1. Introduction

Structural issues that have arisen because of aging aircraft have motivated a focus on the analytical tools needed to assess the growth of small naturally occurring material discontinuities and methods for extending the fatigue life of operational aircraft [

1,

2,

3,

4,

5]. In this context, Appendix X3 of the ASTM fatigue test standard E647-13a and [

6,

7,

8,

9,

10] indicate that the fatigue life of an operational aircraft is largely governed by the growth of cracks that nucleate and grow from small sub-mm material discontinuities. The NASGRO crack growth, expressed by Equation [

11], viz:

where

D,

m,

p and

q are constants,

is the cyclic fracture toughness, and

is defined as an apparent fatigue threshold which is dependent on the crack length and the

ratio, is perhaps the most widely used crack growth equation. A problem with Equation (1) is that the constants

D,

m,

p and

q are not unique, i.e., they are a function of the crack length. Consequently, in order to assess the crack growth in operational aircraft the challenge is to obtain a form of the NASGRO equation where this “artificial” crack length dependency vanishes. In this context, Ritchie, Yu, Blom and Holm [

12], and subsequently [

4], explained that the

da/

dN versus Δ

K relationship associated with the growth of cracks from small naturally occurring defects follows from long crack data by removing the effect of crack closure and other crack tip shielding effects. This is achieved by adopting the Hartman-Schijve variant of the NASGRO crack growth equation [

2,

3,

4,

5,

10,

13,

14,

15,

16] by setting

m = p and

q =

p/2. This yields

When expressed in this form, the Hartman-Schijve variant of the NASGRO equation not only captures the long crack

da/

dN versus Δ

K relationship but the same formulation with the same values of

D and

p and

q and with, as per Appendix X3 of the ASTM fatigue test standard E647-13a, Δ

Kthr set to a small value (for small cracks, Appendix X3 questions the existence of a fatigue threshold) also captures the small crack

da/

dN versus Δ

K relationship, and can be used to accurately predict the growth of small naturally occurring cracks under operational (variable amplitude) flight load spectra [

2,

3,

4,

5,

10,

13,

14,

15,

16]. As such, Equation (2) represents a form of the NASGRO equation that, with the values of

D,

m (=

p),

p and

q (=

p/2) held constant, can be used to compute the growth of both long cracks and also naturally occurring cracks under operational flight loads. To the best of the authors’ knowledge, Equation (2) is the only form of the NASGRO equation that both fulfils the Ritchie, Yu, Blom and Holm requirement and has also been shown to capture the growth of small sub mm cracks under a large number of operational flight load spectra, viz: combat aircraft, civil aircraft, maritime aircraft, etc. [

2,

5,

10,

13,

16]. Furthermore, to the best of the authors’ knowledge, Equation (2) is the only form of the NASGRO equation that has been shown to capture crack growth in AM Ti-6Al-4V fabricated in a wide range of AM processes [

17]. With this in mind, and since if AM is to be used for replacement parts on operational aircraft the ability to assess the parts’ performance under operational flight loads is essential, this paper focuses on the use of Equation (2) to represent crack growth in a range of AM materials.

An additional feature of the Hartman-Schijve equation [

18], i.e., Equation (2), is that, for traditionally manufactured structures and for structures repaired using either externally bonded composite patches or using additively metal deposition, the scatter in the

versus

curves is captured by allowing for the variability in the term

[

3,

4,

10,

13,

14,

15,

16]. Furthermore, as discussed in [

4,

10,

16], the

versus

curve needed to assess the growth of small naturally occurring cracks often can be determined from the corresponding

versus

long crack curve by setting the term

to a small value, typically of the order of 0.1–0.2 MPa

.

Reference [

16] also indicated that while it is commonly believed that two materials with different microstructures will have different (long crack)

versus

curves, the experimental data suggest that this is not necessarily true. Furthermore, as shown in [

16], even if the growth of long cracks in two materials with different microstructures have different

versus

curves, the corresponding small crack curves can be similar [

16].

We also know [

19,

20,

21,

22,

23] that the Hartman-Schijve equation, i.e., Equation (2) with the term

replaced by

and

replaced by

where

is the energy release rate (for metals,

is linearly proportional to

), also holds for cracking in adhesives and delamination growth in both composites and nano-composites. It is also known [

20,

21] that the large scatter seen in the delamination growth curves is also captured by allowing for the variability in the term

and the effect of the test protocol on the cyclic fracture toughness term

.

With these in mind, and noting that the US Navy has announced [

24] that the US Navy aircraft carrier John C. Stennis will become the first US Navy ship to have an advanced manufacturing lab, which will have four 3D printers, the present paper focuses on the topic of the use of AM to ensure continued aircraft availability. There are several ways for this to be achieved, viz:

The repair of damage using additive metal technologies [

25,

26,

27,

28], or by utilizing multiplicative manufacturing [

29], which involves the combination of both additive and subtractive manufacturing.

The replacement of damaged components with additively manufactured parts [

30].

In this context, References [

25,

26,

27,

28] have shown how additive metal technology can be used to:

Restore the load-carrying capacity of corroded wing skins;

Restore the load-carrying capacity of rib-stiffened wing skins with stress corrosion cracking in the ribs;

Seal fasteners and thereby help alleviate the effect of environmental damage;

Help alleviate the effect of multi-site damage in fuselage lap joints;

Increase the fatigue life of wing skins with intergranular cracking at fastener holes; and

Withstand approximately three lifetimes, without cracking or delamination from the airframe, when applied to an F/A-18 center barrel fatigue test article subjected to a measured (operational) flight load spectra.

We have also shown [

5] that crack growth in structures repaired using additive metal technology can be accurately modelled using the Hartman-Schijve crack growth equation, i.e., Equation (2). Consequently, the present paper focuses on the ability of Equation (2) to model crack growth in AM Ti-6Al-4V, AM 316L stainless steel and AM AerMet100 steel. To this end, the present paper builds on the authors’ prior work [

17] where it was shown that, regardless of whether the AM process is:

Electron Beam Melting (EBM);

Direct Metal Laser Sintering (DMLS);

Selective Laser Melt (SLM);

Hot Isostatic Pressing (HIP);

Laser engineered Net Shaping (LENS);

whether the LENS process is low- or high-power;

whether the build direction was horizontal or vertical.

The versus curves, obtained using tests performed as described in the main body of the ASTM E-64-13a fatigue test standard, can be represented reasonably well by the Hartman-Schijve variant of the NASGRO crack growth equation, i.e., Equation (2), with allowance made for changes in the terms and . This finding mimics that discussed above for modelling the variability in the crack growth curves seen in conventionally manufactured metallic structures, structures repaired using additive metal deposition and for modelling the variability of delamination/disbond growth in composite and bonded structures.

The experimental data presented in this paper indicate that for the materials studied (namely AM Ti-6Al-4V, AM 316L stainless steel, and AM AerMet100 steel) the corresponding versus ΔK curves can be represented reasonably well by the Hartman-Schijve variant of the NASGRO crack growth equation. It is also shown that the variability in the various AM versus curves is captured reasonably well by using the curve determined for conventionally manufactured materials and allowing for changes in the threshold and the cyclic fracture toughness terms.

2. Crack Growth in Additively Manufactured Ti-6AL-4V

While AM offers the potential to economically fabricate customized parts with complex geometries, Reference [

31] explained that the mechanical behavior of these materials must be better understood (related statements can be found in the US Federal Aviation Administration review paper [

32], as well as in [

17,

33]) before AM can be utilized for critical load-bearing applications. This is particularly true for aircraft applications where, as detailed in MIL-STD 1530 [

34], the design and certification approval requires analytical tools that are capable of modelling crack growth.

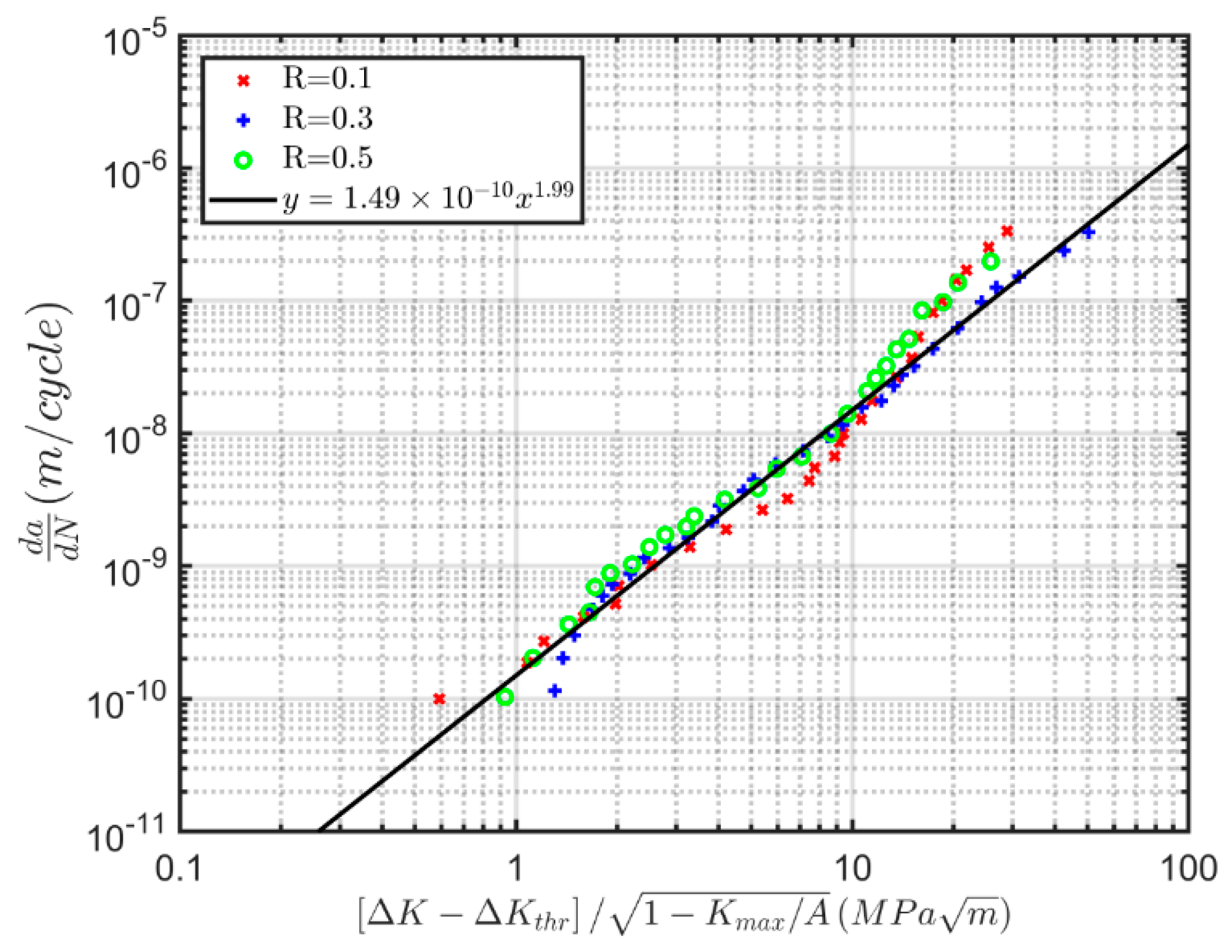

Reference [

32] revealed the

versus

curves associated with crack growth in 34 different AM Ti-6Al-4V tests, which covered a wide range of AM processes including EBM, DML, SLM, HIP, and LENS, could be represented using the Hartman-Schijve, viz:

In this study, the constants

and

were determined using a global optimization scheme that was based on a latin hypercubes approach. The objective function used in the scheme was:

where

is the number of tests,

is an index representing the

th test,

is the value of

for test

,

is the number of data points of test

,

is an index representing the

th data point of test

,

is the value of

for the

th test for the

th data point and similarly

is the relevant data value of

. The objective function defined in Equation (4) was chosen such that it provides a measure of fit quality. Specifically, this value represents the average absolute error of the exponent base 10 of the fit to the measured

data. For each data point we can, in addition, establish the exponent error metric, as follows:

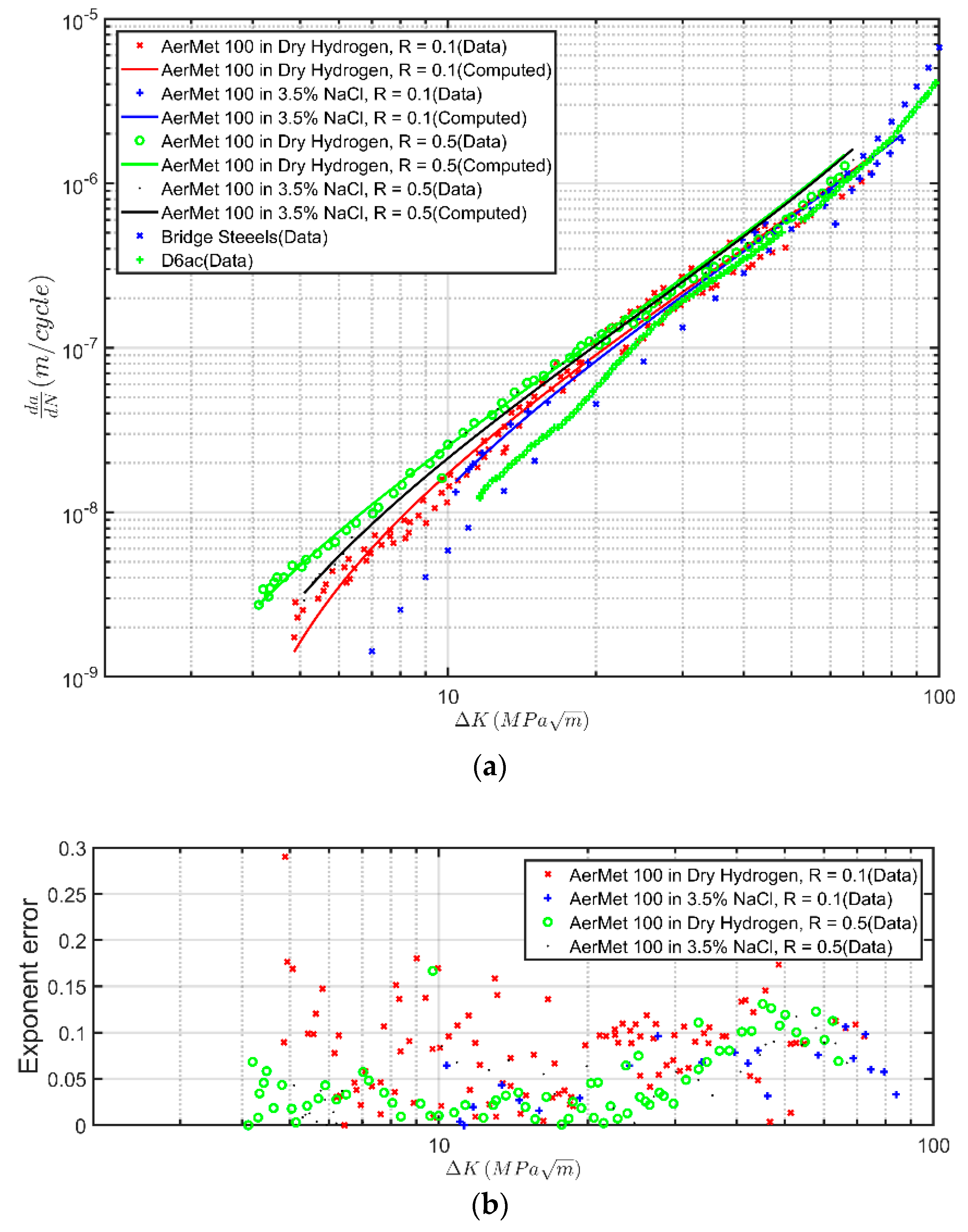

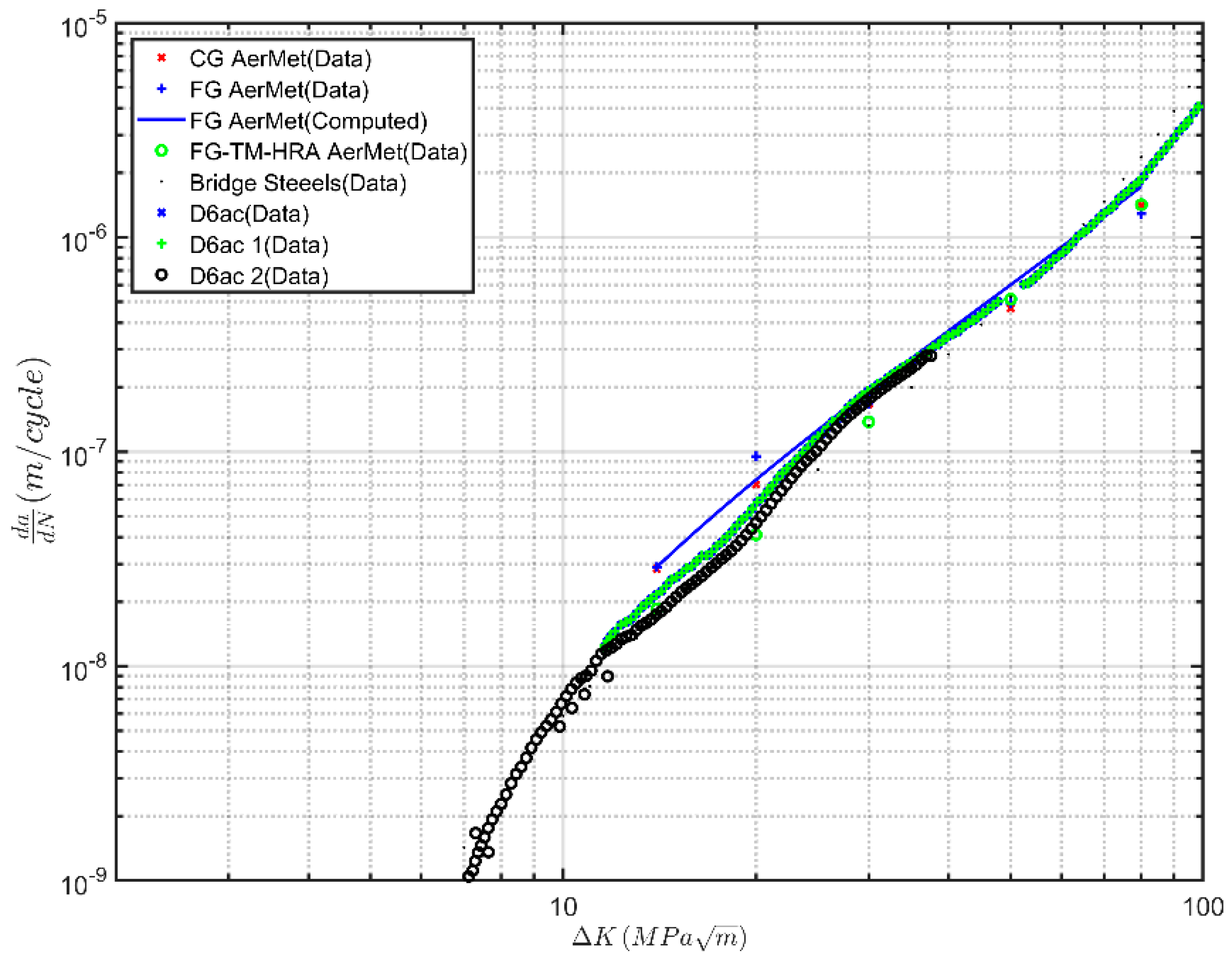

The expression presented by Equation (5) can be plotted to provide a visual depiction of the goodness-of-fit associated with the various instances Equation (2). In this section, we first show that the AM Ti-6Al-4V crack growth data presented in [

35,

36,

37], which were not studied in [

17], also conform to Equation (3).

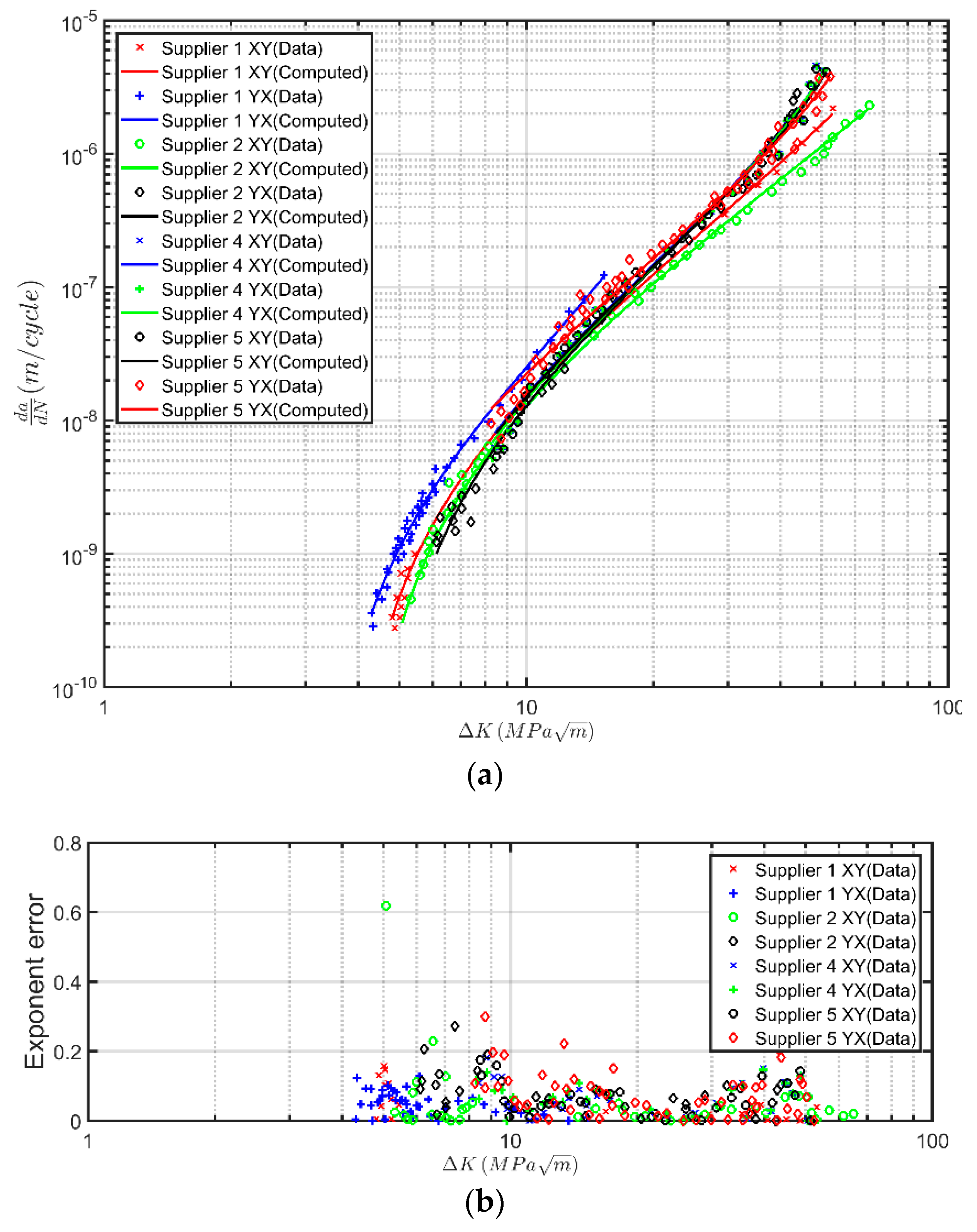

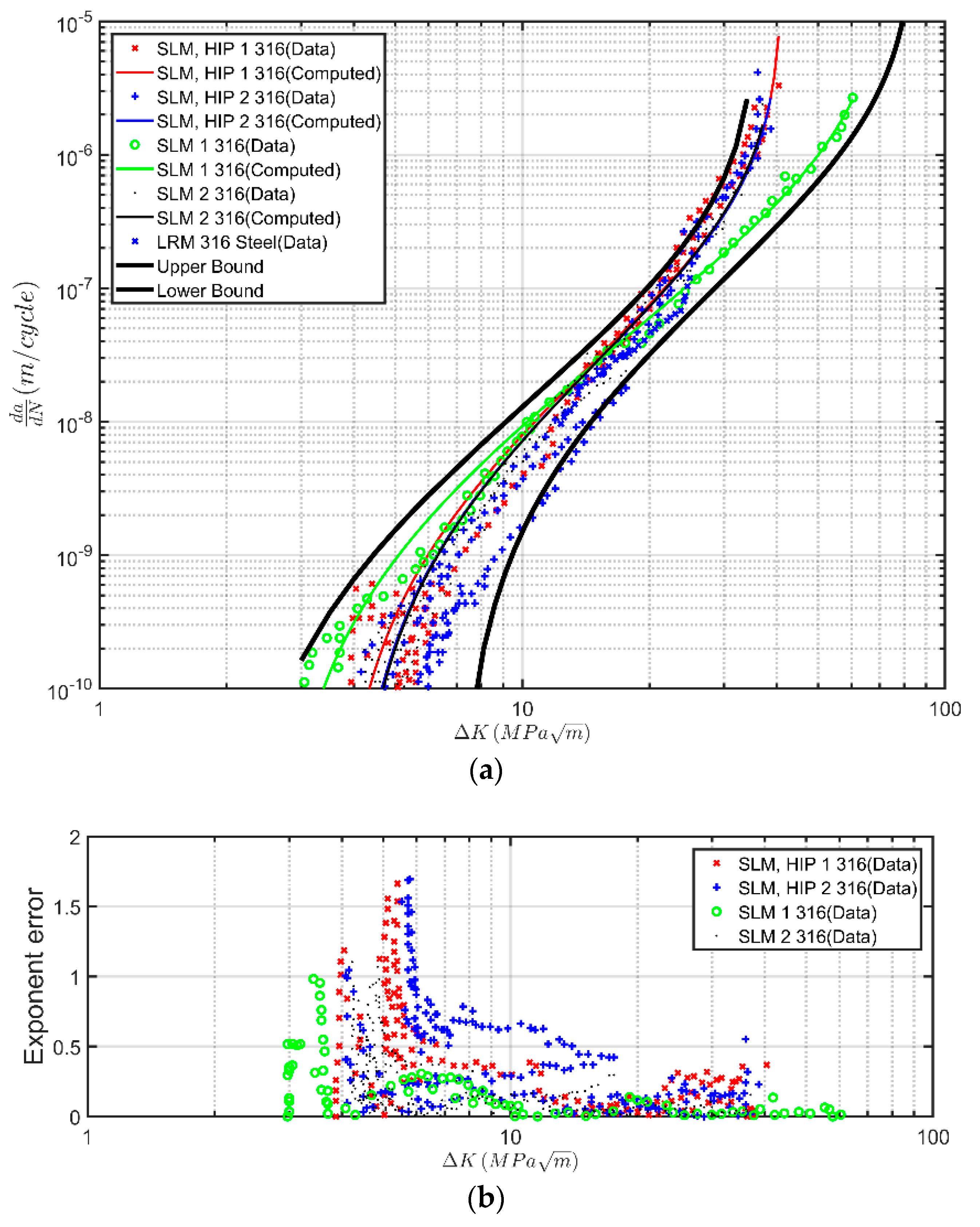

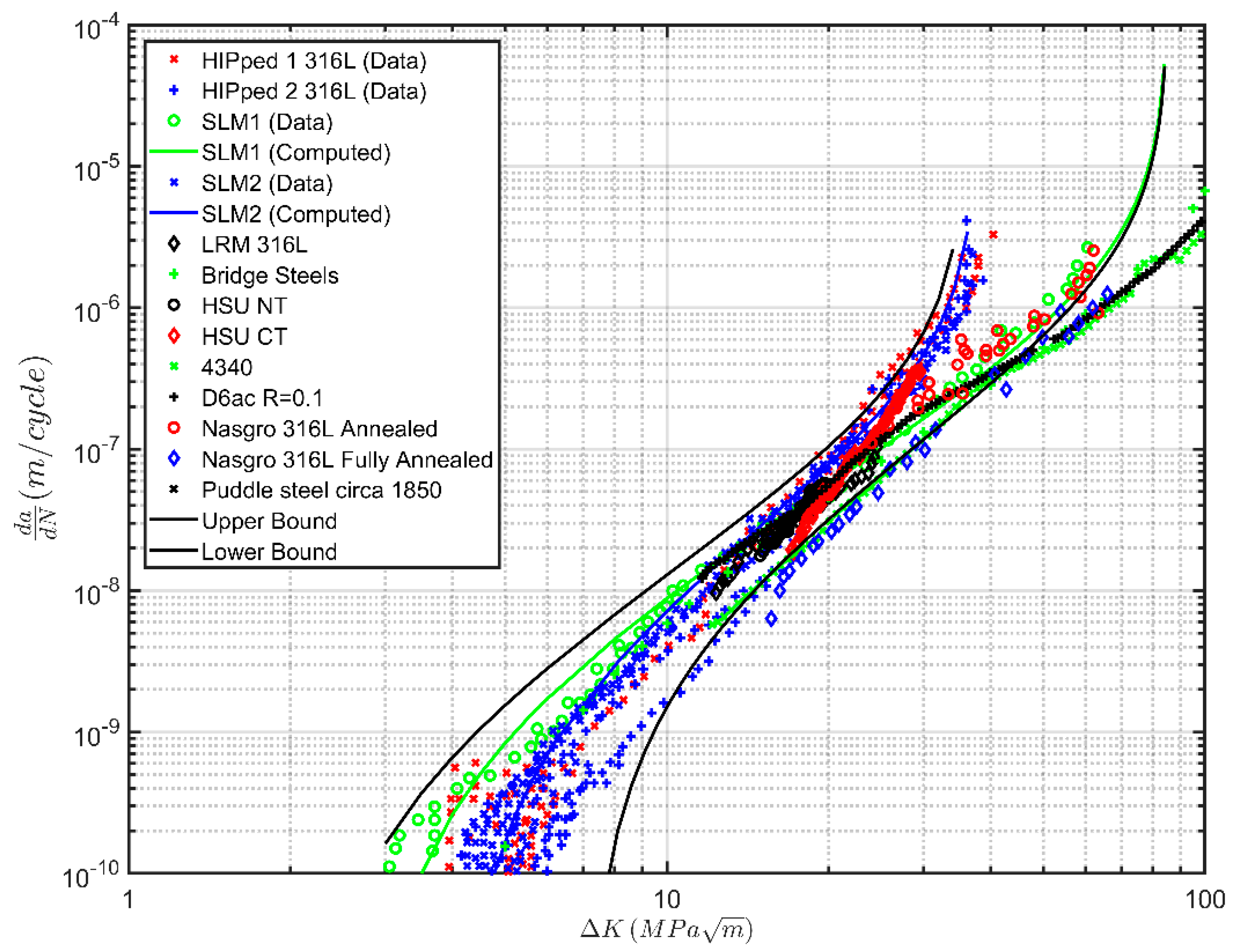

2.1. BELL Helicopter Crack Growth Data

Let us first consider the

versus

curves given by Bell Helicopters [

35] for crack growth in AM Ti-6Al-4V samples that were obtained from several different suppliers, see

Figure 1a. Although [

35] does specifically state what AM process was used to manufacture the test specimens, it states that: “All builds were stress relieved and received Hot Isostatic Pressing (HIP) to ensure optimal mechanical properties”. Equation (3) was used to compute the curves associated with these tests. As per [

4,

10,

31], the values of

and

were chosen to fit the data. The values used are given in

Table 1. As can be seen in

Figure 1, the resultant computed curves are in excellent agreement with the measured data. Furthermore, the error plots of

Figure 1b indicate that the exponent error is well below 1.0, further corroborating the excellent agreement of the fitted parameters with the experimental data. It is interesting to note that the range of the threshold terms is similar to that obtained in [

31] for fatigue tests performed on a range of other AM Ti-6Al-4V specimens.

Table 1 reveals a large variability in the cyclic fracture toughness parameter A. It is postulated that this may be attributed to either lack of data at Region III that does not allow us to obtain estimates with high certainty, or to the nature of AM processes. Further investigation on this matter will be conducted in follow-up work.

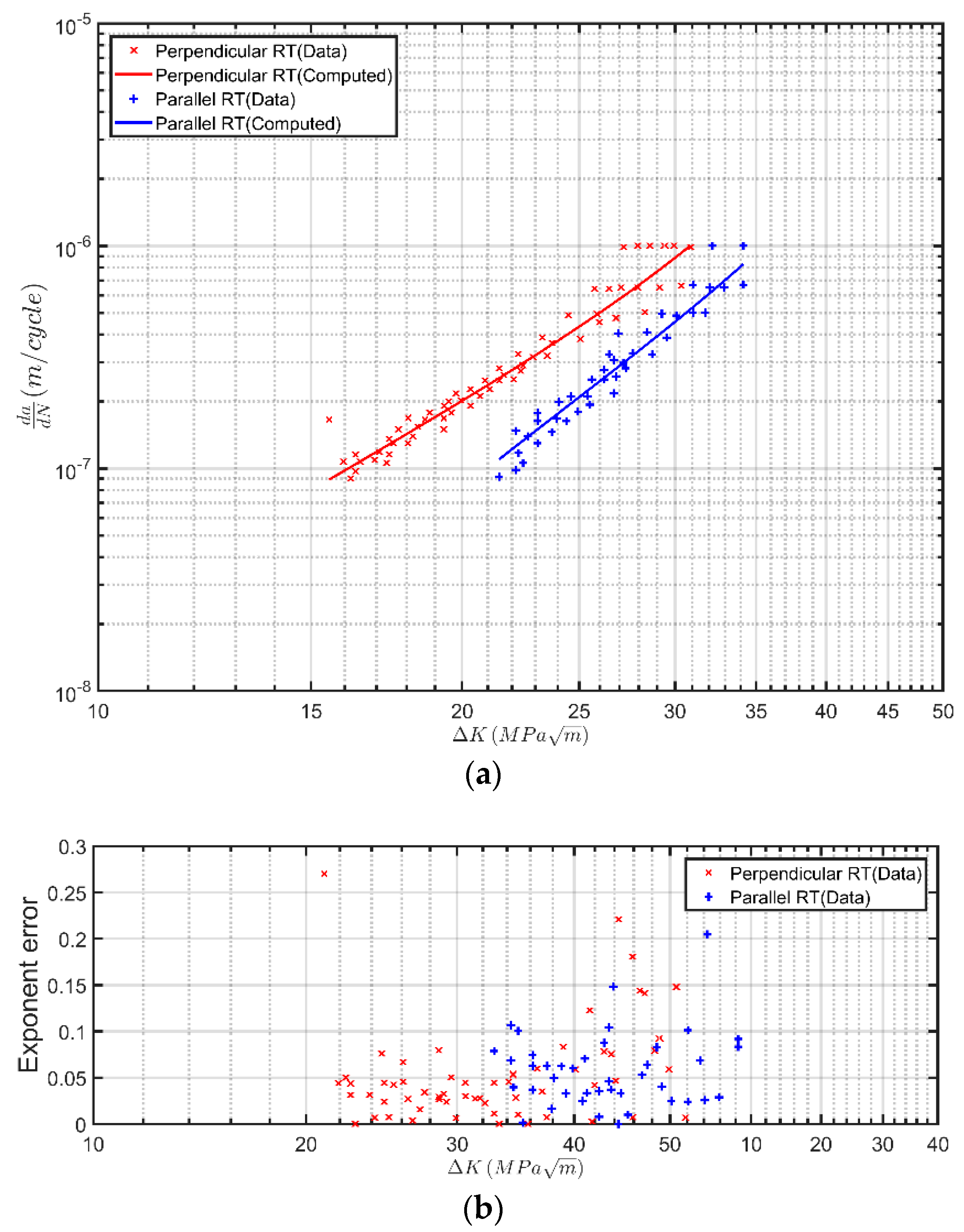

2.2. Laser Metal Wire Deposition (LMwD) Crack Growth Data

To further illustrate that crack growth in AM Ti-6Al-4V can be represented by Equation (3), consider the crack growth data given in [

36] for specimens fabricated using Laser Metal wire Deposition (LMwD). In LMwD, a laser heat source melts a metal wire into the desired shape, and it is, in general, an attractive AM process for larger structures in which a higher deposition rate is required. In these tests, an initial semi-circular fatigue crack, approximately 0.7 mm in depth (except for specimen (2), where the pre-crack was 1.2 mm deep), was created from the notch by cyclic loading at a stress ratio

, a frequency

Hz and a maximum stress of 500

. The tests were stopped at crack lengths around 2.5 mm, and the specimens were subsequently fractured in tension at room temperature.

Figure 2 presents the resultant room temperature

versus

curves for tests where crack growth was either parallel or perpendicular to the build direction. All specimens were post-weld heat-treated and annealed at 704 °C for 2 h and cooled in the furnace to 538 °C, after which the samples were taken out of the furnace and air cooled to room temperature. Reference [

36] stated that this heat treatment is not expected to introduce any significant changes to the microstructure. The specimen surfaces were not machined.

Equation (4) was again used through a global optimization scheme to compute these curves. The identified values of

and

A are given in

Table 2. As per References [

4,

10,

17], and as can be seen in the experimental data, the threshold values for these two tests differ. This is a somewhat expected result, since data are available only in the Paris region. As can be seen in

Figure 2a, the resultant computed curves are in reasonably good agreement with the measured data, an observation that is also corroborated by the error plots in

Figure 2b.

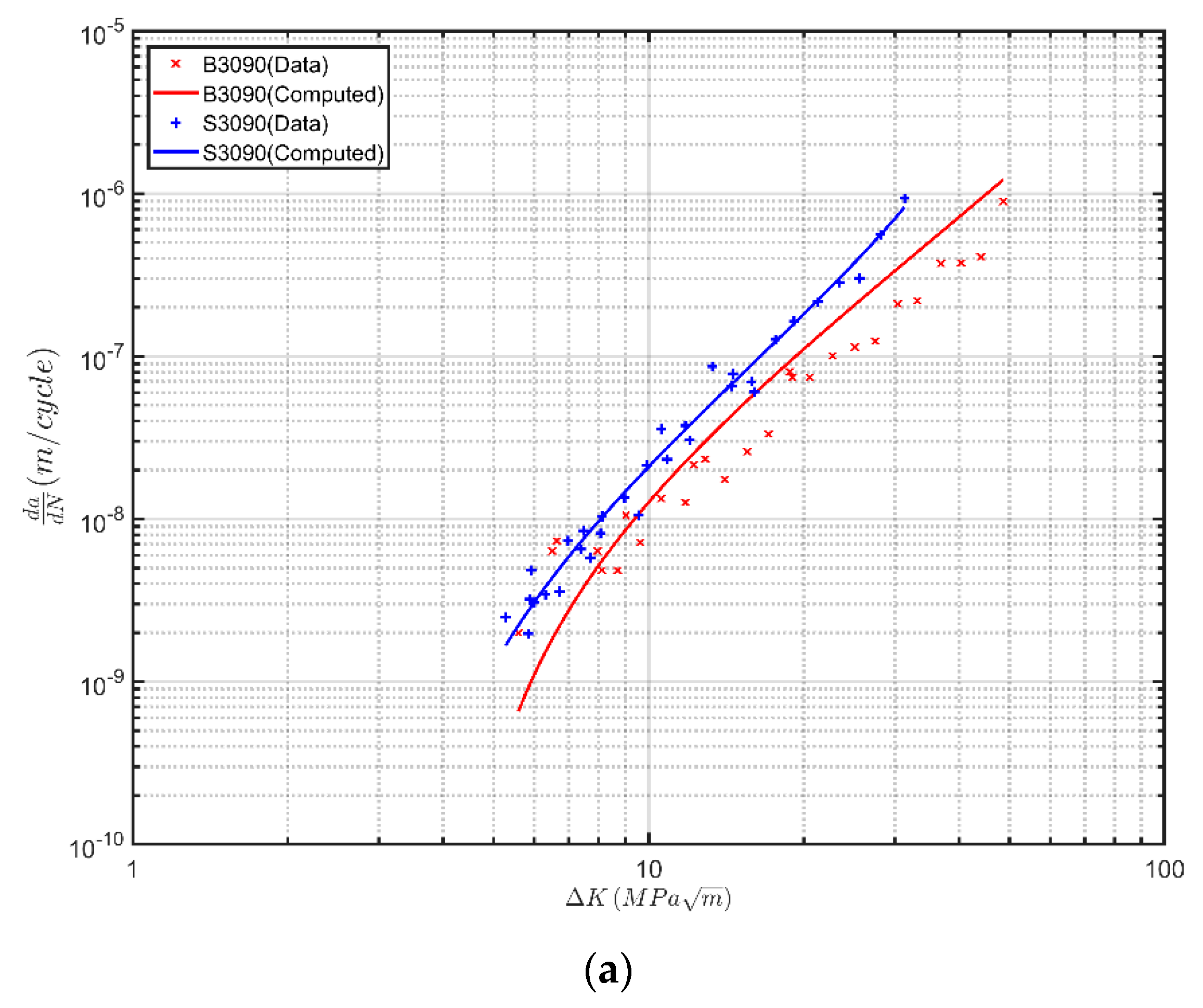

2.3. Boeing India Crack Growth Data

Next consider crack growth data presented by the Boeing India Research Centre [

37] for crack growth in SLM Ti-6AL-4V specimens B3090 and S3090, where growth was parallel to and perpendicular to the build direction, respectively. In these tests, the samples were stress relieved by annealing them at 650 °C for 3 h. The surfaces were not machined.

Figure 3 presents the measured growth data together with those presented in the Bell Helicopter and in the LMwD tests [

35,

36]. Here we see that these three different studies yielded similar

versus Δ

K data. It would therefore be expected that the Boeing India

versus

curves could again be represented as per [

4,

17] by Equation (3), albeit with similar values of

and

. To confirm this, the measured and predicted curves, using the values of

and

given in

Table 3, are shown in

Figure 4.

2.4. Small Crack Growth in LENS Ti-6Al-4V

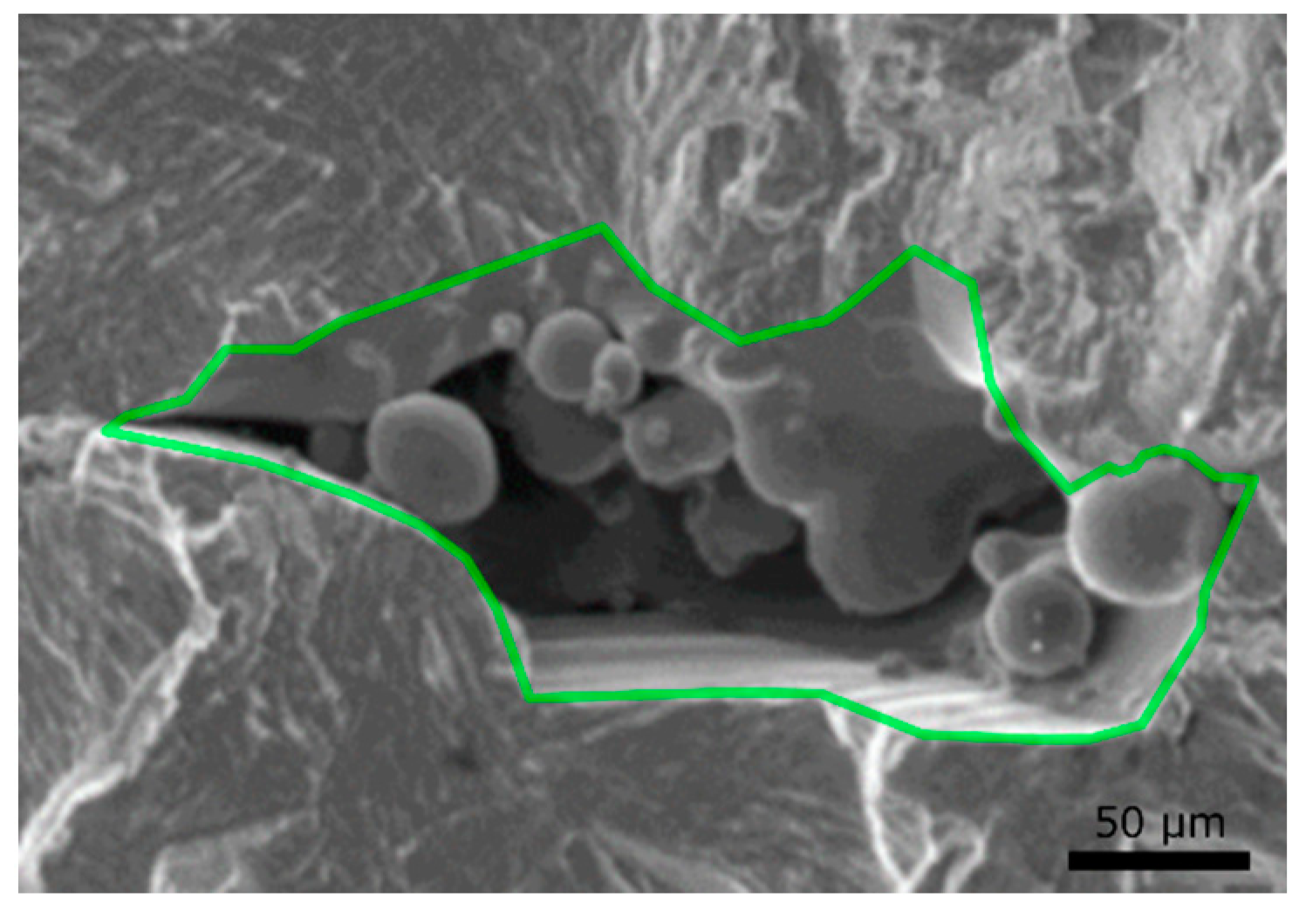

The paper by Zhai et al. [

38] noted that the use of long crack growth

versus

curves to estimate the fatigue life of AM components may be non-conservative (

Figure 5, from [

39], illustrates how cracks can initiate and grow from small sub-mm material discontinuities, in this case a lack of fusion).

As such, let us next consider the growth of sub mm cracks in AM Ti-6Al-4V. As previously noted [

2,

3,

4,

10,

13,

14,

15,

16], it has been shown that the growth of small cracks under both constant amplitude and operational flight load spectra can often be estimated from the Hartman-Schijve long crack representation, i.e., Equation (3), by setting the threshold term

to a small value, typically of the order of 0.1

. As such, the results presented in [

17] suggest that small crack growth in Mil Annealed Ti-6Al-4V should (approximately) conform to Equation (6):

To this end,

Figure 6 presents the

versus

curves associated with the growth of small cracks given in [

40] for post-heat-treated LENS Ti-6Al-4V where the surfaces were not machined. For comparison,

Figure 6 also presents:

At this point, it should be noted that the review paper [

16] revealed that the short crack

versus

curves for the two different aerospace quality Titanium alloys Ti-17 and Ti-6246 were similar to that of a 350

-grade locomotive mild steel. Consequently,

Figure 6 also presents the

versus

small curves associated with a 350

-grade locomotive (mild) steel tested at a range of

R ratios [

44], see

Table 4.

Figure 6 reveals that the

versus

curve associated with the growth of small cracks in LENS Ti-6Al-4V is very similar to that seen for small crack

versus

curves of Mil Annealed Ti-6Al-4V, Ti-6246, and Ti-17, and also to the small crack

versus

curves seen by both D6ac steel and a 350

-grade locomotive steel. We also see that the growth of small cracks in LENS Ti-6Al-4V can be reasonably well represented by Equation (6), which has the value of the fatigue threshold

set to a small value.

As such,

Figure 6 supports the findings presented in [

16] that, while the growth of specimens containing cracks that have been grown from artificially induced notches, as per E647-13a [

6], can show significant microstructural effects, such effects may be not significant in the growth of small cracks. We also see that the small crack growth curve associated with LENS Ti-6Al-4V is similar to that of small cracks in MA Ti-6Al-4V, Ti-17 and Ti-642.

2.5. Discussion

The

versus

curves associated with each of these studies are consistent with Equation (3), and hence with the 34 different AM Ti-6Al-4V specimen test results (previously) analyzed in [

17]. It is also clear that, as per [

17], the cyclic fracture toughness (

) can vary significantly. The variation in the fatigue threshold (

) is also similar to that seen in [

17], and as discussed in [

17], is consistent, albeit in these tests slightly larger, with the variation seen in traditionally manufactured materials. However, according to the statements in Appendix X3 of the tests standard E647-13a [

6]:

“Fatigue cracks of relevance to many structural applications are often small or short for a significant fraction of the structural life.”

“The growth rates of such cracks usually cannot be measured with the standard procedures described in the main body of Test Method E647, which emphasizes the use of large, traditional fracture mechanics specimen geometries.”

“Of greater importance, the growth behavior of these small cracks is sometimes significantly different from what would be expected based on large-crack growth rate data and standard fatigue crack growth analysis techniques. Direct measurement of small-crack growth rates may be desirable in these situations.”

“It is not clear if a measurable threshold exists”.

It follows that the fatigue threshold () associated with naturally occurring cracks in operational AM parts (this assumes that the parts will be annealed) will (in all likelihood) be small. Hence, the variation in the threshold, associated with the fastest growing (lead) cracks in these parts will (likely) be correspondingly small. This now leads us to the question: What is the effect of the variability in the cyclic fracture toughness () on the fatigue life of AM parts. In this context, E647-13a notes that for conventionally manufactured materials, the majority of the operational life of a structure is consumed in the short/small crack regime and that for such naturally occurring cracks the fatigue threshold is small. Consequently, for conventionally manufactured materials the effect on total life of the variability of the apparent toughness term is generally small. In contrast, for AM materials, the variability in can be quite large. As such, the effect of this (large) variability in the cyclic fracture toughness () on the fatigue lives of AM replacement parts needs further investigation.

4. Conclusions

This paper has examined crack growth in three different additively manufactured aerospace materials. It is shown that, in each case, the various

da/

dN versus Δ

K curves can be represented reasonably well by the Hartman-Schijve variant of the NASGRO crack growth equation. It is also shown that, as first revealed in [

17] for crack growth in AM Ti-6Al-4V, the variability in the various

da/

dN versus Δ

K curves is captured reasonably well by using the curve determined for conventionally manufactured materials and allowing for changes in the threshold and the cyclic fracture toughness terms.

Consequently, noting that

it is now known that the effects of micro-structure on the growth of small sub-mm naturally occurring cracks in conventionally manufactured aerospace materials is often small [

16];

that crack growth in conventionally manufactured and AM materials appears to be able to be modelled using the Hartman-Schijve crack growth equation, i.e., Equation (1); and

that the growth of small cracks in LENS Ti-6Al-4V can be reasonably well predicted using the long crack Hartman-Schijve representation and setting the threshold term ΔKthr to a small value.

It is hypothesized that, in Regions I and II, the effect of different microstructures on the growth of naturally occurring sub-mm cracks in AM materials may also be small. This hypothesis needs to be evaluated further via tests on small naturally occurring cracks in AM materials.

If this hypothesis is true, and noting that for small naturally occurring cracks in operational aircraft, the fatigue threshold is likely to be small, then the next question to be addressed is: What is the effect of the variability in the cyclic fracture toughness on the fatigue life of AM parts in operational aircraft. In this context, E647-13a notes that for conventionally manufactured materials, the majority of the operational life of a structure is consumed in the short/small crack regime, and that for such naturally occurring cracks, the fatigue threshold is small. Consequently, for conventionally manufactured materials, the effect on total life of the variability in the apparent toughness term A is generally small. In contrast, for AM materials, the variability in can be quite large. This realization can result in a significant but informed AM part design process and subsequent maintenance cycle specification. In particular, the stochastic variability of the cyclic fatigue threshold can be determined, and appropriate reliability metrics can be incorporated in the design. The relevant metrics can then be used to establish maintenance specifications that include AM part lifetime predictions and replacement timelines. An additional extension can include studies that correlate the cyclic fatigue fracture toughness and the static fracture toughness. This correlation could lead to a significant reduction in the time needed to perform experimental determination of the fatigue crack life of the AM part. It is thus apparent that the effect of this (large) variability in the cyclic fracture toughness () on the fatigue lives of AM replacement parts needs further investigation.