State Monitoring Method for Tool Wear in Aerospace Manufacturing Processes Based on a Convolutional Neural Network (CNN)

Abstract

:1. Introduction

2. Theory and Methodology

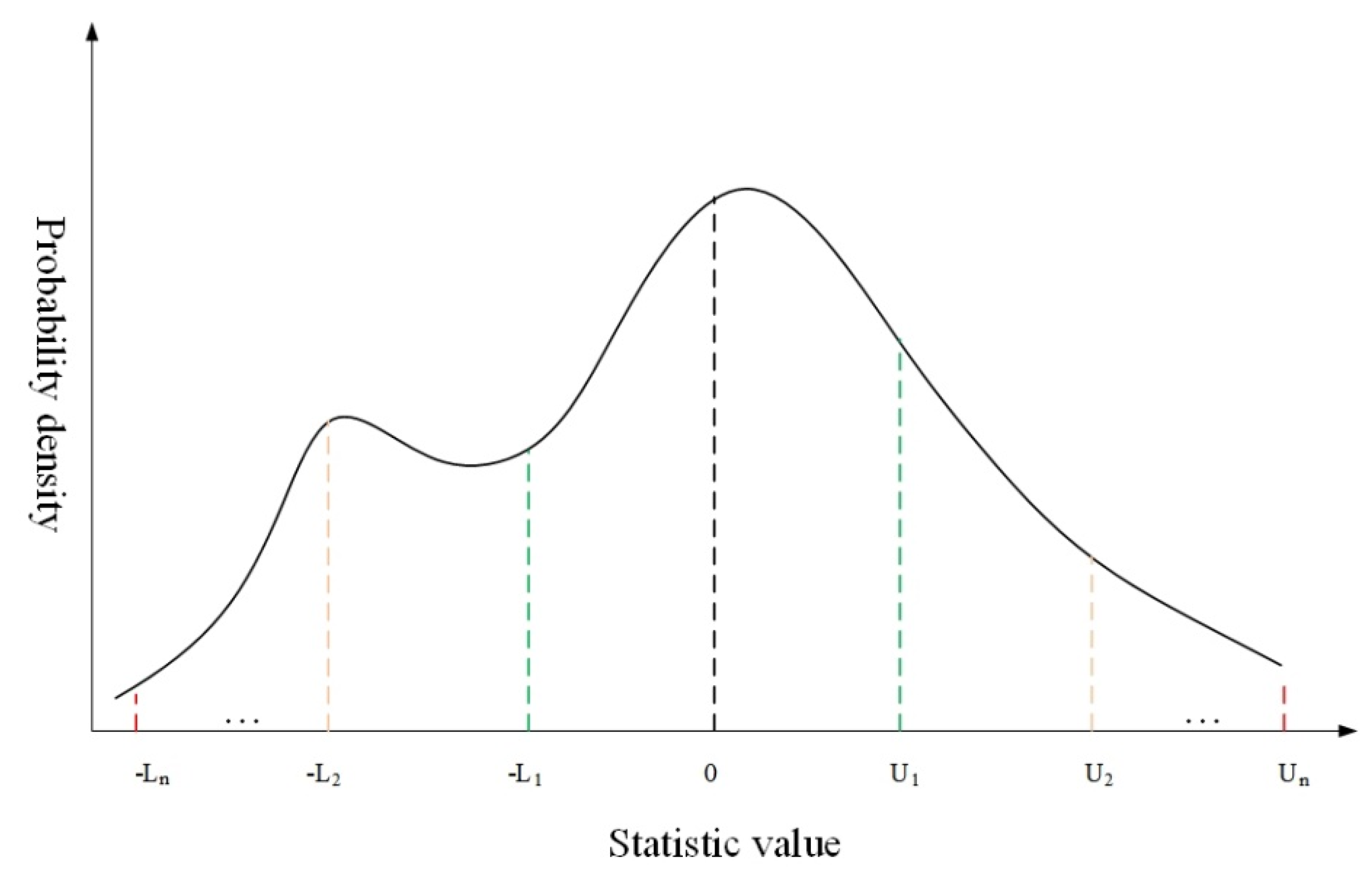

2.1. Kernel Density Estimation

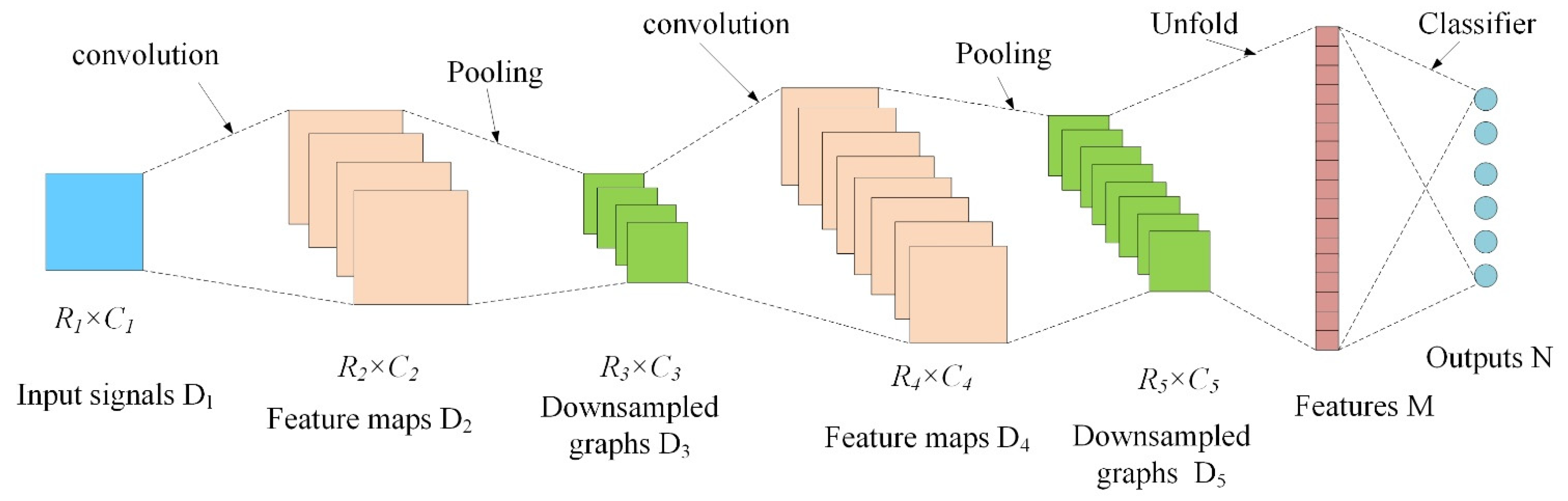

2.2. Convolutional Neural Network

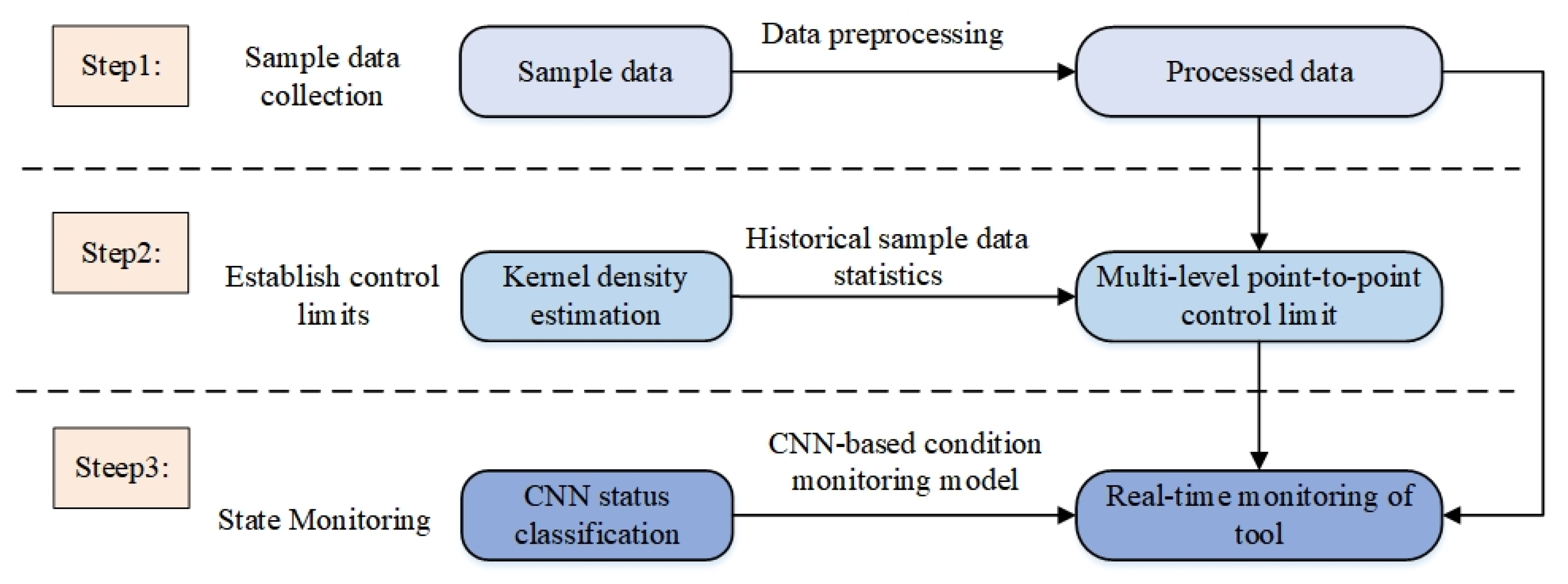

3. Proposed Approach Framework

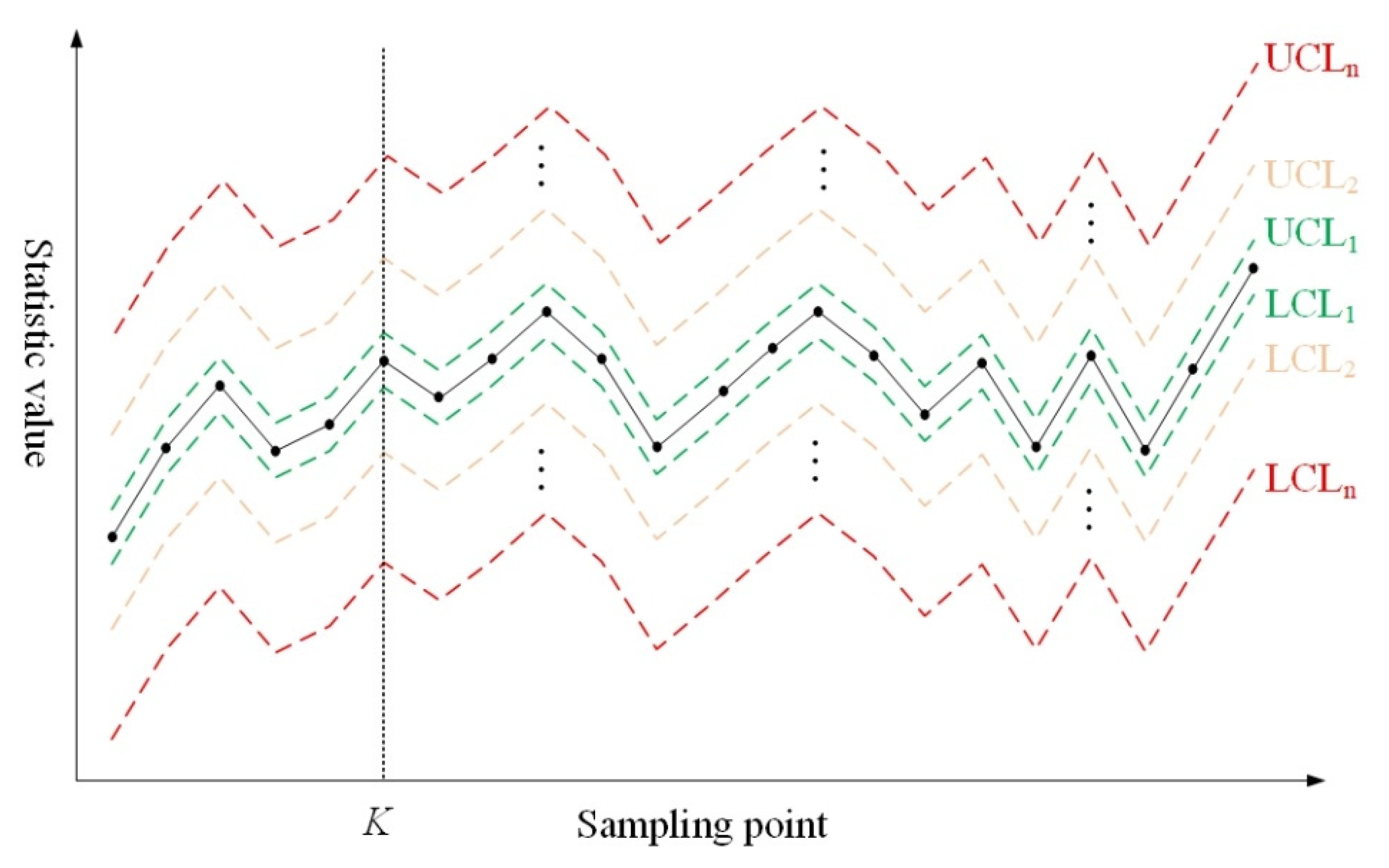

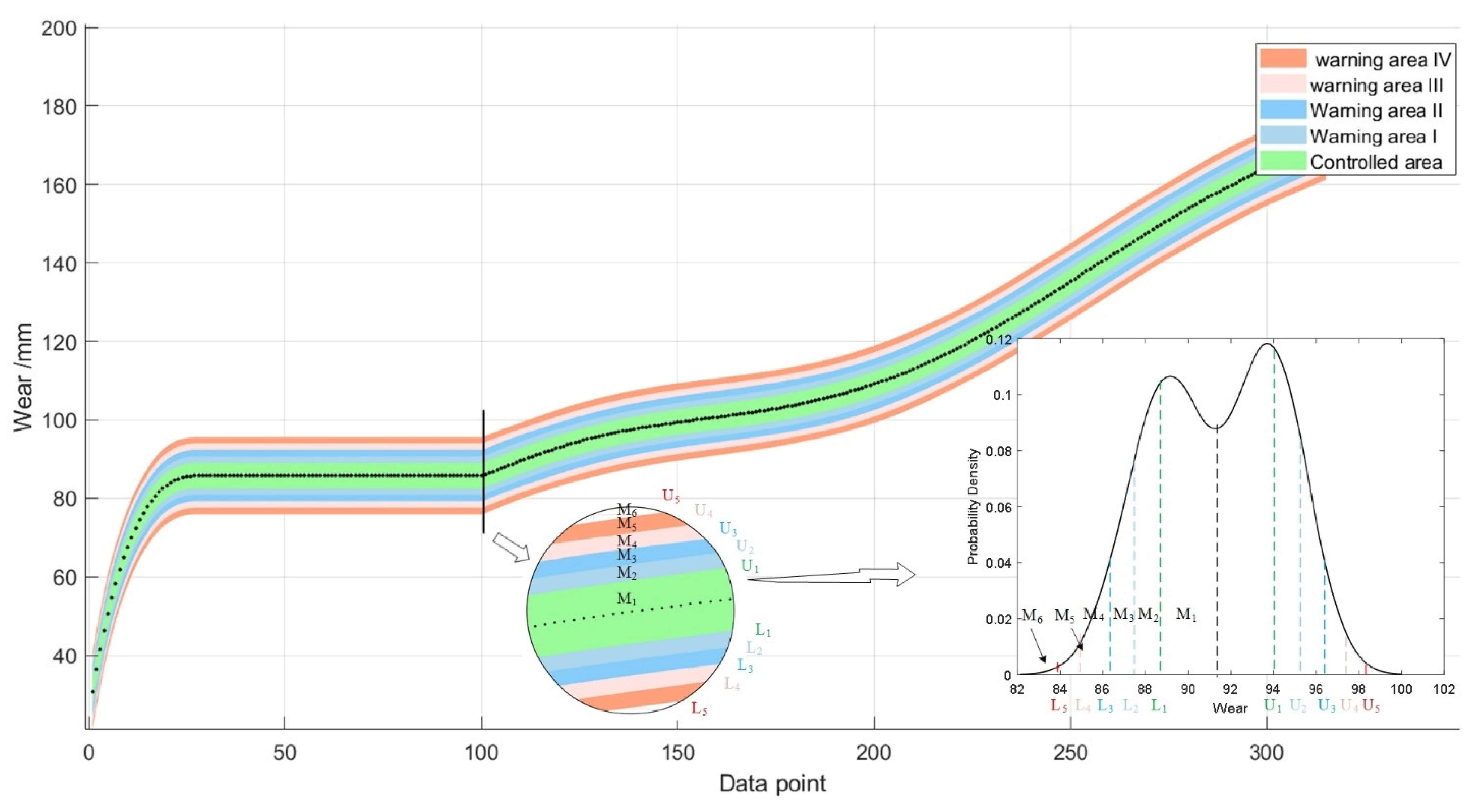

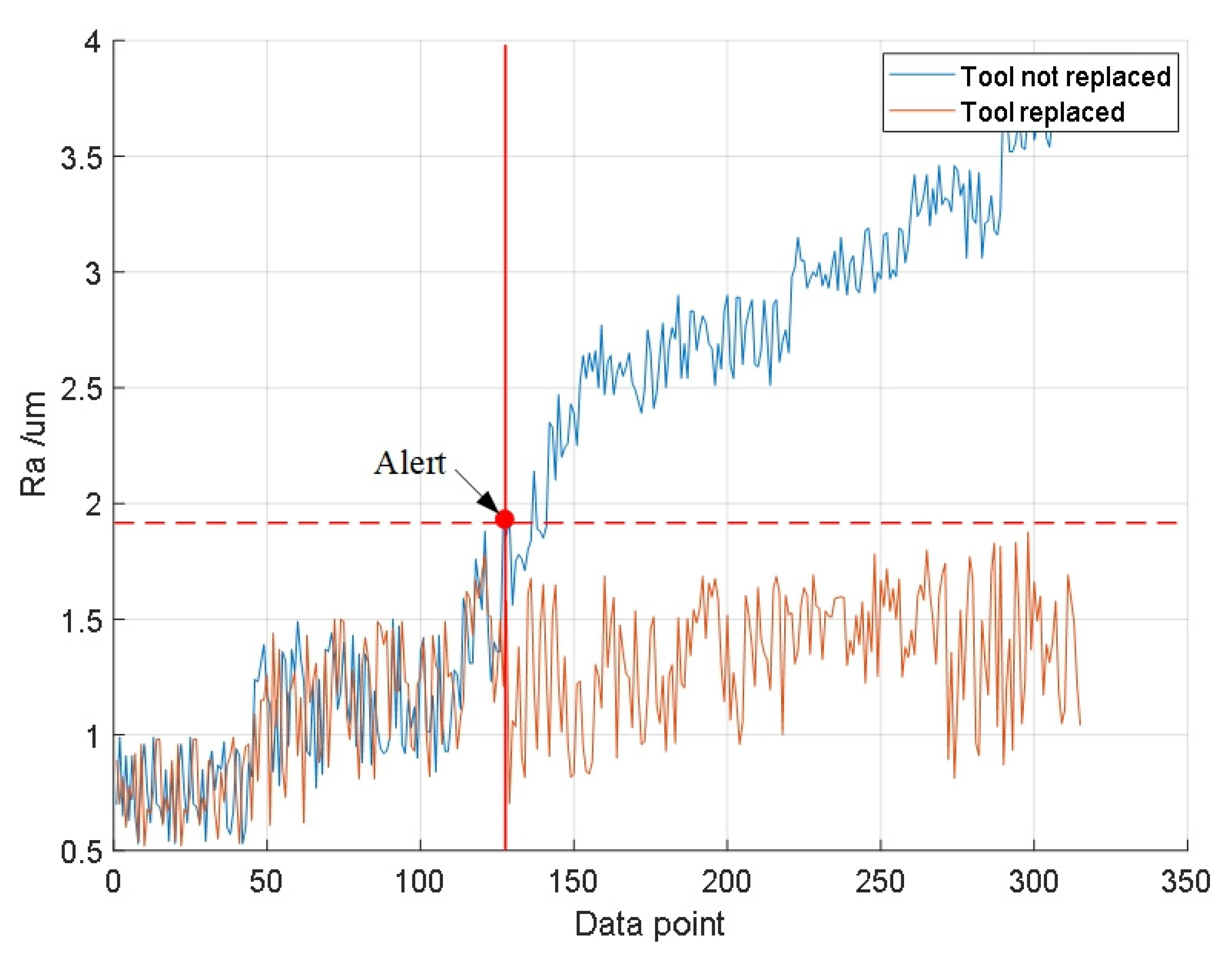

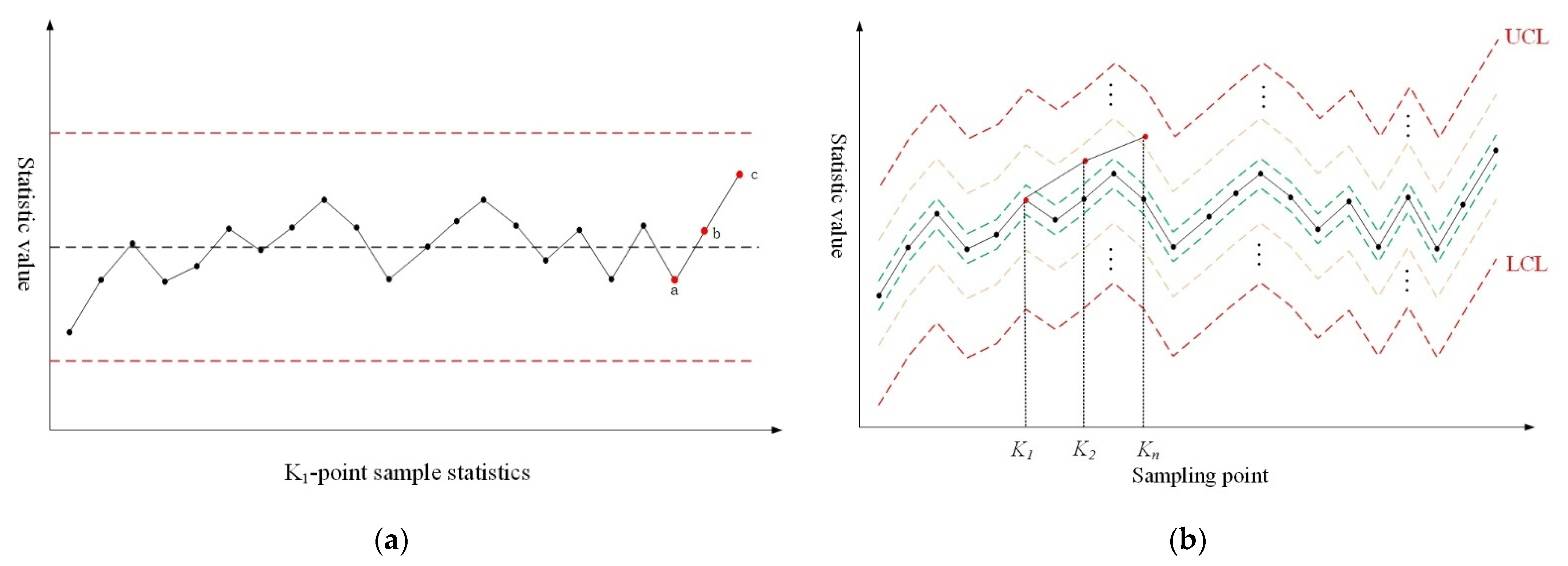

3.1. Construction of Point-to-Point Control Limit

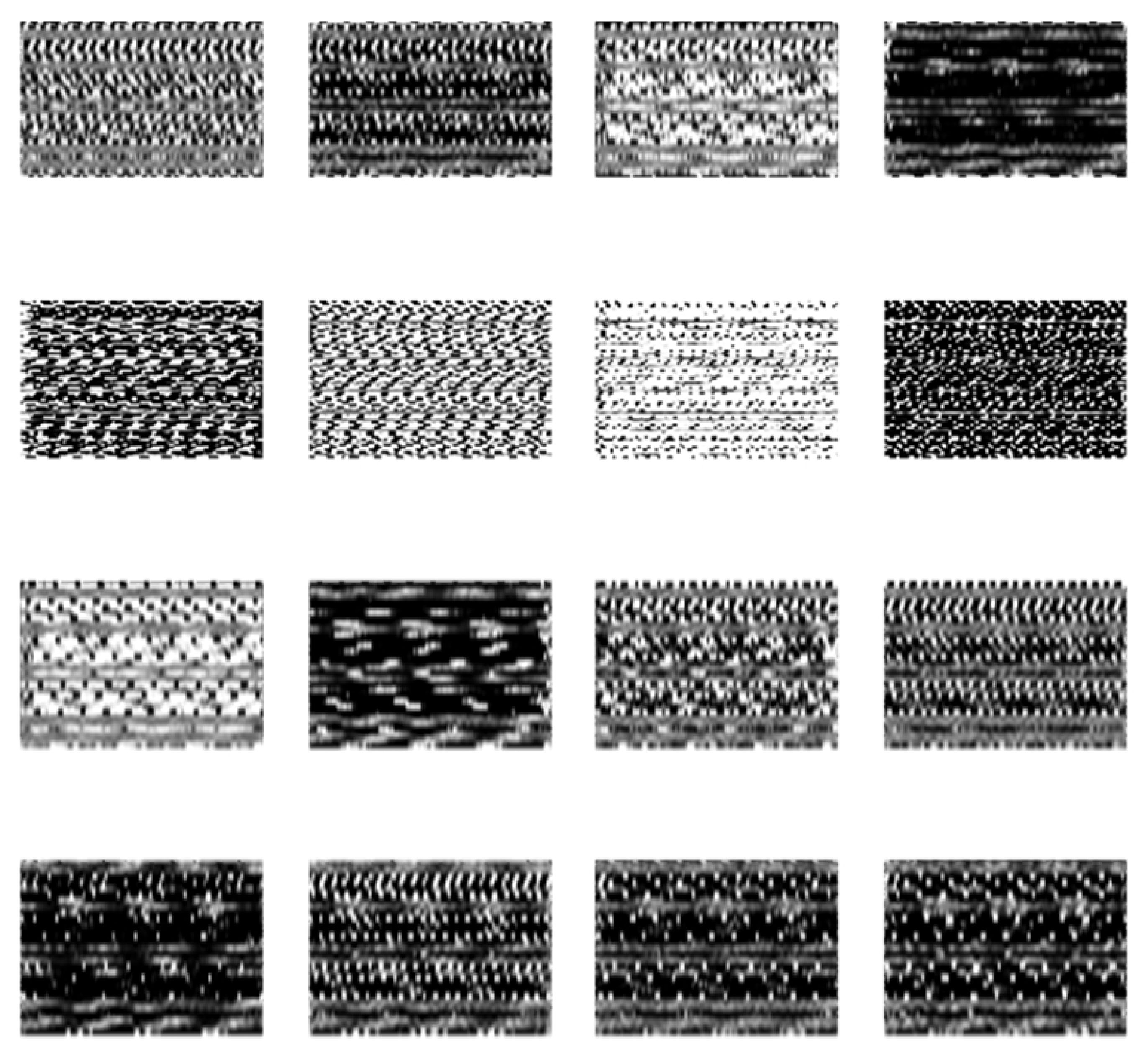

3.2. Condition Monitoring Method Based on CNN Algorithm

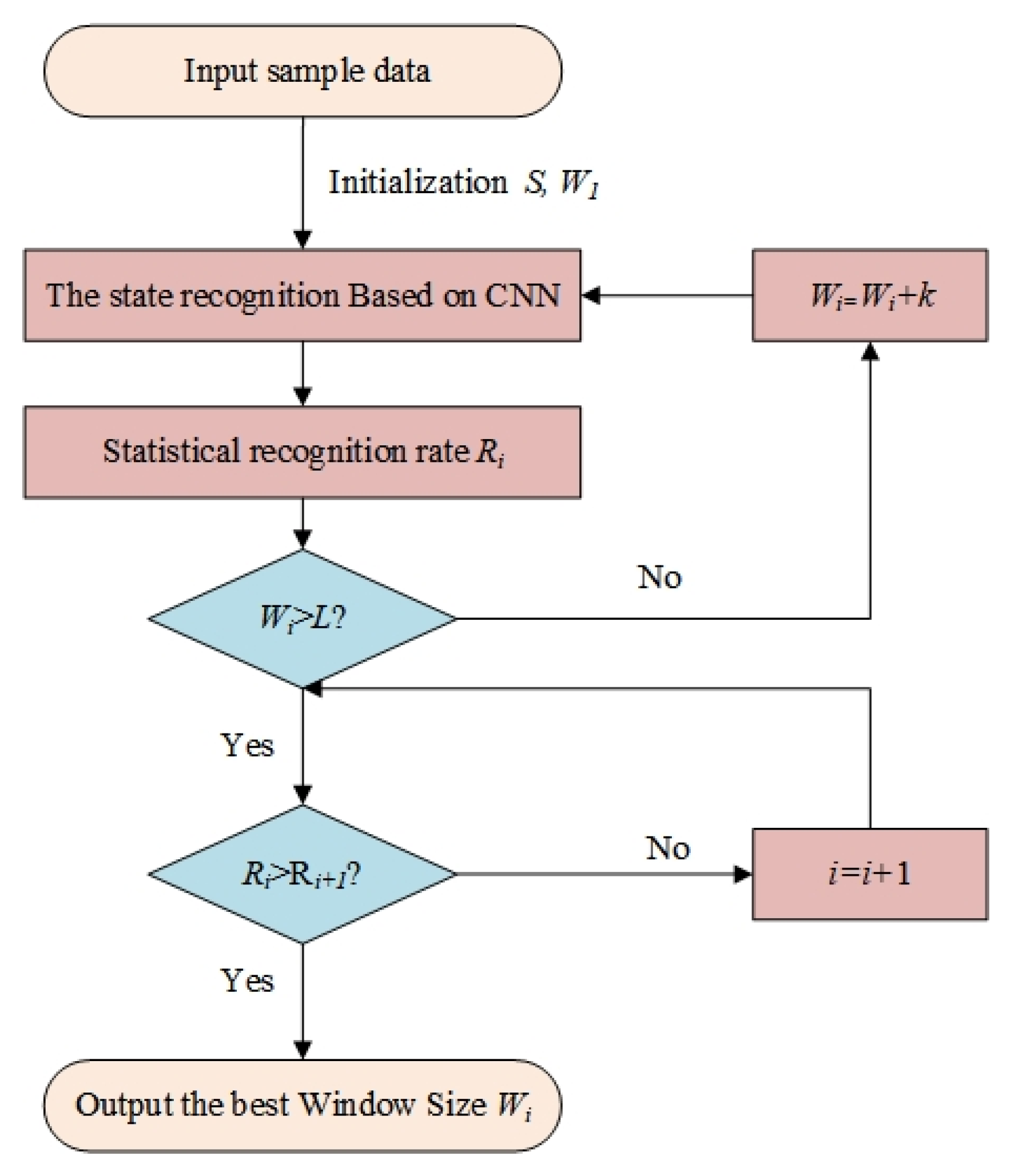

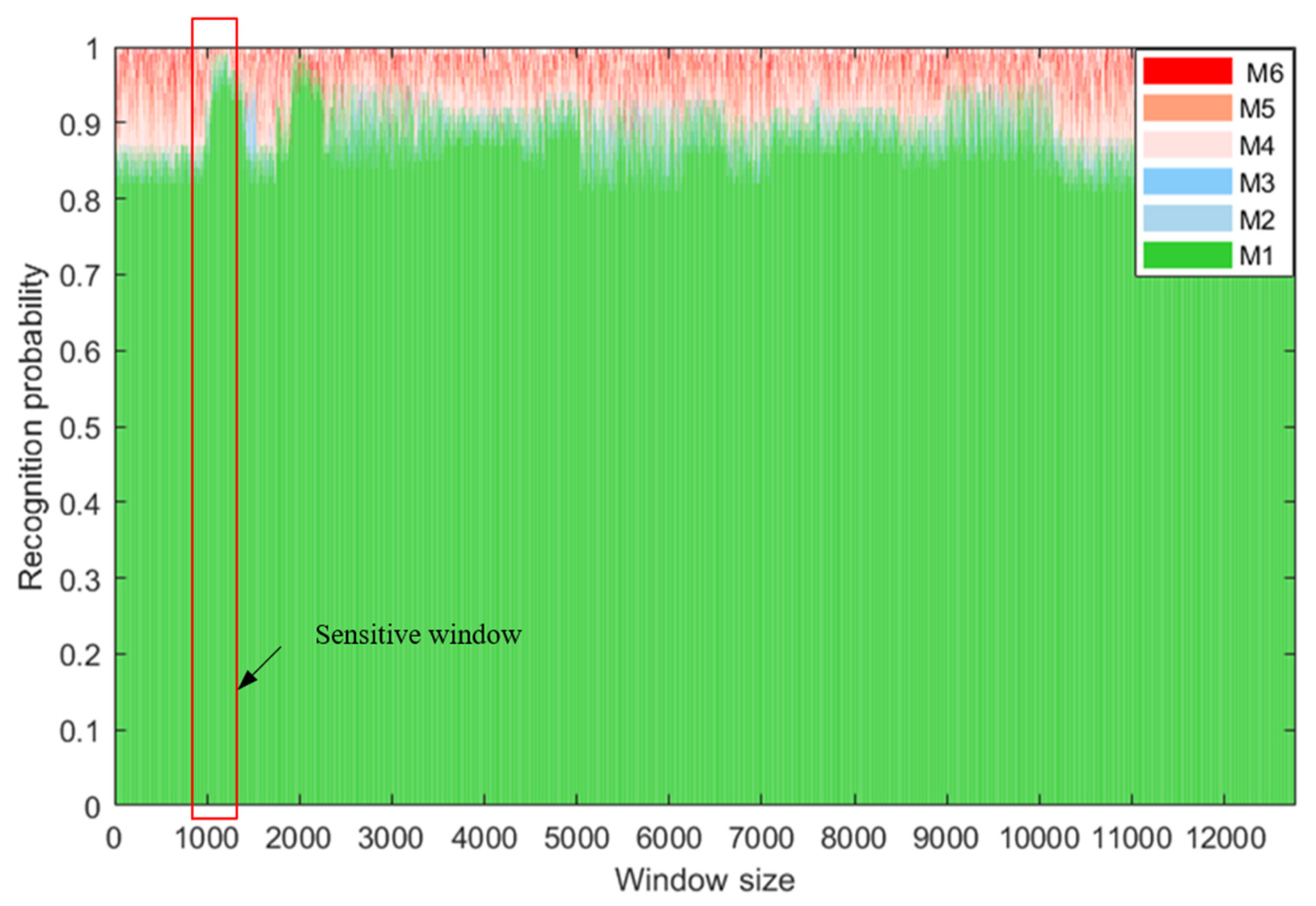

3.2.1. Optimal Sampling Window Determination

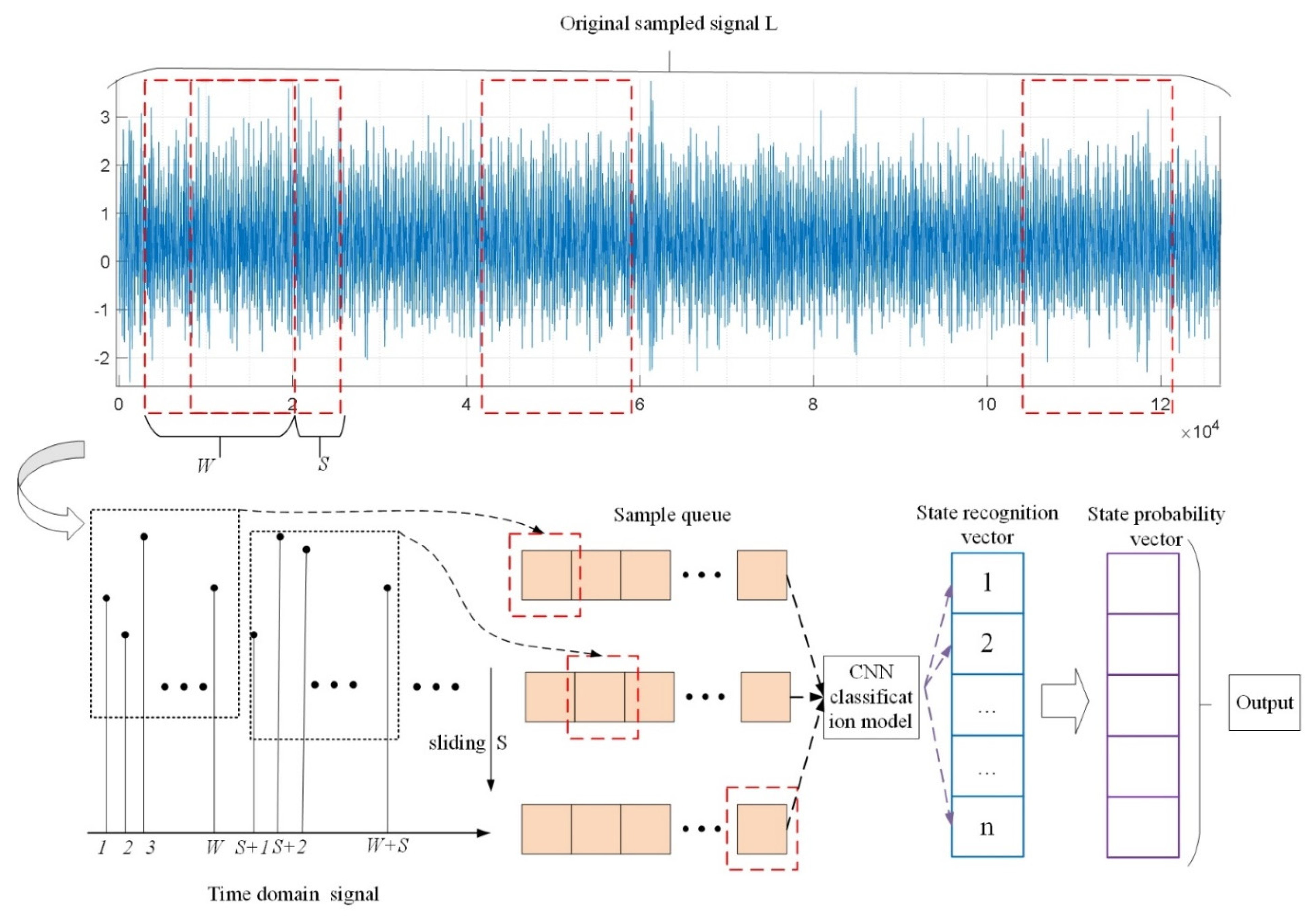

3.2.2. Mobile Sliding Window for State Recognition

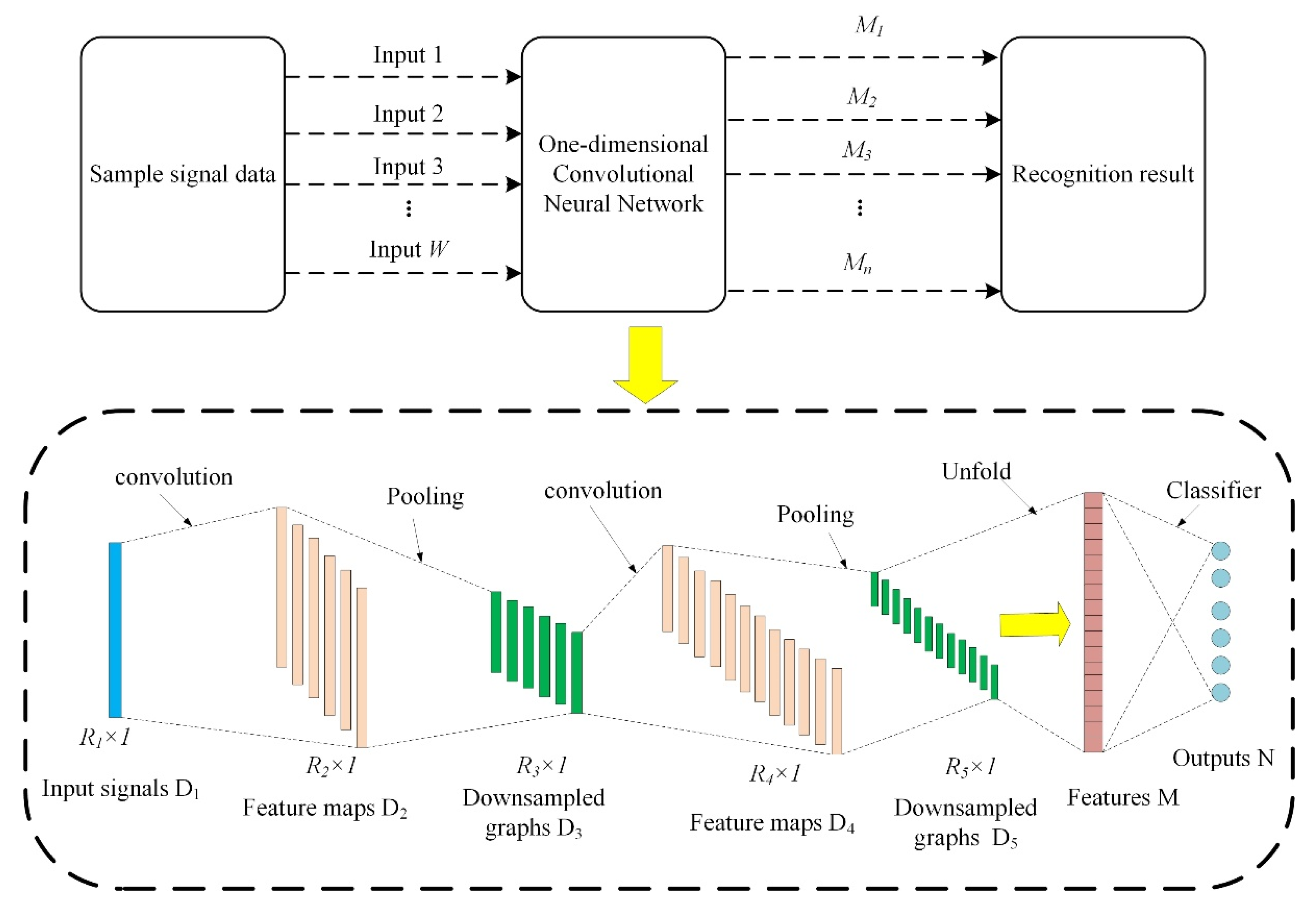

3.2.3. The Wear State Recognition Model with CNN

4. Experiment Verification

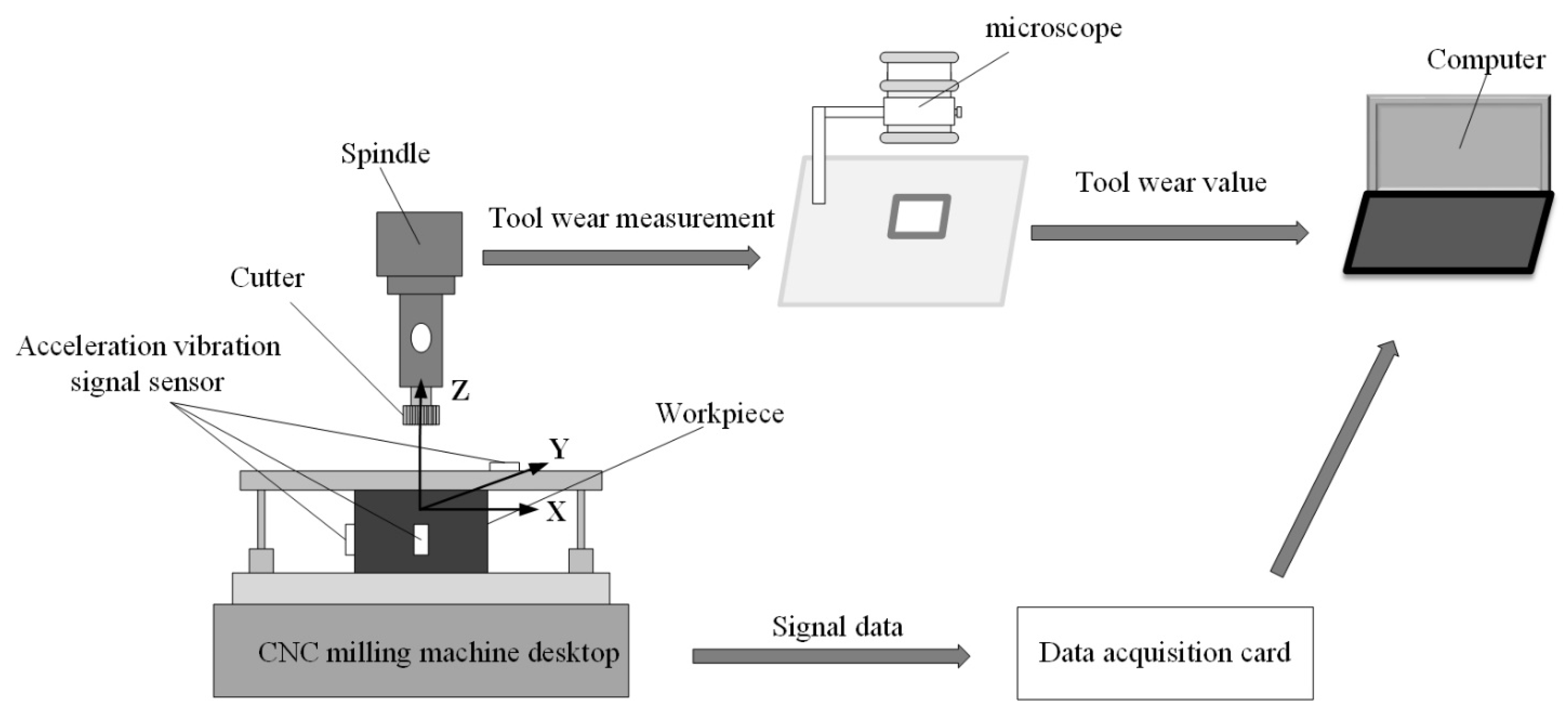

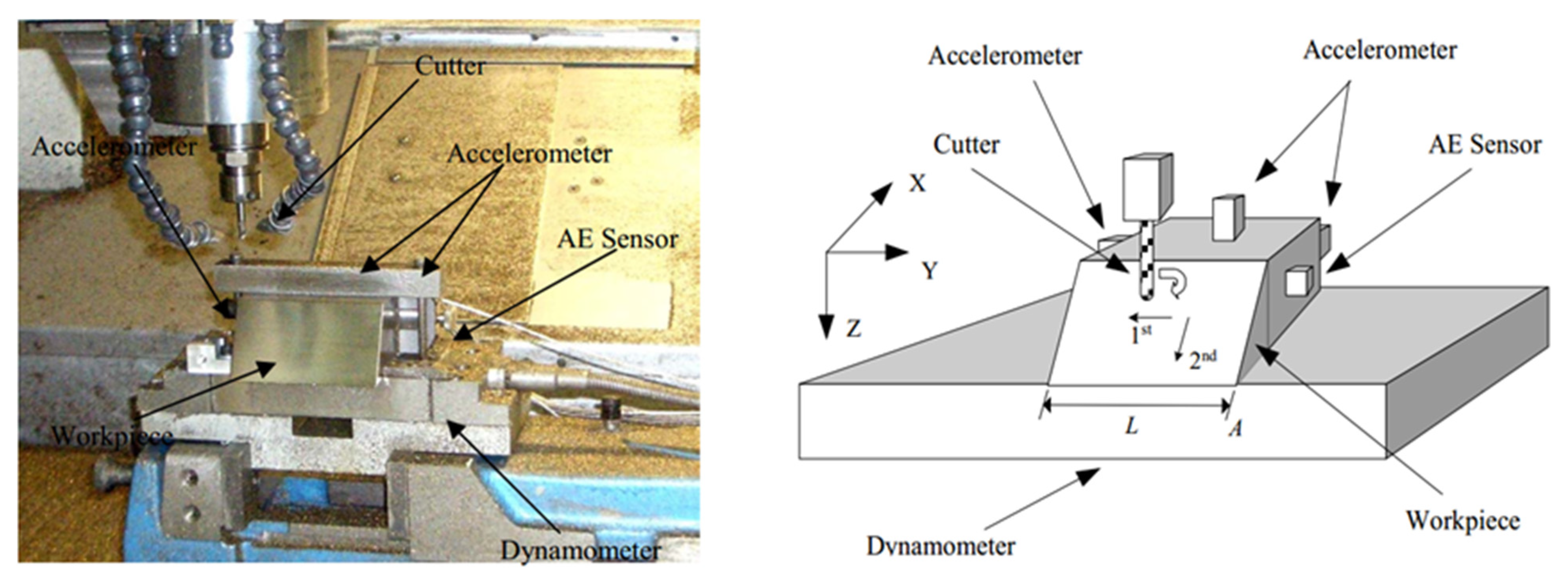

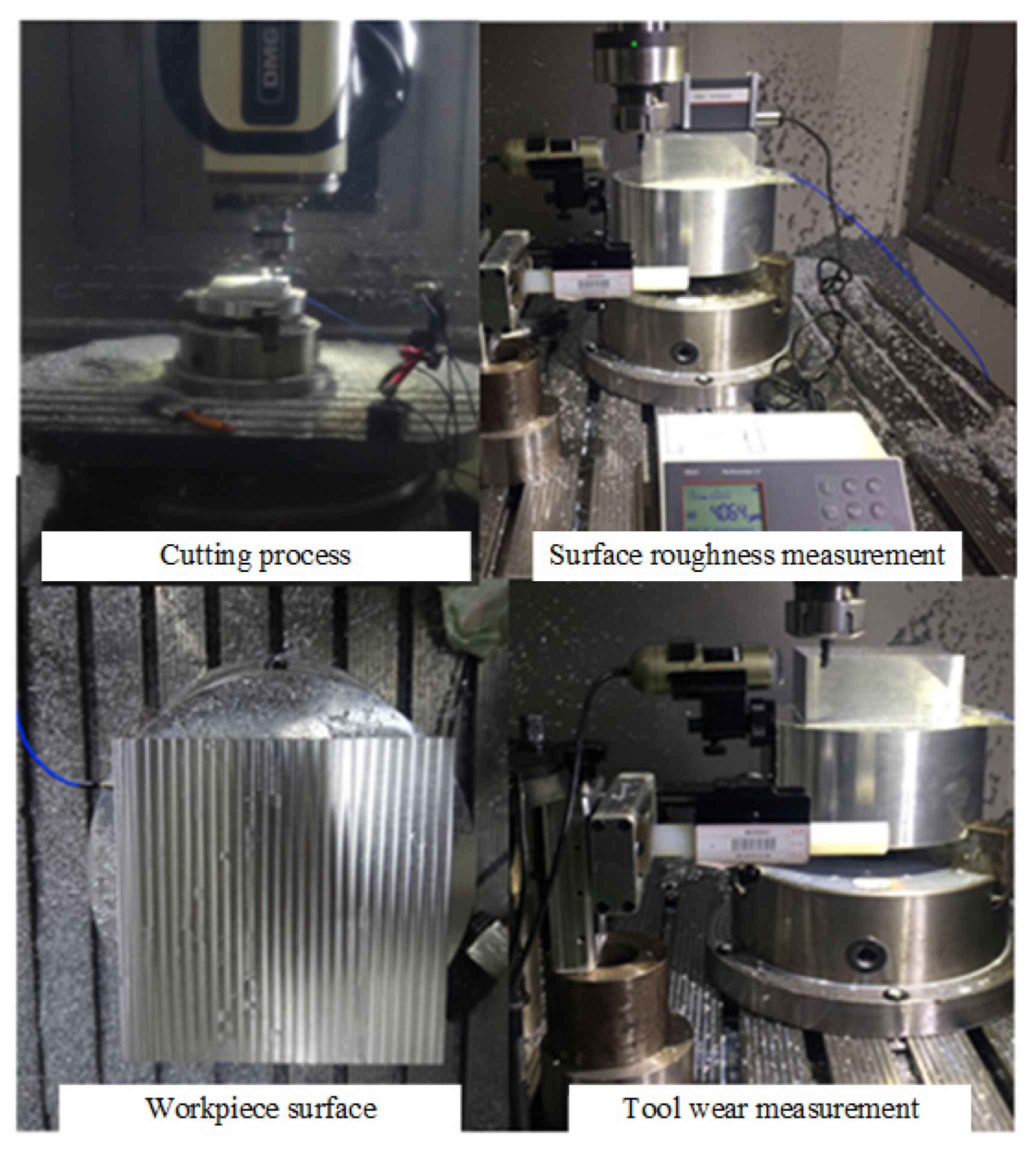

4.1. Experimental Setup

4.2. Verification of Method Validity

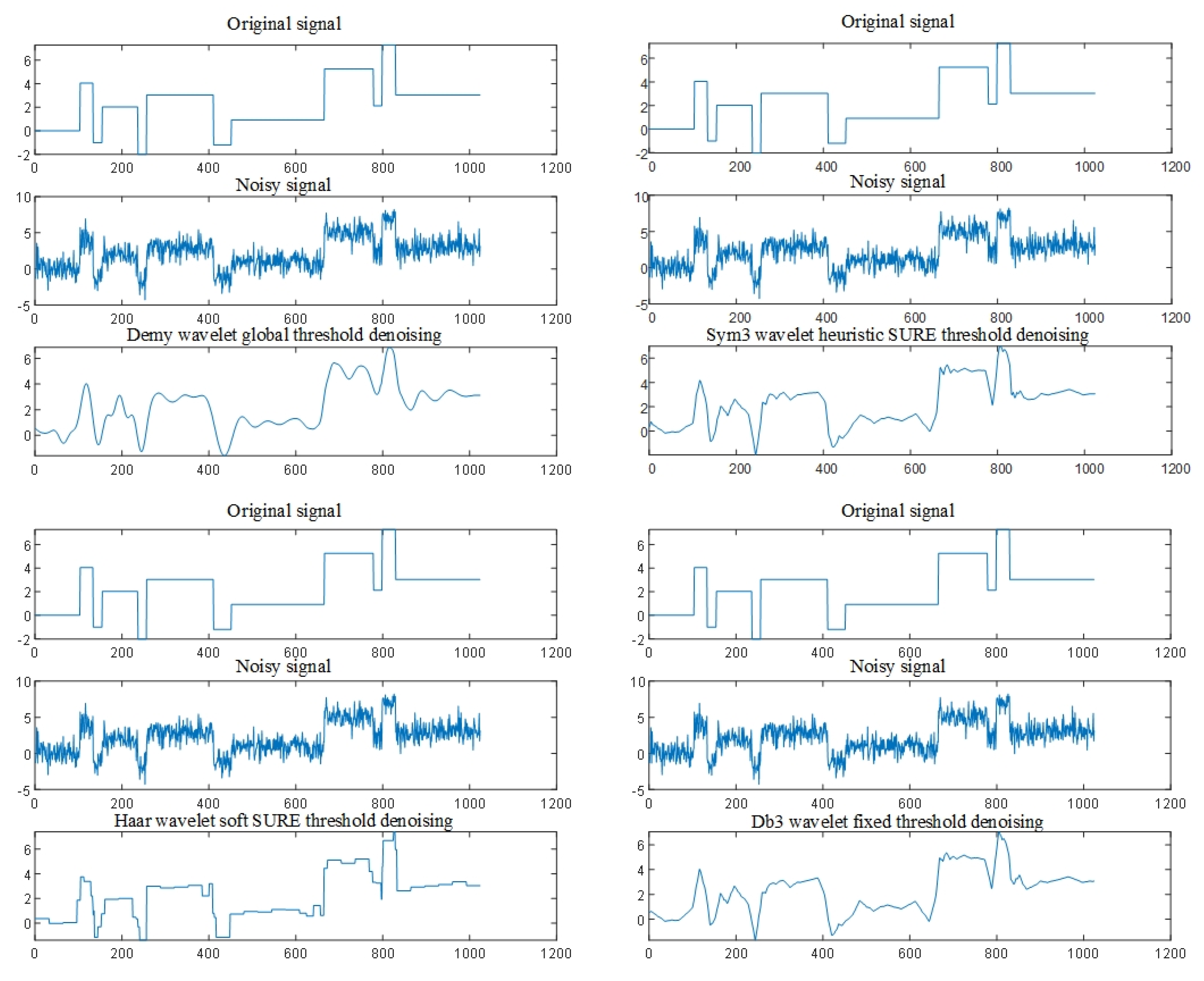

4.2.1. Data Preprocessing and Control Limit Determination

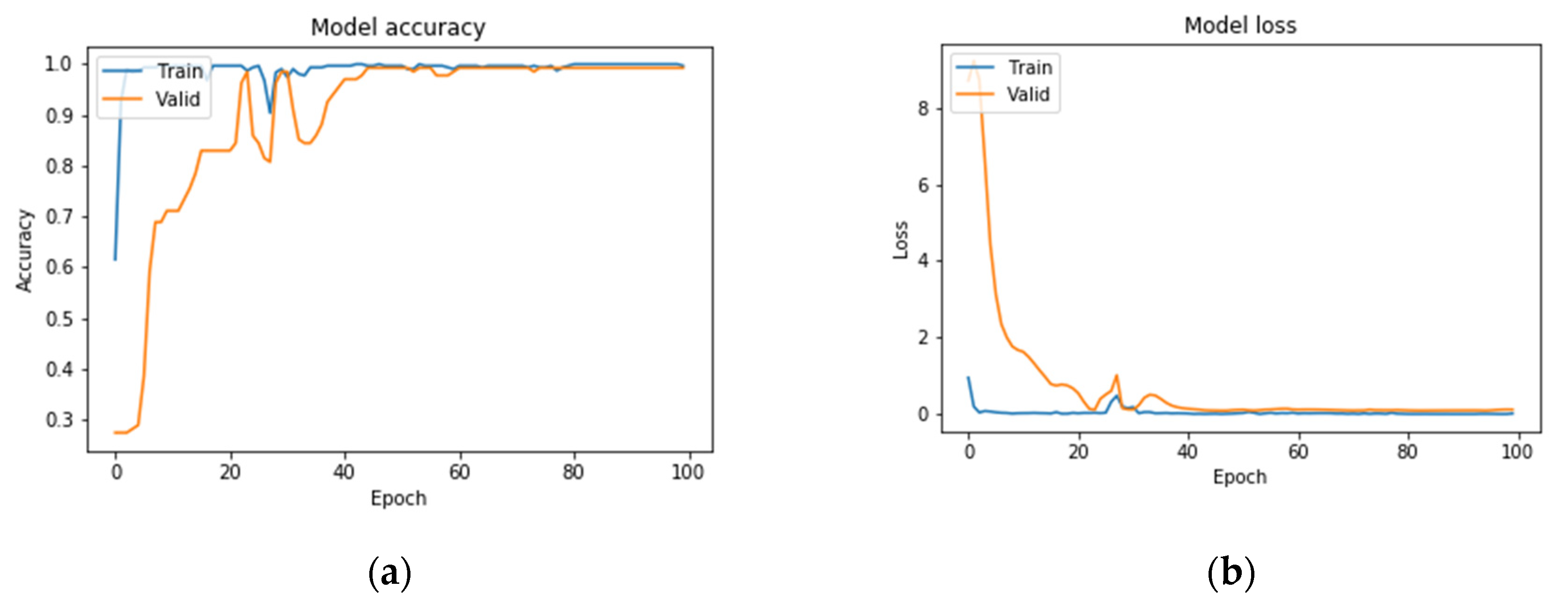

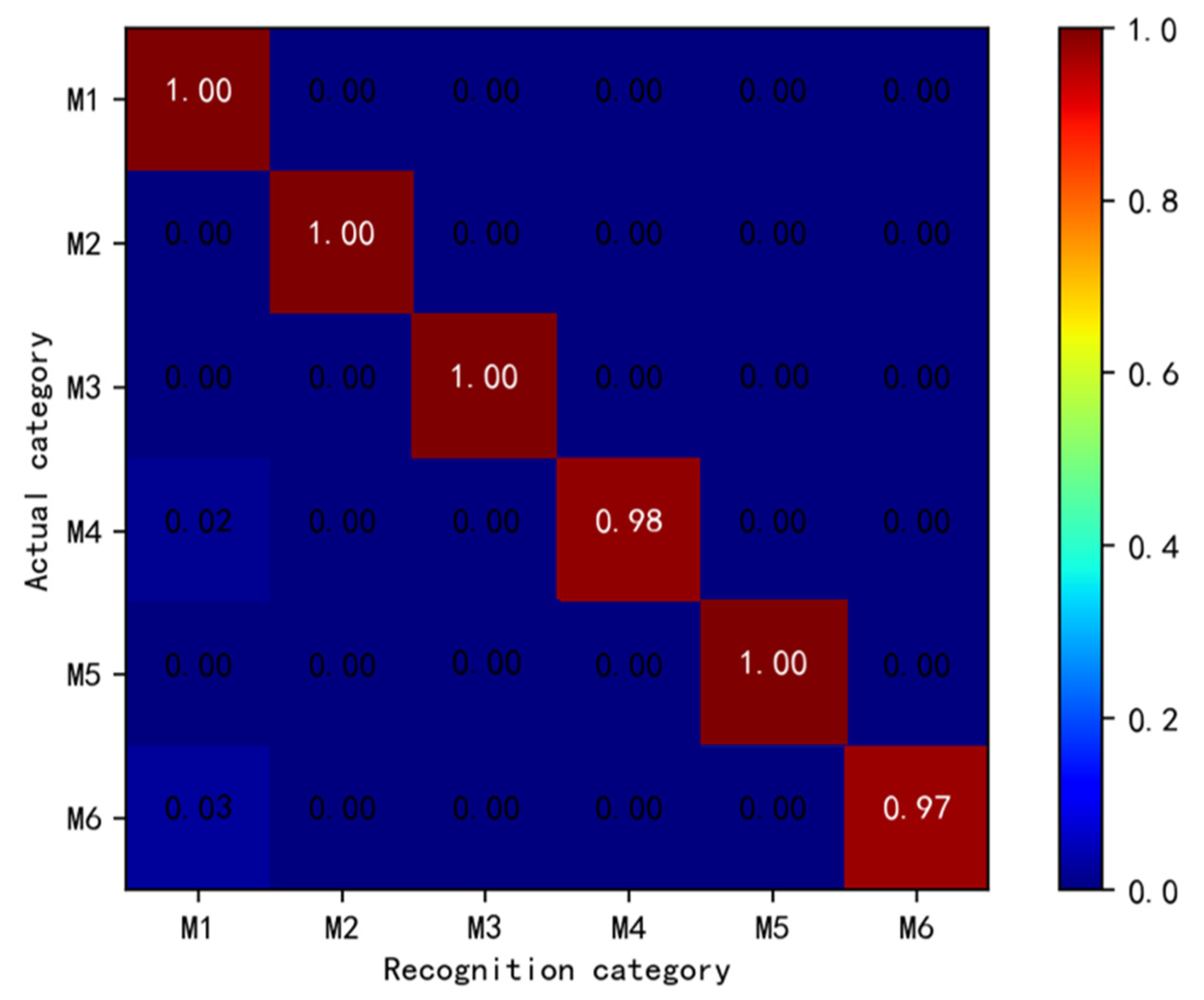

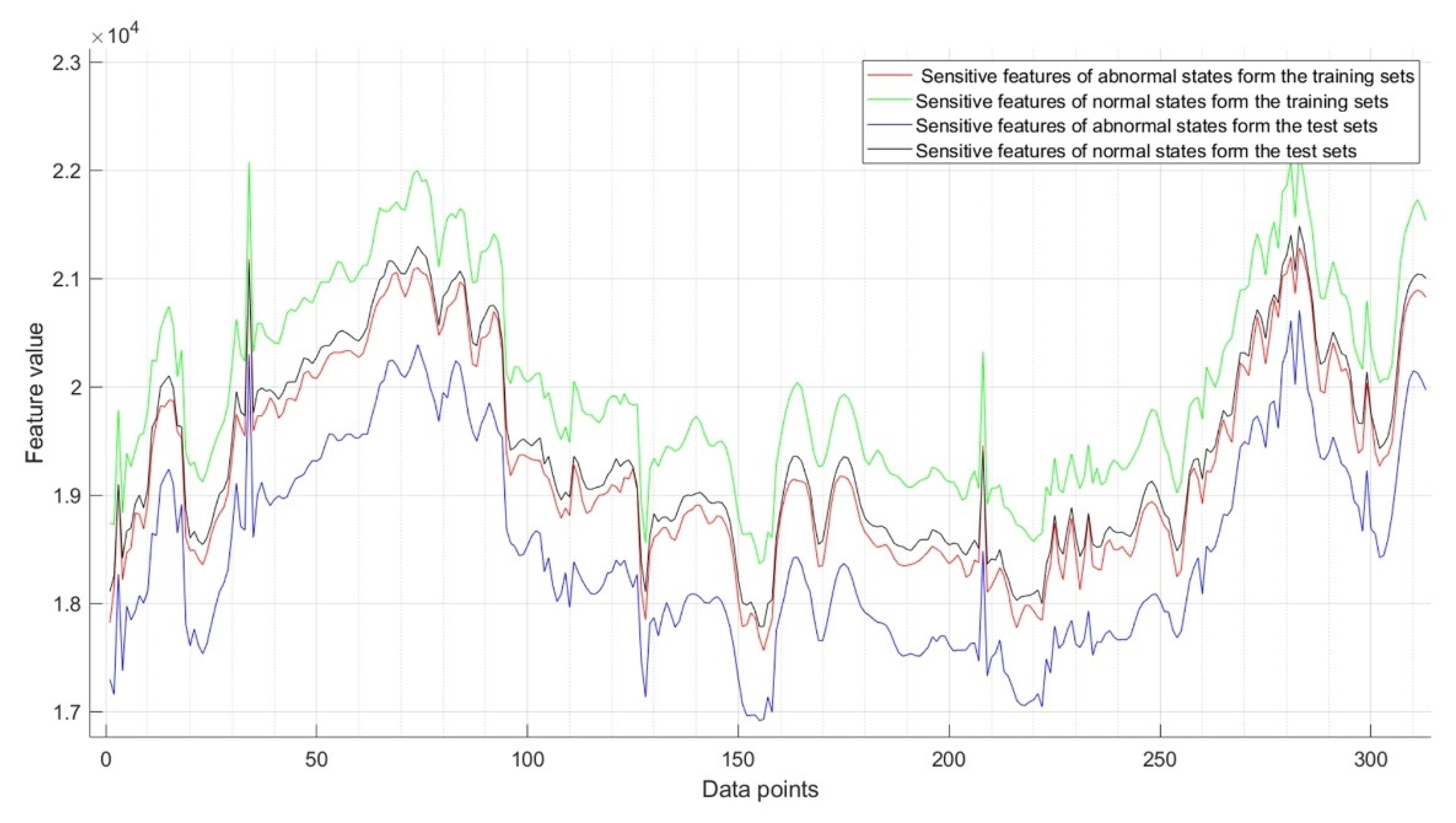

4.2.2. Training and Testing of the CNN Model

4.3. Actual Case Verification

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Z.; Zhang, L. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Measurement 2020, 149, 107002. [Google Scholar] [CrossRef]

- Trzun, Z.; Vrdoljak, M.; Cajner, H. The Effect of Manufacturing Quality on Rocket Precision. Aerospace 2021, 8, 160. [Google Scholar] [CrossRef]

- Djebko, K.; Puppe, F.; Kayal, H. Model-Based Fault Detection and Diagnosis for Spacecraft with an Application for the SONATE Triple Cube Nano-Satellite. Aerospace 2019, 6, 105. [Google Scholar] [CrossRef] [Green Version]

- Hong, W.; Cai, W.; Wang, S.; Tomovic, M.M. Mechanical wear debris feature, detection, and diagnosis: A review. Chin. J. Aeronaut. 2018, 31, 867–882. [Google Scholar] [CrossRef]

- Javed, K.; Gouriveau, R.; Li, X.; Zerhouni, N. Tool wear monitoring and prognostics challenges: A comparison of connectionist methods toward an adaptive ensemble model. J. Intell. Manuf. 2018, 29, 1873–1890. [Google Scholar] [CrossRef]

- Bhuiyan, M.S.H.; Choudhury, I.A.; Dahari, M. Monitoring the tool wear, surface roughness and chip formation occurrences using multiple sensors in turning. J. Manuf. Syst. 2014, 33, 476–487. [Google Scholar] [CrossRef]

- Liu, Y.; Hong, S.; Zio, E.; Liu, J. Fault Diagnosis and Reconfigurable Control for Commercial Aircraft with Multiple Faults and Actuator Saturation. Aerospace 2021, 8, 108. [Google Scholar] [CrossRef]

- Valtierra-Rodriguez, M.; Amezquita-Sanchez, J.; Garcia-Perez, A.; Camarena-Martinez, D. Complete Ensemble Empirical Mode Decomposition on FPGA for Condition Monitoring of Broken Bars in Induction Motors. Mathematics 2019, 7, 783. [Google Scholar] [CrossRef] [Green Version]

- Oo, H.; Wang, W.; Liu, Z. Tool wear monitoring system in belt grinding based on image-processing techniques. Int. J. Adv. Manuf. Technol. 2020, 111, 2215–2229. [Google Scholar] [CrossRef]

- Basora, L.; Bry, P.; Olive, X.; Freeman, F. Aircraft Fleet Health Monitoring with Anomaly Detection Techniques. Aerospace 2021, 8, 103. [Google Scholar] [CrossRef]

- Goodall, P.; Pantazis, D.; West, A. A cyber physical system for tool condition monitoring using electrical power and a mechanistic model. Comput. Ind. 2020, 118, 103223. [Google Scholar] [CrossRef]

- Basora, L.; Olive, X.; Dubot, T. Recent Advances in Anomaly Detection Methods Applied to Aviation. Aerospace 2019, 6, 117. [Google Scholar] [CrossRef] [Green Version]

- Qin, A.; Guo, L.; You, Z.; Gao, H.; Wu, X.; Xiang, S. Research on automatic monitoring method of face milling cutter wear based on dynamic image sequence. Int. J. Adv. Manuf. Technol. 2020, 110, 3365–3376. [Google Scholar] [CrossRef]

- Fernández-Robles, L.; Sánchez-González, L.; Díez-González, J.; Castejón-Limas, M.; Pérez, H. Use of image processing to monitor tool wear in micro milling. Neurocomputing 2020, 452, 333–340. [Google Scholar] [CrossRef]

- Doğru, A.; Bouarfa, S.; Arizar, R.; Aydoğan, R. Using Convolutional Neural Networks to Automate Aircraft Maintenance Visual Inspection. Aerospace 2020, 7, 171. [Google Scholar] [CrossRef]

- Lamraoui, M.; Thomas, M.; El Badaoui, M. Cyclostationarity approach for monitoring chatter and tool wear in high speed milling. Mech. Syst. Signal. Process. 2014, 44, 177–198. [Google Scholar] [CrossRef]

- Mohanraj, T.; Shankar, S.; Rajasekar, R.; Sakthivel, N.R.; Pramanik, A. Tool condition monitoring techniques in milling process—A review. J. Mater. Res. Technol. 2020, 9, 1032–1042. [Google Scholar] [CrossRef]

- Rizal, M.; Ghani, J.A.; Nuawi, M.Z.; Haron, C.H.C. Cutting tool wear classification and detection using multi-sensor signals and Mahalanobis-Taguchi System. Wear 2017, 376–377, 1759–1765. [Google Scholar] [CrossRef]

- Brito, L.C.; Susto, G.A.; Brito, J.N.; Duarte, M.A.V. An explainable artificial intelligence approach for unsupervised fault detection and diagnosis in rotating machinery. Mech. Syst. Signal. Process. 2022, 163, 108105. [Google Scholar] [CrossRef]

- Aykroyd, R.G.; Leiva, V.; Ruggeri, F. Recent developments of control charts, identification of big data sources and future trends of current research. Technol. Forecast. Soc. Chang. 2019, 144, 221–232. [Google Scholar] [CrossRef]

- Fuqua, D.; Razzaghi, T. A cost-sensitive convolution neural network learning for control chart pattern recognition. Expert Syst. Appl. 2020, 150, 113275. [Google Scholar] [CrossRef]

- Lin, C.; Lu, M.; Yang, S.; Lee, M. A Bayesian Control Chart for Monitoring Process Variance. Appl. Sci. 2021, 11, 2729. [Google Scholar] [CrossRef]

- Aziz Kalteh, A.; Babouei, S. Control chart patterns recognition using ANFIS with new training algorithm and intelligent utilization of shape and statistical features. ISA Trans. 2020, 102, 12–22. [Google Scholar] [CrossRef]

- Vapnik, V.N. An overview of statistical learning theory. IEEE Trans. Neural. Netw. 1999, 10, 988–999. [Google Scholar] [CrossRef] [Green Version]

- Yu, M.; Wu, C.; Wang, Z.; Tsung, F. A robust CUSUM scheme with a weighted likelihood ratio to monitor an overdispersed counting process. Comput. Ind. Eng. 2018, 126, 165–174. [Google Scholar] [CrossRef]

- Lee, T.; Baek, C. Block wild bootstrap-based CUSUM tests robust to high persistence and misspecification. Comput. Stat. Data Anal. 2020, 150, 106996. [Google Scholar] [CrossRef]

- Mukherjee, A.; Chong, Z.L.; Khoo, M.B.C. Comparisons of some distribution-free CUSUM and EWMA schemes and their applications in monitoring impurity in mining process flotation. Comput. Ind. Eng. 2019, 137, 106059. [Google Scholar] [CrossRef]

- Dao, P.B. A CUSUM-Based Approach for Condition Monitoring and Fault Diagnosis of Wind Turbines. Energies 2021, 14, 3236. [Google Scholar] [CrossRef]

- Ajadi, J.O.; Zwetsloot, I.M.; Tsui, K. A New Robust Multivariate EWMA Dispersion Control Chart for Individual Observations. Mathematics 2021, 9, 1038. [Google Scholar] [CrossRef]

- Ding, S.; Li, X.; Dong, X.; Yang, W. The Consistency of the CUSUM-Type Estimator of the Change-Point and Its Application. Mathematics 2020, 8, 2113. [Google Scholar] [CrossRef]

- Soualhi, M.; Nguyen, K.T.P.; Medjaher, K. Pattern recognition method of fault diagnostics based on a new health indicator for smart manufacturing. Mech. Syst. Signal. Process. 2020, 142, 106680. [Google Scholar] [CrossRef]

- Nesci, A.; De Martin, A.; Jacazio, G.; Sorli, M. Detection and Prognosis of Propagating Faults in Flight Control Actuators for Helicopters. Aerospace 2020, 7, 20. [Google Scholar] [CrossRef] [Green Version]

- Kim, T.; Cho, S. Optimizing CNN-LSTM neural networks with PSO for anomalous query access control. Neurocomputing 2021, 456, 666–677. [Google Scholar] [CrossRef]

- Mashuri, M.; Ahsan, M.; Lee, M.H.; Prastyo, D.D. PCA-based Hotelling’s T2 chart with fast minimum covariance determinant (FMCD) estimator and kernel density estimation (KDE) for network intrusion detection. Comput. Ind. Eng. 2021, 158, 107447. [Google Scholar] [CrossRef]

- Tian, Q.; Wang, H. Predicting Remaining Useful Life of Rolling Bearings Based on Reliable Degradation Indicator and Temporal Convolution Network with the Quantile Regression. Appl. Sci. 2021, 11, 4773. [Google Scholar] [CrossRef]

- Chen, H.; Xu, K.; Chen, L.; Jiang, Q. Self-Expressive Kernel Subspace Clustering Algorithm for Categorical Data with Embedded Feature Selection. Mathematics 2021, 9, 1680. [Google Scholar] [CrossRef]

- Dai, J.; Liu, Y.; Chen, J. Feature selection via max-independent ratio and min-redundant ratio based on adaptive weighted kernel density estimation. Inf. Sci. 2021, 568, 86–112. [Google Scholar] [CrossRef]

- Shao, R.; Hu, W.; Wang, Y.; Qi, X. The fault feature extraction and classification of gear using principal component analysis and kernel principal component analysis based on the wavelet packet transform. Measurement 2014, 54, 118–132. [Google Scholar] [CrossRef]

- Hou, L.; Qu, H. Automatic recognition system of pointer meters based on lightweight CNN and WSNs with on-sensor image processing. Measurement 2021, 183, 109819. [Google Scholar] [CrossRef]

- Phisannupawong, T.; Kamsing, P.; Torteeka, P.; Channumsin, S.; Sawangwit, U.; Hematulin, W.; Jarawan, T.; Somjit, T.; Yooyen, S.; Delahaye, D.; et al. Vision-Based Spacecraft Pose Estimation via a Deep Convolutional Neural Network for Noncooperative Docking Operations. Aerospace 2020, 7, 126. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, M.; Dai, W. A condition monitoring approach for machining process based on control chart pattern recognition with dynamically-sized observation windows. Comput. Ind. Eng. 2020, 142, 106360. [Google Scholar] [CrossRef]

- Long, Y.; Zhou, W.; Luo, Y. A fault diagnosis method based on one-dimensional data enhancement and convolutional neural network. Measurement 2021, 180, 109532. [Google Scholar] [CrossRef]

- PHM Society. PHM Data Challenge. 2010. Available online: https://www.Phmsociety.org/competition/phm/10S (accessed on 8 October 2021).

- Yan, R.; Gao, R.X.; Chen, X. Wavelets for fault diagnosis of rotary machines: A review with applications. Signal Process. 2014, 96, 1–15. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Machine model | Roders Tech RFM 760 | Radial depth of cut | 0.125 mm |

| Workpiece material | Nickel-based superalloy 718 | axial cutting depth | 0.2 mm |

| Tool | 3-tooth ball nose milling cutter | Number of sensors | 3 |

| Spindle speed | 10,400 RPM | Number of sensing channels | 7 |

| Feed rate | 1555 mm/min | Sampling frequency | 50 kHz |

| Network Layer | Key Parameter | Output Shape | Activation Function |

|---|---|---|---|

| Conv1D | Kernel size = 16, stride = 1 | 1024 × 16 | ReLU |

| Maxpooling1D | Pool size = 2, stride = 1 | 512 × 16 | |

| Conv1D | Kernel size = 32, stride = 1 | 512 × 32 | ReLU |

| Maxpooling1D | Pool size = 2, stride = 1 | 256 × 32 | |

| Flatten | 8192 | ||

| Dense | 6 | ||

| Softmax | Softmax |

| Recognizer | Recognition Accuracy | Average Response Time |

|---|---|---|

| CNN | 97.2% | 0.0661 s |

| SVM | 96.5% | 0.0382 s |

| ANN | 95.1% | 0.0748 s |

| KNN | 94.7% | 0.0537 s |

| Tree | 95.3% | 0.0279 s |

| Test Conditions | Recognition Accuracy of Training Sets | Recognition Accuracy of Training Sets |

|---|---|---|

| 4000 r/min | 100% | 99.5% |

| 6000 r/min | 99.9% | 99.5% |

| 8000 r/min | 99.9% | 99.6% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, W.; Liang, K.; Wang, B. State Monitoring Method for Tool Wear in Aerospace Manufacturing Processes Based on a Convolutional Neural Network (CNN). Aerospace 2021, 8, 335. https://doi.org/10.3390/aerospace8110335

Dai W, Liang K, Wang B. State Monitoring Method for Tool Wear in Aerospace Manufacturing Processes Based on a Convolutional Neural Network (CNN). Aerospace. 2021; 8(11):335. https://doi.org/10.3390/aerospace8110335

Chicago/Turabian StyleDai, Wei, Kui Liang, and Bin Wang. 2021. "State Monitoring Method for Tool Wear in Aerospace Manufacturing Processes Based on a Convolutional Neural Network (CNN)" Aerospace 8, no. 11: 335. https://doi.org/10.3390/aerospace8110335

APA StyleDai, W., Liang, K., & Wang, B. (2021). State Monitoring Method for Tool Wear in Aerospace Manufacturing Processes Based on a Convolutional Neural Network (CNN). Aerospace, 8(11), 335. https://doi.org/10.3390/aerospace8110335