Sources of Onboard Fumes and Smoke Reported by U.S. Airlines

Abstract

1. Introduction

2. Materials and Methods

3. Results

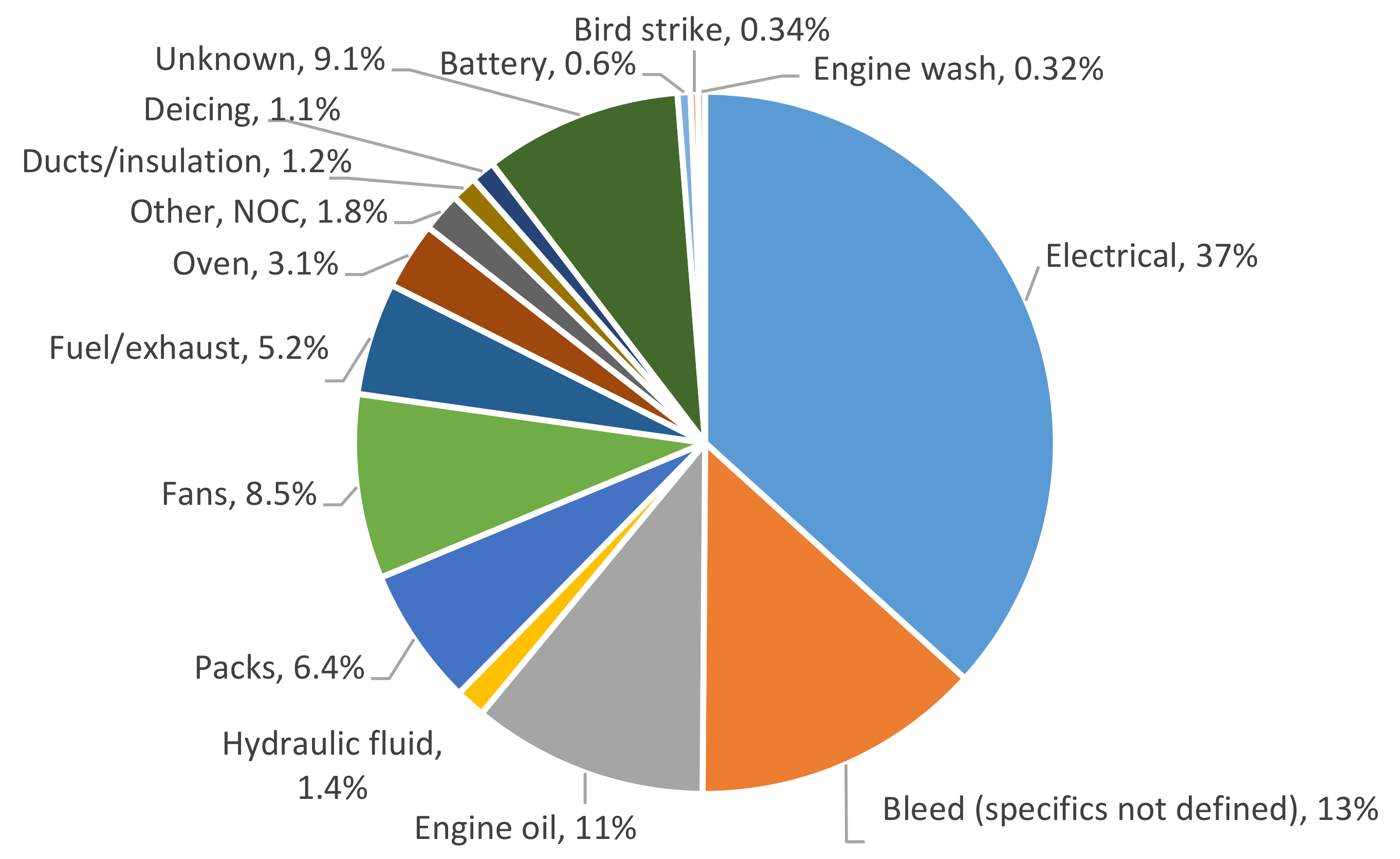

3.1. Types of Onboard Fumes/Smoke Reported by U.S. Airlines

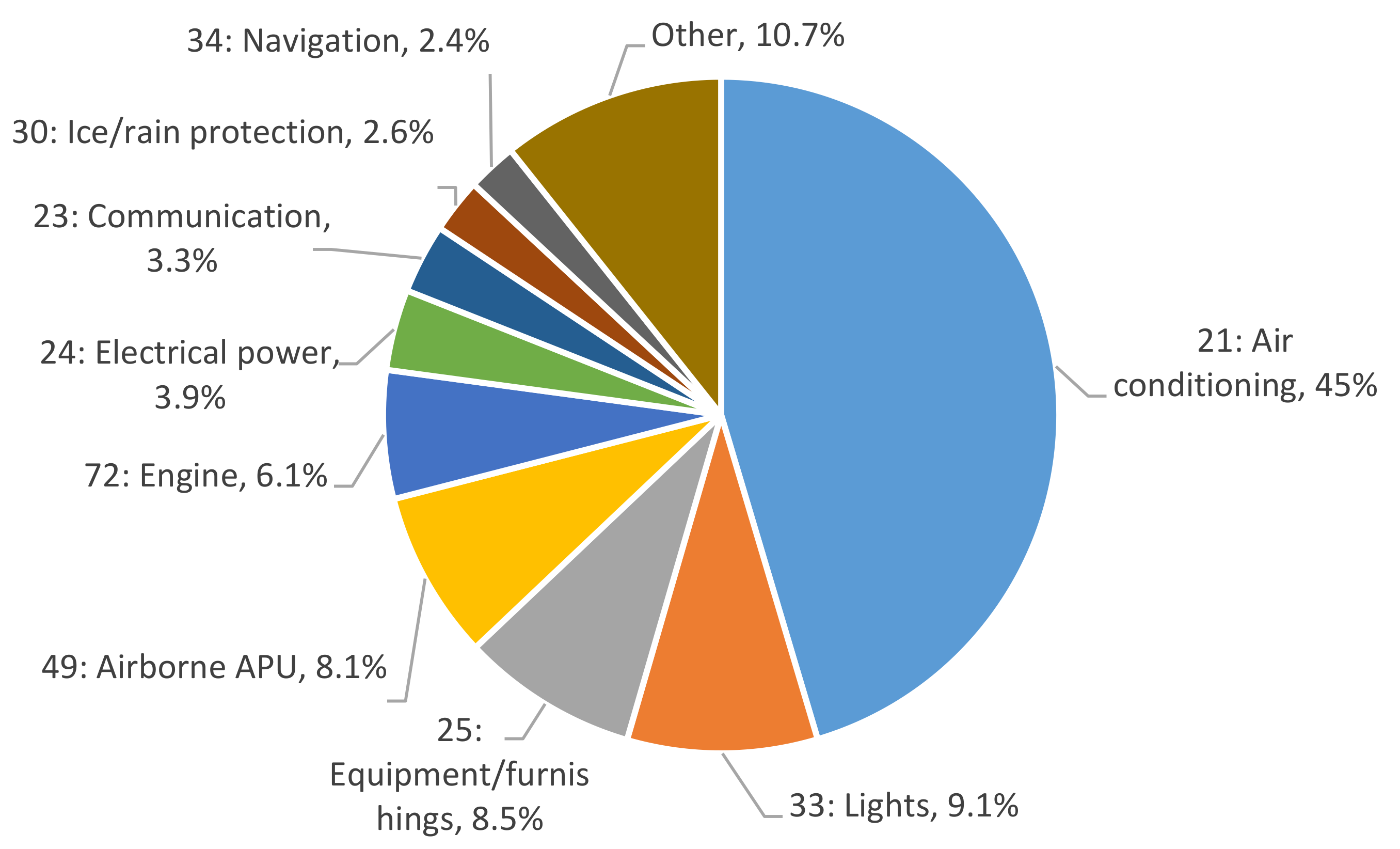

3.2. ATA Chapters, Whole Dataset

3.3. ATA Chapters, Onboard Electrical Fumes/Smoke

3.4. ATA Chapters, Onboard Fume Events (Engine Oil, Hydraulic Fluid)

3.5. ATA Chapters, Onboard Fan-Sourced Fumes, and Smoke

3.6. Other Sources of Onboard Fumes/Smoke

4. Discussion

4.1. Airline Reporting Rules for Onboard Fumes/Smoke

4.2. Underreporting Engine Oil and Hydraulic Fume Events

4.3. Estimates of the Frequency of Engine Oil and Hydraulic Events

4.4. Recommendations to Improve Data Collection for Onboard Fumes/Smoke

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| APU | Auxiliary Power Unit |

| ASRS | Aviation Safety Reporting System |

| ATA | Air Transport Association |

| ATSB | Australian Transport Safety Bureau |

| FAA | United States Federal Aviation Administration |

| NASA | United States National Aeronautics and Space Administration |

| NRC | United States National Research Council |

| NTSB | United States National Transportation Safety Board |

| SDR | Service Difficulty Report |

References

- Johnson, D.W. Turbine engine lubricant and additive degradation mechanisms. In Aerospace Engineering; Intech Open: London, UK, 2018; p. 19. Available online: https://doi.org/10.5772/intechopen.82398 (accessed on 12 April 2021).

- USPTO. Seal Assembly and Method for Reducing Aircraft Engine Oil Leakage; U.S. Patent No. 10927845; assigned to The Boeing Company; Lin, C.-H., Horstman, R., Bates, G., Eds.; US Patent & Trademark Office: Washington, DC, USA, 2021. Available online: https://perma.cc/8D7V-Q863 (accessed on 9 April 2021).

- Michaelis, S. Aircraft clean air requirements using bleed air systems. Engineering 2018, 10, 142–172. Available online: https://doi.org/10.4236/eng.2018.104011 (accessed on 14 April 2021). [CrossRef]

- Chupp, R.E.; Hendricks, R.C.; Lattime, S.B.; Steinetz, B.M. Sealing in Turbomachinery, NASA/TM—2006-214341; National Aeronautics and Space Administration, Glenn Research Center: Cleveland, OH, USA, 2006. Available online: https://perma.cc/PY5C-4LHU (accessed on 12 April 2021).

- Van Netten, C.; Leung, V. Hydraulic fluids and jet engine oil: Pyrolysis and aircraft air quality. Arch. Environ. Health 2001, 56, 181–186. Available online: https://doi.org/10.1080/00039890109604071 (accessed on 12 April 2021). [CrossRef] [PubMed]

- AAIB. Bulletin No. 9/2020, G-EUYB (AAIB-26125), Air Accidents Investigation Branch; UK Department for Transport: Aldershot, UK, 2020. Available online: https://perma.cc/GWD2-RWVW (accessed on 12 April 2021).

- AAIB. Bulletin No. 3/2013, G-FCLA (EW/G2012/10/09). Air Accidents Investigation Branch; UK Department for Transport: Aldershot, UK, 2013. Available online: https://perma.cc/QE5D-SLDX (accessed on 9 April 2021).

- Montgomery, M.R.; Wier, G.T.; Zieve, F.J.; Anders, M.W. Human intoxication following inhalation exposure to synthetic jet lubricating oil. Clin. Toxicol. 1977, 114, 423–426. Available online: https://doi.org/10.3109/15563657708988205 (accessed on 12 April 2021). [CrossRef] [PubMed]

- Armstrong, H.G. Noxious fluids and gases in aviation. In Chapter XI in Principles and Practice of Aviation Medicine; The Williams & Wilkins Company: Baltimore, MD, USA, 1939; pp. 178–180.

- AAIB. Bulletin No. 12/2019, G-YMMU (EW/G2019/07/01). Air Accidents Investigation Branch; UK Department for Transport: Aldershot, UK, 2019. Available online: https://perma.cc/JDZ5-CL54 (accessed on 9 April 2021).

- Murawski, J.T.L. Case study: Analysis of reported contaminated air events at one major U.S. airline in 2009–2010. In Proceedings of the 41st International Conference on Environmental Systems, Portland, Oregon, 17–21 July 2011; American Institute of Aeronautics & Astronautics: Reston, VA, USA, 2011. Paper ID: AIAA2011-5089. Available online: https://doi.org/10.2514/6.2011-5089 (accessed on 12 April 2021). [CrossRef][Green Version]

- Michaelis, S.; Burdon, J.; Howard, C.V. Aerotoxic syndrome: A new occupational disease? Public Health Panor. 2017, 3, 198–211. Available online: https://apps.who.int/iris/handle/10665/325308 (accessed on 12 April 2021).

- Bobb, A.J.; Still, K.R. Known Harmful Effects of Constituents of Jet Oil Smoke; Report No TOXDET-03-04; Naval Health Research Center Detachment (Toxicology), Wright Patterson Air Force Base: Dayton, OH, USA, 2003. Available online: https://perma.cc/DNY6-AGZS (accessed on 12 April 2021).

- ICAO. Circular No. 344-AN/202: Guidelines on Education, Training and Reporting Practices Related to Fume Events; Approved by and published under the authority of the Secretary General; International Civil Aviation Organization: Montreal, QC, Canada, 2015; ISBN 978-92-9249-856-6. Available online: https://perma.cc/R4UZ-DNQH (accessed on 12 April 2021).

- AAIB. Bulletin No. 4/2007, G-JECE (EW/C2005/08/10). Air Accidents Investigation Branch; UK Department for Transport: Aldershot, UK, 2007. Available online: https://perma.cc/7JX9-8JBC (accessed on 12 April 2021).

- Reddall, H.A. Elimination of Engine Bleed Air Contamination. In Proceedings of the SAE Golden Anniversary Aeronautic Meeting, Hotel Statler, Los Angeles, CA, USA, 11–15 October 1955; SAE Technical Paper 550185. SAE Aerospace: Warrendale, PA, USA, 1955. Available online: https://doi.org/10.4271/550185 (accessed on 14 April 2021).

- Schuchardt, S.; Koch, W.; Rosenberger, W. Cabin air quality—Quantitative comparison of volatile air contaminants at different flight phases during 177 commercial flights. J. Build. Environ. 2019, 48, 498–507. Available online: https://doi.org/10.1016/j.buildenv.2018.11.028 (accessed on 14 April 2021). [CrossRef]

- EASA. Research Project: CAQ Preliminary Cabin Air Quality Measurement Campaign; Report No. EASA_REP_RESEA_2014_4; Schuchardt, S., Bitsch, A., Koch, W., Rosenberger, W., Eds.; European Aviation Safety Agency: Cologne, Germany, 2017; Available online: https://perma.cc/EN8D-6YY7 (accessed on 9 April 2021).

- FAA. Bleed Air Contaminants: A review, DOT/FAA/AM-15/20; Day, G.A., Ed.; Civil Aerospace Medical Institute, Federal Aviation Administration: Oklahoma City, OK, USA, 2015. Available online: https://perma.cc/4SGU-GN9T (accessed on 9 April 2021).

- Boeing. Memorandum by the Boeing Company, Seattle, Washington. Submitted to: Air Travel and Health: An Update. UK House of Lords Science and Technology Committee, 1st Report of Session 2007–2008, Published by the Authority of the UK House of Lords. The Stationery Office Limited: London, UK, 2007; pp. 113–115. Available online: https://perma.cc/54L7-E5HR (accessed on 9 April 2021).

- FAA. Flight Standards Information Bulletin for Airworthiness (FSAW) 06-05A: Guidance for Smoke/Fumes in the Cockpit/Cabin. U.S. Federal Aviation Administration: Washington, DC, USA, 2006. Available online: https://perma.cc/N89W-AL8R (accessed on 12 April 2021).

- FAA. Information for operators (InFO) 16009: Title 14 of the Code of Federal Regulations (14 CFR) Part 121, § 121.703 Service Difficulty Reports (SDR); Federal Aviation Administration, Flight Standards Service: Washington, DC, USA, 2016. Available online: https://perma.cc/G4T4-PV86 (accessed on 9 April 2021).

- FAA. Report to Congress on Public Law 112-95, FAA Modernization and Reform Act of 2012, Section 917: Research and Development of Equipment to Clean and Monitor the Engine and Auxiliary Power Unit Bleed Air Supplied on Pressurized Aircraft. Prepared for FAA’s Quality, Integration and Executive Services in Response to FAA’s Aviation Safety legislative Implementation Plan by FAA’s Office of Accident Investigation & Prevention. U.S. Federal Aviation Administration: Washington, DC, USA, 2013. Available online: https://perma.cc/F6SU-KVLG (accessed on 9 April 2021).

- BFU. Study of Reported Occurrences in Conjunction with Cabin Air Quality in Transport Aircraft. Report No. BFU 803.1-14; Bundesstelle Für Flugunfalluntersuchung, German Federal Bureau of Aircraft Accident Investigation: Braunschweig, Germany, 2014. Available online: https://perma.cc/XPR9-GE6E (accessed on 9 April 2021).

- Airbus. A Clean APU Means Clean Cabin Air, Flight Airworthiness Support Technology (FAST). Airbus SAS 2013, 52, 4–9. Available online: https://perma.cc/8PJ2-NVP8 (accessed on 9 April 2021).

- AAIB. Report on the Serious Incident to Boeing 757-236, G-CPER on 7 September 2003; Air Accidents Investigation Branch, UK Department for Transport: Aldershot, UK, 2005. Available online: https://perma.cc/VJ66-3FLR (accessed on 12 April 2021).

- Overfelt, R.A.; Jones, B.W.; Loo, S.M.; Haney, R.L.; Neer, A.J.; Andress, J.R.; Yang, X.; Zitova, A.; Prorok, B.C.; Fergus, J.W.; et al. Sensors and Prognostics to Mitigate Bleed Air Contamination Events; Report No. RITE-ACER-CoE-2012-05, Report Prepared for the Federal Aviation Administration; National Air Transportation Center of Excellence for Research in the Intermodal Transport Environment (RITE) Airliner Cabin Environment Research Program (ACER): Washington, DC, USA, 2012. Available online: https://perma.cc/HCZ8-J687 (accessed on 12 April 2021).

- O’Connor, M.; Stolzer, A. Hazard Identification: Voluntary Safety Reports of Potential Contaminated Bleed Air Events. NIOSH Western States Division and Embry-Riddle Aeronautical University. In Proceedings of the Aerospace Medical Association Annual Scientific Meeting, Las Vegas, NV, USA, 5–9 May 2019; Available online: https://perma.cc/6RAL-BPUP (accessed on 14 April 2021).

- U.S. Public Law 112-381, §917. Research and Development of Equipment to Clean and Monitor the Engine and APU Bleed Air Supplied on Pressurized Aircraft. 14 February 2012. Available online: https://perma.cc/26SZ-557F (accessed on 12 April 2021).

- EASA. Comment Response Document on Notice of Proposed Amendment 2009–10: Cabin Air Quality Onboard Large Aeroplanes; European Aviation Safety Agency: Cologne, Germany, 2011; Available online: https://perma.cc/ZLS5-W2FM (accessed on 13 April 2021).

- ATSB. An Analysis of Fumes and Smoke Events in Australian Aviation, 2008–2012; Aviation Research Report AR-2013-213; Australian Transport Safety Bureau: Canberra, Australia, 20 May 2014. Available online: https://perma.cc/Y2XQ-KSFL (accessed on 13 April 2021).

- PCA. Chapter 6: Conclusions and recommendations. See Section 6.1.8; In Air Safety and Cabin Air Quality in the BAE 146 Aircraft; Senate Rural and Regional Affairs and Transport References Committee of the Parliament of the Commonwealth of Australia: Canberra, Australia, 2000; ISBN 0-642-71093-7. Available online: https://perma.cc/TQ2E-VPG2 (accessed on 13 April 2021).

- NRC. The Airliner Cabin Environment and the Health of Passengers and Crew; U.S. National Research Council; National Academy Press: Washington, DC, USA, 2002; 326p, ISBN 0-309-08289-7. Available online: https://perma.cc/5L4Y-DJT7 (accessed on 14 April 2021).

- FAA. Response to recommendation 1—Air quality and ventilation. In Report to the Administrator on the National Research Council Report, The Airliner Cabin Environment and the Health of Passengers and Crew; U.S. Federal Aviation Administration: Washington, DC, USA, 2002. Available online: https://perma.cc/9QTP-CS82 (accessed on 14 April 2021).

- FAA. Information for Operators (InFO 10019): Smoke/Fumes in the Cabin/Cockpit of Transport Category Aircraft; U.S. Federal Aviation Administration Flight Standards Service: Washington, DC, USA, 2010. Available online: https://perma.cc/E6TB-Q8RE (accessed on 12 April 2021).

- BTS. T-100 Data, All U.S. Carriers, All Airports (2002–2020). Bureau of Transportation Statistics, U.S. Department of Transportation, 2002–2011. Available online: https://perma.cc/3RVC-SSGQ (accessed on 13 April 2021).

- IATA. Global Safety Information Center STEADES Analysis: Smoke and Fumes (Smells in the Cabin and on the Flight Deck). Safety Trend Evaluation, Analysis, and Data Exchange System. Global Safety Information Center, International Air Transport Association: Montreal, Canada, 2013. Available online: https://perma.cc/GAK9-66HW (accessed on 14 April 2021).

- Shehadi, M.; Jones, B.; Hosni, M. Characterization of the Frequency and Nature of Bleed Air Contamination Events in Commercial Aircraft. Indoor Air 2016, 26, 478–488. Available online: https://doi.org/10.1111/ina.12211 (accessed on 12 April 2021). [CrossRef] [PubMed]

- ASHRAE. Section 8.6 (Hydraulic Fluid) and Section 8.7 (Engine Oil). In Air Quality within Commercial Aircraft; ANSI/ASHRAE Standard 161-2018; American Society of Heating Refrigerating, and Air Conditioning Engineers: Atlanta, GA, USA, 2018; ISSN 1041-2336. Available online: https://perma.cc/QDN6-EMJG (accessed on 13 April 2021).

- AAIB. Bulletin No. 6/2009, G-BYAO (EW/C2006/10/08). In Air Accidents Investigation Branch; UK Department for Transport: Aldershot, UK, 2009. Available online: https://perma.cc/Y5YQ-Q7MF (accessed on 13 April 2021).

- U.S. Public Law 108-176, § 815(b)(5). Air Quality in Aircraft Cabins. 12 December 2003. Available online: https://perma.cc/DY4P-UHB8 (accessed on 13 April 2021).

- U.S. Public Law 112-381, §320(a)(4). Study of Air Quality in Aircraft Cabins. 14 February 2012. Available online: https://perma.cc/26SZ-557F (accessed on 13 April 2021).

- FAA. Safety Alert for Operators (SAFO) 18003: Procedures for Addressing Odors, Smoke and/or Fumes in Flight; Federal Aviation Administration, Flight Standards Office: Washington, DC, USA, 2018. Available online: https://perma.cc/GA2E-WWAJ (accessed on 13 April 2021).

- U.S. Public Law 115-254, §326. Aircraft Air Quality. 5 October 2018. Available online: https://perma.cc/H4UK-UPQ8 (accessed on 13 April 2021).

- FAA. Information for Operators (InFO) 21002: Cabin Air Quality Educational Materials; Federal Aviation Administration, Flight Standards Office: Washington, DC, USA, 2021. Available online: https://perma.cc/CS46-CW4E (accessed on 13 April 2021).

| Types/Sources of Onboard Fumes/Smoke (N = 15) |

|---|

| Air conditioning packs (“packs”) |

| Battery (smoking, defective) |

| Bird strike (into engine) |

| Bleed source (specifics undefined) |

| Deicing fluid |

| Duct (blown, disconnected, clogged) and duct insulation |

| Electrical item/system |

| Engine oil |

| Engine wash |

| Fan |

| Fuel/exhaust |

| Hydraulic fluid |

| Oven (in the galley) |

| Other, not otherwise classified |

| Source not identified/report too vague to classify |

| Types of Fans (N = 23) Identified as Sources of Fumes or Smoke in Airline Reports |

|---|

| Air Conditioning Condenser Cooling Fan Advisory fan |

| Aft rack cooling fan |

| APU oil cooling fan |

| Attitude heading reference unit fan |

| Avionics cooling blower fan |

| Avionics vent blower |

| Cargo compartment fan |

| Cargo SD fans 1 and 2 |

| Cargo smoke blower |

| Chiller fan (forward and aft) |

| Equipment cooling fan |

| Exhaust fan |

| Extract fan |

| Flight deck recirculation air fan |

| Galley oven fan |

| Ground cooling fan |

| Heat exchanger cooling fan |

| Instrument cooling fan |

| Inverter fan |

| Lavatory fan |

| Radio rack cooling fan |

| Recirculated air fan |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anderson, J. Sources of Onboard Fumes and Smoke Reported by U.S. Airlines. Aerospace 2021, 8, 122. https://doi.org/10.3390/aerospace8050122

Anderson J. Sources of Onboard Fumes and Smoke Reported by U.S. Airlines. Aerospace. 2021; 8(5):122. https://doi.org/10.3390/aerospace8050122

Chicago/Turabian StyleAnderson, Judith. 2021. "Sources of Onboard Fumes and Smoke Reported by U.S. Airlines" Aerospace 8, no. 5: 122. https://doi.org/10.3390/aerospace8050122

APA StyleAnderson, J. (2021). Sources of Onboard Fumes and Smoke Reported by U.S. Airlines. Aerospace, 8(5), 122. https://doi.org/10.3390/aerospace8050122