Modeling and Investigation of a Turboprop Hybrid Electric Propulsion System

Abstract

1. Introduction

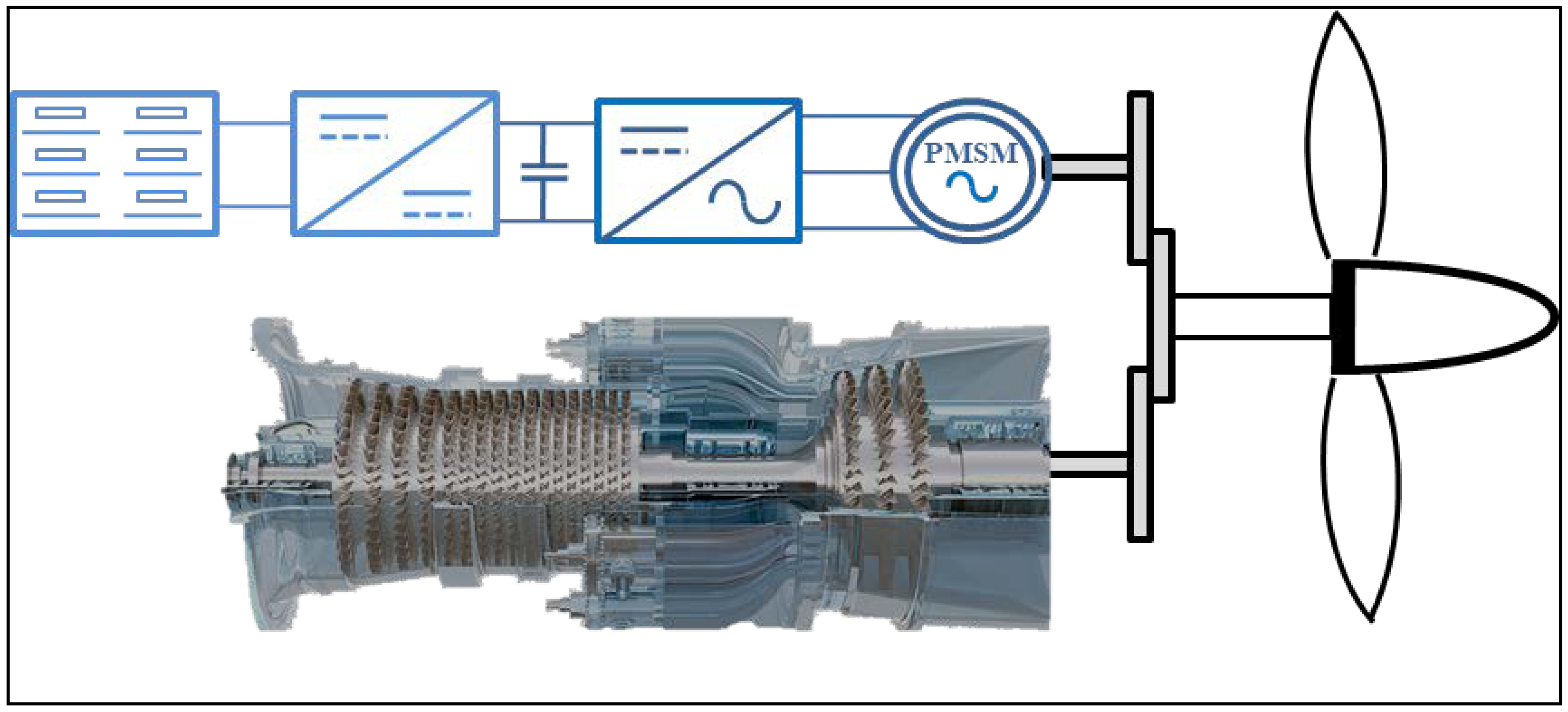

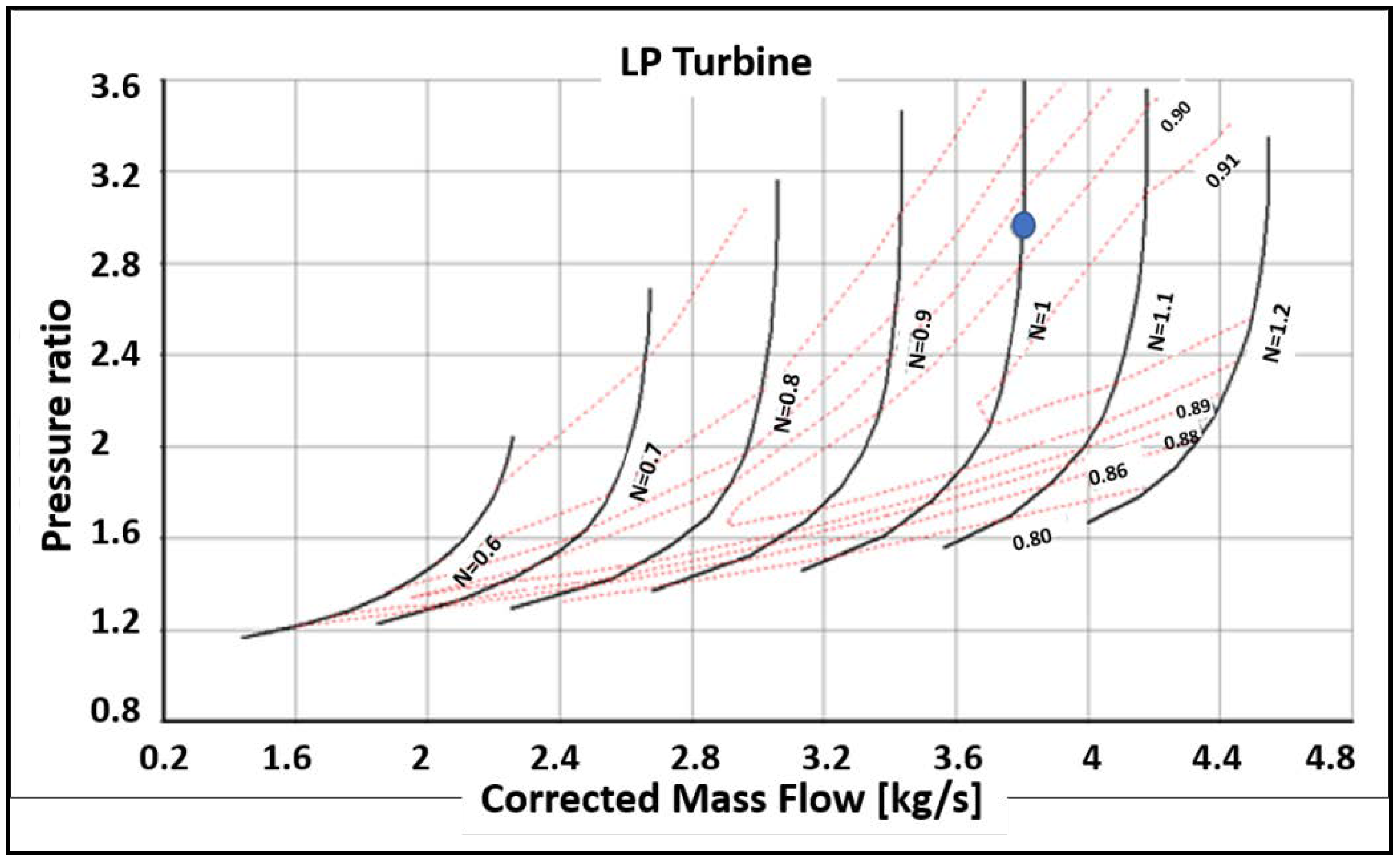

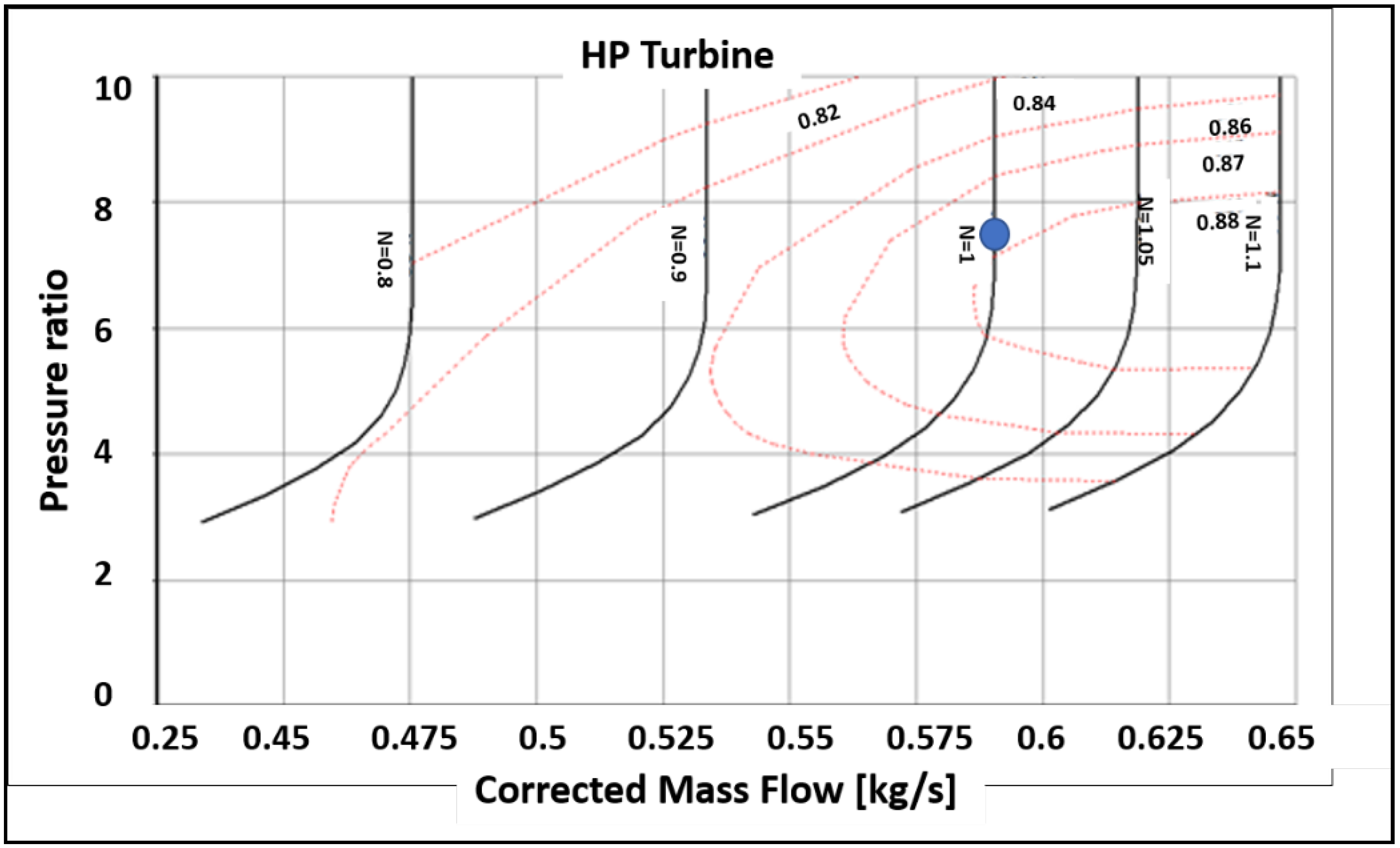

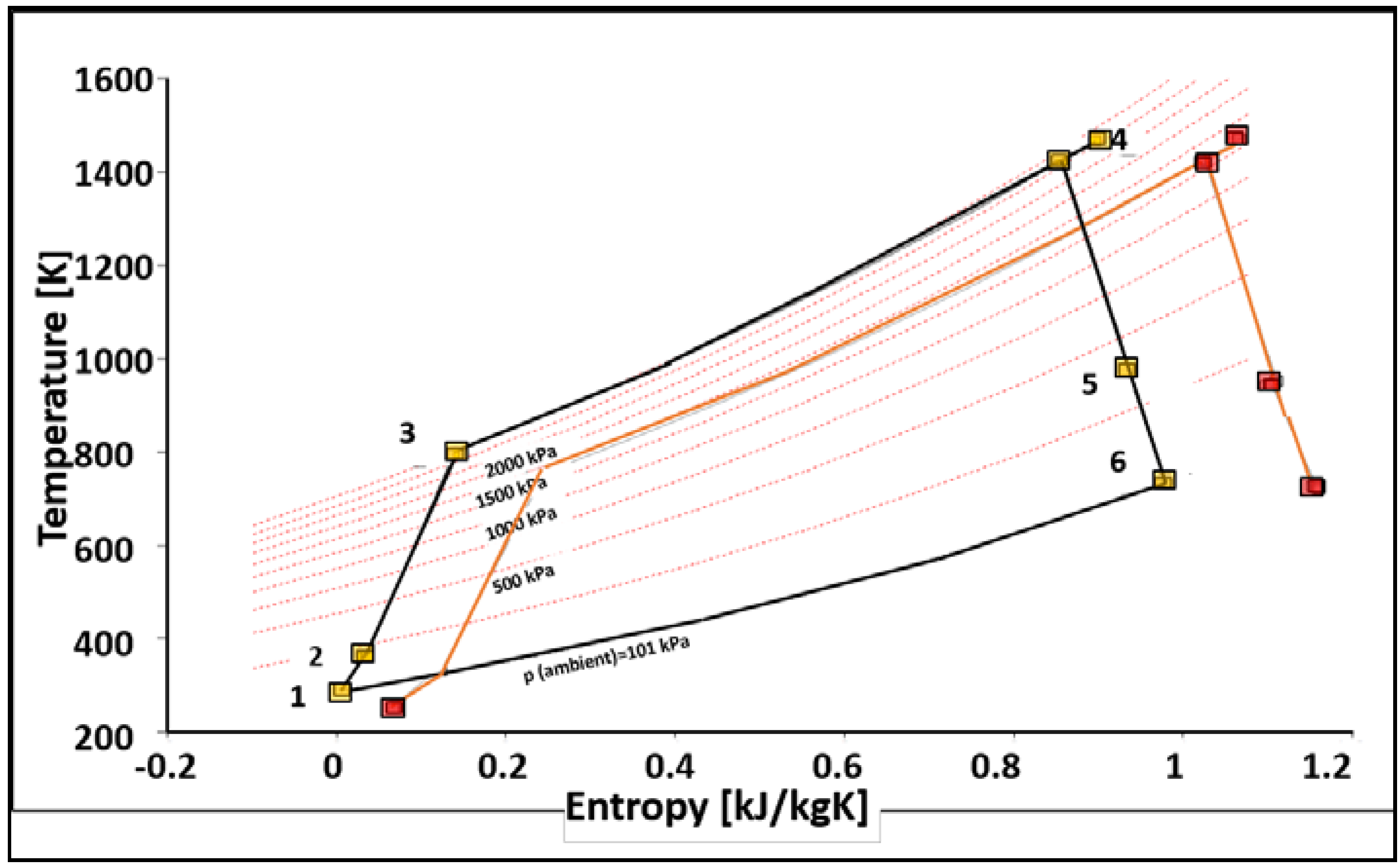

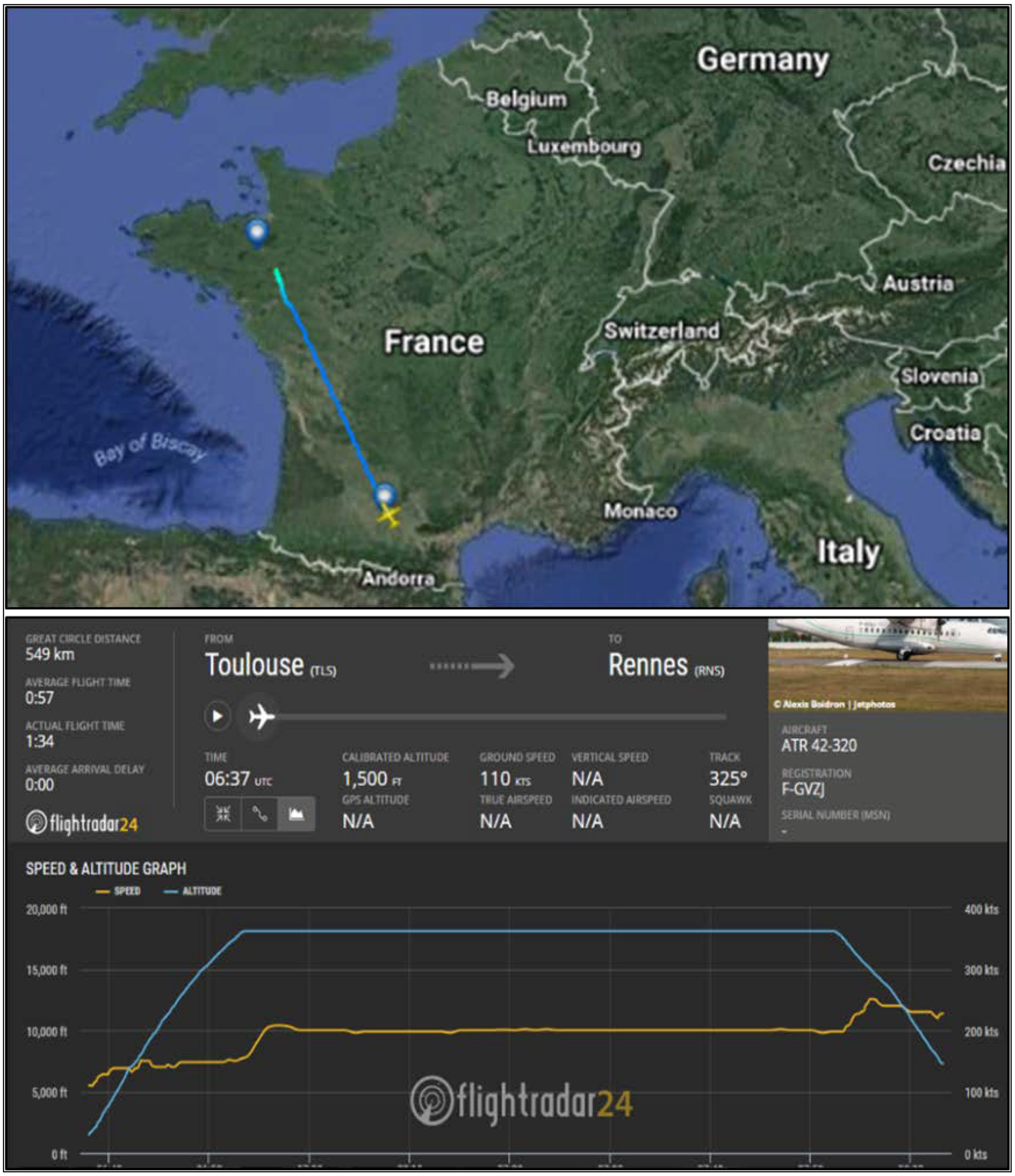

2. Choice of Hybrid Propulsion Configuration

3. Modeling of Propulsion System

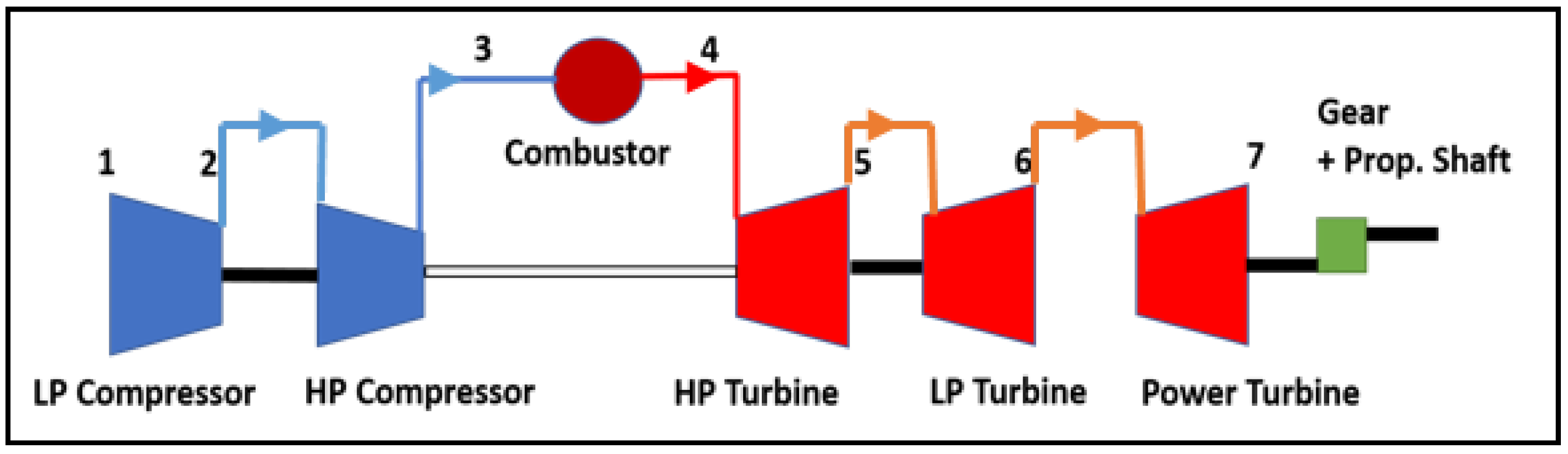

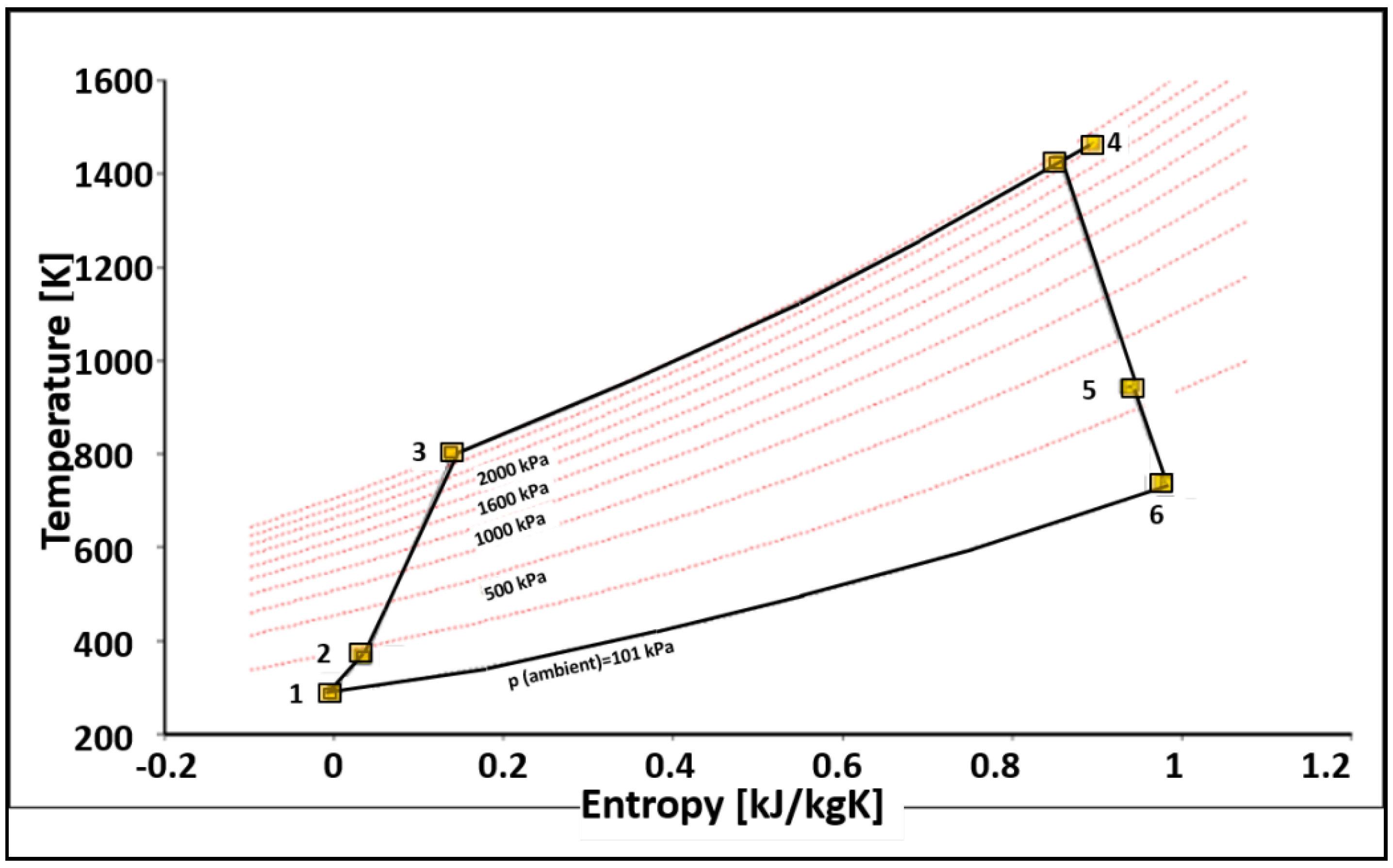

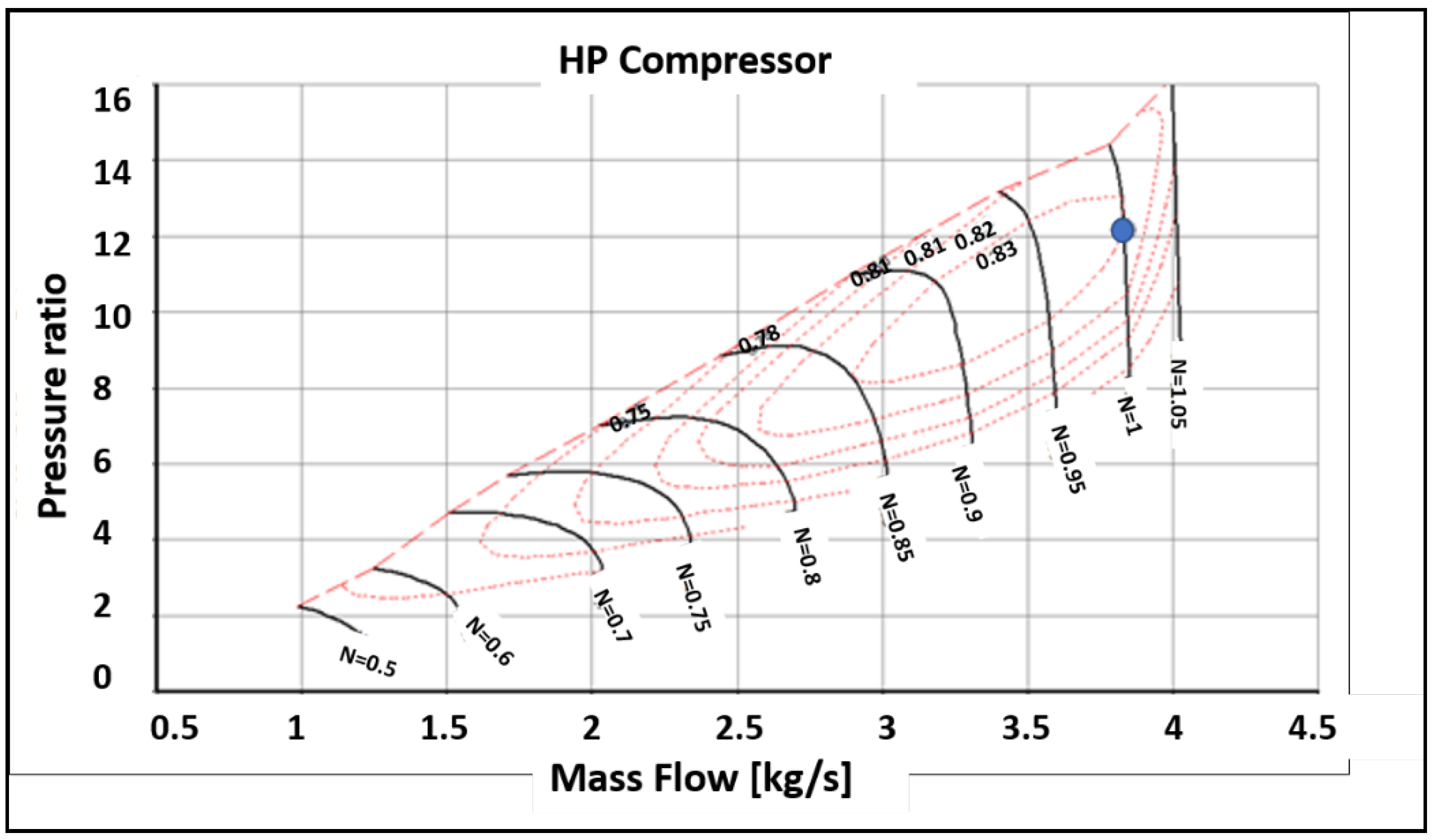

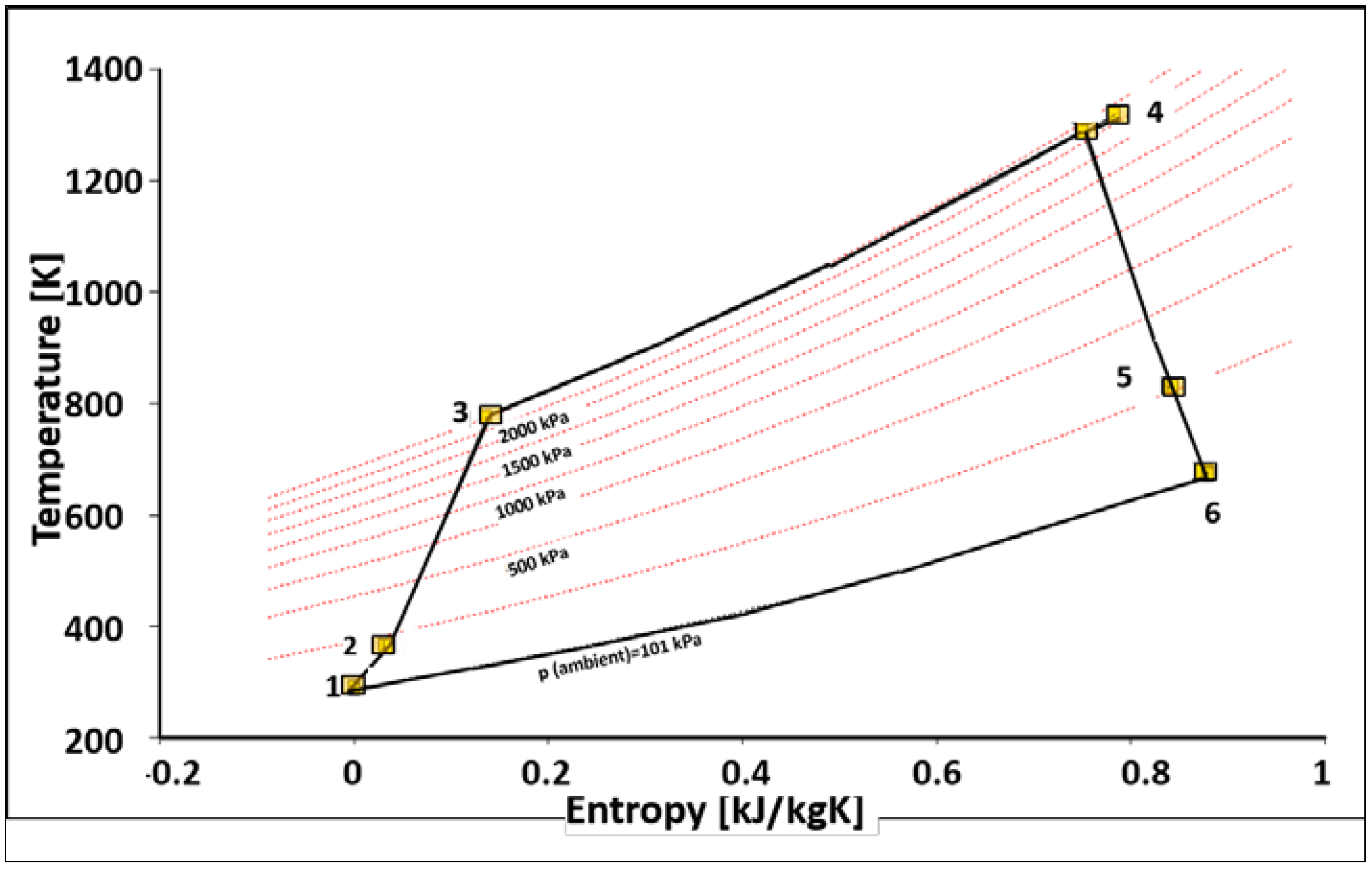

3.1. Base Configuration

3.2. Emissions

4. Hybrid Configuration

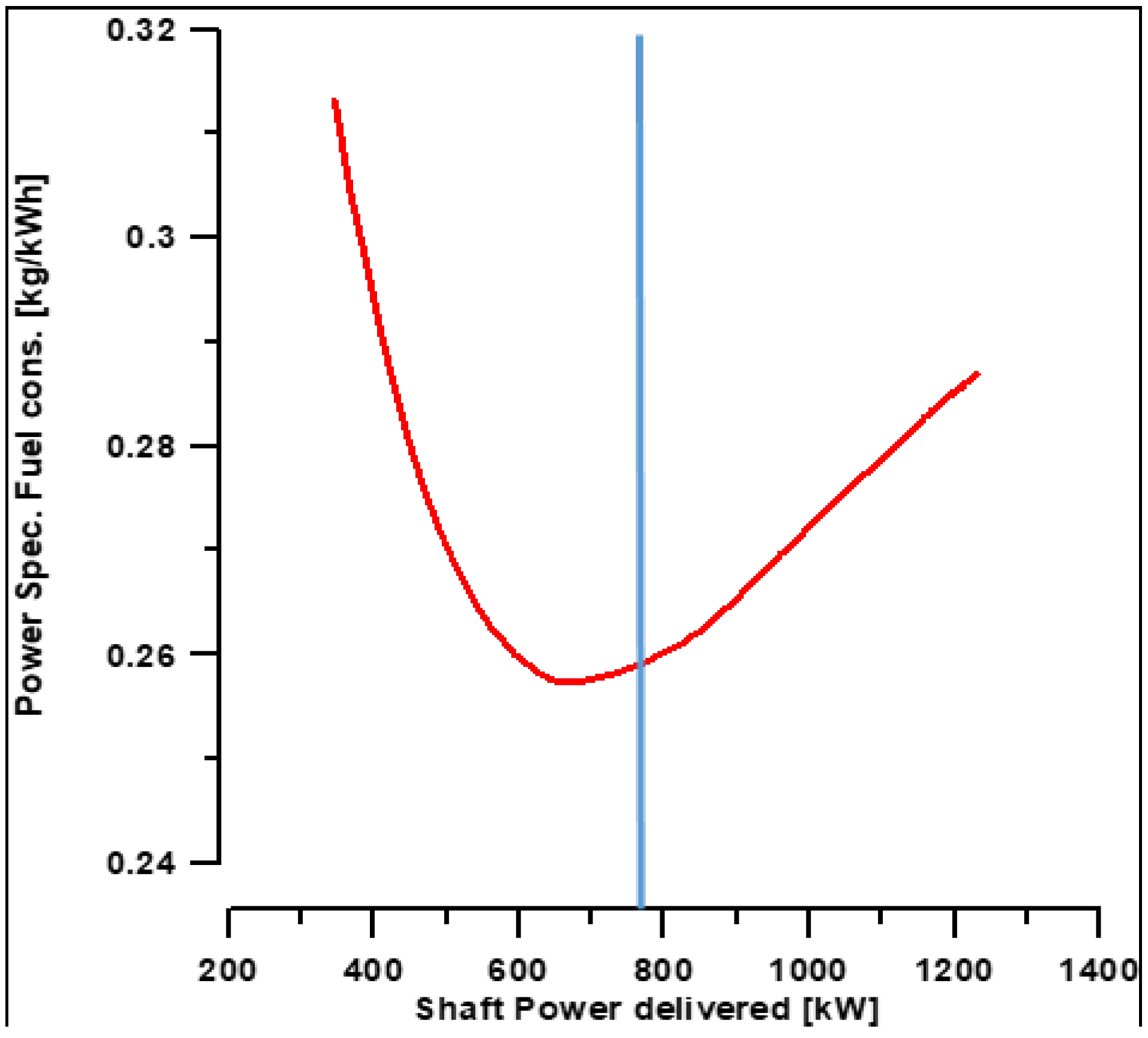

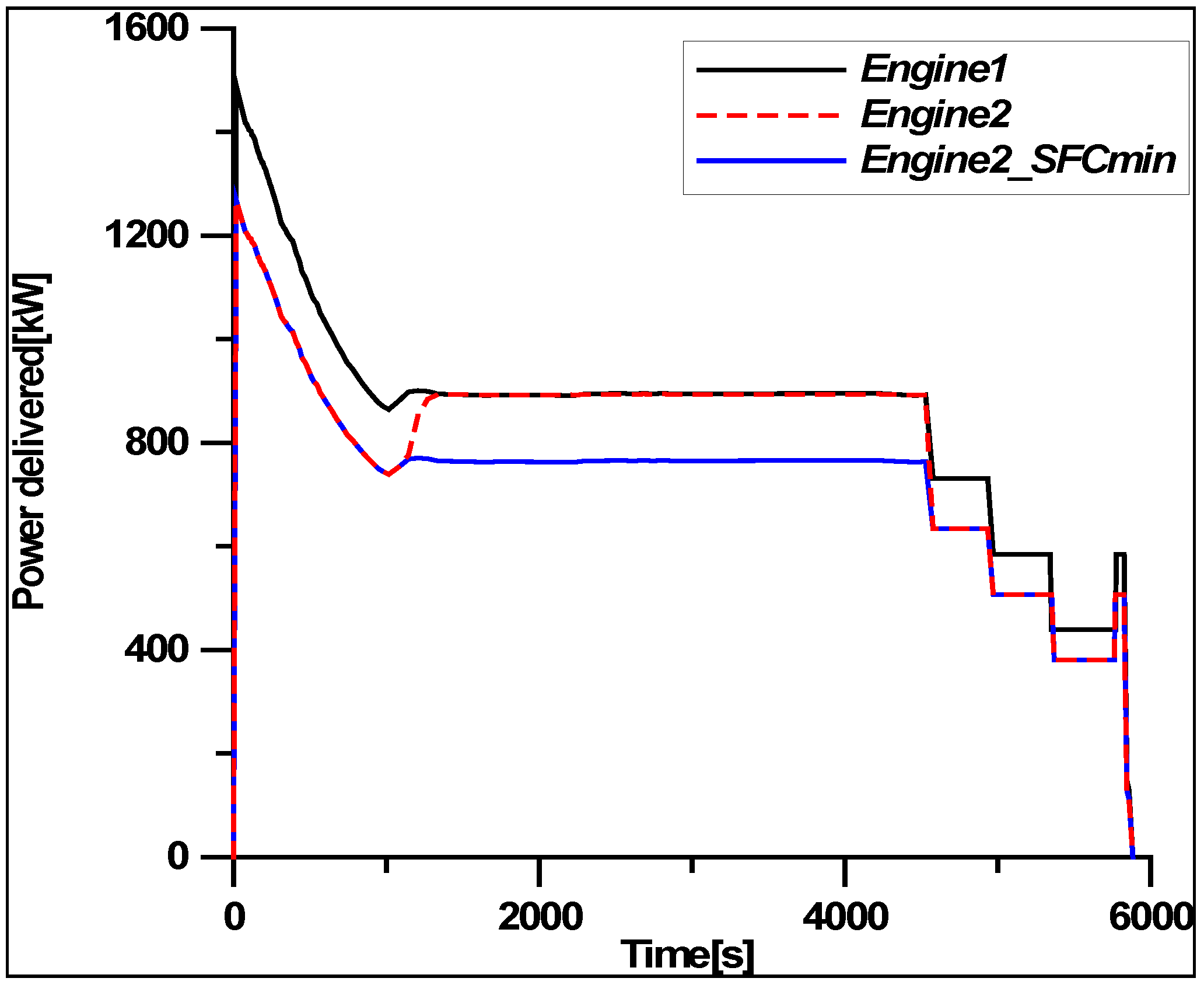

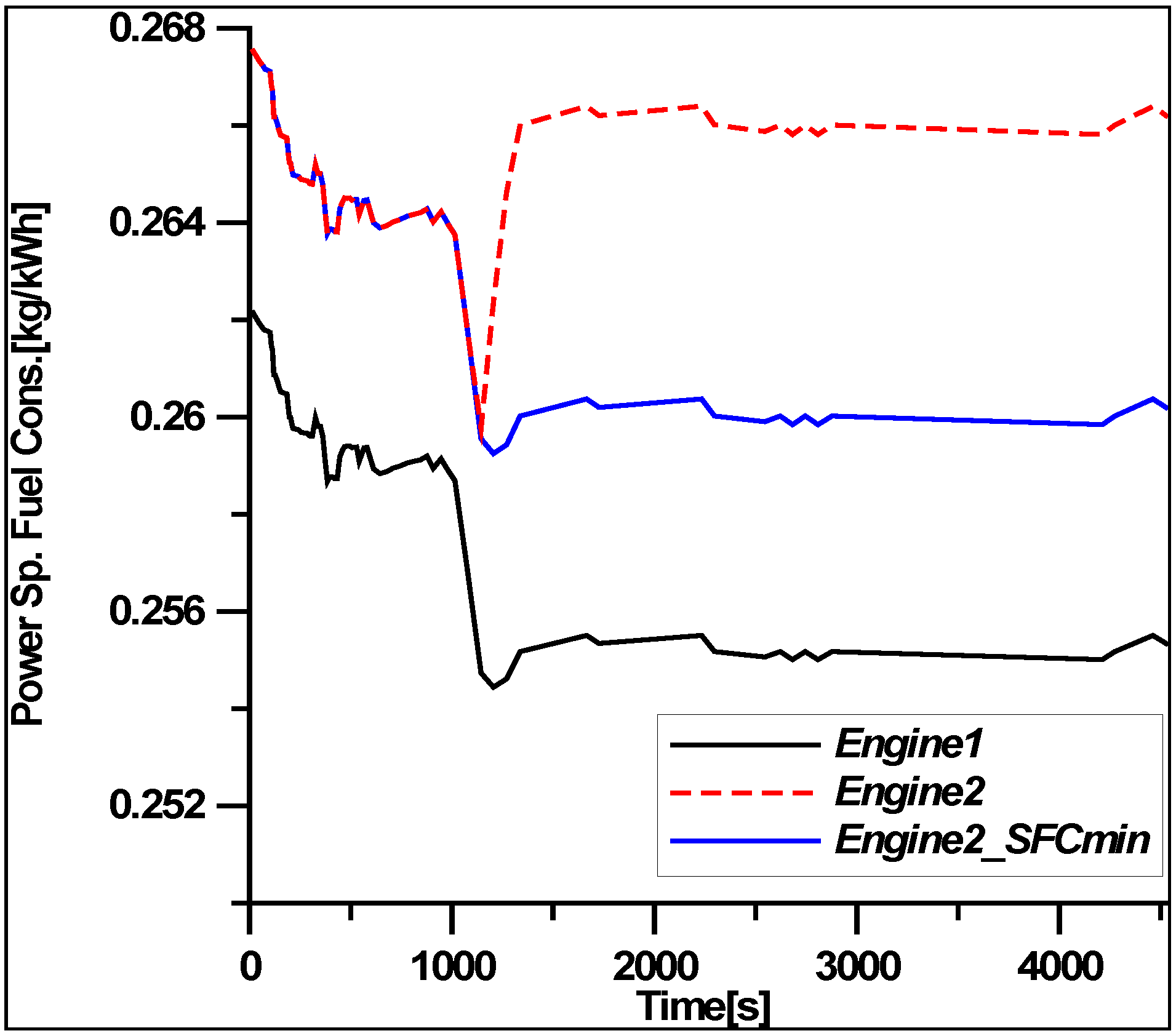

4.1. Configurations with Engine_2

- −

- the gas turbine (Engine_2) keeps the same shaft power of the Engine1 (900 kW), which could allow the use of a permanent magnet synchronous electrical motor (PMSM) only during the take-off phase;

- −

4.2. Configuration with Engine_3

5. Sizing of the Battery Energy Storage System

- (1)

- High power density propulsion motor: due to the high power density and high efficiency, permanent magnet motors are the most suitable motors for the application; in order to increase the reliability, this motor can be realized in multiphase configurations [26]. The use of pitch control for the management of the propulsion power, gives the possibility to keep the angular speed practically constant and obtain a high value of efficiency;

- (2)

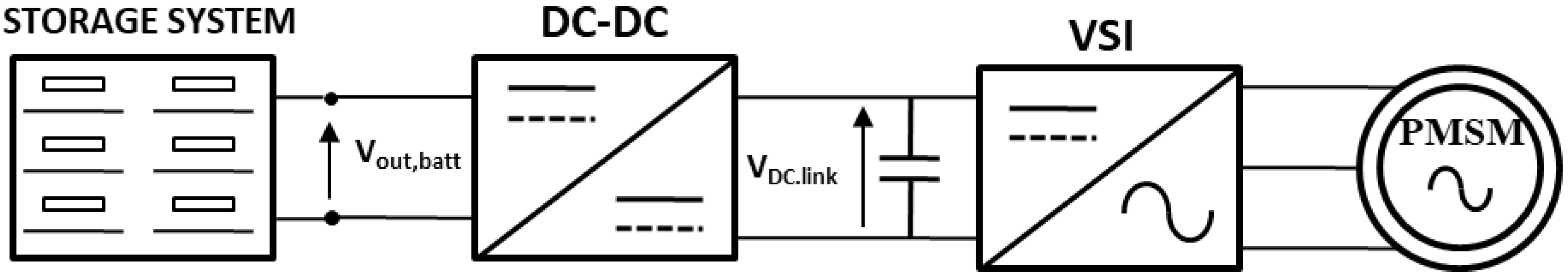

- DC–DC and DC–AC converters: the power converter chain is constituted by the DC–AC converters (typically a voltage source inverter) connected to the terminals of the electric motors [27]. The optimal management of the storage systems needs the use of a DC–DC, which can be made with a typical boost converter, or with the use of a dual active bridge with a rectifier. In the latter case, the use of a medium-high frequency stage permits the reduction of the weight and the achievement of a high ratio between the output and input voltage.

- (3)

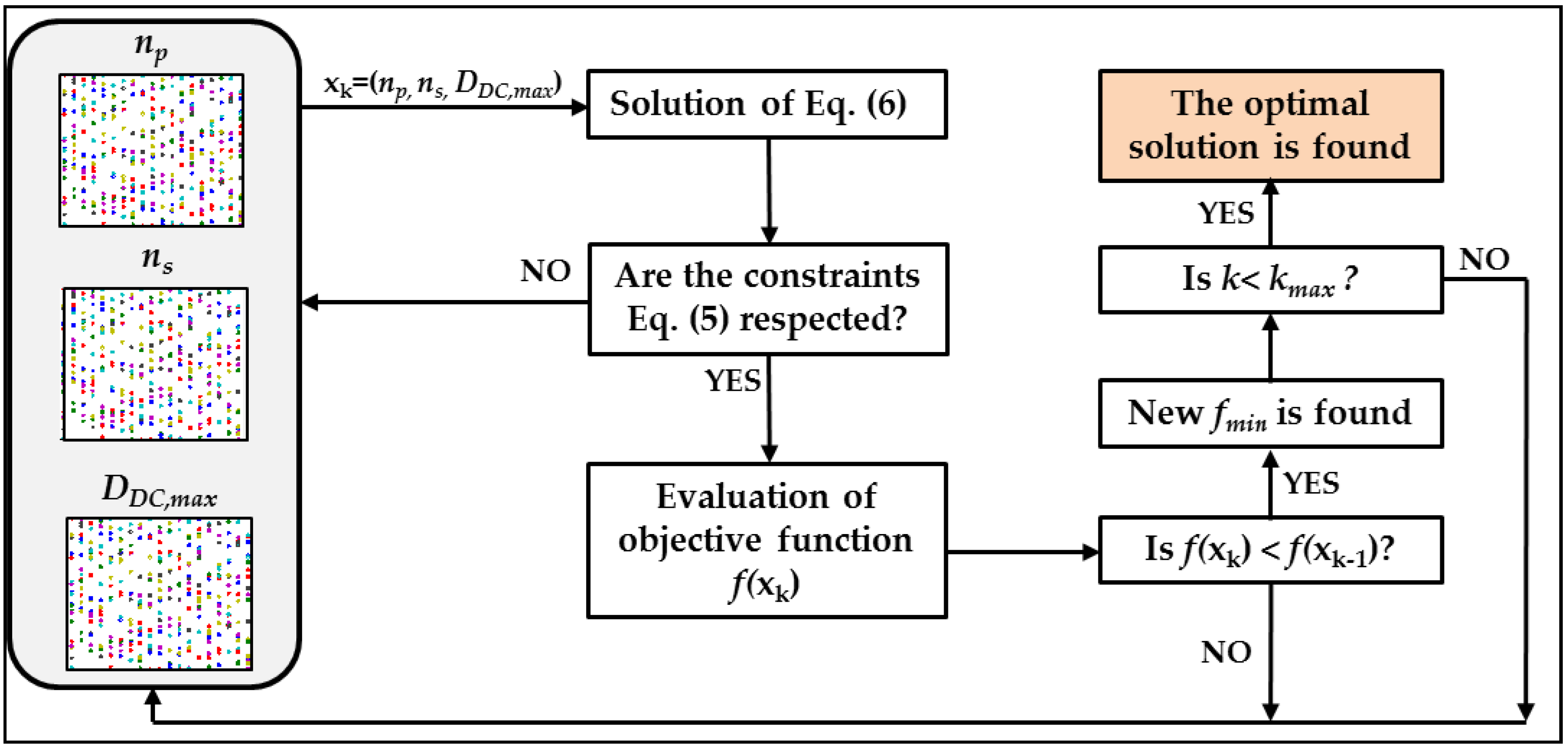

- Storage system: in a hybrid power-train, the storage system could be based on battery, supercapacitors, or flywheel systems. The supercapacitors are widely used when the power profile has a large number of peak power, but their use is limited by the low energy density. Flywheels are characterized by a large lifetime with respect to the other type of storage systems here considered, but the use in electric vehicles is difficult due to safety problems. Therefore, now, a storage system based on Li-ion batteries is the most suitable solution for aircraft hybrid propulsion. The battery storage systems used on-board of the aircraft must be optimized to reduce the total weight. Usually, the optimal design of a battery storage system required respecting some equality and inequality constraints, which depend on the battery cell characteristics and on the type of power converters utilized.

5.1. Optimal Design of Battery Storage Systems

5.2. Solutions of the Optimization Problem

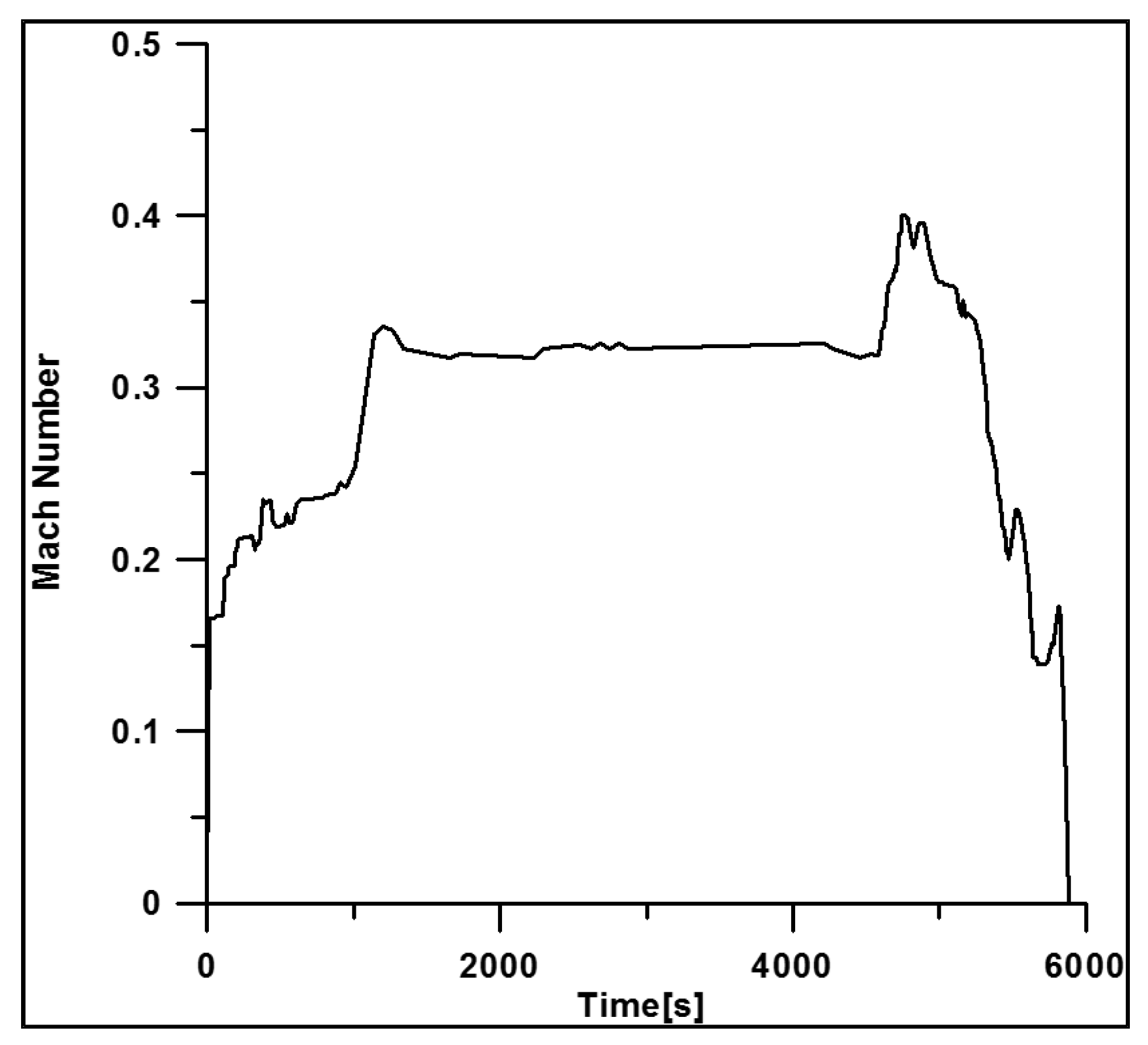

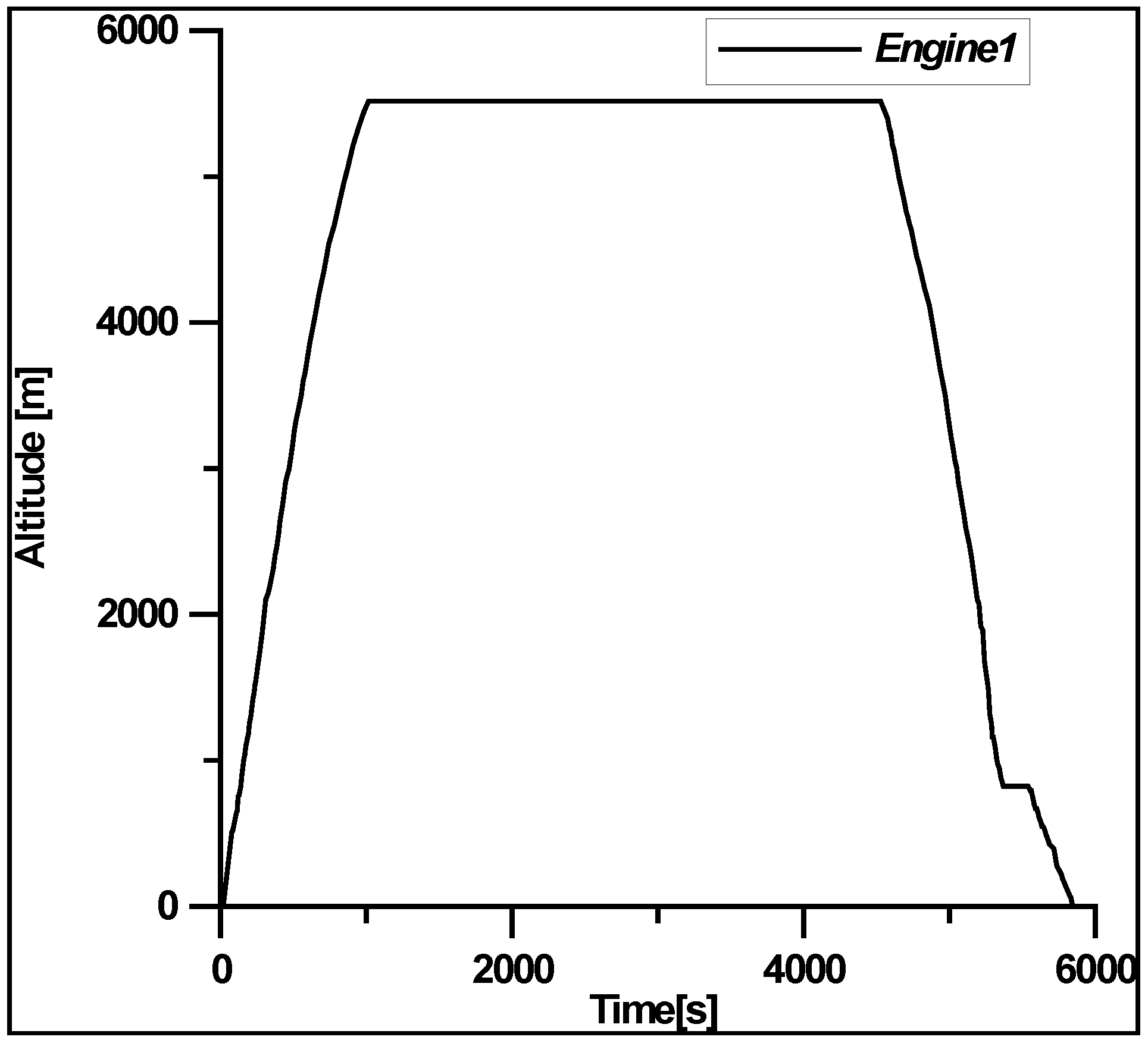

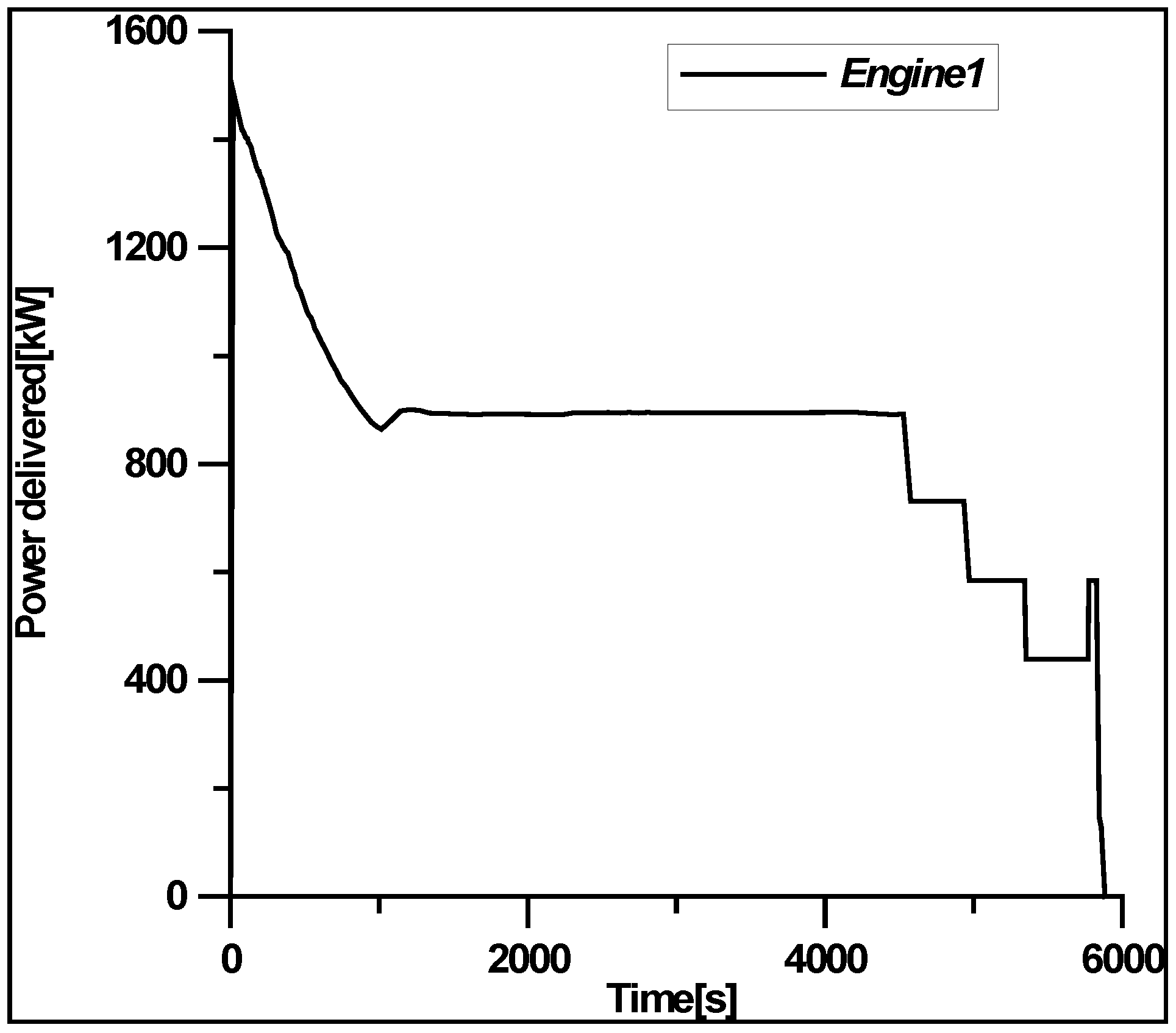

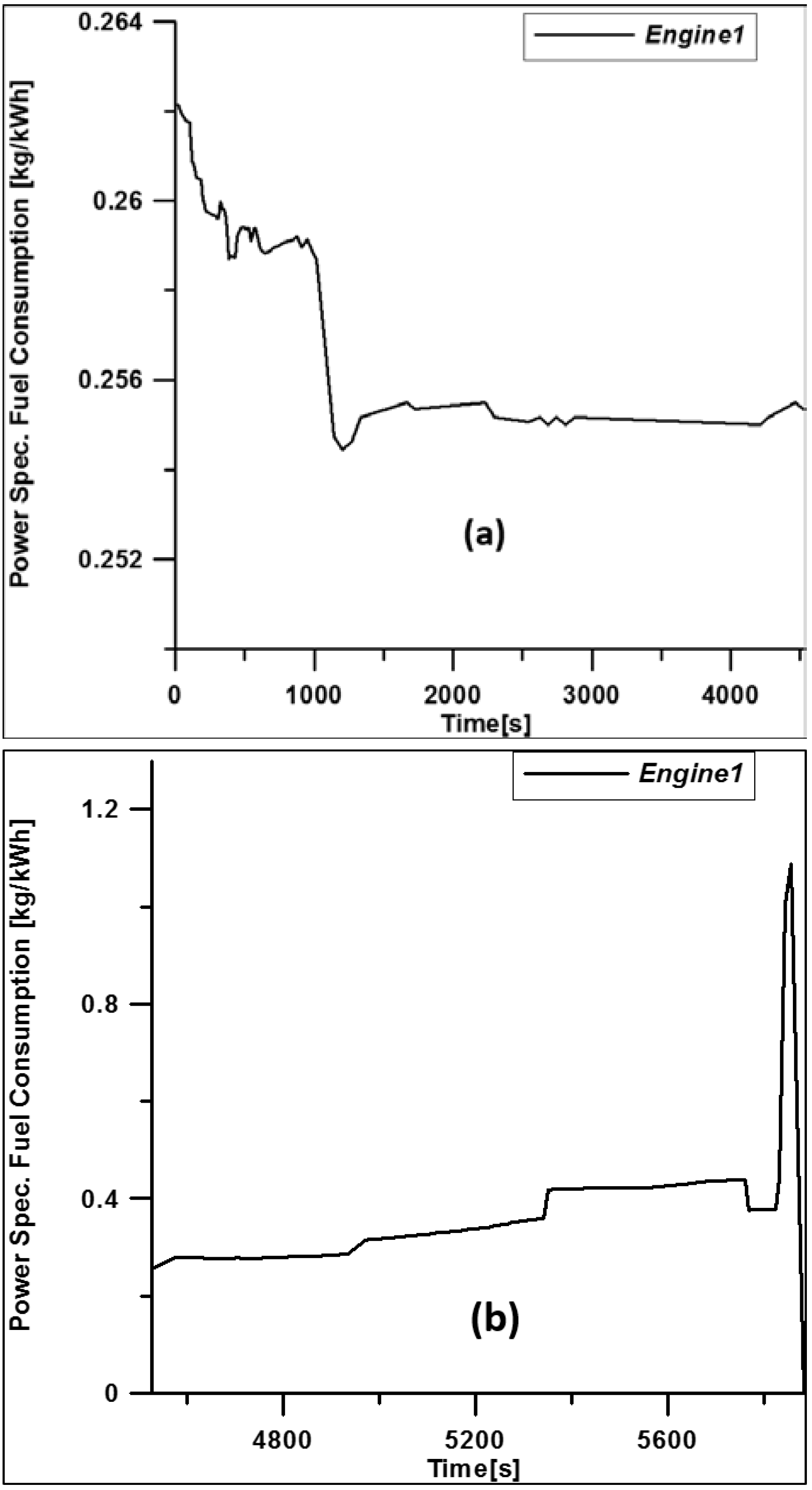

6. Simulation Results

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ACARE | Advisory Council for Aviation Research |

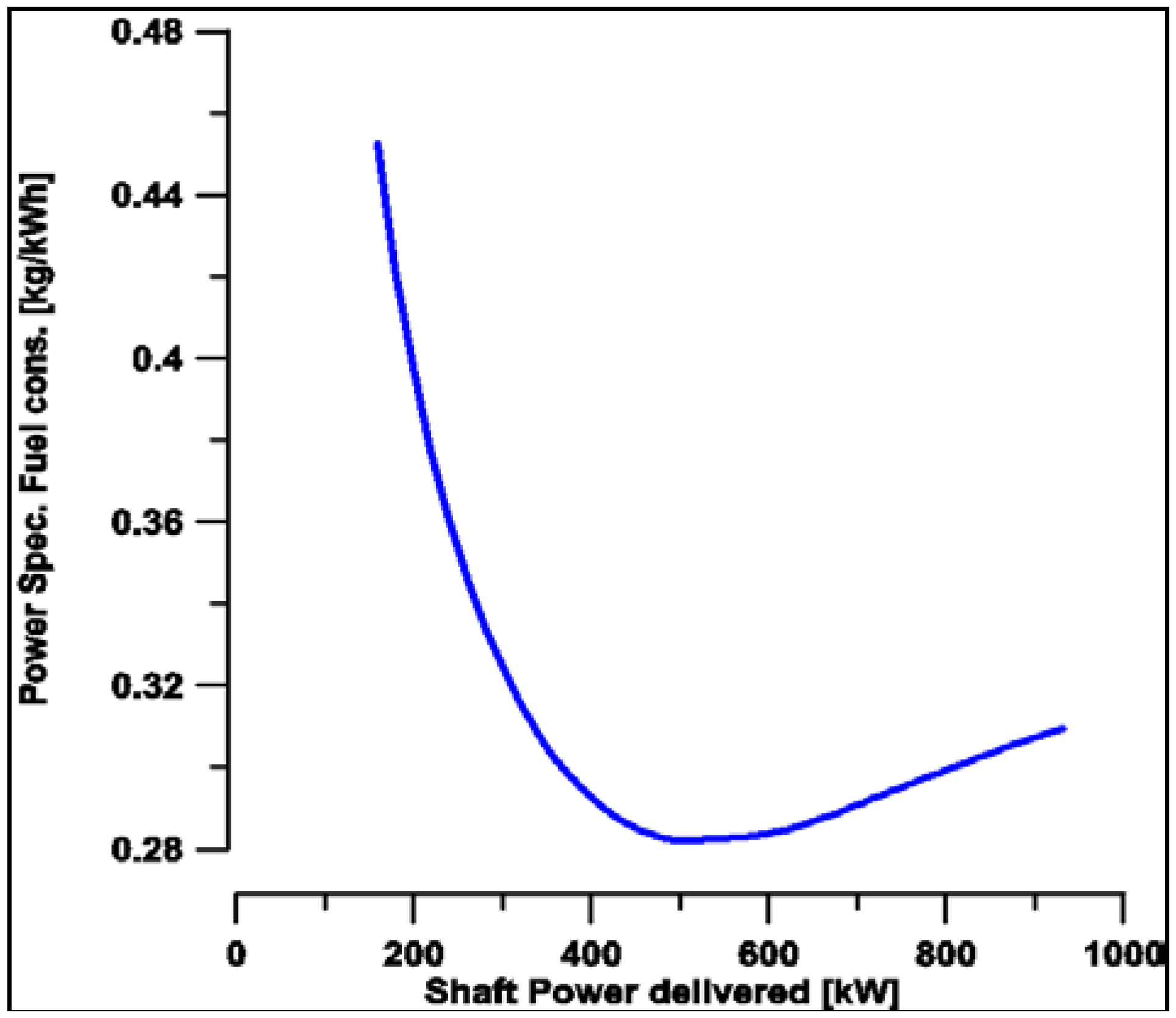

| BSFC (kg/kWh) | brake-specific fuel consumption |

| DDC,max | maximum duty ratio of the DC–DC converter |

| Δ (J/kg) | energy density of cell |

| Eele,req (J) | total electrical energy required during the flight |

| EI (g/kg) | emission index |

| EMs | electric motors |

| F (N) | thrust |

| HP | high pressure |

| h (m) | altitude |

| HEPS | hybrid electric propulsion systems |

| LP | low pressure |

| ICE | internal combustion engine |

| Ibatt (A) | current of a battery cell |

| Imax,disch (A) | maximum discharge current of a battery cell |

| LTO | landing take-off |

| M | Mach number (-) |

| MTOW (kg) | max take-off weight |

| mcell (kg) | mass of a single cell |

| np | number of parallel branches of battery storage system |

| ns | number of series cells of battery pack |

| p (kPa) | pressure |

| Qb (Ah) | cell capacity |

| Rb (Ω) | cell resistance |

| S (g/kg) | severity parameter |

| SOC | state of charge |

| SNOX (g/kg) | NOX severity parameter |

| TIT (K) | turbine inlet temperature |

| TOC | top of climb |

| T/O | take-off |

| t0 (s) | initial time instant of hybrid flight |

| tfin (s) | final time instant of hybrid flight |

| VDC,link (V) | DC-link voltage |

| Vout,batt (V) | output voltage of battery pack |

| ηg | global efficiency of electrical power-train |

References

- ICAO Enviromental Report 2010 Aviation and Climate Change. Available online: https://www.icao.int/environmental-protection/Documents/Publications/ENV_Report_2010.pdf (accessed on 31 October 2018).

- Advisory Council for Aeronautical Research in Europe (ACARE). European Aeronautics: A Vision for 2020. Available online: https://www.acare4europe.org/sites/acare4europe.org/files/document/Vision%202020_0.pdf (accessed on 31 October 2018).

- Pornet, C.; Isikveren, A.T. Conceptual design of hybrid-electric transport aircraft. Prog. Aerosp. Sci. 2015, 79, 114–135. [Google Scholar] [CrossRef]

- Cameretti, M.C.; Del Pizzo, A.; Di Noia, L.P.; Ferrara, M. Preliminary analysis of Hybrid-Electric propulsion system integrated in a regional aircraft. In Proceedings of the AEIT Congress, Bari, Italy, 3–5 October 2018. [Google Scholar]

- Frosina, E.; Senatore, A.; Palumbo, L.; Di Lorenzo, G.; Pascarella, C. Development of a lumped parameter model for an aeronautic hybrid-electric propulsion system. Aerosp. J. 2018, 5, 105. [Google Scholar] [CrossRef]

- Frosina, E.; Senatore, A.; Caputo, C.; Marinaro, G.; Di Lorenzo, G.; Pascarella, C. Modelling of a hybrid-electric light aircraft. Energy Proced. 2017, 126, 1155–1162. [Google Scholar] [CrossRef]

- Perullo, C.; Mavris, D. A review of hybrid-electric energy management and its inclusion in vehicle sizing. Aircraft Eng. Aerosp. Technol. 2014, 86, 550–557. [Google Scholar] [CrossRef]

- Friedrich, C.; Robertson, P.A. Hybrid electric-propulsion for automotive and aviation applications. CEAS Aeronaut. J. 2015, 6, 279–290. [Google Scholar] [CrossRef]

- Pornet, C.; Kaiser, S.; Isikveren, A.T.; Hornung, M. Integrated fuel-battery hybrid for a narrow-body sized transport aircraft. Aircraft Eng. Aerosp. Technol. 2014, 86, 568–574. [Google Scholar] [CrossRef]

- Müller, C.; Kieckhäfer, K.; Spengler, T.S. The influence of emission thresholds and retrofit options on airline fleet planning: An optimization approach. Energy Policy J. 2017. [Google Scholar] [CrossRef]

- Baharozu, E.; Soykan, G.; Baris Ozerdem, M. Future aircraft concept in terms of energy efficiency and environmental factors. Energy 2017, 140, 1368–1377. [Google Scholar] [CrossRef]

- Thauvin, J.; Barraud, G.; Roboam, X.; Sareni, B.; Budinger, M.; Leray, D. Hybrid propulsion for regional aircraft: A comparative analysis based on energy efficiency. In Proceedings of the ESARS-ITEC 2016, Toulouse, France, 2–4 November 2016. [Google Scholar]

- Friedrich, C.; Robertson, P.A. Hybrid-electric propulsion for aircraft. J. Aircr. 2015, 52, 176–189. [Google Scholar] [CrossRef]

- Gladin, J.; Trawick, D.; Perullo, C.; Tai, J.C.M.; Mavris, D.N. Modeling and design of a Partially electric distributed aircraft propulsion system with GT-HEAT. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar]

- Lenssen, R.H. Series Hybrid Electric Aircraft: Comparing the Well-to-Propeller Efficiency with a Conventional Propeller Aircraft. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2016. [Google Scholar]

- Seitz, A.; Schmitz, O.; Isikveren, A.T.; Hornung, M. Electrically powered propulsion: Comparison and contrast to gas turbines. In Proceedings of the Deutscher Luft- und Raumfahrtkongress 2012, Berlin, Germany, 10–12 September 2012. ID: 281358. [Google Scholar]

- Bradley, M.; Droney, C.; Gowda, S.; Kirby, M.; Paisley, D.; Roth, B. NASA N+3 Subsonic Ultra Green Aircraft Research SUGAR Final Review; Boeing Research and Technology Presentation, Boeing Airplane Company; NASA: Washington, DC, USA, 2010.

- Masson, P.J.; Brown, G.V.; Soban, D.S.; Luongo, C.A. HTS machines as enabling technology for all-electric airborne vehicles. Supercond. Sci. Technol. 2007, 20, 748–756. [Google Scholar] [CrossRef]

- Brown, G.V. Weights and efficiencies of electric components of a turboelectric aircraft propulsion system. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011. [Google Scholar]

- Kuhn, H.; Seitz, A.; Lorenz, L.; Isikveren, A.T.; Sizmann, A. Progress and perspectives of electric air transport. In Proceedings of the 28th International Congress of the Aeronautical Sciences (ICAS), Brisbane, Australia, 23–28 September 2012. [Google Scholar]

- ART First Generation. Available online: http://www.atraircraft.com/products_app/media/pdf/ATR_42-300-320.pdf (accessed on 31 October 2018).

- Specific Range Solutions Ltd. Parametric Specific Fuel Consumption Analysis of the PW120A Turboprop Engine. Available online: http://www.srs.aero/wordpress/wp-content/uploads/2009/03/srs-tsd-002-rev-1-pw120a-sfc-analysis.pdf (accessed on 31 October 2018).

- Flightradar 24. Available online: https://www.Flightradar24.Com/How-It-Works (accessed on 31 October 2018).

- Hull, D.G. Fundamentals of Airplane Flight Mechanics; Springer: New York, NY, USA, 2007. [Google Scholar]

- Committee of Aeronautical Technologies; Aeronautics and Space Engineering Board; Commission on Engineering and Technical Systems; National Research Council. Aeronautical Technology for the 21st Century; National Academy Press: Washington, DC, USA, 1992. [Google Scholar]

- Di Noia, L.P.; Rizzo, R. Design of a five-phase permanent-magnet motor for the electric steering of an aircraft nose landing gear. IET Electr. Syst. Transp. 2017, 7, 327–333. [Google Scholar] [CrossRef]

- Brando, G.; Dannier, A.; Del Pizzo, A.; Coppola, M. An all-electric-aircraft tailored SiC-based power factor correction converter with adaptive DC-link regulator. Energies 2017, 10, 1227. [Google Scholar] [CrossRef]

- Military Standard. Aircraft Electric Power Characteristics; Department of Defense Interface Standard (MIL-STD-704); United States Department of Defense: Arlington, VA, USA, 2004.

- Nya, B.H.; Brombach, J.; Schulz, D. Benefits of higher voltage levels in aircraft electrical power systems. In Proceedings of the 2012 Electrical Systems for Aircraft, Railway and Ship Propulsion, Bologna, Italy, 16–18 October 2012; pp. 1–5. [Google Scholar]

- Brombach, J.; Lücken, A.; Nya, B.; Johannsen, M.; Schulz, D. Comparison of different electrical HVDC-architectures for aircraft application. In Proceedings of the 2012 Electrical Systems for Aircraft, Railway and Ship Propulsion, Bologna, Italy, 16–18 October 2012; pp. 1–6. [Google Scholar]

- Berdowski, Z.; van den Broek-Serlé, F.N.; Jetten, J.T.; Kawabata, Y.; Schoemaker, J.T.; Versteegh, R. Survey on Standard Weights of Passengers and Baggage; Report No.: EASA 2008.C.06/30800/R20090095/30800000/FBR/RLO; EASA: Cologne, Germany, 2009. [Google Scholar]

| Max T/O Power at Sea Level (kW) | Overall Pressure Ratio (T/O) | T/O Power at Sea Level (kW) | BSFC (T/O) (kg/kWh) | Max Cruise Power (kW) | Max Cruise TIT (°C) | Compressor Mass Flow (T/O) (kg/s) |

|---|---|---|---|---|---|---|

| 1491 | 12.1 | 1342 | 0.286 | 1231 | 1193 | 6.7 |

| Input Data for Simulation | |||

|---|---|---|---|

| Input Data for Engine1 | Input Data for Flight Power Calculation | ||

| Altitude | 0 | Zero-Lift Drag Coefficient | 0.025 |

| Overall Pressure Ratio (T/O) | 12.1 | Aspect Ratio | 11.08 |

| Compressor Mass Flow (T/O) | 6.7 kg/s | Oswald Factor | 0.85 |

| Mach Number | 0.166 | Wing Area | 54.5 m2 |

| Burner Exit Temperature (TIT) | 1193 °C | Maximum Take-Off Weight | 16,900 |

| Burner Efficiency | 0.995 | ||

| Burner Pressure Ratio | 0.97 | ||

| Fuel Heating Value | 43.1 MJ/kg | ||

| Overboard Bleed | 0.2 | ||

| HP Spool Mechanical Efficiency | 0.99 | ||

| LP Spool Mechanical Efficiency | 0.98 | ||

| Nominal Spool Speed | 29,800 rpm | ||

| Engine Model | PW120A (Engine1) | Engine_2 | Engine_3 |

|---|---|---|---|

| Max Power (kW) | 1491 | 1268 | 930 |

| Weight (kg) | 417 | 270 | 251 |

| Power density (kW/kg) | 3.6 | 4.7 | 3.7 |

| ESFC (kg/kWh) | 0.286 | 0.267 | 0.300 |

| Air mass flow (kg/s) | 6.7 | 6.0 | 5.3 |

| Pressure ratio | 12.1 | 12.5 | 11.0 |

| Δ2 (%) | Δ2_SFCmin (%) | ||

|---|---|---|---|

| CO2 | Take-Off, Climbing | −13.0 | −13.0 |

| Cruise | 3.11 | −12.8 | |

| Descent Landing | −9.94 | −10.3 | |

| Mission | −2.81 | −12.4 | |

| NOx | Take-Off, Climbing | −11.6 | −11.6 |

| Cruise | 38.0 | −11.1 | |

| Descent Landing | −6.51 | −8.19 | |

| Mission | 19.0 | −10.8 | |

| Fuel Consumption | Take-Off, Climbing | −13.0 | −13.0 |

| Cruise | 3.11 | −12.8 | |

| Descent Landing | −9.94 | −10.3 | |

| Mission | −2.81 | −12.4 |

| Δ3 (%) | ||

|---|---|---|

| CO2 | Take-Off, Climbing | −28.84 |

| Cruise | −28.46 | |

| Descent Landing | −24.59 | |

| Mission | −27.79 | |

| NOx | Take-Off, Climbing | −40.72 |

| Cruise | −40.02 | |

| Descent Landing | −34.03 | |

| Mission | −39.42 | |

| Fuel Consumption | Take-Off, Climbing | −28.84 |

| Cruise | −28.46 | |

| Descent Landing | −24.59 | |

| Mission | −27.79 |

| Type of Cells | Vn (V) | Capacity (Ah) | Internal Resistance (mΩ) | Mass of a Single Cell (kg) | Max Continuous Discharge Current |

|---|---|---|---|---|---|

| Cell-1 | 25.2 | 12 | 2.8 | 1.19 | 2 C |

| Cell-2 | 3.6 | 16 | 3.8 | 0.34 | 5 C |

| Cell-3 | 3.6 | 16 | 1.1 | 0.41 | 8 C |

| Cell-4 | 3.6 | 11 | 1.6 | 0.280 | 8 C |

| Cell-5 | 3.6 | 70 | 0.6 | 1.74 | 5 C |

| Cell-6 | 3.6 | 75 | 0.6 | 1.78 | 8 C |

| Cell-7 | 3.7 | 3.3 | 37 | 0.048 | 2 C |

| Cell-8 | 3.7 | 4.25 | 37 | 0.063 | 3 C |

| Cell-9 | 3.7 | 4.7 | 10 | 0.069 | 3 C |

| np | ns | Total Mass (kg) | np | ns | Total Mass (kg) | ||

|---|---|---|---|---|---|---|---|

| 270 V | 540 V | ||||||

| Cell-1 | 126 | 3 | 450 | Cell-1 | 42 | 9 | 450 |

| Cell-2 | 24 | 58 | 473 | Cell-2 | 13 | 107 | 473 |

| Cell-3 | 24 | 58 | 565 | Cell-3 | 13 | 107 | 564 |

| Cell-4 | 46 | 44 | 567 | Cell-4 | 17 | 119 | 566 |

| Cell-5 | 6 | 53 | 553 | Cell-5 | 3 | 106 | 553 |

| Cell-6 | 9 | 33 | 529 | Cell-6 | 3 | 99 | 529 |

| Cell-7 | 291 | 33 | 461 | Cell-7 | 99 | 97 | 461 |

| Cell-8 | 76 | 69 | 330 | Cell-8 | 40 | 131 | 330 |

| Cell-9 | 64 | 74 | 327 | Cell-9 | 64 | 74 | 327 |

| np | ns | Total Mass (kg) | np | ns | Total Mass (kg) | ||

|---|---|---|---|---|---|---|---|

| 270 V | 540 V | ||||||

| Cell-1 | 159 | 6 | 1135 | Cell-1 | 53 | 18 | 1135 |

| Cell-2 | 91 | 55 | 1702 | Cell-2 | 91 | 55 | 1702 |

| Cell-3 | 77 | 65 | 2032 | Cell-3 | 77 | 65 | 2032 |

| Cell-4 | 280 | 26 | 2038 | Cell-4 | 70 | 104 | 2038 |

| Cell-5 | 22 | 52 | 1991 | Cell-5 | 11 | 104 | 1991 |

| Cell-6 | 21 | 51 | 1906 | Cell-6 | 12 | 89 | 1901 |

| Cell-7 | 328 | 74 | 1165 | Cell-7 | 296 | 82 | 1165 |

| Cell-8 | 248 | 76 | 1187 | Cell-8 | 304 | 62 | 1187 |

| Cell-9 | 426 | 40 | 1176 | Cell-9 | 284 | 60 | 1176 |

| np | ns | Total Mass (kg) | np | ns | Total Mass (kg) | ||

|---|---|---|---|---|---|---|---|

| 270 V | 540 V | ||||||

| Cell-1 | 228 | 11 | 2854 | Cell-1 | 141 | 17 | 2852 |

| Cell-2 | 286 | 44 | 4279 | Cell-2 | 104 | 122 | 4279 |

| Cell-3 | 233 | 54 | 5108 | Cell-3 | 233 | 54 | 5108 |

| Cell-4 | 286 | 64 | 5125 | Cell-4 | 176 | 104 | 5125 |

| Cell-5 | 137 | 21 | 5006 | Cell-5 | 21 | 137 | 5006 |

| Cell-6 | 34 | 79 | 4781 | Cell-6 | 34 | 79 | 4781 |

| Cell-7 | 1017 | 60 | 2929 | Cell-7 | 496 | 123 | 2928 |

| Cell-8 | 817 | 58 | 2985 | Cell-8 | 336 | 141 | 2985 |

| Cell-9 | 1530 | 28 | 2956 | Cell-9 | 354 | 121 | 2956 |

| Engine_2 | Engine2_SFCmin | Engine3_SFCmin | |

|---|---|---|---|

| NNRP | 7 | 22 | 54 |

| Engine_2 | Engine2_SFCmin | Engine3_SFCmin | |

|---|---|---|---|

| NNRP | 6 | 20 | 49 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cameretti, M.C.; Del Pizzo, A.; Di Noia, L.P.; Ferrara, M.; Pascarella, C. Modeling and Investigation of a Turboprop Hybrid Electric Propulsion System. Aerospace 2018, 5, 123. https://doi.org/10.3390/aerospace5040123

Cameretti MC, Del Pizzo A, Di Noia LP, Ferrara M, Pascarella C. Modeling and Investigation of a Turboprop Hybrid Electric Propulsion System. Aerospace. 2018; 5(4):123. https://doi.org/10.3390/aerospace5040123

Chicago/Turabian StyleCameretti, Maria Cristina, Andrea Del Pizzo, Luigi Pio Di Noia, Michele Ferrara, and Ciro Pascarella. 2018. "Modeling and Investigation of a Turboprop Hybrid Electric Propulsion System" Aerospace 5, no. 4: 123. https://doi.org/10.3390/aerospace5040123

APA StyleCameretti, M. C., Del Pizzo, A., Di Noia, L. P., Ferrara, M., & Pascarella, C. (2018). Modeling and Investigation of a Turboprop Hybrid Electric Propulsion System. Aerospace, 5(4), 123. https://doi.org/10.3390/aerospace5040123