Hybrid Electric Aircraft Propulsion Case Study for Skydiving Mission

Abstract

1. Introduction

1.1. Skydiving Lift Mission

1.2. Hybrid Electric Propulsion Suitability

2. Materials and Methods

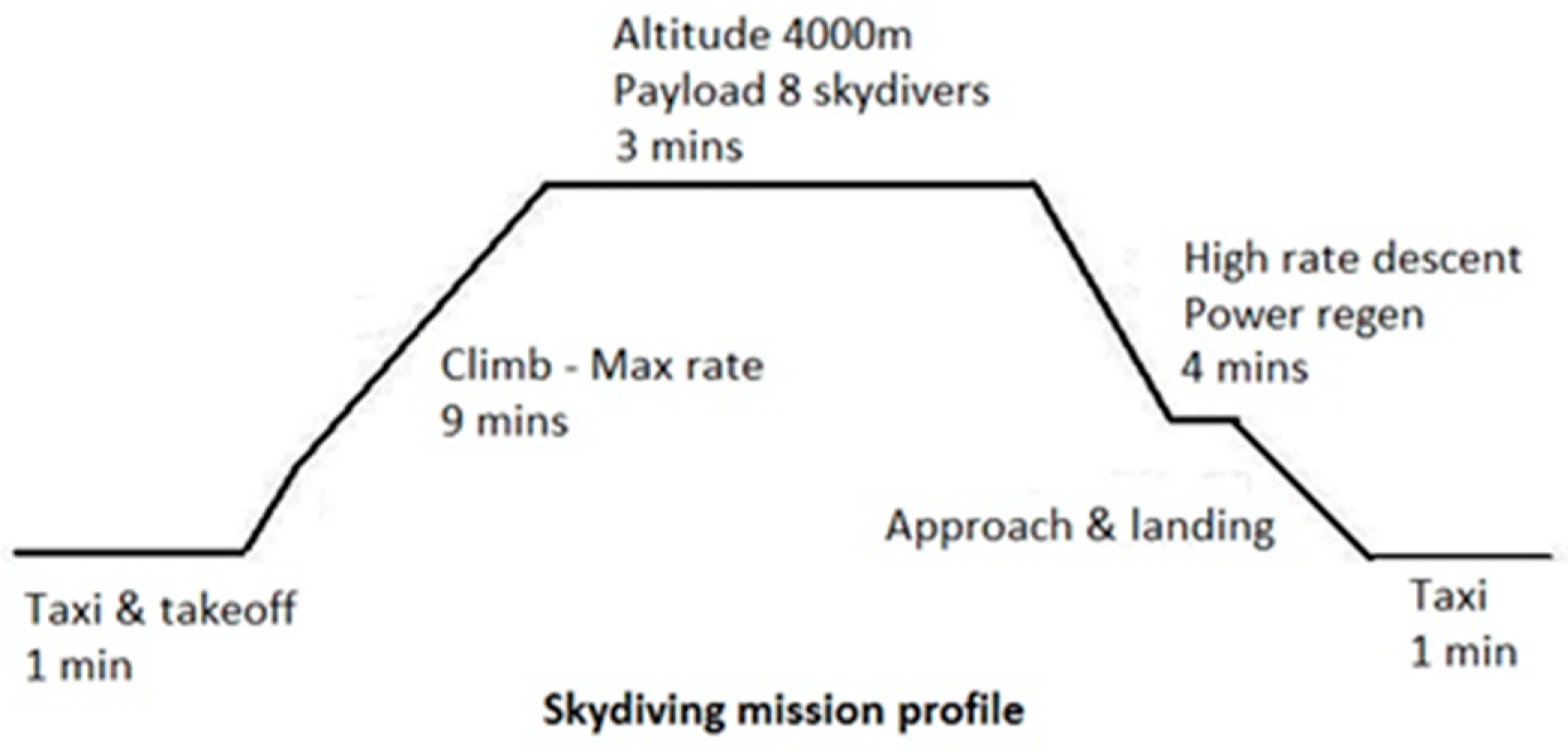

2.1. Mission Profile

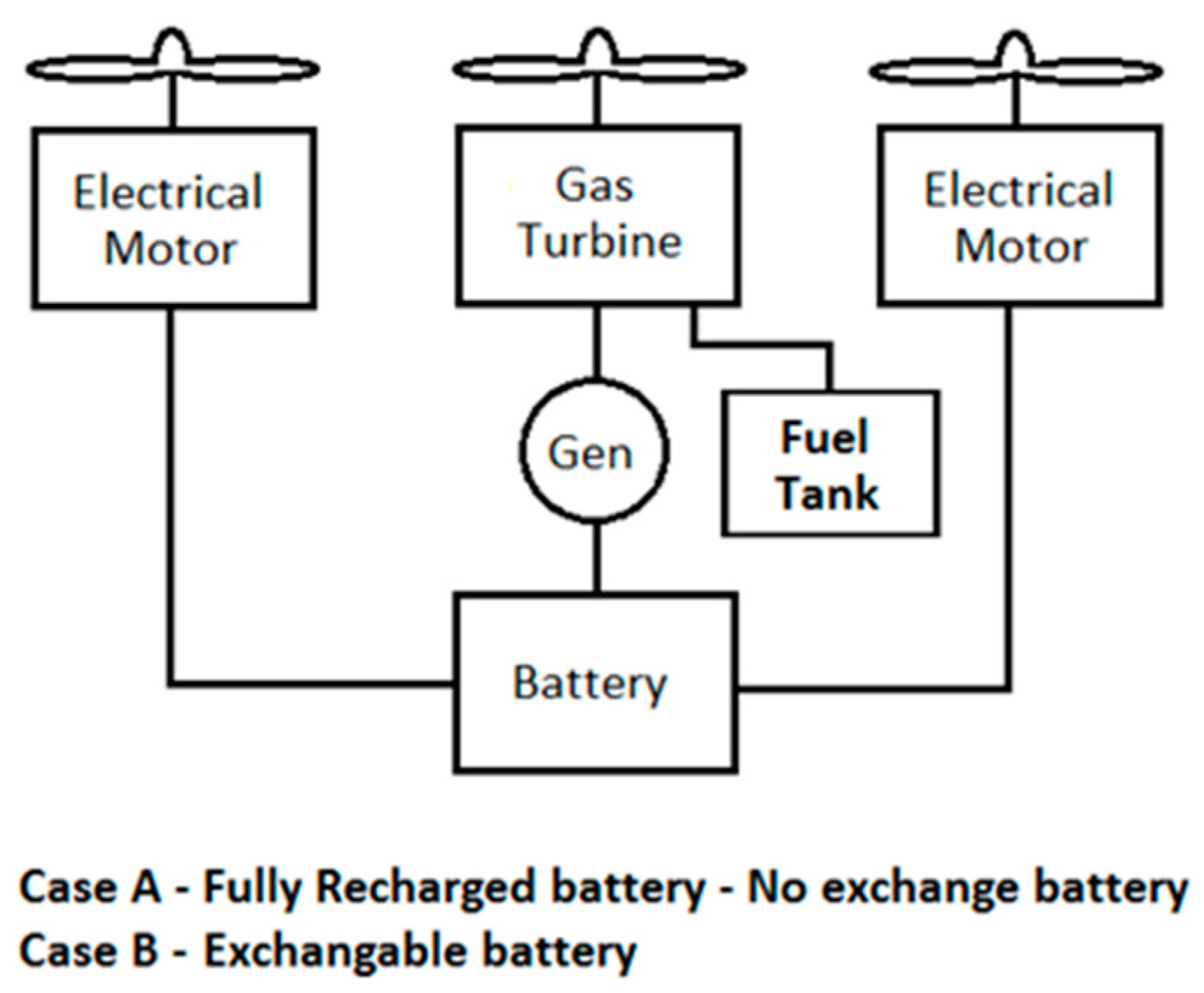

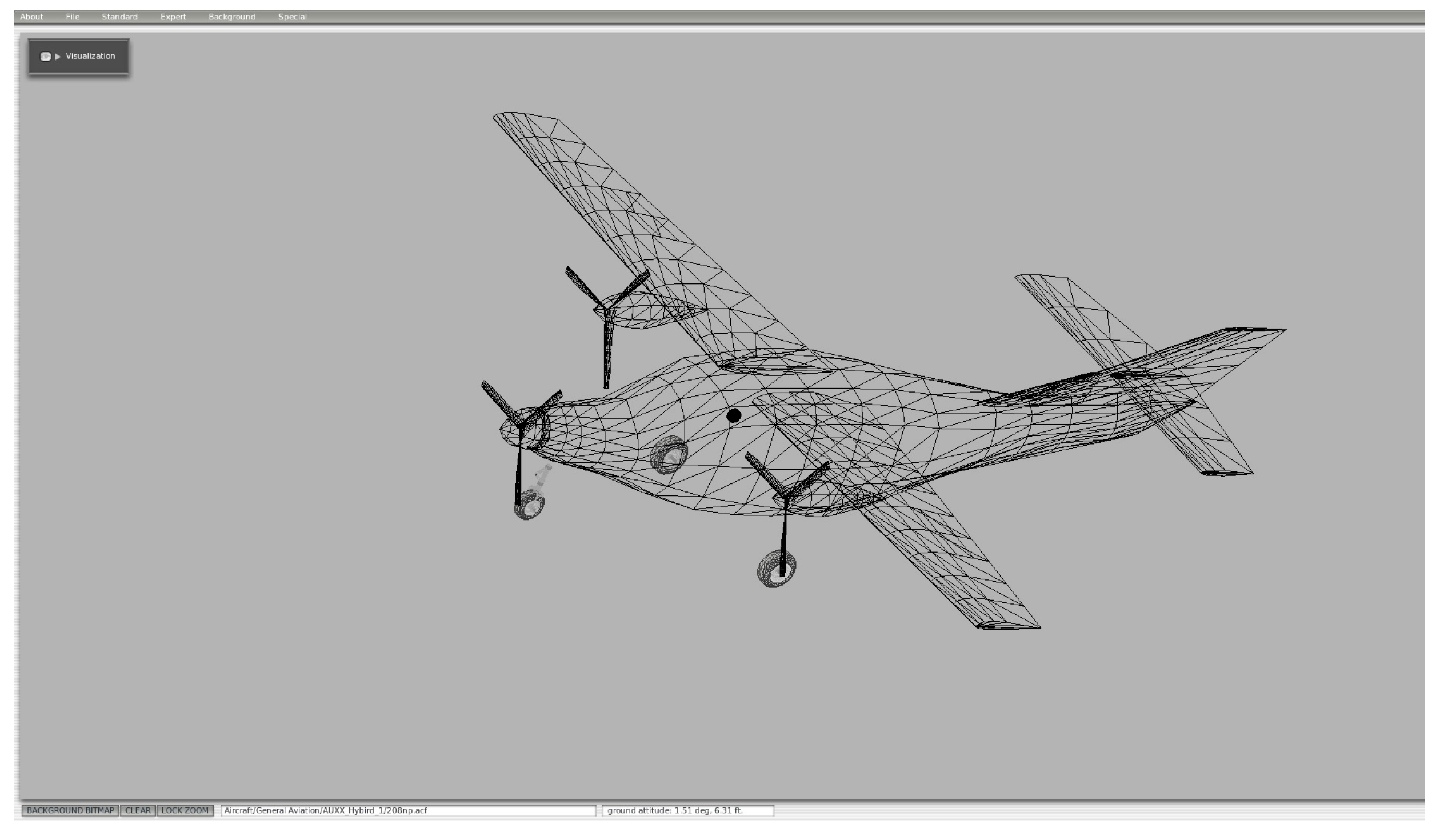

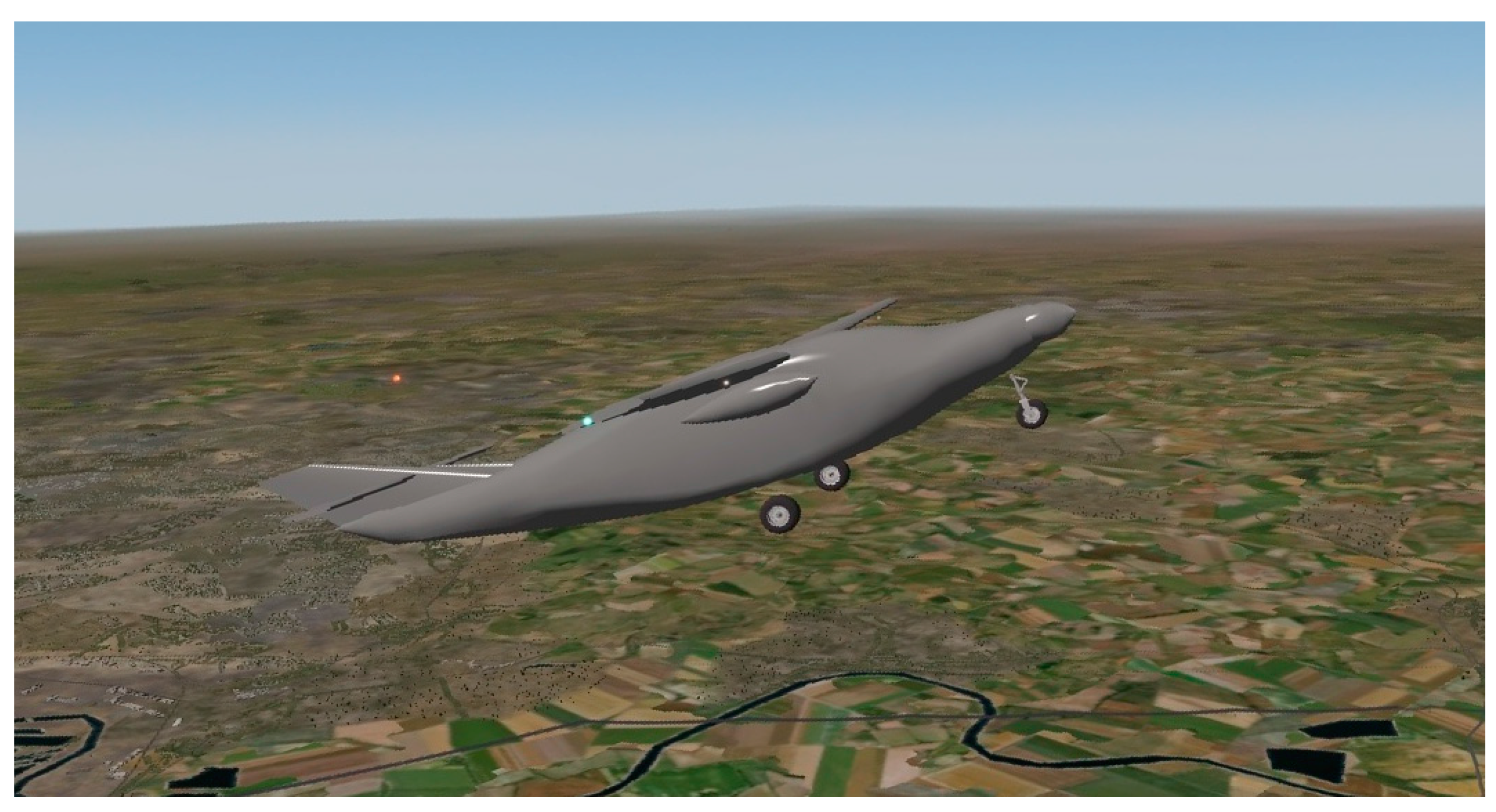

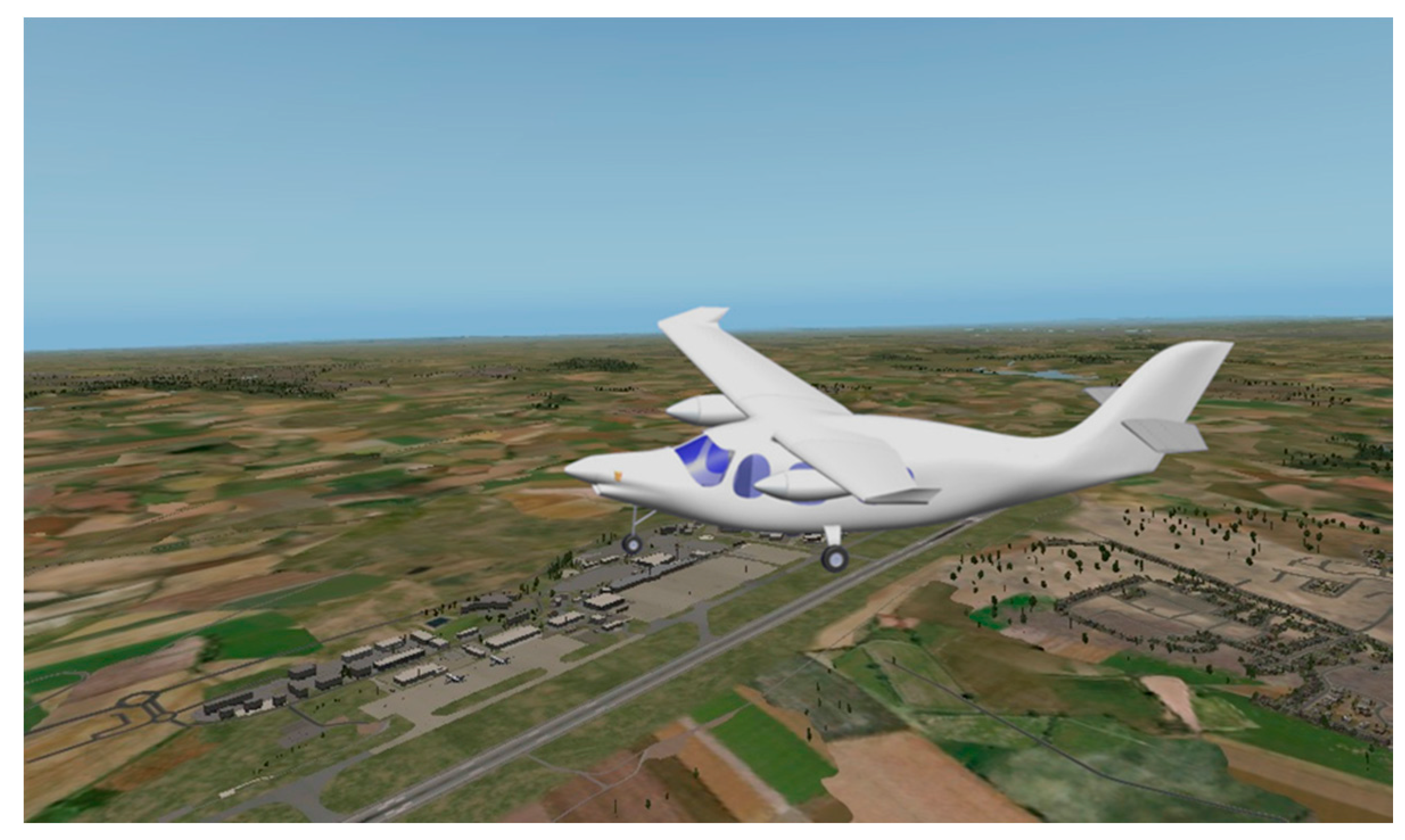

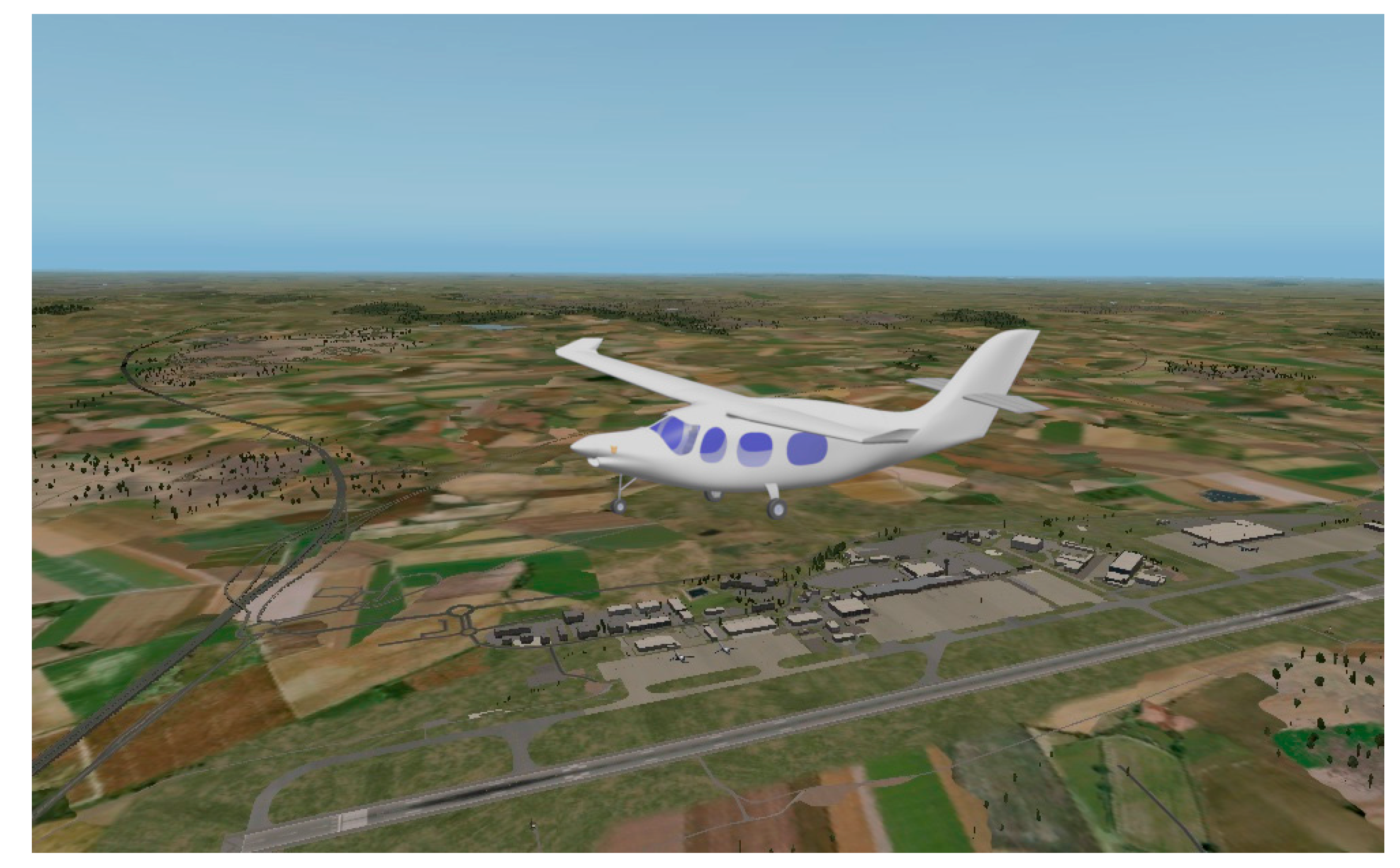

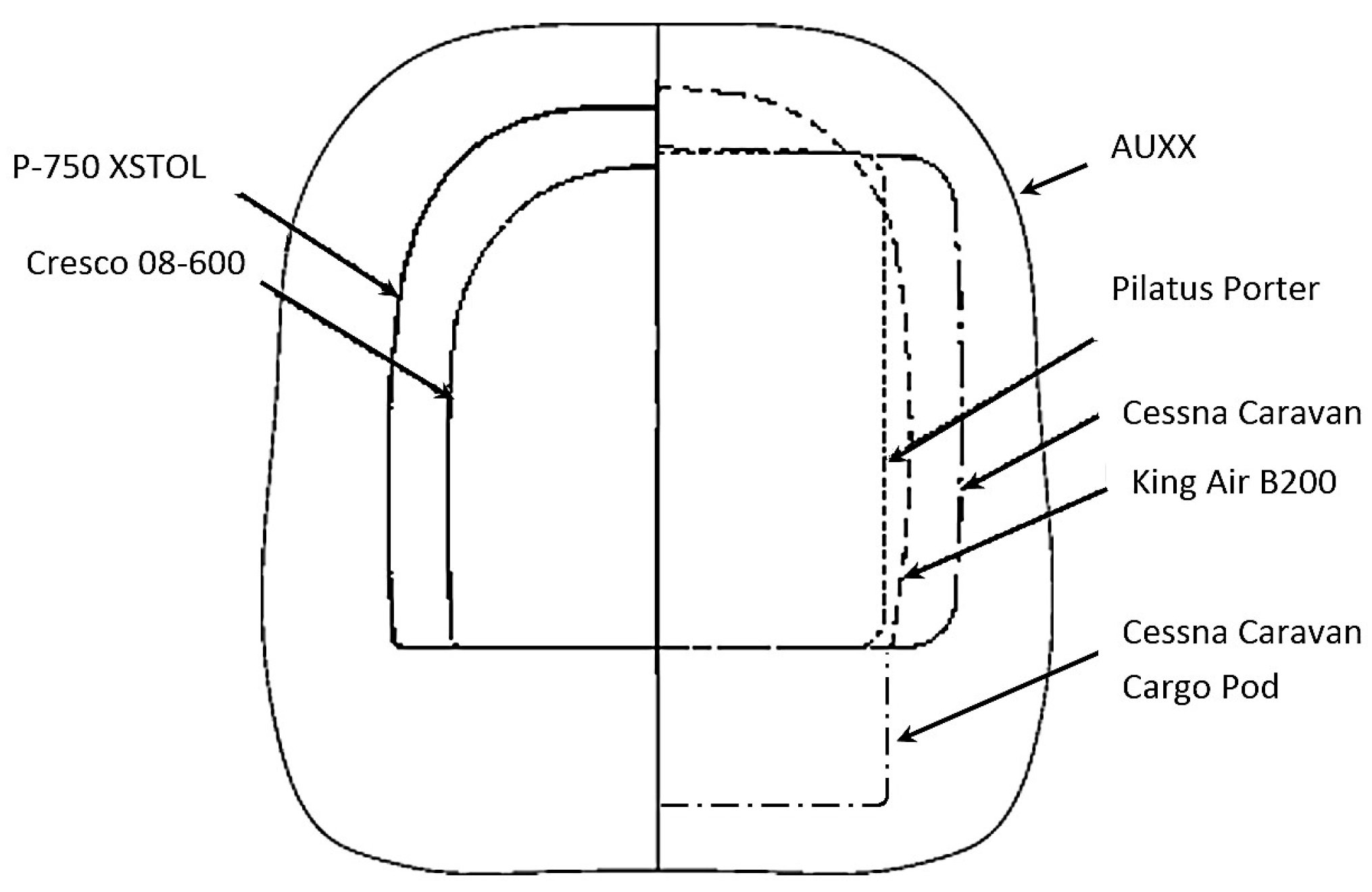

2.2. The Proposed Models

2.3. Mission Energy

- Potential energy requirements to climb;

- Drag energy expended in climb;

- Energy regeneration during descent.

2.4. ICE Limitations

2.5. Rated ICE Power

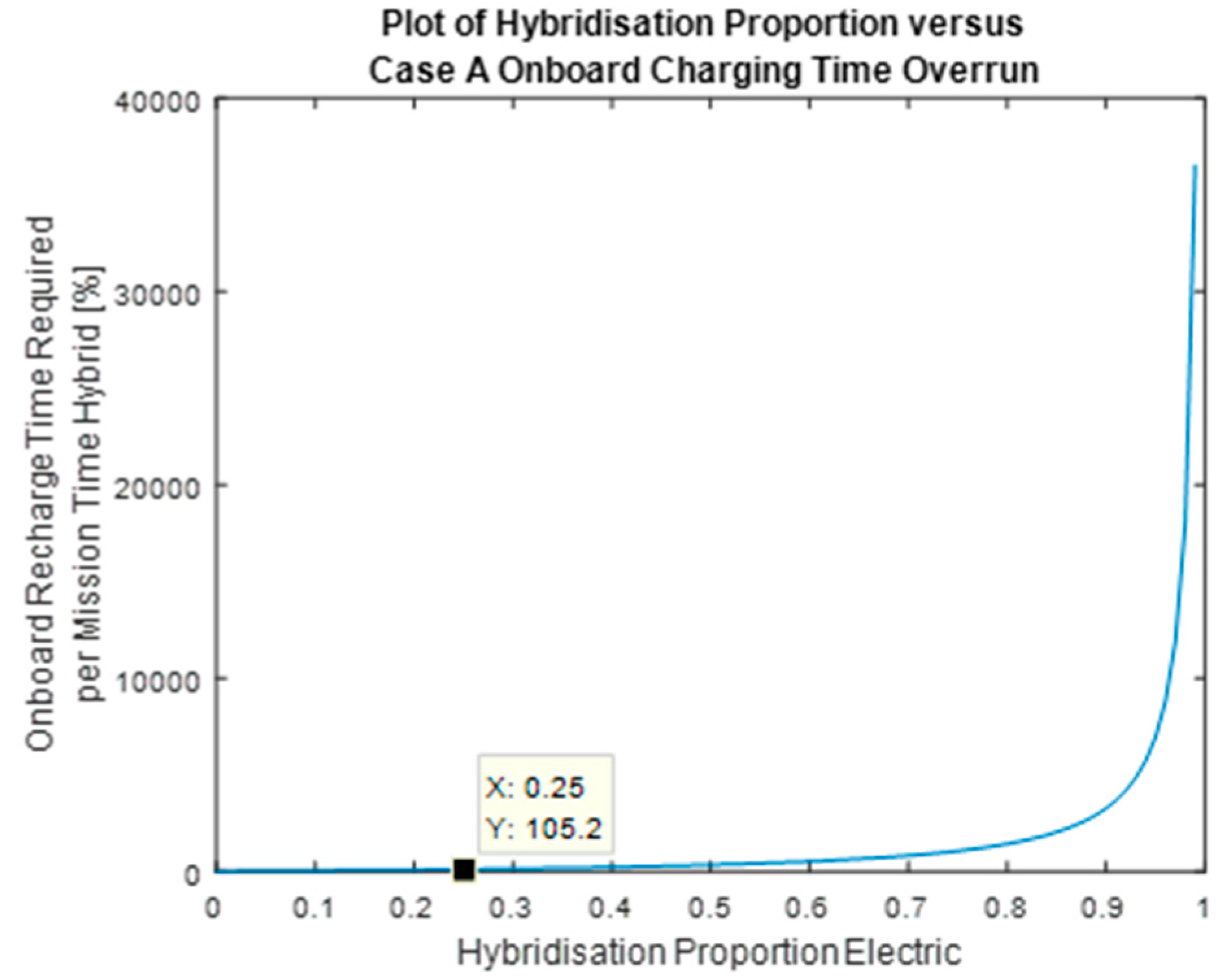

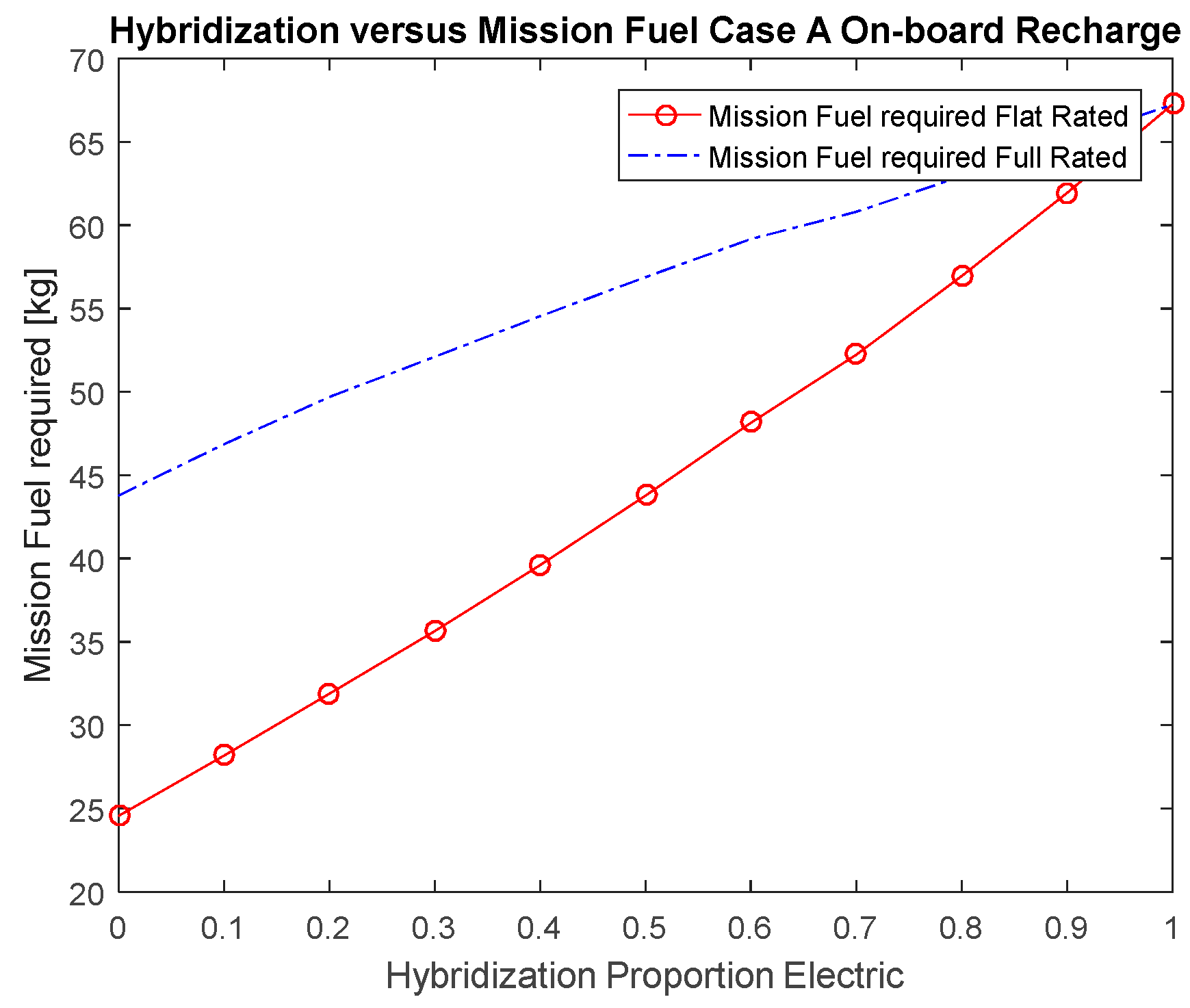

2.6. Recharge Cases

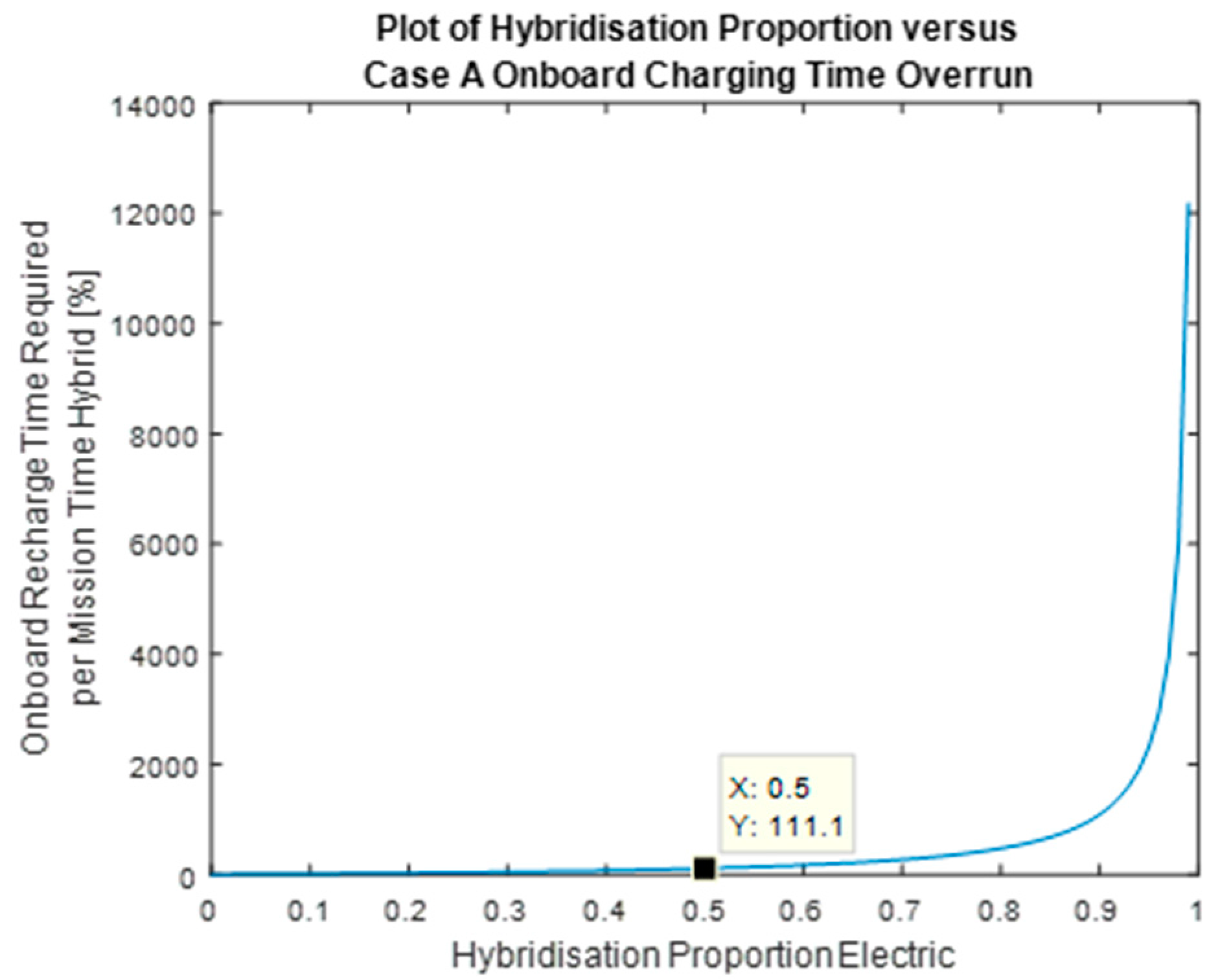

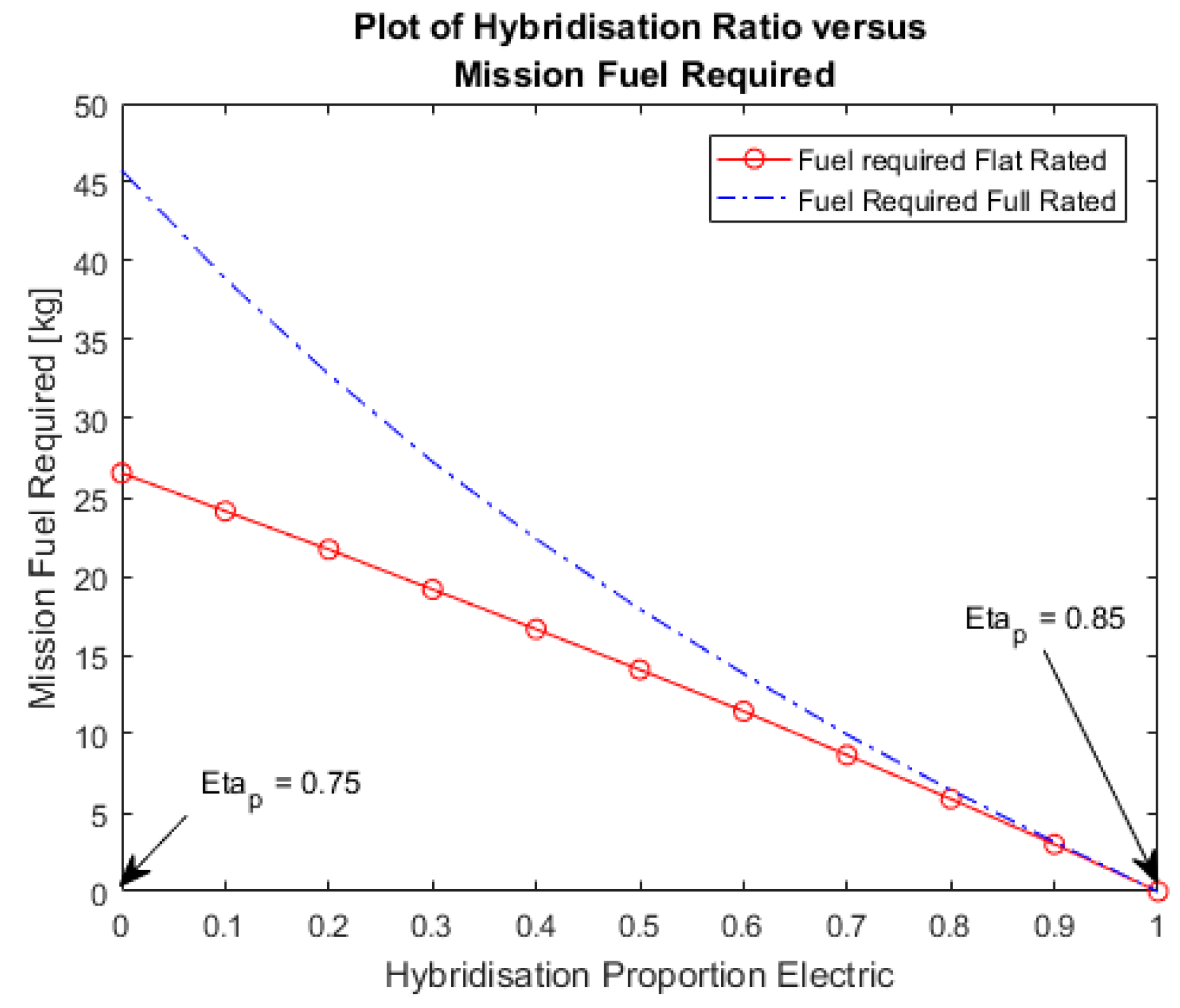

3. Results

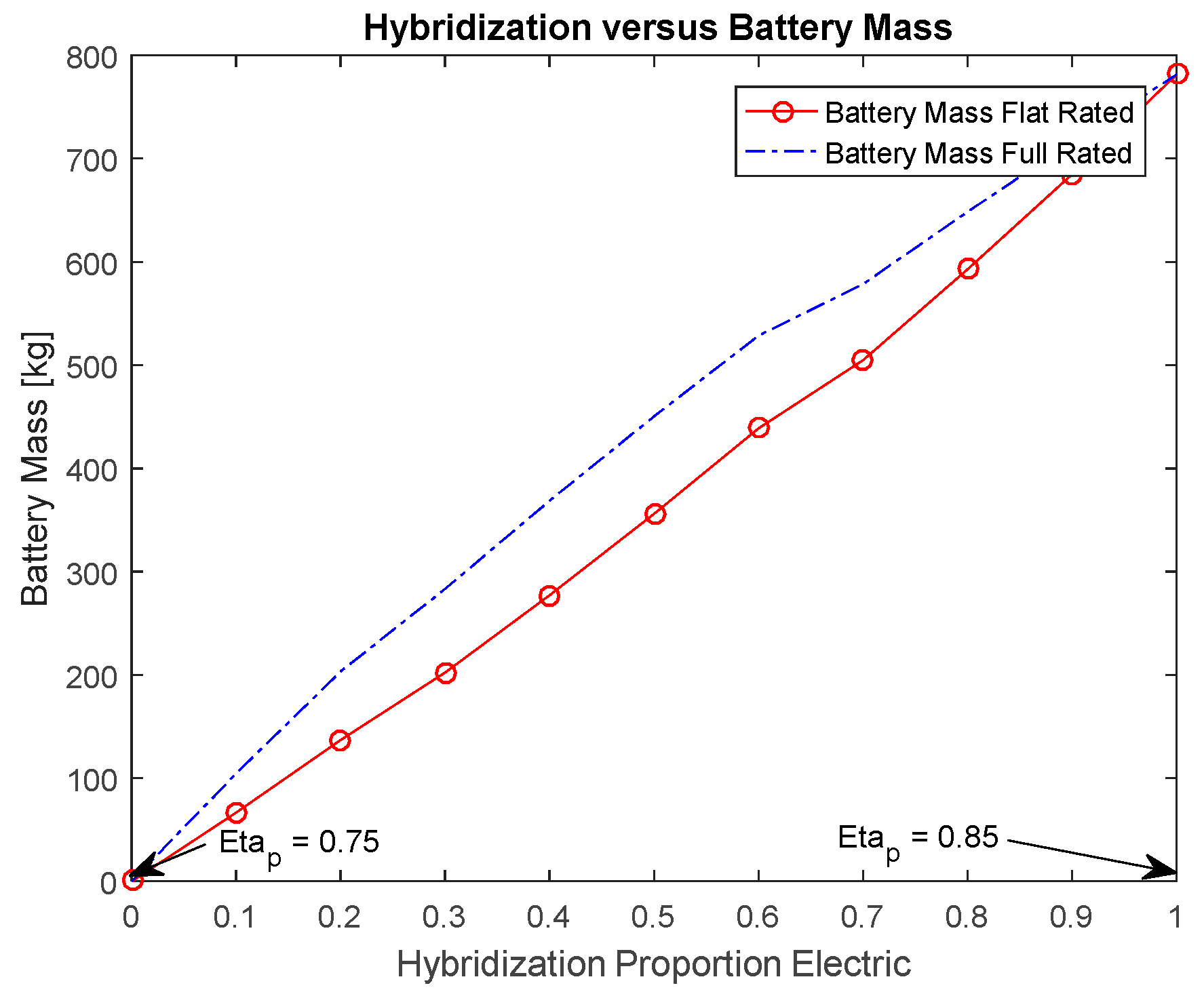

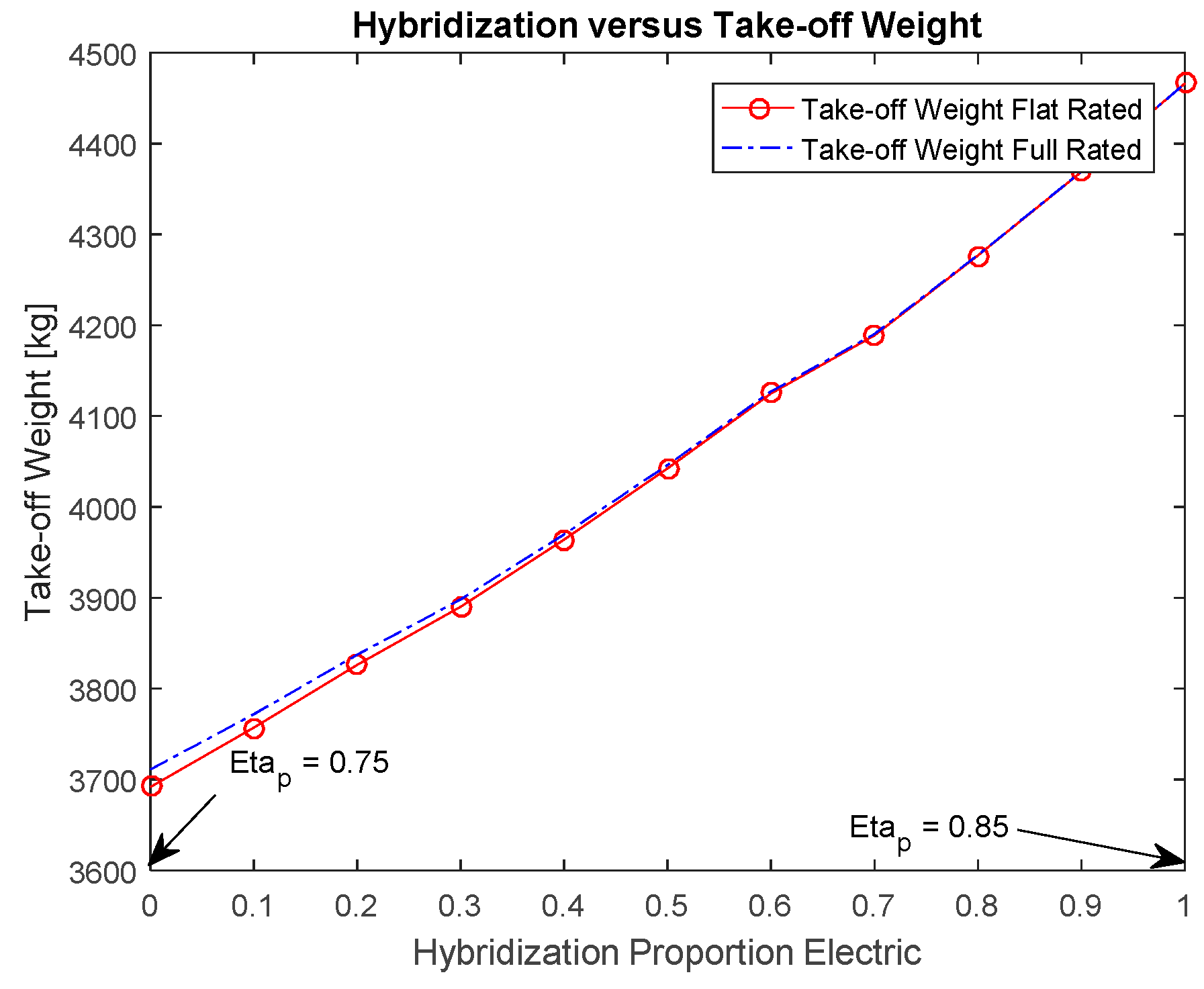

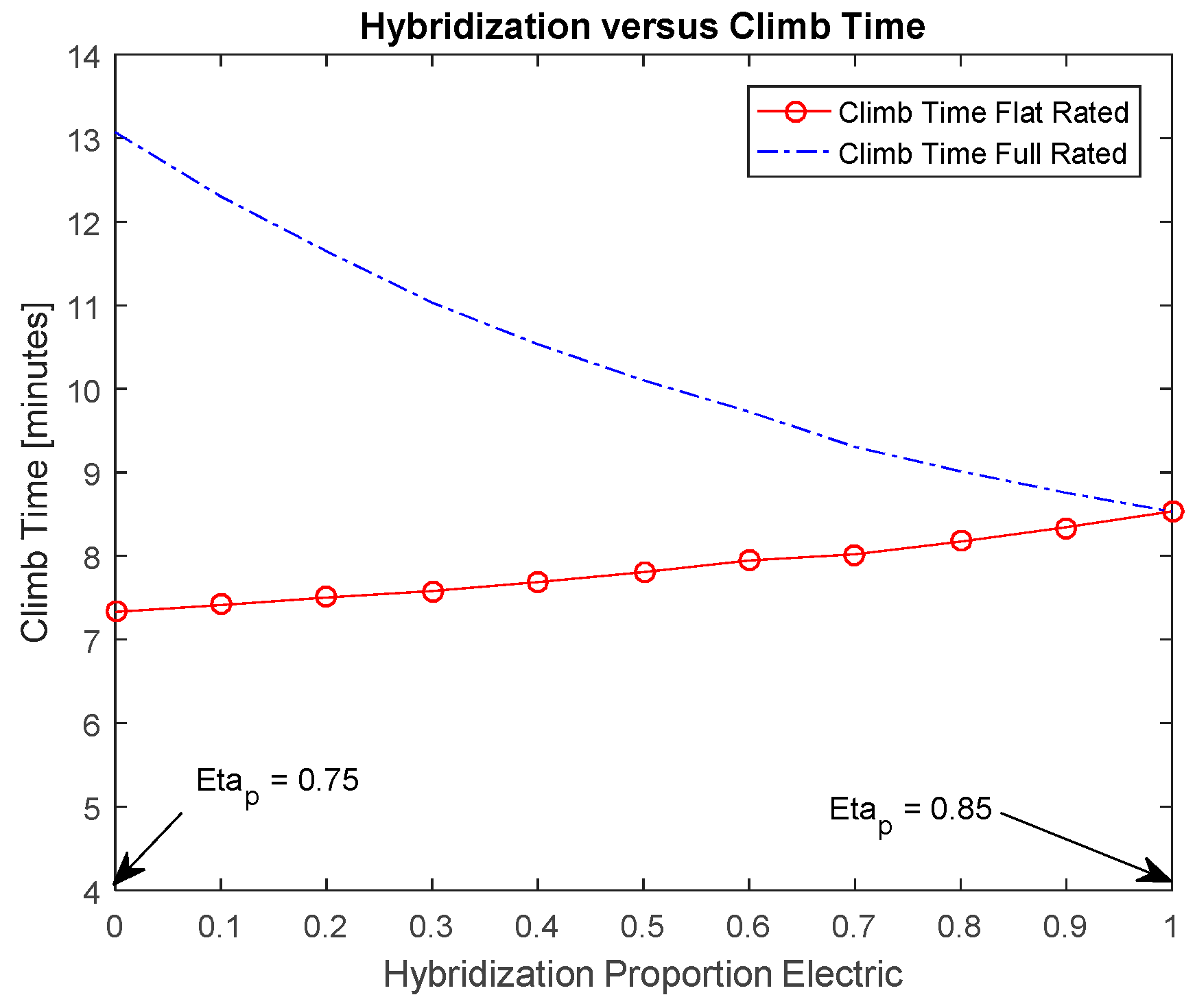

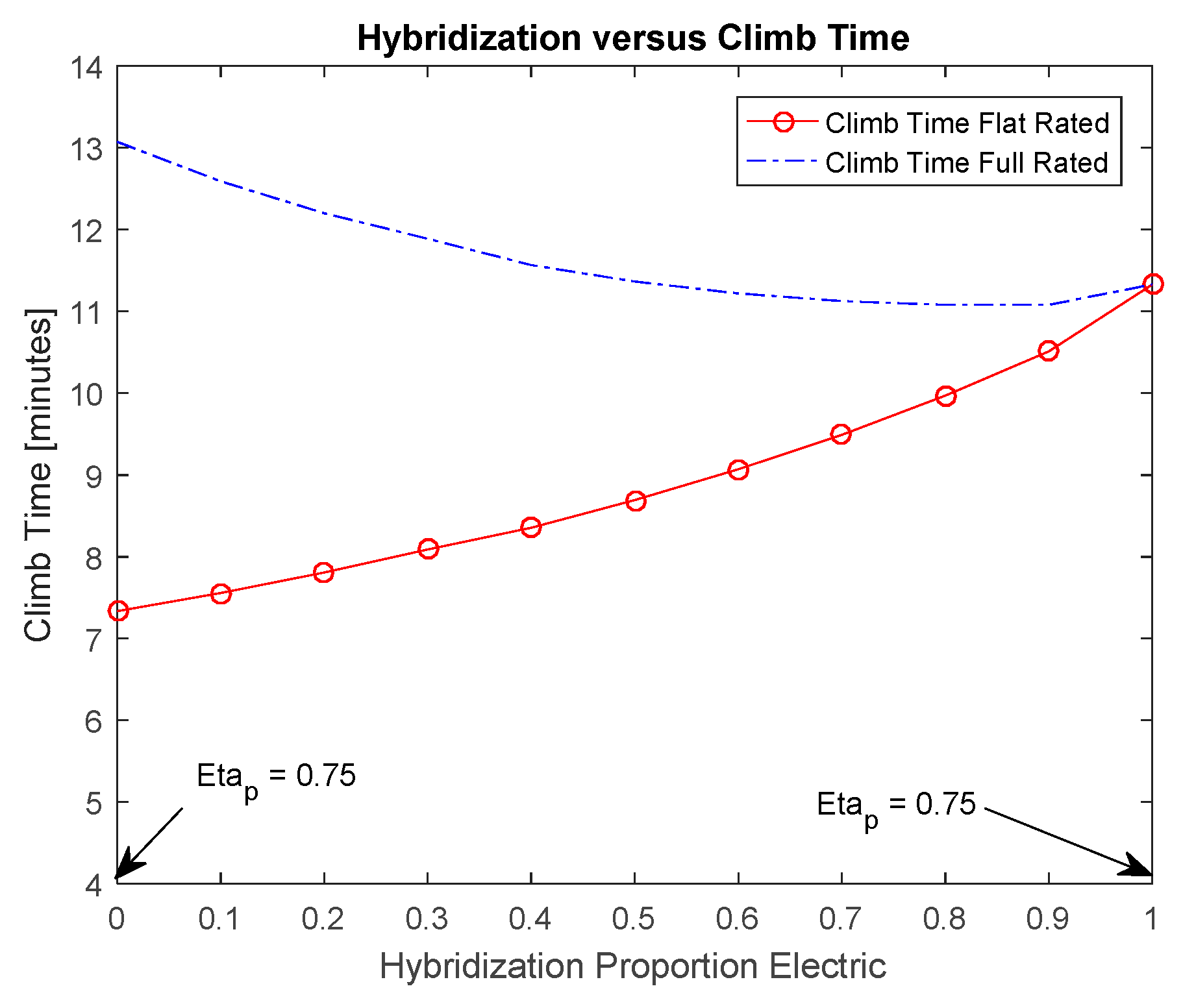

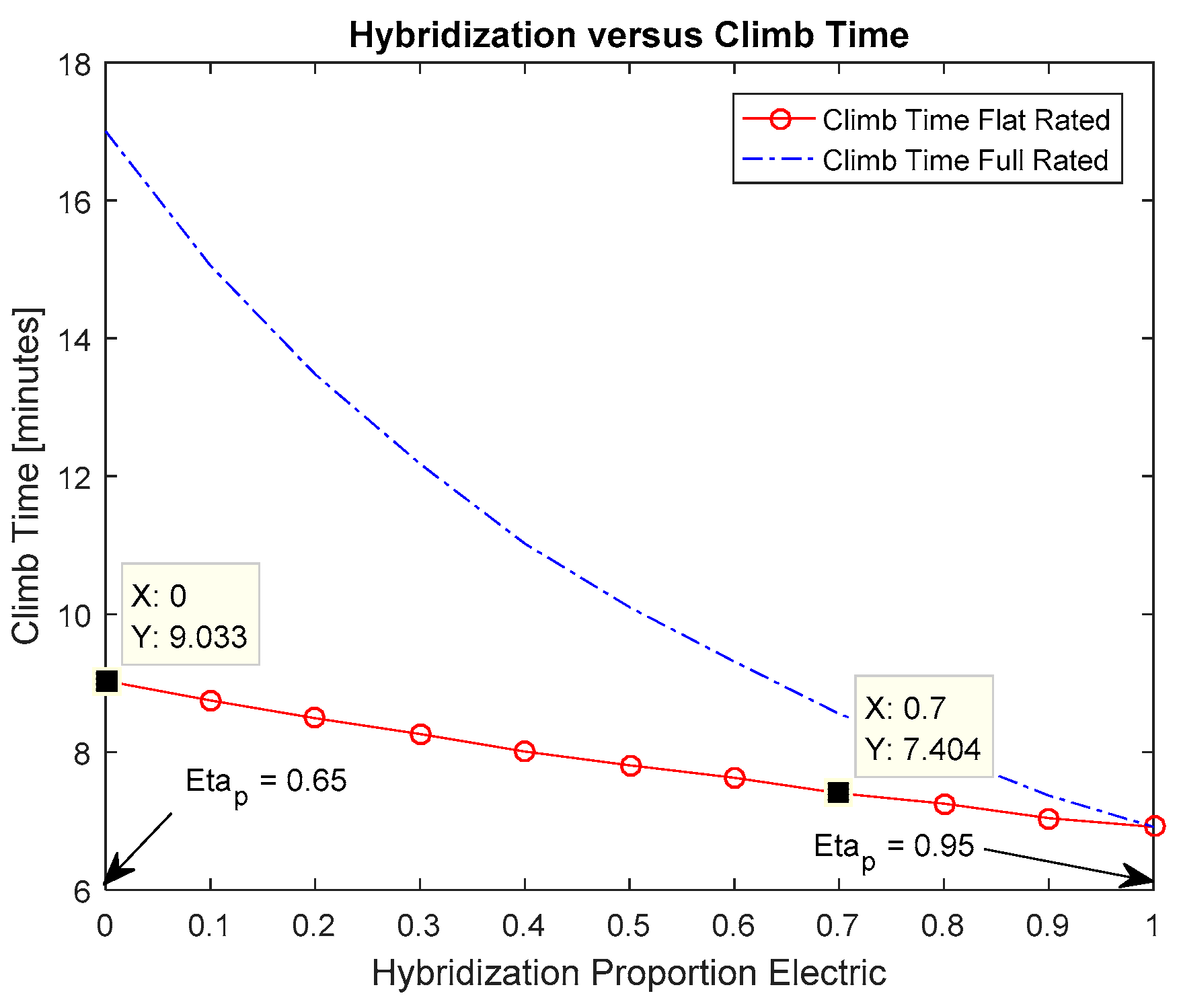

3.1. Hybrid Electric

3.2. Model Assumptions

- High power/weight (where battery storage capacity requirements are low);

- Ease of adding propeller area for any given installed power, allowing greater propulsive efficiency under particular conditions.

3.3. All-Electric

4. X-Plane Modeling

4.1. Multi-Role

4.2. Modularity

5. Future Analysis

Safety and Certification

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Oxford University Press. (2017). Definition of Utility in English. Available online: https://en.oxforddictionaries.com/definition/utility (accessed on 20 July 2017).

- Dropzone Inc. Where to Dropzone. Available online: http://www.dropzone.com/dropzone (accessed on 7 November 2016).

- The USA Parachute Association. Who Skydives? Available online: http://www.uspa.org/facts-faqs/demographics (accessed on 7 November 2016).

- European Commisson. Europe’s Vision for Aviation. Report of the High Level Group on Aviation Research; Directorate-General for Mobility and Transport: Brussels, Belgium, 2011. [Google Scholar]

- Gerada, C.; Galea, M.; Kladas, A. Electrical machines for aerospace applications. In Proceedings of the 2015 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Torino, Italy, 26–27 March 2015; pp. 79–84. [Google Scholar]

- Galea, M.; Hamiti, T.; Gerada, C. Torque density improvements for high performance machines. In Proceedings of the Electric Machines & Drives Conference (IEMDC), Chicago, IL, USA, 12–15 May 2013. [Google Scholar]

- Hepperle, M. Electric Flight—Potential and Limitations; NATO: Brussels, Belgium, 2014. [Google Scholar]

- Specific Range Solutions Ltd. (2009, 2016). Parametric Specific Fuel Consumption Analysis of the PW120A Turboprop Engine. Available online: http://www.srs.aero/wordpress/wp-content/uploads/2009/03/srs-tsd-002-rev-1-pw120a-sfc-analysis.pdf (accessed on 10 November 2016).

- Glesk, T. Requirements Document. In Requirements Document; Glassock, R., Ed.; Air Ute Pty Ltd.: Caloundra, Queensland, Australia, 2012. [Google Scholar]

- Massachusetts Institute of Technology. Thermodynamics and Propulsion. Available online: http://web.mit.edu/16.unified/www/FALL/thermodynamics/notes/node86.html (accessed on 27 February 2017).

- Phillips, W.F. Mechanics of Flight, 2nd ed.; John Wiley and Sons, Inc.: Chichester, UK, 2010. [Google Scholar]

- Glassock, R. Design, Modelling and Measurement of Hybrid Powerplant for Unmanned Aerial Vehicles (UAVs). Master’s Thesis, Master of Engineering, School of Electrical Engineering and Computer Science, Queensland University of Technology, Brisbane, Austria, 2012. [Google Scholar]

- Pornet, C.; Isikveren, A.T. Conceptual design of hybrid-electric transport aircraft. Prog. Aerosp. Sci. 2015, 79, 114–135. [Google Scholar] [CrossRef]

- Plas, A.P.; Sargeant, M.A.; Madani, V.; Crichton, D.; Greitzer, E.M.; Hynes, T.P.; Hall, C.A. Performance of a Boundary Layer Ingesting (BLI) Propulsion System. In Proceedings of the 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–11 January 2007. [Google Scholar]

- Stanford University. (2009). Simple Performance Estimation. Available online: http://adl.stanford.edu/sandbox/groups/aa241x/wiki/e054d/attachments/31ca0/performanceanddrag.pdf (accessed on 30 June 2017).

- Bullis, K. (2013). Once a Joke, Battery-Powered Airplanes Are Nearing Reality. Available online: https://www.technologyreview.com/s/516576/once-a-joke-battery-powered-airplanes-are-nearing-reality/ (accessed on 5 May 2017).

- Rosenfelt, C. (2014). Skydive Aircraft List. Available online: http://skydiverdriver.blogspot.co.uk/p/skydive-aircraft.html (accessed on 17 November 2016).

- PIPISTREL d.o.o. Ajdovščina. (2014). Pipistrel Aircraft—UL 3-Axis AIRCRAFT—Alpha Electro—Overview. Available online: http://www.pipistrel.si/plane/alpha-electro/overview (accessed on 12 December 2016).

- Williams, W.R. A Simulator Based Approach to DT&E of Small UAVs; School of Electrical and Sytsem Engineering, University of South Australia: Mwson Lakes, South Australia, 2002. [Google Scholar]

- Garcia, R.; Barnes, L. Multi-UAV Simulator Utilizing X-Plane. J. Intell. Robot. Syst. 2010, 57, 393–406. [Google Scholar] [CrossRef]

- Lan, C.E.; Roskam, J. Airplane Aerodynamics and Performance; Aviation and Engineering: Ottawa, ON, Canada, 1980. [Google Scholar]

- Federal Aviation Administration. AC 20-128A Design Considerations for Minimizing Hazards Caused by Uncontained Turbine Engine and Auxiliary Power Unit Rotor Failure; The United States Department of Transportation (USDOT): Washington, DC, USA, 1997.

- Honeywell. Available online: https://aerocontent.honeywell.com/aero/common/documents/myaerospacecatalog-documents/BA_brochures-documents/TPE331-12JR_for_850_Caravan.pdf (accessed on 25 May 2017).

- Texas Turbines. (2016). Product Brochures and Spec Sheets Supervan 900. Available online: http://www.texasturbines.com/product-brochures/ (accessed on 25 May 2017).

- Friedrich, C.; Robertson, P.A. Hybrid-electric propulsion for automotive and aviation applications. CEAS Aeronaut. J. 2015, 6, 279–290. [Google Scholar] [CrossRef]

- Fefermann, Y.; Maury, C.; Level, C.; Isikveren, A.T. Hybrid-Electric motive power systems for commuter transport applications. In Proceedings of the 30th Congress of the International Council of the Aeronautical Sciences, Daejeon, Korea, 25–30 September 2016. [Google Scholar]

- Eres, M.H.; Bertoni, M.; Kossman, M.; Scanlon, J. Mapping Customer Needs to Engineering Characteristics: An Aerospace Perspective for Conceptual Design. J. Eng. Des. 2014, 251, 64–87. [Google Scholar] [CrossRef]

- Part 23—Airworthiness Standards: Normal, Utility, Acrobatic, and Commuter Category Airplanes ed: Electronic Code of Federal Regulations; U.S. Government Publishing Office: Washington, DC, USA, 2016.

- Ullman, D.G. The Mechanical Design Process, 4th ed.; McGraw-Hill: New York, NY, USA, 2010. [Google Scholar]

- Gudmundsson, S. General Aviation Aircraft Design—Applied Methods and Procedures, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Markish, J.; Willcox, K. A value-based approach for commercial aircraft conceptual design. In Proceedings of the ICAS2002 Congress, Toronto, ON, Canada, 8–13 September 2002. [Google Scholar]

- Ulrich, K.T.; Eppinger, S.D. Product Design and Development, 5th ed.; McGraw-Hill: New York, NY, USA, 2012. [Google Scholar]

- Eckert, C.; Clarkson, J.; de Weck, O.; Keller, R. Engineering change: Drivers, sources, and approaches in industry. In Proceedings of the 17th International Conference on Engineering Design, Stanford, CA, USA, 21 October 2009. [Google Scholar]

- Eckert, C.M.; Keller, R.; Earl, C.; Clarkson, P.J. Supporting change processes in design: Complexity, prediction and reliability. Reliab. Eng. Syst. Saf. 2006, 91, 1521–1534. [Google Scholar] [CrossRef]

- Clarkson, P.J.; Simons, C.; Eckert, C. Predicting Change Propagation in Complex Design of DETC’01. In Proceedings of the Design Engineering Technical Conference, Pittsburgh, PA, USA, 9–12 September 2001. [Google Scholar]

- Clarkson, P.J.; Simons, C.; Eckert, C. Change prediction for product redesign. In Proceedings of the International Conference on Engineering Design, Glasgow, UK, 21–23 August 2001. [Google Scholar]

| Component | Energy Density (Wh/kg) | Power Density (kW/kg) | Efficiency |

|---|---|---|---|

| EM | − | 6 | 0.9 |

| Power Electronics | − | 6 | 0.9 |

| Battery | 200 | − | 0.9 |

| ICE | 4 | 0.26 |

| Aircraft Model | Installed Power (kW) | Empty Weight 1 (kg) | Payload Weight 1 (kg) | Oswald Efficiency Factor | Propeller Effciency |

|---|---|---|---|---|---|

| AUXX Conventional | 670 | 2700 | 800 | 0.835 | 0.75 |

| AUXX Hybrid | 670 | 2700 + %EPS | 800 | 0.835 | Scaled |

| AUXX All-Electric | 670 | 3500 | 800 | 0.835 | 0.85 |

| Aircraft Model | Installed Power (kW) | Empty Weight 1 (kg) | Payload Weight 1 (kg) | Climb Time Analytic (minutes) | Climb Time Simulation (minutes) |

|---|---|---|---|---|---|

| AUXX Conventional | 670 | 2400 | 800 | 9 | 10.6 |

| AUXX Hybrid | 670 | 3300 | 800 | 7.4 | 8.6 |

| X-Plane Aircraft Model | Installed Power (kW) | Empty Weight 1 (kg) | Payload Weight 1 (kg) | Average Climb Rate to 14,000 ft (ft/min) |

|---|---|---|---|---|

| AUXX Conventional | 670 | 2400 | 800 | 1320 |

| AUXX Hybrid 2 | 670 | 3300 | 800 | 1620 |

| C208 Conventional | 670 | 2200 | 800 | 1550 |

| C208 Hybrid 2 | 670 | 3000 | 800 | 2150 |

| Real Aircraft Data | ||||

| 850HP C208 3 | 635 | 2200 | 1800 | * 1460 4 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glassock, R.; Galea, M.; Williams, W.; Glesk, T. Hybrid Electric Aircraft Propulsion Case Study for Skydiving Mission. Aerospace 2017, 4, 45. https://doi.org/10.3390/aerospace4030045

Glassock R, Galea M, Williams W, Glesk T. Hybrid Electric Aircraft Propulsion Case Study for Skydiving Mission. Aerospace. 2017; 4(3):45. https://doi.org/10.3390/aerospace4030045

Chicago/Turabian StyleGlassock, Richard, Michael Galea, Warren Williams, and Tibor Glesk. 2017. "Hybrid Electric Aircraft Propulsion Case Study for Skydiving Mission" Aerospace 4, no. 3: 45. https://doi.org/10.3390/aerospace4030045

APA StyleGlassock, R., Galea, M., Williams, W., & Glesk, T. (2017). Hybrid Electric Aircraft Propulsion Case Study for Skydiving Mission. Aerospace, 4(3), 45. https://doi.org/10.3390/aerospace4030045