The methodology described above was tested on two case studies. The first concerns the reconfiguration of a GA aerodrome, the Milano–Bresso airport, home of an historical flying school. The second focuses on the the adaptation of a large regional hub, the Athens international airport, which currently hosts a massive traffic of turboprop flights.

3.1. Milano–Bresso Airport

The Milano–Bresso airport “Franco Bordoni-Bisleri” (ICAO code: LIMB), built in 1912, is located in the Milan metropolitan area, Italy. It features a 1080 m × 30 m asphalt runway and is the site of Aero Club Milano (ACM) since 1960. The ACM fleet, providing flying school, leisure flight and air taxi services, is currently composed of 21 aircraft, 20 of which are single-engine propeller-driven models. In the current analysis, it has been hypothesized to switch from the current aircraft models, mainly Cessna C172 (Cessna Aircraft Company, Wichita, KS, USA) and Piper PA-28 (Piper Aircraft, Inc., Vero Beach, FL, USA) four-seaters, to a homogeneous fleet of HE aircraft inspired by the Pipistrel Panthera Hybrid (Pipistrel Vertical Solutions, Ajdovščina, Slovenia). This four-seater is the HE version of the conventionally-powered Panthera, featuring a serial HE power-train. It is being created under the auspices of project MAHEPA and is currently in an advanced state of development, with the maiden flight expected in early 2021. The basic features of the aircraft and its battery pack are reported in

Table 5. Among them, minimum battery life is provided for two reference values of the Depth Of Discharge (DOD). As for the aircraft cost, considering that it is not yet marketed, we assumed a value of 450,000, which appeared representative for a stock purchase. Although not used here, a possible approach to estimate such cost has been recently proposed in [

32].

In order to analytically set up the sizing problem, the recharge power values

and

of the ground recharging devices have been defined at the nominal recharge power of the aircraft, i.e., 60 kW. Similarly, the maximum battery SOC, the recharge efficiency

, and the unit cost

have been defined based on the data in

Table 5. The unit cost of the recharging devices

and

has been fixed at 39.8 k€, with

(10% overhead for maintenance), based on Equation (

5) for the considered recharge power [

30].

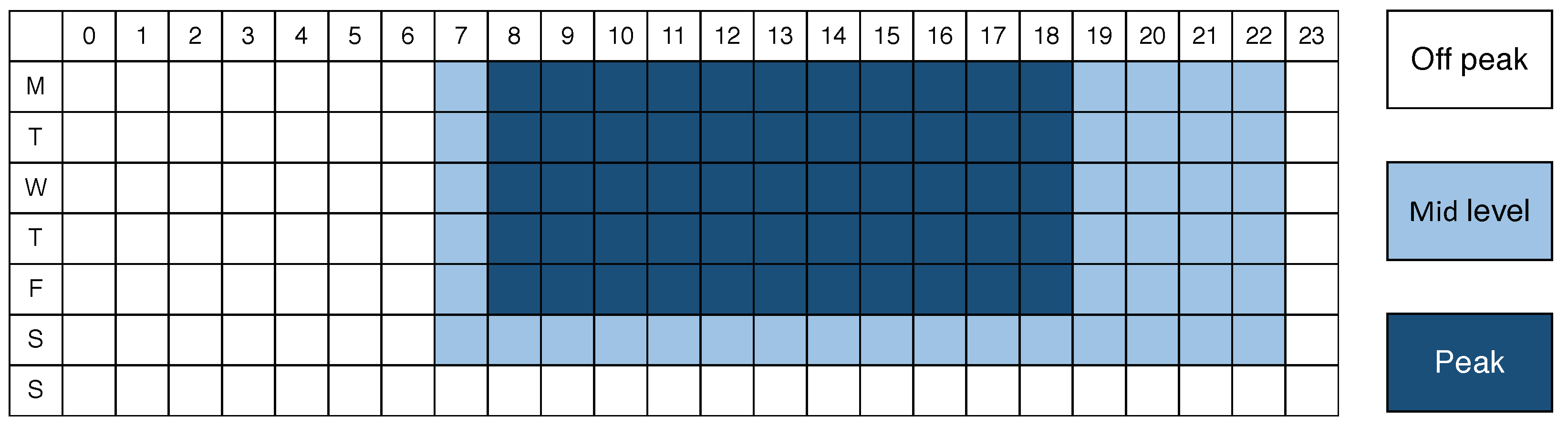

The average electric energy price for the first quarter of 2018 in Italy was considered for the present analysis. The Italian electricity pricing is very complex and includes fixed, transport and system fees. Since 2007, the pricing scheme has been based on three time-dependent fares: F1–Peak, F2–Mid-level, and F3–Off-peak. The scheme is summarized in

Figure 1, where the rows represent the days of the week and the columns the hours of the day. The electricity consumption is billed according to a different consumption charge depending on the time slot during which it is used. Therefore, the energy-related cost of electricity

changes according to the time of the day and day of the week. According to

Figure 1, the three fares do not apply to Saturdays, when only F2 and F3 are adopted, and to Sundays, when only F3 is employed. Numerical values of

and

for LIMB are reported in

Table 6.

LIMB is open to Visual Flight Rules (VFR) traffic only, and operations take place from 08:00 local time to 30 min past sunset. Due to these reasons, the number of departures varies during the year. For the present sizing purposes, movements occurred in November 2017 have been considered, since it turned out that this is the most demanding month of the year. In fact, because of fewer daylight hours available, operations are packed in eight hours only and consequently the number of take-offs per hour increases. In addition, the number of flights increases during the weekend, since there are more people willing to fly in those days. The average hourly flight schedule in November 2017 is reported in

Table 7. This schedule has been employed as the variable

, which represents the number of departures in each time slot. We assumed that every flight takes one hour, as this is a typical value for ACM flight school activities. This schedule has been expanded by reducing the length of each time step

to 15 min, in order to increase accuracy.

Initially, the ARES procedure was applied to the case of the Most Demanding Day (MDD) only, which is usually Saturday; subsequently, it has been extended to the entire week. The first case examined is restricted to the use of BPCs only, without the possibility to resort to BSSs. This is due to the fact that the Panthera Hybrid, in its present configuration, does not support battery swapping.

Table 8 reports the main results of the sizing exercise: the number of recharges corresponds to the input provided by the flight schedule, while all other parameters represent outputs of the procedure. As seen in the left column reporting the values for the MDD in this case, two BPCs are needed. The number of aircraft to fulfil the flight schedule is 11 and it necessarily coincides with the number of batteries. The value of the cost function amounts to 596 for the MDD. This can be ameliorated if the optimizer is left free to choose the best combination of BPCs and BSSs. Indeed, by looking at the center column reporting the values for this enhanced case, a value for the cost function of 570 is achieved, with a saving of 4.3%. In this case, the optimizer provides a solution using two BSSs and, as a result, a different trade-off is obtained, where the number of aircraft necessary for fulfilling the flight schedule is lowered to 10, while the number of batteries is risen to 12, implying two spare batteries. Clearly, the additional cost of this added equipment is more than balanced by the need of one aircraft less in the fleet.

Table 8 also reports the values for the solution extended to the entire week that encompasses the MDD, again with the optimizer free to choose any combination of BPCs and BSSs. It is remarked that the number of aircraft necessary for fulfilling the flight schedule in both cases (39 and 136 flights) is ten, or half of the current fleet size. Also, the number of batteries and BSSs in both cases is the same. The average battery life is less than seven months in the MDD case, while it raises to 28 months when considering the entire week, a case in which battery usage is more evenly distributed. No difference is observed also with regard to the peak value of the electric power drawn from the grid. Looking at the value of the cost function, the MDD amounts to less than 15% of the entire week.

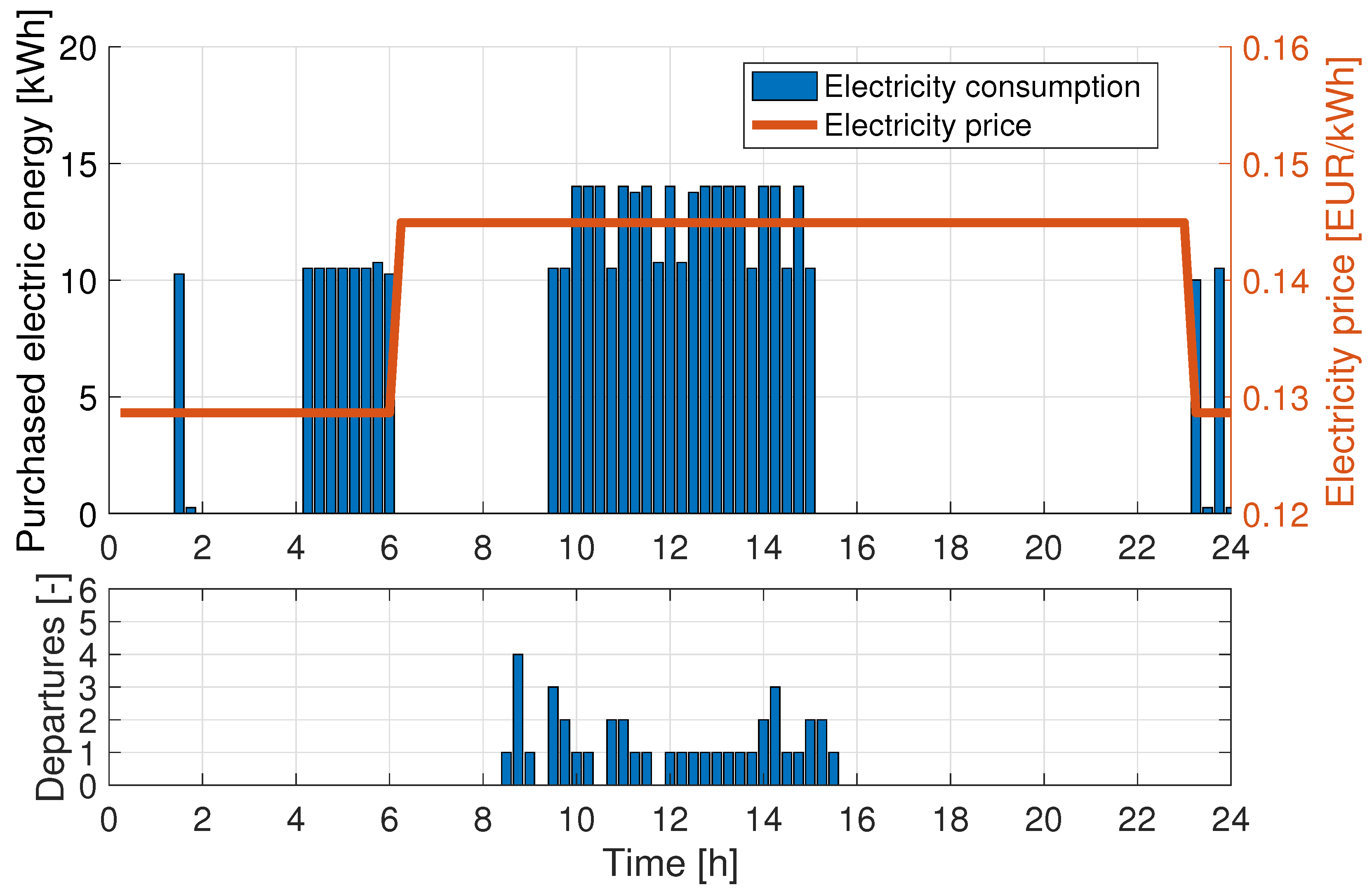

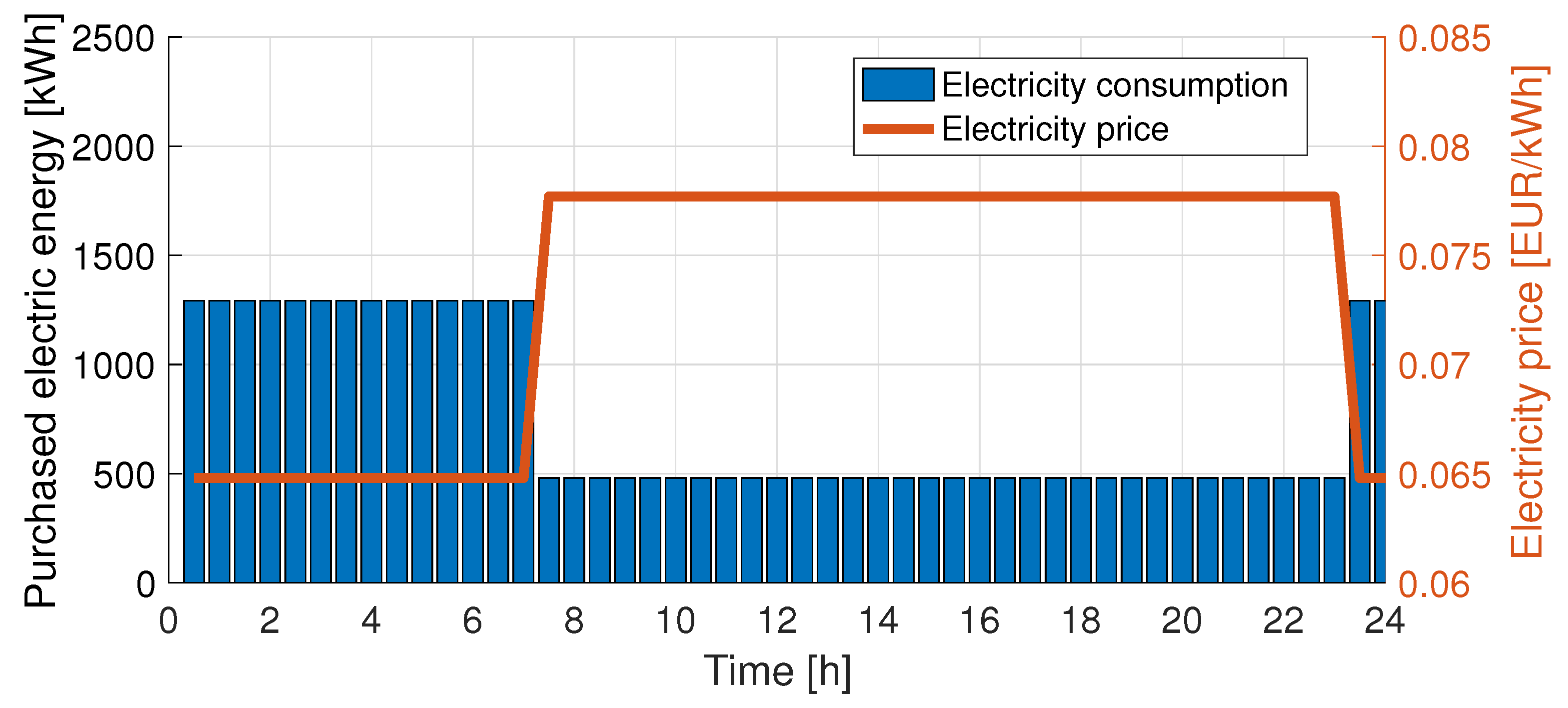

For the MDD case with BPCs only, the outcome in terms of the time history of electricity consumption

is displayed in

Figure 2. In the lower plot, bars show the daily flight schedule, in terms of departures every 15-minute time slot. In the upper plot, blue bars represent the purchased electric energy necessary to recharge the batteries for all time slots, while the orange line indicates the electricity price variation during the day. It is possible to note that night hours, when energy price is lower, are exploited to charge all the batteries before the first flight session begins at 08:30. The time scheduling of the battery charging during night hours, with an accumulation before the rise in electricity fare, is not specially meaningful, as any time slot may be chosen, provided that a single battery is charged within it. The first flights are performed until there are no more fully charged ones available, so that depleted ones are recharged during the day hours up to 15:00. Once the last charged battery is delivered, and no more flights are scheduled, depleted batteries are not recharged before the electricity price decreases again, to take advantage of night-time fares.

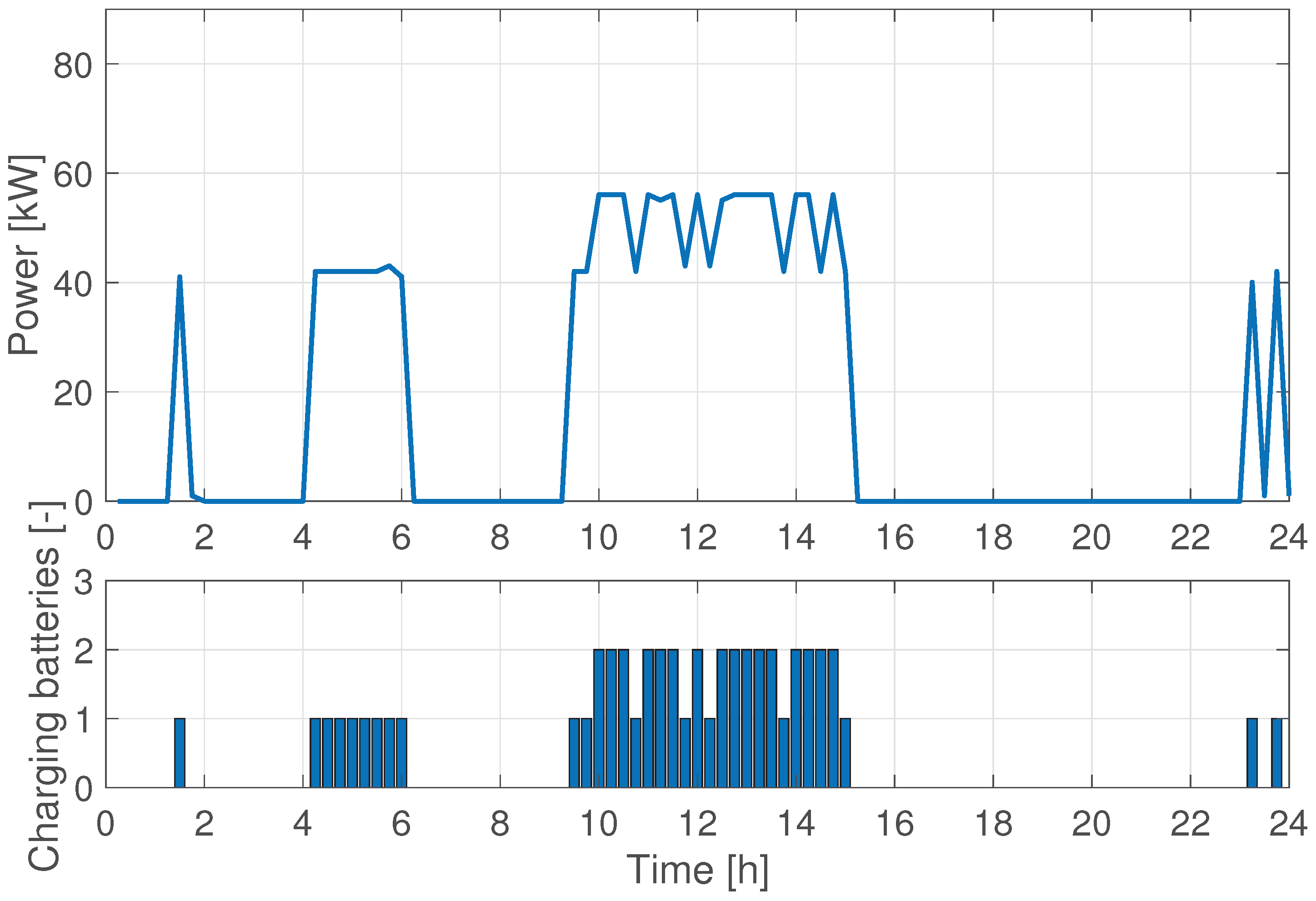

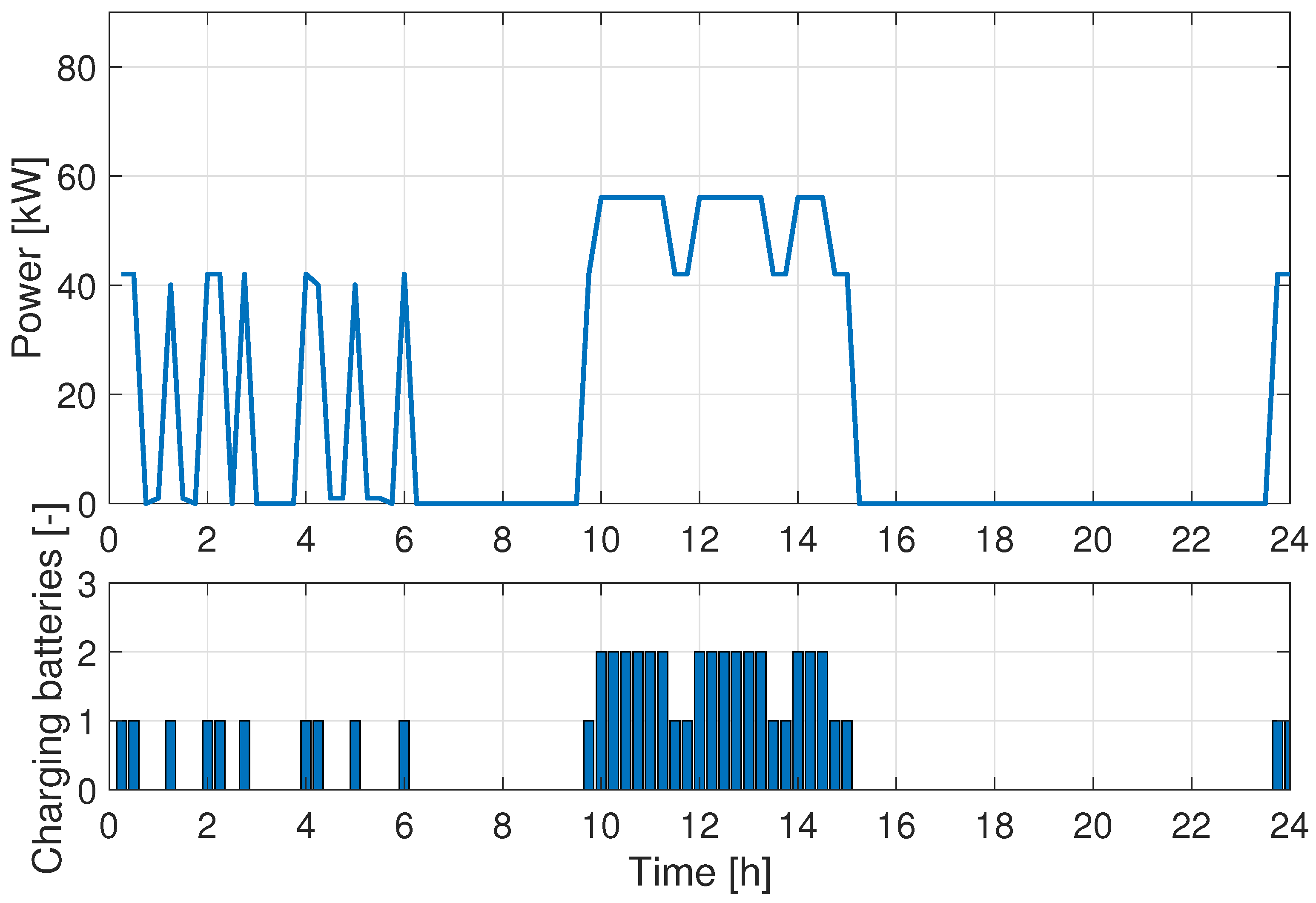

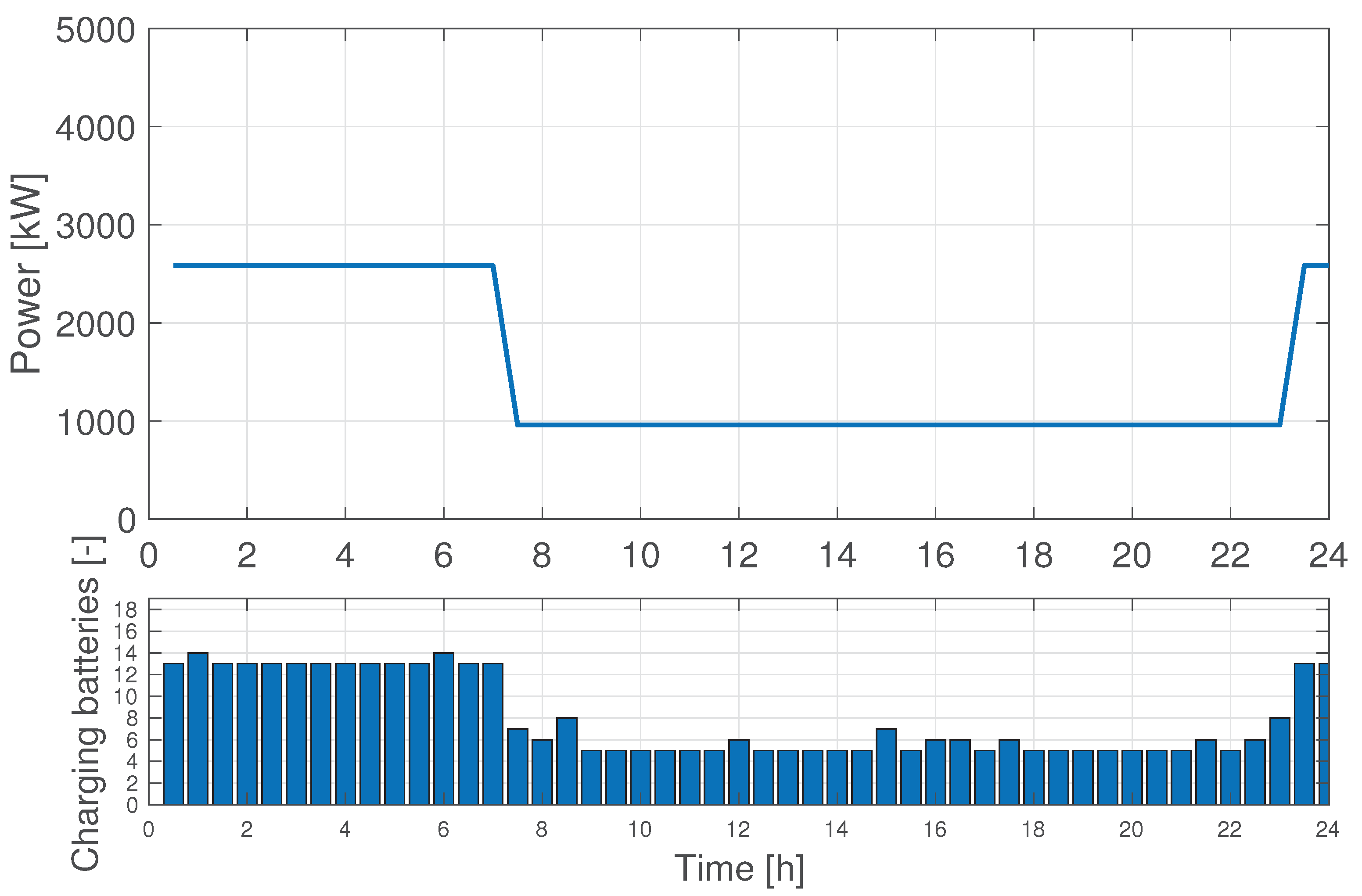

The power consumption for the same case is reported in the upper plot of

Figure 3, while the lower plot displays the number of charging batteries at each time slot. As seen during daytime there are instances in which two batteries are recharged at the same time, although not at full power. The maximum requested power is clearly lower at night and peaks during the day. Finally,

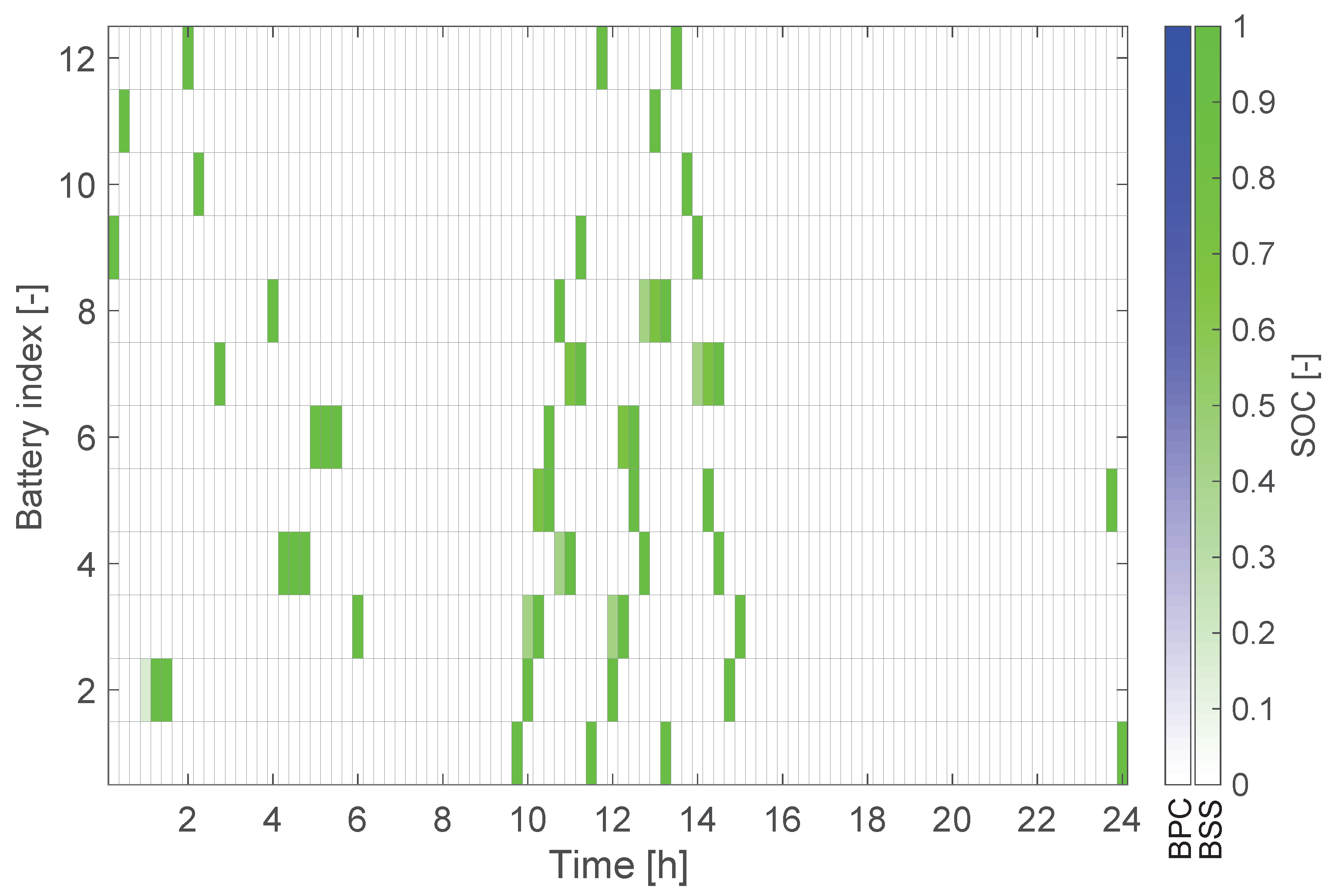

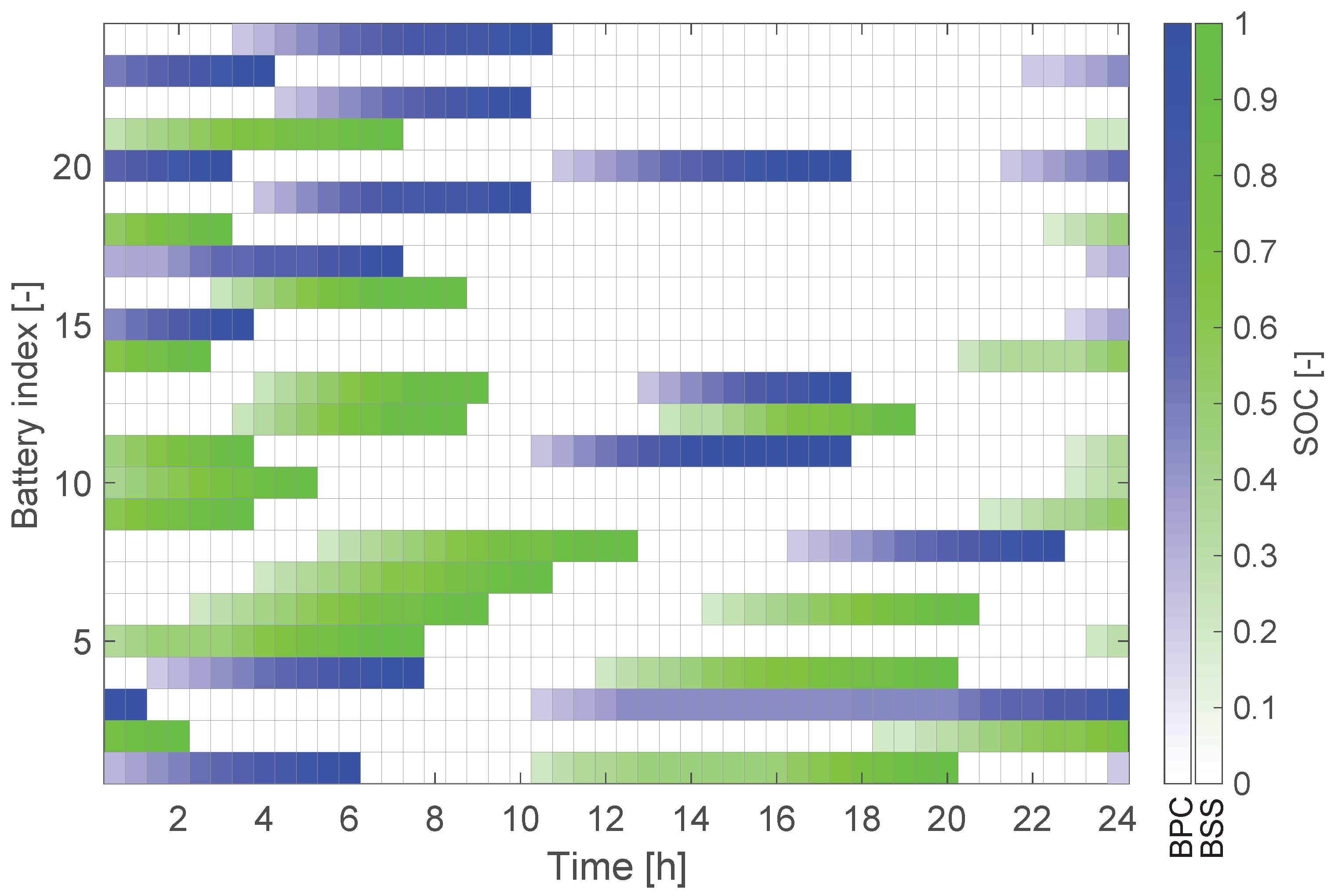

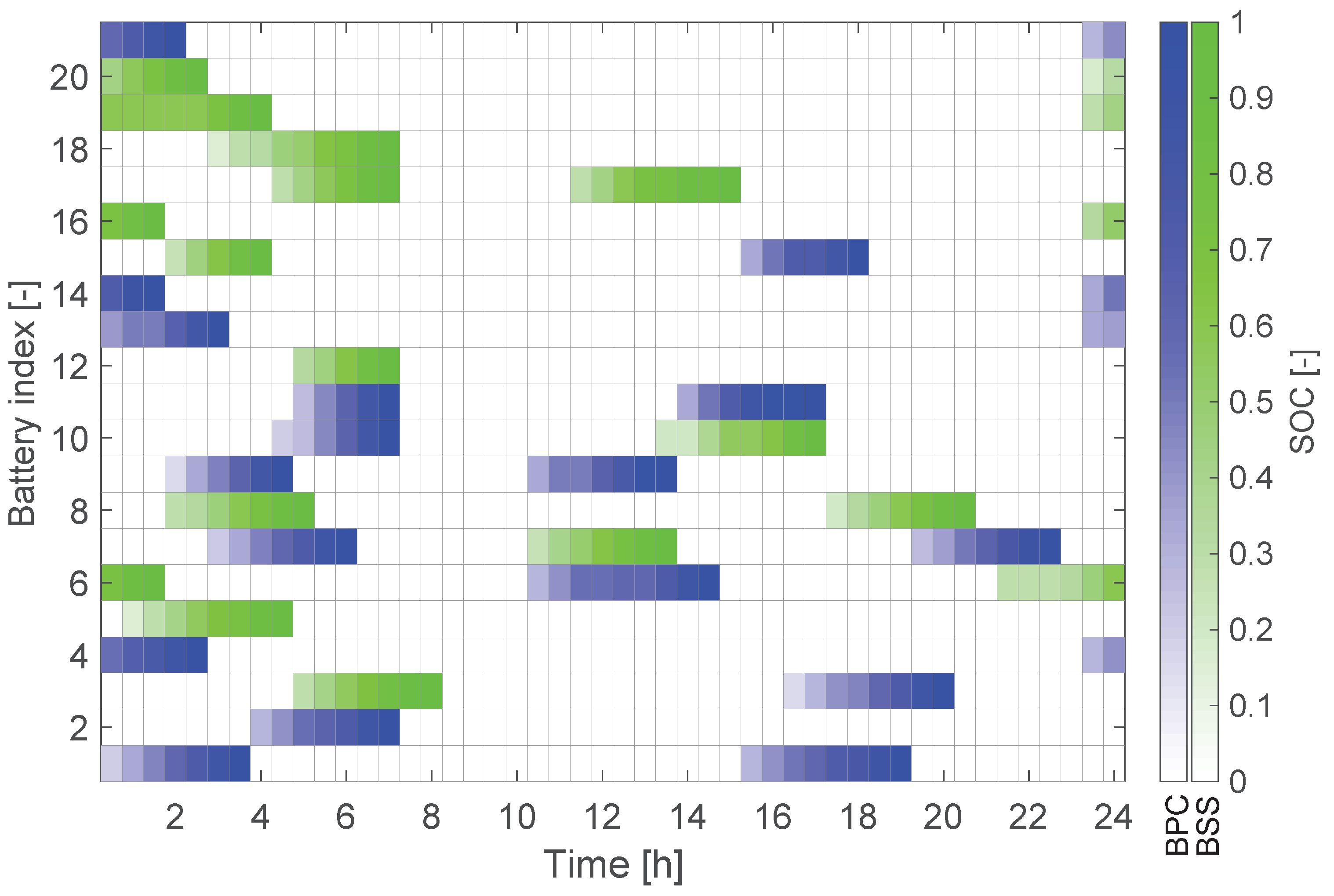

Figure 4 portrays the state of charge of the batteries

throughout the day. Battery charging is a continuous process, with the restriction that a battery must be fully charged before the next one can be plugged in the same charger. The rows in the grid represent each battery, while the columns represent the 15-minute time slots. The cells are colored whenever the battery is plugged in a BPC (blue) or a BSS (green). The color is shaded to represent the SOC, with white corresponding to

and full color with

. It is seen that batteries are often fast-charged to fulfil the demand, taking a single time slot, and therefore being represented by single full-coloured squares. As seen, the solution provides three recharges for five batteries and four for six batteries in the MDD.

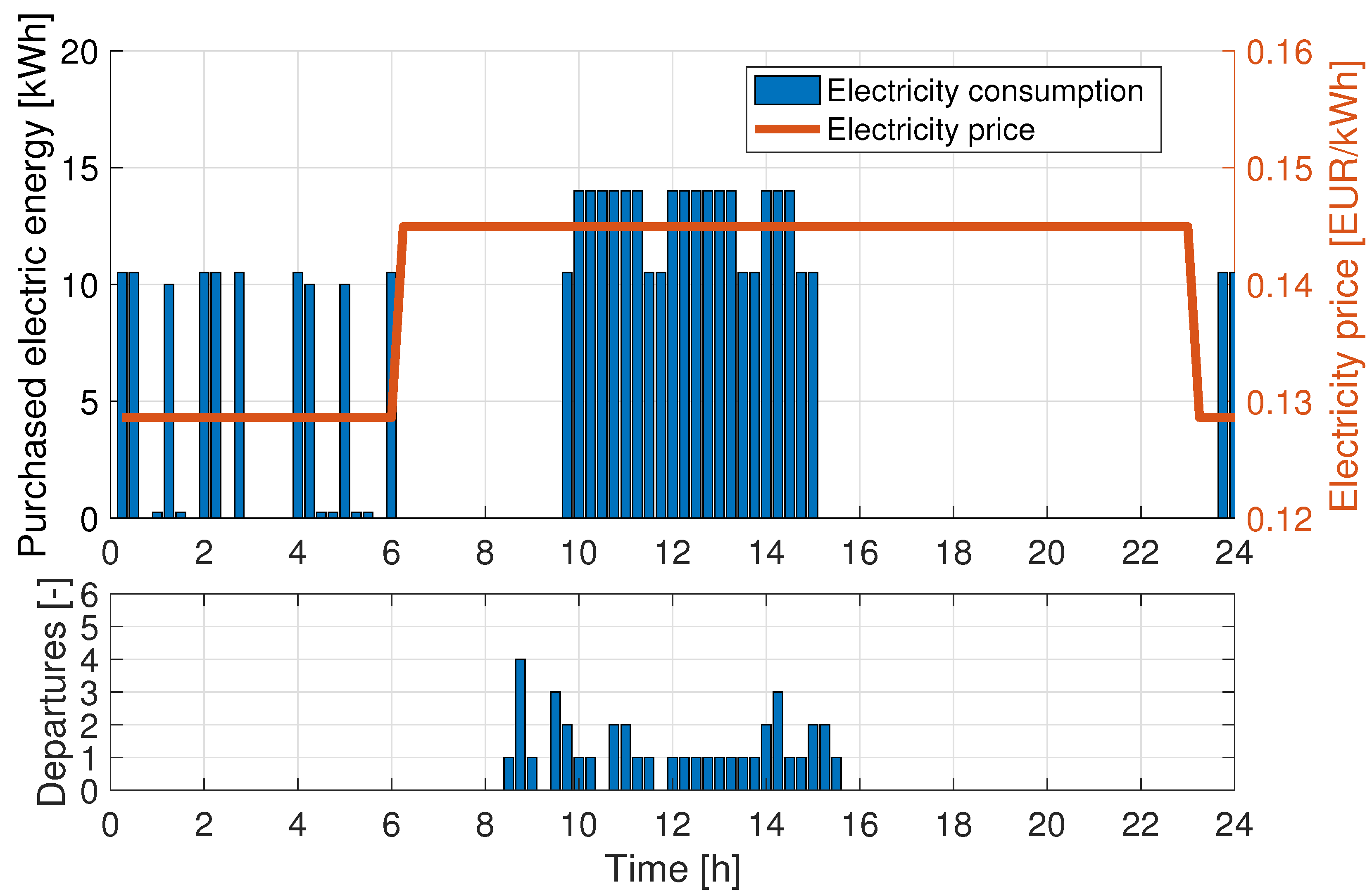

For the fully optimal MDD case, resulting in BSSs only,

Figure 5 provides the time history of energy consumed and

Figure 6 that of the power required. Again, the sparse pattern seen in the recharging schedule during night hours has no special value. The general behavior observed in both energy and power is similar to the case of using only BPCs, with some differences in the need to recharge two batteries at the same time (13 instances instead of 16 in the previous case). As seen in

Figure 7, compared to the BPC-only solution, here batteries are more often fast-charged and the number of recharges varies from two for two batteries, to four for four batteries in the MDD. This lowers the cycles accumulated in the BSS solution, as seen in the values for the time to replace the batteries in

Table 8.

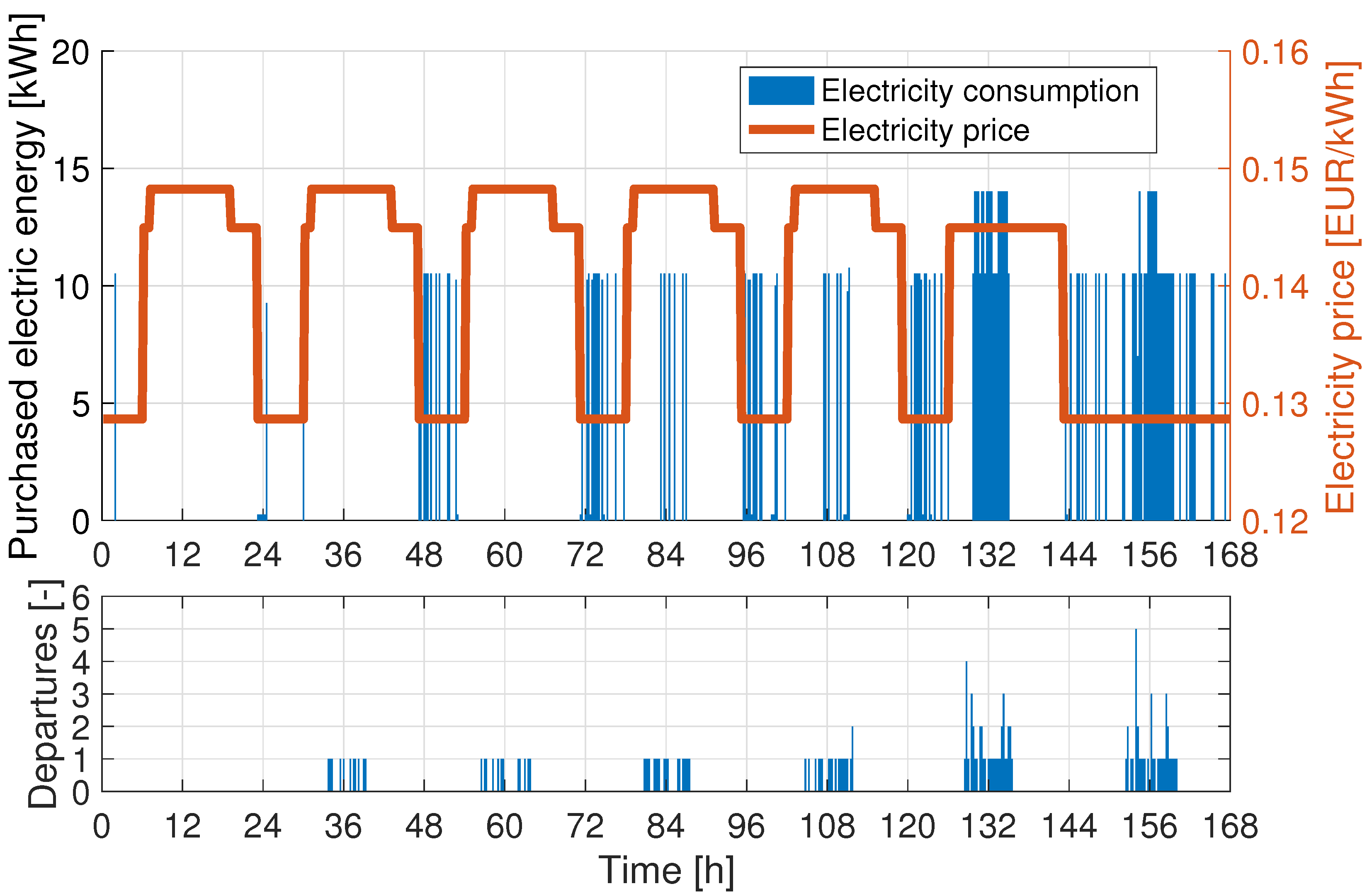

Taking the whole week into account, starting with Monday (from 0 to 24 h) and ending with Sunday (from 144 to 168 h), the results shown in

Figure 8 and

Figure 9 are obtained. No flights are scheduled on Monday, so almost nothing happens until Tuesday night when the batteries used during daytime hours are recharged. As seen, the batteries were charged during Sunday and Monday night. This strategy is repeated up to Thursday (from 48 to 72 h) when it becomes necessary to recharge the batteries also during the day. It clearly appears that Saturday is the most demanding day, for both energy consumption and required power, followed by Sunday, which features a widely different energy pricing and therefore allows recharging during daytime hours even if the battery is not used for a flight in that day.

3.2. Athens International Airport

Athens International Airport “Eleftherios Venizelos” (ICAO code: LGAV) is the primary airport that serves the city of Athens and the region of Attica, Greece. It is the country’s busiest airport, serving as the main hub of Aegean Airlines, the largest Greek airline by total number of passengers carried, as well as other Greek airlines. This has been selected for this study since it was the European airport with the largest number of propeller-driven regional aircraft movements in the years 2015–2019 [

33]. In particular, regional flights in LGAV are still operated by turboprop aircraft, connecting the numerous Greek islands to the mainland. As propeller-driven regional liners appear interesting for the future implementation of environmentally-friendly HE models for short-haul transportation services, the LGAV study may be used to provide useful information for such an operational scenario.

The main regional airplanes operating at LGAV are the Bombardier Dash 8 Q400 (shortened as DH8 in the following), the ATR42, and the ATR72. These aircraft can carry 78, 48, and 70 passengers, respectively. In order to carry out a realistic analysis, we assumed to replace the current conventionally-powered fleet with new models featuring a serial HE power-train, such as those considered in the MAHEPA project. The sizing of the aircraft, including that of their propulsion systems, has been carried out through HYPERION, a preliminary sizing tool dedicated to PE and HE fixed-wing aircraft developed at the Department of Aerospace Science and Technology, Politecnico di Milano [

9,

10]. In order to obtain such sizing, it is necessary to define a specialized mission profile in which all flight operations below a defined Hybrid-Electric Transition Altitude (HETA) are performed in a zero-emission PE mode. This includes taxi-out, take-off, initial climb, final descent, approach, landing, and taxi-in. Possibly loiter may be included as well. Above the HETA, the fuel-burning PGS is turned on, for providing energy during the rest of the flight phases, as well as for recharging the batteries, if needed. This strategy allows to drastically reduce chemical and noise emissions in the vicinity of the origin and destination airports and of the related overflown communities, and is considered an important advantage provided by serial HE power-trains. For the present analysis, the HETA was set to 3000 ft.

The technical specifications of the electric-powered airplane design solutions are the result of a clean-sheet conceptual design loop starting from mission and certification requirements (i.e., they do not correspond to any ‘retrofit’ of existing models). For the sake of clarity, the serial HE airplanes sized through HYPERION are named as the mission performance corresponding model by adding an “HE-” prefix. The resulting battery capacity for each design solution is summarised in

Table 9 together with the assumed corresponding budgetary price (including cells and battery pack), computed using 2018 Lithium-ion battery price values, i.e., approximately 176 €/kWh [

34]. The assumed charging/discharging efficiency and battery life values are the same as seen in

Table 5. The selected chargers maximum power has been raised to make a complete charge possible in a reasonable amount of time, given the sizeable increase in battery capacity with respect to the Milano–Bresso fleet. In particular, 200 kW and 400 kW rated power values for both BSS and BPC chargers were considered.

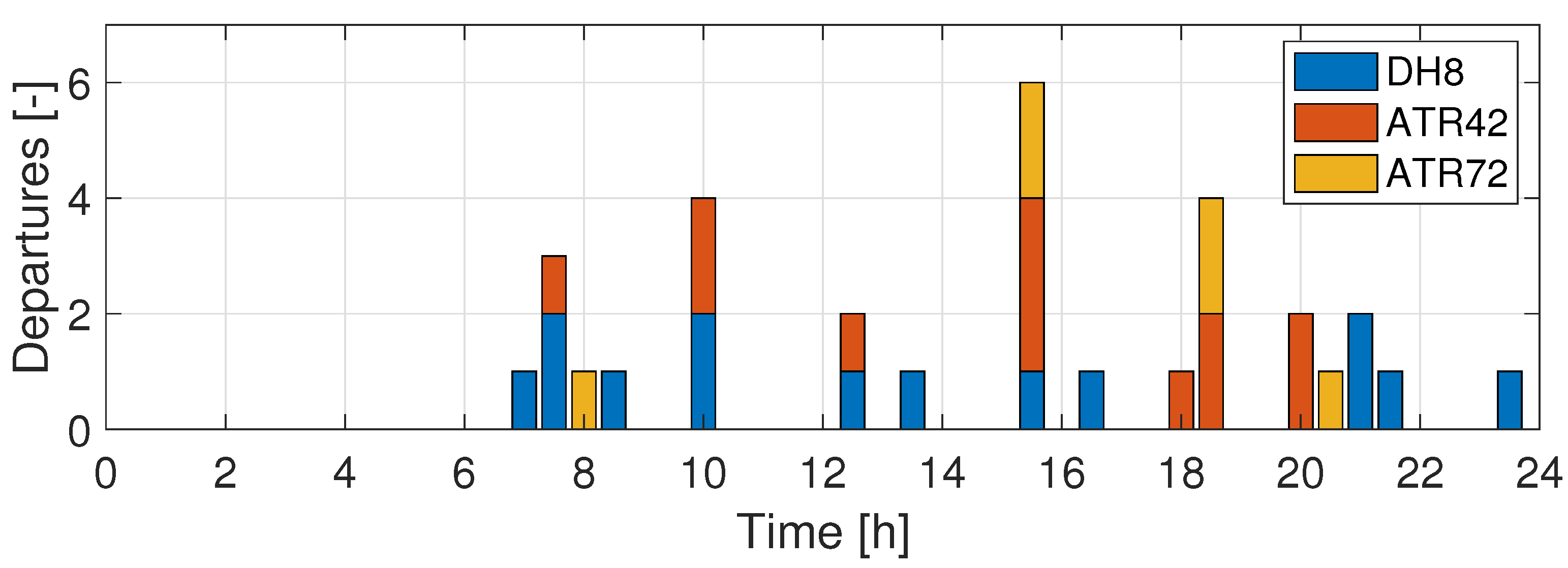

In contrast to the Milano-Bresso study, complete departure/arrival data for the full year could not be retrieved for Athens International Airport. Therefore, an average daily flight schedule for the selected airplanes was estimated using public data (the information retrieved on the Flight Radar 24 Live Air Traffic website was used [

35]). While not sufficient to insure the capability to operate in the MDD, this preliminary investigation provides an illustration of the methodology and its potential in dealing with larger and more diverse case studies. During a typical day, there are approximately 30 departures that are relevant to the present analysis: 14 flights are performed with the DH8, 12 with the ATR42, and 6 with the ATR72. The flights are distributed during the day as reported in

Figure 10. The length

has been set to 30 min in this case. No operations take place before 06:00 local time. We assumed that every aircraft performs a flight to another airport and comes back in three hours. Electricity prices in Greece for the year 2018 were assumed, as reported in

Table 10. Unlike the Italian case, the energy and power components both depend on the time of the day, being set at different values for Daytime (weekdays, from 07:00 to 23:00) and Nighttime (weekdays, from 23:00 to 07:00, and weekends).

The results of the ARES procedure applied to the cases of 200 kW and 400 kW chargers are shown in

Table 11 in a similar fashion to

Table 8, here augmented by the detail of the different aircraft and battery types. It is observed that, when using 200 kW chargers, the number of aircraft necessary to fulfil the 32-flight schedule is 14, with six HE-DH8, six HE-ATR42, and four HE-ATR72. A mix of eight BSSs and six BPCs is needed to recharge a total of 24 batteries, i.e., ten more than the number of aircraft, to be swapped. The value of the cost function amounts to 44,908. When switching to 400 kW chargers, some important changes in the solution can be remarked. While the total cost is reduced by 1.43% and the necessary fleet is unchanged, the number of batteries is lowered to 21 (only seven spare) and the number of chargers to five BSSs and five BPCs. We note that the expected battery life is worsened, from one year and eight months to one year and six months, due to more frequent recharge cycles and that–for the same amount of energy drawn from the grid–the energy cost is slightly lower, meaning that less charging is necessary during daytime as a result of the quicker recharge allowed by the higher power rating of the chargers. On the other hand, power cost is increased, hinting to a higher power drain on average.

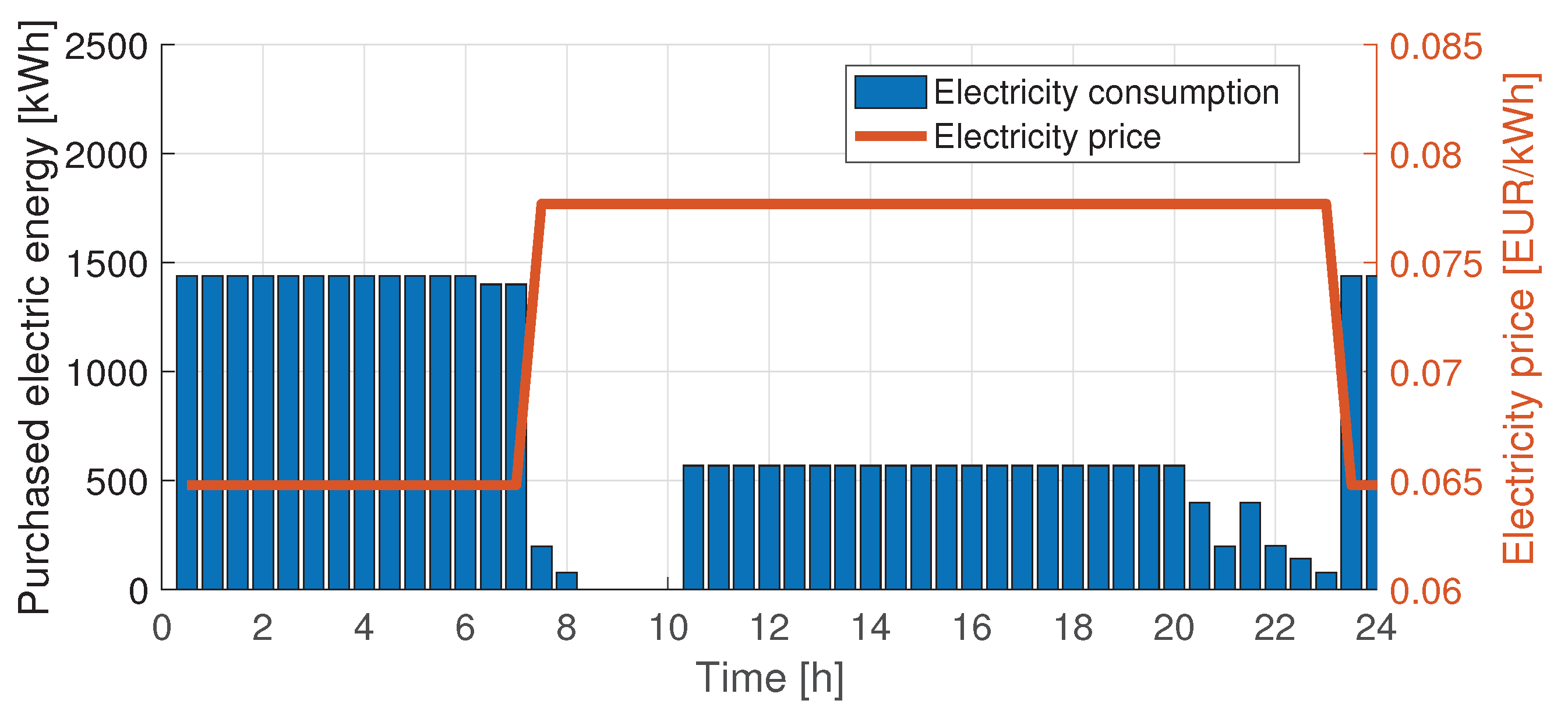

Figure 11 provides the time history of energy consumption considering 200 kW chargers. As apparent the solution provides constant nighttime and constant daytime energy drains, clearly with a much larger value for night hours when the energy and power pricing is lower.

Figure 12 depicts the corresponding power consumption in the upper plot and the battery charging scheduling in the lower plot. Batteries are recharged continuously during the 24 h, from a minimum of five to a maximum of fourteen simultaneously engaged. Notwithstanding the constant power required from the grid in the two time partitions, there are small variations in the number of batteries being simultaneously charged. This is due to the tuning of the power at with each battery is recharged and is clearly visible in

Figure 13 reporting the battery state of charge

throughout the day. In the figure, batteries from 1 to 10 are for the HE-DH8, from 11 to 19 for the HE-ATR42, and from 20 to 24 for the HE-ATR72. Compared to the Panthera Hybrid case, the amount of energy stored in each battery is so high that even with the a nominal charger power higher than three times the minimum time to fully recharge a battery ranges from five hours for the HE-ATR42 to seven hours for the HE-DH8. By looking at the colored patterns, it is observed that in some cases, a battery of the HE-DH8 type may take up to 15 h to recharge completely, at a reduced power setting, which is more than double the duration necessary at 200 kW power.

Figure 14 provides the time history of energy consumption for the more powerful 400 kW chargers. Here, the constant pattern at night is basically preserved, while a significant variation in the energy demand is seen during daytime. In fact, the chargers allow a quicker operation for each battery, so that all of them are completely recharged during nighttime and there is almost no need for continuing the process in the early daytime hours, at the rising of the energy and power pricing.

Figure 15 illustrates the corresponding power consumption and the battery charging scheduling. The quicker recharging times, compared to the 200 kW case, are clearly visible, together with the power tuning that may change the recharge duration for a given battery. A maximum of nine batteries is simultaneously charged in this case.

Figure 16 shows the time evolution of the battery state of charge, where now batteries from 1 to 8 are for the HE-DH8, from 9 to 16 for the HE-ATR42, and from 17 to 21 for the HE-ATR72. It is seen that the much faster recharging process (the maximum charging time is 5 h) allows more batteries to be served twice during the day when compared to the 200 kW case and even one to be charged thrice. Indeed, in the previous case, the batteries charged only once were 16 (67% of the total), while now they amount to 11 (52% of the total).