Design of the Electronic Engine Control Unit Performance Test System of Aircraft

Abstract

1. Introduction

2. Engine Model

2.1. Target Engine

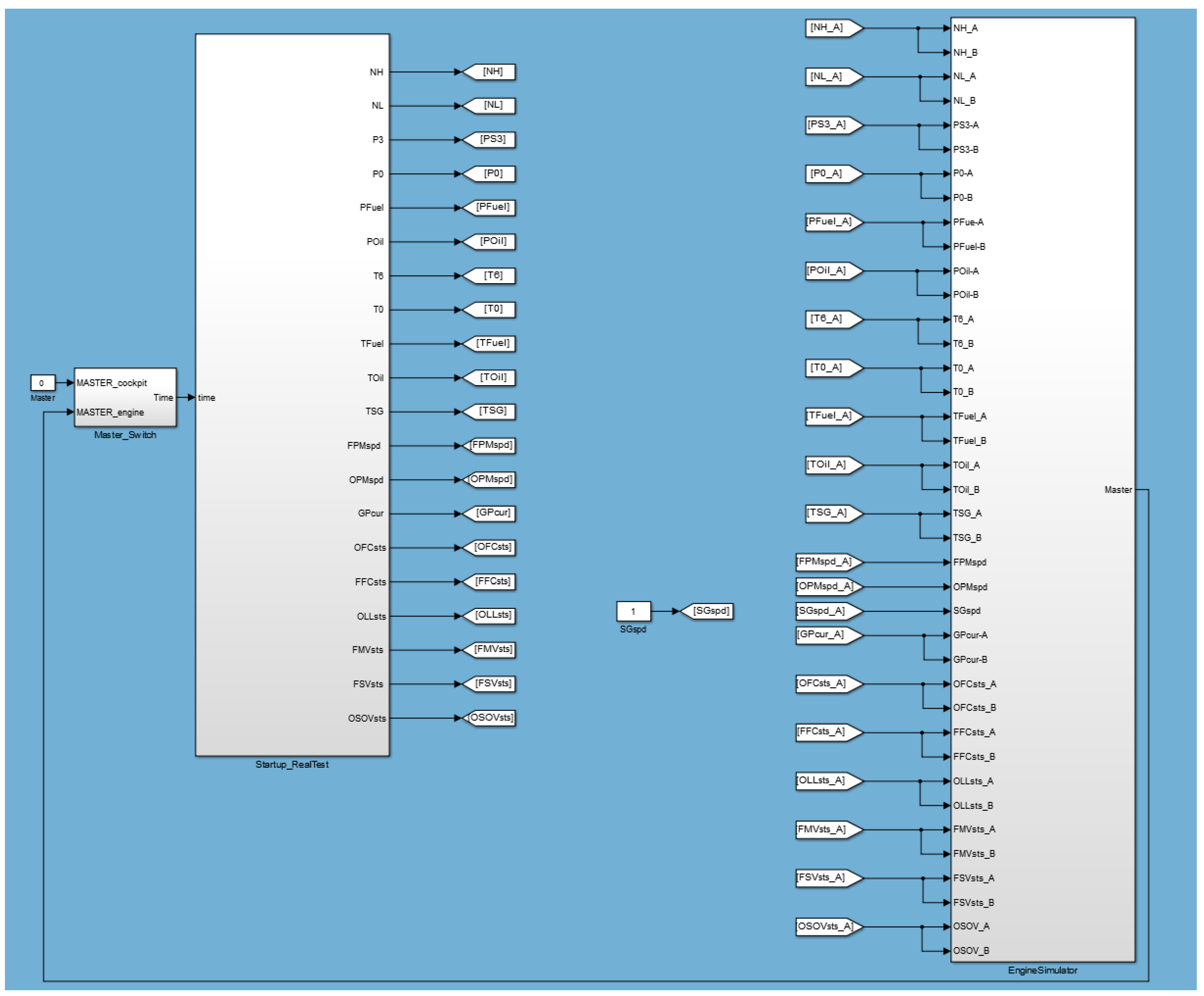

2.2. Real-Time Startup Phase Engine Modeling

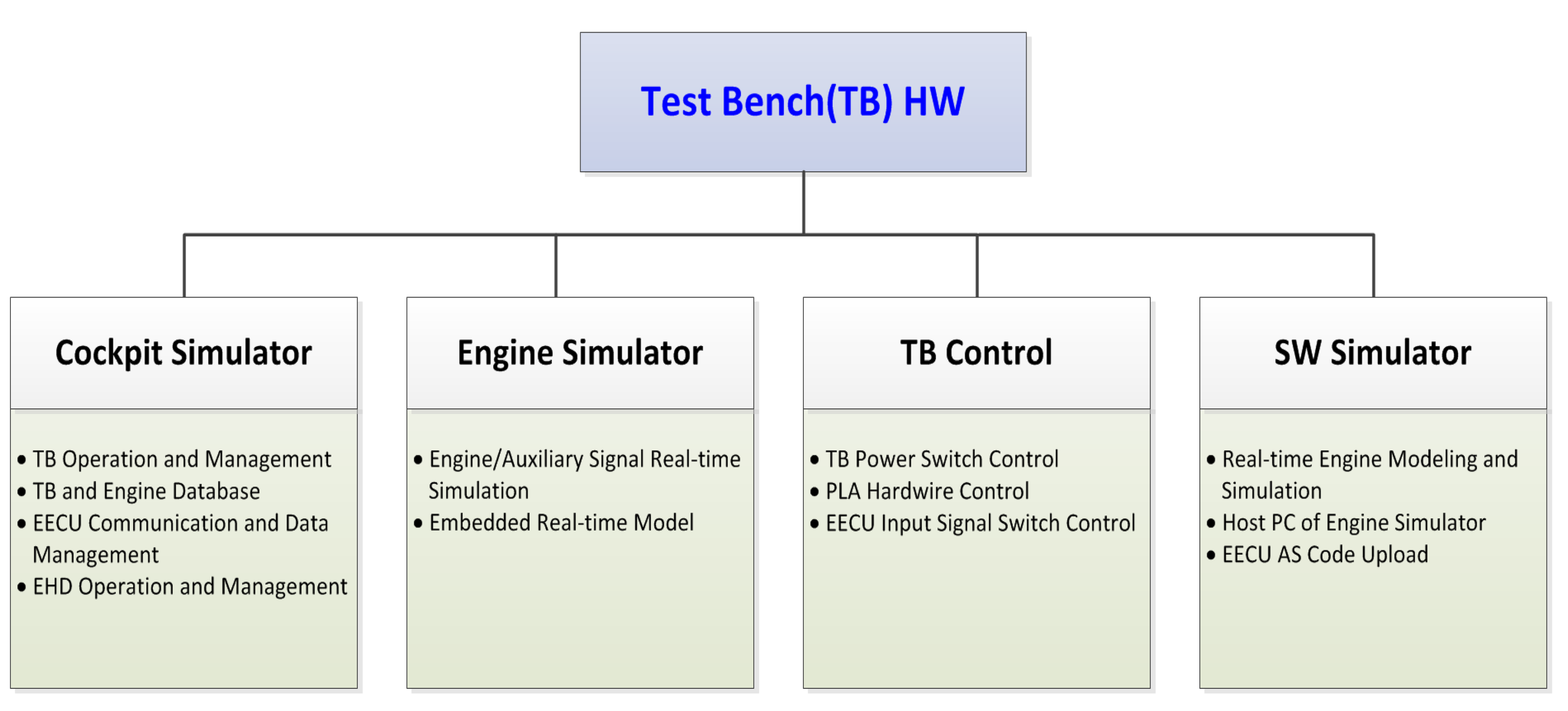

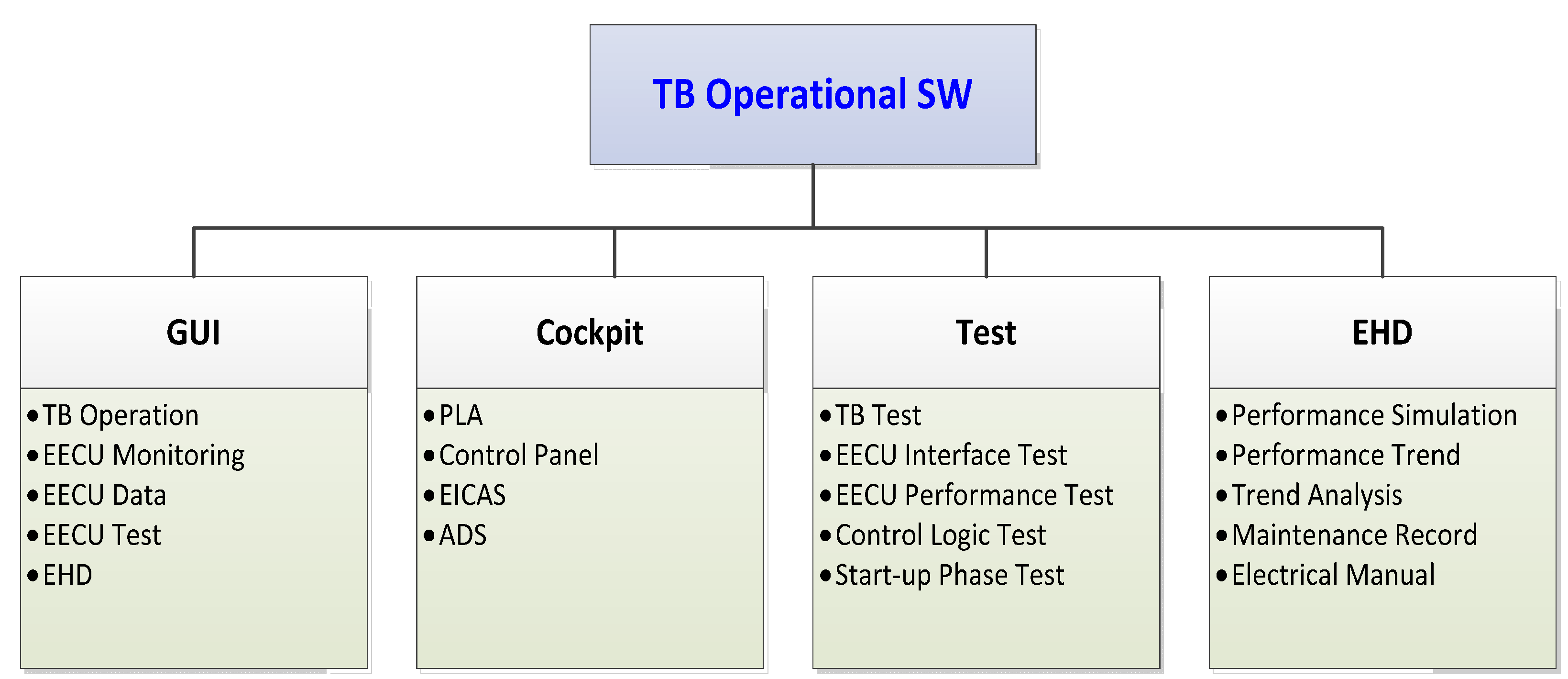

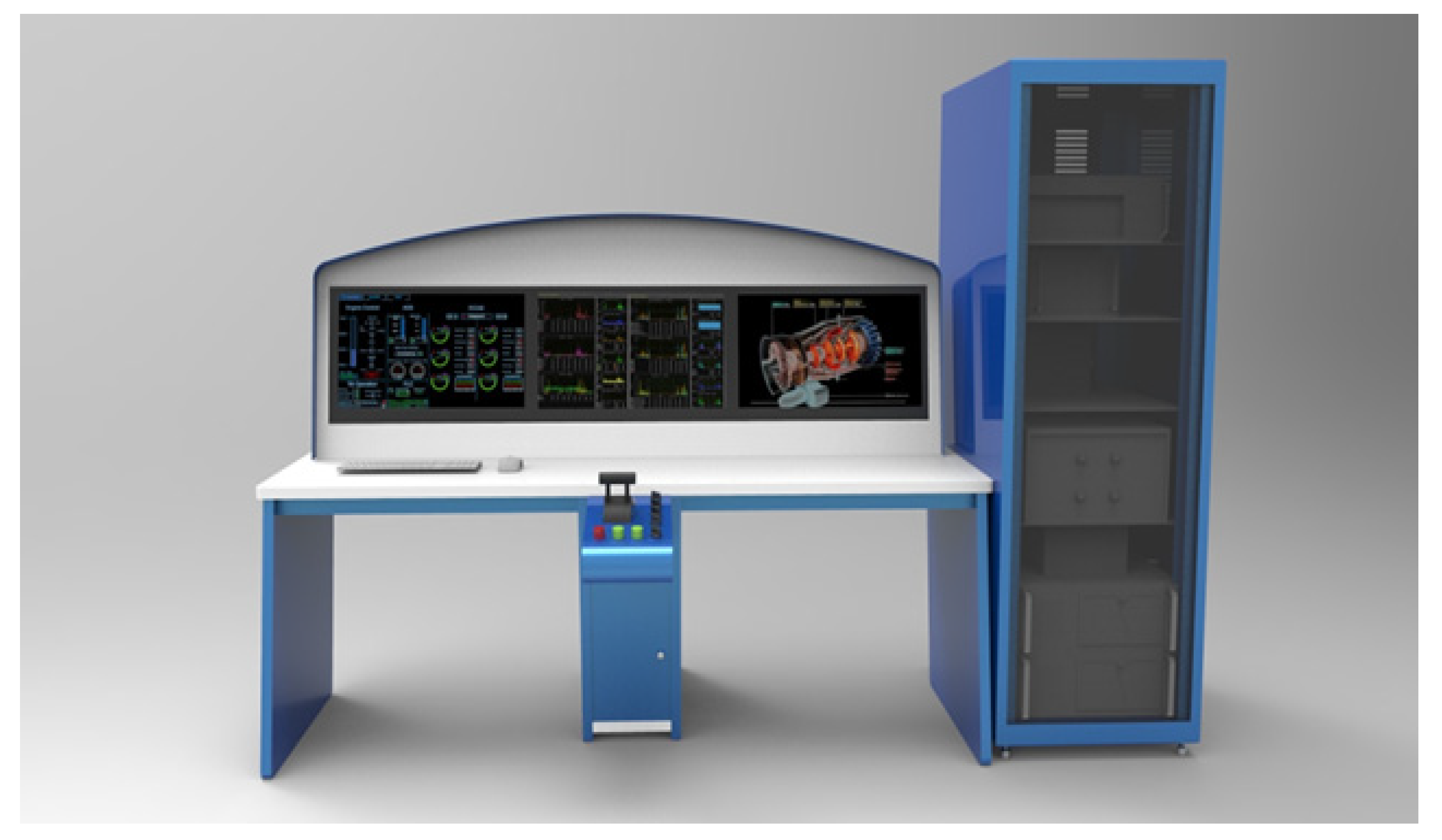

3. Test Bench Development

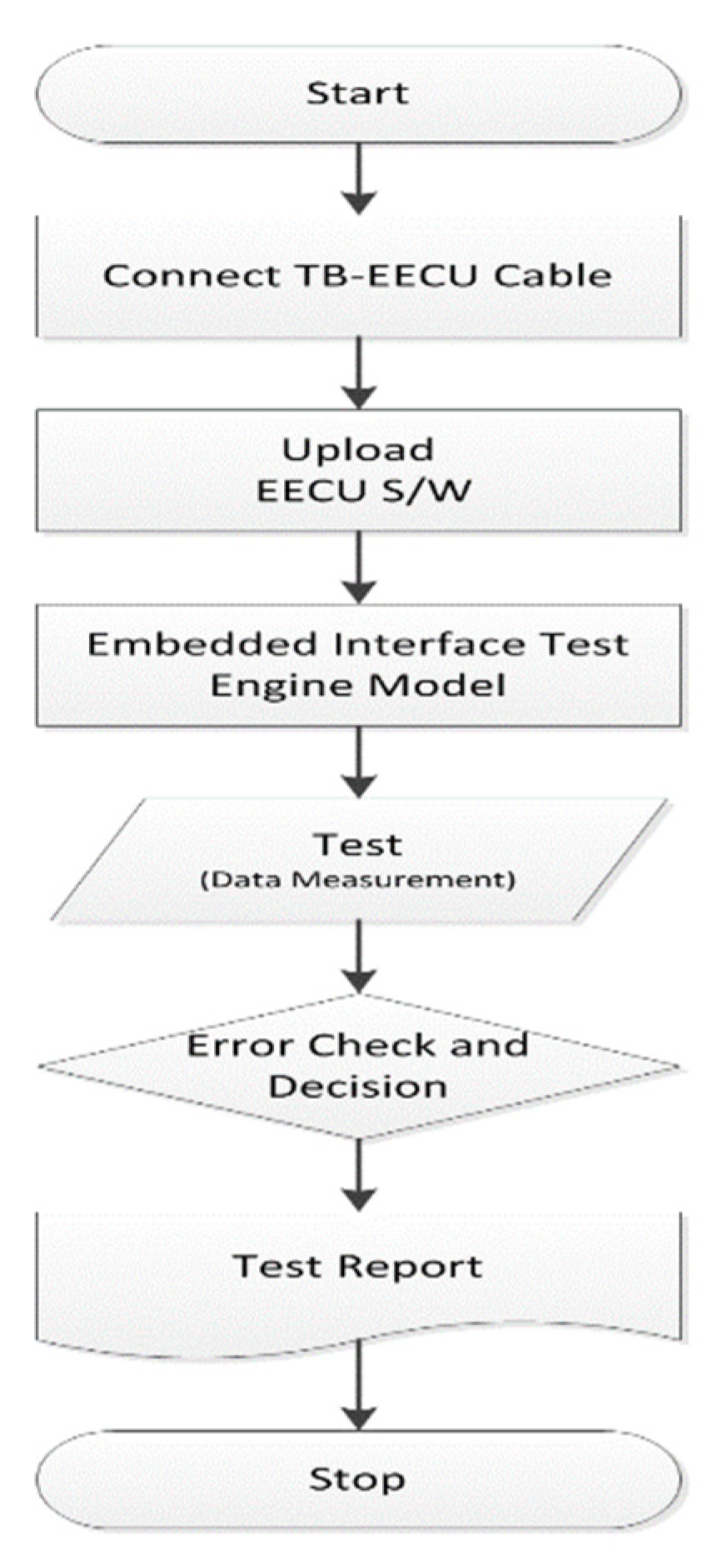

4. EECU Verification Test

4.1. Functional Test of Test Bench

4.2. EECU Interface and Interworking Test

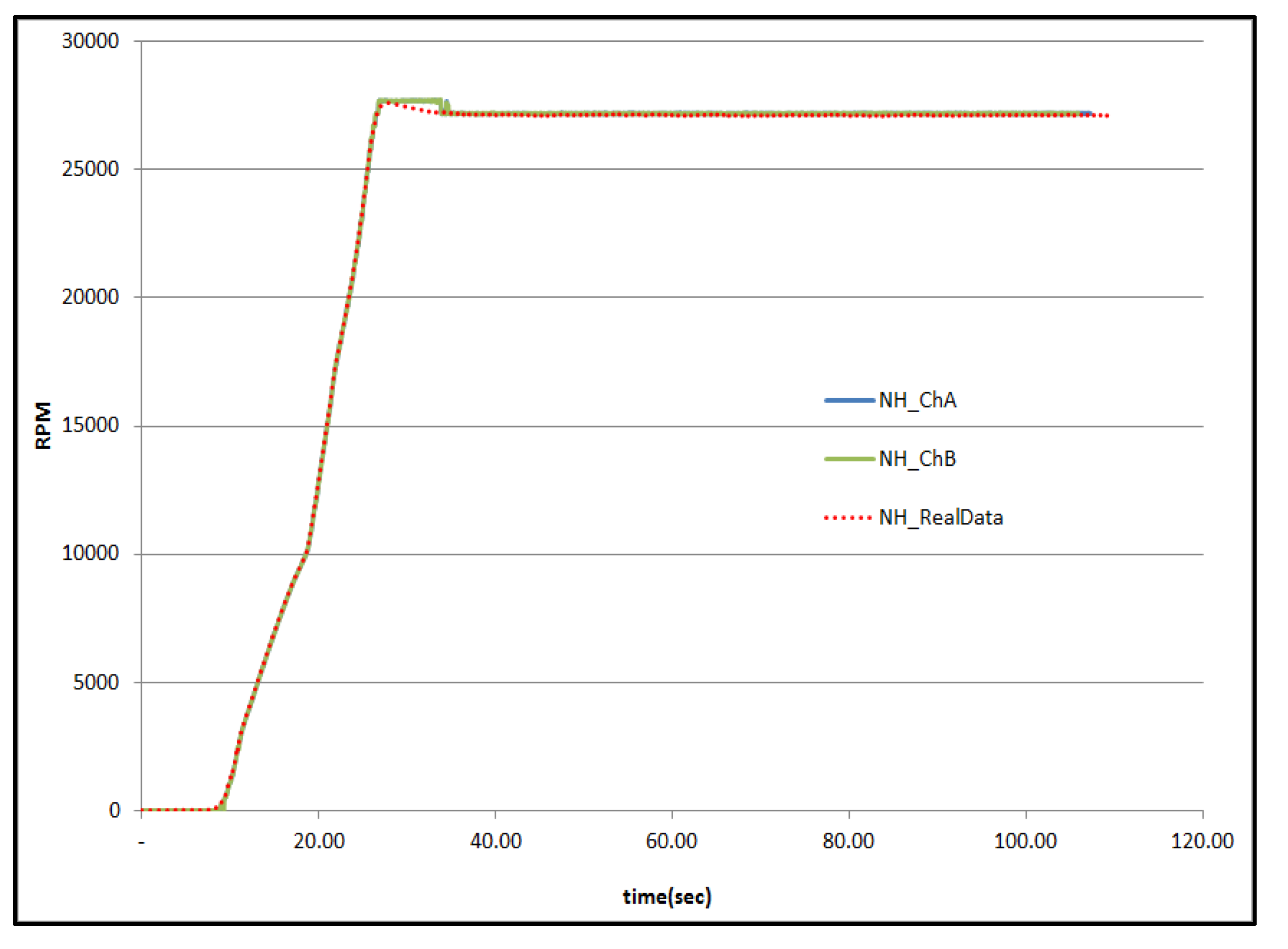

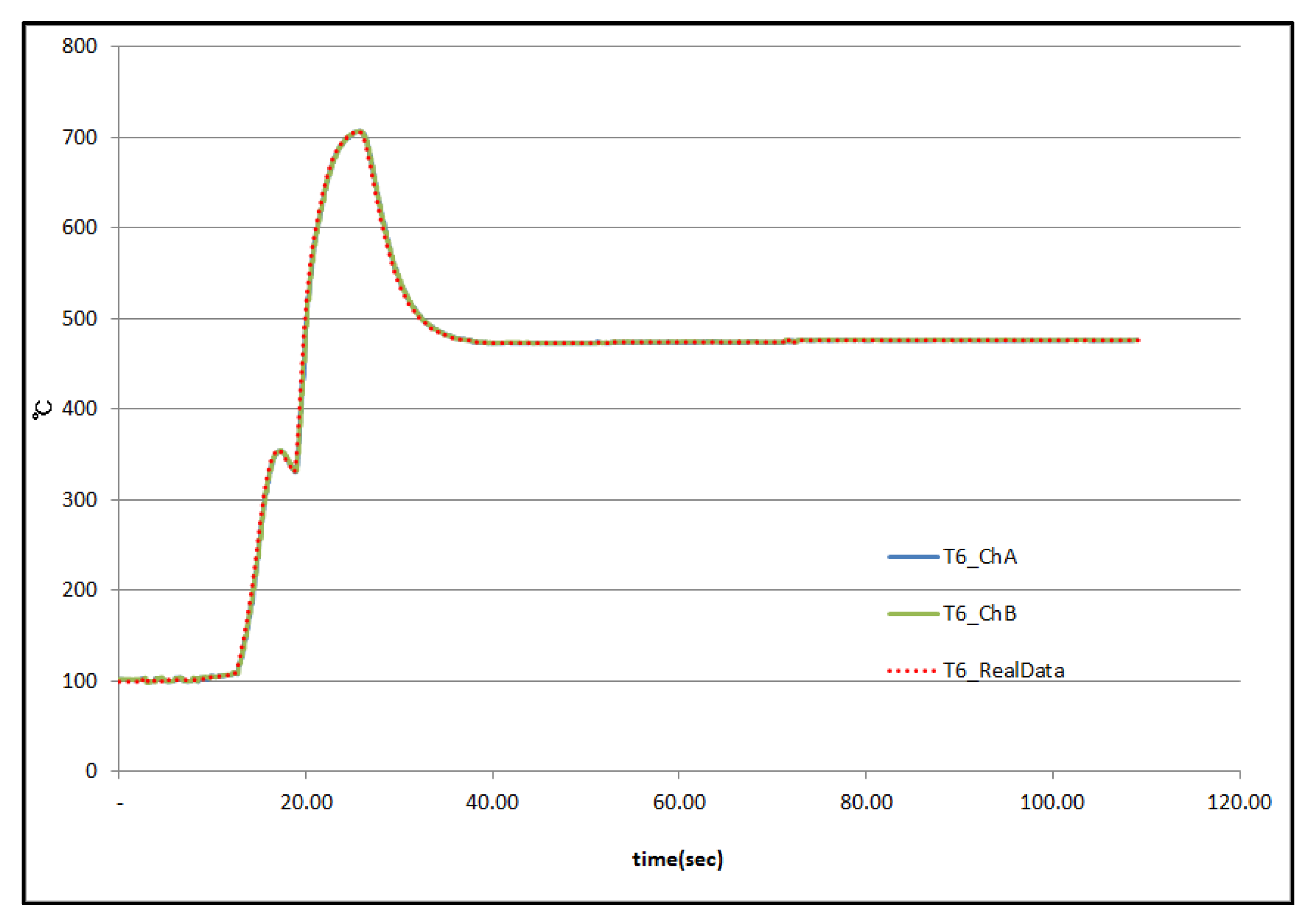

4.3. Real-Time Engine Model Verification Test

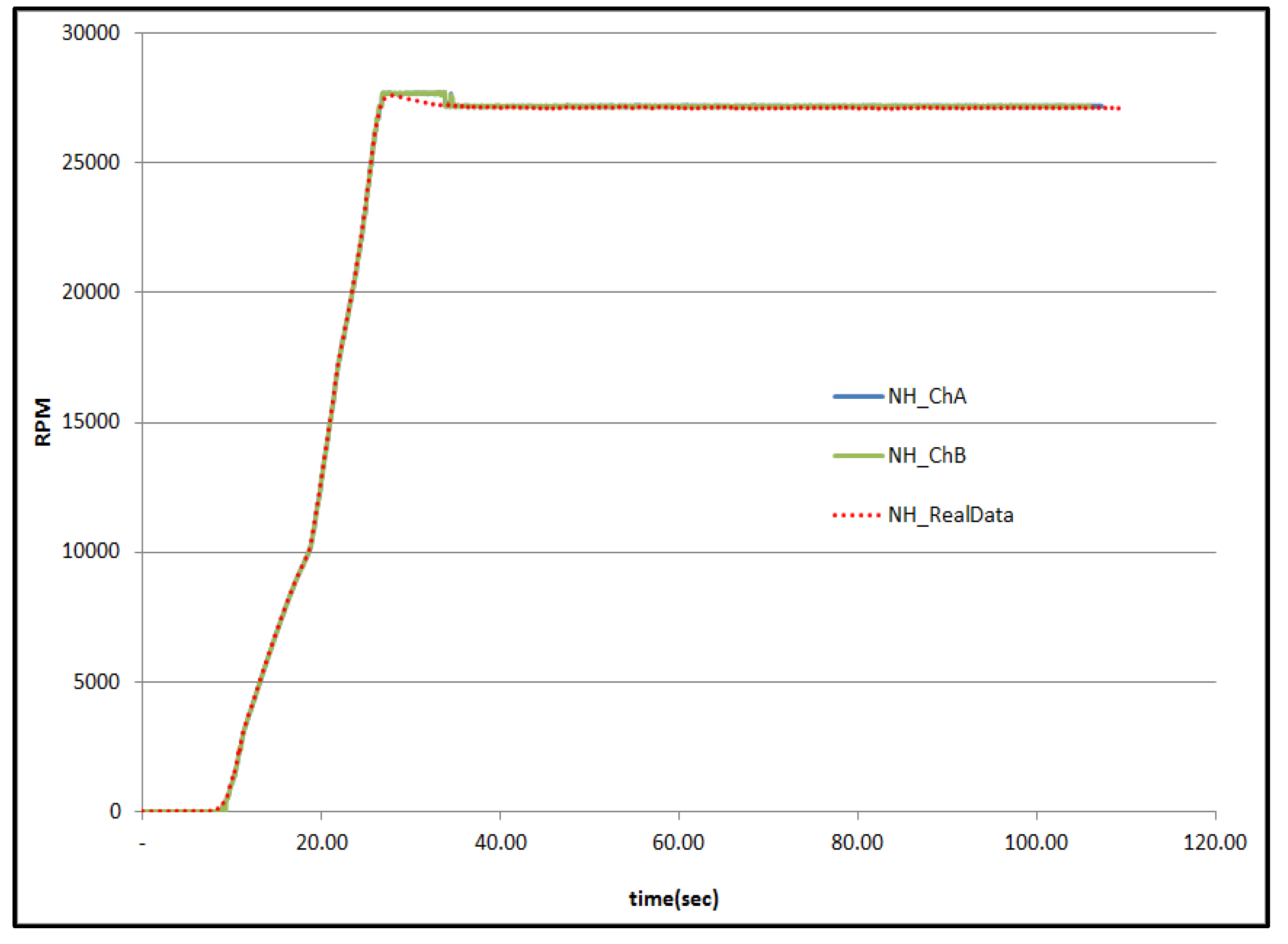

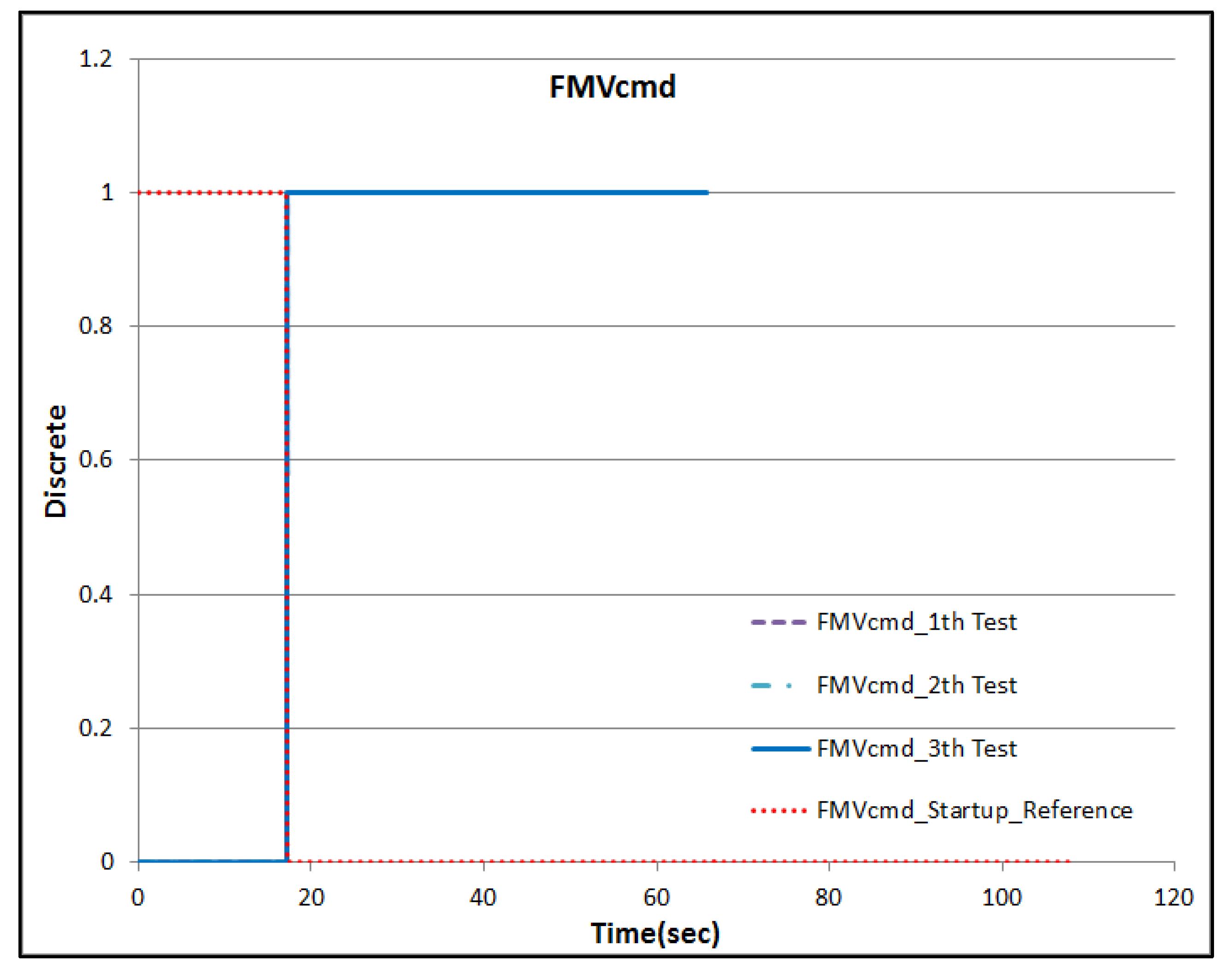

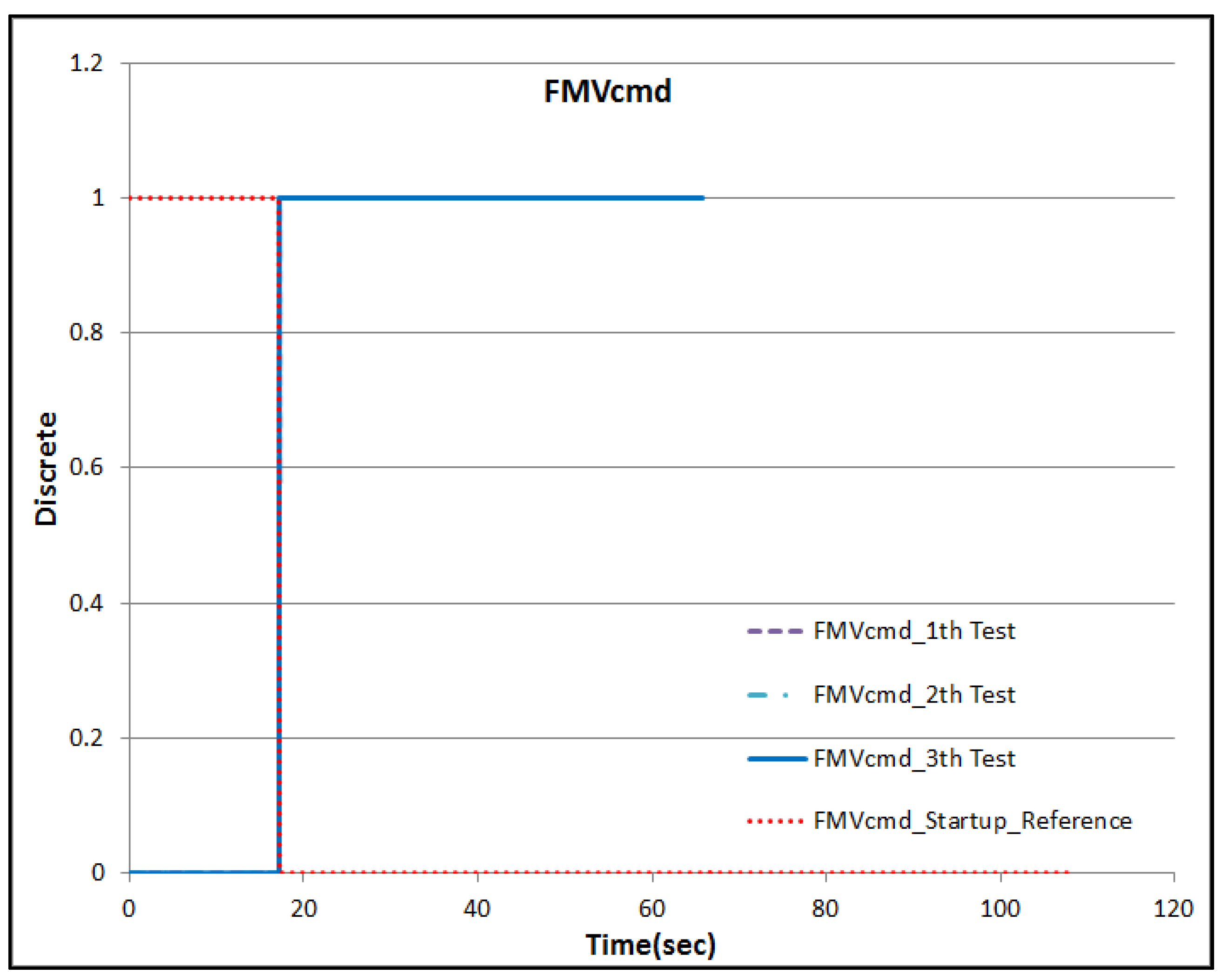

4.4. Startup Phase Control Logic Verification Test

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EECU | electronic engine control unit |

| ρ | density |

| t | time |

| ν | volume |

| LHV | fuel calorific value |

| DPcold | cold loss of combustor |

| DPhot | heat loss of combustor |

| Kcold | cold loss value |

| Khot | heat loss value |

| RRF | ram recovery coefficient |

| RTD | resistance temperature diode |

| PTC | positive temperature coefficient thermistor |

| EHD | engine health diagnostic |

| GUI | graphical user interface |

| EECU | electronic engine control units |

| P | pressure |

| NL (t) | the number of revolutions of low pressure at time t |

| B | operating point |

References

- Lobo, L.M.; Dufour, C.; Mahseredjian, J. Real-time simulation of more-electric aircraft power sytems. In Proceedings of the EPE’13 ECCE Europe Conference, Lille, France, 3–5 September 2013; pp. 1–10. [Google Scholar]

- Davies, W.J.; Hoelzer, C.A.; Vizzini, R.W. F-14 aircraft and propulsion control integration evaluation. J. Eng. Power 1983, 105, 663–668. [Google Scholar] [CrossRef]

- Yamane, H.; Takahara, Y.; Oyobe, T. Aspects of aircraft engine control systems R&D. Control Eng. Pract. 1997, 5, 595–602. [Google Scholar]

- Schwamm, F. FADEC computer systems for safety critical application. In Proceedings of the ASME the 1998 International Gas Turbine & Aeroengine Congress & Exhibition, Stockholm, Sweden, 2–5 June 1998; pp. 1–8. [Google Scholar]

- Hjelmgren, K.; Svensson, S.; Hannius, O. Reliability analysis of a single-engine aircraft FADEC. In Proceedings of the IEEE Reliability and Maintainability Symposium, Anaheim, CA, USA, 19–22 January 1998; pp. 401–407. [Google Scholar]

- Ito, K.; Nakagawa, T. Optimal self-diagnosis policy for FADEC of gas turbine engines. Math. Comput. Model. 2003, 38, 1243–1248. [Google Scholar] [CrossRef]

- Ding, S.; Qiu, T.; Liu, X.; Zhang, S. FHA method for VBV position control function of FADEC system based on aero-engine dynamic model. Procedia Eng. 2011, 17, 567–579. [Google Scholar]

- Pogorelov, G.I.; Kulikov, G.G.; Abdulnagimov, A.I.; Badamshin, B.I. Application of neural network technology and high-performance computing for identification and real-time hardware-in-the-loop simulation of gas turbine engines. Procedia Eng. 2017, 176, 402–408. [Google Scholar] [CrossRef]

- Choi, K.; Jang, S.-A.; Choi, K.; Eom, J.S.; Lee, B.S.; Son, Y.C.; Ryu, H. Development of an integrated high fidelity helicopter and engine simulation for control system design. J. Korean Soc. Aeronaut. Space Sci. 2010, 38, 249–257. [Google Scholar]

- Lee, K.-Y.; Han, S.-H.; Jin, Y.-K.; Lee, S.-J.; Kim, K.-S. A study on certification of electronic engine controls. J. Korean Soc. Aeronaut. Space Sci. 2005, 33, 104–109. [Google Scholar]

- Jung, J.-H.; Lee, S.-H.; Park, S.-W.; Jeong, I.-M.; Lee, S.-B. T-50 engine airstart test. J. Korean Soc. Aeronaut. Space Sci. 2006, 34, 90–95. [Google Scholar]

- Lu, F.; Braun, E. Rotating detonation wave propulsion: Experimental challenges, modeling, and engine concepts. J. Propuls. Power 2014, 30, 1125–1142. [Google Scholar] [CrossRef]

- Jafari, S.; Nikolaidis, T. Meta-heuristic global optimization algorithms for aircraft engines modelling and controller design; a review, research challenges, and exploring the future. Prog. Aerosp. Sci. 2019, 104, 40–53. [Google Scholar] [CrossRef]

- Jafari, S.; Fashandi, S.A.M.; Nikolaidis, T. Modeling and control of the starter motor and start-up phase for gas turbines. Electronics 2019, 8, 363. [Google Scholar] [CrossRef]

- Montazeri-Gh, M.; Fashandi, S.A.M. Bond graph modeling of a jet engine with electric starter. Proc. Inst. Mech. Eng. G J. Aerosp. Eng. 2019, 233, 3193–3210. [Google Scholar] [CrossRef]

- Imani, A.; Montazeri-Gh, M. A multi-loop switching controller for aircraft gas turbine engine with stability proof. Int. J. Control Autom. Syst. 2019, 17, 1359–1368. [Google Scholar] [CrossRef]

- Salehi, A.; Montazeri-Gh, M. Hardware-in-the-loop simulation of fuel control actuator of a turboshaft gas turbine engine. Proc. Inst. Mech. Eng. M 2019, 233, 969–977. [Google Scholar] [CrossRef]

- Montazeri-Gh, M.; Rasti, A. Analyzing different numerical linearization methods for the dynamic model of a turbofan engine. Mech. Ind. 2019, 20, 303. [Google Scholar] [CrossRef]

- Song, M.; Jianguo, T.; Sanmai, S. Optimization for the starting process of turbofan engine under high-altitude environment. IEEE Access 2018, 6, 55797–55806. [Google Scholar] [CrossRef]

- Bai, J.; Liu, S.; Wei, W. The nonlinear single controller of DGEN380 aero engine design. Int. J. Aerosp. Eng. 2019, 7209428, 1–12. [Google Scholar] [CrossRef]

- Qian, Y.; Ye, Z.; Zhang, H. LPV/PI control for nonlinear aeroengine system based on guardian maps theory. IEEE Access 2019, 7, 125854–125867. [Google Scholar] [CrossRef]

- Yazar, I.; Kiyak, E.; Caliskan, F. Simulation-based dynamic model and speed controller design of a small-scale turbojet engine. Aircr. Eng. Aerosp. Technol. 2018, 90, 351–358. [Google Scholar] [CrossRef]

- Beneda, K. Development of a modular FADEC for small scale turbojet engine. In Proceedings of the 2016 IEEE 14th International Symposium on Applied Machine Intelligence and Informatics (SAMI), Herlany, Slovakia, 21–23 January 2016. [Google Scholar]

- Lutambo, J.; Wang, J.; Yue, H. Aircraft turbine engine control systems development: Historical perspective. In Proceedings of the 2015 34th Chinese Control Conference (CCC), Hangzhou, China, 28–30 July 2015. [Google Scholar]

- Jie, B.; Shuai, L.; Wang, W. An integrated controller design for a small aero-engine. In Proceedings of the 2019 Chinese Control and Decision Conference (CCDC), Nanchang, China, 3–5 June 2019. [Google Scholar]

- Victor, S.; Taymans, A.; Melchior, P. Robust control system design of a turbofan. In Proceedings of the International Conference on Fractional Differentiation and Its Applications, Novi Sad, Republic of Serbia, 18–20 July 2016. [Google Scholar]

- Connolly, J.W.; Csank, J.; Chicatelli, A.; Franco, K. Propulsion controls modeling for a small turbofan engine. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10–12 July 2017. [Google Scholar]

- Connolly, J.W.; Csank, J.; Chicatelli, A. Advanced control considerations for turbofan engine design. In Proceedings of the 52nd AIAA/SAE/ASEE Joint Propulsion Conference, Salt Lake City, UT, USA, 25–27 July 2016. [Google Scholar]

- Csank, J.; Connolly, J.W. Model-based engine control architecture with an extended Kalman Filter. In Proceedings of AIAA Guidance, Navigation, and Control Conference, San Diego, CA, USA, 4–8 January 2016. [Google Scholar]

- Andoga, R.; Fozo, L.; Judicak, J.; Breda, R.; Szabo, S.; Rozenberg, R.; Dzunda, M. Intelligent situational control of small turbojet engines. Int. J. Aerosp. Eng. 2018, 8328762, 1–16. [Google Scholar] [CrossRef]

- Walsh, P.P.; Fletcher, P. Gas. Turbine Performance, 2nd ed.; Blackwell Science: Oxford, UK, 2004; pp. 444–476. [Google Scholar]

| Specification | Value |

|---|---|

| Maximum take-off thrust (TOP, ISA, SL, MN0) | 2500 N |

| Specific fuel consumption (SFC TOP) | 0.0438 kg/N/h |

| Maximum cruise thrust (MCR, ISA, SL, MN0.338) | 1170 N |

| Specific fuel consumption (SFC MCR) | 7.58 |

| Weight (without nacelle) | 80 kg |

| Classify | Specification | ||

|---|---|---|---|

| Engine Simulator | Output | Temperature Sensor | RTD (8 Ch), Thermocouple (6 Ch), PTC (2 Ch) |

| Pressure Sensor | 12 Ch | ||

| Glowplug Current | 2 Ch | ||

| RPM Sensor | 4 Ch | ||

| PLA Sensor | 2 Ch | ||

| Frequency | 6 Ch | ||

| Discrete | 14 Ch | ||

| Input | Discrete | 12 Ch | |

| PWM | 6 Ch | ||

| Cockpit Simulator | Communication | ARINC429 (2 Ch), RS232 (2 Ch), Ethernet (2 Ch) | |

| Output | PLA Sensor | 2 Ch | |

| Discrete | 22 Ch | ||

| Input | Discrete | 22 Ch | |

| No. | Test Items | Standard | Method | Reference | Measurement (Case No.) | Decision | |||

|---|---|---|---|---|---|---|---|---|---|

| X1 | X2 | X3 | |||||||

| 1 | CH. A Discrete Output | Master (0/5 V, FS ± 10%) | Digital Multimeter | 0 V < X < 2.6 V (ON) | 0.698 | 0.699 | 0.698 | OK | |

| 2.6 V < X < 5 V (OFF) | 4.05 | 4.05 | 4.05 | ||||||

| 2 | IGN | 0 V < X < 2.6 V (ON) | 0.702 | 0.703 | 0.701 | OK | |||

| DCRANK | 0 V < X < 2.6 V (ON) | 0.684 | 0.684 | 0.684 | |||||

| WCRANK | 0 V < X < 2.6 V (ON) | 0.696 | 0.696 | 0.696 | |||||

| 3 | Normal | IGN | 2.6 V < X < 5 V (OFF) | 4.8 | 4.8 | 4.8 | OK | ||

| DCRANK | 2.6 V < X < 5 V (OFF) | 4.8 | 4.8 | 4.8 | |||||

| WCRANK | 2.6 V < X < 5 V (OFF) | 4.8 | 4.8 | 4.8 | |||||

| 4 | WOW (0/5 V, FS ± 10%) | 0 V < X < 2.6 V (ON) | 0.704 | 0.704 | 0.704 | OK | |||

| 2.6 V < X < 5 V (OFF) | 4.8 | 4.8 | 4.8 | ||||||

| 5 | CH_A | 0 V < X < 2.6 V (ON) | 0.7 | 0.7 | 0.7 | OK | |||

| CH_AUTO | 0 V < X < 2.6 V (ON) | 0.692 | 0.692 | 0.692 | |||||

| CH_B | 0 V < X < 2.6 V (ON) | 0.690 | 0.690 | 0.690 | |||||

| 6 | OFCsts (0/5 V, FS ± 10%) | 0 V < X < 2.6 V (ON) | 0.142 | 0.141 | 0.141 | OK | |||

| 2.6 V < X < 5 V (OFF) | 4.21 | 4.22 | 4.22 | ||||||

| No. | Test Items | Test Result | ||

|---|---|---|---|---|

| Ch. A | Ch. B | |||

| 1 | Discrete Output | MASTER | OK | OK |

| 2 | IGN | OK | OK | |

| 3 | DCRANK | OK | OK | |

| 4 | WCRANK | OK | OK | |

| 5 | NORMAL | OK | OK | |

| 6 | WOW | OK | OK | |

| 7 | CH_A | OK | OK | |

| 8 | CH_AUTO | OK | OK | |

| 9 | CH_B | OK | OK | |

| 10 | OFCsts | OK | OK | |

| 11 | FFCsts | OK | OK | |

| 12 | OLLsts | OK | OK | |

| 13 | FMVsts | OK | OK | |

| 14 | FSVsts | OK | OK | |

| 15 | OSOVsts | OK | OK | |

| 16 | Discrete Input | GPcmd | OK | OK |

| 17 | FMVcmd | OK | OK | |

| 18 | FSVcmd | OK | OK | |

| 19 | OSOVcmd | OK | OK | |

| 20 | SGstart | OK | OK | |

| 21 | SGmode | OK | OK | |

| 22 | Analog Output | PS3 | OK | OK |

| 23 | P0 | OK | OK | |

| 24 | PFuel | OK | OK | |

| 25 | POil | OK | OK | |

| 26 | T6 | OK | OK | |

| 27 | T0 | OK | OK | |

| 28 | TFuel | OK | OK | |

| 29 | TOil | OK | OK | |

| 30 | TSG | OK | OK | |

| 31 | GPcur | OK | OK | |

| 32 | PLA | OK | OK | |

| 33 | NH | OK | OK | |

| 34 | NL | OK | OK | |

| 35 | FPMspd | OK | OK | |

| 36 | OPMspd | OK | OK | |

| 37 | SGspd | OK | OK | |

| 38 | Analog Input | FPMcmd | OK | OK |

| 39 | OPMcmd | OK | OK | |

| 40 | SGcmd | OK | OK | |

| No. | Test Items | Standard | Method | Reference | Measurement (Case No.) | Decision | ||

|---|---|---|---|---|---|---|---|---|

| 1 | CH. A Discrete Output | Master (ON/OFF) | MASTER Switch | ON | ON | ON | ON | OK |

| OFF | OFF | OFF | OFF | |||||

| 2 | IGN (ON) | MODE Switch | IGN | IGN | IGN | IGN | OK | |

| DCRANK (ON) | DCRANK | DCRANK | DCRANK | DCRANK | ||||

| WCRANK (ON) | WCRANK | WCRANK | WCRANK | WCRANK | ||||

| 3 | NOMAL (ON) | NOMAL | NOMAL | NOMAL | NOMAL | OK | ||

| 4 | WOW (ON/OFF) | WOW Switch | Ground | Ground | Ground | Ground | OK | |

| Flight | Flight | Flight | Flight | |||||

| 5 | CH_A | Channel Switch | CH_A | CH_A | CH_A | CH_A | OK | |

| CH_AUTO | CH_AUTO | CH_AUTO | CH_AUTO | CH_AUTO | ||||

| CH_B | CH_B | CH_B | CH_B | CH_B | ||||

| 6 | OFCsts (0/5 V) | Engine Simulator | Discrete, 0 | Clogged | Clogged | Clogged | OK | |

| Discrete, 1 | Not Clogged | Not Clogged | Not Clogged | |||||

| 7 | FFCsts (0/5 V) | Engine Simulator | Discrete, 0 | Clogged | Clogged | Clogged | OK | |

| Discrete, 1 | Not Clogged | Not Clogged | Not Clogged | |||||

| 8 | OLLsts (0/5 V) | Engine Simulator | Discrete, 0 | Low Oil | Low Oil | Low Oil | OK | |

| Discrete, 1 | Enough Oil | Enough Oil | Enough Oil | |||||

| 9 | FMVsts (0/5 V) | Engine Simulator | Discrete, 0 | Open | Open | Open | OK | |

| Discrete, 1 | Closed | Closed | Closed | |||||

| 10 | FSVsts (0/5 V) | Engine Simulator | Discrete, 0 | Open | Open | Open | OK | |

| Discrete, 1 | Closed | Closed | Closed | |||||

| 11 | OSOVsts (0/5 V) | Engine Simulator | Discrete, 0 | Open | Open | Open | OK | |

| Discrete, 1 | Closed | Closed | Closed | |||||

| No. | Test Items | Test Result | ||

|---|---|---|---|---|

| Ch. A | Ch. B | |||

| 1 | Discrete Output | MASTER | OK | OK |

| 2 | IGN | OK | OK | |

| 3 | DCRANK | OK | OK | |

| 4 | WCRANK | OK | OK | |

| 5 | NORMAL | OK | OK | |

| 6 | WOW | OK | OK | |

| 7 | CH_A | OK | OK | |

| 8 | CH_AUTO | OK | OK | |

| 9 | CH_B | OK | OK | |

| 10 | OFCsts | OK | OK | |

| 11 | FFCsts | OK | OK | |

| 12 | OLLsts | OK | OK | |

| 13 | FMVsts | OK | OK | |

| 14 | FSVsts | OK | OK | |

| 15 | OSOVsts | OK | OK | |

| 16 | Discrete Input | GPcmd | OK | OK |

| 17 | FMVcmd | OK | OK | |

| 18 | FSVcmd | OK | OK | |

| 19 | OSOVcmd | OK | OK | |

| 20 | SGstart | OK | OK | |

| 21 | SGmode | OK | OK | |

| 22 | Analog Output | PS3 | OK | OK |

| 23 | P0 | OK | OK | |

| 24 | PFuel | OK | OK | |

| 25 | POil | OK | OK | |

| 26 | T6 | OK | OK | |

| 27 | T0 | OK | OK | |

| 28 | TFuel | OK | OK | |

| 29 | TOil | OK | OK | |

| 30 | TSG | OK | OK | |

| 31 | GPcur | OK | OK | |

| 32 | PLA | OK | OK | |

| 33 | NH | OK | OK | |

| 34 | NL | OK | OK | |

| 35 | FPMspd | OK | OK | |

| 36 | OPMspd | OK | OK | |

| 37 | SGspd | OK | OK | |

| 38 | Analog Input | FPMcmd | OK | OK |

| 39 | OPMcmd | OK | OK | |

| 40 | SGcmd | OK | OK | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kho, S.; Park, H. Design of the Electronic Engine Control Unit Performance Test System of Aircraft. Aerospace 2021, 8, 158. https://doi.org/10.3390/aerospace8060158

Kho S, Park H. Design of the Electronic Engine Control Unit Performance Test System of Aircraft. Aerospace. 2021; 8(6):158. https://doi.org/10.3390/aerospace8060158

Chicago/Turabian StyleKho, Seonghee, and Hyunbum Park. 2021. "Design of the Electronic Engine Control Unit Performance Test System of Aircraft" Aerospace 8, no. 6: 158. https://doi.org/10.3390/aerospace8060158

APA StyleKho, S., & Park, H. (2021). Design of the Electronic Engine Control Unit Performance Test System of Aircraft. Aerospace, 8(6), 158. https://doi.org/10.3390/aerospace8060158