Architecture of Distributed Control System for Gearbox-Free More Electric Turbofan Engine

Abstract

:1. Introduction

2. Fields of Interest Requiring Investigation

3. Methods and Tools of Investigation

4. Results

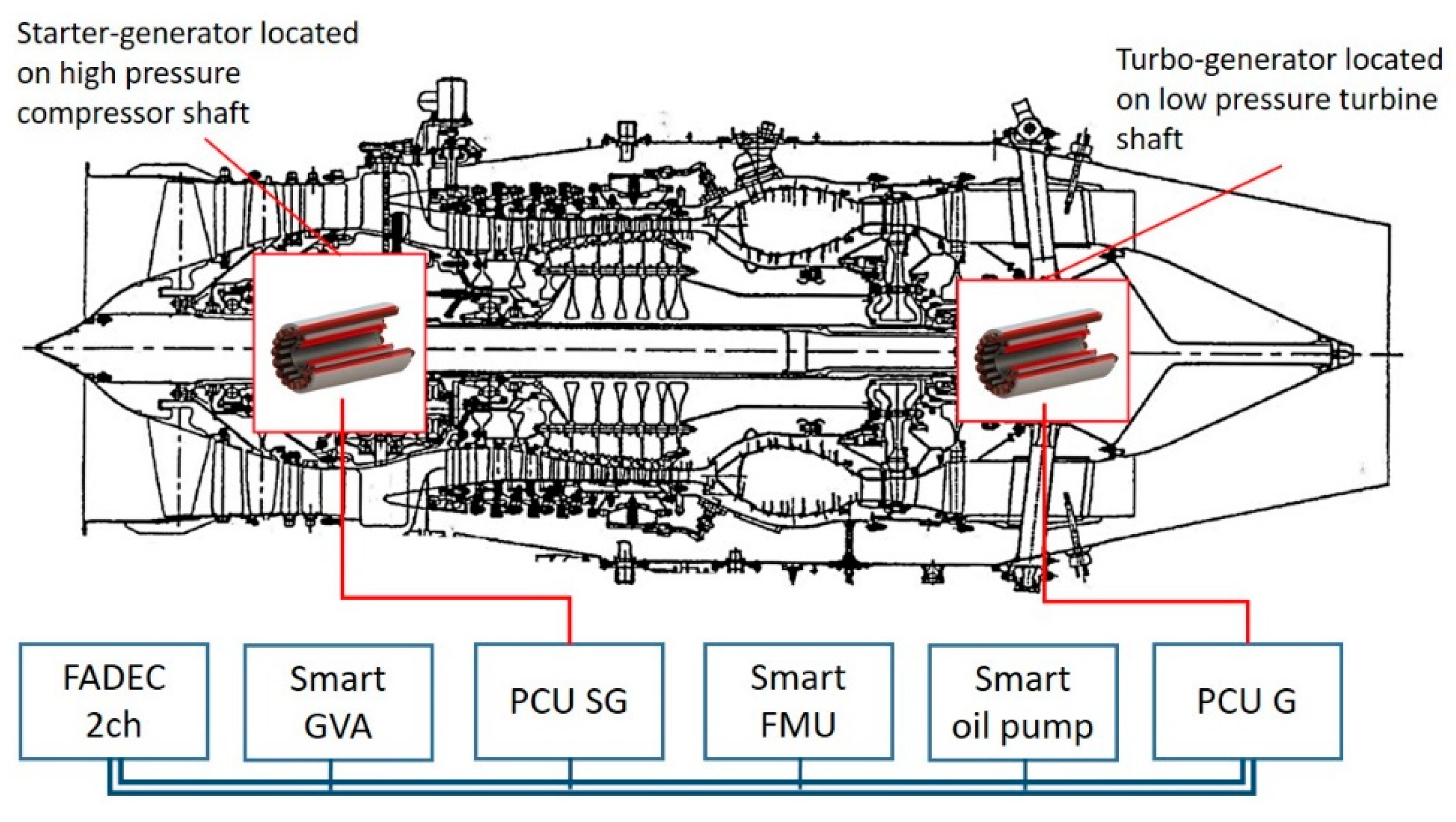

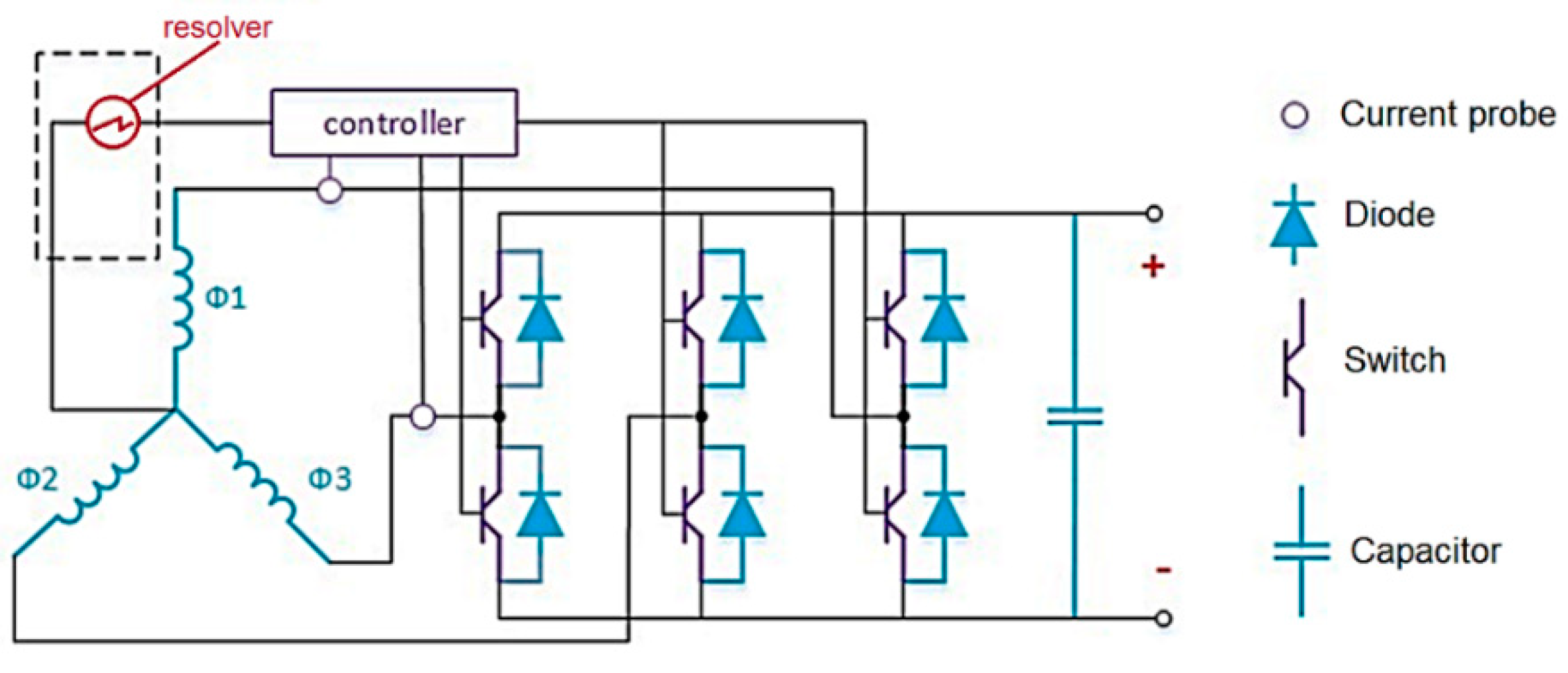

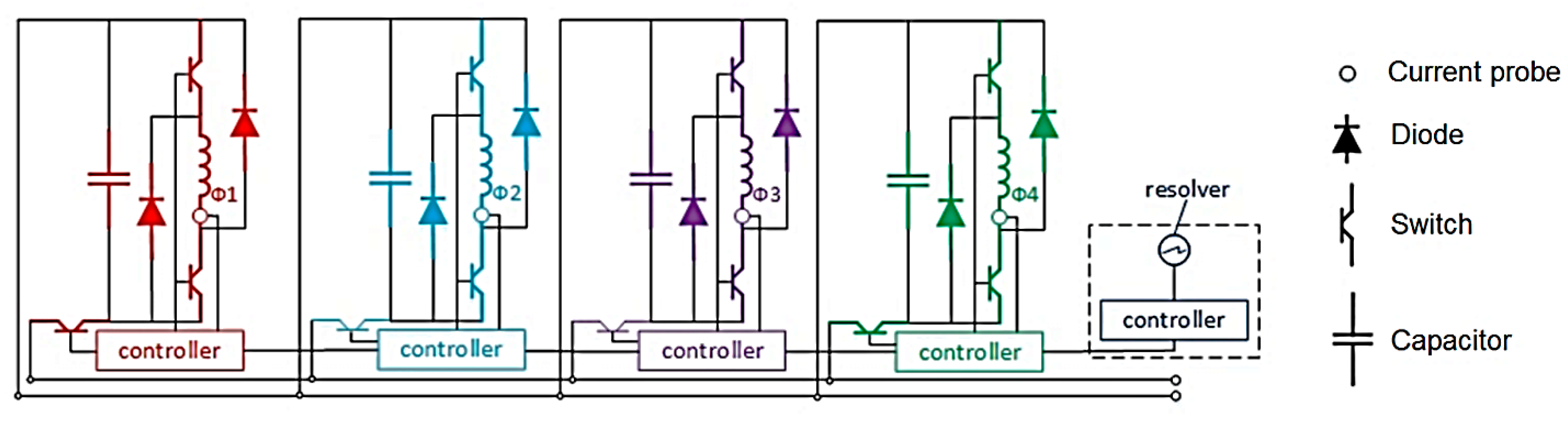

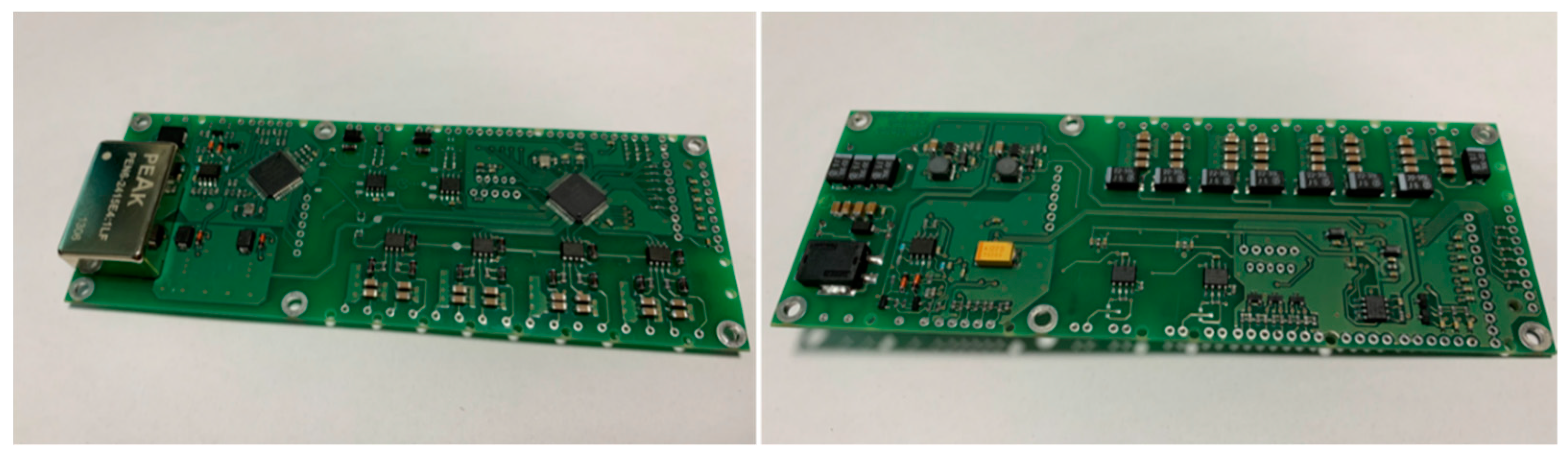

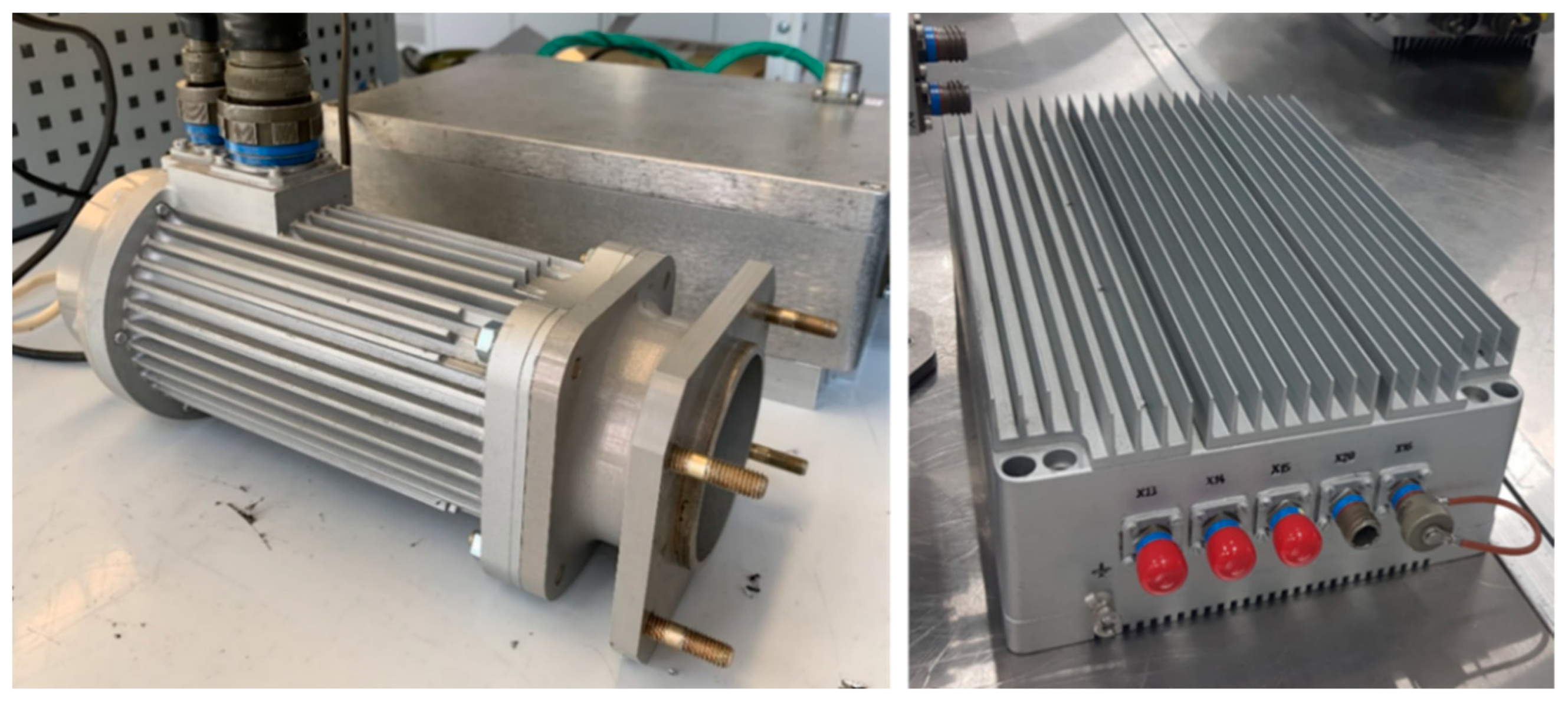

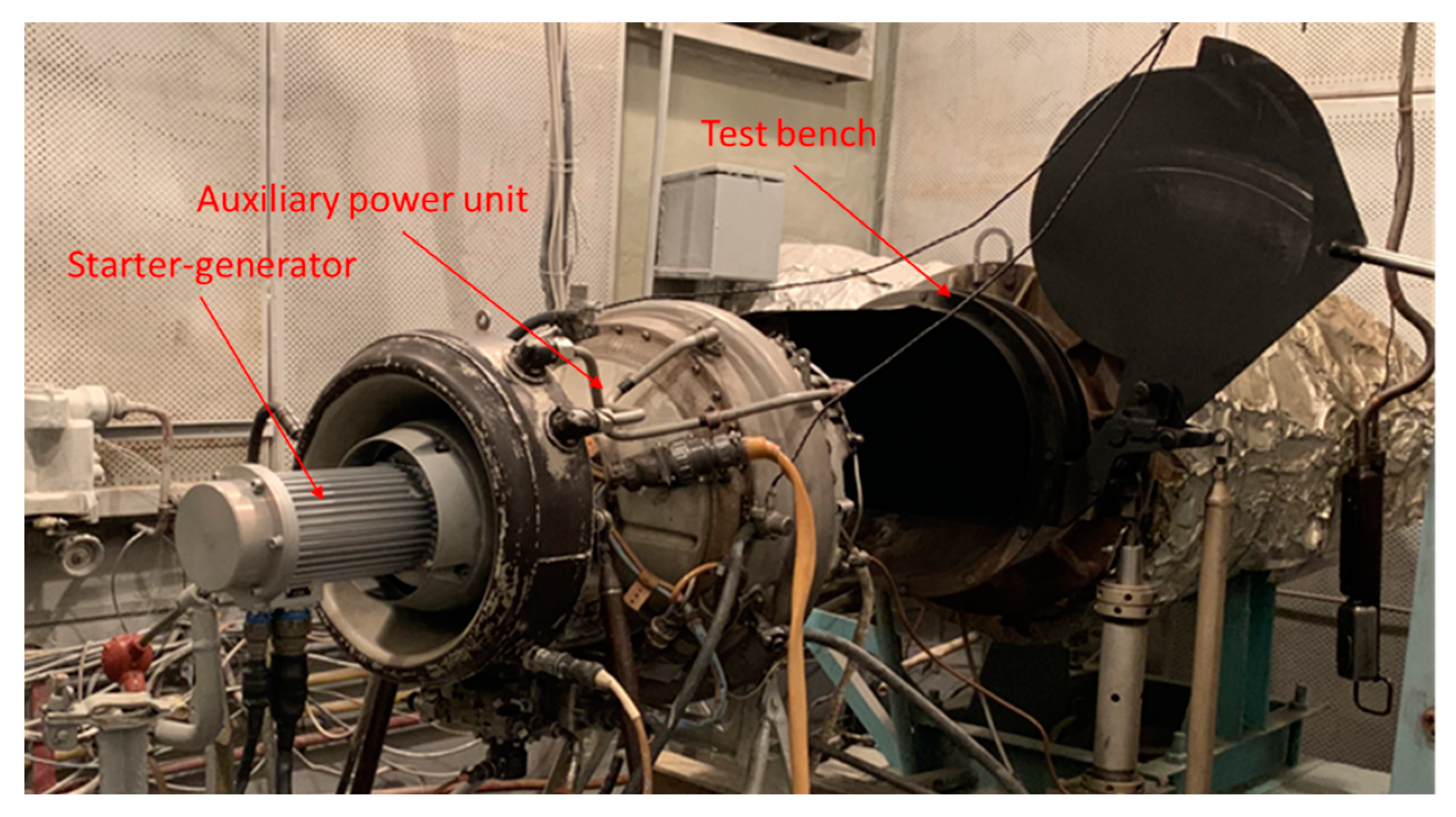

4.1. Starter and Turbine Generators

- -

- a separate controller is used for each phase, interacting with the rest through the digital data bus;

- -

- the loss of one of the four phases does not lead to a loss of electric machine control (both at starter and generator modes);

- -

- the use of a special observer allows the use of a sensorless control and monitoring scheme;

- -

- the observer remains operable even in case of failure of three out of four phases, which makes it possible to control the emergency operation of the generator.

- The start-up of an aircraft engine from the starter-generator of JSC FED was tested.

- The engine starting time was 12 s (transition to idle with starter-generator output power up to 16 kW).

- During operating at generator mode, the stability of the output voltage at 270VDC was confirmed. Deviations from the rating during load on/off switching were less than 10 V, which is within the permissible limits according to the MIL-STD-704 standard.

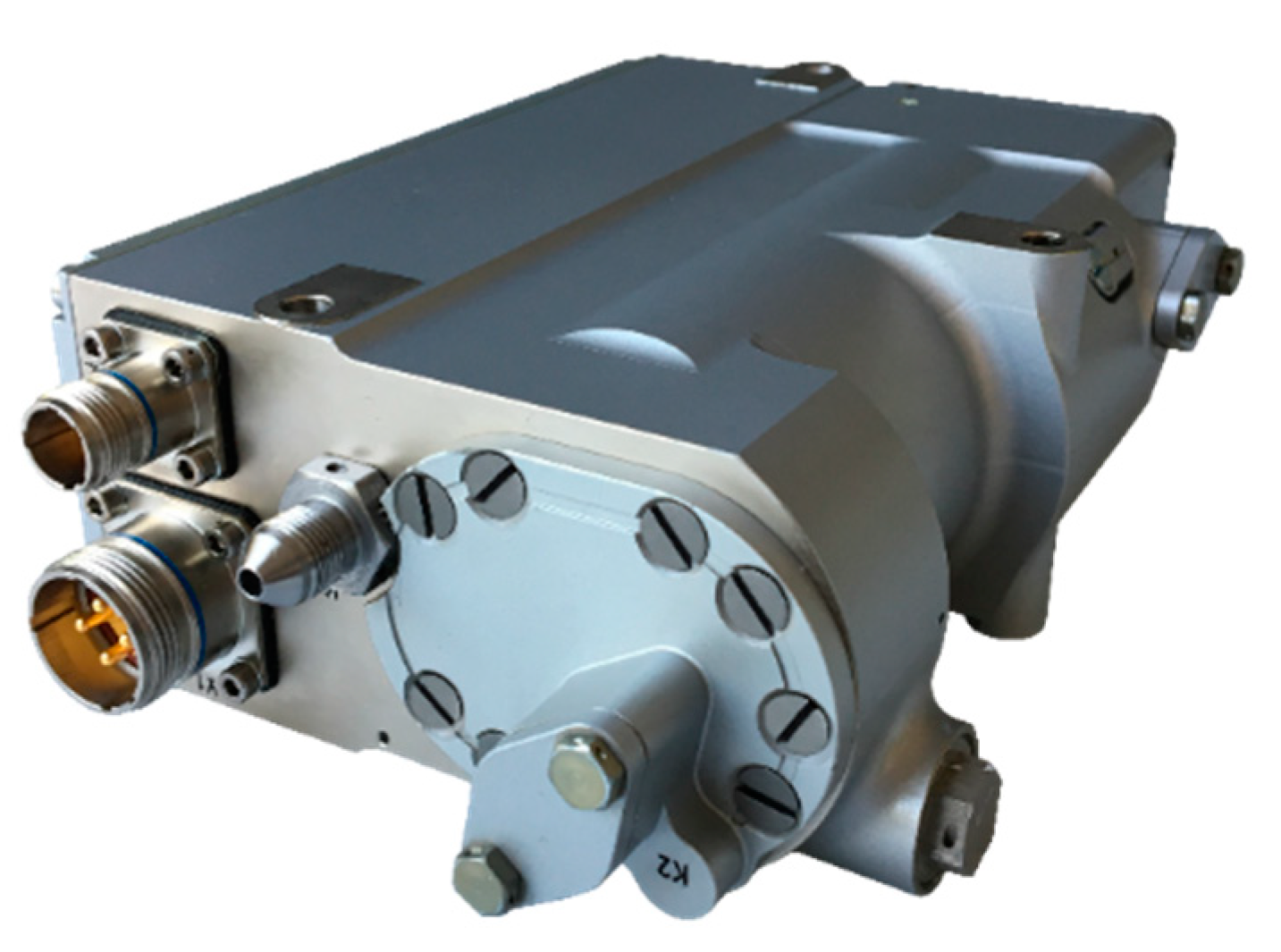

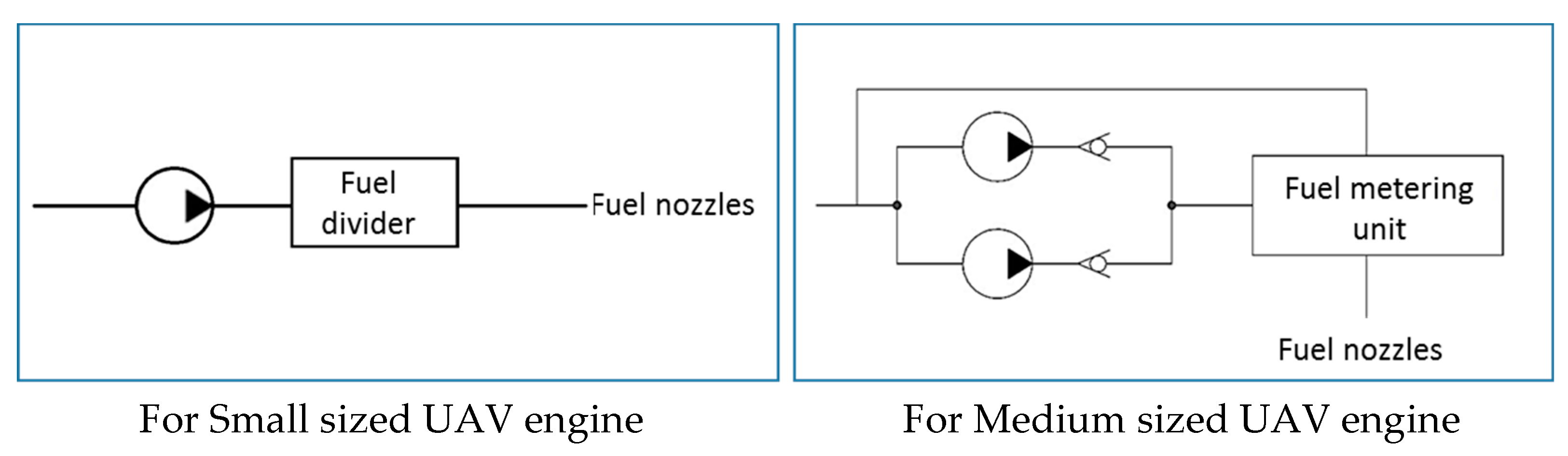

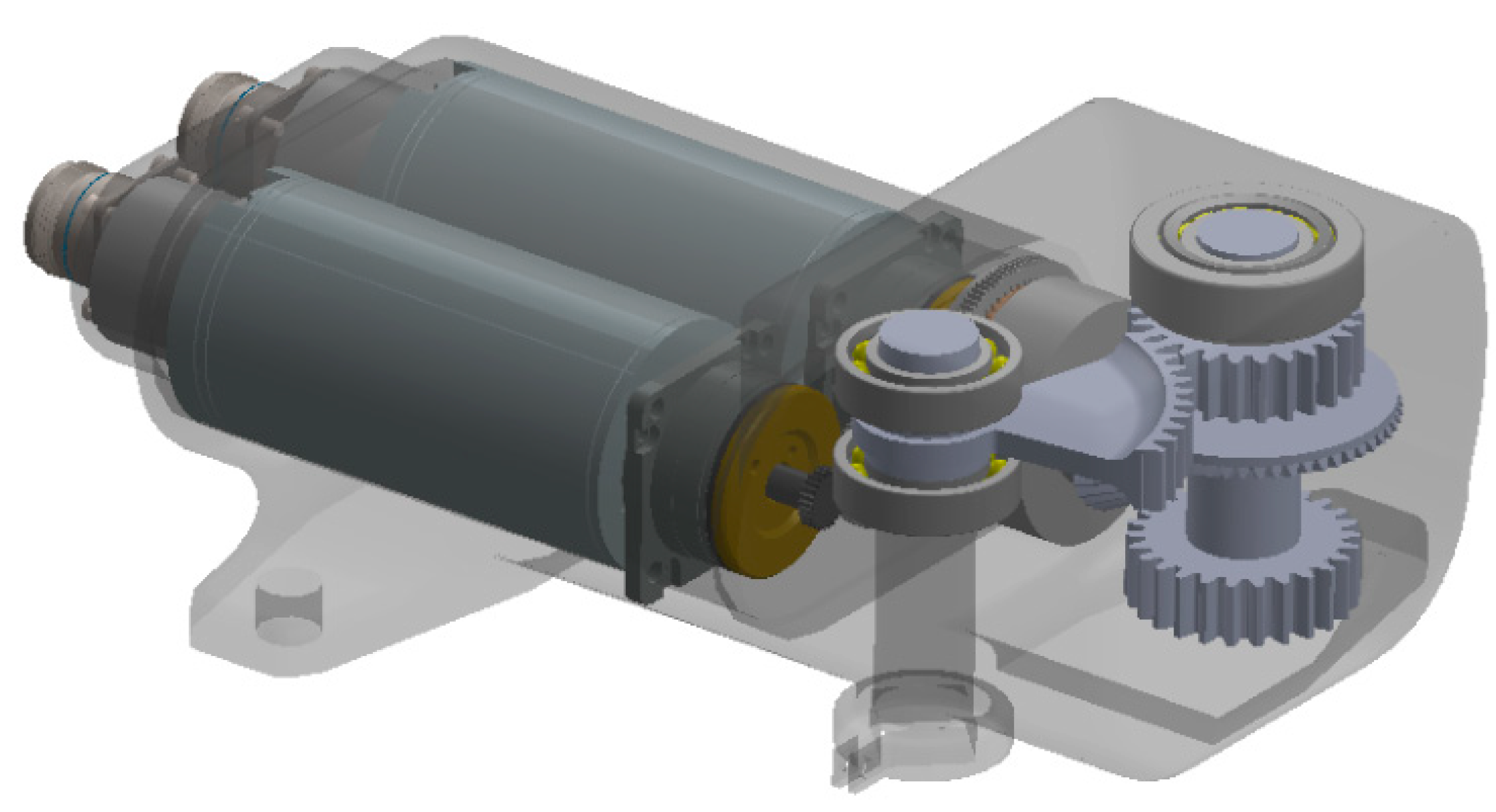

4.2. Electrically Driven Fuel Pump

4.3. Oil Pump

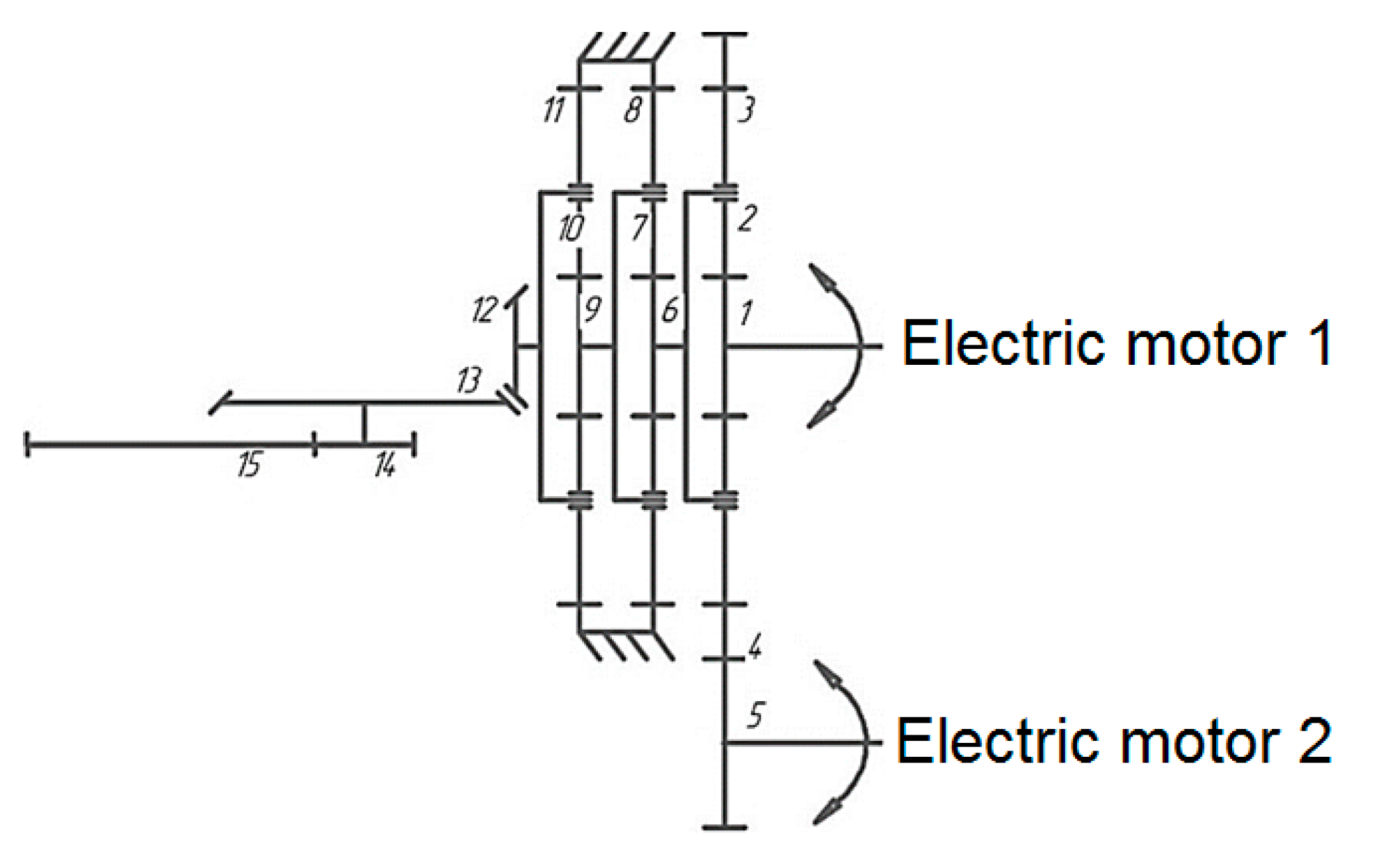

4.4. Guide Vanes Actuator

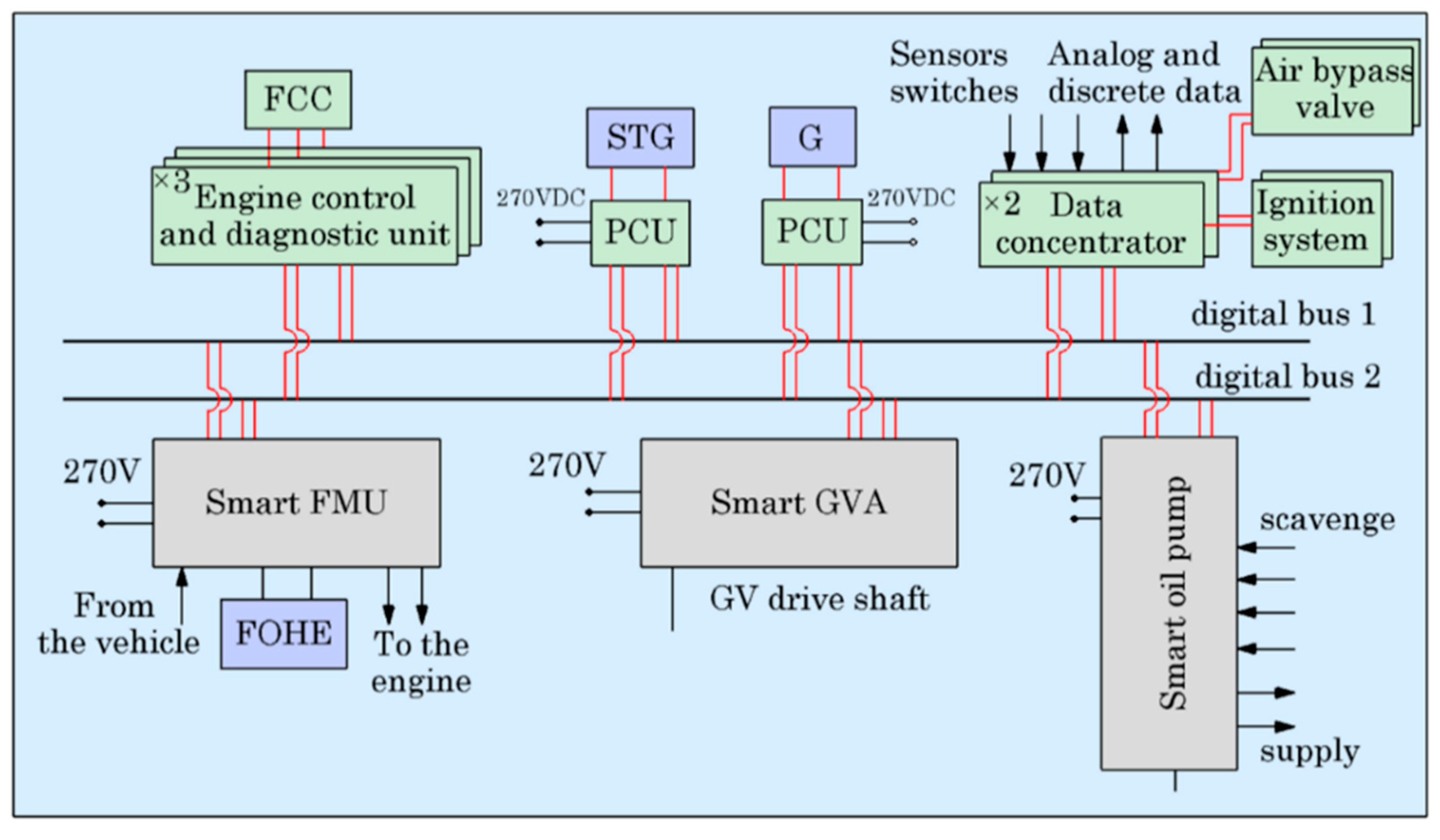

4.5. Engine Control System

5. Conclusions

- As SG or G, it is suggested to use SRM electric machines located directly on the shafts of the high-pressure compressor and low-pressure turbine.

- It is proposed to use independent controllers for each phase to increase the reliability of the system and the ability to control SG and G electrical machines in sensorless mode.

- It is proposed to use electric-driven integrated pumps as fuel metering units, in which the pump, electric motor and power electronics are located in one case.

- For the lubrication subsystem, it is proposed to use electrically driven pumps with the placement of several pumps on one shaft. Redundancy is provided by using two independent electrically driven pumps with the ability of transition to a forced operation mode in case of failure of one of them.

- It is proposed to use a rotary electromechanical guide vanes actuator with a redundant motor and a braking device. This solution ensures the autonomy of the actuator and reduces the overall dimensions.

- For the engine control system, the FCC redundancy is proposed, with the use of independent digital communication buses and a partially distributed architecture.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Kim, S.J.; Ki, T. Variable guide vane scheduling method based on the kinematic model and dual schedule curves. Appl. Sci. 2020, 10, 6643. [Google Scholar] [CrossRef]

- Kai, N.; Yongjiang, L.; Zhanbo, M.; Tianhao, W.; Yihua, H.; Huiqing, W.; Yangang, W. Electrical and electronic technologies in More-Electric Aircraft. A review. IEEE Access 2019, 7, 76145–76166. [Google Scholar]

- Morioka, N.; Takeuchi, M.; Oyori, H. Moving to an All-Electric Aircraft System. IHI Eng. Rev. 2014, 47, 33–39. [Google Scholar]

- Abdul Sathar Eqbal, M.; Fernando, N.; Marino, M.; Wild, G. Hybrid propulsion systems for remotely piloted aircraft systems. Aerospace 2018, 5, 34. [Google Scholar] [CrossRef] [Green Version]

- Frosina, E.; Senatore, A.; Palumbo, L.; Di Lorenzo, G.; Pascarella, C. Development of a lumped parameter model for an aeronautic hybrid electric propulsion system. Aerospace 2018, 5, 105. [Google Scholar] [CrossRef] [Green Version]

- Lambert, P.; Alejo, D.; Fefermann, Y.; Maury, C.; Thoraval, B.; Salanne, J.; Isikveren, A. Long-term hybrid-electric propulsion architecture options for transport aircraft. In Proceedings of the Greener Aviation 2016, Brussels, Belgium, 11–13 October 2016. [Google Scholar]

- Huang, L.; Yu, T.; Jiao, Z.; Li, Y. Active load-sensitive electro-hydrostatic actuator for more electric aircraft. Appl. Sci. 2020, 10, 6978. [Google Scholar] [CrossRef]

- Maré, J.-C. Practical considerations in the modelling and simulation of electromechanical actuators. Actuators 2020, 9, 94. [Google Scholar] [CrossRef]

- Sarlioglu, B.; Morris, C. More electric aircraft—Review, challenges and opportunities for commercial transport aircraft. IEEE Trans. Transp. Electrif. 2015, 1, 56–64. [Google Scholar] [CrossRef]

- Wheeler, P.; Clare, J.; Trentin, A.; Bozhko, S. An overview of the more electrical aircraft. J. Aerospace Eng. 2012, 227, 578–585. [Google Scholar] [CrossRef]

- Bennett, J. Fault Tolerant Electromechanical Actuators for Aircraft. Ph.D. Thesis, Newcastle University, Newcastle upon Tyne, UK, 2010. [Google Scholar]

- Abba, F.; Rachek, M. Time-stepping FEM-based multi-level coupling of magnetic field–electric circuit and mechanical structural deformation models dedicated to the analysis of electromagnetic actuators. Actuators 2019, 8, 22. [Google Scholar] [CrossRef] [Green Version]

- Madonna, V.; Giangrande, P.; Galea, M. Electrical power generation in aircraft: Review, challenges and opportunities. IEEE Trans. Transp. Electrif. 2018, 4, 646–659. [Google Scholar] [CrossRef]

- Nøland, J.; Leandro, M.; Suul, J.; Molinas, M. High-power machines and starter-generator topologies for more electric aircraft: A technology outlook. IEEE Access 2020, 8, 130104–130123. [Google Scholar] [CrossRef]

- MacMinn, S.; Jones, W. A very high speed switched-reluctance starter-generator for aircraft engine applications. In Proceedings of the IEEE National Aerospace and Electronics Conference, Dayton, OH, USA, 22–26 May 1989. [Google Scholar]

- Geest, M.; Polinder, H.; Ferreira, J.; Zeilstra, D. Design and testing of a high-speed aerospace permanent magnet starter/generator. In Proceedings of the 2015 International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles (ESARS), Aachen, Germany, 3–5 March 2015. [Google Scholar]

- Vepa, R. Modeling and dynamics of HTS motors for aircraft electric propulsion. Aerospace 2018, 5, 21. [Google Scholar] [CrossRef] [Green Version]

- Shoujuna, S.; Weiguo, L.; Peitsch, L.; Schaeferb, U. Detailed design of a high speed switched reluctance starter/generator for more/all electric aircraft. Chin. J. Aeronaut. 2010, 23, 216–226. [Google Scholar] [CrossRef] [Green Version]

- Jafari, S.; Miran Fashandi, S.A.; Nikolaidis, T. Modeling and control of the starter motor and start-up phase for gas turbines. Electronics 2019, 8, 363. [Google Scholar] [CrossRef] [Green Version]

- Khowja, M.R.; Vakil, G.; Gerada, C.; Patel, C.; Odhano, S.; Wheeler, P. Integrated motor drive: Mass and volume optimization of the motor with an integrated filter inductor. Energies 2021, 14, 4564. [Google Scholar] [CrossRef]

- Nicola, C.-I.; Nicola, M.; Selișteanu, D. Sensorless control of PMSM based on backstepping-PSO-type controller and ESO-type observer using real-time hardware. Electronics 2021, 10, 2080. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, C.; Liu, S.; Song, Z. Deadbeat predictive current control for series-winding PMSM drive with half-bridge power module-based inverter. Energies 2021, 14, 4620. [Google Scholar] [CrossRef]

- Belkhier, Y.; Achour, A.; Shaw, R.N.; Ullah, N.; Chowdhury, M.S.; Techato, K. Fuzzy supervisory passivity-based high order-sliding mode control approach for tidal turbine-based permanent magnet synchronous generator conversion system. Actuators 2021, 10, 92. [Google Scholar] [CrossRef]

- Lakhe, R.K.; Chaoui, H.; Alzayed, M.; Liu, S. Universal control of permanent magnet synchronous motors with uncertain dynamics. Actuators 2021, 10, 49. [Google Scholar] [CrossRef]

| № | Parameter | Medium-Size UAV | Small-Size UAV | |

|---|---|---|---|---|

| SG | G | SG | ||

| 1 | Rotor speed range, rpm | up to 40,000 | up to 15,000 | up to 45,000 |

| 2 | Max output power in starter mode, kW | 40 | - | 20 |

| 3 | Max output power in generator mode, kW | 25 | 30 | 14 |

| № | Subsystem | Small Sized UAV | Medium Sized UAV |

|---|---|---|---|

| 1 | Engine start and power generation | Four phases SRM SG | Four phases SRM SG and G |

| 2 | Fuel metering | Electrically driven fuel pump | Redundant system with two electrically driven fuel pumps and fuel metering unit |

| 3 | Oil pump | Electrically driven oil pump unit | Redundant system with two oil pump units and integrated electric motors |

| 4 | Guide vanes actuator | Not required | Electromechanical with redundant two independent electrical motors |

| 5 | Engine control system | One channel FCC with single digital bus | Triple redundant FCC with two independent digital buses |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popov, V.; Yepifanov, S.; Kononykhyn, Y.; Tsaglov, A. Architecture of Distributed Control System for Gearbox-Free More Electric Turbofan Engine. Aerospace 2021, 8, 316. https://doi.org/10.3390/aerospace8110316

Popov V, Yepifanov S, Kononykhyn Y, Tsaglov A. Architecture of Distributed Control System for Gearbox-Free More Electric Turbofan Engine. Aerospace. 2021; 8(11):316. https://doi.org/10.3390/aerospace8110316

Chicago/Turabian StylePopov, Viktor, Sergiy Yepifanov, Yevhenii Kononykhyn, and Aleksandr Tsaglov. 2021. "Architecture of Distributed Control System for Gearbox-Free More Electric Turbofan Engine" Aerospace 8, no. 11: 316. https://doi.org/10.3390/aerospace8110316

APA StylePopov, V., Yepifanov, S., Kononykhyn, Y., & Tsaglov, A. (2021). Architecture of Distributed Control System for Gearbox-Free More Electric Turbofan Engine. Aerospace, 8(11), 316. https://doi.org/10.3390/aerospace8110316