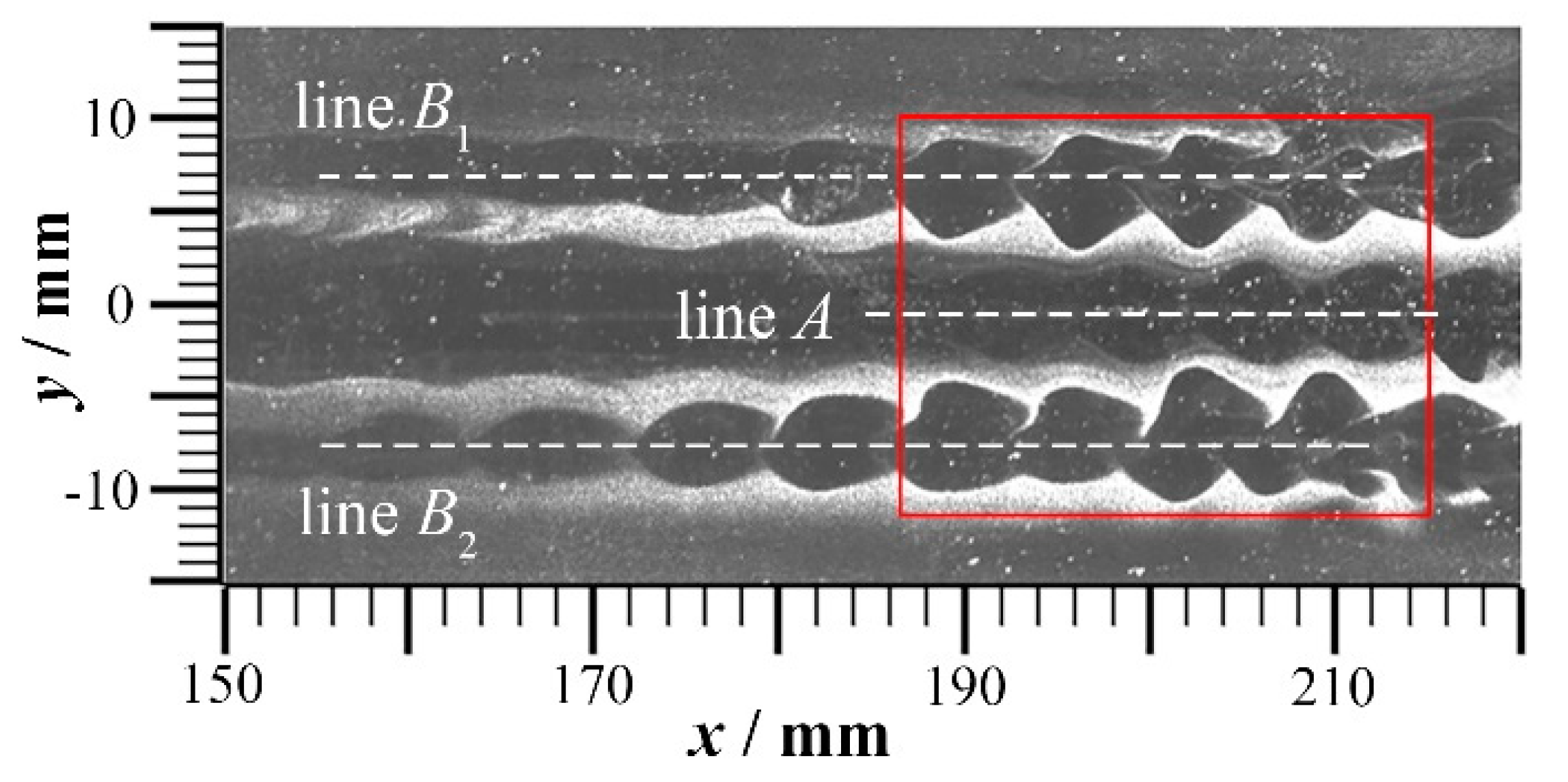

Figure 9 presents a local magnification at

x = 110 mm–310 mm in

Figure 8b. According to the rectangular region displayed in the figure, the gourd-shaped hairpin vortex structures were staggered in the horseshoe vortex and the wake flow field behind the roughness element.

3.3. Three-Dimensional Structure Analysis of the Roughness Element Wake Flow Field

Based on the results of

Section 3.2, the hairpin vortex structure was a crucial flow structure in the wake flow field of the roughness element. As the single plane cannot reflect the three-dimension characteristics of the flow structure, in this research, such features of the wake flow field structure were examined and predicted by combining the two plane images.

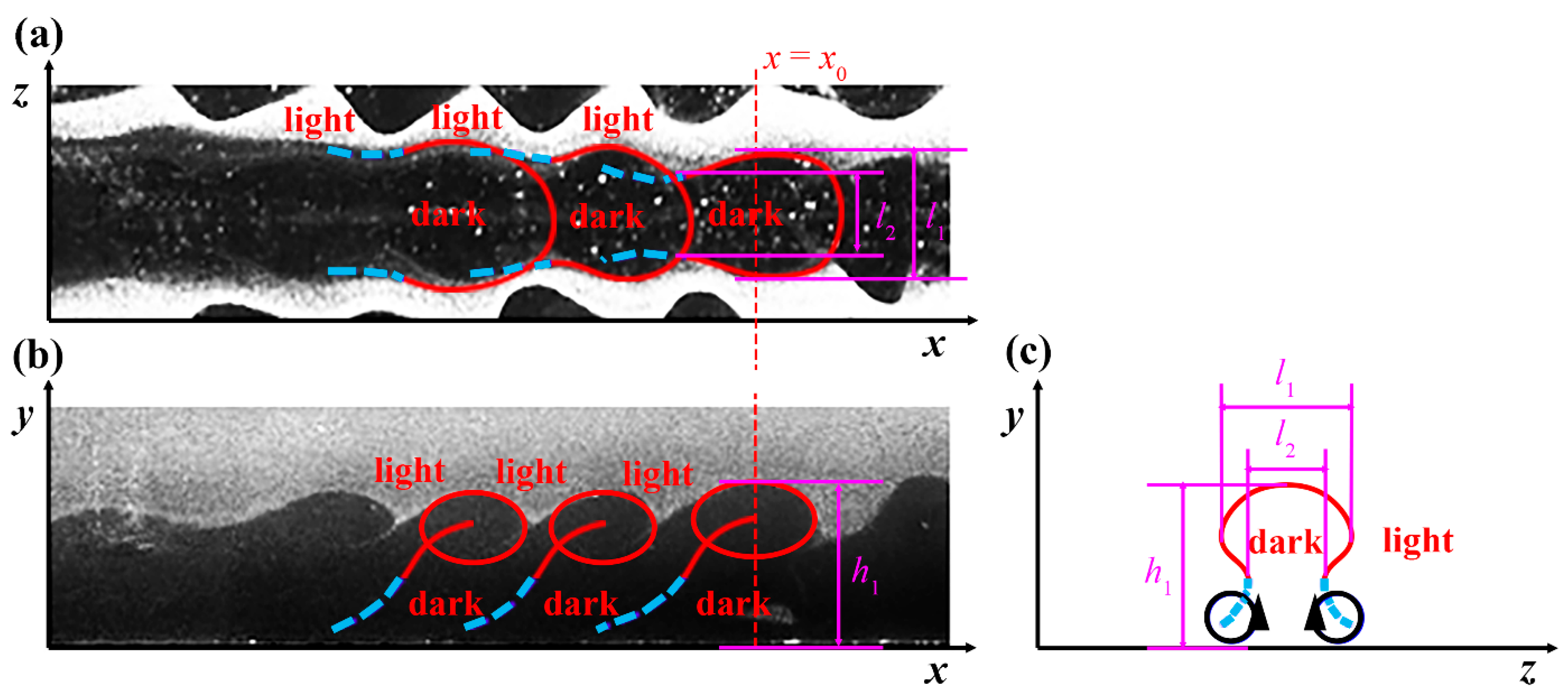

The flow field structure in the

yz-plane was predicted based on the NPLS images of the flow field in the

xy- and

xz-planes behind the roughness element. According to the ideal hairpin vortex model proposed by Theodorsen [

38,

39], it is known that the inner side of the hairpin vortex induces the rise (ejection motions) of the low-density flow field in the boundary layer, and the outer side of the hairpin vortex induces the mainstream high-density flow field into the boundary layer (sweep motions). Based on the principle of the NPLS technology, the low-density area inside the hairpin vortex corresponds to the dark area, the outside high-density region is associated with the bright area, and the vortex tube position of the hairpin vortex is pertinent to the bright-dark junction in the image. The hairpin vortex structures in various planes are examined in

Figure 10. The flow field structure of the

xz-plane at

y = 3 mm is displayed in

Figure 10a. The vortex tube position of the hairpin vortex structure located above the

xz-plane is marked by the red solid line, and the vortex tube position of the hairpin vortex leg below the plane is marked by the light cyan dotted line. On the

xz-plane, the wider part of the gourd-shaped structure is associated with the head of the hairpin vortex, and the narrower part corresponds to the neck of the hairpin vortex. The width of the head and width of the neck in order are denoted by

and

. The hairpin vortex structure in

Figure 10a corresponding to the position in the

xy-plane is shown in

Figure 10b. The upper boundary of the hairpin vortex head arranged along the flow direction formed the wave-shaped structure as illustrated in

Figure 8a, and the height of the hairpin vortex head is denoted by

. Based on the demonstrated results in

Figure 10a,b, the hairpin vortex structure in the

yz-plane at

was predicted (see

Figure 10c). According to the ideal hairpin vortex model, the structure of the hairpin vortex leg (light cyan dotted line) is constantly rising and connected at the head (red-solid line). There is a pair of a quasi-streamwise vortex with opposite rotation directions near the wall, as shown in the black circle in

Figure 10c, and the arrow indicates the rotation direction of the streamwise vortex.

Based on

Figure 10, the flow structure in the

yz-plane at various streamwise positions was predicted by the wake flow field image of the roughness element in

Figure 8 (see

Figure 11). The plotted results indicate that the hairpin vortex structures appeared in the horseshoe vortex at

x = 150 mm, each of which was similar to that presented in

Figure 10c. At

x = 170 mm, the hairpin vortex in the horseshoe vortex developed gradually, and the scale grew. The quasi-streamwise vortex at the leg position induced a pair of opposite flow vortexes in the inner wake region, as shown in the black circle near the wall in

Figure 11b. The arrow represents the rotation direction of the streamwise vortex. At the downstream position

x = 180 mm, the scale of the hairpin vortex structure in the horseshoe vortex further increased, and the induced streamwise vortex further developed and gradually configured a new hairpin vortex structure, as illustrated in

Figure 11c, which corresponded to the first vortex rolled up in front of the red dotted rectangular region in

Figure 8a. According to the staggered arrangement phenomenon of the hairpin vortex in

Figure 9, the head of the hairpin vortex on both sides was not in the same

yz-plane as the head of hairpin vortex in the middle region. A light cyan dotted line is employed to represent the head structure of the hairpin vortex in the middle region that is out of the

yz-plane, and the red -solid line is employed to represent the leg structure of the hairpin vortex. At

x = 190 mm in

Figure 11d, the hairpin vortex of the middle wake flow developed further, and the scale increased in the

yz-plane. The downward sweep of the outer side of the hairpin vortex leg induced the local acceleration development of the hairpin vortex on both sides. The original symmetrical hairpin vortex on both sides of the horseshoe vortex turned to be unsymmetrical (red dotted line), the structure scale of the inner part became larger (red-solid line), and the inner part gradually moved closer to the wake flow (see

Figure 11d). This fact corresponds to the phenomenon that the inner of the horseshoe vortex approaches inward and increases in the scale presented in

Figure 8b.

In view of the above analysis, it was found that the mechanism induced by the horseshoe vortex and the wake flow structure of the roughness element generated the staggered arrangement of the hairpin vortex observed in the xz-plane. The hairpin vortex in the upstream horseshoe vortex induced the formation of the hairpin vortex in the wake flow and then induced the inner development of the hairpin vortex in the downstream horseshoe vortex. The further enhancement of this mutual induction mechanism makes it difficult to maintain the hairpin vortex structure in the wake flow and the horseshoe vortex, resulting in an almost simultaneous breakdown of all vortex structures.

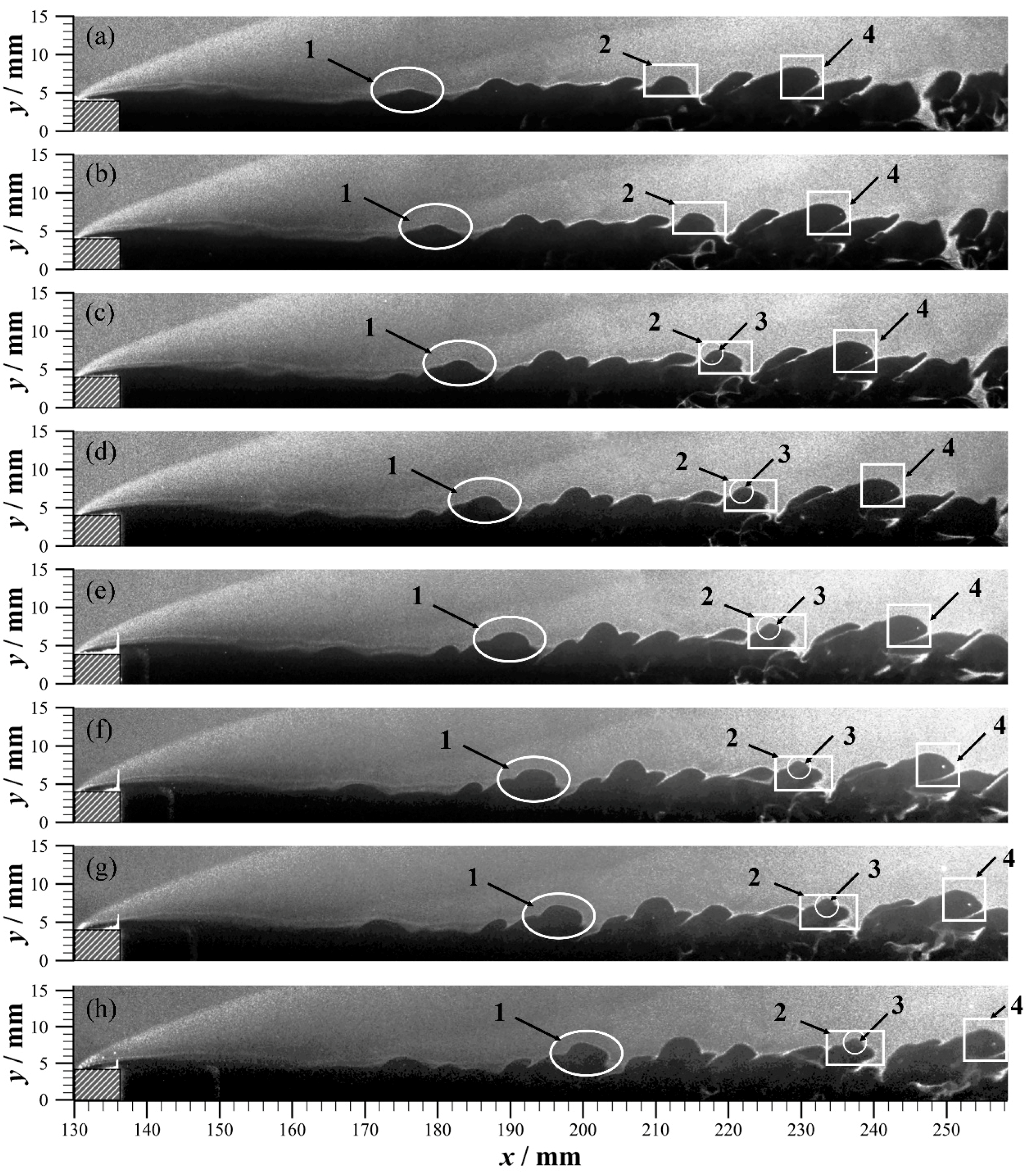

3.4. Time Evolution Characteristic of the Wake Flow Field of a Roughness Element in the xy-Plane

In order to examine the time evolution characteristics of the downstream wake flow field of the roughness element, the time-resolved NPLS technique was exploited to obtain eight time-correlated streamwise image sequences of the wake flow field of the roughness element with

= 2 (see

Figure 12). The view field ranged in the following intervals:

x = 130 mm–258 mm,

y = 0 mm–15 mm, the resolution was 83.3 μm/pixel, and the time interval between adjacent images was 5 μs. The flow direction was from left to right, and the actual unit Reynolds number was 1.37 × 10

7 m

−1.

The evolution process of the wake vortex structure in terms of the flow direction can be observed in

Figure 12. The wake vortex structure moved with the flow direction, while a small deformation occurred. Typical vortex structures 1–4 were selected along various flow directions to analyze the dynamic evolution of a single vortex structure in the wake flow. In the elliptical region of

Figure 12, vortex 1 was initially a single small protuberance structure. Due to the induction of the horseshoe vortex on both sides, the height of vortex 1 increased continuously in 35 μs. The vortex 1 sheared with the mainstream, exhibited obvious inclination, and formed a clear hairpin vortex structure. The height of the downstream vortex 2 (the rectangular region in

Figure 12) was basically unchanged during the time of 35 μs, and its tilt angle was larger than that of vortex 1. At the same time, a new smaller scale vortex structure 3 was induced on the vortex 2, and vortex 3 moved rapidly downstream along the outer boundary of the vortex 2, as presented in the circular region in

Figure 12. In the further downstream position, due to the growth of height, the velocity difference between the adjacent vortex structures decreased, the shear effect weakened, the vortex structure remained basically unchanged, and there was no new generated small-scale vortex. This reveals that the vortex structure had developed to a relatively stable state, as vortex 4 in the square region in

Figure 12. By analyzing the variations of the overall vortex structure in the wake flow, it is detectable that the farther away from the vortex structure of the roughness element, the stronger the oblique tensile effect is.

In order to further quantify the evolution process of the vortex structure in the wake flow, the average streamwise velocity of vortex 1–4 and the instantaneous streamwise velocity distribution were assessed. Based on the displacements of vortex structures in

Figure 12a,h, the average velocities could be extracted, as listed in

Table 2. It can be seen from

Figure 12a that the height of vortex 1, 2, and 4 magnified gradually. The higher the normal height of the flow structure wall in the boundary layer is, the higher the streamwise velocity is, so the average streamwise velocities of large-scale vortex structures 1, 2, and 4 increased in turn, which is consistent with the results provided in

Table 2. The small-scale vortex 3 was induced by vortex 2 while following vortex 2. Although the heights of vortexes 3 and 4 were essentially the same, the average velocity of vortex 3 was higher than that of vortex 4.

Based on the artificial image recognition of the vortex structure, the instantaneous streamwise velocity

u of the vortex structure was obtained from the adjacent images.

Figure 13 illustrates the instantaneous streamwise velocity distribution corresponding to vortex 1–4 in two adjacent images. The plotted results reveal that the instantaneous velocity of vortex 1 increased with time, which is consistent with the increasing height of vortex 1 in

Figure 12. The height of vortex 2 was basically unchanged, and the corresponding instantaneous velocity varied slightly. However, as the structural scale of small-scale vortex 3 increased, its induced effect on vortex 2 made the velocity of vortex 2 relatively lessen, and the velocity of vortex 3 relatively increased. The instantaneous velocity of vortex 4 fluctuated around 730 m∙s

−1, equal to 0.93 of the free flow velocity

, which was evaluated to be 786 m/s, as presented in

Table 1, which indicates that vortex 4 reached a relatively stable state, which is consistent with the variation of the flow structure observed in

Figure 12.

By examining the dynamic evolution process of the vortex structure with various streamwise positions in the wake flow field, it is observable that in the upstream position, it presents the evolution of independent vortex structure, as shown in vortex 1. In the middle position, it developed into the interaction of multiple scale vortex, similar to vortexes 2 and 3. Further downstream, it gradually reached the stable state, and the vortex structure remained basically unchanged, such as vortex 4.

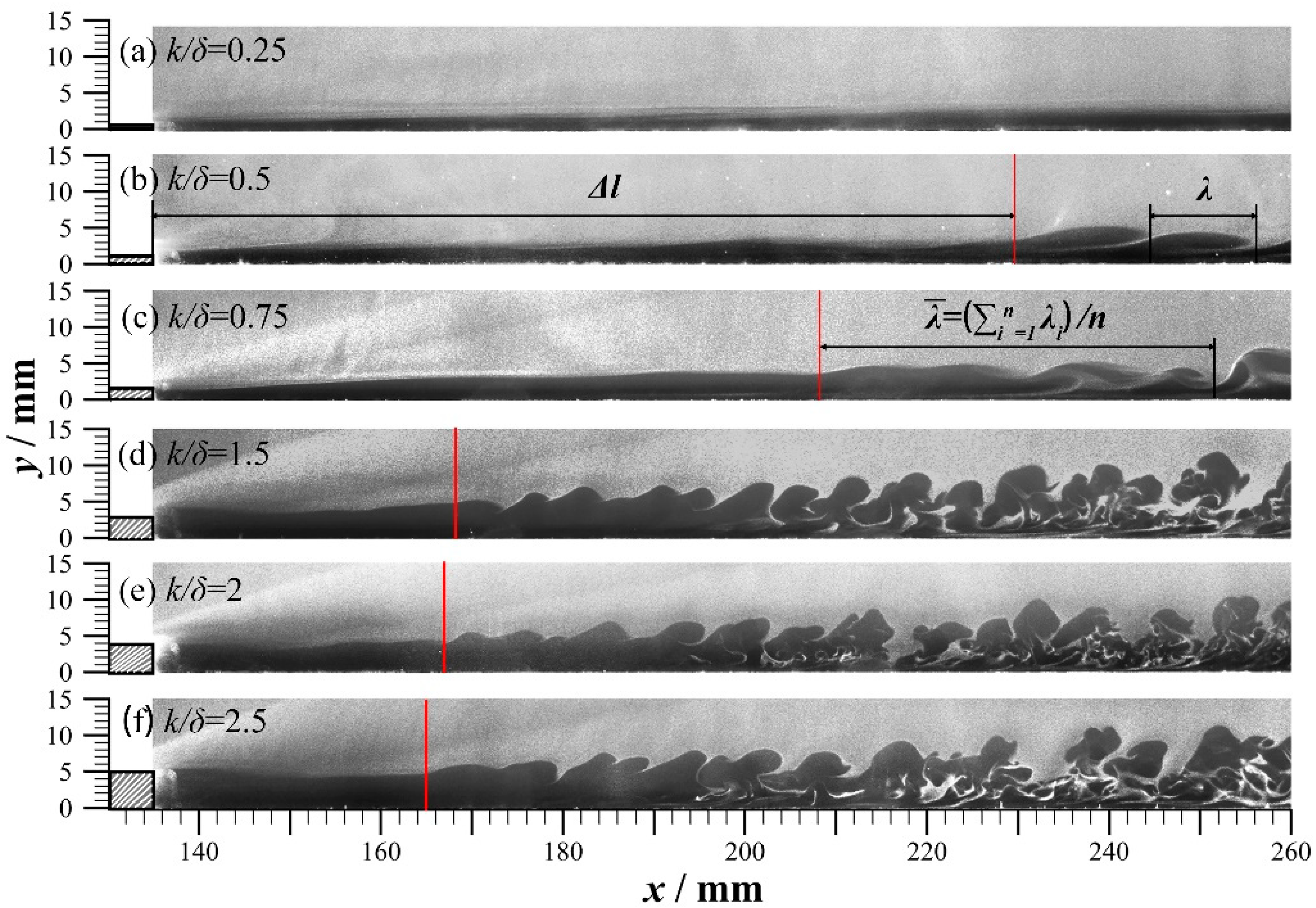

3.5. Comparison of the Wake Flow Field Structure of Roughness Elements with Various Heights

In order to investigate the influence of REH on the wake flow field, the flow structures of roughness element with

= 0.25, 0.5, 0.75, 1.5, 2, and 2.5 were examined. The obtained results are presented in

Figure 14. The image shooting range was specified by

x = 136 mm–260 mm,

y = 0 mm–15 mm, the spatial resolution was 103 μm/pixel, and the flow direction was from left to right. In the experimentation, the actual Reynolds number of each group slightly fluctuated due to the small variation of the incoming flow parameters during the operation of the wind tunnel.

In order to qualitatively compare the influence of the roughness element with various heights on the wake boundary transition, the streamwise position of the first vortex structure in the wake flow was exploited as the basis for comparison and marked with the red vertical line. The distance from the roughness element to the red vertical line was specified as Δ

l. As presented in

Figure 14a, there was no vortex structure in the wake flow field of the roughness element with

= 0.25, which is similar to the smooth plate flow field presented in

Figure 7. In the wake flow field of the roughness element with

= 0.5, the first large-scale vortex structure appeared at

x = 230 mm, and Δ

l = 93.7 mm (see

Figure 14b). Compared with the roughness element characterized by

= 0.25, the wake boundary layer transition of the roughness element with

= 0.5 occurred earlier. Based on the definition of critical height by Schneider [

16], the minimum REH which begins to affect the boundary layer transition is the critical REH. Therefore, the critical REH was less than 0.5

δ under the current flow condition, but it was impossible to determine whether the critical REH was less than 0.25

δ.

As

grew in the range of 0.5–1.5, the position of the first vortex structure in the flow field extended upstream, and the value of Δ

l lessened from 93.7 mm to 31.7 mm, associated with the red vertical line in

Figure 14b–d. Based on the analysis given in

Section 3.4, the rapid development of the wake boundary layer was induced by the horseshoe vortex. With the growth of the REH, the vortex structure height in the horseshoe vortex rose, and the inducing effect on the vortex structure in the wake boundary layer was enhanced. As a result, the position of the large-scale vortex structure in the wake boundary layer was closer to the upstream. Compared with

Figure 14d–f, it is detectable that the position of the first vortex structure in the wake boundary layer was essentially the same as the growth of the REH with

= 1.5–2.5, and Δ

l ≈ 30 mm, indicating that the REH had no apparent influence on the position of the large-scale vortex in the current height range.

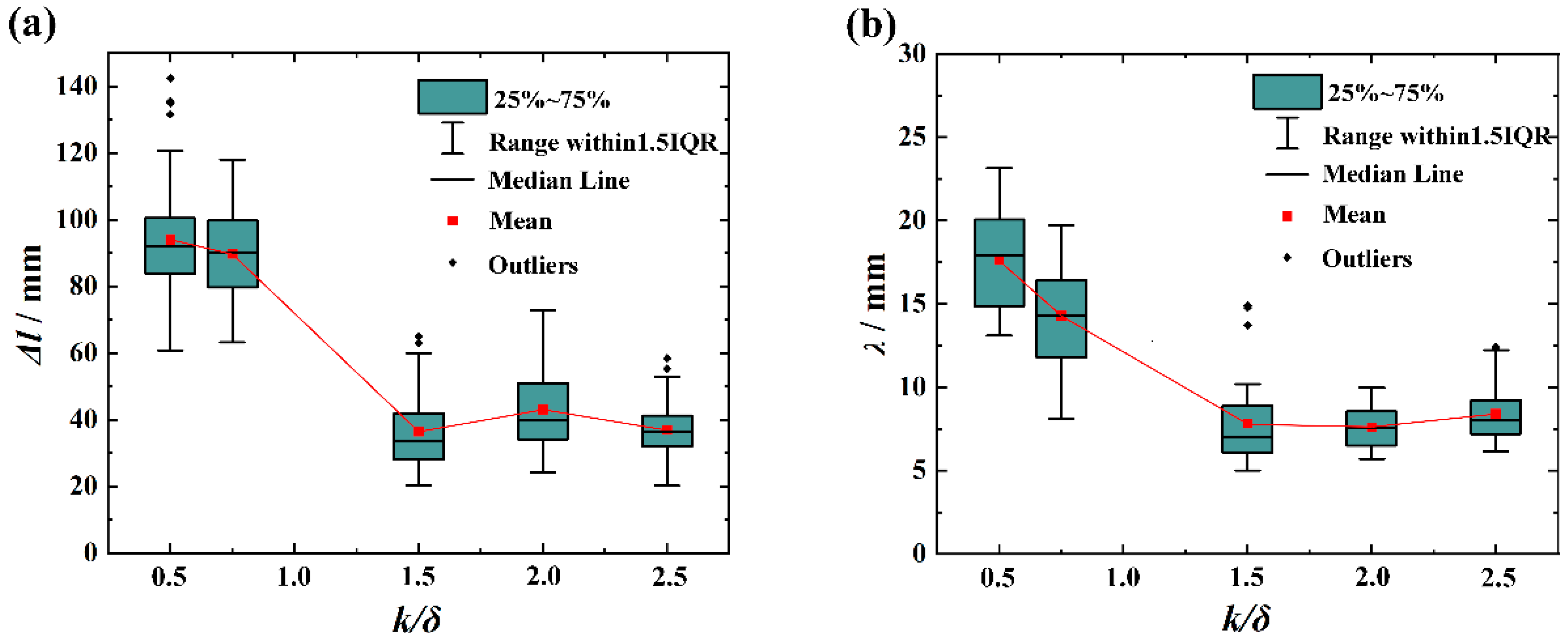

It should be noticed that the position of the vortex structure in a single image is random, and the distribution law of average streamwise position with the REH cannot be reflected. In order to roughly infer the influence of the REH on the wake boundary layer transition, statistical analysis of flow distance Δ

l was carried out by 50 images based on the artificial image recognition (see

Figure 15a). We used box-and-whiskers plots to perform statistical analysis on 50 samples. In the box-and-whiskers plot, there is a middle line in the box, which denotes the median of the data. The upper and lower bottom of the box represent the upper quartile of the data (Q3) and lower quartile (Q1), which means that the box contains 50% of the data. Q3 and Q1 represent the 75th and 25th data of samples after arranging from small to large, respectively. The discrepancy between Q3 and Q1 is also known as the interquartile range (IQR). Based on the range of 1.5 IQR, the upper and lower edges of the box-and-whiskers plot represent the maximum and minimum values of the set of data. The data of samples outside this range are outliers, as presented in

Figure 15a. The plotted results in

Figure 15a reveal that Δ

l lessened from 94 mm to 35.4 mm with the growth of

in the range of

= 0.5–1.5, indicating that the height of the roughness element can apparently promote the wake boundary layer transition. However, as

was higher than 1.5, Δ

l did not vary remarkably (its value was almost about 40 mm), indicating that the height of the roughness element does not affect the wake boundary layer transition. However, the statistical results obtained from the 50 images may still not be enough to represent the whole population. From the qualitative perspective, it can be considered that 1.5

δ is close to the effective height proposed by Van Driest [

9] under the current state, that is, the REH when the transition position extends upstream and is closest to the roughness element.

In order to compare the influence of the REH on the large-scale vortex in the wake boundary layer, the wavelength of the large-scale vortex in a single image was recorded as

λ. Further, the ratio of the total wavelength of all large-scale vortex

in the image to the number of large-scale vortex

n was recorded as the average wavelength

(see

Figure 14b,c). It is noted from

Figure 14 that when the relative REH (i.e.,

) magnified from 0.5 to 1.5, the average wavelength

lessened from 13 mm to 5.8 mm, while the relative REH varied in the range of 1.5–2.5,

≈ 6.3 mm, and the average wavelength did not noticeably vary. It is worth mentioning that the scale of the large-scale vortex in a single image is random and the statistical analysis was carried out on the average wavelength

by artificially recognizing the 50 images (see

Figure 15b). The upper boundary of the error bar represents the maximum of the average wavelength

, and the corresponding lower boundary represents the minimum of the average wavelength

. As presented in

Figure 15b, the average wavelength

sharply lessened from 17.63 mm to 7.25 mm with the growth of

in the range of 0.5–1.5, corresponding to the phenomenon that the average wavelength of the vortex structure became smaller and smaller in

Figure 14b–d. It is indicated that the REH in this range had an apparent influence on the large-scale vortex in the wake boundary layer. As the relative REH (

) reached 1.5, the average wavelength

was around 7.75 mm, indicating that for the roughness element with

> 1.5, the REH had no noticeable consequence on the large-scale vortex in the wake flow.

By comparing

Figure 15a and

Figure 15b, the results reveal that the variation of the flow distance (Δ

l) and average wavelength (

) as a function of

as consistent. Compared with the roughness element with

= 0.5, the Δ

l of the roughness element associated with

= 1.5 reduced by about 62%, and the average wavelength

lessened by about 59%. Due to the lessening of the average wavelength

of the large-scale vortex structure, the interaction between the vortex was enhanced, which led to the advance of the vortex structure in the flow field and the decrease in the flow distance Δ

l. For the roughness element with

= 1.5–2.5, the changes of Δ

l and

with the REH were not understandable, indicating that the interaction between the resulted vortexes was stable.

The effect of REH on the boundary layer transition in the wake flow field was scrutinized by implementing the transient image and statistical analysis. The demonstrated results indicate that there was no vortex structure in the image for the roughness element with = 0.25, and it was impossible to judge its effect on the boundary layer transition, and the vortex structure that appeared in the image was pertinent to the roughness element with = 0.5. Therefore, the critical REH was less than 0.5 δ, but it was impossible to judge the size between the critical REH and 0.25 δ. For the roughness element with = 0.5–1.5, the transition position moved forward rapidly with the growth of the REH. By approaching to 1.5, the position of the first vortex in the wake boundary layer did not noticeably change. The REH had no apparent influence on the transition position, and the effective REH was close to 1.5 δ. Since the boundary layer transition was promoted between the critical REH and the effective REH, it had a trivial effect beyond this range. In the different REHs in this paper, the promoting effect of the boundary layer transition was apparent between 0.25 δ and 1.5 δ, but it was strongly weakened beyond 1.5 δ. As a result, we think that 0.25 δ and 1.5 δ can be employed as reference heights representing the critical REH and the effective REH respectively to provide a basis for the precise prediction and flow control of the boundary layer transition in the current state.