Innovative Methods to Enhance the Combustion Properties of Solid Fuels for Hybrid Rocket Propulsion

Abstract

:1. Introduction

2. Literature Survey and Objective

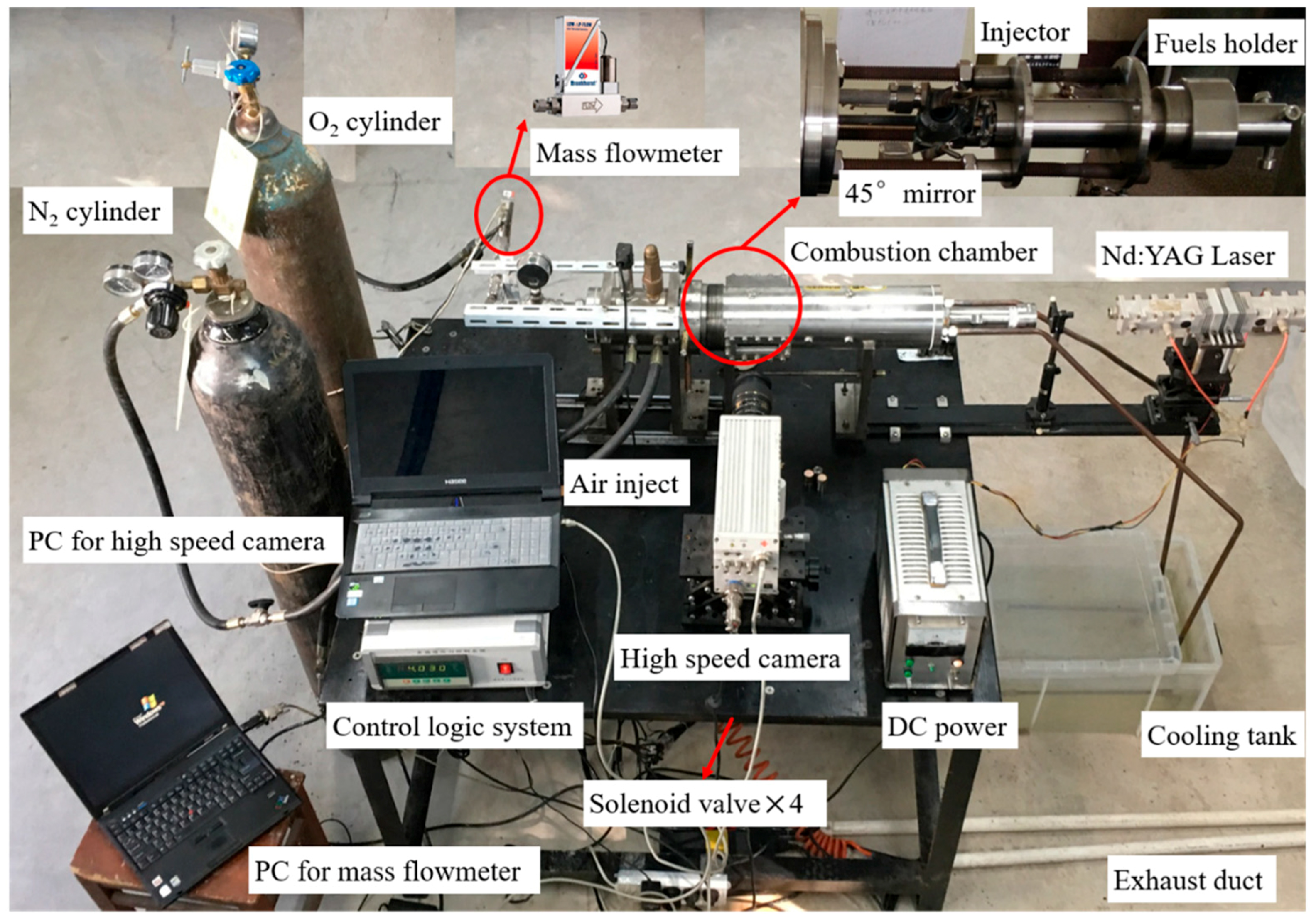

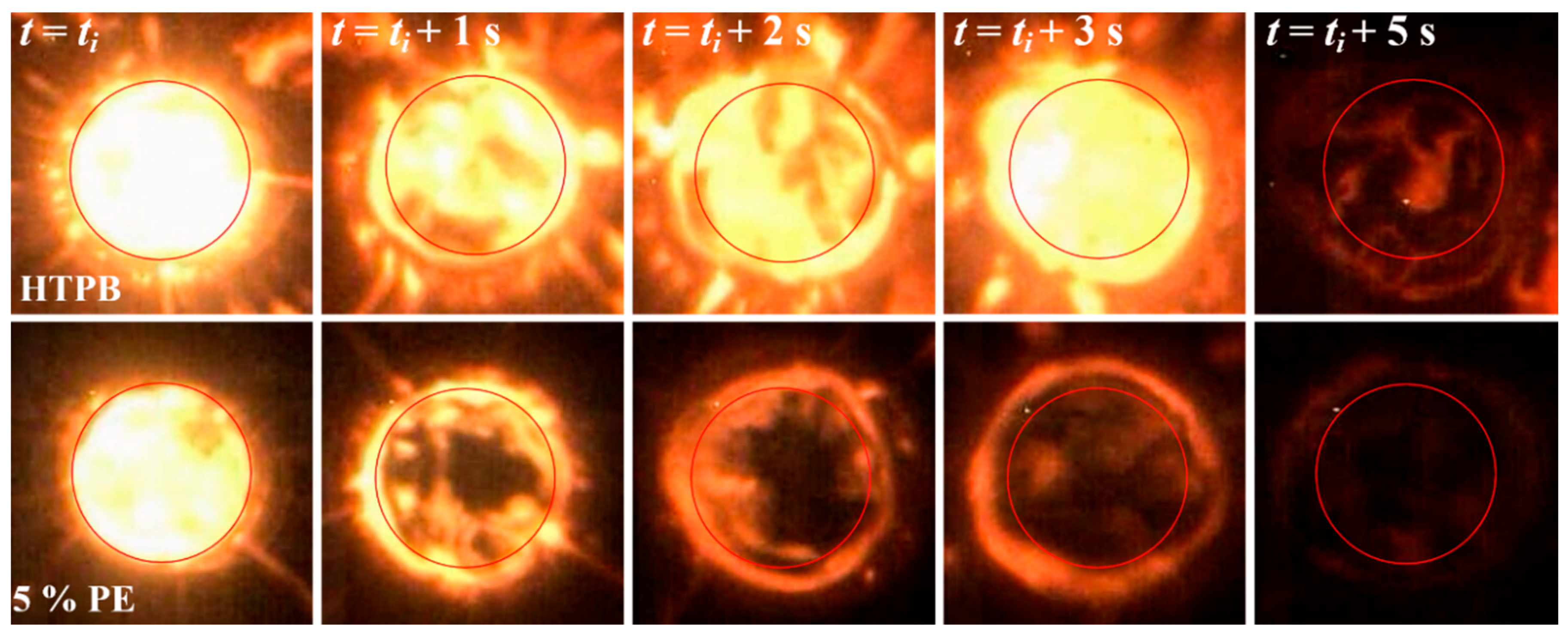

3. Experimental

Combustion Characterization

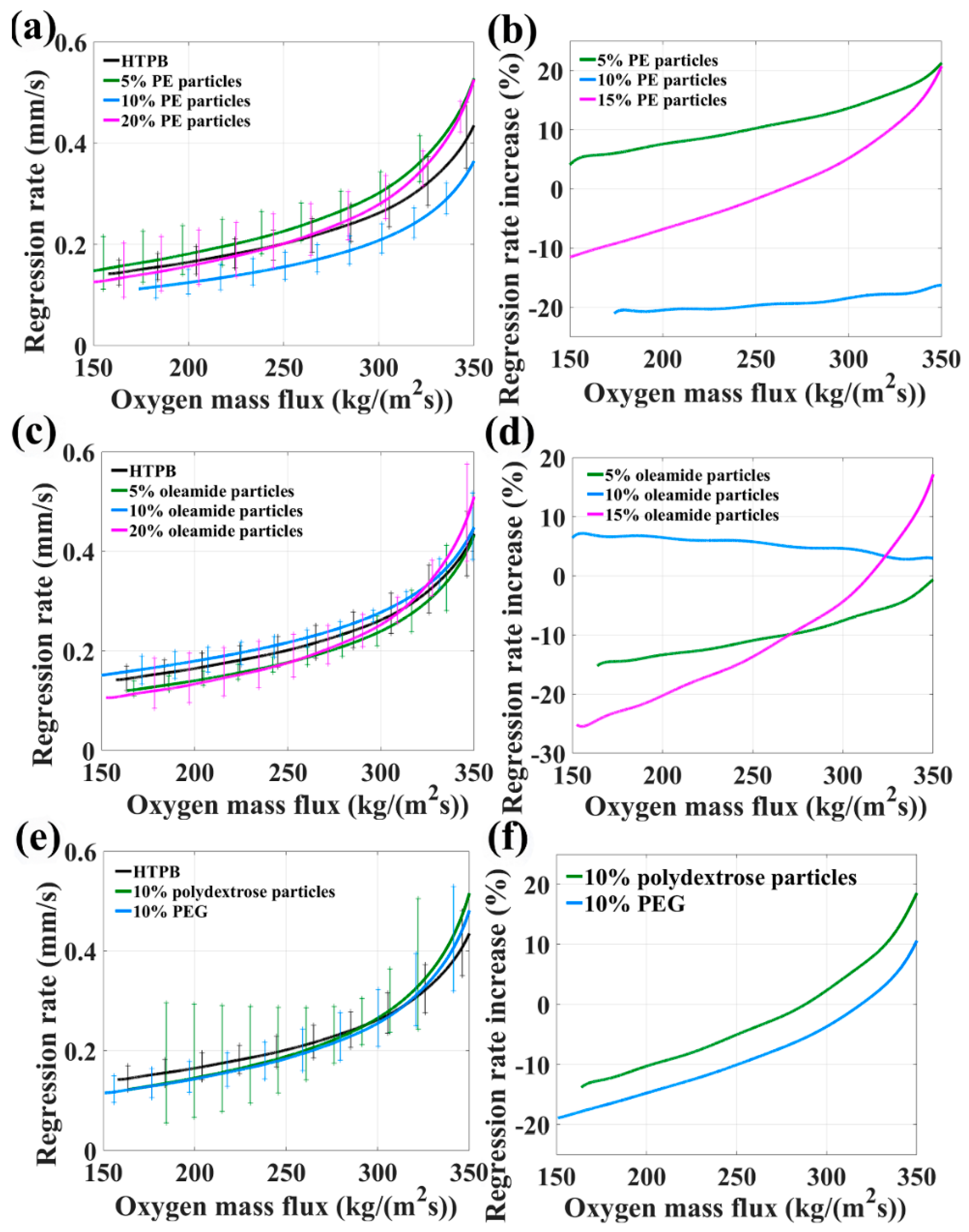

4. Low-Energy Polymer Particles/HTPB

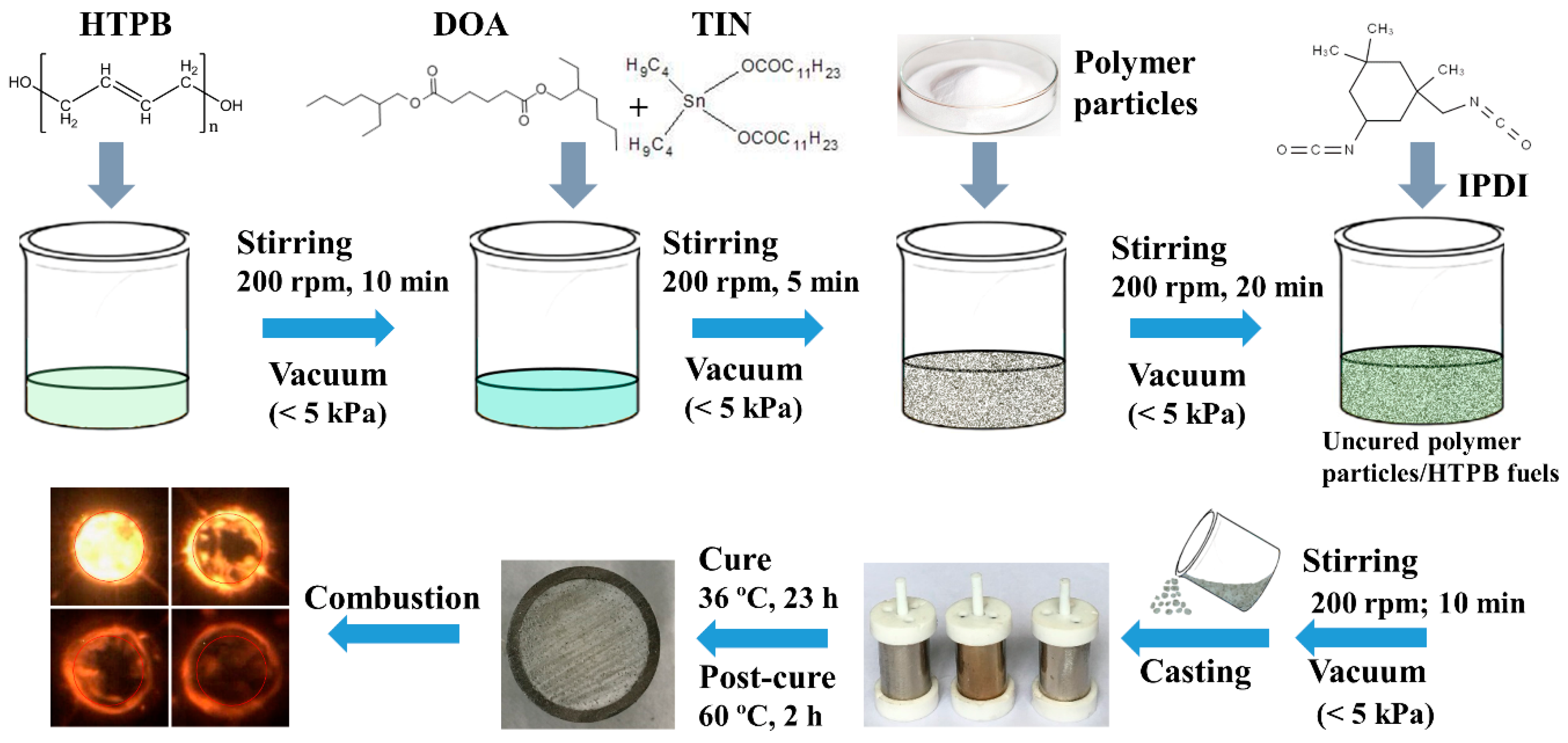

4.1. Low-Energy Polymer Particles/HTPB Fuel Preparation

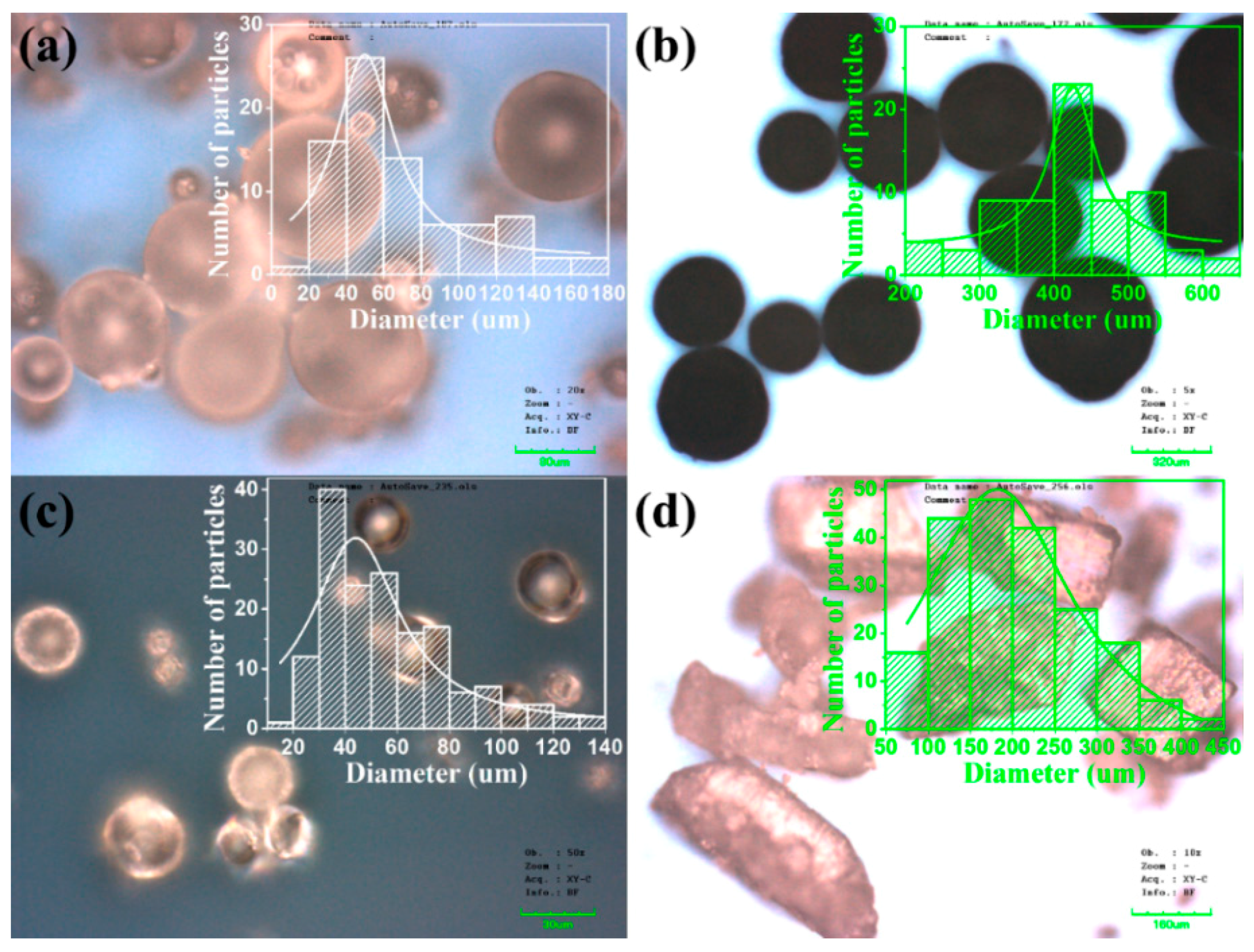

4.2. Low-Energy Polymer Particles Morphology

4.3. Low-Energy Polymer Particles/HTPB Composite Fuel Combustion

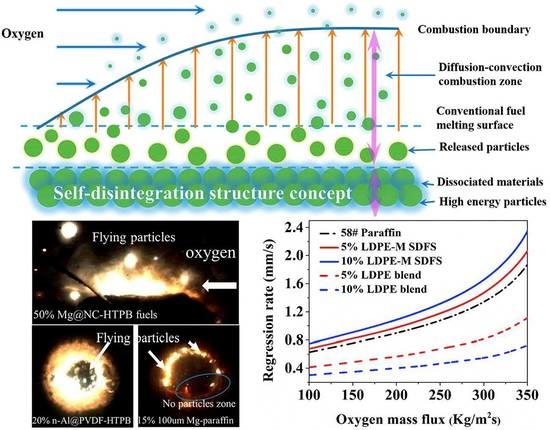

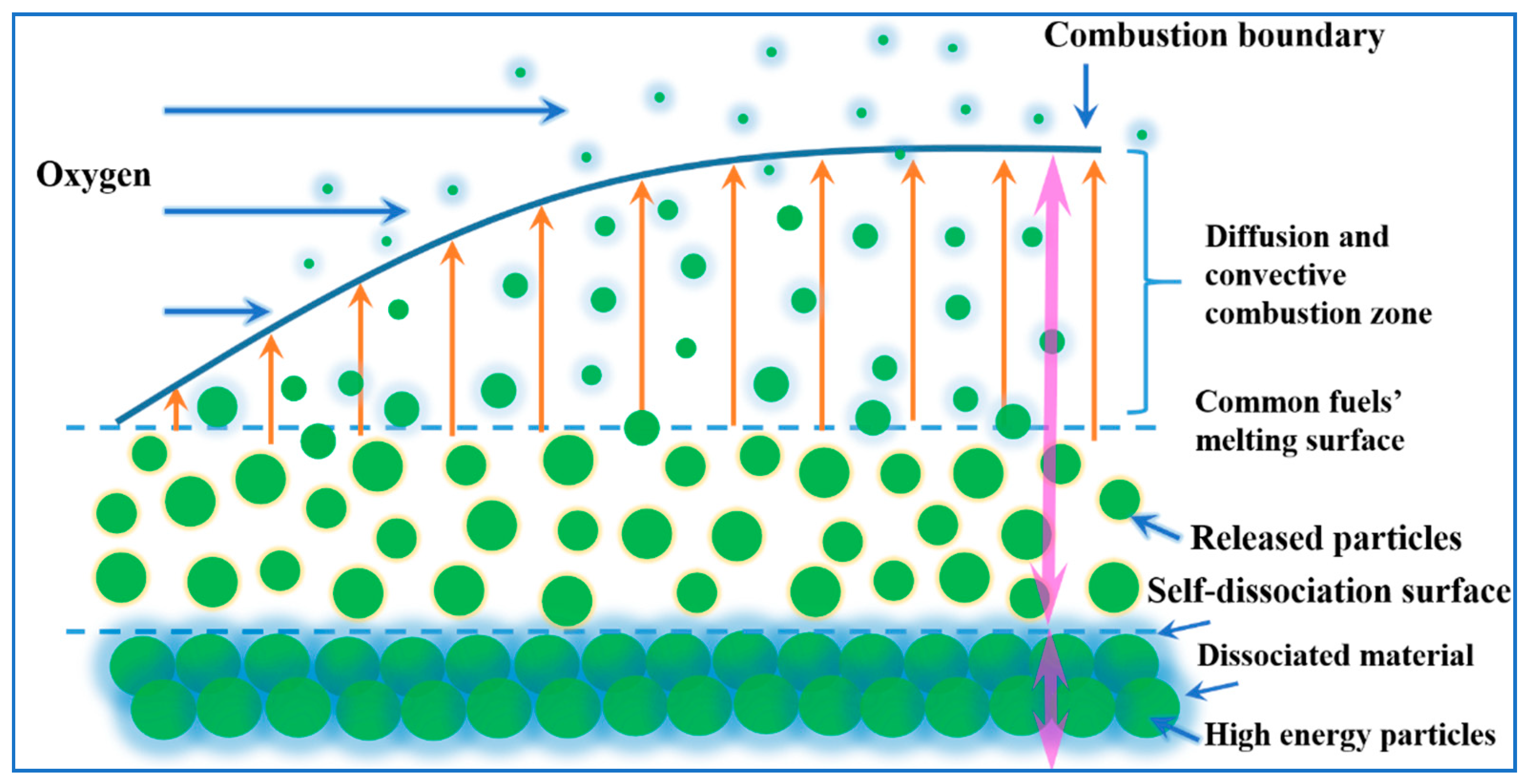

5. Self-Disintegration Fuel Structure (SDFS)/Paraffin

5.1. Polystyrene Particles/Paraffin Fuel Combustion

5.2. Double-Base Particles/Paraffin Fuel Combustion

5.3. Low-Density Polyethylene Particles/Paraffin Fuel Combustion

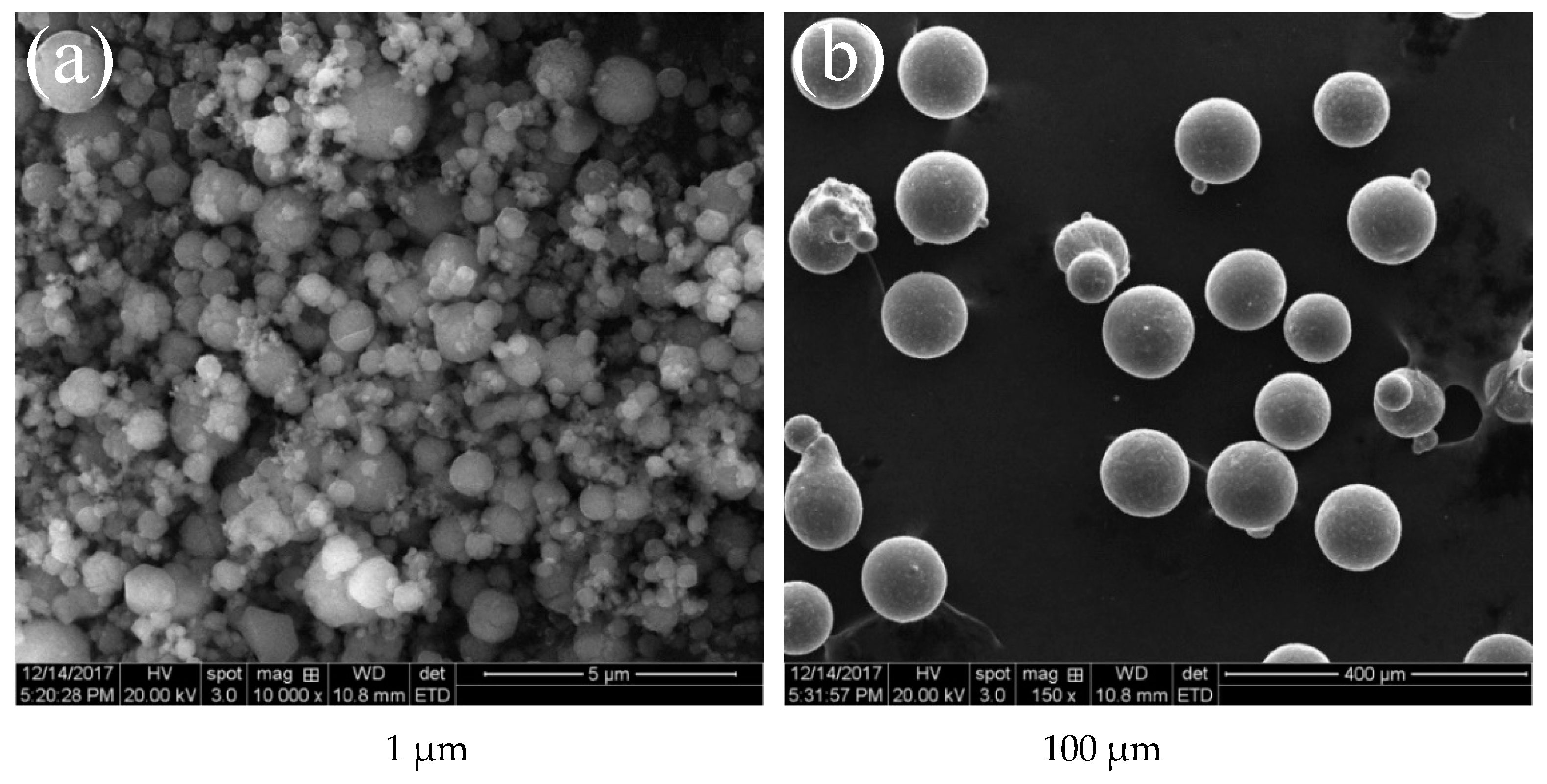

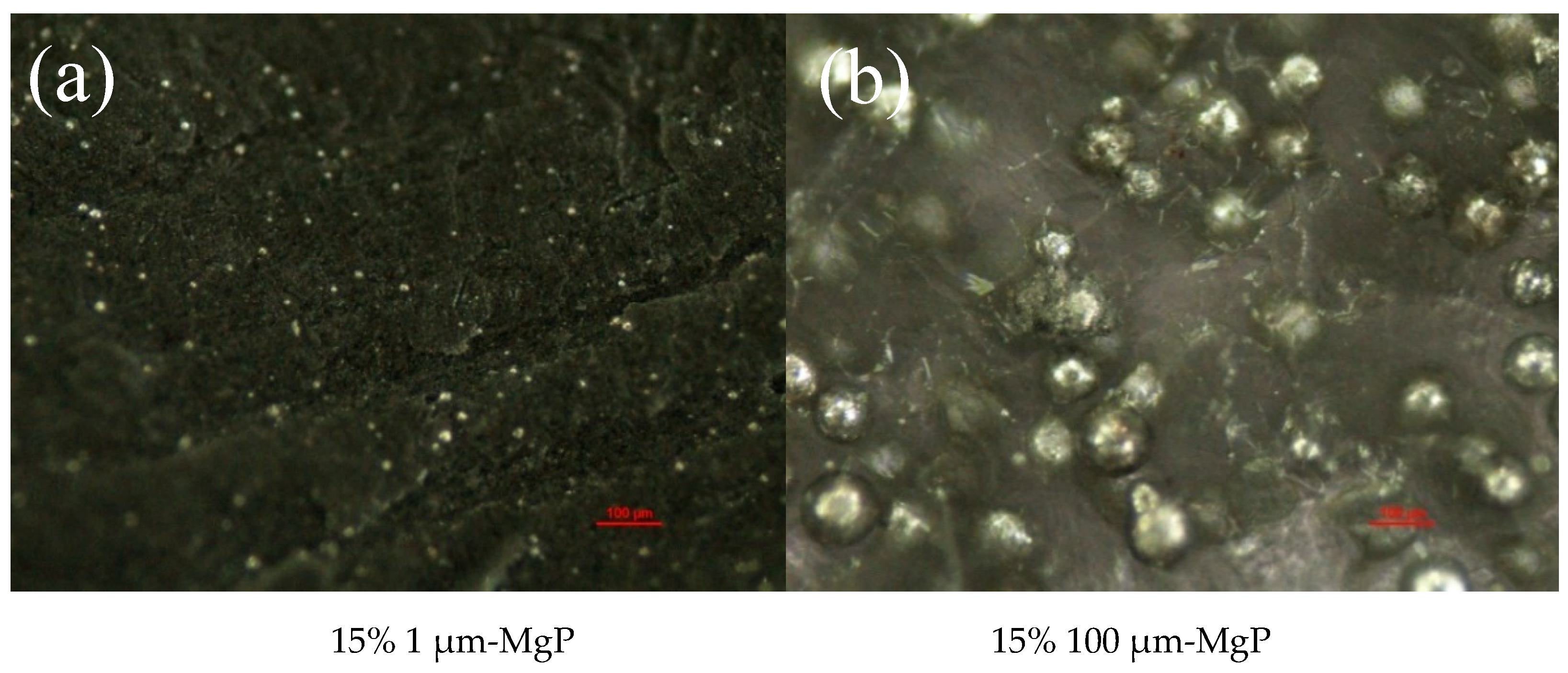

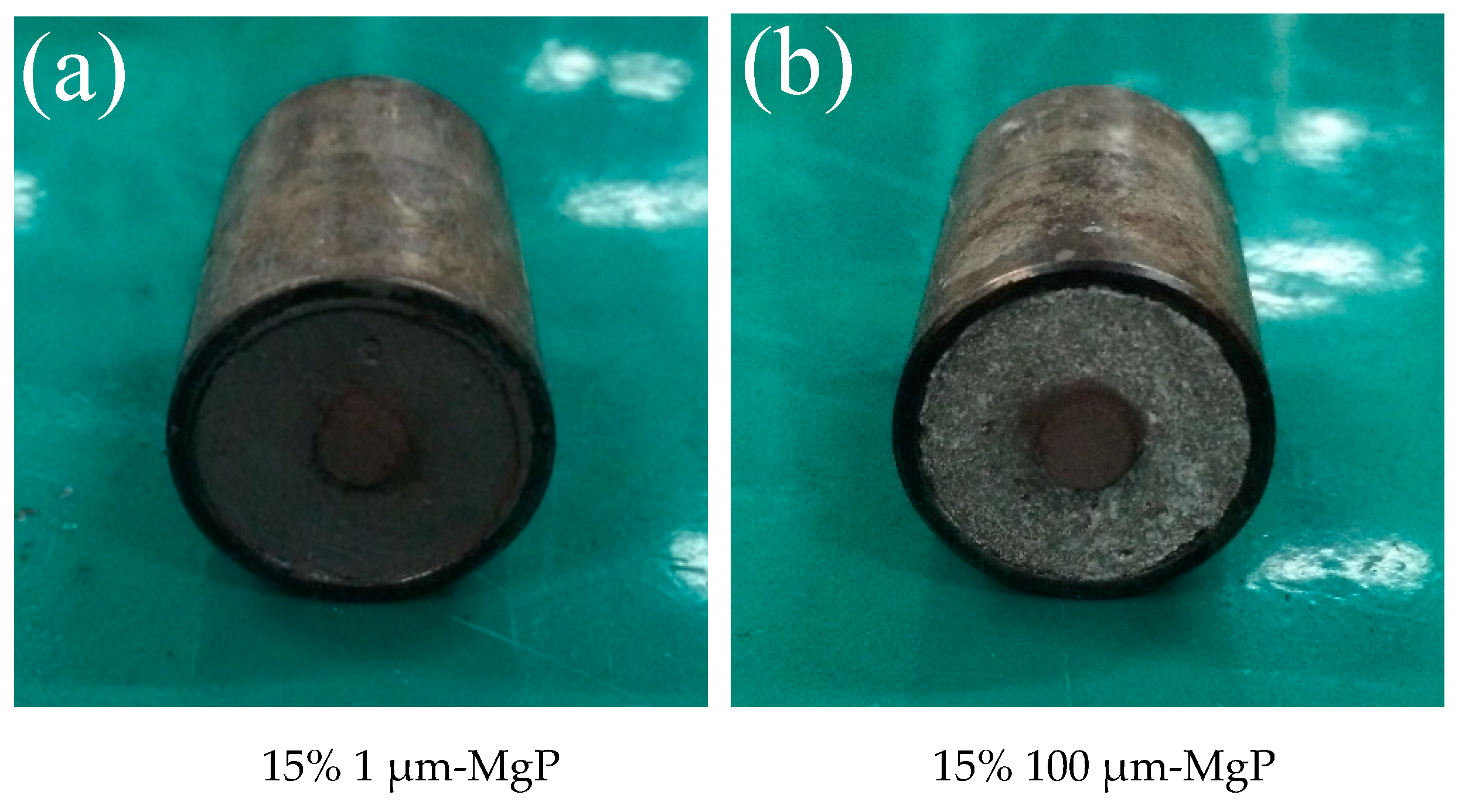

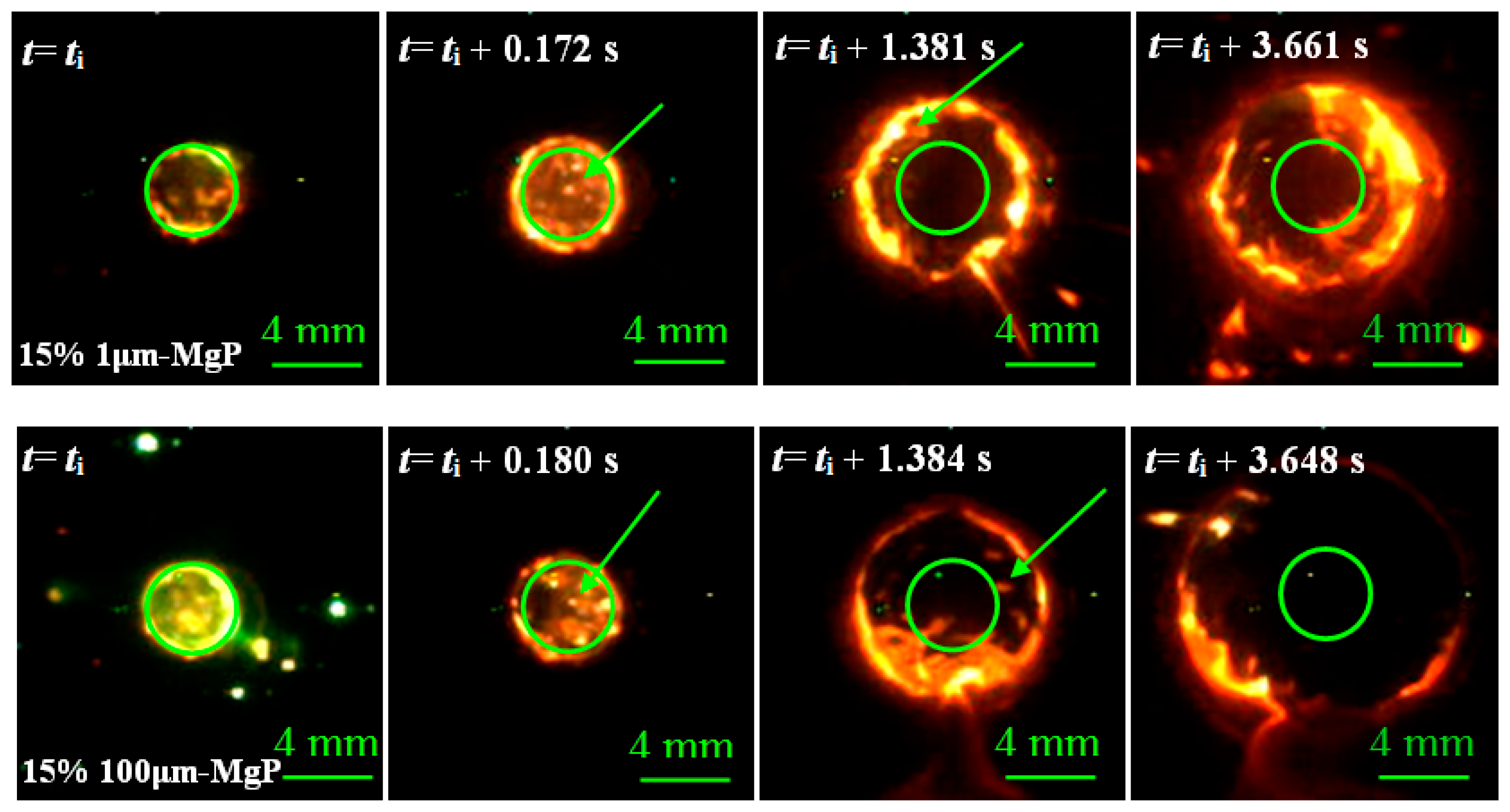

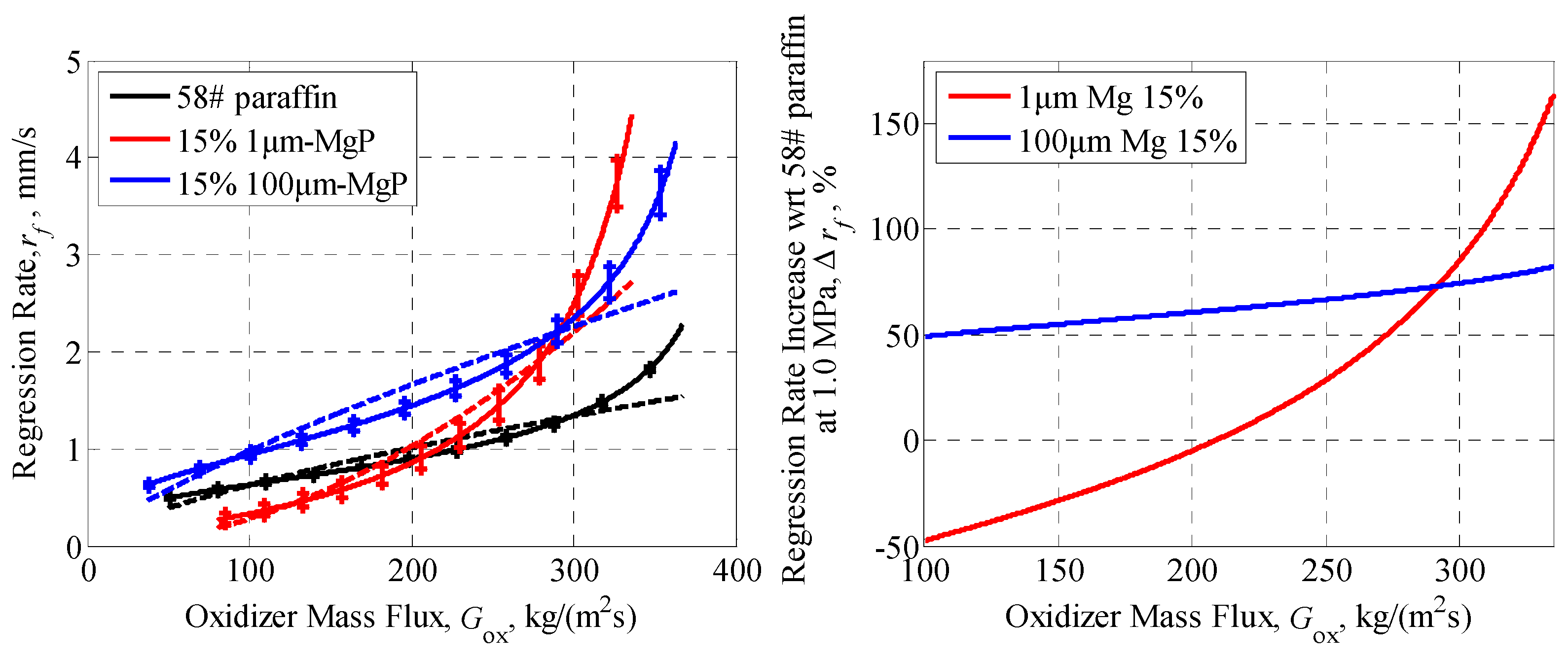

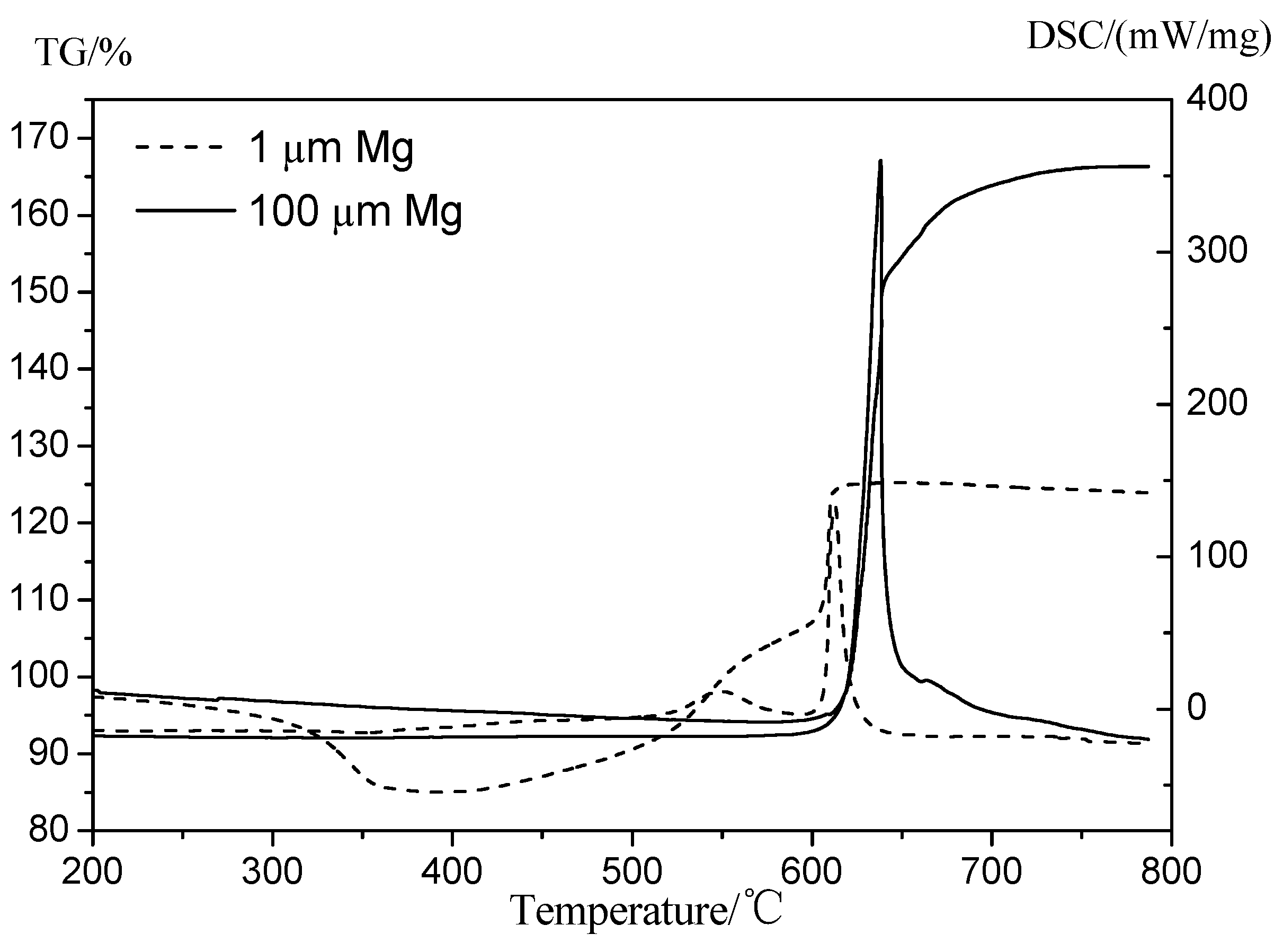

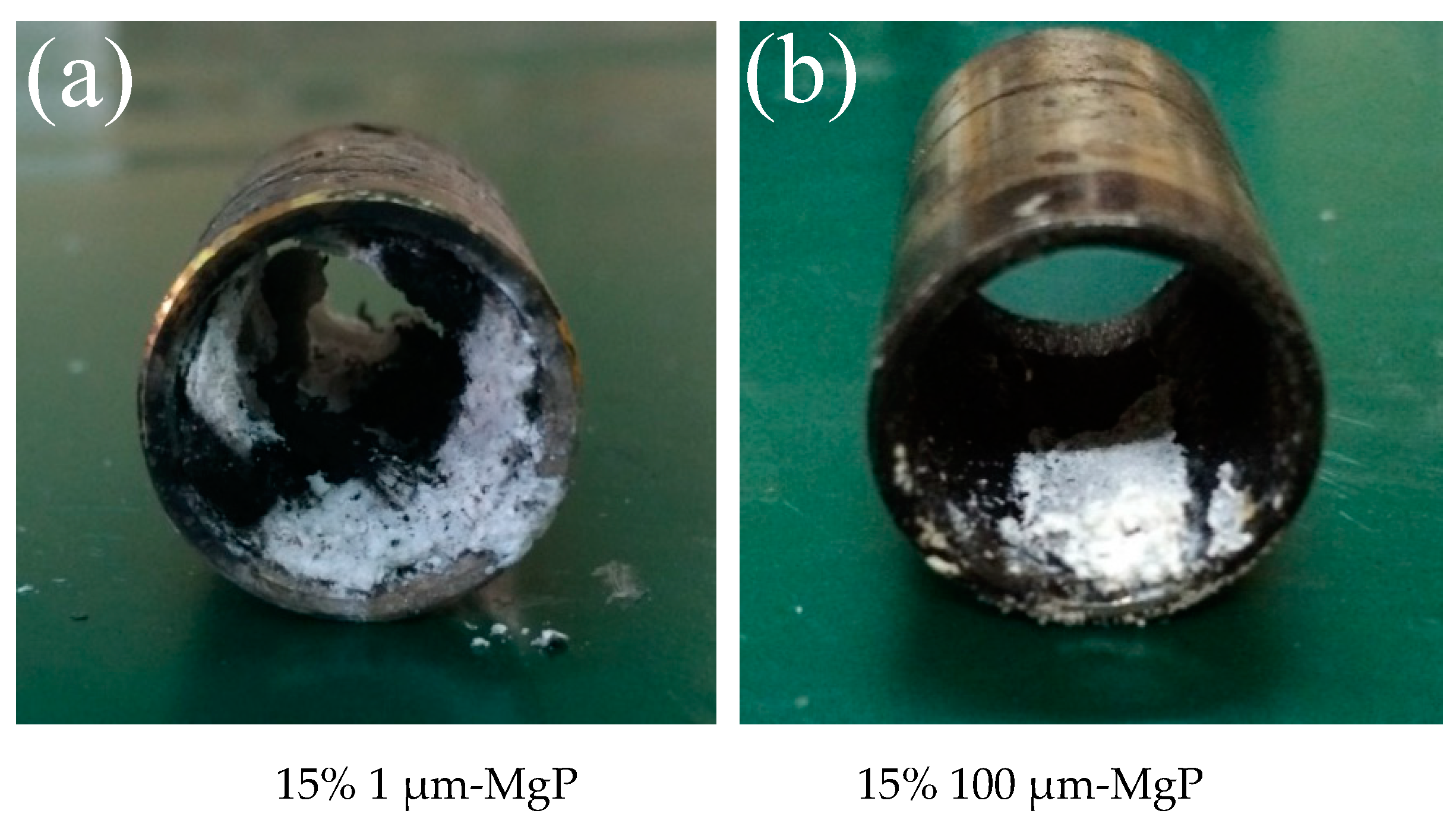

5.4. Magnesium Particles/Paraffin Fuel Preparation and Combustion

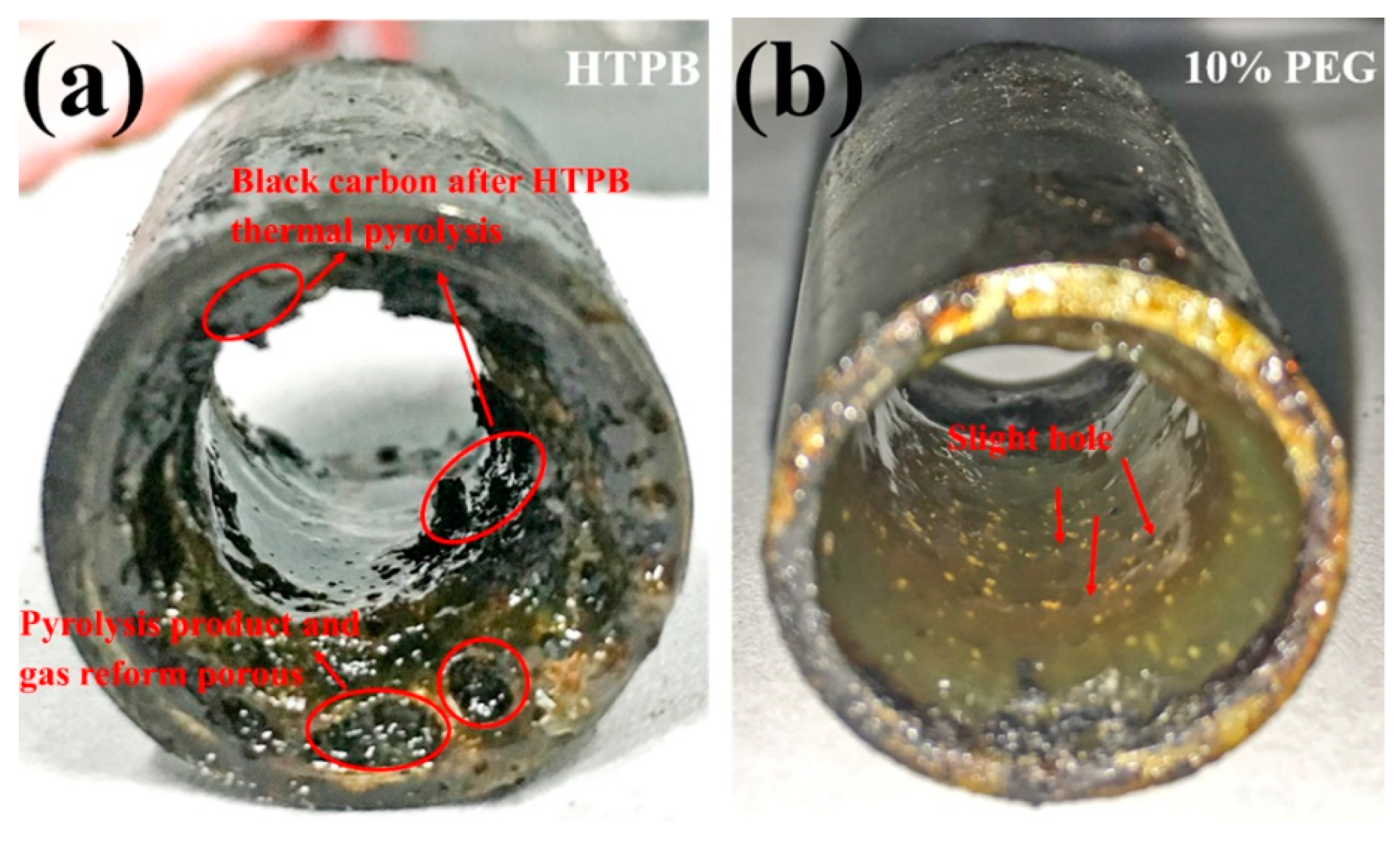

6. Porous Layer Combustion Fuels

7. High Thermal Conductivity Fuels

8. Paraffin Fuels with Better Mechanical Properties

9. Concluding Remarks

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Roman and Greek symbols | |

| ΔD | diameter variation of the inner burning surface |

| Gox(t) | oxygen mass flux, kg/(m2·s) |

| rf (t) | regression rate at time t |

| Ab | combustion surface area |

| density of the fuel | |

| multiplicative factor in Equation (1) | |

| power in Equation (1) | |

| PEG | polyethylene glycol |

| PE paraffin | low molecular mass polyethylene |

| TIN | dibutyltin diacetate |

| IPDI | isophorone diisocyanate |

| PS | polystyrene |

| DB | double-base |

| LDPE | low-density polyethylene |

| ADCA | azodicarbonamide |

| 2D | two-dimensional |

| Acronyms | |

| MgP | Magnesium particles |

| HRE | hybrid rocket engine |

| HTPB | hydroxyl-terminated polybutadiene |

| TNT | 2,4,6-Trinitrotoluene |

| AlH3 | Aluminum hydride |

| SDFS | Self-disintegration fuel structure |

| NUST | Nanjing University of Science and Technology |

| OD | outer diameter |

| ID | inner diameter |

| IPDI | isophorone diisocyanate |

| SPLab | Space Propulsion Laboratory at Politecnico di Milano |

| CLSM | Confocal Laser Scanning Microscope |

| SEM | scanning electron microscope |

| DSC | differential scanning calorimetry |

| TG | thermogravimetry |

References

- Altman, D. Highlights in Hybrid Rocket Propulsion, Volume 10 of IWCP ‘In-Space Propulsion’; DeLuca, L.T., Sackheim, R.L., Palaszewski, B.A., Eds.; Grafiche GSS: Bergamo, Italy, 2005; Chapter 17. [Google Scholar]

- DeLuca, L.T. Energetic Problems in Space Propulsion, Chapter 12, Hybrid Rocket Propulsion; Premani Snc: Pantigliate, Italy, 2009. [Google Scholar]

- Chiaverini, M.J.; Kuo, K.K. Fundamentals of Hybrid Rocket Combustion and Propulsion; Progress in Astronautics and Aeronautics: Reston, VA, USA, 2007; pp. 3–4. [Google Scholar]

- Potter, C.R. Design of Economical Upper Stage Hybrid Rocket Engine; University of Tennessee Honors Thesis Projects; University of Tennessee: Knoxville, TN, USA, May 2012; Available online: https://trace.tennessee.edu/utk_chanhonoproj/1619 (accessed on 7 March 2019).

- Soller, S.; Maeding, C.; Preclik, D.; Martin, F.; Cretella, A.; De Amicis, P.; Orlandi, O.; Theil, D. Development roadmap and design of demonstrators for hybrid rocket propulsion in Europe. In Proceedings of the 4th European Conference for Aerospace Sciences (EUCASS), Saint Petersburg, Russia, 4–8 July 2011. [Google Scholar]

- Schmierer, C.; Tomilin, K.; Kobald, M.; Steelant, J.; Schlechtriem, S. Analysis and preliminary design of a hybrid propulsion lunar lander. In Proceedings of the Space Propulsion Conference, Rome, Italy, 2–6 May 2016. SP2016-3124677. [Google Scholar]

- Martin, F.; Chapelle, A.; Lemaire, F. Promising space transportation applications using hybrid propulsion. In Proceedings of the 4th European Conference for Aerospace Sciences (EUCASS), Saint Petersburg, Russia, 4–8 July 2011. [Google Scholar]

- Wright, A.; Foley, P.; Tilahun, D.; Reason, M.; Bryant, C.; Patton, J.; Hudson, M. The effect of high concentration guanidinium azo-tetrazolate on thrust and specific impulse of a hybrid rocket. In Proceedings of the 36th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Las Vegas, NV, USA, 24–28 July 2000. AIAA-2000-3885. [Google Scholar]

- George, P.; Krishnan, S.; Varkey, P.M.; Ravindran, M.; Ramachandran, L. Fuel regression rate in hydroxyl-terminated polybutadiene/gaseous-oxygen hybrid rocket motors. J. Propuls. Power 2001, 17, 35–42. [Google Scholar] [CrossRef]

- Galfetti, L.; Merotto, L.; Boiocchi, M.; Maggi, F.; DeLuca, L.T. Experimental investigation of paraffin based fuels for hybrid rocket propulsion. In Proceedings of the 5th European Conference for Aerospace Sciences (EUCASS), Munich, Germany, 1–5 July 2011. [Google Scholar] [CrossRef]

- Karabeyoglu, M.A.; Zilliac, G.; Castellucci, P.; Urbanczyk, P.; Stevens, J.; Inalhan, G.; Cantwell, B.J. Development of high burning rate hybrid rocket fuel flight demonstrators. In Proceedings of the 39th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Huntsville, AL, USA, 20–23 July 2003. AIAA-2003-5196. [Google Scholar]

- Karabeyoglu, M.A.; Zilliac, G.; Cantwell, B.J.; Dezilwa, S.; Castellucci, P. Scale-up tests of high regression rate paraffin-based hybrid rocket fuels. J. Propuls. Power 2004, 20, 1037–1045. [Google Scholar] [CrossRef]

- Karabeyoglu, M.A.; Altman, D.; Cantwell, B.J. Combustion of liquefying hybrid propellants: Part 1, general theory. J. Propuls. Power 2002, 18, 610–620. [Google Scholar] [CrossRef]

- Karabeyoglu, M.A.; Cantwell, B.J. Combustion of liquefying hybrid propellants: Part 2, stability of liquid films. J. Propuls. Power 2002, 18, 621–630. [Google Scholar] [CrossRef]

- George, P.; Krishnan, S.; Varkey, P.M.; Ravindran, M.; Ramachandran, L. Hybrid rocket fuel combustion and regression rate study. In Proceedings of the 28th Joint Propulsion Conference and Exhibit, Nashville, TN, USA, 20–23 July 1992. AAA-92-3302. [Google Scholar] [CrossRef]

- Carmicino, C.; Sorge, A.R. Role of injection in hybrid rockets regression rate behavior. J. Propuls. Power 2005, 21, 606–612. [Google Scholar] [CrossRef]

- Lee, C.; Na, Y.; Lee, J.W.; Byun, Y.H. Effect of induced swirl flow on regression rate of hybrid rocket fuel by helical grain configuration. Aerosp. Sci. Technol. 2007, 11, 68–76. [Google Scholar] [CrossRef]

- Armold, D.M. Formulation and Characterization of Paraffin-Based Solid Fuels Containing Swirl Inducing Grain Geometry and/or Energetic Additives. Master’s Thesis, The Pennsylvania State University, University Park, PA, USA, 11 April 2014. Available online: https://etda.libraries.psu.edu/catalog/21836 (accessed on 7 March 2019).

- Lips, H. Metal combustion in high performance hybrid rocket propulsion systems. In Proceedings of the 12th Propulsion Conference, Palo Alto, CA, USA, 26–29 July 1976. [Google Scholar] [CrossRef]

- Karabeyoglu, A. Mixtures of nitrous oxide and oxygen (nytrox) as oxidizers for rocket propulsion applications. In Proceedings of the 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Denver, CO, USA, 2–5 August 2009. AIAA-2009-4966. [Google Scholar] [CrossRef]

- Karabeyoglu, M.A. Nitrous oxide and oxygen mixtures (nytrox) as oxidizers for rocket propulsion applications. J. Propuls. Power 2015, 30, 696–706. [Google Scholar] [CrossRef]

- Risha, G.; Boyer, E.; Wehrman, R.; Evans, B.; Kuo, K.K. Nano-sized aluminum and boron-based solid fuel characterization in a hybrid rocket engine. In Proceedings of the 39th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Huntsville, AL, USA, 20–23 July 2003. AIAA-2003-4593. [Google Scholar] [CrossRef]

- Risha, G.; Boyer, E.; Wehrman, R. Performance comparison of HTPB-based solid fuels containing nano-sized energetic powder in a cylindrical hybrid rocket motor. In Proceedings of the 38th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Indianapolis, IN, USA, 7–10 July 2002. AIAA-2002-3576. [Google Scholar] [CrossRef]

- Calabro, M. LOX/HTPB/AlH3 hybrid propulsion for launch vehicle boosters. In Proceedings of the 40th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Fort Lauderdale, FL, USA, 11–14 July 2003. AIAA-2004-3823. [Google Scholar] [CrossRef]

- Carmicino, C.; Sorge, A.R. Experimental investigation into the effect of solid-fuel additives on hybrid rocket performance. J. Propuls. Power 2015, 31, 699–713. [Google Scholar] [CrossRef]

- Shen, R.Q.; Tang, Y.; Chen, S.H.; Zhao, Q.; Zhang, W.; Ye, Y.; DeLuca, L.T. Self-disintegration effects on the regression rate of composite polymer particle paraffin fuel (CM3PF). In Proceedings of the 7th European Conference for Aeronautics and Space Sciences (EUCASS), Milan, Italy, 3–6 July 2017. [Google Scholar]

- Tang, Y.; Chen, S.; Zhang, W.; Shen, R.; DeLuca, L.T.; Ye, Y. Flame Visualization and Combustion Performance of Composite Energetic Particle Paraffin-based Fuels for Hybrid Rocket Propulsion. Int. J. Energ. Mater. Chem. Propuls. 2017, 16, 49–59. [Google Scholar]

- Tang, Y.; Zhang, W.; Chen, S.H.; Yu, H.S.; Shen, R.; DeLuca, L.T.; Ye, Y. A novel polyethylene particles/paraffin-based self-disintegration fuel for hybrid rocket propulsion. Int. J. Energ. Mater. Chem. Propuls. 2018, 17, 205–216. [Google Scholar] [CrossRef]

- Chen, S.H.; Tang, Y.; Yu, H.S.; Bao, L.; Zhang, W.; DeLuca, L.T.; Shen, R.; Ye, Y. The rapid H2 release from AlH3 dehydrogenation forming porous layer in AlH3/hydroxyl-terminated polybutadiene (HTPB) fuels during combustion. J. Hazard. Mater. 2019, 371, 53–61. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.H.; Tang, Y.; Zhang, W.; Shen, R.; DeLuca, L.T.; Ye, Y. Effect of azodicarbonamide particles on the regression rate of hydroxyl-terminated polybutadiene (HTPB)-based fuels for hybrid rocket propulsion. Int. J. Energ. Mater. Chem. Propuls. 2017, 16, 103–114. [Google Scholar] [CrossRef]

- Chen, S.H.; Tang, Y.; Yu, H.S.; Guan, X.Y.; DeLuca, L.T.; Zhang, W.; Shen, R.; Ye, Y. Combustion enhancement of hydroxyl-terminated polybutadiene by doping multiwall carbon nanotubes. Carbon 2019, 144, 472–480. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, S.H.; Zhang, W.; Shen, R.; DeLuca, L.T.; Ye, Y. Mechanical modifications of paraffin-based fuels and the effects on combustion performance. Propellants Explos. Pyrotech. 2017, 16, 103–114. [Google Scholar] [CrossRef]

- DeLuca, L.T.; Galfetti, L.; Maggi, F.; Colombo, G.; Merotto, L.; Boiocchi, M.; Paravan, C.; Reina, A.; Tadini, P.; Fanton, L. Characterization of HTPB-based solid fuel formulations: Performance, mechanical properties, and pollution. Acta Astronaut. 2013, 92, 150–162. [Google Scholar] [CrossRef]

- DeLuca, L.T.; Galfetti, L.; Colombo, G.; Maggi, F.; Bandera, A.; Boiocchi, M.; Gariani, G.; Merotto, L.; Paravan, C.; Reina, A. Time-resolved burning of solid fuels for hybrid rocket propulsion. In Proceedings of the 3rd European Conference for Aerospace Sciences (EUCASS), Versailles, France, 6–10 July 2009. [Google Scholar] [CrossRef]

- Zilliac, G.; Karabeyoglu, M. Hybrid rocket fuel regression rate data and modeling. In Proceedings of the 42th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Sacramento, CA, USA, 9–12 July 2006. AIAA-2006-4504. [Google Scholar] [CrossRef]

- Guo, X.; Li, F.; Song, H.; Liu, G.; Kong, L.; Li, M.; Chen, W. Combustion Characteristics of a Novel Grain-Binding High Burning Rate Propellant. Propellants Explos. Pyrotech. 2008, 33, 255–260. [Google Scholar] [CrossRef]

- DeLuca, L.T.; Galfetti, L.; Severini, F.; Rossettini, L.; Meda LMarra, G.; D’Andrea, B.; Weiser, V.; Calabro, M.; Vorozhtsov, A.B.; Glazunov, A.A.; et al. Physical and Ballistic Characterization of AlH3-Based Space Propellants. Aerosp. Sci. Technol. 2007, 11, 18–25. [Google Scholar] [CrossRef]

- DeLuca, L.T.; Rossettini, L.; Kappenstein, C.; Weiser, V. Ballistic Characterization of AlH3-Based Propellants for Solid and Hybrid Rocket Propulsion. In Proceedings of the 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit Denver, Denver, CO, USA, 2–5 August 2009. AIAA 2009-4874. [Google Scholar]

- Kobald, M.; Schmierer, C.; Ciezki, H.K.; Schlechtriem, S.; Toson, E.; DeLuca, L.T. Viscosity and Regression Rate of Liquefying Hybrid Rocket Fuels. J. Propuls. Power 2017, 33, 1245–1251. [Google Scholar] [CrossRef]

| Polymer Particles | Source | Molecular Mass | Melting Point (°C, 1 atm) | Boiling Point (°C, 1 atm) | Density (g/cm3) |

|---|---|---|---|---|---|

| HTPB | [31] | - | 413 | 453 | 0.922 |

| PE paraffin | Dinghai Plastic Chemical Co., Ltd. (Dongguan, China) | 2000–5000 | 96 | 270 | 0.94 |

| Oleamide | 281.5 | 72–77 | 433.3 | 0.879 | |

| Polydextrose | Weiduome Food Co., Ltd. (Shen Zhen, China) | Average–3200 | 153–158 | 410.8 | 1.587 |

| PEG6000 | Ipsen S.A. (Boulogne-Billancourt, France) | 5500–7500 | 64–66 | >250 | 1.27 |

| Fuel Name | HTPB | DOA | IPDI | TIN | Polymer Particles |

|---|---|---|---|---|---|

| Pure HTPB | 78.86 | 13.04 | 7.67 | 0.43 | 0% |

| 5% Polymer/HTPB | 74.91 | 12.39 | 7.29 | 0.41 | 5% |

| 10% Polymer/HTPB | 70.97 | 11.74 | 6.90 | 0.39 | 10% |

| 20% Polymer/HTPB | 63.09 | 10.43 | 6.14 | 0.34 | 20% |

| Fuel Name | rf Increase at 350 kg/(m2·s) | rf Increase at 150 kg/(m2·s) | Gox Range from 150 to 310 kg/m2·s | R2 |

|---|---|---|---|---|

| Pure HTPB | - | - | 0.970 | |

| 5% PE paraffin | 20.7% | 4.2% | 0.970 | |

| 10% PE paraffin | 3.2% | −21.1% | 0.971 | |

| 20% PE paraffin | −0.7% | −11.3% | 0.970 | |

| 5% oleamide | 3.0% | −15.5% | 0.970 | |

| 10% oleamide | 7.8% | 2.9% | 0.970 | |

| 20% oleamide | 18.6% | −25.4% | 0.971 | |

| 10% polydextrose | 10. 6% | −14.1% | 0.976 | |

| 10% PEG6000 | 21. 4% | −19.0% | 0.970 |

| Fuel Name | Melting Point (°C) | Combustion Heat (kJ/g) | Density (g/cm3) | Compressive Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| Paraffin #58 | 58.3 | 47.36 | 0.917 | 2.84 | 2.76 |

| Paraffin #90 | 72.2 | 46.19 | 0.927 | 1.40 | 2.78 |

| Fuel Name | Average rf Increase | ar | nr | R2 |

|---|---|---|---|---|

| Paraffin #58 | - | 0.048 ± 0.001 | 0.566 ± 0.004 | 0.917 |

| 5% DB | 30% | 0.045 ± 0.001 | 0.624 ± 0.005 | 0.895 |

| 10% DB | 38% | 0.040 ± 0.001 | 0.656 ± 0.006 | 0.875 |

| 15% DB | 47% | 0.039 ± 0.001 | 0.669 ± 0.006 | 0.889 |

| 20% DB | 59% | 0.033 ± 0.001 | 0.707 ± 0.006 | 0.884 |

| Fuel Name | rf Increase at 367 kg/(m2·s) | ar | nr | R2 |

|---|---|---|---|---|

| Paraffin #58 | - | 0.048 ± 0.001 | 0.566 ± 0.004 | 0.917 |

| 15% LDPE small | 21.0% | 0.002 ± 0.0001 | 1.140 ± 0.013 | 0.817 |

| 15% LDPE medium | 11.2% | 0.006 ± 0.0004 | 0.938 ± 0.012 | 0.848 |

| 15% LDPE large | −1.6% | 0.019 ± 0.001 | 0.732 ± 0.007 | 0.827 |

| Particle Size (μm) | Active Content (%) | Specific Surface Area (m2/g) | Volume Density (g/cm3) | Density (g/cm3) | Crystal Shape |

|---|---|---|---|---|---|

| 1 | 99.9 | 18.75 | 1.17 | 1.70 | sphere |

| 100 | 99.9 | 3.64 | 3.95 | 1.70 | sphere |

| Fuel Name | Formulation (Mass Fraction/%) | Density (g/cm3) |

|---|---|---|

| 15% 1 μm-MgP | 15% 1 μm Mg particles + 85% paraffin | 0.957 |

| 15% 100 μm-MgP | 15% 100 μm Mg particles + 85% paraffin | 0.928 |

| Fuel Name | rf Increase at 335 kg/(m2·s) | rf Increase at 100 kg/(m2·s) | ar | nr | R2 |

|---|---|---|---|---|---|

| paraffin #58 | - | - | 0.048 ± 0.001 | 0.566 ± 0.004 | 0.917 |

| 1 μm MgP | 163.2% | −47.6% | 3.22 × 10−5 ± 2.66 × 10−6 | 1.954 ± 0.016 | 0.907 |

| 100 μm MgP | 82.1% | 49.2% | 0.049 ± 0.001 | 0.656 ± 0.006 | 0.887 |

| Fuel Name | rf Increase at 350 kg/(m2·s) | rf Increase at 150 kg/(m2·s) | Gox Range from 150 to 310 kg/m2·s | R2 |

|---|---|---|---|---|

| Pure HTPB | - | - | 0.944 | |

| 5% 40–80 μm AlH3 | 48.51% | 47.89% | 0.971 | |

| 10% 40–80 μm AlH3 | 85.75% | 9.15% | 0.969 | |

| 20% 40–80 μm AlH3 | 3.22% | 14.79% | 0.969 | |

| 5% 80–200 μm AlH3 | 37.70% | 21.83% | 0.970 | |

| 10% 80–200 μm AlH3 | 48.74% | 69.72% | 0.968 | |

| 20% 80–200 μm AlH3 | 14.71% | 16.20% | 0.968 |

| Fuel Name | rf Increase at 365 kg/(m2·s) | rf Increase at 150 kg/(m2·s) | Gox Range from 150 to 350 kg/m2·s | R2 |

|---|---|---|---|---|

| Pure HTPB | - | - | 0.944 | |

| 0.5% CNT | 11.2% | 27.0% | 0.947 | |

| 1% CNT | 31.6% | 25.0% | 0.947 | |

| 2% CNT | −21.3% | −26.4% | 0.947 | |

| 3% CNT | −39.7% | −36.6% | 0.975 |

| Name | Average rf Increase (100~350 kg/(m2·s)) | ar | nr | R2 |

|---|---|---|---|---|

| Paraffin #58 | - | 0.048 ± 0.001 | 0.566 ± 0.004 | 0.917 |

| 5% LDPE-M SDFS | 9.0% | 0.035 ± 0.001 | 0.646 ± 0.005 | 0.877 |

| 5% LDPE blend | −39.0% | 0.018 ± 0.001 | 0.673 ± 0.006 | 0.879 |

| 10% LDPE-M SDFS | 22.2% | 0.044 ± 0.001 | 0.622 ± 0.005 | 0.891 |

| 10% LDPE blend | −58.9% | 0.010 ± 0.001 | 0.710 ± 0.007 | 0.850 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Tang, Y.; Zhang, W.; Shen, R.; Yu, H.; Ye, Y.; DeLuca, L.T. Innovative Methods to Enhance the Combustion Properties of Solid Fuels for Hybrid Rocket Propulsion. Aerospace 2019, 6, 47. https://doi.org/10.3390/aerospace6040047

Chen S, Tang Y, Zhang W, Shen R, Yu H, Ye Y, DeLuca LT. Innovative Methods to Enhance the Combustion Properties of Solid Fuels for Hybrid Rocket Propulsion. Aerospace. 2019; 6(4):47. https://doi.org/10.3390/aerospace6040047

Chicago/Turabian StyleChen, Suhang, Yue Tang, Wei Zhang, Ruiqi Shen, Hongsheng Yu, Yinghua Ye, and Luigi T. DeLuca. 2019. "Innovative Methods to Enhance the Combustion Properties of Solid Fuels for Hybrid Rocket Propulsion" Aerospace 6, no. 4: 47. https://doi.org/10.3390/aerospace6040047

APA StyleChen, S., Tang, Y., Zhang, W., Shen, R., Yu, H., Ye, Y., & DeLuca, L. T. (2019). Innovative Methods to Enhance the Combustion Properties of Solid Fuels for Hybrid Rocket Propulsion. Aerospace, 6(4), 47. https://doi.org/10.3390/aerospace6040047